Page 1

Section 1 - How to Rebuild a Baumfolder

NOTE: There are several bolts with the same diameter and thread but different lengths.

Do not interchange bolts of different lengths. The length is very important.

1. Before working on the folder: DISCONNECT ALL ELECTRICAL POWER

SUPPLY TO THE FOLDER to prevent accidental start of the folder. Check level

across the number one roller and from front to back of left and right frame. Check to

insure you have all the parts and tools necessary such as reamers, gauges, and etc. It is

2. Remove all guards covering area where you are working. If side guard you are removing

3. Remove drive belts. If you are not familiar with the equipment, I

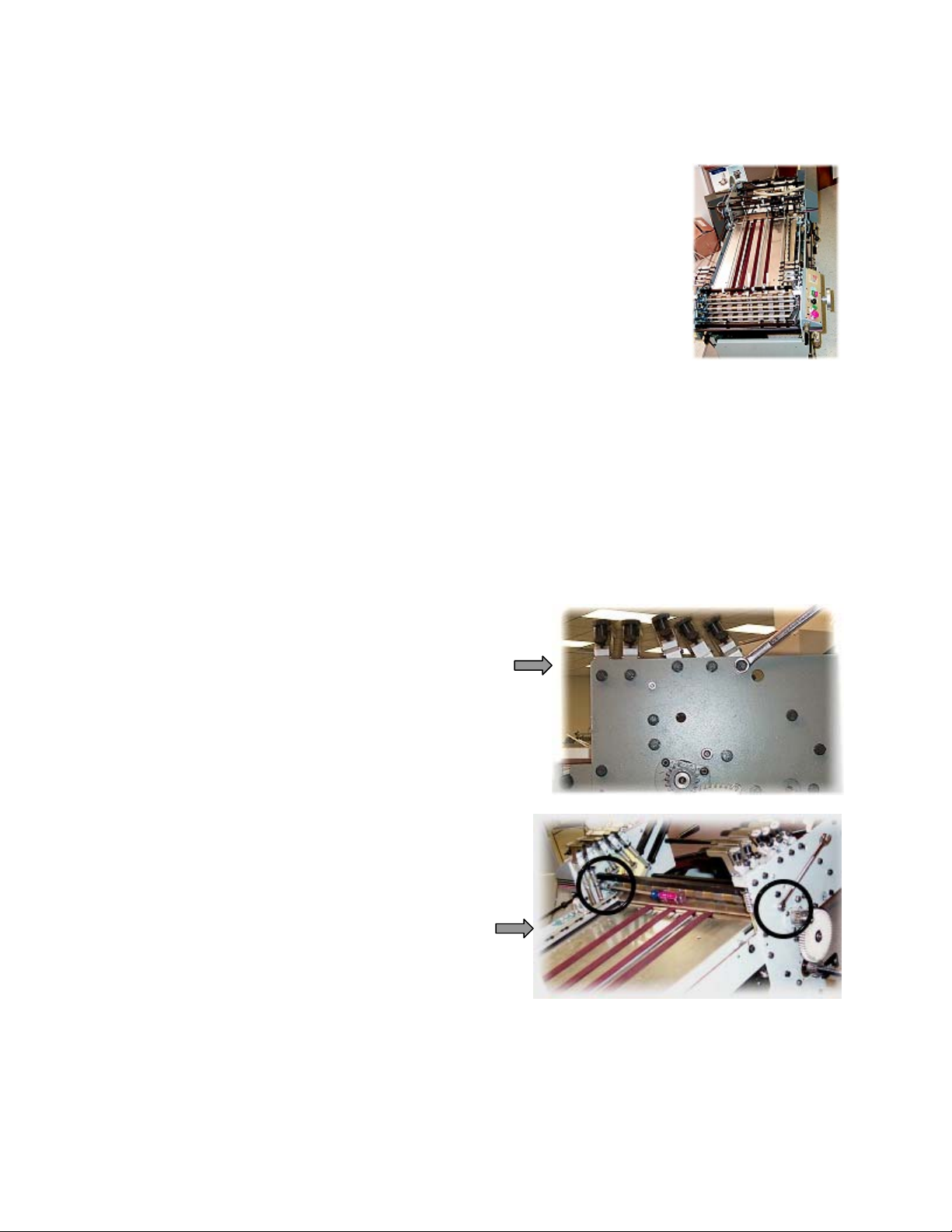

4. Remove the drive gears on the outside of the frame

5. Remove fold plates on the section you are working

6. To remove the fold rolls, loosen the set screw in the collar

7. Make a note of the location of the witness marks for

helpful to clean area around the folder so if you drop anything, it will be easier to find.

has electrical wires in it, do not stretch the wires. The wire may pull out of the terminal

and cause a short when you check the folder. Normally the wires are long enough that the

controls can be placed in a position where it is out of the way while working on the

folder. You may have to remove the hand wheel on the 500 series to allow the wires to

pass between the frame and the throw off rod. Caution should be exercised when

replacing the guard not to pinch lead wires between the guard and the frame causing a

short in the electrical system.

suggest you put tape on the belt and identify its location for later

convenience.

on the non-operator side of the folder section you

are working on. Use your parts book if you have

trouble remembering how it goes back or draw a

sketch for future reference.

on. Store them in a manor that the nose of the fold

plate or the plate itself is not damaged.

of each fold roll (usually on the left end of the fold roll)

and move collar toward the body of the fold roll.

future reference. You can achieve the proper space

between the fold rolls with the eccentrics 180 degrees off

until you get to the number 5 fold roll. You want to know

where to start when setting the rollers.

8. Do not remove the plate rails or if applicable the eccentric deflector studs. You can

remove the fold rollers with the rails and studs in place. This will save time later when

setting fold plates.

Section 1 - Page 1

Page 2

Section 1 - How to Rebuild a Baumfolder..... continued

9. It is not necessary to remove the register table to change the fold rollers, but I recommend

it to allow better access when removing rollers and later when setting the eccentrics and

fold plate setting on # 2 and # 4 plate and rolls.

10. To remove register table:

A) Remove paper hold downs

B) Remove tuck in shoes.

C) Remove marbles from marble guide.

D) Remove marble guide.

E) Remove side guide. Slide register belt under marble guide

over to get to the flat head screws that fastens the side guide.

F) Remove tape tighten assembly. (under register table) loosen

2 bolts on each end and slide assembly toward operator side

from above the belts and below the register table.

G) Remove taper plate between feeder and register tapes (a flat head screw on each

end.)

H) Lift up on the large tape roll, (by feeder), on the non-operator side of the folder

and slide it toward you to remove it.

I) Have two people, one on each side of the register to hold the register while

removing the four bolts that fastens it to the frame. Then lower the end toward the

feeder down and forward and lift up the opposite end until the register clears the

Baumsets/ roller adjustment stems. Then lift the register to a safe location where it

will not be damaged.

J) To replace register when finished, reverse procedure I through A.

11. Remove slitter shafts.

12. Remove all tension block bolts. Ten (five on

each side) on a three or four plate folder, six

(three on each side on a two plate folder.

13. If the folder has oil lines, remove oil lines from

the roll boxing and main drive roll.

Remove the clip that fastens the oil lines to the

frame on the operator side just above the number

one roller.

14. Remove the right and left roll boxing eccentric

from the number one fold roller. (Note: these

eccentric bolts are usually fine thread. Most of

the other bolts are course thread.) Lift the

number one roll up and out of the folder.

15. Continue step number 14 on the #2, then #4,

then #5, then#3 rollers in that order. Rollers

number 5 and 3 should come under the roll

bank and toward the delivery end of the roll bank to remove.

16. Remove hand wheel on operator side of the folder. If the hand wheel is not free of the

fold rollers, it should be left off or replaced by one that engaged when you want to turn

the folder by hand.

Section 1 - Page 2

Page 3

Section 1 - How to Rebuild a Baumfolder..... continued

17. Remove the three flat head bolts on the main drive roll sleeve on the operator side of the

folder. Remove the main drive roll sleeve, and slide the main drive roll out through the

opening in the frame.

18. Remove the left hand main drive roll sleeve.

(Caution) mark the main drive roll sleeves so they are

not put on wrong side when reassembling unit. The oil

hole will be in the wrong location.

PREPARATION TO INSTALL NEW ROLLERS

19. The main drive roll sleeves have two brass bushings, one pressed in from each side and a

space between the bushings. Press both bushings out. Then press in the new bushing in

from the flange side of the main drive roll sleeve until it is flush with the sleeve. Then

press the second one in on the small end of the main drive roll sleeve, (end toward the

body of the roll,) leaving the bushing extend .015 out of the main drive roll sleeve. This

allows the collar or the roll gear to run against the bushing instead of the metal in the

main drive roll sleeve.

20. Hand ream the bushing with a standard 7/8 of inch, or the diameter of the main drive roll

journal (shaft). Normally you do not ream an oilite bushing, but the folder will be oiled

and does not depend on the oil in the bushing. Repeat step 19 and 20 on the opposite

main drive roll sleeve.

21. Insert both right and left main drive roll sleeves and tighten the three flat head bolts in

both without the main drive roll. check the location of the oil hole in the main drive

sleeve to insure correct position of the sleeves.

22. Insert the proper diameter lining bar through the main drive roll sleeve and to about one

quarter of an inch from the opposite main drive roll sleeve. With no pressure, move the

lining bar up and down watching to see if it centers with the bushing in the main drive

roll sleeve. Then move the lining bar from side to side. If the lining bar is low in

relationship to the bushing in the main drive sleeve, put a shim at the top of the main

drive roll sleeve between the flange and the frame, leaving the shim at least one inch past

the flange. This would allow you to tape the shim to the frame so when you remove the

main drive roll sleeve to install the main drive roller, you would not loose the alignment.

Go from one side to the other until the lining bar turns free and with as few shims as

possible.

23. Now add the reamer to the end of the lining bar and ream from left to right then right to

left. Remove the main drive roll sleeve and install the new main drive roll. When

installing the roll gear, note one side of the i.d. of the gear has a bevel. The bevel should

go toward the body of the roller. Compare the main drive roll with the roll you removed

to be sure the flats on the journal is in the correct location. The main drive roll should

have a gear on one end and a collar on the other. On most eight and sixteen page units, it

will have a roll gear on one end and the crosscarrier drive gear on the other.

24. Replace the main drive roll sleeve and just smug up the three flat head bolts. Turn the roll

with your fingers and tighten the flat head bolts one at a time. The roll should turn easy

Section 1 - Page 3

Page 4

Section 1 - How to Rebuild a Baumfolder..... continued

while you tighten the bolts. If one makes the roll turn harder, you probably don't have it

align correctly.

25. Now trim off the shims that were taped to the frame even with the flanges on the main

drive roll sleeve.

PREPARING IDLER ROLLERS FOR INSTALLATION.

1. Most idler roll has the same journal on both ends. There should be a key way close to the

body of the roll. Insert the woodruff key, and with a fine file smooth any ruff edges of the

key.

2. The roll gear should have a square edge in the center opening and a beveled edge. The

beveled side should go toward the body of the roll. Line the gear on the roller journal,

shaft), with the woodruff key and press the gear on the journal until the gear is against the

body of the roll. Careful that the gear is pressed on straight and is aligned with the key. If

not, the metal scrapped from the key and/or the journal will not allow the gear to fit tight

against the body of the roll.

3. Remove the collars from the old idler rolls, clean the collar and remove any burrs with

fine emery cloth. Place the collar on the opposite journal against the body of the idler roll

and just snug the set screw against the flat area provided on the roll journal.. Any time

you tighten the set screw against the rounded part of the journal, it will leave a burr on

the journal and it will be difficult if not impossible to move the collar later. Complete

steps 2 and 3 on the three other idler rolls on a two plate folder or five idler rolls on a

three or four plate folder.

PREPARING ROLLER BOXING FOR INSTALLATION.

1. You will have either six or ten roller boxing depending on the number of fold plates in

the folder. Do all of them in pairs. Example, do both number one boxings, then number

two and etc.. Before you begin, Insert a new eccentric in the eccentric hole in the roll

boxing to make sure the roll boxing is not worn.

2. Before you press out the old bushing, the older folders had a small set screw with a point

on it that screwed into the bushing under the boxing. Check and if it has one, loosen the

set screw before pressing out the bushing. The cherry wood bushings and brass bushings

are pressed in and reamed the same way.

3. Check each roll boxing before pressing in the new bushing to insure you can drill the oil

hole in the bushing AFTER it is pressed in. If not, measure the location of the oil hole in

the roll boxing and drill a slightly larger hole in the bushing and line it with the oil hole in

the roll boxing before pressing the bushing into the roll boxing. When starting the

bushing, start the beveled end of the bushing into the beveled side of the roll boxing.

Allow the bushing to extend .015 past the surface on the side of the roll boxing toward

the body of the roll. Usually you can look on the side of the roll boxing for the witness

mark for the eccentric to identify the side toward the fold roll. Again this is to allow the

collar/gear to run against the bushing instead of the metal roll boxing. If this is not done,

the folder may begin squealing after it runs for a couple of hours. Then it is fun trying to

locate the location of the noise.

4. After pressing in the bushings in all of the roll boxings, tighten the set screw if the roll

boxing has one. Place the roll boxings in pairs, back to back and insert a 1/2" shaft

through the eccentric holes to align the two boxings. Now run a reamer the diameter of

the roller journal (shaft) through both bushings. Use an expansion reamer, to ream out

.002, again running through both bushings. The bushing on the idler rollers should be

.002 larger than the roller journal.

Section 1 - Page 4

Page 5

Section 1 - How to Rebuild a Baumfolder..... continued

5. Continue this procedure for all the roll boxings, then insert the new eccentric in the roll

boxing putting a light weight oil on the eccentric as you insert them.

6. Use a light weight oil to apply to the journal of the idler rolls. Then install the number

three right and left roll boxing on the roller journal. The roll gear should be next to the

right roll boxing. Install it back into the folder in reverse order that you removed them.

7. Continue this process with the number five roll, and then four, two, and number one rolls.

AFTER THE ROLLS ARE INSTALLED

1. Set the protractor at five degrees,(the indicator

would be at 95 degrees.) Be sure the #1 and

main drive rolls are together by tightening the

adjustment knob until the washer under the roll

boxing is about 1/16

th

below the roll boxing at

all times during the adjustments.

2. Place the protractor on the end of the #1 and the

main drive roll as shown in Figure 1.

3. Refer to the notes as to the location of the

eccentric and start with the witness mark of the eccentric in that position. Rotate the

eccentric until the protractor bubble is five degrees in front of the main drive roll. Repeat

for the other end of the number one roll. Check both ends again to insure both ends are

the same, (five degrees.)

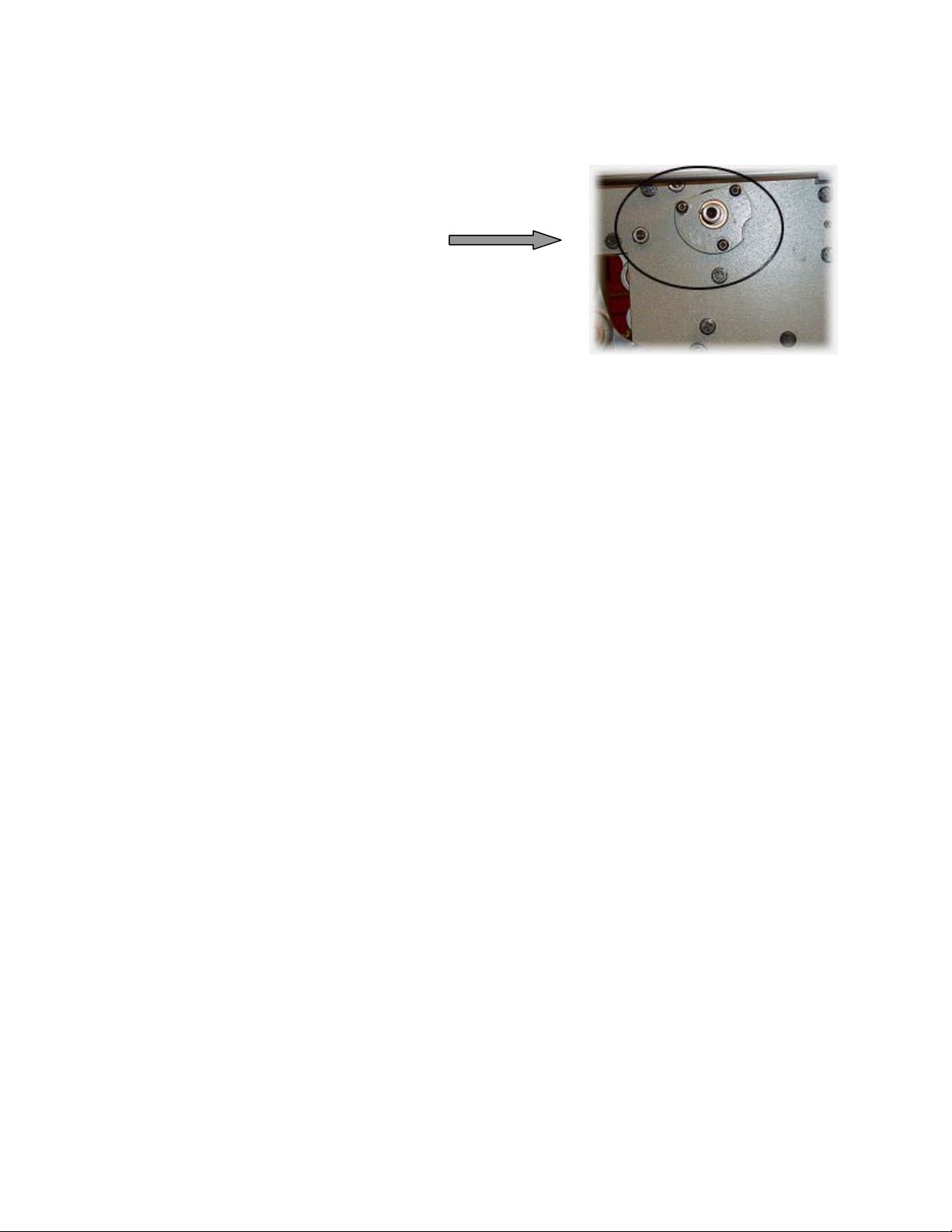

NOTE: Be sure the high point, (see Figure 2 below), of the eccentric is the same

direction on both sides. It is possible to get the same reading with the eccentric 180

degrees off, but the pivot point will be different.

Figure # 2

4. To set the end play in the number one roll, insert a ten thousands feeler gauge between

the collar on the roller and the roll boxing. Use a flat blade screw driver between the

other side of the collar and the body of the roller moving the roll toward the gear side of

the roll. Hold a very light pressure and tighten the set screw in the collar. You should be

able to move the feeler gauge in and out with slight drag. Separate the number one roll

and the main roll. Work the number one roll side ways and you should have very little

movement.

5. Take the end play out of the main drive roll without using the feeler gauge. It should not

have end play BUT allow the roll to turn free without a bind. Tighten the number one

roll against the main drive roll until the washer under the roll boxing has no tension but is

still in contact with the roll boxing.

6. Loosen the set screw in the tension adjusting

screw and loosen the tension on the spring on the

right and left roll boxing. Now tighten it until the

tension adjusting screw just begins to put pressure

on the spring, then turn it one and one half turns

on a adjust adjustment screw with course threads

or two turns on a adjustment screw with fine

threads. To test the tension, you can insert a fine

Section 1 - Page 5

Page 6

Section 1 - How to Rebuild a Baumfolder..... continued

blade screw driver between the number one roll and main drive roll on the bear bands,

noting the pressure when opening and the snap together as you remove it. It should be

about the same on both sides. Now the rolls and the roll gear should be aligned and turn

free using your fingers to turn the rolls without the number two roll in contact with the

main drive roll.

7. Now bring the number two roll into contact with the main drive by rotating the eccentric

on the right and left side to the approximant original position and tighten the roller

tension screw until the washer below the roll boxing is about 1/16

th

. below the roll

boxing. Watch to maintain this space while you are adjusting the roll or you could get a

false setting. Move the number three roll

away so it has no contact with the number

two roll. Insert the roll gage between the

one and two roll on the right side of the

roll as indicated in Figure 3. Turn the

right eccentric until there is a very light

tension on the gage block.( a tolerance of

up to + .003 of a inch as long as both

sides are the same.) Repeat the process on

the left side and check back and forth

until both ends are .718 of a inch. Set the

end play the same as you did with the

number one roll. Now loosen the tension

spring screw on both sides until the

number two roll falls away from the main drive roll with changing the tension screw

setting.(not allowing the tension screw to turn while loosing the spring tension.)now

tighten both right and left tension spring screw at the same time until the number two roll

just touches the main drive roll, then a complete one and one half turns on the course

thread adjustment screw or two complete turns on the fine thread adjustment screw.

Check the tension with the screw driver the same as you did on the first roll. The gear

side may feel slightly different due to the mash of the gears.

Figure 3

8. Repeat the same process with the number three roll as you did with number two roll, then

with number four and five roll the same as you did with number two roll.

9. Now all of the rolls and roll gears should be in line. All

of the idler rolls, (all rolls except the main drive roll)

should have .010 of an inch end play. You should be

able to lay a straight edge from the number one roll

down across the number two roll and the number four

roll on the right and left ends and touch all three rolls.

You should also be able to turn the entire roll bank, (all

six rolls,) with your fingers.

10. See instructions on how to check fold plates and

deflectors to check or install the plates and/or

deflectors.

Section 1 - Page 6

Page 7

Section 1 - How to Rebuild a Baumfolder..... continued

11. Install the gears and belts on the non-operator side of the folder.

12. Replace the register table in reverse order that it was removed.

13. Replace ALL guards. Replace the slitter shaft. If you rebushed the slitter shaft boxings,

put the right and left boxing in place and line ream from left to right then right to left.

then install the slitter shafts, gears, and collars. If you have to line ream the slitter

boxings, do it BEFORE installing the guard.

14. Replace the hand wheel with a new free wheeling hand wheel.

15. Turn the folder over by hand several times to be sure nothing binds or rubs.

16. Square the side guide on the register with the number one roll.

17. Set all fold rolls, see section on calibrating baumsets and setting rollers.

18. Again turn folder over by hand and if every thing is free, apply power supply, turn folder

on and off to verify there is no electrical or mechanic problems and if not, run the folder

slow for a few minutes. Turn off the folder to see if there are any hot spots, Make SURE

power is turned off. If every thing is free, set up the folder and check for folder

accuracy.

NOTE: These instructions use the dimension 5° and .718 for some models of Baumfolders.

Other models use different dimensions – See the following section “Baumfolder and

O&M Gauges” for the proper dimensions for your folder.

Section 1 - Page 7

Page 8

ROLL GAUGE .718 Part Nbr 38334

PLATE GAUGE Part Nbr 91319

DEFLECTOR GAUGE

Part Nbr: For Parallel 10978

For 8 & 16 page 10613

FOLD PAN SETTINGS DEFLECTOR SETTINGS

PARALLEL

‘ A ‘

#1 Fold Pan .015 #1 Deflector .015

#2 Fold Pan .015 #2 Deflector .015

#3 Fold Pan .025 #3 Deflector .025

#4 Fold Pan .025 #4 Deflector .025

#1 Fold Pan .020 #1 Deflector .015

#2 Fold Pan .020 #2 Deflector .015

#3 Fold Pan .025 #3 Deflector .030

#4 Fold Pan .030 #4 Deflector .035

#1 Fold Pan .020 #1 Deflector .015

#2 Fold Pan .020 #2 Deflector .015

#3 Fold Pan .030 #3 Deflector .035

#4 Fold Pan .035 #4 Deflector .040

End play in Rolls .10

To ADJUST Fold Pans – Use Rail Ecc.

Front Ecc. - In & Out plus

Rear Ecc. - Up & Down only

‘ A ‘

8-PAGE

16-PAGE

Up & Down

Section 1 - Page 8

Loading...

Loading...