Page 1

BAUMFOLDER

CORP.

WetScore

INSTALLATION,

INSTRUCTION

&

PARTS

MANUAL

FOR

1300/1400

SERIES

FOLDERS

BAUMFOLDER CORP . 2003 Printed in U.S.A. TP10320A

PAGE 1 TP10320A

Page 2

©

BAUMFOLDER CORPORATION

All Rights Reserved

WARNING

• Do not operate this machine without all guarding in place.

• Do not make adjustments or perform maintenance on this machine with power on.

• Keep the machine and the work area clean and free of spills to prevent accidents.

• Be sure to replace any safety decals that may have been detached for any reason.

BAUMFOLDER reserves the right to make changes in design or to make additions or improvements

in its products without imposing any obligation upon itself to install them on its previously

manufactured products. It is recommended that modifications to this equipment not be made without

the advice and express written consent of BAUMFOLDER.

FOLDER IDENTIFICATION

MODEL NO: ________________________________ SERIAL NO: ______________________________

SALES AGENCY: _____________________________________________________________________

INSTALLED BY: _______________________________________________ DATE: ________________

PHONE NO: ________________________________

TP10320A PAGE 2

Page 3

Contents

SECTION 1:

SAFETY.......................................................................................................................................................4

BASIC ..............................................................................................................................................................4

ADDITIONAL NOTES ..................................................................................................................................... 4

SECTION 2:

HOW WetScore WORKS ...........................................................................................................................5

SECTION 3:

SET UP ........................................................................................................................................................6

1.0 ALCOHOL/W A TER MIXTURE ................................................................................................................. 6

2.0 NUMBER of SCORES ................................................................................................................................6

3.0 BLEEDING AIR from TUBING ................................................................................................................... 6

4.0 LOWING PIVOT ROD into PLACE ............................................................................................................7

5.0 PROPER NEEDLE for JOB ..........................................................................................................................7

6.0 PLACEMENT of NEEDLES on STOCK .....................................................................................................7

7.0 FLOW RA TE ADJUSTMENT .................................................................................................................... 8

8.0 PHOTO SENSOR POSITIONING ............................................................................................................... 8

SECTION 4:

REFILLING BOTTLE ..............................................................................................................................8

1.0 FLUID LEVEL .............................................................................................................................................8

2.0 BLEEDING AIR ..........................................................................................................................................8

WHILE RUNNING JOB ..........................................................................................................................8

1.0 FLUID LEVEL .............................................................................................................................................8

2.0 NEEDLE FLOW RA TE ............................................................................................................................... 8

3.0 PHOTO SENSOR LED INDICA TOR .......................................................................................................... 8

4.0 JAMMED SHEETS .................................................................................................................................... 8

5.0 FOLDER STOPS RUNNING .......................................................................................................................9

WHEN JOB’S FINISHED ........................................................................................................................9

SECTION 5:

OPERATING TIPS ....................................................................................................................................9

1.0 WetScore with MECHANICAL SCORES ....................................................................................................9

2.0 WetScore with PERFORA TORS.................................................................................................................9

3.0 W etScore ACROSS PRINTED SOLIDS ......................................................................................................9

4.0 WetScore with COA TED STOCK............................................................................................................. 10

5.0 SQUARE SIDE-GUIDE ............................................................................................................................. 10

6.0 WetScore with LIGHT STOCK................................................................................................................. 10

SECTION 6:

MAINTENANCE.....................................................................................................................................11

SECTION 7:

TROUBLSHOOTING ............................................................................................................................12

SECTION 8:

INSTALLATION & PARTS ...................................................................................................................14

PAGE 3 TP10320A

Page 4

SAFETY FIRST

BASIC

10. Make sure that all safety devices are in place before

restarting the machine.

Y our new BAUMFOLDER paper folding machines have been

designed in accordance with the latest safety specifications.

The warning and caution labels on the machine must remain

in place. Make sure all guarding provided is in place before

starting up and running the machine.

Due to the nature of the work process of paper folding

machines, there are parts and areas on the machine which

cannot be completely covered without interfering with the

operation of the machine. Therefore, sound personal work

habits and strict observance of all safety precautions is

required for the protection of the operator, co-workers, and

the machine.

Be certain to follow these

safety precautions:

1. Study the safety instructions at your plant and those

provided in this manual.

2. Study the operating instructions carefully before

operating the machine.

3 . Make sure that your co-workers are familiar with the

work process, potential danger areas,

and all necessary safety measures.

11. Never clean moving parts of the machine (rollers, shafts,

etc.) or remove any test sheets or paper jams while the

machine is running.

12 . Keep the floor around the entire machine clean. Immedi-

ately clean up any oil, grease, or paint spills from the

floor . Remove tools, cleaning cloths, and paper scraps

from all work areas.

13. Never allow unauthorized personnel to make adjustments

on the machine, remove problem sheets, or start the

machine.

14 . Never climb over the machine or crawl into it while it is

turned on.

15 . Immediately repair or replace any safety devices which

have become ineffective or are missing.

16. Report any exposed cables or exposed electrical connections.

17 . Always have a certified qualified electrician perform all

electrical maintenance.

18 . Do not make adjustments or perform maintenance with

the power on.

4 . Make sure that the machine is in good working order

before turning it on.

5. If the machine suddenly stops for whatever reason, do

not restart it right away. Someone may have stopped the

machine, but failed to press the emergency (Stop)

button. If the machine is restarted unexpectedly , your

co-worker could be seriously injured.

6. Always press the emergency (Stop) button first if you

stop the machine for adjustments or maintenance work

which must not be done while the machine is in operation.

7 . For extensive maintenance or repair work, turn off the

main power supply .

8 . Never use improper or defective tools.

9 . After making adjustments or after doing maintenance or

repair work, always make sure that all tools and other

objects are removed from the machine. Otherwise, they

might fall into the machine, causing severe damage or

injuries.

19 . Become familiar with and follow the safety labels on the

next page. Replace any of these labels that are damaged

or lost.

Additional Notes:

20. Do not attempt to remove a paper jam, no matter how

minor it may appear to be, while the machine is running.

21. When cleaning the fold rolls, use the handwheel for

turning. Be sure the power to the machine is off.

22. Turn off the machine before making any adjustments to

the scoring, perforating, or slitting attachments. Keep

hands and clothing away from the slitter shafts when the

machine is running.

TP10320A PAGE 4

Page 5

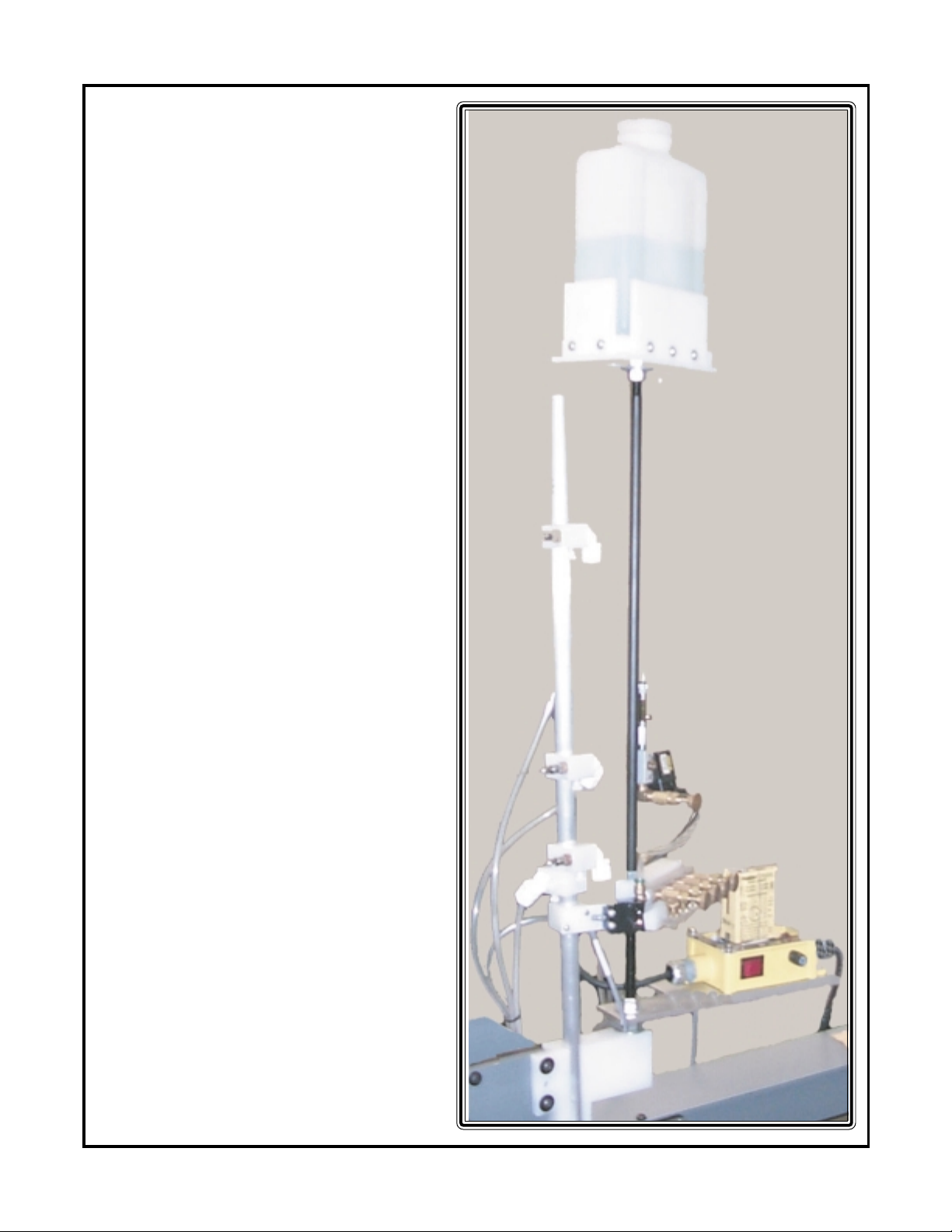

How The WetScore Works

5 . Keep all tubing away from fold rollers. Do not

operate the folder without guards in place.

The WetScore is designed to give you absolutely

straight, tight and consistent folds out of your existing

folder.

New or well used, your folder will show an improvement

in perfomance with the addition of the WetScore; increased

running speeds, tighter more accurate folds, less waste and a

reduction of downtime.

The WetScore applies a fine line of an alcohol/water

mixture to the sheet, breaking the grain of the stock, prior

to the sheet entering the fold rollers. This eliminates the

bother of getting a straight score out of the parallel section

of your folder. The wet line applied to the sheet on the

register table is always straight, as long as the sheet

registers to the guide before reaching the WetScore needle

applicators. For this reason the WetScore is installed on the

folder as close to the fold rollers as possible.

The WetScore applies a fine line to the stock regardless

of the speed at which the folder is running. By placing the

needle applicators directly upon the stock, the surface

tension of the fluid is overcome and the WetScore is able to

apply the fluid to the stock by capillary action. The effective

result of this action is that the faster you run the folder, the

faster the flow of fluid onto the stock! For this reason it is

essential that the needles are always in contact with the

surface of the stock when using the W etScore.

6. To avoid unnecessary wear of the tubing, keep tubing

from resting on the cross carrier drive rollers of the

right angle unit.

7 . Prolonged operation of the WetScore will result in the

heating of the shut-off solenoid. Use caution when

handling.

8 . Alcohol/water solution is flammable. Keep away from

excessive heat or open flame!

The WetScore is the only product of its type that

features an automatic shut-off to prevent build-up of fluid on

the folder. The shut-off is accomplished by a signal sent

from a photoelectric sensor to a control modulated amplifier.

The amplifier has a built in delayed off signal that is preset at

the factory for 1 second. If the WetScore sensor does not

detect a second sheet within 1 second, the Amplifier will

send a signal to the solenoid stopping the flow of fluid to

the control valves. For this reason a small amount of fluid

will be seen falling between sheets during the running of a

job, as well as when the folder stops running.

MACHINE SAFETY

1 . Needles are Sharp! Place needles in needle holders

on control amp base when not in use. Use caution

when handling!

2. Unplug WetScore when not in use.

3 . Wipe up all spills.

4. Do not operate without the amp housing cover in

place. No user serviceable parts inside.

PAGE 5 TP10320A

Page 6

SET UP

1.0 THE RIGHT ALCOHOL/WA TER

MIXTURE

3.0 BLEEDING AIR FROM THE TUBING

The WetScore uses a mixture of Isopropyl ALcohol

(Commonly known as Rubbing Alcohol) and water . The

alcohol serves two purposes. First, it acts as a drying agent

to cause rapid evaporation of the solution from the signatures. Secondly , it insures that the fluid maintains a uniform

line upon the stock. For these reasons it is important that

the solution be mixed in the proper proportions. T oo little

alcohol in the solution and the fluid will tend to spread out

upon the sheets in a ribbon rather than a fine line and the

signatures will feel excessively wet. T oo much alcohol and

the fluid will have a difficult time absorbing into the stock

and inconsistent folds will result.

As a rule of thumb, during operation of the WetScore

the signatures should feel wet to the touch immediately after

folding and dry within 3 to 5 minutes. You should be able to

smell the alcohol on the signatures. The folded signatures

should appear flat. If the signatures appear to be rippled

along the scored and folded edge you are using too much

water and we advise remixing your solution. To avoid

unwanted downtime, we advise keeping a premixed container

of solution nearby the folder to fill the water bottle during

operation of the WetScore.

The Greatest factor in insuring a strong flow

of fluid through the WetScore is the asbence of

air in the tubing that runs from the bottle to the

control valves.

A. BLEEDING THE TUBING FROM THE

ON/OFF SOLENOID TO THE CONTROL

VALVES

1 . Plug the WetScore into a 110V . outlet.

2 . Make sure that the LED indicator light on the

photoelectronic sensor is not lit,indicating that

the solenoid is closed.

3 . Close all of the control valves.

4 . Remove the rubber cap from the end port of

the control valves.

5. Place a rag over the open port to catch fluid

when the solenoid is opened.

2.0 DETERMINE THE NUMBER OF

SCORES

In most cases you will want to use the WetScore when

you are folding in the 8 page (right angle). We recommend

using the WetScore not only for those situations in which

you would normally use a mechanical score, but for folding

with perforators as well. The WetScore is not meant to

replace the perforators, but operates in addition to them.

The resulting signatures will be flatter, usually eliminating

dog-ears and assuring you straight perforations.

6. Place your free hand under the sensor to

open the solenoid.

7. Allow fluid to run through the system until no

air is visible in the tubing between the solenoid

and the control valves.

8 . Remove your hand from under the sensor,

when the flow of fluid stops, replace the cap

on the open port.

TP10320A PAGE 6

Page 7

B. BLEEDING THE TUBING FROM THE

CONTROL VALVES TO THE NEEDLES

1 . Remove needles from the nozzles.

2 . To avoid spilling the fluid upon the folder, it is

recommended that you remove the nozzles

from their holders.

3 . Hold the nozzles away from the folder and

point them into a pail or absorbent rag to

catch the fluid when it leaves the nozzle.

4. Open the appropriate control valves.

5. THE PROPER NEEDLE FOR THE JOB

The WetScore is installeed with 23 guage needles. W e

have found that for most of the work that comes through the

shop these are sufficient. However , for heavy stock; 80 lb.

or greater; you may wish to use a bigger needle. Make sure

that the needles are not bent. Secure the needles in the

nozzles. The nozzles are internally threaded to fit the

needles, no tools are necessary. Insert the needles into the

nozzles and hand tighten, do not over tighten.

6. PLACEMENT OF THE NEEDLES UPON

THE STOCK

5. Hold your hand under the sensor to open the

on/off solenoid.

6 . Bleed the tubing until the fluid flows consis-

tently from the nozzle.

7 . It is customary for some air to remain in the

tubing after bleeding. This will usually not

affect the flow .

4.0 LOWERING THE PARALLEL UNIT

PIVOT ROD INTO PLACE

A. Make sure that the needles are not in the nozzles.

B. Lower the rod slowly to ensure that the nozzle

holders as well as the sensor do not sit upon the

shoe-in guides, register table sheet holddowns, or

side guide.

C. Snap rod into place on the support bracket.

A. POSITIONING OF THE NEEDLES IN

RELATION TO THE REGISTER TABLE

AND TAPE DRIVE ROLLER.

Adjustment is made by sliding the nozzle (needle

attached) in and out of the nozzle holder .

1 . The ideal location of the end of the needle is be-

tween the register roller and the plate of the register

table so that any drips from the needles will fall to

the floor and not build up on the register

table.

2 . Secure the needle nozzle in position within the

nozzle holder by means of the nylon set screw on

the side of the nozzle holder .

B. POSITIONING OF THE NEEDLE IN

RELATION TO THE PAPER STOCK

Adjustment is made by rotating the nozzle holder

about the pivot rod to the proper position on the

stock.

1. With the pivot rod down, run a sheet to be scored

under the rod until the registermark for the folder(or

a premarked scoring mark) is under the rod.

2 . Slide the nozzle holder with the needle in place

along the rod until it is over your mark.

3 . Rotate the nozzle holder down until the needle lies

on top of the mark and secure it in position by

tightening the nylon set screw on the top of the

nozzle holder . Hand tighten only .

4. When the needle is in the proper position it should

be touching the stock, with a slight downward

pressure. Do not lower it too far however as it will

retard the motion of the stock.

PAGE 7 TP10320A

Page 8

7.0 ADJUSTMENT OF FLOW RA TE

A. With the folder off, place your hand under the

sensor and open the appropriate control valve.

B. Watch for air bubbles in the tubing to move indicat-

ing flow from the needles.

C. Adjust control valves until the flow is greater than 2

drops per second from the needles.

D . If the proper flow cannot be obtained see TROUBLE

SHOOTING section of the manual.

WHILE RUNNING A JOB WITH

WetScore

1.0 CHECK THE FLUID LEVEL OF THE

BOTTLE

Never let the bottle run dry , unwanted air will fill the

lines. If the flow is sluggish, or signatures feel dry , fill the

bottle, the flow is gravity fed and dependent upon

presssure from the bottle.

2.0 W A TCH THE FLOW RA TE OF THE

NEEDLES UPON THE STOCK

8.0 POSITIONING OF PHOTOELECTRIC

SENSOR

A. The sensor is of the photoreflective type, it does not

require a “hole” under it to see through. Simply

position it over the sheet so that it does not interfere

with the side guide, shoe-ins, nozzle holders, etc.

B. Run one sheet under the sensor and watch to see if

the LED light on the sensor is lit when the sheet is

present, and off when not.

C. Adjust by rotating as necessary.

REFILLING THE BOTTLE

1.0 FLUID LEVEL OF THE BOTTLE

When refilling the alcohol/water solution in the bottle, it

is recommended that the bottle be only filled to 90% of

capacity.

2.0 BLEEDING AIR FROM THE TUBING

When the needle is on the sheet and the folder is

running, the line of fluid laid down by the WetScore should

approximate the size of the needle used. Check to be sure

that the needle is in constant contact with the sheet.

Do not allow space between the sheet and the needle.

The WetScore uses capillary action to pull the fluid out of

the needle by the motion of the stock underneath it. If the

needle is allowed to pour fluid upon the sheet, it will become

difficult to obtain a consistet flow and uniform score along

the sheet.

When the folder is running and the sheet gap is under

the needle, a drop of fluid should be visible at the end of the

needle prior to the next sheet running under the needle. A

strong flow may be desirable for heavy uncoated stock.

Signatures should feel slightly wet to the touch along

the scored edge.

3.0 CHECK THE LED INDICAT OR ON THE

PHOTOELECTRIC SENSOR

While the folder is running, the LED indicator light on

the photoelectric sensor should be off when there is no

sheet under the sensor. The indicator should blink on and

off with the sheet. If it is constantly on, raise the sensor

slightly to ensure that the solenoid will shut off when the

folder stops running.

When filling the bottle, always bleed the tubing between

the on/off solenoid and the control valves. Air may become

trapped in the solenoid and an inconsistent flow will result if

not removed.

It is usually not necessary to bleed the tubing to the

needles if there is adequate flow between the solenoid and

the control valves. For procedure see instructions above.

4.0 REMOVING JAMMED SHEETS

NEVER PULL SHEETS OUT OF THE FOLDER

WHEN THE NEEDLES ARE IN CONTACT

WITH THE SHEET. NEEDLES MAY BEND

AND YOU WILL LOSE YOUR SHEET REGISTER!

TP10320A PAGE 8

Page 9

When running sheets through the folder by hand,if it

becomes necessary to back the sheet out, always lift the

rod to ensure that the sheets do not jam into the needles.

They may cause the needles to bend and you will lose your

register!

OPERATING TIPS

1.0 WetScore IN COMBINA TION WITH A

MECHANICAL SCORE

If a sheet is under a needle or the sensor when the

folder stops, remove it before restarting the folder. It may

be wet and may cause a jam-up in the rollers.

5.0 WHEN THE FOLDER STOPS RUNNING

A. Remove the sheets from under the sensor and

needles so that the needles do not flow.

B . If the folder will be off longer that 10 minutes:

1 . Turn off the control valves to prevent air from

entering the tubing.

2 . Unplug the electrical cord(optional).

C . If the folder will be off less that 10 mins.,no need

to shut off the control valves.

NEEDLES WILL CONTINUE TO DRIP DUE TO

PRESSURE IN THE TUBING FOR SEVERAL

SECONDS AFTER THE ON/OFF SOLENOID

CLOSES.

WHEN YOU FINISH A JOB

A. Remove needles and place them in the holes on

the Amplifier housing support base for safety.

Due to the variable nature of the many types of stock

operators are forced to deal with these days, there is no rule

as to when to use a combination of mechanical scoring and

WetScore. We have found however, that for certain heavy

sheets, as well as cover stock, that the combination of the

WetScore with a mechanical score in the pull-out rollers of

the folder produces exceptional results. This is especially

true when using the WetScore to apply a score to the last

fold of a 16pg. signature. Many times the use of a mechanical score alone produces cracking or tearing of the signatures along the folded edge of the sheet. The addition of the

water/alcohol line from the WetScore should eliminate this

problem.

2.0 WetScore IN COMBINA TION WITH

PERFORATORS.

In many cases when folding 16 pg. or 32 pg. signatures

for the perfect-binder, case binding, or other subsequent

operations, it is desirable for the folded signatures to be as

flat as possible. Bundling devices are commonly used to

flatten the signatures after folding. We have found that the

use of the WetScore, in addition to the perforators used for

folding, produces signatures that are absolutely flat, usually

eliminating the need for bundling. Additionally the

WetScore greatly reduces the common problem of dogearred

corners when used in this way. The WetScore is not meant

to be a replacement for the use of perforations, rather an aide

to their effective use.

B. Unplug the WetScore.

C. Raise the pivot rod and secure it in the upright

position by use of the Velcro strap on the hanger

rod

D . Close all of the control valves.

E. The water bottle may hang full from its hanger

until needed for the next job.

3.0 WetScore ACROSS PRINTED

SOLIDS OR ALONG “BLEEDS”

Use caution when applying a WetScore wetted line

across bleeds or printed solids(i.e. reflex blue ink). The

interaction of the alcohol with the ink may cause the ink

vehicle to break down, producing offsetting along the folded

edge. This is especially common when running coated or

varnished stock. If possible, we recommend applying the

WetScore upon the opposite side of the sheet from any

bleeds or solids. Many times this can be accomplished by

changing the configuration of the folder set-up, i.e. by

running the job down in the second plate as opposed to up

in the first plate.

Additionally, applying a solution that contains less

alcohol will usually aide in preventing offsetting of the ink.

However, as the solution decreases in alcohol strength, its

ability to maintain a uniform line on the sheet also decreases.

PAGE 9 TP10320A

Page 10

The flow of fluid may also be adjusted by the control

valves to apply a minimum of solution to the stock.

If you do not succeed in reducing the offset by any of

the above means, we recommend that you do not use the

WetScore, proceed with conventional mechanical scoring of

the sheet.

4.0 WetScore WITH COA TED STOCK

The ability of the alcohol/water solution to absorb into

the sheet decreases with an increase in density of the sheet

coating. Hence the effectiveness of the WetScore decreases

as the sheet coating increases. The WetScore system is

designed primarily for uncoated work. We have found that

when used on coated sheets, the WetScore may prove

helpful in reducing the “cracking” that commonly occurs

along the folded edge of the signatures. Careful attention to

the flow rate of the needles when running coated sheets is

advised.

5.0 IMPORT ANCE OF HAVING A

SQUARE SIDE-GUIDE

One of the primary advantages of using the WetScore is

it’s capable of giving you absolutely straight scores that are

applied to the sheet prior to the sheet entering the fold

rollers. For this reason it is absoltely essential that the

register side-guide to be square to the fold rollers.

6.0 WetScore ON VER Y LIGHT SHEETS

For very light sheets, we recommend that the flow rate

of the needles be adjusted to a minimum. If the score

obtained is still not fine enough, we suggest using a smaller

diameter needle.

TP10320A PAGE 10

Page 11

MAINTENANCE

WEEKL Y

1 . Bleed all needle tubing.

2 . Using an air compressor, blow out any solids that may

have become trapped in the needles, i.e.-offset powder ,

paper particles etc. (remove needles from nozzles first).

MONTHLY

1. Tighten all support bolts on the brackets connecting

the WetScore to the folder rails, some loosening may

occur due to folder vibration. Bolts should be snug

with a wrench, do not overtighten.

2 . Check for sharply bent or highly worn needles replace if

necessary.

YEARL Y

1 . Replace all PVC tubing that seems brittle or abnormally

hard.

A. Use caution when removing the tubing from the

control valve ports as the tubing through use

will become slightly bonded to the brass. It is

recommended that you use an Exacto knife or

sharp blade to cut the tubing away from the

port. Do not attempt to pull the tubing off of

the port, damage to the control valves may

result.

B. Always replace tubing with the appropriate

type.

2 . Check for leaks in the control valves. Replace if needed.

PAGE 11 TP10320A

Page 12

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE WHAT TO DO

Poor or no flow from needles Sensor LED is lit when holding

your hand under it:

1 .No water in the bottle Fill bottle with solution

2 . Excessive air in the tubing Bleed air from tubing

3 .Tip of the needle is excessively Replace

worn

4 .Control valve is closed Open

5 .Needle is not in contact with Adjust

the sheet

6 . Solids trapped in needles Remove the needles from the nozzles

Sensor LED not lit when holding

your hand under it:

and blow out the needles with an air

compressor

Solution leaks at needle/nozzle

connection

Sheet is excessively wet,

score not a fine line

1. WetScore unplugged Plug in outlet

2. Malfunction in Modulated Amp. Contact your dealer Rep.

1 . Needle is cracked Replace

2. Needle is not securely Tighten

fastened to nozzle

1. Flow rate is to great Adjust control valve for

proper flow

2 . Needle is to large for light Change to smaller guage needle

weight sheet

3 .To much water in solution Remix solution using

greater amount of alcohol

4. Coating of sheet is to great Recommend use of mechanical scoring

for WetScore use

TP10320A PAGE 12

Page 13

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE WHAT TO DO

Build up of fluid upon

register table

1 . Improper setting of nozzle Readjust nozzle between register

within nozzle holder tape drive roller and register table

Inconsistent Folds

1. Positioning of W etScore Readjust to proper position

needles is out of register

2 . Poor or no flow from See above

needles

3. Folder plate stop set off of Readjust to proper position

proper position

4. Alignment ofWetScore needle to Realign the WetScore needle to the

mechanical score is improper mechanical score

Ink is offseting along the

folded edge

Solution leaks from control

valve port

Needles do not shut off

Discoloration of signatures

along scored edge

1. Sheet coating is to dense for Use of WetScore is not recommended

absorbtion of alcohol solution,

alcohol is breaking down the ink

1 . PVC tubing hardened Replace, see instructions

and brittle

2. Control valve has Replace

cracked

1. Sensor is set to low Adjust sensor so that the LED light is

off when sheet is absent

1 .Paper stock is highly alkaline Reduce the amount of alcohol in

(acid free paper) solution to approx. 30%

PAGE 13 TP10320A

Page 14

1300 SERIES INST ALLA TION INSTRUCTIONS

0.375 in.

0.350 in.

1.500 in.

2 x 0.250 in.

Thru

TP10320A PAGE 14

0.250 in.

Thru

0.875 in.

0.188 in.

Page 15

1300 SERIES INST ALLA TION INSTRUCTIONS

Block mounts to the

2 - M6x30 BHD Screws

2 - M6 Fender Washers

2 - M6 Flat Washers

2 - M6 Lock Nuts

inside surface of the frame

flush with the top of the

frame.

1 - M6x30 BHD Screw

1 - Clamp

1 - Spacer

1 - M6 Flat Washer

1 - M6 Lock Nut

PAGE 15 TP10320A

Page 16

1400 SERIES INST ALLA TION INSTRUCTIONS

OPERATOR'S SIDE

(inside frame view, not to scale)

0.625 in.

7.750 in.

0.750 in.

Drill & Tap for

M6 x 1.00

2 Plcs.

NON-OPERATOR'S SIDE

(inside frame view, not to scale)

0.500 in.

3.500 in.

1.500 in.

TP10320A PAGE 16

Drill & Tap for

M6 x 1.00

2 Plcs.

Page 17

1400 SERIES INST ALLA TION INSTRUCTIONS

OPERATOR'S SIDE

(inside frame view, not to scale)

Bracket mounts to the

inside surface of the frame.

NON-OPERATOR'S SIDE

(inside frame view, not to scale)

Block mounts to the

inside surface of the frame.

PAGE 17 TP10320A

Page 18

TP10320A PAGE 18

BAUM

31

22

10

23

17

24

20

21

41

36

26

25

27

42

38

40

39

37

19

3

18

16

4

43

6

7

4

9

12

11

5

44

15

28

29

9

30

1

2

DESCRIPTION:DESCRIPTION:

DESCRIPTION:

DESCRIPTION:DESCRIPTION:

UNIT NAME:UNIT NAME:

UNIT NAME:

UNIT NAME:UNIT NAME:

2

30

32

WETSCORE ASSEMBLYWETSCORE ASSEMBLY

WETSCORE ASSEMBLY

WETSCORE ASSEMBLYWETSCORE ASSEMBLY

3

30

33

WETSCOREWETSCORE

WETSCORE

WETSCOREWETSCORE

30

4

14

13

8

1

30

34

35

ASSEMBLY NUMBER:ASSEMBLY NUMBER:

ASSEMBLY NUMBER:

ASSEMBLY NUMBER:ASSEMBLY NUMBER:

267-861-BG-01267-861-BG-01

267-861-BG-01

267-861-BG-01267-861-BG-01

REV:REV:

REV:

REV:REV:

1 21 2

1 2

1 21 2

SHEET OFSHEET OF

SHEET OF

SHEET OFSHEET OF

Page 19

267-861-BG-01

BAUM

ITEM NO. DESCRIPTION PART NO. QTY.

1 PJ604-06 MOUNTING BRACKET 268-096-01-00 1

2 PJ604-42 INJECTOR SUPPOR T ARM 268-097-01-00 1

3 PJ604-07 FLUID CONT AINER SUPPOR T 268-098-01-00 1

4 PJ604-10 NEEDLE V AL VE 268-099-01-00 5

5 PJ604-30 STRAIGHT TUBE FITTING 268-100-01-00 1

6 PJ604-09 MANIFOLD 268-101-01-00 1

7 PJ604-11 MANIFOLD BRACKET 268-102-01-00 1

8 PJ604-12 SENSOR AMP . MOUNTING BRACKET 268-103-01-00 1

9 PJ604-17 SENSOR AMP . MODULE 268-104-01-00 1

1 0 PJ604-26 MALE 3 POLE RECEPT ACLE 268-105-01-00 1

11 PJ604-28 FUSE 268-106-01-00 1

12 PJ604-24 FUSE HOLDER 268-107-01-00 1

13 PJ604-22 T & B CABLE STRAIN RELEIF 268-108-01-00 2

14 PJ604-23 ROCKER SWITCH 268-109-01-00 1

15 PJ604-21 ELECTRIC PLUG 268-110-01-00 1

16 PJ604-08 SOLENOID V A LVE 268-111-01-00 1

17 PJ604-33 1/8 NPT STREET ELBOW 268-112-01-00 1

18 PJ604-37 V A LVE MTG . BRACKET 268-113-01-00 1

1 9 PJ604-32 VINYL TUBING 10 in. Lg. 268-114-01-00 1

20 PJ604-27 QUICK DISCONNECT 268-115-01-00 1

2 1 PJ604-32 VINYL TUBING 24 in. Lg. 268-116-01-00 1

22 PJ604-13 CONT AINER SUPPORT 268-117-01-00 1

23 PJ604-15 CONTAINER RET AINER 268-118-01-00 2

24 PJ604-14 CONTAINER RET AINER 268-119-01-00 1

25 PJ604-20 POLYETHYLENE BOTTLE 268-120-01-00 1

26 PJ604-31 BULKHEAD FITTING 268-121-01-00 2

27 PJ604-40 SEAL W ASHER 268-122-01-00 2

28 PJ604-03 SENSOR MOUNTING BLOCK 268-123-01-00 1

2 9 PJ604-04 SENSOR MOUNTING BAR 268-124-01-00 1

3 0 PJ604-16 NYLON THUMB SCREW 268-125-01-00 9

3 1 PJ604-25 3 POLE 90ß CONNECTOR 268-126-01-00 1

32 PJ604-02-1 NOOZLE HOLDER 268-127-01-00 1

33 PJ604-02-2 NOOZLE HOLDER 268-128-01-00 1

34 PJ604-02-3 NOOZLE HOLDER 268-129-01-00 1

35 PJ604-02-4 NOOZLE HOLDER 268-130-01-00 1

3 6 PJ604-32 VINYL TUBING 9 in. Lg. 268-131-01-00 1

37 PJ604-01 PIPE TO LEUR THREAD ADAPTER 268-132-01-00 4

38 PJ604-29 90ß ELBOW 268-133-01-00 4

39 PJ604-18 LEUR ADAPTER 268-134-01-00 4

40 PJ604-41 FIBER W ASHER 268-135-01-00 4

4 1 PJ604-32 VINYL TUBING 60 in. Lg. 268-136-01-00 4

42 PJ604-19 HYPODERMIC NEEDLE 268-137-01-00 4

4 3 TYPE SJ 16/3 ELECTRIC CABLE 2 ft. Lg. 268-138-01-00 1

4 4 TYPE SJ 16/3 ELECTRIC CABLE 10 ft. Lg. 268-139-01-00 1

2 22 2

2 22 2

2 2

REV:REV:

REV:REV:

REV:

SHEET OFSHEET OF

SHEET OFSHEET OF

SHEET OF

267-861-BG-01267-861-BG-01

267-861-BG-01267-861-BG-01

267-861-BG-01

ASSEMBLY NUMBER:ASSEMBLY NUMBER:

ASSEMBLY NUMBER:ASSEMBLY NUMBER:

ASSEMBLY NUMBER:

WETSCOREWETSCORE

WETSCOREWETSCORE

WETSCORE

WETSCORE ASSEMBLYWETSCORE ASSEMBLY

WETSCORE ASSEMBLYWETSCORE ASSEMBLY

WETSCORE ASSEMBLY

DESCRIPTION:DESCRIPTION:

DESCRIPTION:DESCRIPTION:

DESCRIPTION:

UNIT NAME:UNIT NAME:

UNIT NAME:UNIT NAME:

UNIT NAME:

PAGE 19 TP10320A

Loading...

Loading...