Page 1

1 2

3

4 5

6

7 8 9

C

0

x

D

PROGRAMMABLE

BAUM USA

Original Operating Instructions

High-Speed Cutter

BAUMCUT 31.5

i

Page 2

Index page

Control Panel / Operating Elements ............................................................... E - 4

Explanation of Pictographs on the Display ......................................................E - 5

Chapter Survey ...............................................................................................E - 6

Introduction ..................................................................................................... E - 7

Technical Data/Machine Layout/Transport and Installation ....................K1 - 1

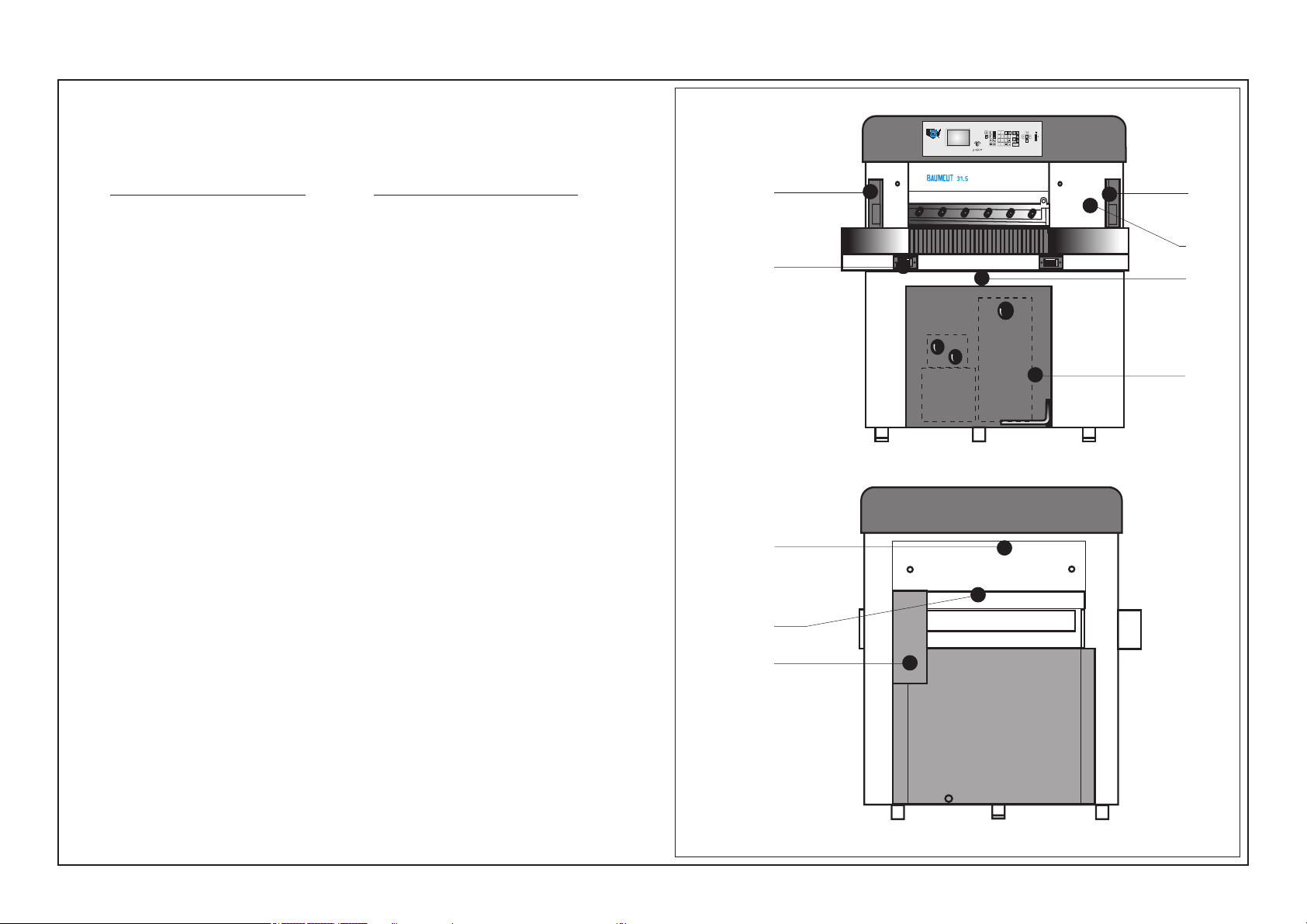

Machine Layout ............................................................................................K1 - 2

Plan .............................................................................................................. K1 - 3

Transport and Installation of the Machine .....................................................K1 - 4

Place of Installation ...................................................................................... K1 - 4

After the Installation of the Machine.............................................................. K1 - 4

Power Supply ............................................................................................... K1 - 5

Type plate .....................................................................................................K1 - 6

Safety Relevant Machine Elements .............................................................. K1 - 7

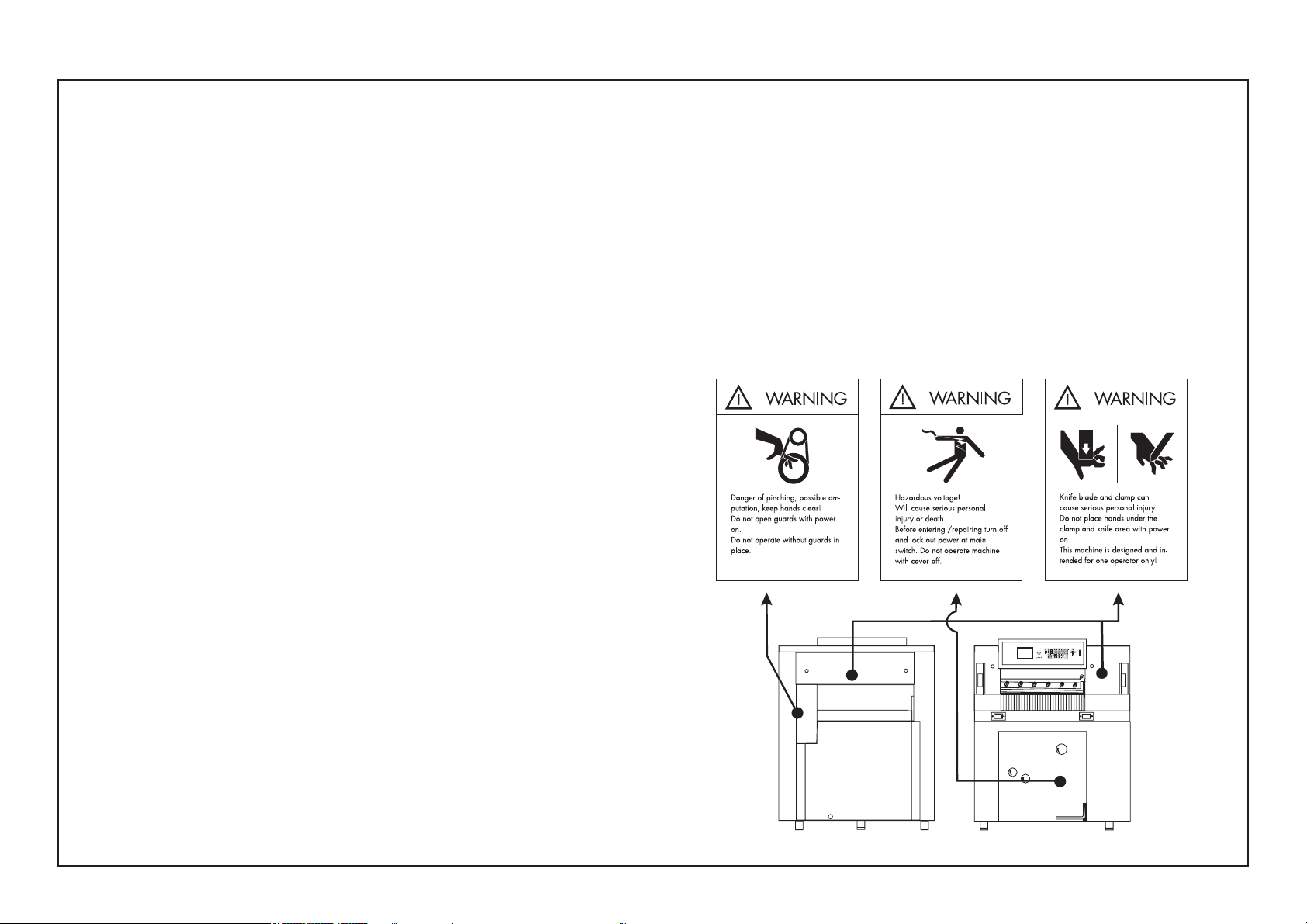

Accident prevention warning labels at BAUM cutters. ................................... K1 - 8

Safety Relevant Machine Elements .............................................................. K1 - 8

Safety Signs ................................................................................................. K1 - 9

Technical Data ............................................................................................ K1 - 10

Permissible Environmental and Operating Conditions ................................ K1 - 10

Hydraulic Data ............................................................................................ K1 - 10

Safety Precautions ..................................................................................... K1 - 10

Residual Risk ............................................................................................. K1 - 10

Technical Data ............................................................................................ K1 - 11

Safety ........................................................................................................... K2 - 1

Start Up ....................................................................................................... K3 - 1

Switching Machine ON ................................................................................. K3 - 2

Turning Machine OFF................................................................................... K3 - 2

Measurement Display and Measurement System ........................................ K3 - 3

Manual Operation .......................................................................................K4 - 1

Cutting Line Indicator, Mechanical with Clamp.............................................. K4 - 2

Cutting Line Indicator, Optical .......................................................................K4 - 2

Setting of Measurements (Backgauge Movement) by Hand ......................... K4 - 2

Clamp Pressure Adjustment ......................................................................... K4 - 3

Setting the Clamping Time ........................................................................... K4 - 3

Clamping and Cutting ................................................................................... K4 - 3

Light Barrier ..................................................................................................K4 - 4

Continuation: Light Barrier ............................................................................ K4 - 5

Air Table ....................................................................................................... K4 - 6

Clamping with False Clamp Plate ................................................................. K4 - 6

Automatic Operation ............................................................................... K5A - 1

Introduction ................................................................................................. K5A - 2

Basic Displays ............................................................................................ K5A - 3

Basic Display: Program Data ......................................................................K5A - 3

Contin.: Basic Display: Program Data ......................................................... K5A - 4

Basic Display: Program Information ........................................................... K5A - 5

Basic Display: Program Directory ............................................................... K5A - 6

Basic Display: Main Menu (Function Survey) .............................................. K5A - 7

Menu "Help":............................................................................................... K5A - 7

Explanation of pictographs .........................................................................K5A - 7

Cursor Movement in Basic Display .............................................................K5A - 8

Automatic Backgauge Adjustment through Numerical Keyboard ................ K5A - 9

Deletion of a Wrong Input ......................................................................... K5A - 10

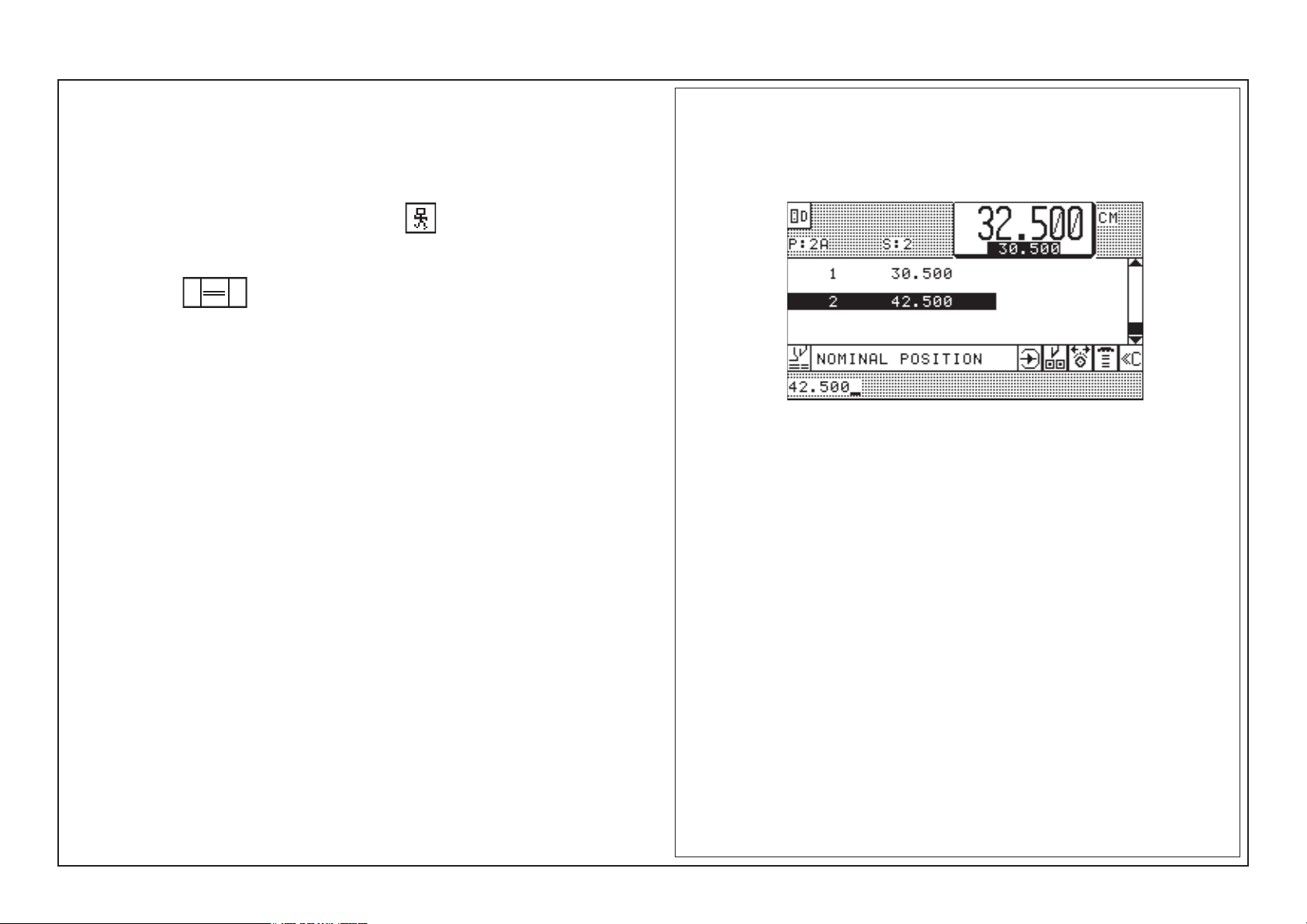

Moving Backgauge to a Nominal Position (Positioning) ............................K5A - 10

Input Error: Value of Nom. Backgauge Position too Low/High ..................K5A - 10

Selection of a Free Program/Display of the Next Free Program ............... K5A - 11

Selecting a Program .................................................................................K5A - 12

Continuing: Selecting a Program .............................................................. K5A - 13

Storage of Measurements ........................................................................ K5A - 14

Setting Up a Cutting Program, Example 1 ................................................ K5A - 15

Setting Up a Cutting Program, Example 2 ................................................ K5A - 16

Correction of an Input Error ...................................................................... K5A - 17

Automatic ON/OFF ...................................................................................K5A - 18

Running a Cutting Program ...................................................................... K5A - 19

Storing of Program Informations ............................................................... K5A - 20

Deletion of a Step Number........................................................................ K5A - 21

Deletion of One/Several Program(s) ......................................................... K5A - 22

Deletion of Complete Memory .................................................................. K5A - 23

Inserting of Measurements into a Program ...............................................K5A - 24

Storing of Measurements According to Printed Image ..............................K5A - 24

Calculator Functions .................................................................................K5A - 25

Negative Sign ...........................................................................................K5A - 26

Using Backgauge Position of Calculations ............................................... K5A - 26

Machine Functions and Additional Functions (Menu Keys) ................ K5B - 1

Machine Function: Main Menu (Function Survey) ...................................... K5B - 2

Menu "Help":.............................................................................................. K5B - 2

Explanation of pictographs ........................................................................ K5B - 2

Service ...................................................................................................... K5B - 3

E - 2

Page 3

Index

Select Language/Measuring Unit ............................................................... K5B - 3

Knife Compensation ................................................................................. K5B - 4

Resting Time for Knife at BDC................................................................... K5B - 5

Maintenance Cut Counter .......................................................................... K5B - 6

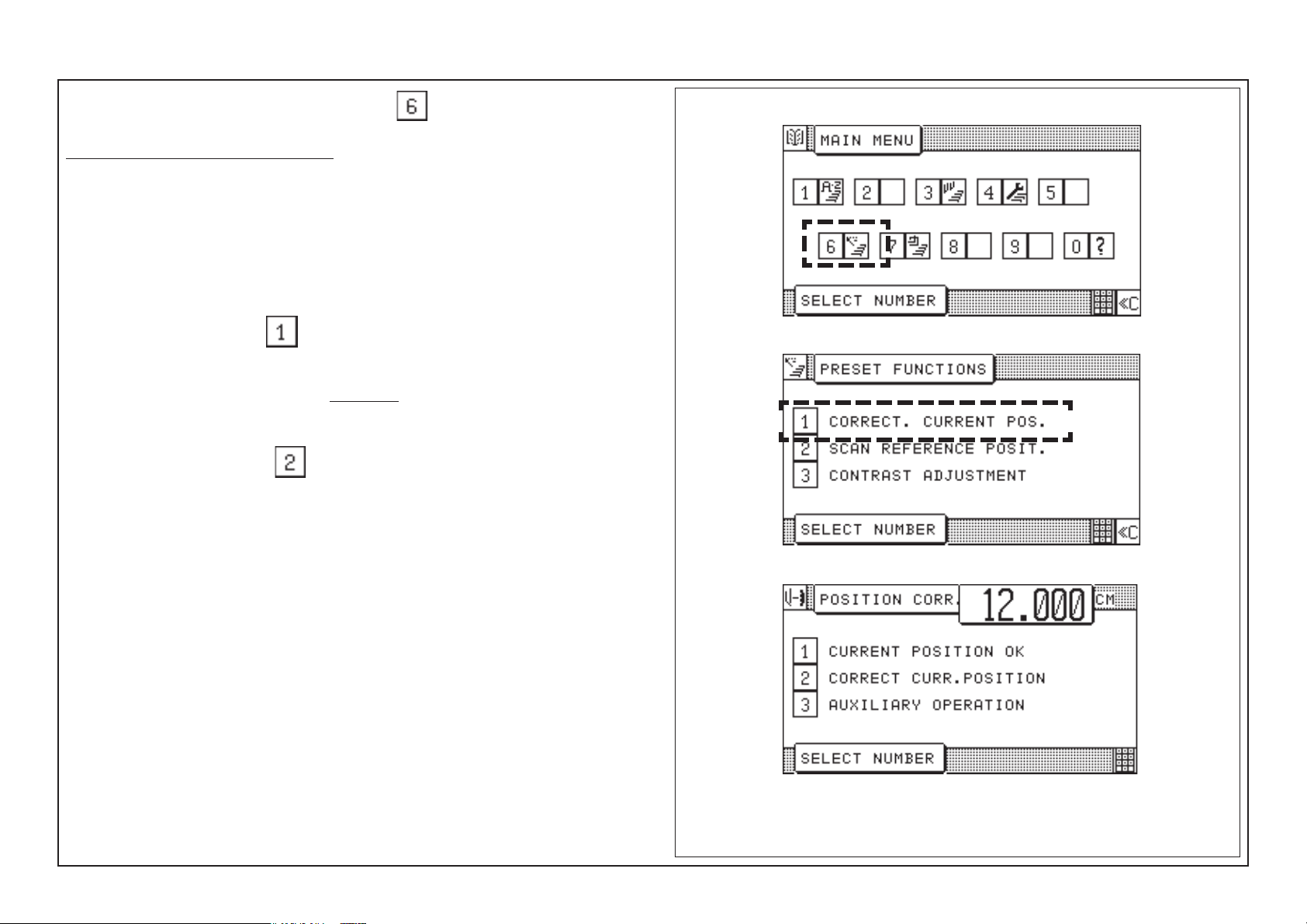

Preset Functions ....................................................................................... K5B - 7

Continuing: Preset Functions ..................................................................... K5B - 8

Adjustment of Display Contrast ................................................................. K5B - 9

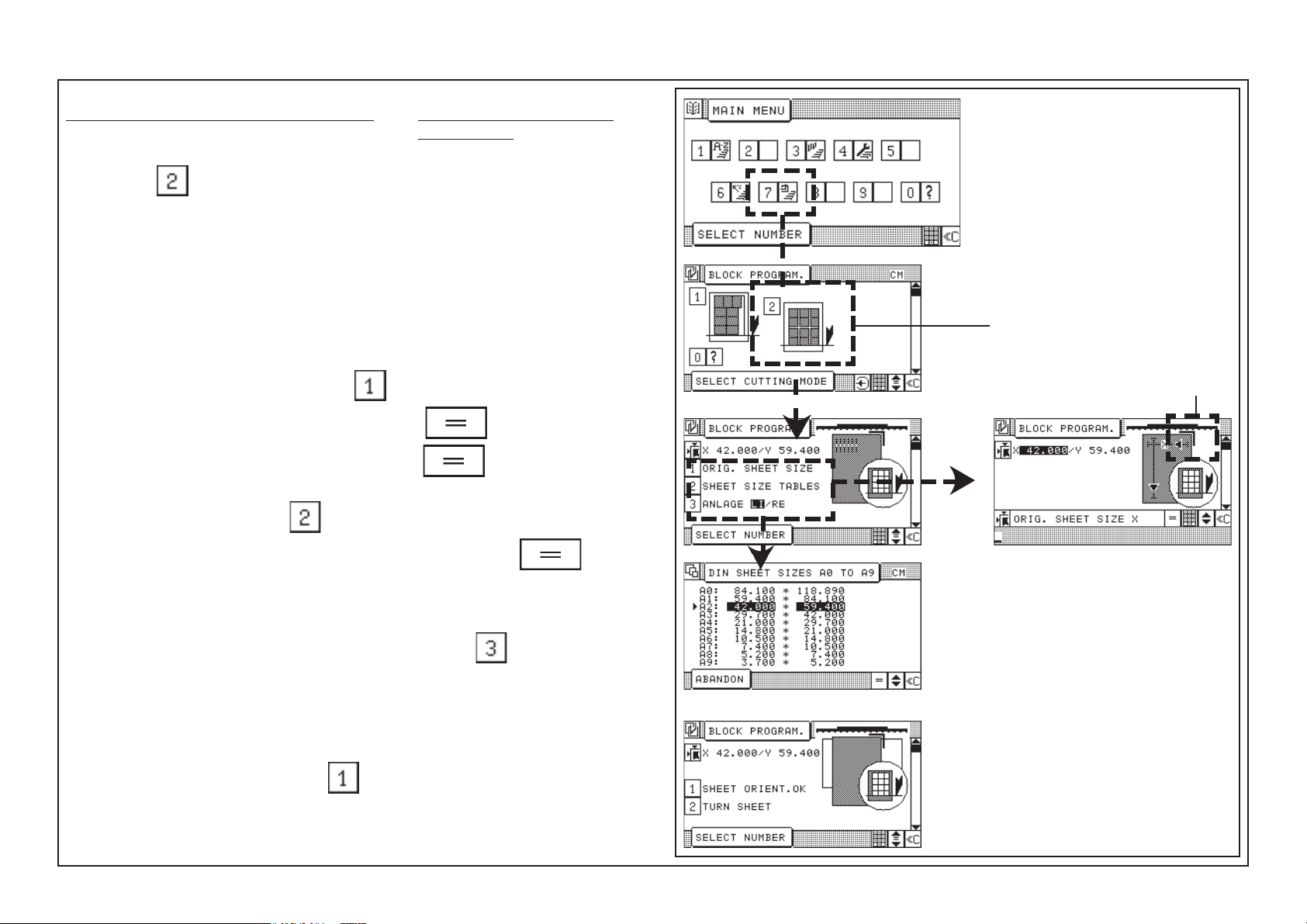

Block Programming ................................................................................. K5B - 10

Variation 2................................................................................................ K5B - 10

(with edge trim preadjusting) ................................................................... K5B - 10

Variation 1................................................................................................ K5B - 10

Variation 3................................................................................................ K5B - 10

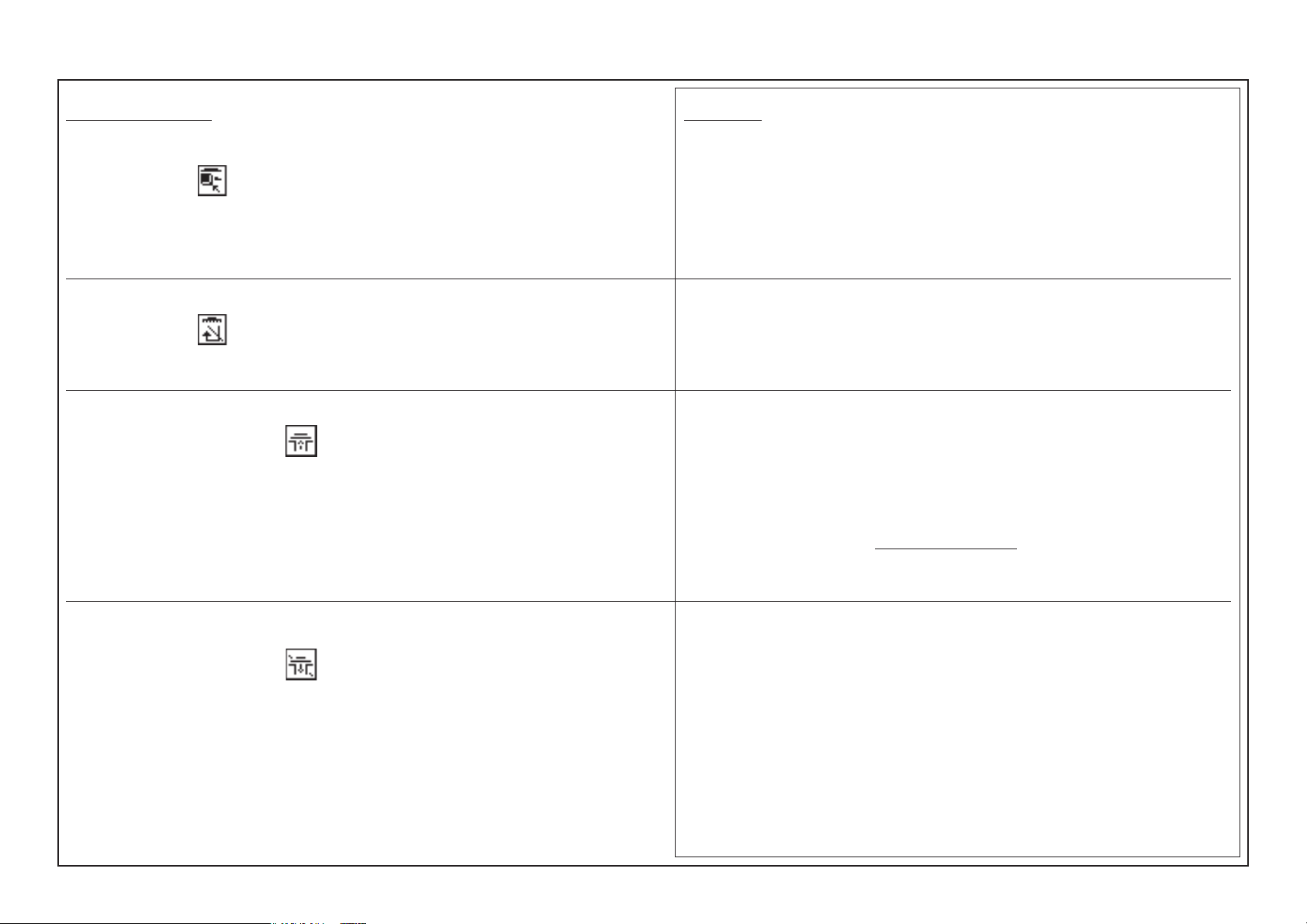

Function "Help"Explanation of pictographs and description of functions .. K5B - 12

Four trim cut ............................................................................................ K5B - 13

Four trim cut with labels ........................................................................... K5B - 14

Menu Key: Additional Functions ............................................................ K5C - 1

Storage of Additional Functions with Cut Size ............................................ K5C - 2

Subsequent Storing of Additional Functions............................................... K5C - 2

List of Additional Functions ........................................................................ K5C - 3

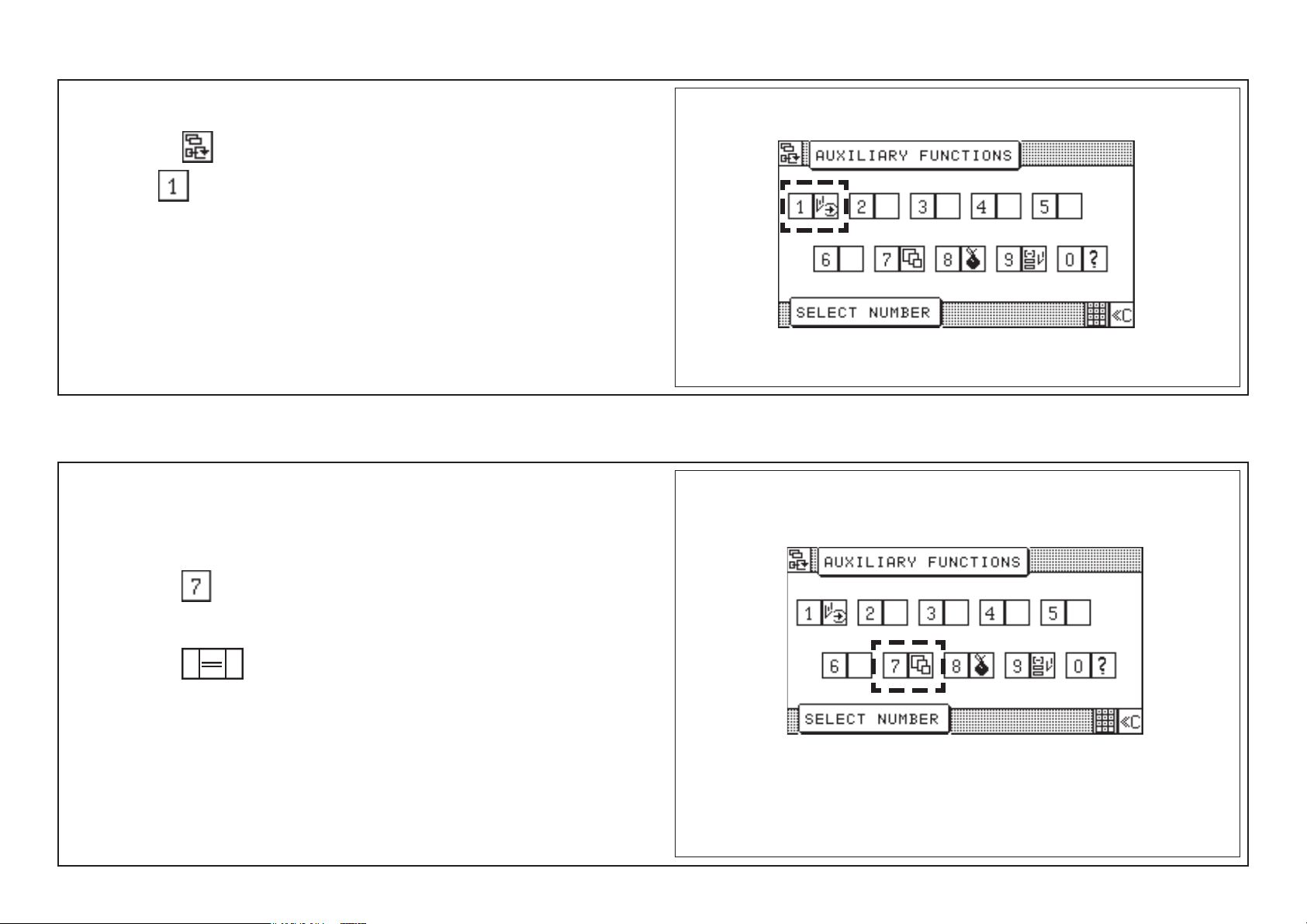

Menu Key: Auxiliary Functions .............................................................. K5D - 1

Cut and Record ......................................................................................... K5D - 2

Sheet Size Tables ...................................................................................... K5D - 2

Subtraction Repetition Unit ........................................................................ K5D - 3

Graphics OFF ............................................................................................ K5D - 3

Menu Key: Machine Parameters ............................................................ K5E - 1

Prepressure Time ...................................................................................... K5E - 2

Resting time for knife at BDC .................................................................... K5E - 2

Knife Change .............................................................................................. K6 - 1

Changing of cutting stick .............................................................................. K6 - 5

Malfunctions/Breakdowns .........................................................................K7 - 1

Electrical Malfunctions/Breakdowns ............................................................. K7 - 2

Start - Up Breakdown: Scan Reference Point/Auxiliary Mode ....................... K7 - 3

Mechanical Breakdown:Rupture of a Knife Bar/Clamp Recuperating Spring K7 - 4

Maintenance ................................................................................................ K8 - 1

Basic information about servicing and maintenance work ............................ K8 - 2

E - 3

Page 4

1 2

3

4 5

6

7 8 9

C

0

x

D

PROGRAMMABLE

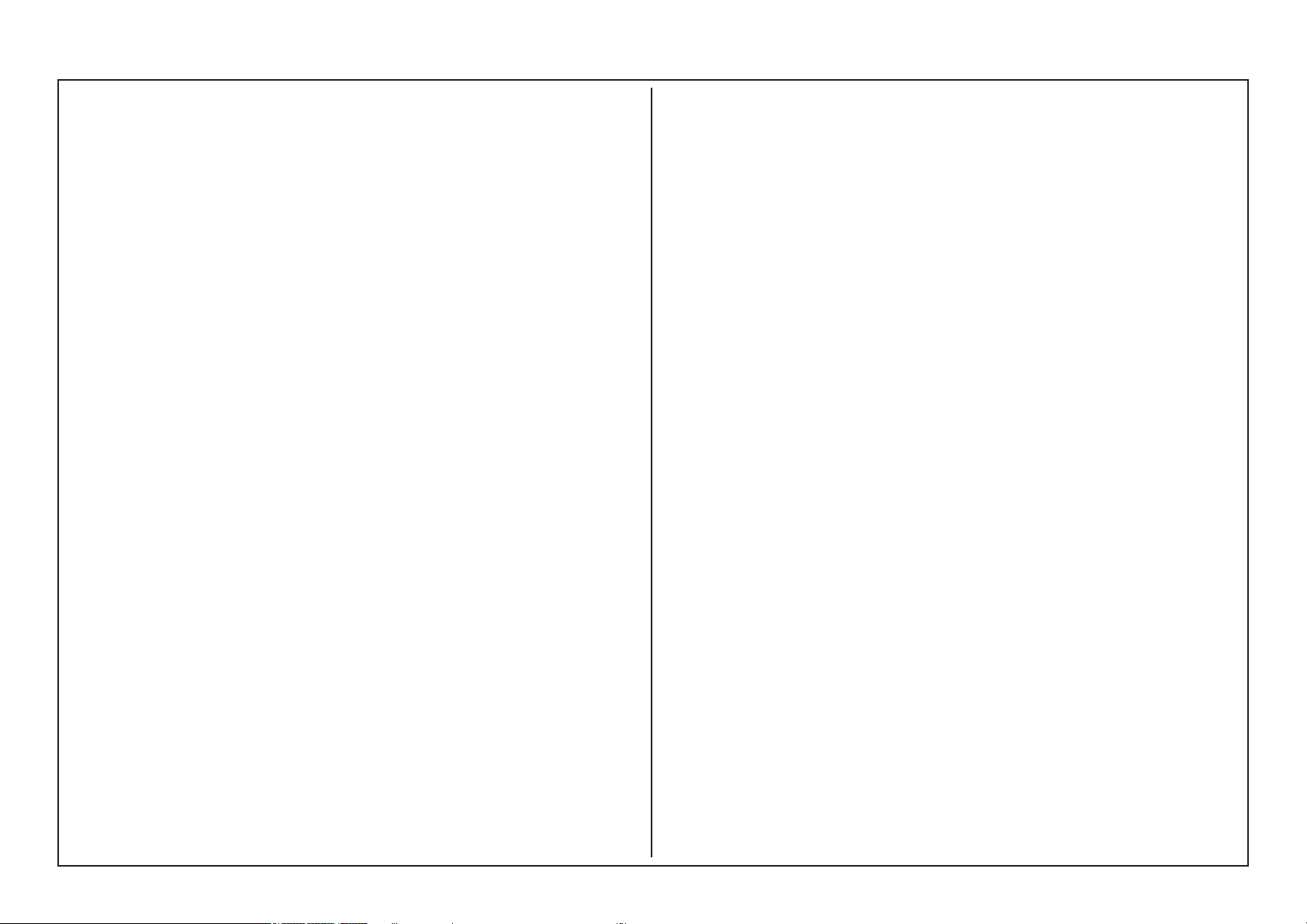

Control Panel / Operating Elements

i

21 3

Automatic ON

Automatic OFF

Program Data

Program Information

Function Survey (Main Menu)

Program Directory

Program Selection

E - 4

Machine Parameter

Auxiliary Program Functions

Additional Functions

Numerical keyboard

Division

Multiplication

Addition

Subtraction

Enter

Insert; subsequent insertion of

data

Delete

Correction (of stored data)

Equal key

Transfer key: Transfer backgauge

pos. into input field

Clear input field

Decimal point

Cursor

(4 keys: right, left, up, down;

Center key: Additional cursor

motion; cursor in basic position

1 Display

2 Turning knob for backgauge move-

ment

(Electronic hand wheel)

3 Switch for optical cutting line

indicator and table light ON

Page 5

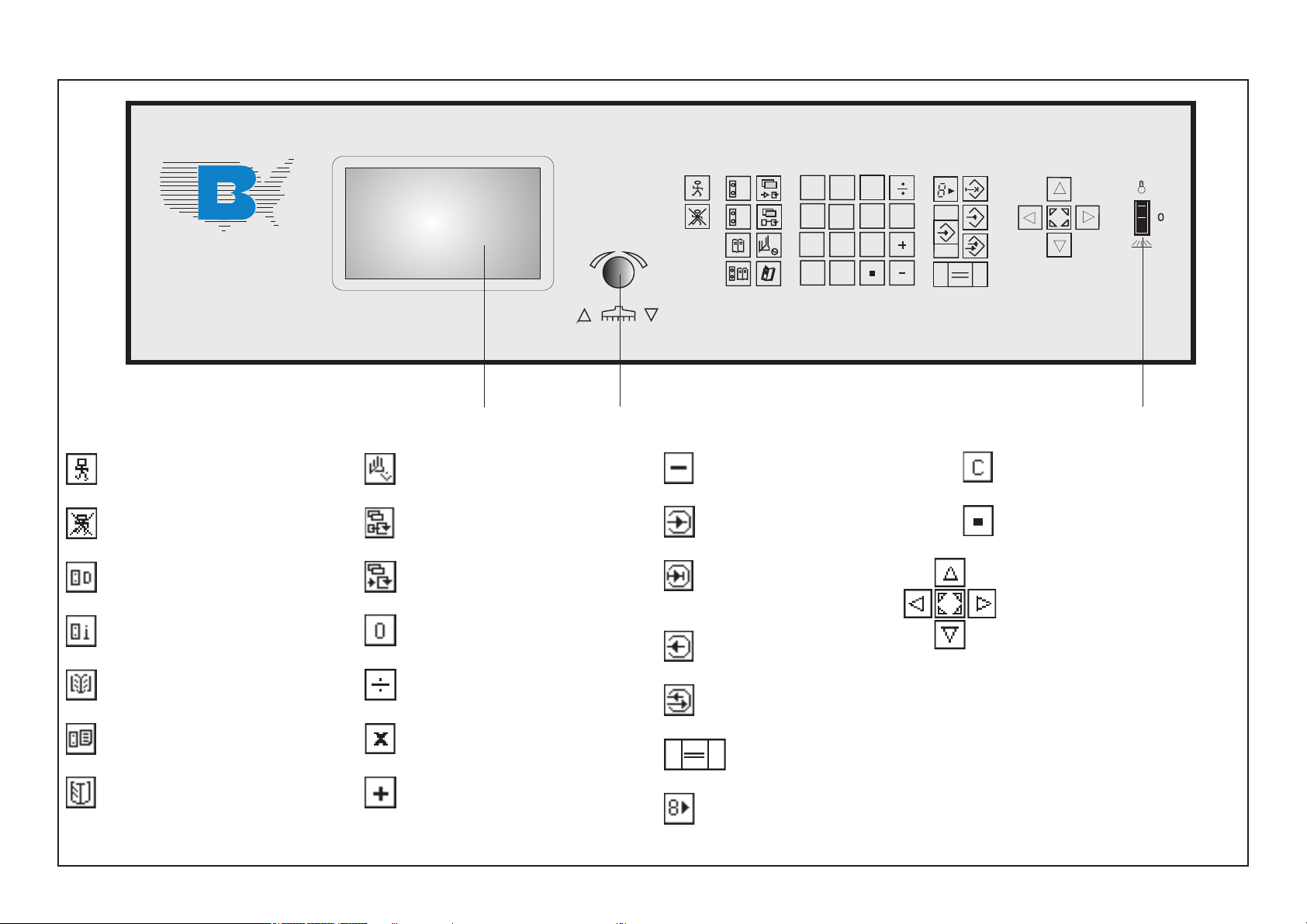

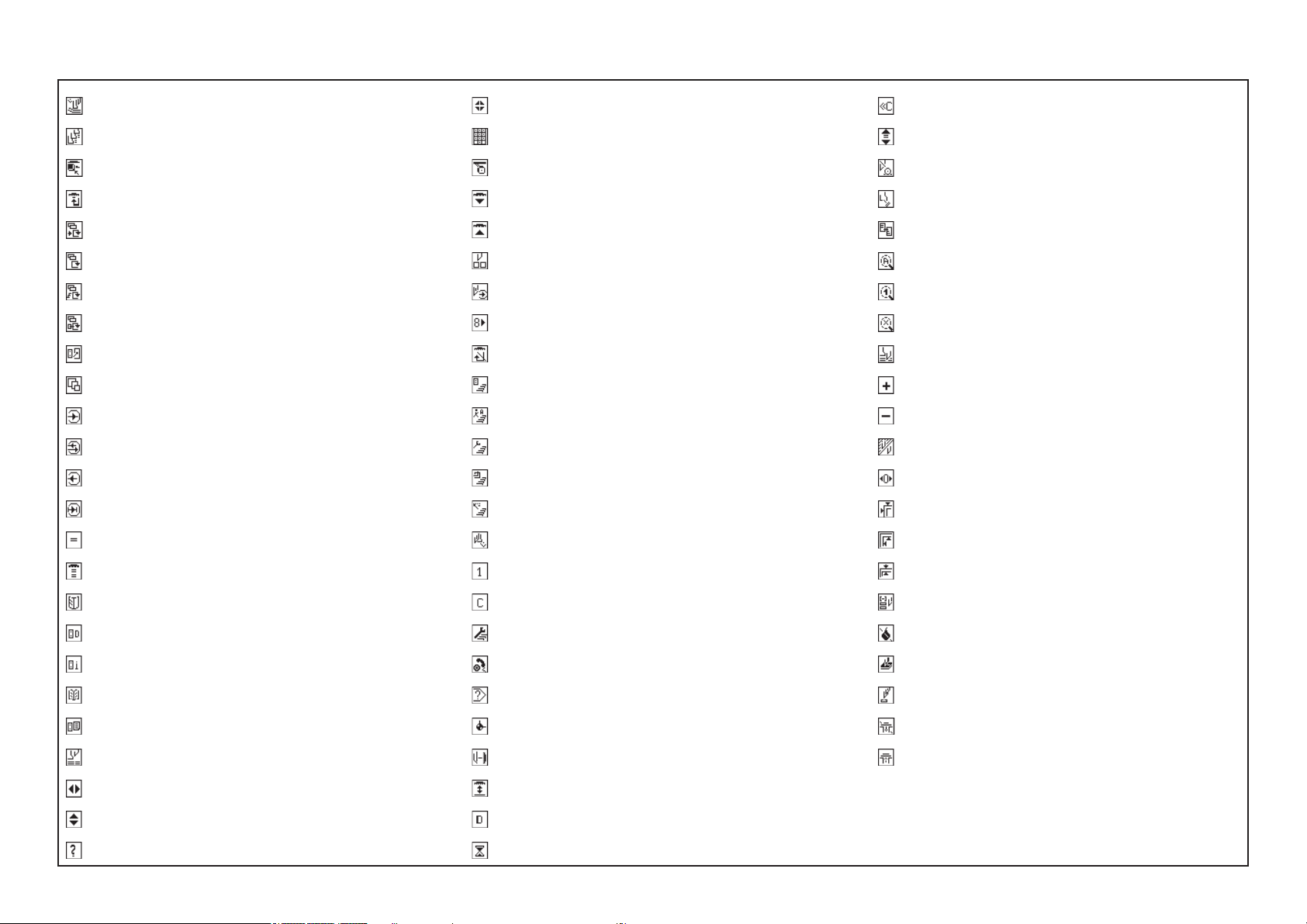

Explanation of Pictographs on the Display

Pre clamping time

Clamping force grade

Feed mark

Programmable ejector

External special functions

Program functions

Program parameters

Various auxiliary functions

Free program

Paper sizes

Enter

Correction

Delete

Insert

Key Equal

Key Cursor Home

Numerical keyboard

Hand wheel/electr. hand wheel

Sensor key forward

Sensor key reverse

Cut buttons

Marking during cutting

Actual to nominal position

Automatical ejector off

Function survey/Memory

function survey/Language

Function survey/Service

Function survey/Block programming

Function survey/preset functions

Machine parameters

Clear/Exit

Spare cursor

Main drive unit not ready

Press pedal

Order

Look for order

Select program number

Delete program number

Under cut

Plus/positive sign

Minus/negative sign

Change contrast of display

Spare cursor

Original sheet size/Block programming

Label size/Block programming

Key Positioning (2x Ist-Gleich)

Program selection

Program data display

Program information

Function survey

Program directory

Nominal position

Key Cursor right/left

Key Cursor up/down

Help

Number (1 - 0)

Clear/Clear input

Service

Call sevice

Error

Reference run

Correct basic position

Correct actual position

German (Language)

Please wait

Edge trim/Block programming

( - ) Subtraction repetition unit

Grafics off

Block programming

Knife/Lower dead point time

Air table Off

Air table ON

E - 5

Page 6

Chapter Survey

Chapter Survey Page

1.0 Technical Data/Machine Layout/Transport and Installation of Machine/

Safety Relevant Machine Elements ................................................................................ K1 - 1

2.0 Safety.............................................................................................................................. K2 - 1

3.0 Start Up........................................................................................................................... K3 - 1

4.0 Manual Operation ........................................................................................................... K4 - 1

5.0 Automatic Operation .................................................................................................... K5A - 1

E - 6

6.0 Knife Change .................................................................................................................. K6 - 1

7.0 Malfunctions/Breakdowns ............................................................................................... K7 - 1

8.0 Maintenance ................................................................................................................... K8 - 1

Page 7

Introduction

BAUM cutting machines form a part of the wide range of products manufactured by the BAUM company.

Decades of experience in constructing high speed cutting machines and peripheral equipment, together with state-of-the-art engineering and manufacturing procedures,

careful testing and highest quality standards ensure the reliability and performance of your BAUM machine.

Please pay special attention to the following information:

• The section on “Safety” in the operating instructions!

• The operating instructions are not meant as an instruction for repair. Such work should be carried out by BAUM service, exclusively.

• Use only original BAUM spare parts; indicate type and machine number in your requests.

• Illustrations in the operating instructions/spare parts catalogue may deviate from the real design. Nevertheless, the information given is not altered by this.

• The use of the aids mentioned in the operting instructions, such as oils, greases, cleansing agents etc. refers to the preparation date of these instructions.

The complete Technical Documentation should always be kept near the machine.

We recommend to read these operating instructions carefully prior to commissioning the machine, because we shall not be liable for any damage or breakdown resulting

from any nonobservance of these operating instructions.

Copyright

All rights reserved for this document. No part of it may be duplicated or brought to the notice of other people in any form without our express consent.

Any violation engages to damages.

The Operating Instructions must be stored for future use!

E - 7

Page 8

E - 8

Page 9

1.0

Technical Data / Machine Layout / Transport and Installation

of the Machine / Safety Relevant Machine Elements

K1 - 1

Page 10

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGRAMMABLE

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

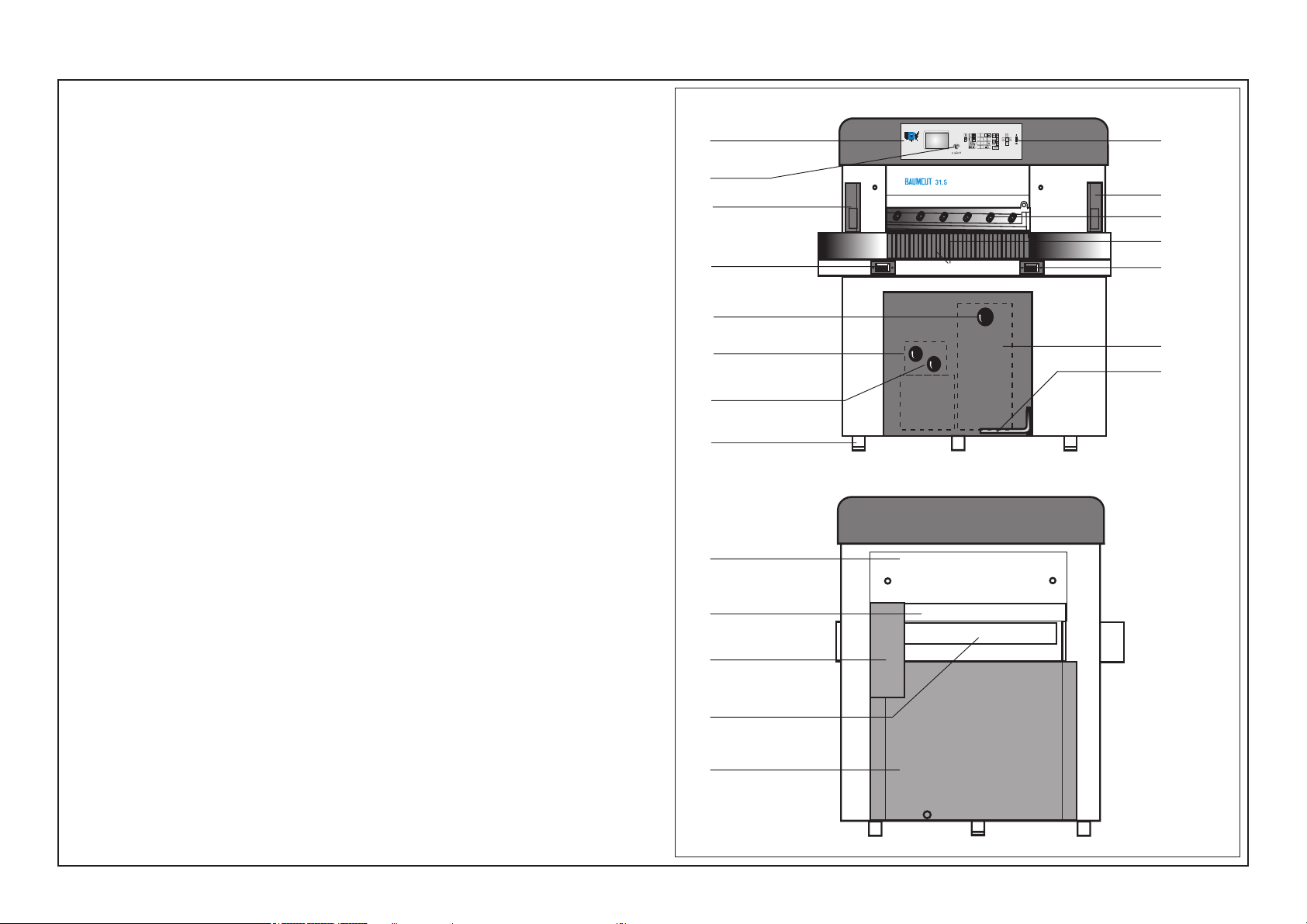

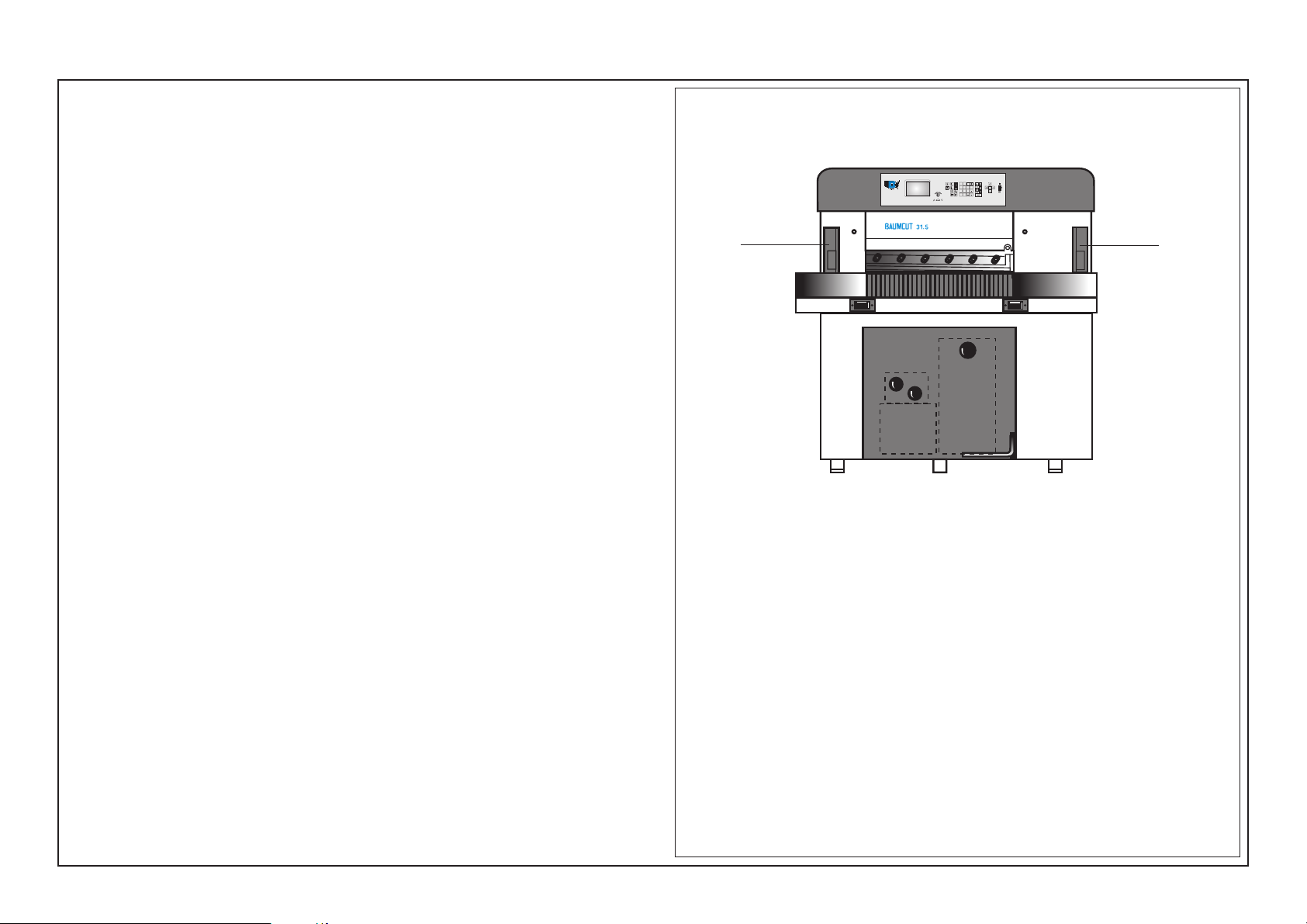

Machine Layout

Front side (operating side)

1 Main switch

2 Control panel with display

3 Electronic hand wheel / fine adjustment of cut size

4 Cut buttons

5 Clamping pressure adjustment

6 Clamp and knife bar with knife

7 Switch for cutting line indicator/ Table lamp

8 Backgauge with rakes

9 Cutting stick / Cutting line

10 Pedal

11 Protective guard for backgauge drive

12 Light barrier with guard

13 Guards - front side

14 Guards - rear side

2

7

3

12

12

6

9

44

1

18

13

10

5

17

Rear side

16

15 Guard - rear table

16 Guard to prevent reaching under the clamp bar

17 Foot

18 Turning knob for knife change

K1 - 2

15

11

8

14

Page 11

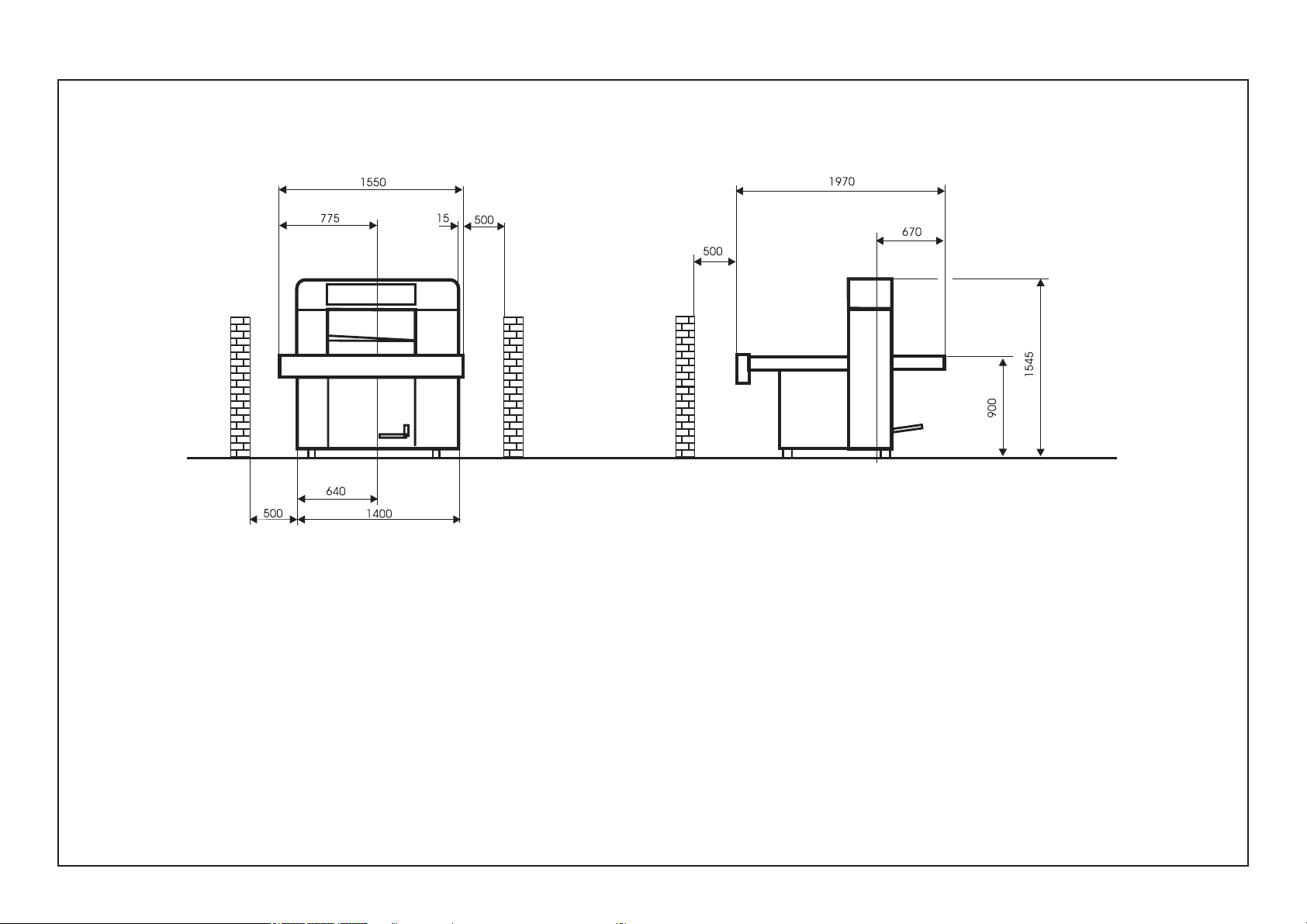

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

Plan

Dimensions in mm!

K1 - 3

Page 12

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

Transport and Installation of the Machine

After Unloading

• Remove all packing and wrapping material

• Check machine and accessories for damages

• Check for missing parts

Have the machine installed by BAUM service personnel, exclusively!

The installation of the machine requires special skills which can be guaranteed only by especially trained experts of BAUM agencies.

Arbitrary working on the machine may damage the machine itself or other

material property of the user or cause accident endangering life and limb

of the staff.

The machine must be unpacked, moved, transferred and installed by

authorized BAUM Service Technicians only. Dangers might arise from the

machine itself or from its packing if it is unpacked, moved, transferred or

installed with unsuitable devices.

While the machine is unpacked, moved, transferred and installed, no other

persons must be present in the range of the machine or its packing.

The BAUM Service Technician must also take care that no unauthorized

persons work at the machine, its packing or the installation equipment.

In Case of Complaints

Immediately send written note to:

• Railway or shipping company

• Insurance company

• BAUM / Agency

Place of Installation

The location must meet the following requirements:

• Vibration free location

• Even concrete flooring, concrete property class min. (N/mm²) according to

eurocode 2: C20/25 or according to DIN1045: B 25.

• Observe carrying capacity!

• Avoid possible accidents of operator by uneven flooring

• Adhere to minimum distance from buildings or peripheral equipment (see

plan)

After the Installation of the Machine

K1 - 4

1. Remove anti rust paint (agent: kerosene, gasoline) from the machine on

the site of installation

Note:

Do not use any sharp tools to remove anti-rust paint!

2. Clean plastic covers only with plastic cleansing agent

3. Final check according to check list

4. Have handover signed

Page 13

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGRAMMABLE

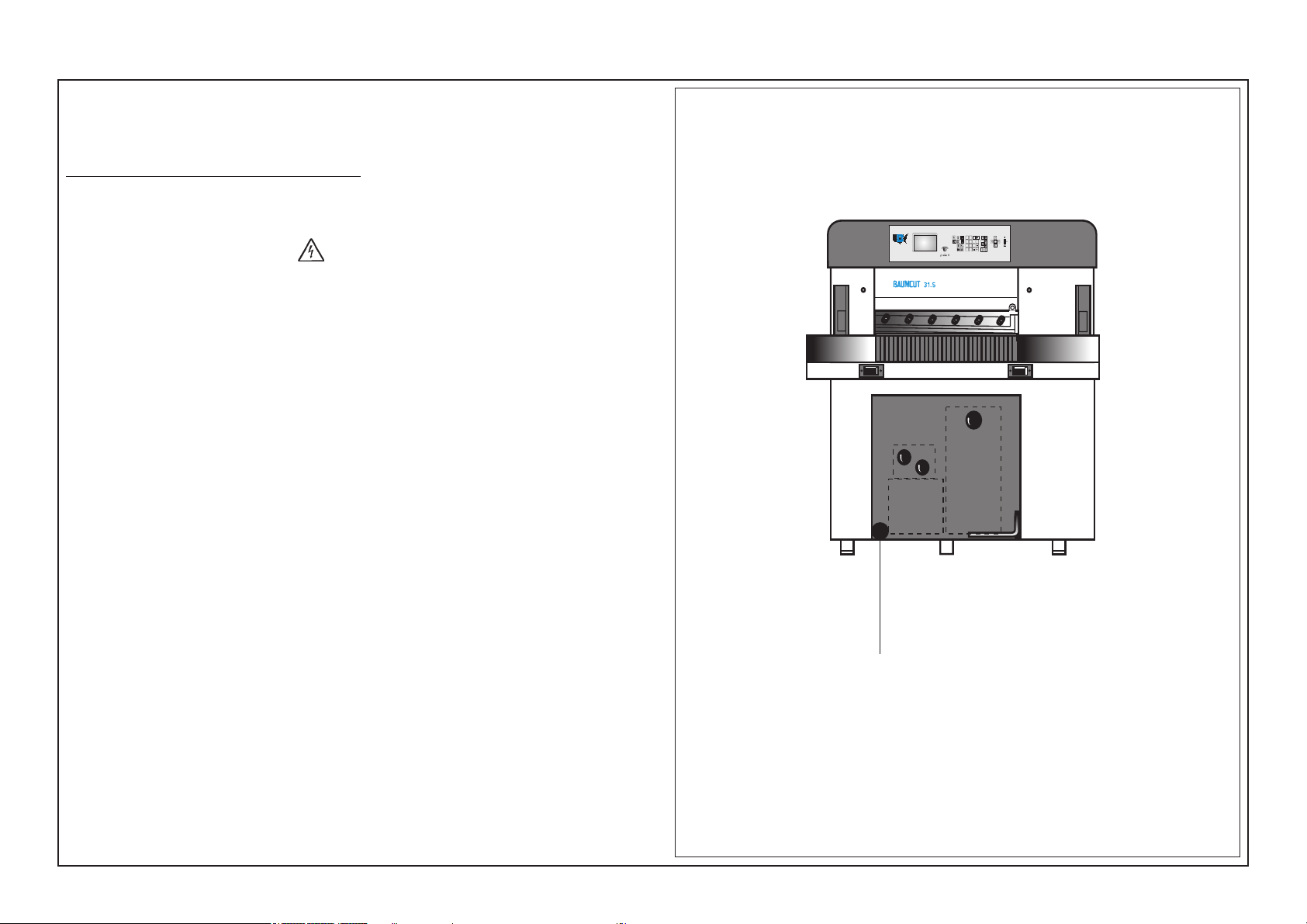

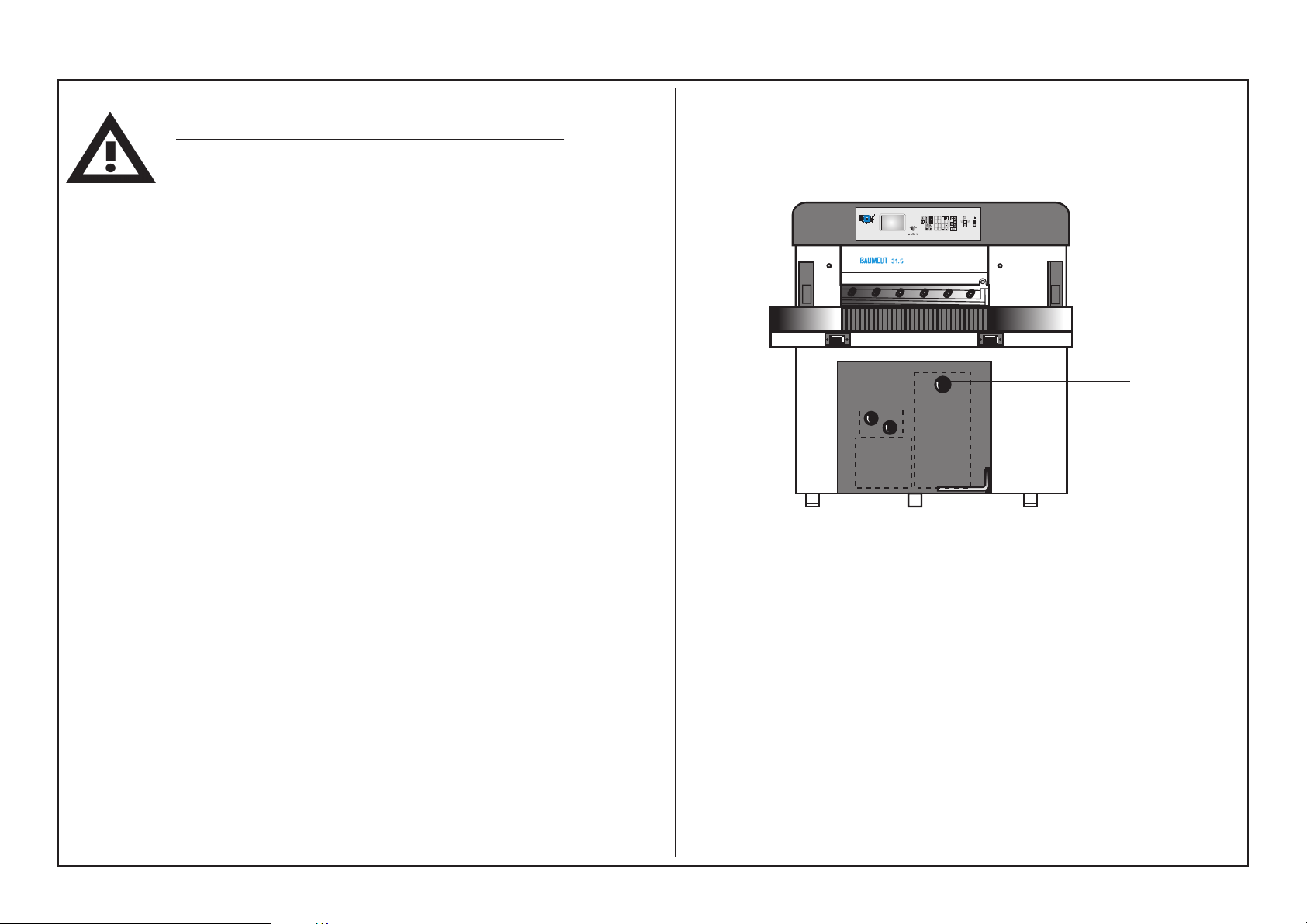

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

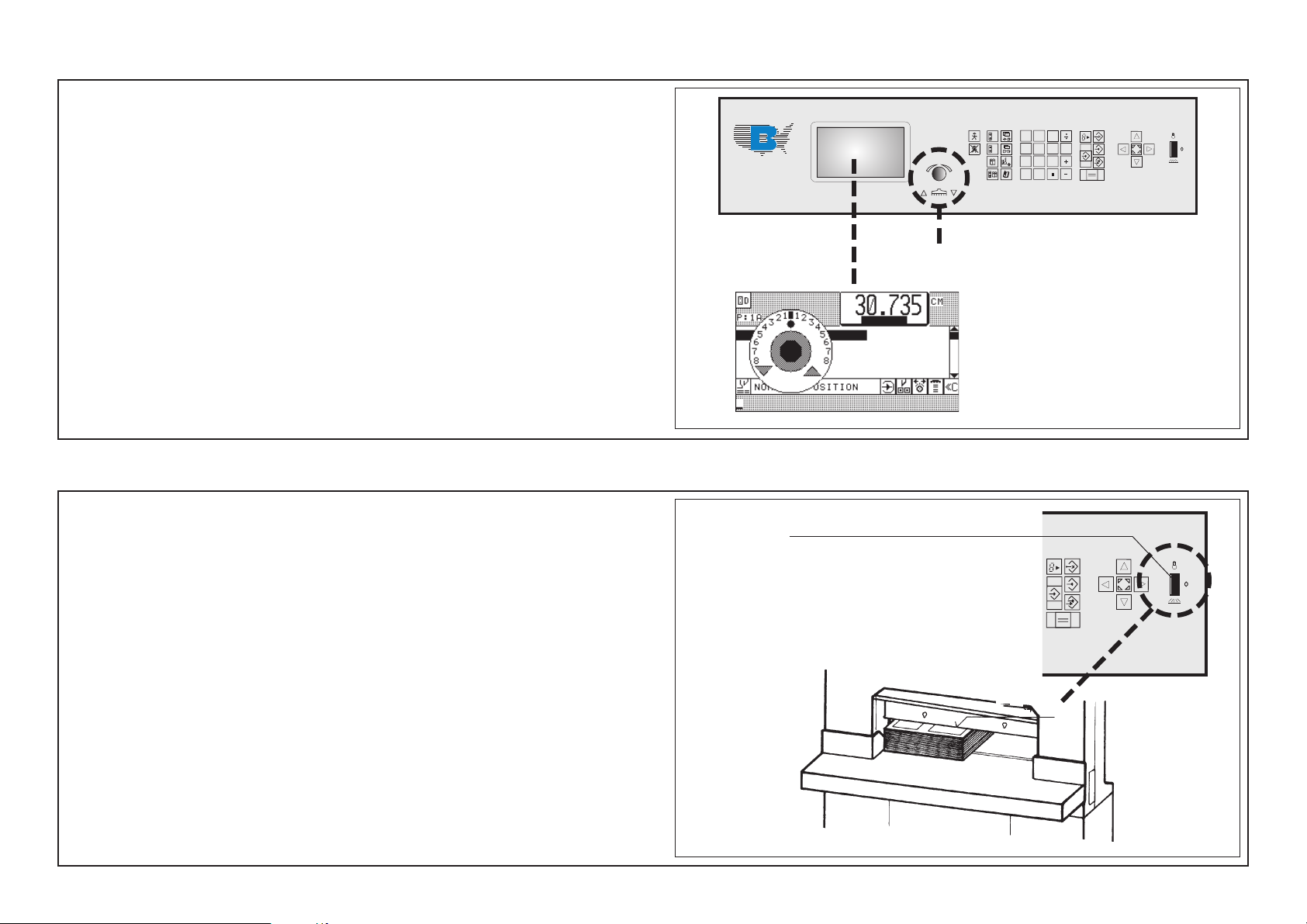

Power Supply

The machine is to be connected by an authorized electrician, only!

Connect machine according to diagram!

• When the system is operated with residual current breaker, use a residual current breaker ( > 30 mA ) for each machine!

• All the cables marked with a symbol, as well as any cables with

orange sheath are still alive even if the main switch has been shut off.

Energy supply is made from the rear of the machine.

Power supply is located within the connection box; access via front guard.

Front side (Operating side)

Energy lead wire

K1 - 5

Page 14

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

Type Plates

Type plate

The machine designation including

• manufacturer‘s address

• model

• machine number

• date of fabrication

• electric. equipment

is indicated on the machine type plate.

Type plate

Model

Serial No.

/PE AC

Adolf Mohr

Maschinenfabrik

65719 Hofheim/Ts

Germany

mfd.

V

Hz

A

K1 - 6

Page 15

1 2

3

4 5

6

7 8 9

C

0

x

D

PROGRAMMABLE

1.0 Technical Data/Machine Layout/Transport and Installation of Machine/Safety Relevant Machine Elements

Safety Relevant Machine Elements

1 Main switch

2 Light barrier (20 - channel)

Capacity to recognize object: 25 mm

Min. distance of light barrier: Total reaction time of system:

328 mm < 120 ms

3 Knife bar spring assembly (mechanical lock against lowering of knife

bar)

4 Clamping bar spring assembly (mechanical lock against lowering of

clamping bar)

5 Two-handed cutting release with simultaneity control and anti-repeat

circuit

6 Electronics:

- Failsafe control by multiple self-diagnostics

- Machine self-diagnostics with error message

7 Guard to prevent reaching under the clamp bar

8 Rear-table guard

Front side (operating side)

i

22

3

5

4

6

Rear side

7

9 Guard of backgauge drive unit

Safety Auxiliary Tools

Angle for jogging the cutting material

Knife protection for knife change

Working Area of Operating Personnel

Working area is the complete front side (operating side) of the machine.

8

9

K1 - 7

Page 16

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

Safety Relevant Machine Elements

Accident prevention warning labels at BAUM cutters.

Placement of the warning label

Warning labels are of little value if the foreseeable user cannot see them at the

appropriate time, i.e., before he or she encounters the hazard. Labels, therefore,

should be placed near the hazard and in such a position that the worker will see

and be able to read them before encountering the hazard.

Durability

Accident prevention warning labels should be kept sufficiently durable to remain

easily readable at an appropriate distance for a reasonable life.

Placement of the warning labels

Label 1 (1x):

Location:

At backgauge drive

guard.

BAUM order no.:

281267

Label 2 (1x):

Location:

At the lower front of the

cutter.

BAUM order no.:

281266

Label 3 (2x):

Location:

At the front and the rear

of the cutter.

BAUM order no.:

281268

K1 - 8

Page 17

Safety Signs

Safety Signs / Warning Signs

In order to ensure maximum safety the machine / system is provided with safety

signs. Safety signs are either standardized safety signs warning of risks or

danger, or warning signs alerting the operating or service staff of

- any forbidden actions at the machine / system,

and/or

- informing about any load limits, such as the max. carrying capacity of the

machine and/or its load carrying unit.

Safety signs must be durable and have to be kept in a perfectly visible condition.

Warning signs ought to be visible in good time even from a great distance.

The machine /system may be provided with the following safety or warning

signs on various components of the machine:

Warning: Dangerous voltage

(e. g. electrical connector boxes, control boxes/

control cabinets of machine control systems)

K1 - 9

Page 18

1.0 Technical Data/Machine Layout/Transport and Installation of Machine/Safety Relevant Machine Elements

Technical Data

Permissible Environmental and Operating Conditions

Operate the machine in closed areas, exclusively!

Air humidity: 35% - 95% (non condensing)

Ambient air temperature: +5°C - +40°C

Hydraulic Data

Hydraulic pressure, max.: 160 bars!

Safety Precautions

• Minimum age of operating staff: 18 years!

• Before starting any work at the machine - read safety section of manual!

• During the working process no other persons must enter the working area or

interfere with the process

• Use the angle included in the scope of supply for positioning the cutting

material

Residual Risk

In spite of the safety measures provided by construction there remains a residual risk when operating the machine.

This residual risk mainly concerns the danger of contusions and cuts during

clamping, cutting or knife change as well as handling the cutting material in

general, if the necessary care is neglected.

The parts especially affected are the upper extremities of the operating staff especially their arms and hands.

Special care must be taken when performing the knife change. It may only be

carried out by personnel especially trained for this job!

During knife change no other persons must enter the working area of the

machine (cuts)!

• Knife change may only be carried out by personnel especially trained for this

purpose

• Utmost care must be taken when handling the knife!! Always deposit or

transport the knife in the knife case.

• Use only undamaged and sharp knives!

• During the cutting no tool or objects - such as e.g. T-wrench must be on the

machine table in order to prevent them from reaching unintentionally under

the clamp and/or knife during the cutting process. There is a high risk of

injuries due to little parts of the knife edge coming off in splinters.

• Observe the procedures described in case of malfunctions and the maintenance intervals indicated.

K1 - 10

Page 19

1.0 Technical Data/Machine Layout/Transport and Installation of the Machine/Safety Relevant Machine Elements

Technical Data

Cutting width 80 cm / 31,5"

Clamp opening 10 cm / 3,93"

Feed depth 80 cm / 31,5

Power requirement (main motor):

3 phase 4,2 kW / 5,4 H.P.

Net weight 900 kg / 1983 lbs

Width 155 cm / 61"

Length 197 cm / 77,5"

Height 155 cm / 61"

Front table length 67 cm / 26,4"

Table height 90 cm / 35,4"

Clamp pressure, min. 200 daN / 440 lbs

max. 2700 daN / 5950 lbs

Knife thickness 11,75 mm / 0,4"

Attention!

The wire cross section of the main power supply according to the countrys

regulations.

Same regulations according the plug connectors.

Noise emission

Metering of noise level according to DIN EN 13023, LpA (dB):

76,5 with 300 cuts/hour (manual feeding)

79,5 with 600 cuts/hour (manual feeding)

Extraneous and room noise correction has been carried out.

Grinding reserve, max. 2,5 cm / 1"

Smallest cut

without false clamp, min. 1,5 cm / 0,6"

with false clamp, min. 5 cm / 1,96"

Backgauge speed 0 - 13 cm/sek.

Knife speed/min.20

Voltage supply (3 phase) 200 - 240, 50/60Hz

Fusing 3 x 20A

daN = kp

K1 - 11

Page 20

K1 - 12

Page 21

2.0

Safety

Any person on the user´s premises concerned with

the operation, maintenance and repair of the machine, resp., is expected to have read and comprehended the section on "Safety"

K2 - 1

Page 22

Foreword to the operating instructions

These operating instructions are designed to familiarize the

user with the machine/plant and its designated use.

The instruction manual contains inportant information on

how to operate the machine/plant safely, properly and most

efficiently. Observing these instructions helps to avoid

danger, to reduce repair costs and downtimes and to

increase the reliability and life of the machine/plant.

The instruction manual is to be supplemented by the

respective national rules and regulations for accident

prevention and environmental protection.

Fundamental safety instructions

Warning and symbols

The following signs and designations are used in the manual

to designate instructions of particular importance

Note/Attention: refers to special information on

how to use the machine/plant

most efficiently

Symbol: refers to orders and prohibitions

designed prevent injury or

extensive damage

Operating the machine within the limits of its designated use

also involves the instructions set out in the operating manual

and complying with the inspection and maintenance directives.

Organizational measures

The operating instructions must always be at hand at the

place of use of the machine/plant.

In addition to the operating instructions, observe and instruct

the user in all other generally applicable legal and other

mandatory regulations relevant to accident prevention and

environmental protection.

The operating instructions must always be available wherever the machine/plant is in use.

These operating instructions must be read and applied by

any persons in charge of carrying out work with and on the

machine/plant such as

- operation including setting up, troubleshooting in the

course of work, evacuation of production waste, care and

disposal of fuels and consumables.

- maintenance (servicing, inspection, repair) and/or

- Transport

In addition to the operating instructions and to the mandatory rules and regulations for accident prevention and environmental protection in the country and place of use of the

machine/plant, the generally recognized technical rules for

safe and proper working must also be observed.

Basic operation and designated use of the machine/

plant

The machine/plant has been built in accordance with stateof-the-art standards and the recognized safety rules.

Nevertheless, its use may constitute a risk to life and limb of

the user or of third parties, or cause damage to the machine

and to other material property.

The machine/plant must only be used in technically perfect

condition in accordance with its designated use and the

instructions set out in the operating manual, and only by

safety-conscious persons who are fully aware of the risks

involved in operating the machine/plant. Any functional

disorders, especially those affecting the safety of the

machine/plant, should therefore be rectified immediately.

The machine is meant exclusively for cutting leaved

materials, such as paper, cardboard or plastic films.

Any other use, such as the cutting of harder, especially

thicker materials and materials of other kinds, as well as any

further use beyond this, is considered as not being in

accordance with the designated use. Such materials may be

processed only according to prior agreement with the

manufacturer of this machine and after a written confirmation by the manufacturer. The manufacturer/supplier cannot

be held liable for any damage resulting from such use. The

risk of such misuse lies entirely with the user.

These compulsory regulations may also deal with the

handling of hazardous substances, issuing and/or wearing

of personal protective equipment, or traffic regulations.

The operating instructions must be supplemented by

instructions covering the duties involved in supervising and

notifying, special organizational features, such as job

organization, working sequences or the personnel entrusted

with the work.

Personnel entrusted with work on the machine must have

read the operating instructions and in particular the chapter

on safety before beginning work. Reading the instructions

after work has begun is too late. This applies especially to

persons working only ocassionally on the machine, e. g.

during setting up or maintenance.

Check - at least from time to time - whether the personnel is

carrying out the work in compliance with the operating

instructions and paying attention to risks and safety factors.

For reasons of security, long hair must be tied back or

otherwise secured, garments must be close-fitting and no

jewellery - such as rings - may be worn. Injury may result

from being caught up in the machinery or from rings catching on moving parts.

Use protective wherever required by equipment by the

circumstances or by law.

K2 - 2

Page 23

Observe all safety instructions and warnings attached to the

machine/plant.

See to it that safety instructions and warnings attached to

the machine are always complete and perfectly legible.

In the event of safety-relevant modifications or changes in

the behaviour of the machine/plant during operation, stop

the machine/plant immediately and report the malfunction to

the competent authority/person.

Never make any modifications, additions or conversions

which might affect safety without the supplier´s approval.

This also applies to the installation and adjustment of safety

devices and valves as well as to welding work on loadbearing elements.

Spare parts must comply with then technical requirements

specified by the manufacturer. Spare parts from original

equipment manufacturers can be relied to do so.

Never modify the software of programmable control systems.

Replace hydraulic hoses within stipulated and appropriate

intervals even if no safety-relevant defects have been

detected.

Adhere to prescribed intervals or those specified in the

operating instructions for routine checks and inspections.

Selection and qualification of personnel - Basic responsibilities

Any work on and with the machine/plant must be executed

by reliable personnel only. Statutory minimum age limits

must be observed.

Employ only trained or instructed staff and set out clearly the

individual responsibilities of the personnel for operation, setup, maintenance and repair.

Make sure that only authorized personnel works on or with

the machine.

Define the machine operator´s responsibilities - also with

regard to observing traffic regulations - giving the operator

the authority to refuse instructions by third parties that are

contrary to safety.

Do not allow persons to be trained or instructed or persons

taking part in a general training course to work on or with the

machine/plant without being permanently supervised by an

experienced person.

Work on the electrical system and equipment of the machine/plant must be carried out only by a skilled electrician or

by instructed persons under the supervision and guidance of

a skilled electrician and in accordance with electrical

engineering rules and regulations.

Work on the hydraulic system must be carried out only by

personnel with special knowledge and experience of

hydraulic equipment.

Safety instructions governing specific operational

phases

Standard operation

Avoid any operational mode that might prejudicial to safety.

Take the necessary precautions to ensure that the machine

is used only when in a safe and reliable state.

Operative machine only if all protective and safety-oriented

devices, such as removable safety devices, emergency

shut-off equipment, sound-proofing elements and exhausters, are in place and fully functional.

Check the machine/plant at least once per working shift for

obvious damage and defects. Report any changes (incl.

changes in the machine´s working behaviour) to the competent organization/person immediately. If necessary, stop the

machine immediately and lock it.

In the event of malfunctions, stop the machine/plant immediately and lock it. Have any defects rectified immediately.

During start-up and shut-down procedures always watch the

indicators in accordance with the operating instructions.

Before starting up or setting the machine/plant in motion,

make sure that nobody is at risk.

Never switch off or remove suction and ventilation devices

when the machine is in operation.

Special work in conjunction with utilization of the

machine/plant and maintenance and repairs during

operation; disposal of parts and consumables

Observe the adjusting , maintenance and inspection activities and intervals set out in the operating instructions,

including information on the replacement of parts and

equipment. These activities may be executed by skilled

personnel only.

Brief operating personnel before beginning special operations and maintenance work, and appoint a person to

supervise the activities.

In any work concerning the operation, conversion or adjustment of the machine and its safety-oriented devices or any

work related to maintenance, inspection and repair, always

observe the start-up and shut-down procedures set out in

the operating instructions and the information on maintenance work.

Ensure that the maintenance area is adequately secured.

If the machine/plant is completely shut-down for maintenance and repair work, it must be secured against inadvertent

starting by:

- locking the principal control elements and removing the

ignition key and/or

- attaching a warning sign to the main switch.

Clean the machine, especially connections and threaded

unions, of any traces of oil or preservatives before carrying

out maintenance/repair. Never use aggressive detergents.

Use lint-free cleaning rags.

Always tighten any screwed connections that have been

loosened during maintenance and repair.

Any safety devices removed for set-up, maintenance or

repair purposes must be refitted and checked immediately

upon completion of the maintenance and repair work.

Ensure that all consumables and replaced parts are disposed of safely and with minimum environmental impact.

K2 - 3

Page 24

Warning of special dangers

Any procedure impairing the safety at the machine must be

refrained from. In particular do not

- reach into the range of knife and clamp, use auxiliary

tools (e. g. material gauge)

- reach into the range between clamp and cutting material

gauge (backgauge with rake) on the machine rear table

- with Autotrim function:

entering the opened table crack to remove residual cuttings.

Only do that with the machine switched off.

- at machines with attached and/or separately installed

peripheral equipment with lifting/swivelling/moving and/or

clamping function:

do not enter or reach into the danger zone during movement

(provide guard rail)

- The knife may only be changed by personnel especially

instructed for this purpose

Electrical energy

Use only original fuses with the specified current rating.

Switch off the machine/plant immediately if trouble occurs in

the electrical system.

Work on the electrical system or equipment may only be

carried out by a skilled electrician himself or by specially

instructed personnel under the control and supervision of

such electrician and in accordance with the applicable

electrical engineering rules.

If provided for in the regulations, the power supply to parts

of machines and plants, on which inspection, maintenance

and repair work is to be carried out must be cut off. Before

starting any work, check the de-energized parts for the

presence of power and ground or short-circuit them in

addition to insulating adjacent live parts and elements.

The electrical equipment of machines/plants is to be inspected and checked at regular intervals. Defects such as loose

connections or scorched cables must be rectified immediately.

Necessary work on live parts and elements must be carried

out only in the presence of a second person who can cut off

the power supply in case of danger by actuating the emergency shut-off or main power switch. Secure the working

area with a red-and-white safety chain and a warning sign.

Use insulated tools only.

Before starting work on high-voltage assemblies and after

cutting out the power supply, the feeder cable must be

grounded and components, such as capacitors, shortcircuited with a grounding rod.

Gas, dust, steam and smoke

Carry out welding , flame-cutting and grinding work on the

machine/plant only if this has been expressly authorized, as

there may be a risk of explosion and fire.

Before carrying out welding, flame-cutting and grinding

operations, clean the machine/plant and its surroundings

from dust and other inflammable substances and make sure

that the premises are adequately ventilated (risk of explosion).

Observe any existing national regulations if work is to be

carried out in narrow rooms.

Hydraulic and pneumatic equipment

Work on hydraulic equipment may be carried out only by

persons having special knowledge and experience in

hydraulic systems.

The pneumatic equipment at the machine must only be

connected to plant compressed-air supply system secured

against overpressure.

Check all lines, hoses and screwed connections regularly

for leaks and obvious damage. Repair damage immediately.

Splashed oil may cause injury and fire.

Depressurize all systems sections and pressure pipes

(hydraulic system, compressed-air system.

Hydraulic and compressed-air lines must be laid and fitted

properly. Ensure that no connections are interchanged. The

fittings, lenghts and quality of the hoses must comply with

the technical requirements.

Oil, grease and other chemical substances

When handling oil, grease and other chemical substances,

observe the product-related safety regulations.

Be careful when handling hot consumables (risk of burning

or scalding)

K2 - 4

Page 25

3.0

Start Up

Attention!

Prior to any commissioning and any change of shifts the operating

staff has to check if the safety-related machine elements are in proper service condition and complete.

K3 - 1

Page 26

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGRAMMABLE

3.0 Start Up

Switching Machine ON

Attention!

Prior to any commissioning and any change of shifts

the operating staff has to check if the safety related

machine elements are in proper service condition and

complete.

1. Turn main switch (2) from "0" to "I"

< Control voltage is switched on.

After several seconds display shows Program data display >

Turning Machine OFF

1. Wait until automatic operations have ended.

2. Turn main switch from " I " to "0" position

to prevent a start-up of the machine:

Place padlock into main switch, lock it and remove the key.

2

K3 - 2

Page 27

3.0 Start Up

Measurement Display and Measurement System

After switching on, the "Program Data Display"* appears on the screen.

It shows among other things...

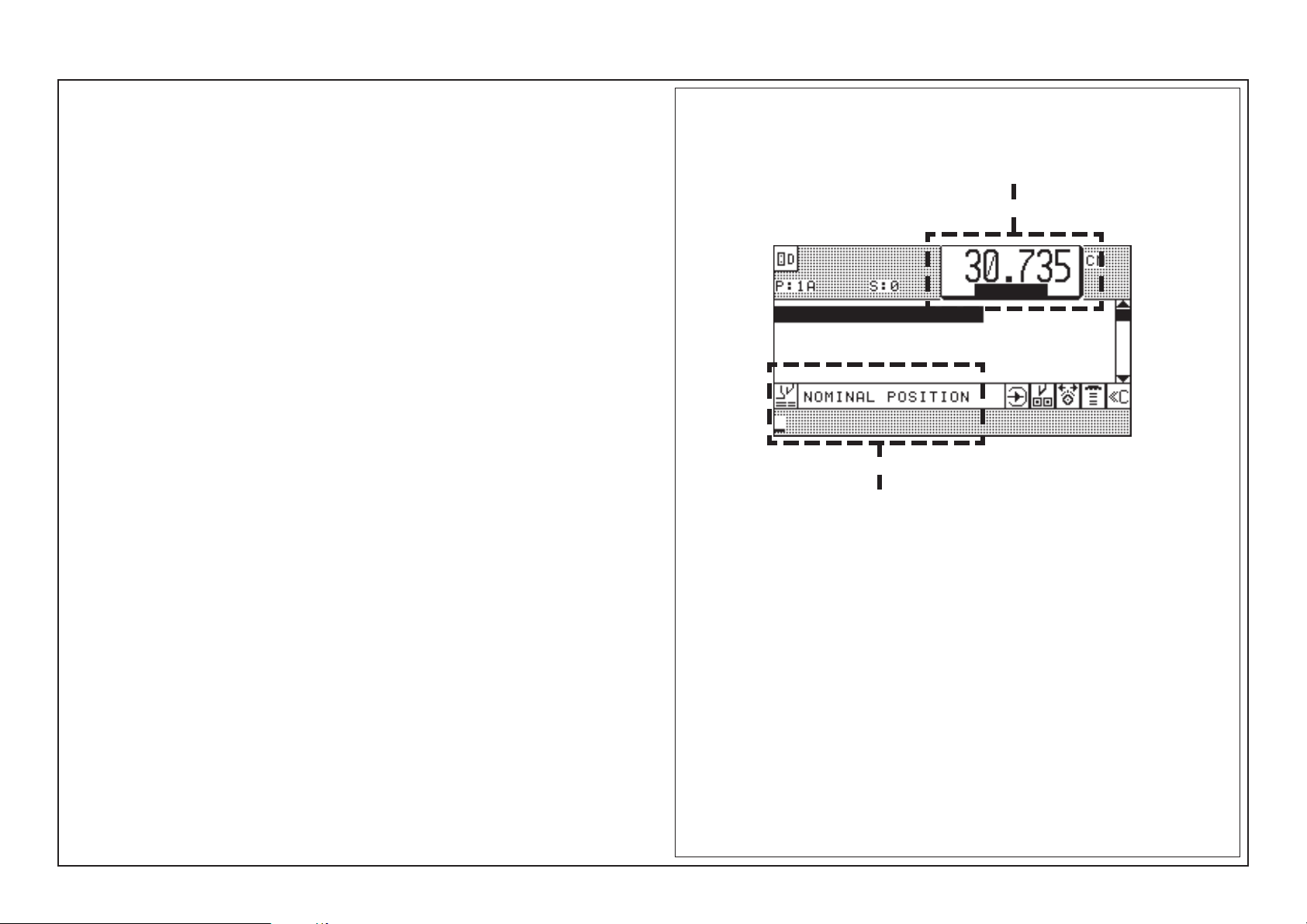

on the upper screen (A): ACTUAL POSITION

on the lower screen (Nominal position input field, B):

NOMINAL POSITION INPUT

The actual position (A) shows the real backgauge position in mm, cm, inches or

sun = 1/10 shaku (Japan).

Measurement system can be changed - see "Function Survey, page K5B - 3"

* If this fails, see Malfunctions/Breakdowns, page K7 - 5.

Program Data Display

A

B

K3 - 3

Page 28

K3 - 4

Page 29

Manual Operation4.0

K4 - 1

Page 30

1 2

3

4 5

6

7 8 9

C

0

x

D

PROGRAMMABLE

4.0 Manual Operation

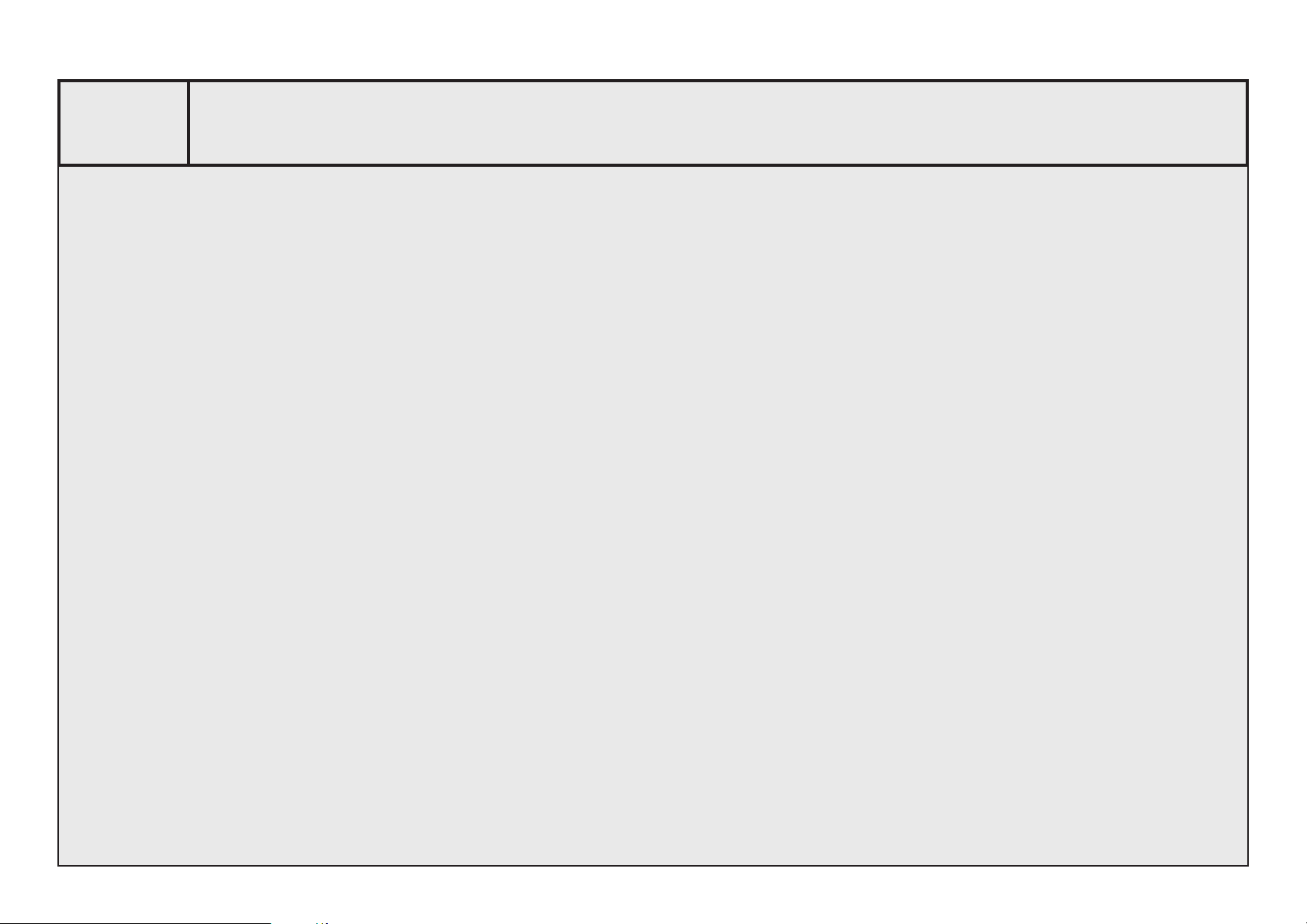

Setting of Measurements (Backgauge Movement) by Hand

Press electronical hand wheel and hold it in this position; turn hand wheel

to the left = forward movement of the backgauge

or

to the right = reverse movement of the backgauge

The backgauge speed gets faster by turning the electronical hand wheel to the

left/right .

Cutting Line Indicator, Mechanical with Clamp

Lower clamp with pedal onto stock:

The front edge (a) of the clamp is identical to the cutting line and can be used as

cutting line indicator. Clamp can be stopped in any position.

Max pressure with fully activated pedal: 30 daN

i

3

8

Cutting Line Indicator, Optical

Actuate toggle switch (8) at main switch plate

Upper position: Table light ON

middle position: "0" - position

lower position: Optical cutting line indicator ON. A thin light line indicates the

cutting line; the table light is switched off at that moment.

K4 - 2

RAMMABLE

a

Page 31

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGRAMMABLE

4.0 Manual Operation

Clamping and Cutting

Starting the cut:

Push both cut buttons (4) simultaneously.

(Hold buttons until knife is on upstroke)!

Interrupting the cut:

Release one or both cut buttons

(clamp and knife stop immediately and move back to initial position).

Continuing the cut:

Release and simultaneously push both cut buttons.

Clamp Pressure Adjustment

Turn knob (5) to desired position

Stepless adjustment - ranges of adjustment:

180 - 2700 daN (daN = kp)

Setting the Clamping Time

For bulky cutting material, it may be of advantage to set an extended clamping

time prior to cutting.

The clamping time is set via selection menu - refer to "Machine Parameter Select "Pre-clamping time"

4

5

180

2700

2500

5

2000

500

1000

1500

K4 - 3

Page 32

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGRAMMABLE

4.0 Manual Operation

Light Barrier

The lightbarrier (17) forms a curtain of invisible beams in front of the knife.

Any obstacle in the beams will stop clamping and cutting.

In that case the clamp can still be lowered with the pedal (indication of

cutting line).

Interference into the light curtain causes:

• clamping bar and knive stopped instantaneously and move back to initial

position

• a beep sound

• the monitor to display the message: CUT INTERRUPTED

To continue the cutting process:

Release cut buttons; trigger the cut again

The light barrier used is an infrared light barrier with twenty channels and a selfinspection system. This monitoring is indicated optically in the left-hand light

barrier (receiver side) by LEDs as part of a display unit.

The machine control system generates a test signal whenever ..

• a cut is released

• the lower dead centre of the knife is reached

• cutting is interrupted

1717

K4 - 4

Page 33

4.0 Manual Operation

Continuation: Light Barrier

Meaning of LEDs in display unit

D1 D2 D3 D4 D5 D6 Meaning

_________________________________________________________________

on on on on off off Protect. area „unobstructed“, light

reception excellent

off on on on off off Protect. area „unobstructed“, light

reception good

off off on on off off Protect. area „unobstructed“, light

reception just sufficient

on on off off on on Protect. area obstructed or a test is

performed

off off off off on on Protect. area has never been

unobstructed since Voltage ON

flashing off off on on Error

Display unit in the left-hand part of the light barrier (receiver side):

D2

D4

D6

D5

D1

D3

Attention!

In the case of a breakdown of the display unit the safety function of the

light barrier will not be impaired!

K4 - 5

Page 34

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGRAMMABLE

4.0 Manual Operation

Clamping with False Clamp Plate

The clamp plate avoids clamping marks on sensitive stock.

Attaching false clamp plate:

Push plate against clamp from underneath until you hear guide pins (6.1)snap.

Removing of false clamp plate:

1. Lower clamp with pedal approx. 2" above table and fix it in this position.

2. Press two screw drivers simultaneously into the drillings (6.2) in the clamp.

False clamp plate is dropped!

Air Table

The table surface of the machine is equiped with air jets. After turning on the air

supply, the stock can be moved easily.

6.2

6.1

Turning the air on: Press left cut button (4a)

Turning the air off: Press right cut button (4b)

K4 - 6

4a

4b

Page 35

5.0

Automatic Operation

K5A - 1

Page 36

Introduction

A position (cut size) entered via numerical keyboard can be stored permanently.

Any number of cut sizes necessary for the processing of a pile of material can be input and

stored.

All the data (cut sizes, information, additional functions) concerning one particular order

can be stored under one program number.

Cut sizes can also be stored automatically when a cut is triggered.

A programmable automatic function enables the advance movement of the cutting material

to the next position stored once a cut has been performed.

The machine is provided with a subtraction repeat unit to process invariable cutting

sequences in a fast and simple way.

Functions of the menu keys*

Key "Main menu (Function Survey)"

Select language

Select measuring unit

Service

Knife compensation

Resting time for knife at BDC

Maintenance cut counter

Preset functions

Reference run

Adjustment of display contrast

Correction of current position

Block programming

Help

All the data and information are shown on four basic displays:

1. Program Data

2. Program Information

3. Main menu (Function Survey )

4. Program Directory

Program Data display and Program Information display are meant for the input of cut sizes

or the display of additional information concerning a particular program.

Operator prompting on all display levels and input of clear text via softkey input (function

pictographs (symbols) on the display)

The Program Directory display shows all the assigned programs contained in the memory.

By means of the Function Survey display it is possible to select various machine

functions.

The keyboard of the operating panel with its menu keys makes it possible to store additional functions for individual cut sizes, which accompany and facilitate or accelerate the

working sequence.

Menu key "Additional Functions"

Automatic ejector OFF

Jogging mark

Help

Menu key "Machine Parameters"

Pre-pressing time

Resting time for knife at BDC

Menu key "Auxiliary Functions"

Programming with cut

Sheet size tables

Subtraction repetition unit

Graphics OFF

Help

Direct keys: Automatic Function ON, Automatic Function OFF, Program Selection,

Numerical Keyboard (with 4 fundamental operations of arithmetic),

Correction, Insert, Delete, Store, Cursor Keys, Backgauge Movement with

Electronical Hand Wheel

* Technical alterations reserved!

K5A - 2

Page 37

5.0 Automatic Operation

Basic Displays

1. Program Data: key

2. Program Information: key

Basic Display: Program Data

Press key < display shows program data display:(appears automatically after start-up*)

Explanation of Program-Data-display:

1 Program head (menu pictograph, program number (P: 1A) with memory

segment (S: 0) designation A )

2 Data section (3 step number visible on one page

3 Input section

3. Main Menu (Function Survey): key

4. Program Directory: key

6

1

4

10

5

4 Size display

5 Display of additional functions stored with step number

6 Status display (current machine function)

7 Display section Additional Function (after selection

8 Pictographs for user prompting (possible operating functions)

9 Current programming function with pictograph

10 Rolling bar (movement by cursor keys)

2

9

8

3

* If this fails, see "Malfunctions/Breakdowns, page K7 - 2"

7

K5A - 3

Page 38

5.0 Automatic Operation

Contin.: Basic Display: Program Data

Conc. 1 Program Head shows:

P: Program number of indicated program with memory segment

e.g. 1A = program 1, memory segment A and program protection (asterisk)

S: Quantity of step numbers assigned by the program

Conc. 2 Program Data section shows:

e.g. 1 step number of program (with abbrev. for particu-

lar additional functions such as Eltrotact

etc.)

Pictograph(s) additional function(s) stored:

Display of pictograph/s (symbol(s) of additional

function(s) stored

Conc. 3 Input section shows:

Data (cut size)/arithmetic functions entered

Conc. 5 Display of Additional functions

Display of the pictograph/s representing the Additional function/s

Conc. 6 Status display "Actual machine function"

Display of the pictograph representing the actual machine function

Conc. 7 Display section "Additional function"

Indication of the additional function to be stored after function has

been selected from menu.

Conc. 8 Pictographs user prompting

Indication of possible operating functions in the current menu

image

Conc. 9 Actual programming function with pictograph

Indication of current programming function as a plain text and asa

pictograph

Conc. 4 "Position display“ section shows:

ACTUAL POSITION Actual backgauge position/measuring unit

NOMINAL POSITION Indication of nominal position

K5A - 4

Conc. 10 Scroll bar

For paging through the actual menu image; movement by cursor

keys

Page 39

5.0 Automatic Operation

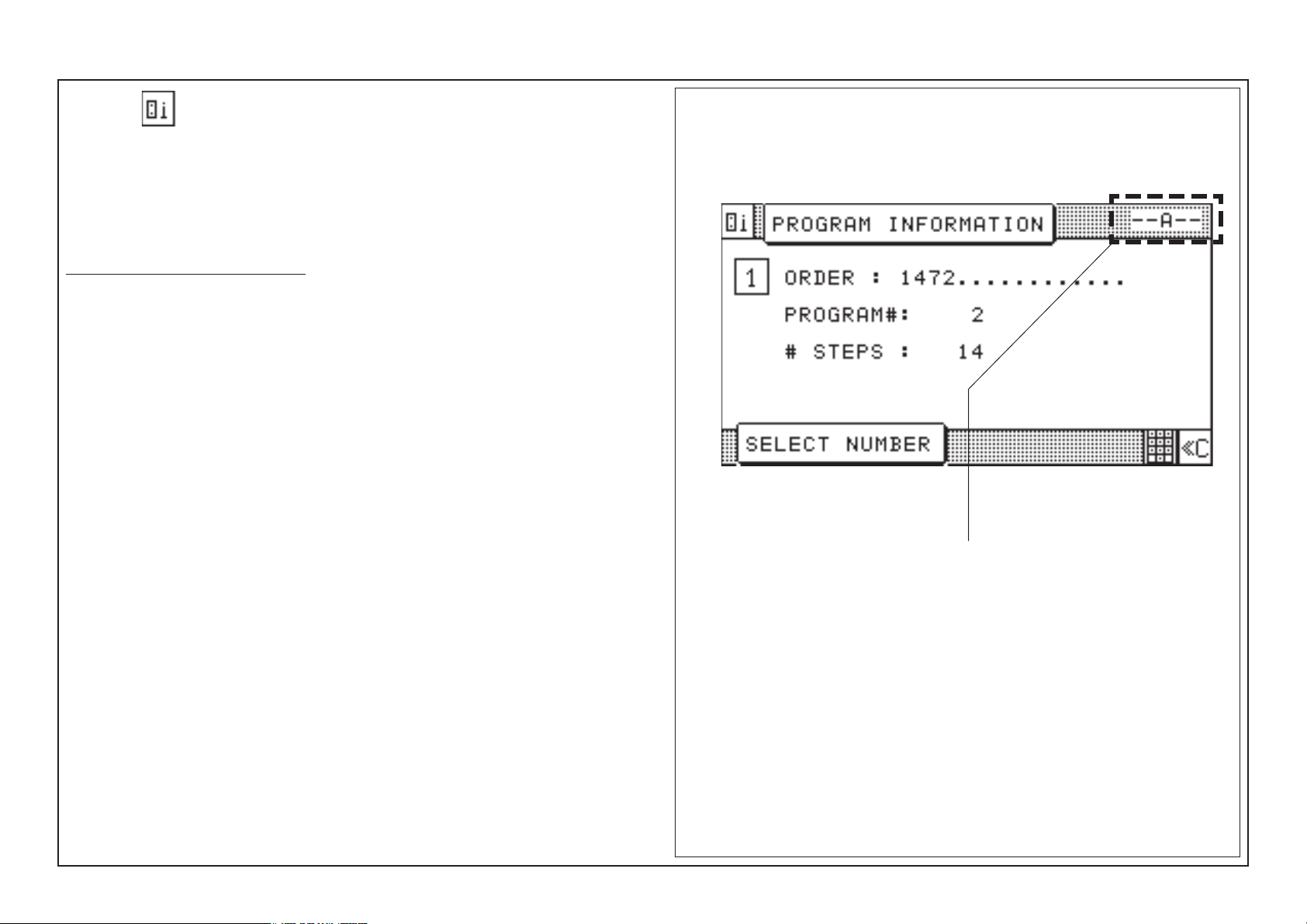

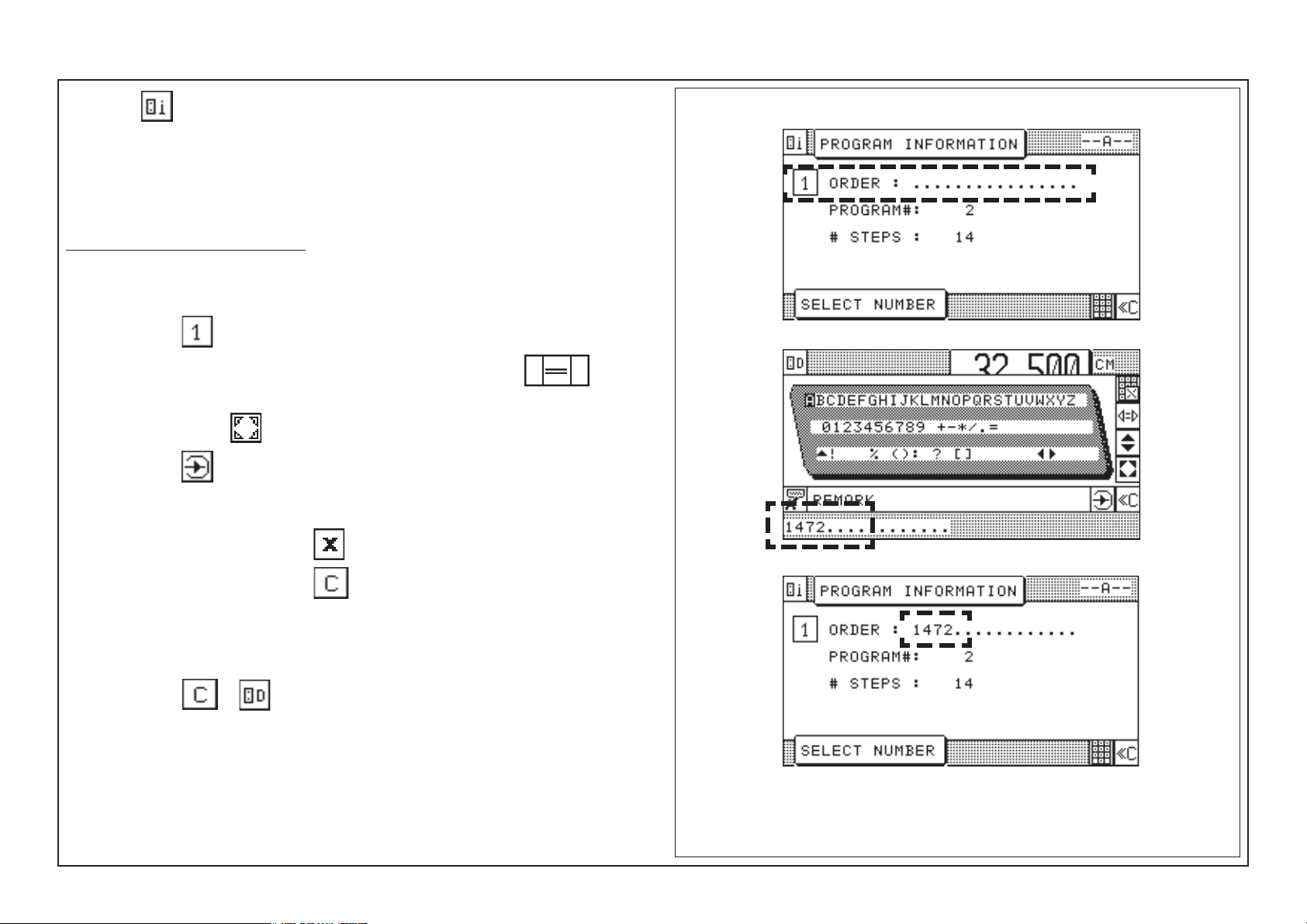

Basic Display: Program Information

Press key

The Program Information display shows information about the currently selected

program. These pieces of information can be complemented by entering an order

number or order name in clear text. The alpha input is performed via a keybord

displayed on the screen.

Input capacity: max. 16 characters!

For the storing of information - refer to page K5A - 20.

Program Information display:

display "memory segment"

K5A - 5

Page 40

5.0 Automatic Operation

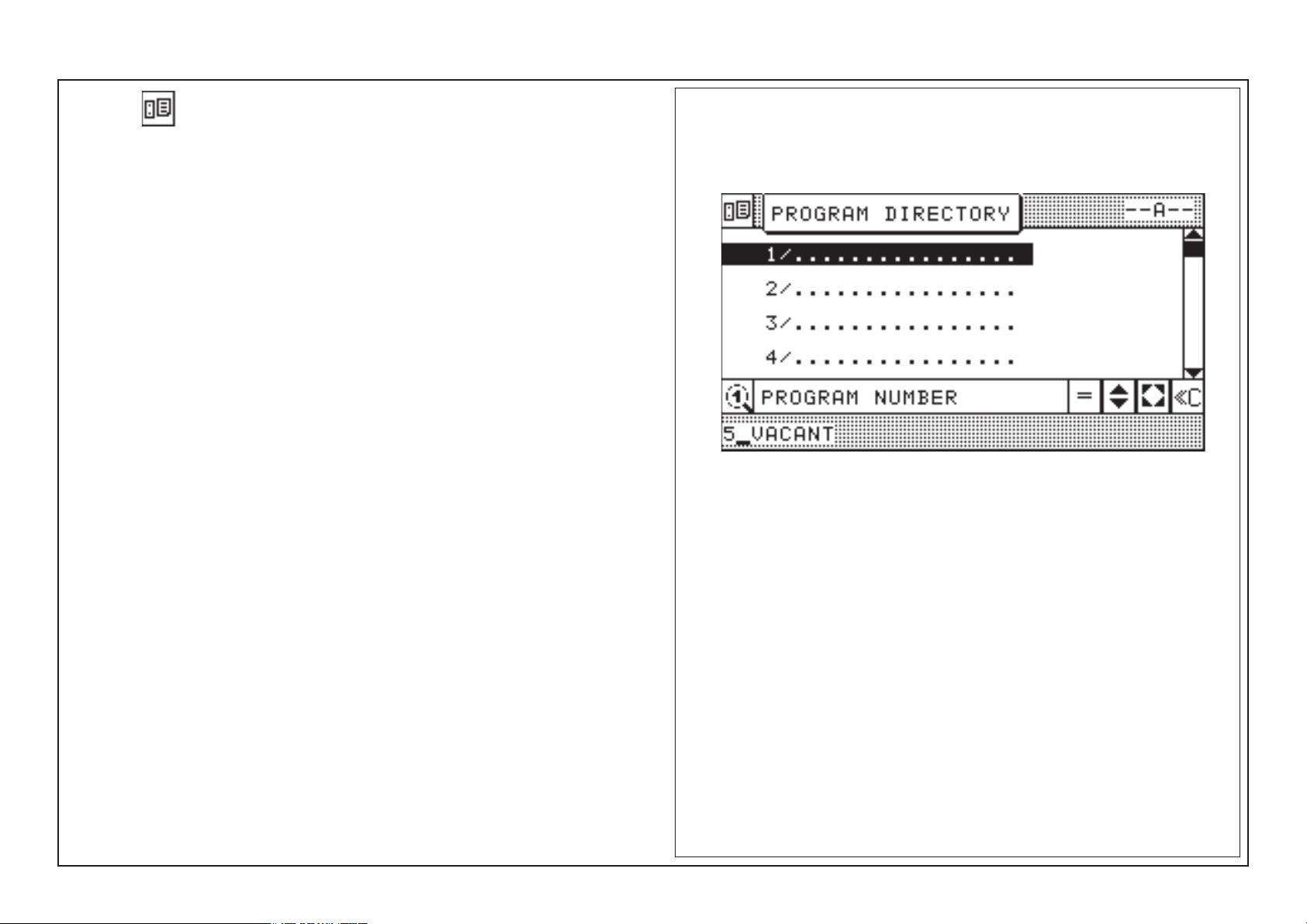

Basic Display: Program Directory

Press key

The program-survey shows all stored programs of the selected memory with the

following data:

(screen top): e.g.: - A - = memory "A"

e.g.: 1/ = program number

e.g.: 1/1575 = order number/order name

PROGRAM NUMBER

5_VAC. = display of number of the next free

program of the actual memory section

Note:

One "page" of the display can show a maximum of 4 programs.

If more than one page is used, you can turn to next page with cursor key

(observe rolling bar on display)

Basic display "Program Directory"

Other input modes in this display:

• program selection

• program deletion

• memory deletion

K5A - 6

Page 41

5.0 Automatic Operation

Basic Display: Main Menu (Function Survey)

Press menu key

The Main Menu (Function Survey) contains a selection menu of various machine

functions.

It provides the user with the possibility to select functions which „accompany“ the

sequence of operation, i.e. such functions are either set at the start of the operation or in case of need.

Select and run any of the operation see K5B - 2

Basic display "Main Menu" (Function Survey):

Menu "Language/Select measuring unit"

Menu "Knife":

Knife compensation

Resting time for knife at BDC

Maintenance cut counter

Menu Service:

access with code number

Menu:

"Block Programming"

Menu "Preset functions":

Correction of current position

Reference run

Adjustment of display contrast

Menu "Help":

Explanation of

pictographs

K5A - 7

Page 42

1 2

3

4 5

6

7 8 9

C

0

x

D

PROGRAMMABLE

5.0 Automatic Operation

Cursor Movement in Basic Display

Cursor = indicator

The basic displays contain two kinds of cursor :

A. Cursor "step" ( in program data section)

B. Cursor "input" (flashes in input section)

Cursor movement:

Meaning:

Cursor "step":

Cursor "input":

Operation

pressing of keys or once

< cursor moves to next step (up or down) or input digit >

Cursor keys

i

Cursor "step"

pressing of keys constantly:

< cursor moves constantly up/down >

only cursor "step":

if together with key or key is pressed

< cursor will "jump" to first or last step >

K5A - 8

Cursor "input"

Page 43

5.0 Automatic Operation

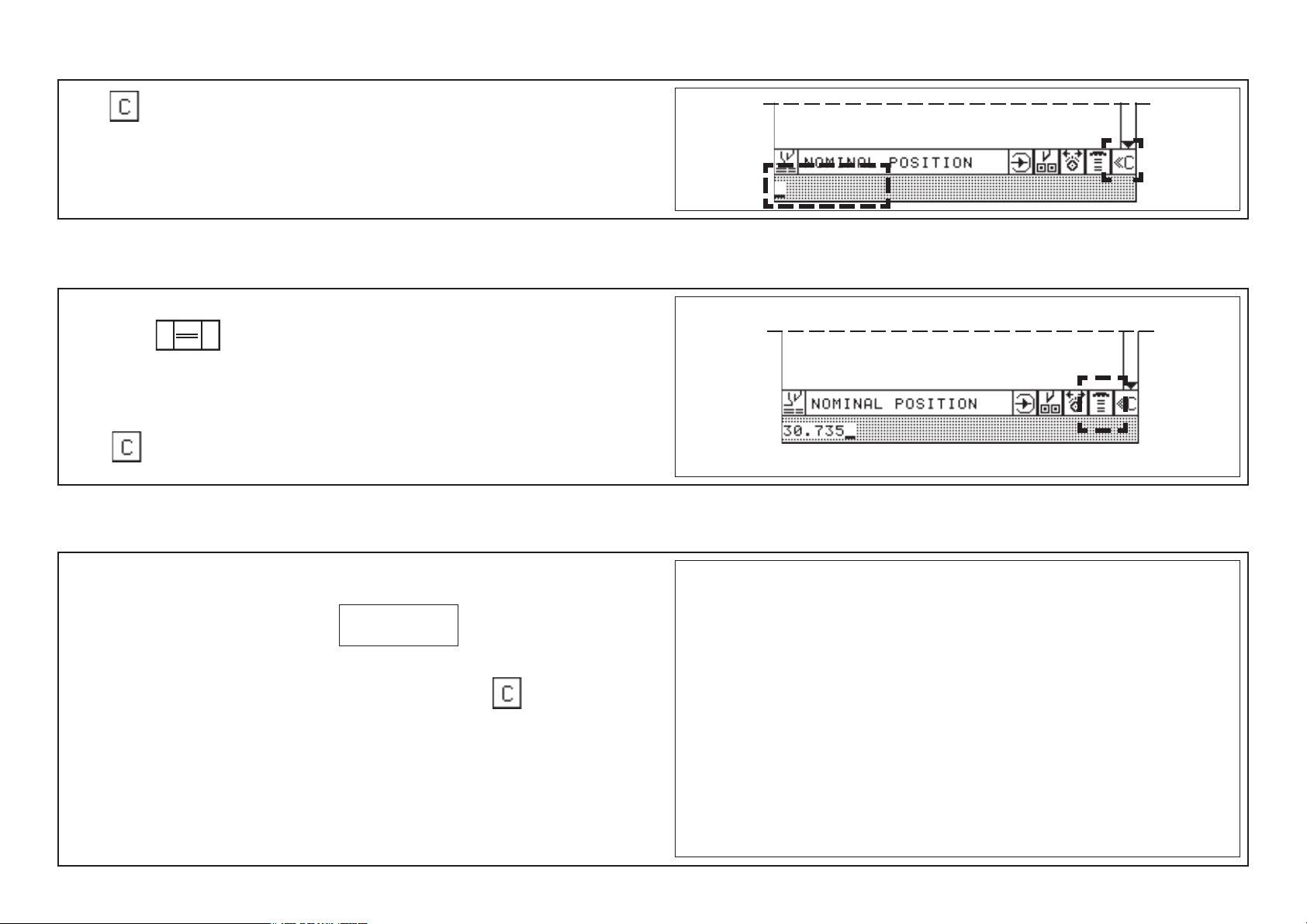

Automatic Backgauge Adjustment through Numerical Keyboard

Conditions: Automatic OFF

A Measurement input with metric system (cm)

Example:

Size Key input

1. 30,735

2. Positioning, press 2 x shortly

_________________________________________________________________

B Measurement input in inches

Same way of input as for metric system

however

value in inches entered as a fraction:

Example:

Program data display:

Size Key input

1. 12 1/2"

2. Positioning, press 2 x shortly

Note:

For whole sizes (no digits behind decimal point) zeroes do not have to be

keyed in. This is done automatically.

after 1. input: input section shows 30.735

after 2. input : backgauge moves

after backgauge stops: measurement display shows 30.735

K5A - 9

Page 44

5.0 Automatic Operation

Deletion of a Wrong Input

Press

< input section is deleted >

Moving Backgauge to a Nominal Position (Positioning)

1. Enter nominal position

2. Press twice shortly

< backgauge moves to nom. pos. forward or backward >

Deletion of a wrong input

Press

Input Error: Value of Nom. Backgauge Position too Low/High

If a nominal size is inserted which cannot be reached by the backgauge the

following reaction will be caused:

< a beep will sound - display: SIZE ERROR

Remedy: 1. Press any key on numerical keyboard e.g.:

2. Insert correct size

K5A - 10

Page 45

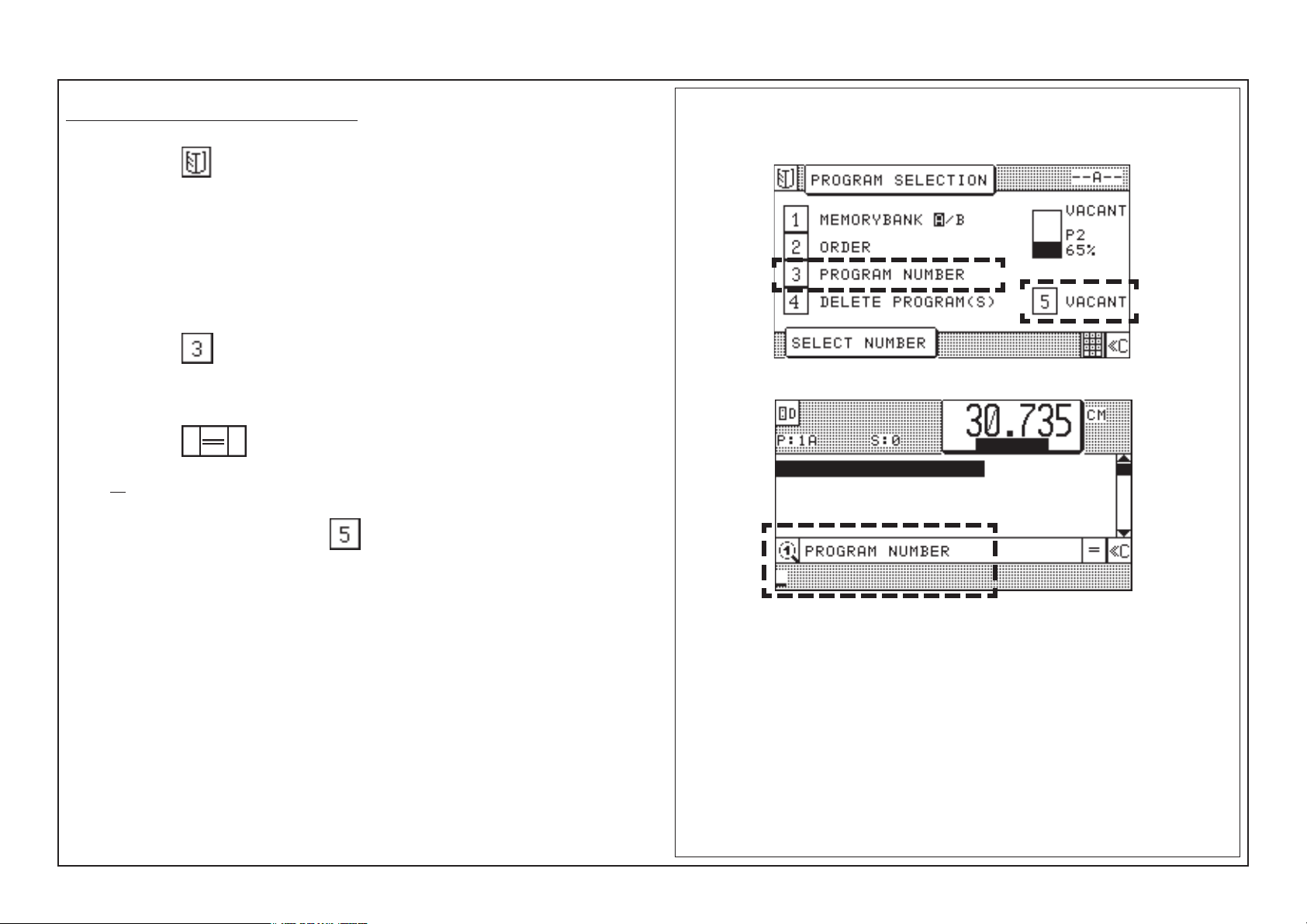

5.0 Automatic Operation

Selection of a Free Program/Display of the Next Free Program

Possible in all 4 basic monitor displays!

1. Press key "Program Selection"

< Selection menu appears;

Assignment display in the right-hand section of the image: display of free

programs of selected memory segment A in % >

Make selection "Program Number":

2. Press key

3. Enter desired program number

4. Press key < Program Data display of the program appears >

or

5. Select free program - press key < next free program appears >

Display (example):

K5A - 11

Page 46

5.0 Automatic Operation

Selecting a Program

Two calling modes:

A. According to program number

B. According to order number/order name

A. According to Program number:

1. Press key "Program selection" < menu appears >

2. Select "program number" with key

3. Enter desired program number

4. Press key

< program data display of selected program appears >

Example:Possible in all 4 basic monitor displays!

B. According to order number:

Note: Previous storing of order number/order name to a program is

conditional (see "Storing of program information", page K5A - 20)

1. Press key "Program selection" < menu appears >

2. Select "Order" < alpha keyboard appears on display >

3. Enter order number/order name via softkey selection

K5A - 12

Page 47

1 2

3

4 5

6

7 8 9

C

0

x

D

PROGRAMMABLE

5.0 Automatic Operation

Continuing: Selecting a Program

Select a character using the cursor keys (with the equal key you

can jump over five characters in a line), then press cursor key "Home"

* < character is inserted into input section >

4. Press key (multiply)

Numerical keyboard

5. Press key

< the desired program (order) appears in the data section, the resp. order

number/order name is faded in. The fading in is automatically cleared upon

the next data input >

* Note:

Input of order number/order name can be done by entering only a part of the

name or the number.

After pressing the "equal" key the computer will "search" for the desired order

according to the entered characters.

In case memory contains several orders with the same characters display will

show the next program number/name whose characters matches the entered

characters.

i

K5A - 13

Page 48

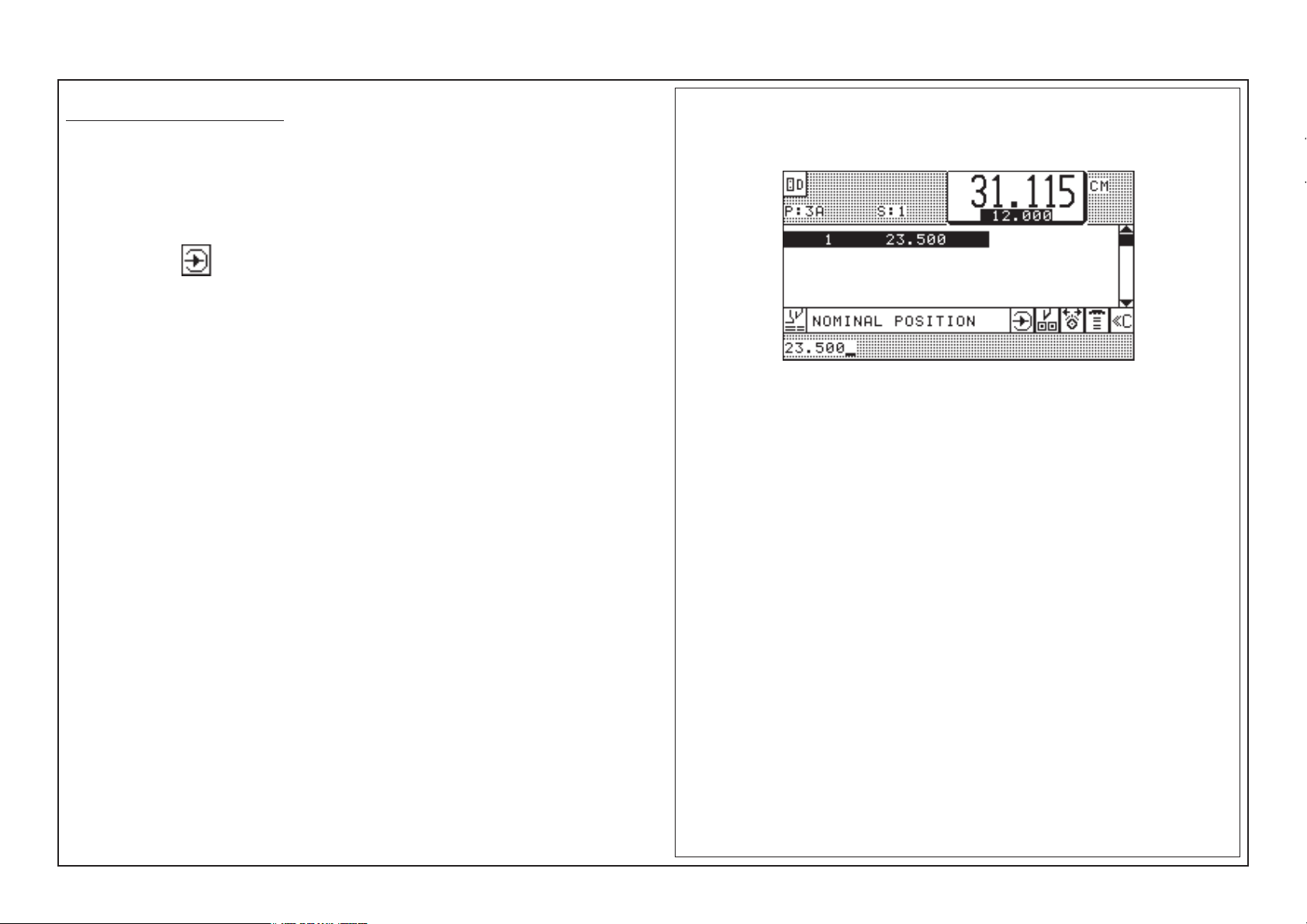

5.0 Automatic Operation

Storage of Measurements

Only in Program data display!

1. Select free program

2. Enter desired size with numerical keyboard (e.g. size 23,5 cm)

3. Press key "Enter"

< beep sounds;

nominal position is on step 1 in program data section >:

Note:

Display can show up to 3 steps (lines). When entering step 4 former step 1 will

disappear into screen memory.

K5A - 14

Page 49

5.0 Automatic Operation

Setting Up a Cutting Program, Example 1

Two side trim on size DIN A3

untrimmed size 31 x 43 cm

Cut sizes to be stored on program no. 3A

1. Cut size: 30,5 cm

2. Cut size: 42,5 cm

Key input:

1. Call program 3A

2.

3.

Running the program:

Press key (Automatic ON)

Press key twice

< backgauge moves to first cutting position; after the cut is triggered:

ejector moves forward automatically; after that the second cutting position is

approached >

2. 42,5 cm

1. 30,5 cm

Program data display after key input:

K5A - 15

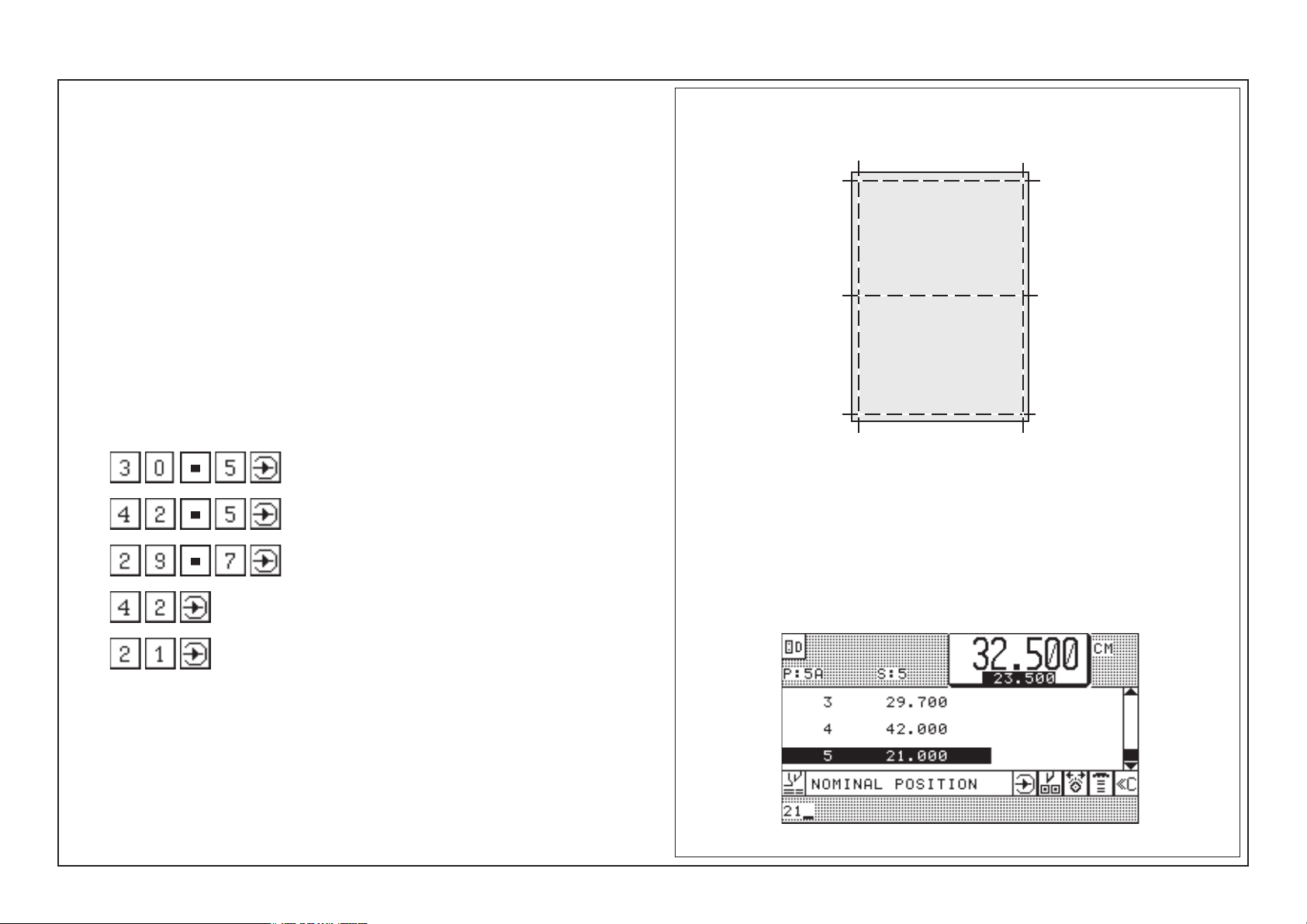

Page 50

5.0 Automatic Operation

Setting Up a Cutting Program, Example 2

Four edge trim with following cuts;

starting size DIN A3 untrimmed 31 x 43 cm;

finish size DIN A4 (21 x 29,7 cm)

Cut sizes:

1. 30,5 cm

2. 42,5 cm

3. 29,7 cm

4. 42.0 cm

5. 21,0 cm

Cut sizes to be stored in program 4A

Key input:

1. Call program 5A

2.

1. 30,5 cm

4. 42,0 cm

5. 21,0 cm

2. 42,5 cm

3. 29,7 cm

3.

4.

5.

6.

K5A - 16

Program data display after key input:

Page 51

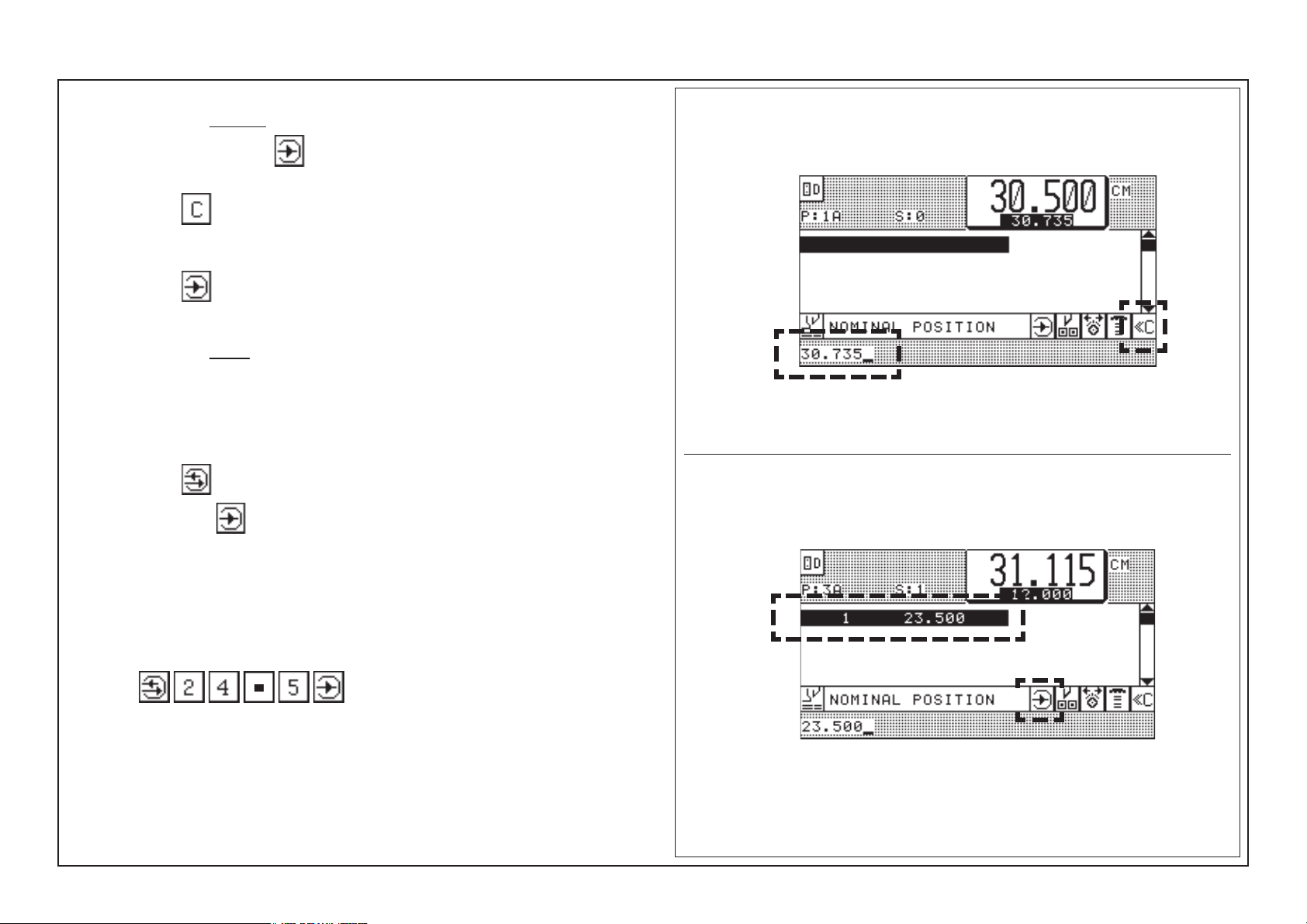

5.0 Automatic Operation

Correction of an Input Error

A. Correcting before storing

(prior to pressing of key "Enter" ; nom.pos. is shown in input section

1. Press key < nom. pos. in input section disappears >

2. Enter correct size/comment

3. Press key "Enter"

B. Correcting after storing

(Nom. pos. is shown in program-data section)

1. Select step number (cursor)

2. Press key "Correction"

3. Enter right size "Enter"

4. Press key

Example: size 23.500 cm in program

has to be changed to 24.5 cm

Key input:

< nom. pos. in program data section is deleted and replaced by new

measurement >

K5A - 17

Page 52

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGPROGRAMMABLE

5.0 Automatic Operation

Automatic ON/OFF

Funtion: Automatic backgauge advance to the next step number

after cutting process

Automatic ON:

Press key < after cut: automatic backgauge advance to next cut size;

display reads: AUTOMATIC

Automatic OFF:

Press key

Attention!

When Automatic is switched on the following operations are not possible:

• programming

• automatic setting of backgauge through size input

Positioning check in automatic operation

For example, when a positioning process in automatic operation has been interrupted (cutting position has not been reached!) and the operator tries to release a

cut in automatic mode after that, a visual and audible indication is made "GO TO

POSITION".

When the position must be moved to:

Press key twice

K5A - 18

Page 53

5.0 Automatic Operation

Running a Cutting Program

Example: Setting a cutting program, example 1

1. Call program 2A < display shows program data of program 2A >

2. Switch on Automat forward: press key

Operation mode: AUTOMATIC

3. Press key 2 x shortly < backgauge moves to 1. cut size >

4. Align stock

5. Make cut

After cut:

- backgauge advances approx. 5 cm/2" (ejector)

- then reverse to 42.500 (with air table)

6. Turn stock by 90° and line up

7. Make cut

after last cut of a program:

- cursor jumps back to 1. step

- backgauge moves to that size

K5A - 19

Page 54

5.0 Automatic Operation

Storing of Program Informations

Press key "Program Information"

The Program Information display shows information about the currently selected

program. These pieces of information can be complemented by entering an order

number or order name in clear text. The alpha input is performed via a keybord

displayed on the screen.

Input capacity: max. 16 characters!

Storing "Order"

1. Press key < keyboard is displayed >

2. Select a character using the cursor keys (with the equal key you

can jump over five characters in a line).

3. Press cursor key "Home" < character is inserted into input section >

4. Press key "Enter"

< beep sounds; information is stored in the line "ORDER" >

Deleting an input: 1. Press key (multiply)

2. Press key

End of information input:

1. Press key or < Program Data display appears >

K5A - 20

Page 55

5.0 Automatic Operation

Deletion of a Step Number

1. Select program < program data display appears >

2. Select step (with cursor)

3. Press key "Delete"

4. Press key

< size (step) is deleted. note:all following steps move down by one

number >

K5A - 21

Page 56

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGPROGRAMMABLE

5.0 Automatic Operation

Deletion of One/Several Program(s)

Possible variations: 1. Deleting in Program Data Display and

Program Information Display

2. Deleting in Program Directory Display

1. Deleting in Program Data Display and Program Information

Display

Attention! In the Program Directory display only the current shown

program can be deleted.

1. Press key program selection < menu appears >

2. Select"Delete program/s" with key

< program data display appears >

3. Program number to be deleted appears in input section

4. Press key "Enter" < current program is deleted >

2. Deleting in Program Directory Display

In the Program Directory display one or several programs can be

deleted!

1. Press key "Program Directory"

2. Press key "Program selection" < menu appears >

3. Select "Delete program/s" with key

4. Enter program number to be deleted e.g.

or deleting of several programs, input e.g.:

5. Press key "Enter"

K5A - 22

Page 57

1 2

3

4 5

6

7 8 9

C

0

x

D

i

PROGPROGRAMMABLE

5.0 Automatic Operation

Deletion of Complete Memory

1. Select Program Directory: press key < menu appears >

2. Press key "Program Selection" < menu appears >

3. Press key "Delete program(s)"

4. Press keys

5. Press key "Enter" < complete memory is deleted >

K5A - 23

Page 58

5.0 Automatic Operation

Inserting of Measurements into a Program

1. Select program < program data display appears >

2. Select step that will receive new measurement (cursor)

3. Press key "Insert" < step is left open for entry >

4. Enter measurement (e.g. 30.500)

5. Press key "Enter"

Storing of Measurements According to Printed Image

1. Select free program

2. Press key "Actual - Nominal Position"

< actual size appears in input section >

3. Align stock at backgauge

Example:

4. Adjust backgauge by handwheel to correct cut position

(use optical/mechanical cutting line indicator)

5. Press key "Enter" < actual size is stored >

< function is switched off automatically when automatic function is

switched on >

K5A - 24

Page 59

1 2

3

4 5

6

7 8 9

C

0

x

D

APROGRAMMABLE

5.0 Automatic Operation

Calculator Functions

Conditions: Automatic OFF

The digital and calculator keys enable 4 basic arithmetic operations.

They can be used to calculate cut sizes.

The calculation and the solution are always displayed in the input section.

Note:

Pressing of keys "+", "-", "x" and ":" will always result in the display of the last

digital input of the previous calculation.

This will be deleted during the new input.

To set backgauge to a calculated size

Press key twice shortly

To store this size:

Press key "Enter"

Overflow Indicator

If the solution of a calculation exceeds 999.999

< a beep will sound; mode display: DIGIT OVERFLOW >

Remedy: clear last input by pressing twice;

enter new figure

i

PROGRAMM

K5A - 25

Page 60

5.0 Automatic Operation

Negative Sign

Negative result of a calculation

< minus (" - ") sign appears before number in input section >

If this result is a cutting size the negative sign needs to be deleted

Press key < minus sign disappears >

Using Backgauge Position of Calculations

If you have set the backgauge to a cut size on a printed sheet and you want to

use this for further calculations:

Press key < actual size appears in input section >

Switching the function off:

Press the same key again

K5A - 26

active function

Page 61

1 2

3

4 5

6

7 8 9

C

0

x

D

5.0 Automatic Operation

Machine Functions and Additional Functions (Menu Keys)

Machine Functions

Machine functions are basic functions of the machine. They can be changed for

the program sequence.

The machine functions can be selected by pressing one of the following pushbuttons:

• Main Menu (Function Survey) (page K5B - 2)

• Auxiliary Functions (page K5D - 1)

• Machine Parameters (page K5E - 1)

Additional Functions

The running of cutting programs can be further automated by using additional

functions.

For this purpose, a multi-function key is available to the user.

• Additional Functions (page K5C - 1)

Operating panel with menu keys:

Additional Functions

Auxiliary Functions

i

After any of the menu keys has been pressed a survey menu is opened which

offers several functions.

The corresponding subfunctions of the menu keys are selected by choosing the

respective identification number of the pictograph (symbol) and can be transferred into the currently selected program.

A special function stored will be indicated in the Program Data display as a

pictograph (symbol) behind the cut size.

It is possible to store several additional functions into one step number.

Machine Parameters

Main Menu

(Function Survey)

K5B - 1

Page 62

5.0 Automatic Operation

Machine Function: Main Menu (Function Survey)

Key "Main Menu"

Key "Main Menu" includes the following functions*:

Select language

Select measuring unit

Knife compensation

Resting time for knife at BDC

Maintenance cut counter

Service

Preset functions

Reference run/Auxiliary operation

Correction of current position

Adjust ment of display contrast

Block programming

Help

* Technical alterations reserved!

Menu " Language/Select measuring unit"

Menu "Knife":

Knife compensation

Resting time for knife at BDC

Maintenance cut counter

Menu Service:

access with code number

K5B - 2

Menu "Block Programming"

Menu "Preset functions":

Correction of current position

Reference run

Adjustment of display contrast

Menu "Help":

Explanation of

pictographs

Page 63

5.0 Automatic Operation

Select Language/Measuring Unit

Select "Main Menu" (Funtion survey)

Press key < menu appears >

Select function (LANGUAGE or MEASURING UNIT):

1. Key input: (language) or (measuring unit)

2. Select language or measuring unit: Enter number

Service

After selection display of machine identification (electronical type plate)

appears.

Possible inputs:

• Machine equipment

• BAUM safety check

• Name of inspector

You can jump to the next input line by pressing key .

You can move to the next pages with the help of the Cursor keys.

To store your entries: press key "Enter". .

The additional functions of the "Service menu" are only accessible to

BAUM service or its agencies. Access only after entering a code number.

K5B - 3

Page 64

5.0 Automatic Operation

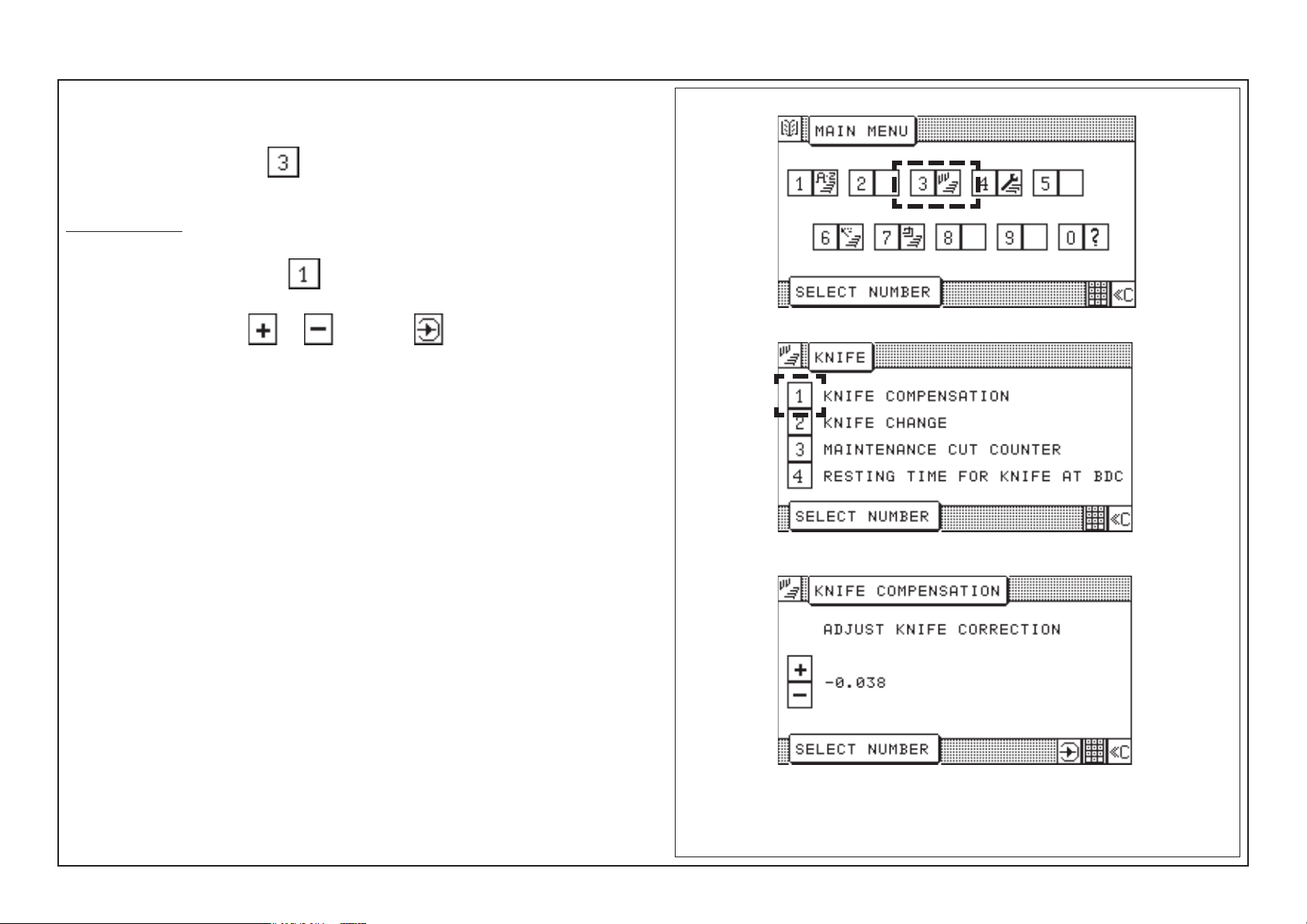

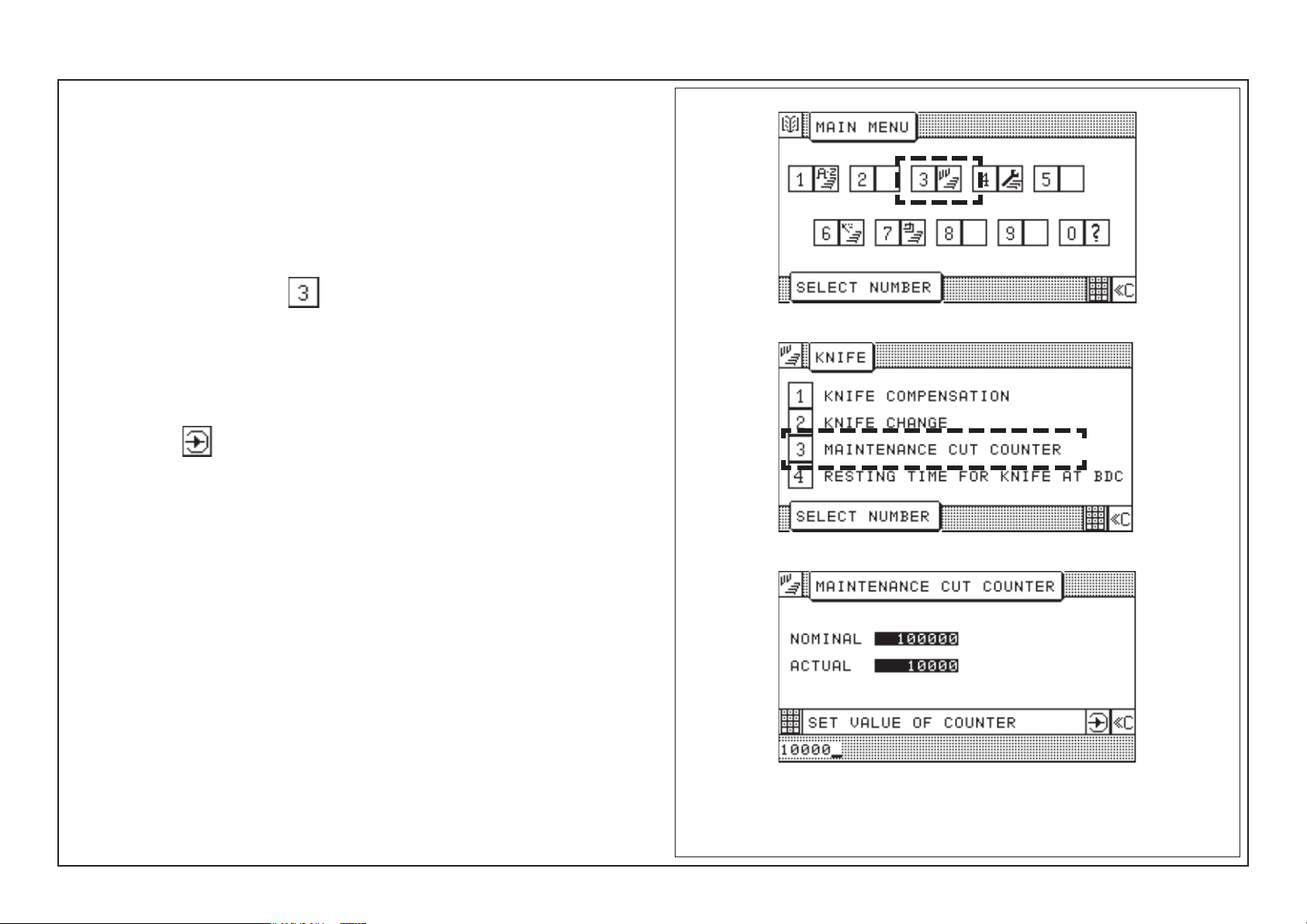

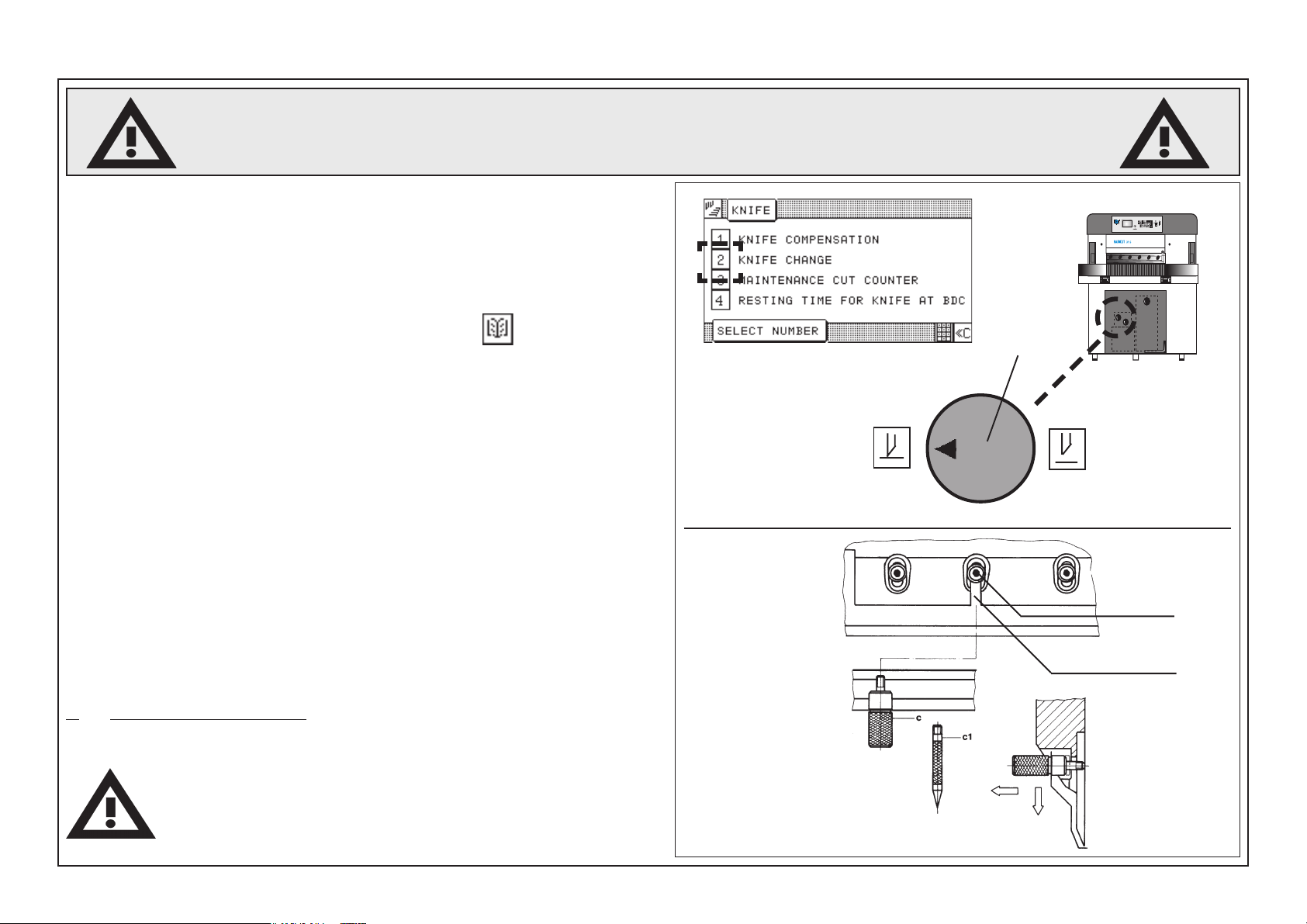

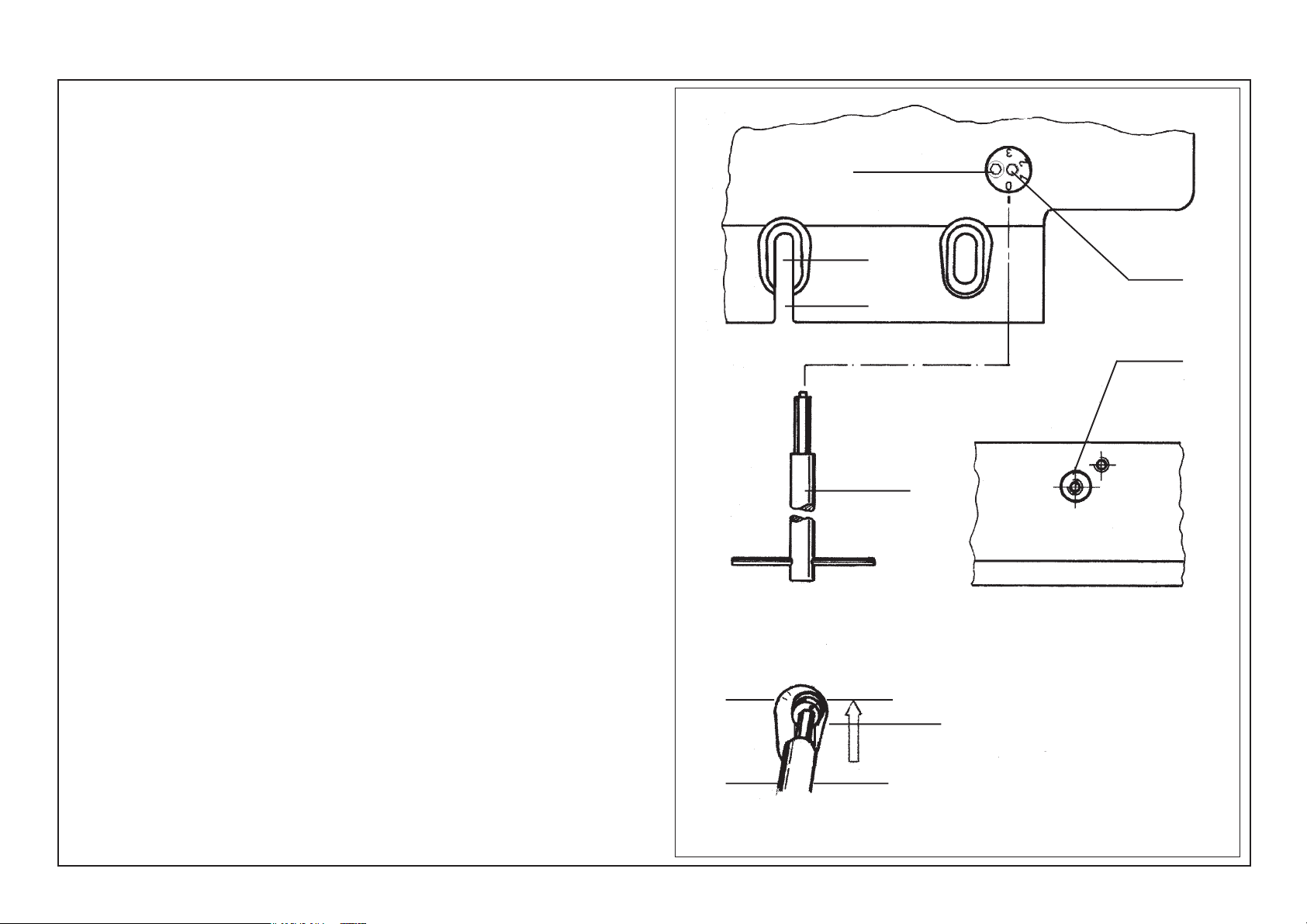

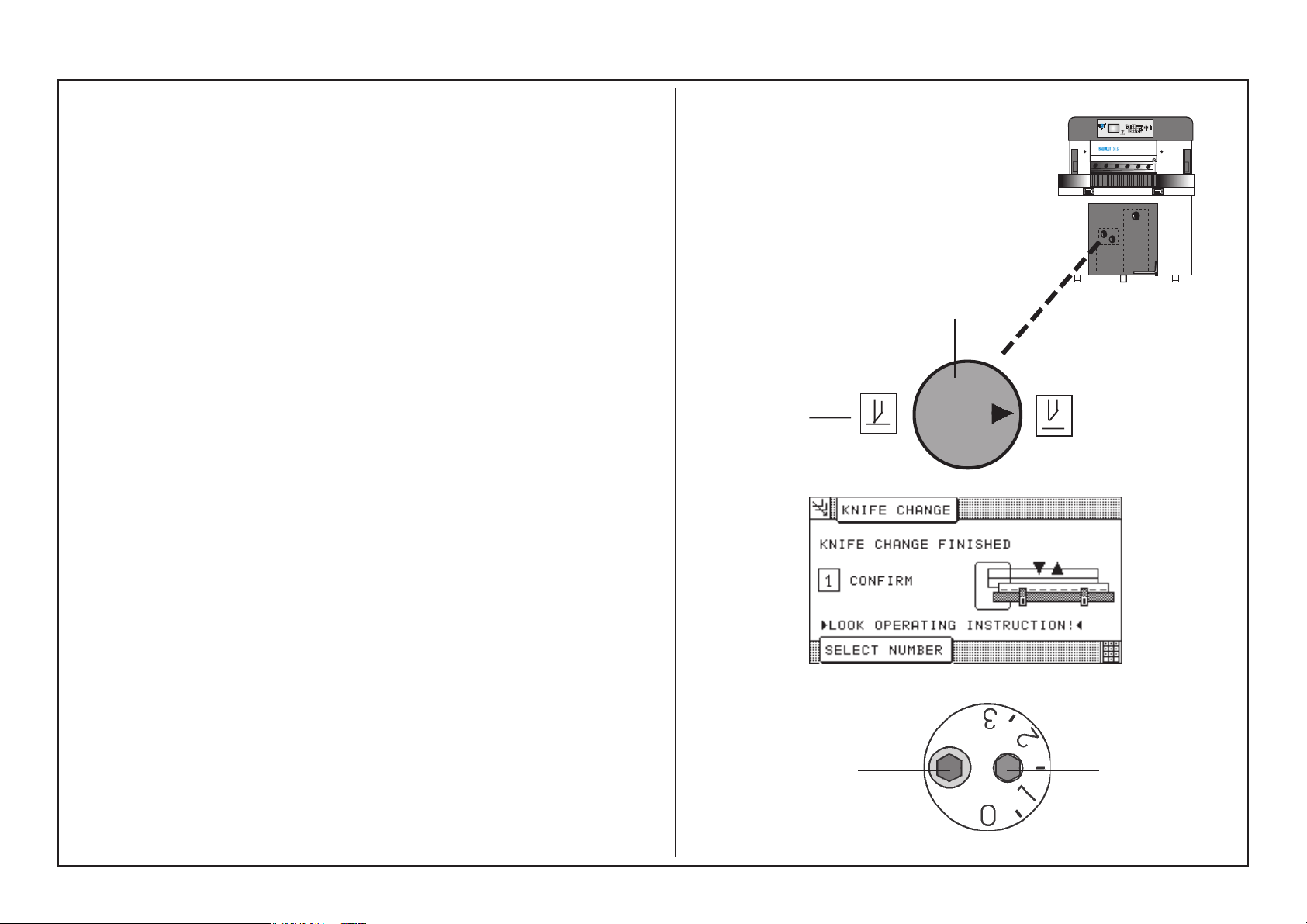

Knife Compensation