Page 1

Pneumatic Gatefold Installation Instructions

For

Baum 2018, 2020 Pile & Continuous Feed Folder

models

This manual is a supplement to the operating manual. It is to be used for initial installation by a

Baum authorized field technician. For actual setup and operation of the gatefold, see the

operator’s manual.

© Baumfolder Corporation., Printed in USA TP10407

Page 2

Inspect shipment carefully for any damage immediately. If freight damage occurs, contact the

freight carrier immediately. Do not discard crating materials until installation is complete.

Make sure that all parts are shipped with the unit. A gatefold attachment includes:

1) Gatefold plate

1) Optical sheet sensor with cord

1) Encoder cable

1) Main control box

• Note that an air compressor is not supplied with the unit. It is recommended to use an air

supply with (90) PSI or (5) bar air pressure.

• Note that the airline fitting to connect to the customer air supply is not included due to the

variety of possibilities. Be sure to measure and procure the correct connection. Note that a

water trap is recommended to eliminate condensation from the air system.

• Note that the pneumatic gatefold does not require a stationary deflector above in the #2

foldplate position. Previous electronic gatefold designs required a stationary deflector for

mounting in the foldplate position above the gatefold plate when installed in the folder.

• The incoming electrical power for the gatefold control box is supplied using the X10

connector on the left-hand side of the main operator’s control box of the Baum folder. Later

models include this plug as standard equipment on the main box. Some early model Baum 20

series folders do not have this connection pre-wired. If your Baum 2018 or 2020 folder does

not have the X10 connector, contact the Baum parts department for the correct plugs and the

Baumfolder technical support department for wiring information for your folder.

• Note that these instructions are for the initial installation. The instructions for installation for

each use afterward are found in the operator’s manual. You must follow the set procedure for

installation for operation for successful results.

• The control box of the gatefold attachment can also be used for specified gluing operations

with addition of the proper gluing heads and modifications to the folder. Both inline and inplate gluing applications are adaptable. For more information on folding and gluing, refer or

request a copy of the Baum “Gluer Guide”. Baum offers complete segmented fold rollers and

grooved foldplates to meet these needs. Using genuine Baum parts is required to maintain the

factory parts warranty on new Baum installations. Use of other manufacturer’s parts will void

the factory warranty.

• The timed perforations function on the control is not applicable to the Baum 20 series

folders. This feature requires pre-slittershafts on the folder that are not available on the Baum

20 Series.

• Wiring information shown is applicable to Baum 20 series with DCT500 electrical design.

To connect to Baum 20 series folders previous to this design, contact the Baum technical

support department at 1-800-543-6107.

1) Mounting post with air regulator and

hoses attached

1) Mounting hardware for post

1) Operation manual

2

Page 3

1. Install mounting post to feeder

frame on the non-operator side of

the folder. Drill (2) ¼ inch or 6.5mm

diameter clearance holes in the

frame as shown. Use the hardware

kit supplied to mount the post to the

frame.

2. Place the control unit on top of

the mounting post. Install the power

cord. Connect the Optical sheet sensor

to Input 1. Connect the electrical cord

from the gatefold plate to Output 1.

Connect the encoder cable to the

Encoder connection. View shown is

from the backside.

3. Disconnect power from folder.

Wire the other end of the Encoder

cable to the main electrical box on the

folder. Insert encoder cable through

an opening available in the back of

the main control box of the folder.

Go to connector block 2X15. Connect

the gatefold encoder cable wire #1 to

pin #1 with the white wire.

Connect gatefold encoder cable wire

#2 to pin #2 with green #2 wire.

3

Page 4

4. Remove wire #13L1 from the side of Auxiliary

contact block K2. Move this wire up to the open side

of terminal 12L1 on the terminal strip TB-1.

5. Connect the blue air line hose to the air regulator at one end and to the gatefold plate at the

other end. The connections are brass quick connect couplings. It is best to do this without air

pressure in the line.

6. Connect the airline from the air

regulator to the incoming air supply.

Note that (90) PSI or (5) bar is

required for the correct operation.

4

Page 5

7. Install the gatefold foldplate in the #4 foldplate

position. Make sure that there is no interference.

Turn the handwheel on the folder to check. If there

is interference use Baum gage kit #261-998-BG01 from the Baum Parts Department to set

clearances by adjusting the plate stops correctly.

8. Connect the power cord for the gatefold control

box to electrical connection X10 on the left-hand

side of the main folder control box. If the X10

connector is not on the main box, order part

number 263-564-01-00 from the Baumfolder Parts

Department. Contact the Baum technical support

department for correct wiring information.

9. Fasten the optical sheet sensor to the underneath

side of the #3 foldplate on a rib. Locate the sensor

all of the way forward against the front lower

support rail. Tighten the setscrew in the side. You

can use the long-handled 4mm-ball driver that is

standard with the folder to adjust the setscrew.

10. Connect the air supply and set the pressure

regulator to (5) bar on the gauge. Pull up on the

adjustment knob to make adjustments.

5

Page 6

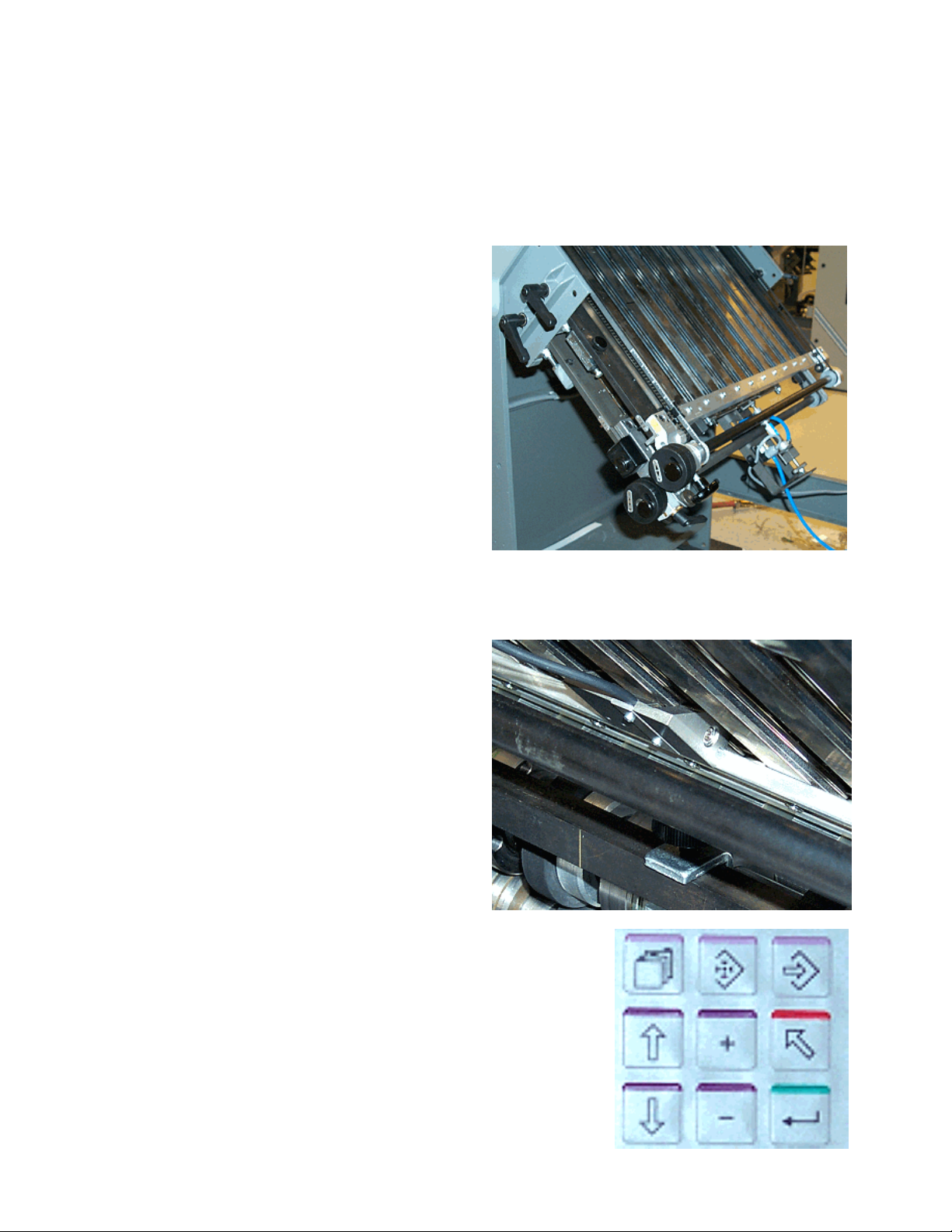

To set the control panel readout for proper machine size and

language, perform the following:

1. Press the main power button in the lower left-hand corner of the

gatefold control to turn power on.

2. Select channel #1 using the channel selection button.

• The message

(German) language.

• If the control is in English the readout will be

need to change the language to English, follow these steps.

2. Press the enter button in the data entry keys in the lower left-hand

corner. The word

Use the plus and minus buttons to set the width to 52cm if required.

3. Press the down arrow button located in the data panel in the lower

left-hand corner. The words

4. Press the down arrow button again and the words

“ 1 Falzlange L1” will appear if the readout is in Deutsche

“1 Foldlength L1”. If you

“Arbeitbreite 52” will appear.

“Diagnose” will appear.

“Sprache (lingua)” will appear.

5. Press the plus or minus button to select English.

6. Press the confirm button with the arrow going at an angle to secure the

setting. The words

selected.

“1 Folding Length L1” will appear if channel “1” is

6

Page 7

Setting up a Job to test.

It is important to set up a gatefold job

(1) step at a time. Work from the feeder

forward. Make your setup procedure the

same steps as the paper would travel

through the folder.

1. Always hand fold a sample as close

as possible to the final result that is

required. Mark the sample and place it where you can refer back to it. Note that

you must leave approximately 3mm or 1/8 inch gap between the (2) panels that

fold in toward each other. Use the conveniently located scale on the register

table to measure all dimensions. The “0” location of the scale is against the side

of the aluminum block where the scale starts.

2. After setting up the feeder and

register table, set up the fold head.

DO NOT INSTALL THE

GATEFOLD PLATE AT THIS

TIME. Begin by inserting sheets of

the stock to be folded into the

Baumsets as follows:

• Baumset #1 (1) Thickness

• Baumset #2 (1) Thickness

• Baumset #3 (1) Thickness

• Baumset #4 (2) Thicknesses

• Baumset #5 (4) Thicknesses (You will add more later to this one)

3. Set foldplate #1 to open folding position and set the length measured on the

first flap (L1). In the example of an 11 x 17 sheet, the first fold length will be 41/4 inches. Remove the #2 and #4 plates and leave these positions open so that

the paper can fall onto the floor. Turn the handwheel on the folder before

starting to insure that all foldplates are not rubbing. Feed test sheets at the speed

you expect to be folding and match the fold from the first panel to match the

sample. Make sure this fold is acceptable before proceeding.

7

Page 8

4. Reinstall foldplate #2 and have it set to deflect the paper. Leave #4 position

open without a foldplate. Set foldplate #3 open to folding to make the second

foldlength (L2). On an 11x17 sheet this length will be approximately 8-1/2

inches. Send test sheets and match against sample until fold is satisfactory.

5. Install the gatefold plate in the #4

position. Do not connect the power

supply to the gatefold. Pull the

movable sheet-tucking device down

away from the fold rollers to allow the

sheet to enter the plate in the

deactivated mode. Set the analog

readout device for fold depth to

approximately 105mm for an 11x17

gatefold. For other lengths, measure

the sample and set accordingly. Run

test sheets until the proper fold length

is achieved. The test sheets will exit

onto the delivery stacker with the last flap trailing the sheet. Pick up the sheet

and fold the flap in to test the length setting.

6. Install the Optical position sensor

under the #3 foldplate. This may

already be installed from previous

setup. Make sure that the sensor is

located down as far as it can be set

closest to the fold rollers.

7. Set up the Gatefold Control settings. You must set

the L1, L2 and the position sensor settings to run the

job.

8

Page 9

9

9

Page 10

10

Page 11

Send test samples and look for inside “dog ears” or damaged edges to the inside

edges. These are a signal that the timing needs to be adjusted. Do not adjust the

fold lengths. This is not the problem. If you follow the step by step procedures,

setting the timing is the only change required to complete the accuracy.

Box Folds:

You will now see a “double crease” or a box fold on one of the gates. To relieve

this, add the same amount of sheet thicknesses to each side Baumset for the #5 fold

roller. The more paper added to the Baumset, relaxes the tension and alleviates the

double crease. You will get a softer fold. To flatten the fold, add the Baum 8-page

right angle folder at the exit of the parallel folder. Set all foldplates on deflect

positions. Set all Baumsets in the 8-page folder to (4) thicknesses. This will flatten

the sheet if required.

11

Page 12

1-800 543-6107

Baumfolder Corporation

1660 Campbell Rd. Sidney, OH 45365

12

Loading...

Loading...