Page 1

BA U

M

BAUM 26/BAUM 30

1ST STATION FOLDER

W/CONTINUOUS FEED

INSTRUCTION MANUAL

©Baumfolder Corp., 2004 Printed in U.S.A. TP10476-1

PAGE 1 TP10476-1

Page 2

© 2004 BAUMFOLDER CORPORATION

All Rights Reserved

WARNING

• Do not operate this machine without all guarding in place.

• Do not make adjustments or perform maintenance on this machine with power on.

• Keep the machine and the work area clean and free of spills to prevent accidents.

• Be sure to replace any safety decals that may have been detached for any reason.

Baumfolder Corporation reserves the right to make changes in design or to make additions or

improvements in its products without imposing any obligation upon itself to install them on its

previously manufactured products. It is recommended that modifications to this equipment not be

made without the advice and express written consent of Baumfolder Corporation.

FOLDER IDENTIFICATION

MODEL NO: _______________________________ SERIAL NO: _____________________________

SALES AGENCY: ____________________________________________________________________

INSTALLED BY: _____________________________________________ DATE: ________________

PHONE NO: _______________________________

TP10476-1 PAGE 2

Page 3

CONTENTS

DESCRIPTION PAGE

I.) Safety .................................................................................................................................................................. 6

II.) Warning Labels ................................................................................................................................................. 9

III.) Introduction Overview ..................................................................................................................................... 10

IV.) Transportation/Installation .............................................................................................................................. 10

V.) Electrical Connections .................................................................................................................................... 11

1.0 .Wiring the Unit ................................................................................................................................... 11

1.1 . Pump & Blower Connections .............................................................................................................. 11

VI.) Feeder Operation .............................................................................................................................................. 12

1.1 . Air and Vacuum Setting....................................................................................................................... 13

1.2 . Sheet Separation and Suction Force .................................................................................................... 14

1.3 . Register Table and Double Sheet Detector ......................................................................................... 15

VII.) Baumset Adjustment ........................................................................................................................................ 16

1.0 .Adjusting Folding Rollers ................................................................................................................... 16

VIII.) Installing Fold Plates ....................................................................................................................................... 17

IX.) Operator Controls ............................................................................................................................................ 17

1.0 . Setting Folding Speed ......................................................................................................................... 17

1.1 .Setting Stacker Belt Speed ................................................................................................................... 17

1.2 .Emergency Stop Button ....................................................................................................................... 17

1.0 Control Panel BAN-5 ................................................................................................................................ 18

1.1 . Displays............................................................................................................................................... 18

1.2 .Machine Status Indicators .................................................................................................................. 18

1.3 .Machine Control Pushbuttons ............................................................................................................ 19

1.4 . Keypad Buttons with Selection Indicators .......................................................................................... 19

1.5 . Keypad Buttons for Selection Adjustments ........................................................................................ 19

2.0 RUN M ODE F UNCTIONS ................................................................................................................................20

2.1 . Machine Setup and Diagnostic Mode ................................................................................................. 20

2.2 . Counter Setup Mode ........................................................................................................................... 26

2.3 .Learn Mode ......................................................................................................................................... 27

2.4 . Make Ready Mode .............................................................................................................................. 28

2.5 .Network Job Mode .............................................................................................................................. 28

2.6 .Production Mode ................................................................................................................................ 29

3.0 CONTROLLER I NPUT D ESCRIPTIONS .............................................................................................................. 30

4.0 Process Variables ..................................................................................................................................... 32

4.1 . Total Input Count ................................................................................................................................ 32

4.2 . Total Output Count ............................................................................................................................. 32

4.3 .Batch Down Count .............................................................................................................................. 32

4.4 .Number of Batches .............................................................................................................................. 32

4.5 . Current Rate ......................................................................................................................................... 32

4.6 . Main Drive Run Time .......................................................................................................................... 32

4.7 . Main Drive Velocity ............................................................................................................................. 32

4.8 .Waste Count ....................................................................................................................................... 33

5.0 COUNTER SETUP VARIABLES ....................................................................................................................... 33

5.1 . Batch Preset......................................................................................................................................... 33

5.2 . Batch Output Type .............................................................................................................................. 33

5.3 .Batch Output Time .............................................................................................................................. 33

5.4 . Sheet Length ....................................................................................................................................... 33

5.5 . Gap Length .......................................................................................................................................... 33

5.6 . Suction Length .................................................................................................................................... 33

6.0 SYSTEM M ESSAGES AND R UN M ESSAGES ....................................................................................................... 34

6.1 . Power-Up Fault Messages .................................................................................................................. 34

6.2 . Run Time Fault Messages ................................................................................................................... 35

6.3 . Machine Run Error Messages ............................................................................................................. 36

PAGE 3 TP10476-1

Page 4

CONTENTS

DESCRIPTION PAGE

X.) Setting Fold Plates ........................................................................................................................................... 38

XI.) Scoring/Slitting/Perforating ........................................................................................................................... 39

1.0 . Slitter Shaft Removal ........................................................................................................................... 39

1.1 . Scoring ................................................................................................................................................ 39

1.2 . Perforating ........................................................................................................................................... 39

1.3 . Slitting ................................................................................................................................................. 39

1.4 . Trimming Edges of Booklets ................................................................................................................ 40

1.5 . Trimming a Strip from Center of Sheet ................................................................................................. 40

1.6 . Blade Installation ................................................................................................................................. 40

XII.) Lubrication/Maintenance ................................................................................................................................. 42

XIII.) Technical Specifications & Accessories ......................................................................................................... 43

XIV.) Troubleshooting ............................................................................................................................................... 44

XV.) Service ............................................................................................................................................................ 46

TP10476-1 PAGE 4

Page 5

List of Tables

DESCRIPTION PAGE

Table 1. Machine Setup Parameter List ................................................................................................................................ 20

Table 2. Statistics ................................................................................................................................................................. 21

Table 3. Machine Settings .................................................................................................................................................... 22

Table 4. Machine Diagnostic Parameter List ......................................................................................................................... 23

Table 5. Safety Settings ........................................................................................................................................................ 24

Table 6. Machine Statistics .................................................................................................................................................. 24

Table 7. Machine Operating Statistics ................................................................................................................................. 25

Table 8. Output Type Animations ....................................................................................................................................... 26

Table 9. Count Source Selection ........................................................................................................................................... 26

Table 10. Learn Mode Status ................................................................................................................................................ 27

Table 11.Suction Mode Symbols .......................................................................................................................................... 27

Table 12. Suction Length Function ....................................................................................................................................... 28

Table 13. Determining the Large Display Contents ............................................................................................................... 29

Table 14. Reset Mode Selection ............................................................................................................................................ 29

Table 15. Inputs .................................................................................................................................................................... 30

Table 16. LED Status Indicators ............................................................................................................................................ 32

Table 17. Output Delay and Duration ................................................................................................................................... 33

Table 18. Power Up Fault Messages ..................................................................................................................................... 34

Table 19. Run Time Fault Messages ..................................................................................................................................... 35

Table 20. Machine Run Error Messages ............................................................................................................................... 36

PAGE 5 TP10476-1

Page 6

FUNDAMENTAL SAFETY

INSTRUCTIONS!

The diagrams and descriptions used in these instructions are not necessarily

applicable to the specification of the machine supplied. Modifications, made

for reasons of technical or operational improvement, are embodied without

notice.

TP10476-1 PAGE 6

Page 7

FUNDAMENTAL SAFETY

INSTRUCTIONS!

These operating instructions are designed to familiarize

the user with the machine and its designated use.

The instruction manual contains important information on

how to operate the machine safely, properly and

most efficiently. Observing these instructions helps to

avoid danger, to reduce repair costs and downtimes and

to increase the reliability and life of the machine.

In addition to the operating instructions and to the mandatory rules

and regulations for accident prevention and environmental protection

in the country and place of use of the machine, the generally

recognized technical rules for safe and proper working must also be

observed.

The following signs and designations are used in the

manual to designate instructions of particular importance.

1.0.3

The machine/installation is designed exclusively for paper finishing

of minimum and maximum sheet sizes (see corresponding operating

instructions). Using the machine/ installation for purposes other than

those mentioned above is considered contrary to its designated use.

The manufacturer/supplier cannot be held liable for any damage or

injury arising from such misuse. The risk of such misuse lies entirely

with the user.

Operating the machine within the limits of its designated

use also involves observing the instructions set out in the

operating manual and complying with the inspection and

maintenance directives. The working temperature of the

machine should range between 0° and 55° C.

1.1 Organizational measures

1.1.1

The operating instructions must always be at hand at the

place of use of the machine/plant, e.g. by stowing them in the tool

compartment or tool box provided for such purpose.

Important

(refers to special information on how to use the

machine/plant most efficiently)

Attention

(refers to special information and/or orders and

prohibitions directed towards preventing

damage)

Danger

(refers to orders and prohibitions designed prevent injury or extensive damage)

1.0 Basic operation and designated use

of the machine/plant

1.0.1

The machine /plant has been built in accordance with

state-of-the art standards and the recognized safety rules.

Nevertheless, its use may constitute a risk to life and limb

of the user or of third parties, or cause damage to the

machine and to other material property.

1.1.2

Personnel entrusted with work on the machine must have

read the operating instructions and in particular the chapter on

safety before beginning work. Reading the instructions after work

has begun is too late. This applies especially to persons working

only occasionally on the machine, e.g. during setting up or

maintenance.

1.1.3

For reasons of security, long hair must be tied back or

otherwise secured, garments must be close fitting and no

jewelry, such as rings, may be worn. Injury may result

from being caught up in the machinery or from rings

catching on moving parts.

1.1.4

Observe all safety instructions and warnings attached to

the machine/plant.

1.1.5

See to it that safety instructions and warnings attached to

the machine are always complete and perfectly legible.

1.1.6

In the event of safety relevant modifications or changes in

the behavior of the machine/plant during operation, stop

the machine/plant immediately and report the malfunction

to the competent authority/person.

1.0.2

The machine/plant must only be used in technically perfect

condition in accordance with its designated use and the

instructions set out in the operating manual, and only by

safety-conscious persons who are fully aware of the risks

involved in operating the machine/plant. Any functional

disorders, especially those affecting the safety of the

machine/plant, should therefore be rectified immediately.

1.1.7

Never make any modifications, additions or conversions

which might affect safety without the supplier’s approval.

This also applies to the installation and adjustment of

safety devices and valves as well as to welding work on

load-bearing elements.

PAGE 7 TP10476-1

Page 8

1.1.8

Spare parts must comply with the technical requirements specified by

the manufacturer. Spare parts from original equipment manufacturers

can be relied to do so.

1.1.9

Report any accident that occurs due to a malfunction of the machine

though all prescribed safety precautions were observed directly to

our agency or to the Heidelberg service department (VFKD).

1.2 Selection and qualification of personnel

- Basic responsibilities

1.3.1.4

Before starting up or setting the machine/plant in motion, make sure

that nobody is at risk.

1.3.2

Special work in conjunction with utilization of the machine/plant and

maintenance and repairs during operation; disposal of parts and

consumables.

1.3.2.1

Always press the emergency (Not-Stop) button first, if you stop the

machine for adjustments or maintenance work which must not be

done while the machine is in operation.

1.2.1

Employ only trained or instructed staff and set out clearly the

individual responsibilities of the personnel for operation, set-up,

maintenance and repair.

1.2.2

Make sure that only authorized personnel work on or with the

machine.

1.2.3

Work on the electrical system and equipment of the machine/plant

must be carried out only by a skilled electrician or by instructed

persons under the supervision and guidance of a skilled electrician and

in accordance with electrical engineering rules and regulations.

1.2.4

Work on gas fueled equipment (gas consumers) may be carried out by

specially trained personnel only.

1.3 Safety instructions governing specific

operational phases

1.3.1 Standard operation

1.3.1.1

Avoid any operational mode that might be prejudicial to safety.

1.3.2.2

For extensive maintenance or repair work, turn off the main power

supply.

1.3.2.3

After making adjustments or after doing maintenance or repair work,

always make sure that all tools or other objects are removed from the

machine. Otherwise they might fall into the machine, causing severe

damage or injuries.

1.3.2.4

Keep the floor around the entire machine clean. Immediately clean

any oil, grease or paint spills up off the floor. Remove tools, cleaning

cloths or paper scraps from all work areas.

1.3.2.5

Never operate a folding machine without buckle plates or deflectors

since these are protective as well.

1.3.2.6

Never clean moving parts of the machine (rollers, shafts) or remove

any test sheets, spoiled sheets or bits of paper in such areas.

1.3.2.7

Observe the adjusting, maintenance and inspection activities and

intervals set out in the operating instructions, including information

on the replacement of parts and equipment. These activities may be

executed by skilled personnel only.

1.3.1.2

Take the necessary precautions to ensure that the machine is used

only when in a safe and reliable state. Operate the machine only if all

protective and safety oriented devices, such as removable safety

devices, emergency shut-off equipment, sound proofing elements

and exhausters, are in place and fully functional.

1.3.1.3

Check the machine/plant at least once per working shift for

obvious damage and defects. Report any changes (incl. changes in the

machine’s working behavior) to the competent organization/person

immediately. If necessary, stop the machine immediately and lock it.

TP10476-1 PAGE 8

1.3.2.8

Brief operating personnel before beginning special operations and

maintenance work, and appoint a person to supervise the

activities

..

.

..

1.3.2.9

If the machine/plant is completely shut down for maintenance and

repair work, it must be secured against inadvertent starting by:

– locking the principal control elements and

removing the ignition key and/or

– attaching a warning sign to the main switch.

Page 9

1.4.1 Electric energy

1.4.1.1

Use only original fuses with the specified current rating. Switch off

the machine/plant immediately if trouble occurs in the electrical

system.

1.5 Description and definition of the safety

labels and pictographs on the machine

Replace damaged pictographs with new ones. The corresponding

reference numbers are indicated.

1.4.1.2

If provided for in the regulations, the power supply to parts of

machines and plants, on which inspection, maintenance and repair

work is to be carried out, must be cut off. Before starting any

work, check the de-energized parts for the presence of power

and ground or short-circuit them in addition to insulating adjacent

live parts and elements.

1.4.1.3

The electrical equipment of machines/plants is to be inspected and

checked at regular intervals. Defects such as loose connections or

scorched cables must be rectified immediately.

1.4.1.4

Necessary work on live parts and elements must be carried out only

in the presence of a second person who can cut off the power

supply in case of danger by actuating the emergency shut-off or

main power switch. Secure the working area with a red and white

safety chain and a warning sign. Use insulated tools only.

1.4.1.5

Only unplug or plug in electrical connectors if the main switch

has been disconnected.

Warning!

Folding rollers rotate in opposite directions.

Keep hands away from rollers while the machine

is running!

Warning!

To avoid bruising, keep hands away when

operating moving machine parts!

Warning!

Do not reach into moving belts!

Warning!

Be careful! Height adjustment devices

might cause bruising!

Warning!

Only operate machine when covers are

closed.

1.4.1.6

Only connect the folding units and no machines of other brands to

the existing connectors. Any electrical connection of STAHL

folding machines with other brands needs our express consent.

1.4.1.7

For electrical connection, observe the prescribed admissible voltage

and frequency.

1.4.1.8

Keep switch cabinets closed.

1.4.2

Oil, grease and other chemical substances

1.4.2.1

When handling oil, grease and other chemical substances,

observe the product related safety regulations.

1.6 Explanation of the pictographs used

in the operating instructions

Warning!

You might risk bruising when

moving the machine.

PAGE 9 TP10476-1

Page 10

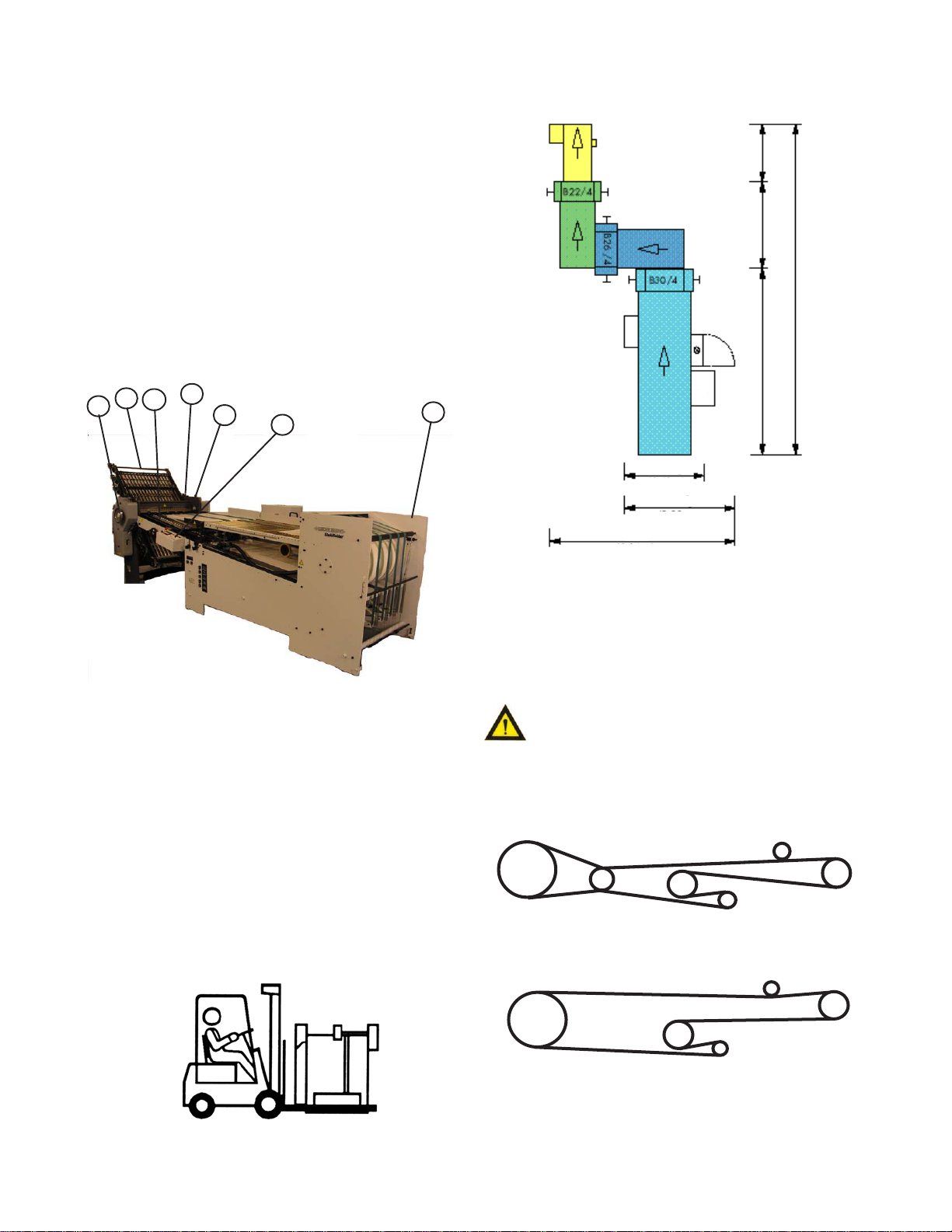

INTRODUCTION OVERVIEW

The 1st station (parallel) folder with continuous

feeder contains the following main components (Figure 1):

1. Continuous Feeder

2. Register

3. 1st Station Folder (Parallel)

4. Fold Roller Baumset settings

5. Fold Plates

6. Slitter Shafts (not shown)

7. Delivery (Stacker, not shown)

8. Operator Controls

9. Double Sheet Detector (not shown)

10. Vacuum Pump (not shown)

11. Handwheel

11

5

3

2

4

8

1

(3.03m)

119"

54.5"

(1.38m)

(1.97m)

77.5"

(1.17m)

(1.73m)

(3.78m)

46"

68"

149"

(6.73m)

265"

Figure 1

TRANSPORTATION/INSTALLATION

As soon as you receive your new folder, and before

removing the machine from the skid, check carefully for any

damage to the shipments. If any damage is found, promptly

contact your Baumfolder sales representative.

To lift the folder from the skid, place the fork lift rails

under the crossmembers as shown in Figure 2. Note that the

fork lift must have at least a 1500 lb. capacity.

Remove all rust protection coating after unpacking the

folder.

Remove the connecting bolts from the side frame at the

front of the register. Move the feeder next to the properly

aligned fold head and adjust it so that the holes in the

register and in the side of the folder are at the same height.

Remove the transport supports after you

align the feeder.

Install the drive belts on the folding unit and check

their tension.(Figure 3)

BAUM 26

Figure 2

TP10476-1 PAGE 10

BAUM 30

Figure 3

Page 11

ELECTRICAL CONNECTIONS

1.0 Wiring the Unit (3 phase)

All repair or disassembly work must be performed

by qualified personnel. Before inspecting the

electrical system, always turn the main power

switch OFF before opening the door of the circuit

cabinet.

Check that your power supply meets the requirements

given in the machine specifications. Use an allen wrench to

unlock the circuit cabinet door and open it.

Feed the power supply cable from your distribution

panel through the side of the circuit cabinet. Connect the

customer's supply conductors to the main disconnect at L1,

L2 & L3. Connect the earth ground conductor to the adjacent

ground terminal block.

Before operating the folder for the first time, measure

the line to line voltage to determine where to set the transformer tap. Turn off the main disconnect and move the 7L3

tap of the transformer to the appropriate voltage tap of the

transformer.

Turn the main power switch to the "ON" position.

Switch the pumps on momentarily and check for proper

pump rotation as indicated by the rotation arrow on the

respective pumps. Immediately turn off the pumps if the

rotation is wrong. If both motors are turning in the wrong

direction, switch any two wires at the main disconnect

switch. If only one rotation is incorrect, interchange any two

of the three wires #1, #2, or #3 at their appropriate terminal

block connection point.

1.1 Pump & Blower Connections

Once the pump and blower rotational directions have

been checked and verified, connect the vacuum hose and the

blower hose to their appropriate tubes and secure them with

hose clamps.

PAGE 11 TP10476-1

Page 12

CONTINUOUS FEEDER OPERATION

1.0 Loading the Continuous Feeder

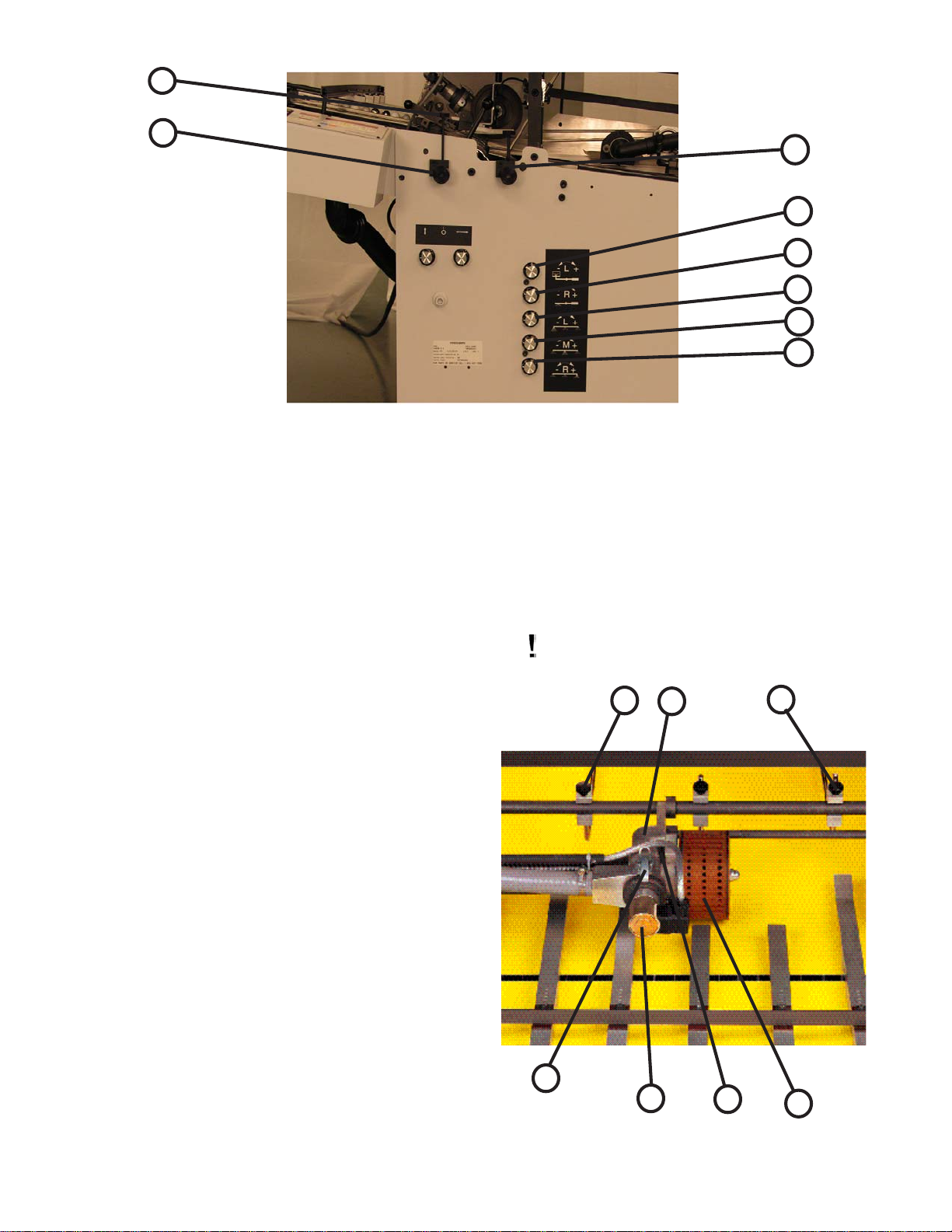

Before loading the sheets, use the knobs (Figure 4-1) of

the side guide to set the side for the correct folding format

according to the scale on the feeder. Make certain that you

always maintain the required 8-12 mm gap between the

incoming sheets and the alignment ruler.

The bottom table is equipped with a conveyor belt that is

wide enough to stretch across all usable formats. When you

change sheet formats, you must also adjust the lower side

rails.

1

Figure 4

The deflector belts (5-1) that are wrapped around the

reversing drum operate independently of the loading and

outfeed tables. It will rarely be necessary to change the belt

position. Make certain that the belts are not placed on the

sheet edge (5-2). With the feeder running, use the lever to

move the deflector belts to their proper position.

2

1

Figure 5

When loading the feeder, make certain that the paper

stack does not exceed the maximum height of 3.00" or 8cm.

When feeding a new sheet stack, e.g. when

changing to a new sheet size, help the first

sheet along until it is taken up between the

reversing drum and the deflection belts.

This is done by pressing the stack down on

the middle conveyor belt while pushing the

stack forward at the same time until it is

securely held by the reversing drum and

the deflection belts.

The suction plate blower can be moved or

unscrewed for more convenient sheet

removal.

A movable feeder sensor switch (6-1) is located under the

sucker wheel (6-2). This tab is activated by the leading edge

of the sheet stream, thus providing fully automated control of

the sheet stack feed.

The position of the leading sheet edge at the switch tab

determines the speed at which the stack is advanced; therefore, the stack speed is automatically adjusted to any production speed.

TP10476-1 PAGE 12

Page 13

Stack feeding is stopped automatically if the tab of the

switch is pushed beyond a preset point by the leading sheet

edge (6-3).

Make certain that the switch tab remains

in a verticle position during the sheet

feed operation and that it does not

vibrate (flutter) with each passing sheet.

The position of the switch tab is set at the factory. If

necessary, it can be adjusted both horizontally and vertically

by knobs located on the feeder side frame.

Place the lateral blower (7-1) along the edge of the sheet

stack and the holddown wheels (7-2) on the trailing edge of

the top feeding sheet.

2

Figure 6

1

3

Figure 7

1.1 Air and Vacuum Settings

Use knob (8-1) to adjust the height of the front blowers

and set the angle of the air flow with the lever (8-2) above

the knob. The pointer on the operator side shows airflow

direction.

Use knob (8-3) to adjust the position of the transfer plate.

The distance between the top of the stack and the bottom

of the sucker wheel should be about 1 cm. Lift the

transport plate for large sheets or drooping sheet edges.

Lower the transport plate for small sheets.

1 2

Use knob (8-4) to adjust the air volume that the suction

plate blowers produce.

Use knobs (8-5 thru 8-8) to adjust the air volume produced by the front blowers separately for each section.

Symbols by the knobs indicate the zone which each

knob regulates.

PAGE 13 TP10476-1

Page 14

2

1

Figure 8

3

4

5

6

7

8

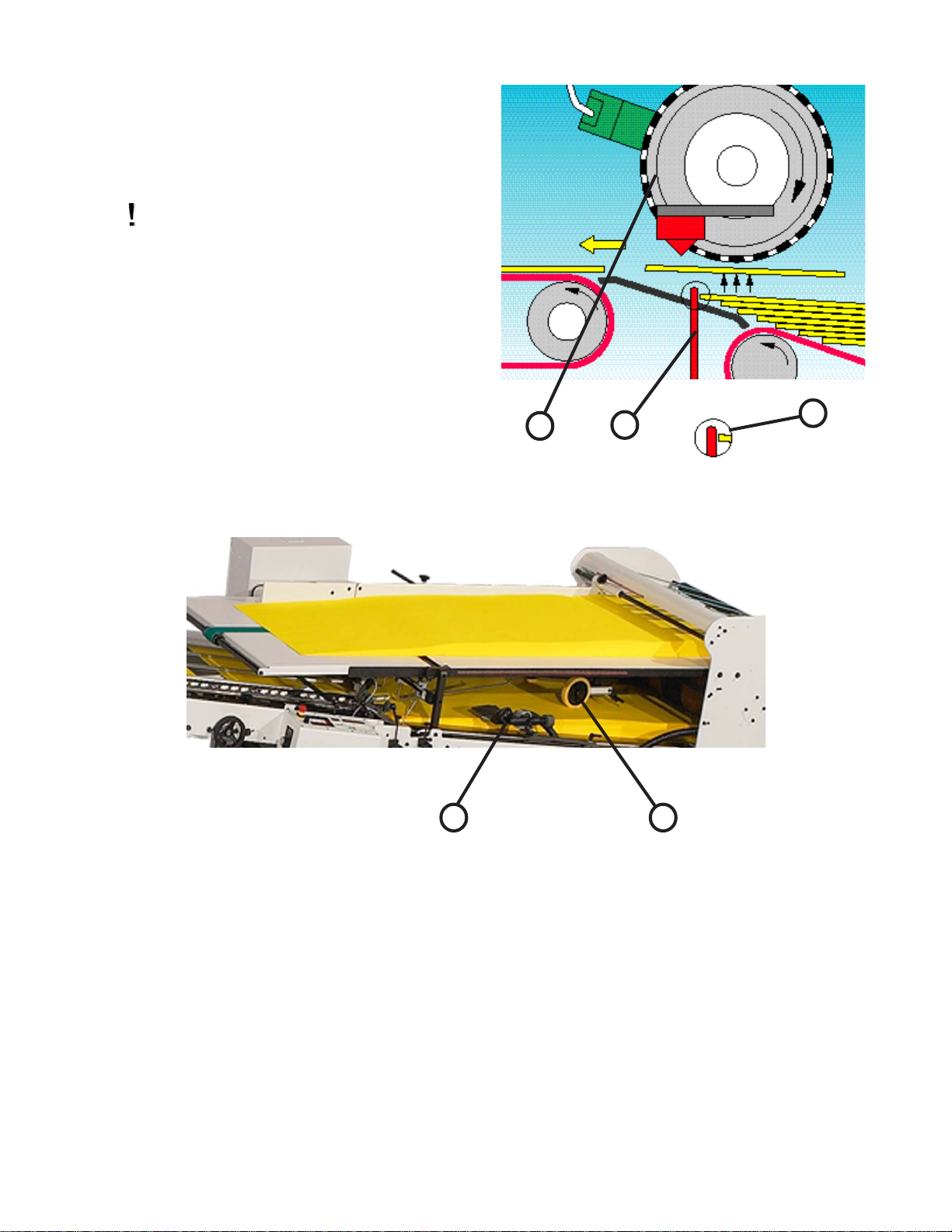

1.2 Sheet Separation and Suction Force

The holddowns (9-1) on the two sides of the sucker wheel

(9-2) should always be positioned slightly lower than the

sucker wheel. This causes the sheet which is sucked against

the wheel to arch up slightly allowing the top sheet to be

peeled away from a second sheet which may be clinging to it.

With stiff and heavy paper, the holddowns must be set so that

the suction wheel can still pick up the sheet.

The suction wheel is controlled by a solenoid valve (9-3).

The normal setting is indicated with a red mark.

The point at which the suction is applied can be adjusted

by swinging the suction point forward or backward with the

knob (9-4).

It may be necessary to move the suction point back if the

leading edge is curled down, or forward if the leading edge is

curled up. This adjustment can be further assisted by raising

or lowering the bridge with the knob.

The solenoid valve can be quickly and easily removed by

releasing the clamps (9-5) to allow dry cleaning of the inner

piston. To clean the piston cavity, unscrew and remove the

back cover (9-6) on the solenoid block and pull a soft cloth

through from the threaded side of the hole. Do not use any

solvent, lubricating agents or air blasts.

Be careful not to damage the piston or it's

bushing.

1

5

Figure 9

6

3

4

1

2

TP10476-1 PAGE 14

Page 15

Adjust the front blowers in such a way that the sheet

stack is fanned across the entire sheet width.

Use less air for thin paper so that the

sheets are not pushed back. The sheets

must not arch because it may cause them

to stick together.

The lateral blowers (suction plate blowers figure 10)

must be positioned so that the blowers rest on the sheet stack

at a slight angle.

The balance is adjusted at the rear counter weight. The

swing span can be adjusted by restricting the lift range. The

suction plate blower is positioned with the front most third of

the blower opposite the guidestop .

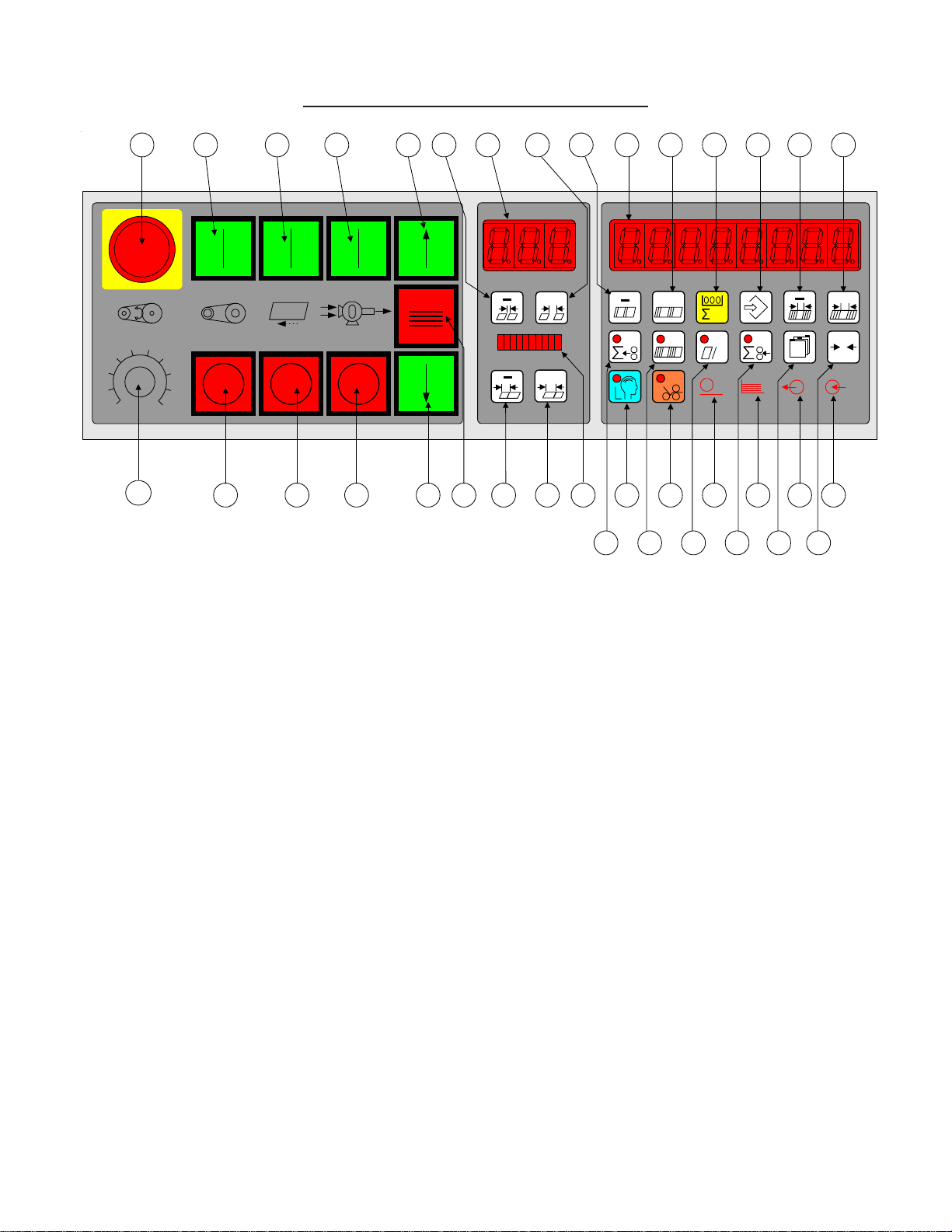

1.3 Register Table and Double Sheet Detector

Access to the feed register is provided by the pivoting of

the upper feed table.

1. Turn the lead screw adjustment handle to set the

register drive straight edge to the desired sheet size.

2. The first hole of the marble holder must always have

a plastic ball installed. The other holes can be fitted

with either steel or plastic balls. It is suggested that

one uses as many light weight balls as possible for

optimum sheet alignment. Use at least 1 to 2 steel

balls in the last two holes nearest the fold rolls to

hold the sheet edge in place during folding.

Figure 10

2

1

3. Holddown bars (11-1) are positioned above the

register table to prevent the sheets from rising up as

they are transported along the register. Slide these

bars along the stop rails (11-2) to adjust the

holddowns according to the sheet size.

4. A scale (12-1) indicates when the register straight

edge is positioned at right angles to the fold rolls.

The knurled wheel (12-2) is used to to fine adjust the

guide edge if perforations or folds are skewed. This

fine adjustment can be made while the folder is

running.

5. The double sheet detector (13-1) is set by raising the

arm (13-2) and inserting two strips of the paper (13-

3) being ran between the block (13-4) and the arm.

When doing this, be certain that the paper strips are

slid under the arm of the retainer spring (13-5) so

that they will not fall out when the arm is raised.

Figure 11

1

2

Figure 12

PAGE 15 TP10476-1

Page 16

When a single sheet passes through, the scanner element (13-

6) stays in the off-position. When a double sheet is fed, the

scanner is activated and drawn into the microswitch (13-7) and the

double is stopped. Only the sheet feed is switched off. To remove

the double sheet, raise the arm. After fault removal, reset the

"sheet-feed" start switch.

For thin paper, loosen the knurled screw and reset the lever

spring tension. Afterwards retighten the knurled screw.

7

6

2

3

Figure 13

4

5

BAUMSET ADJUSTMENT

1.0 Adjustment of Folding Rollers

Folding accuracy is determined largely by precise adjustment of the folding rollers.

Using the Baumset precision adjustment device, the correct setting of the rollers can be made simply by inserting the

appropriate paper thickness between the adjustment plates. (See Figure 14)

With multiple thicknesses, insert single strips of the paper being folded equal to the number of sheets passing through

that roller combination..

Since the adjustment spindle acts directly on the folding rollers, clearance settings are exact.

Another method for setting the folding rollers is to insert paper strips between them by touch and adjusting the

pressure by turning the knurled screw.

The numbers on the Baumset adjustment knobs correspond to the buckle-plate numbers into which the sheet is fed. All

upper buckle plates have odd numbers while the plates below are even.

The Baumset adjustment device is correctly zeroed at the factory. If any adjustment is necessary, strips of single paper

thickness should be placed under every adjustment plate. The folding rollers are then reset by drawing strips of uniform

thickness through the appropriate pair of rollers as far as possible to the other side.

At the same time, the knurled screws are adjusted so that the strips can be withdrawn when medium drag is felt. When

this operation is complete, the dial rings are reset to zero.

1

Figure 14

TP10476-1 PAGE 16

Page 17

INSTALLING FOLD PLATES

OPERATOR CONTROLS

Install the fold plates into the folder. Lock the fold

plates in position with the clamping levers (15-1). See "Fold

Pan" section for fold plate setting procedure.

Plug the stacker power cable into the corresponding

outlet on the main control enclosure on the continuous

feeder.

Pull the handwheel (Figure 1-11) to manually turn the

fold rollers to be sure that they are operating smoothly.

Check for any foreign material, and be sure that the deflectors do not touch the fold rollers.

The main operator control panel (Figure 16) is located on

the right side of the register. See the "Control Panel" section

for a detailed description of all the buttons.

1.0 Setting Folding Speed

The speed of the fold rollers may be set while the folder

is running! This is done by adjusting the speed control

potentiometer located on the top left side of the main control

panel. Clockwise rotation speeds the folder up; counterclockwise rotation slows the folder down.

1.1 Setting Stacker Belt Speed

An infinite speed range between high and low is set by

turning the control knob (Figure 17-1).

1.2 Emergency Stop Button

When an emergency stop button (16-1 & 17-2) is

pressed, the result is:

Sheet feed - stop

Folder drive - stop

The pressure/vacuum pump continues to operate. The

emergency stop button must be pulled to release before the

machine can be restarted. An error message "Stop" will

appear on the readout.

The emergency stop buttons are found at the main

operator control panel (16-1) and the delivery control (17-2).

Figure 15

Figure 16

1

1

2

1

Figure 17

PAGE 17 TP10476-1

Page 18

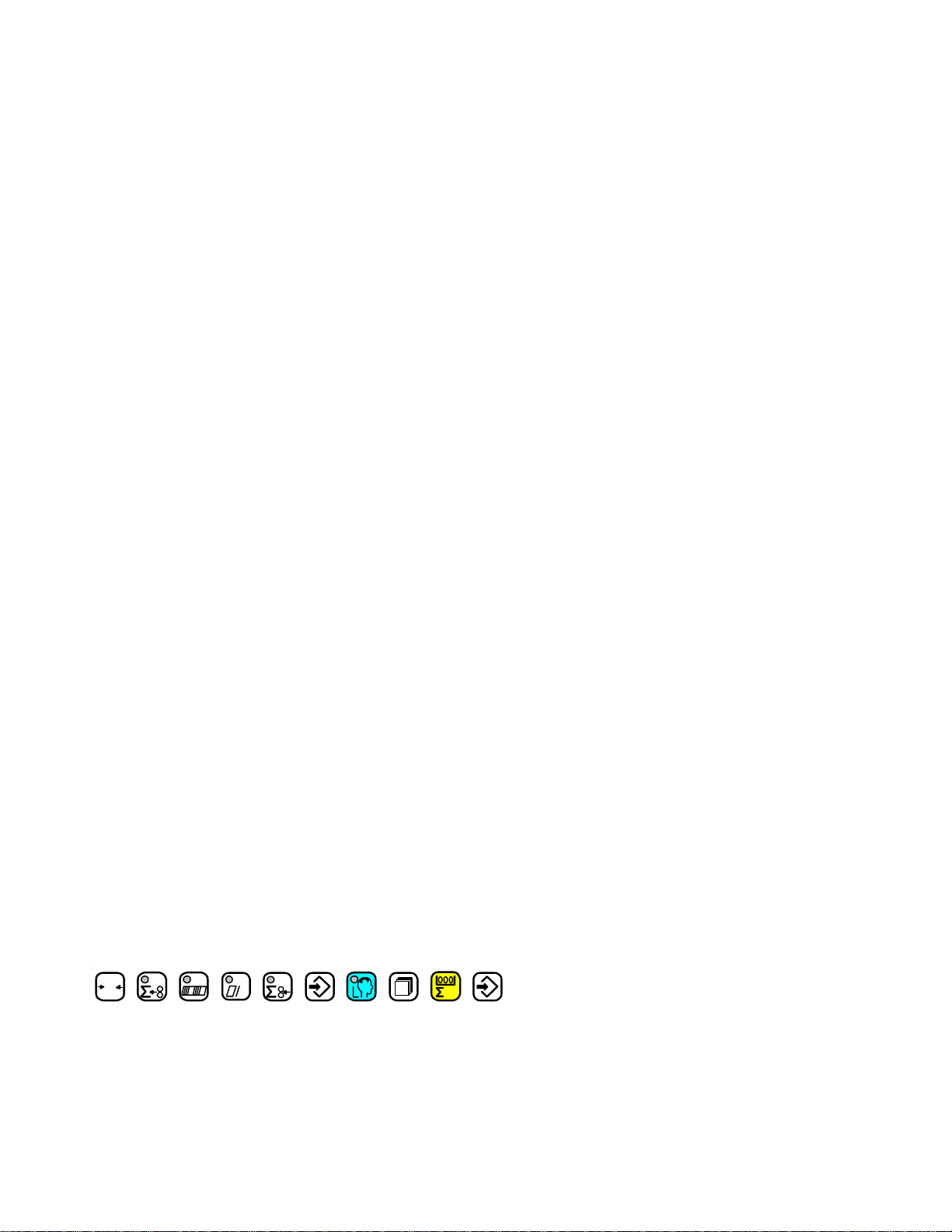

1.DCT500 Control Panel BAN-5

1 29 30 31 32 3325 2824 28 12 10 1417

56

4

3

2

1

DCT 500

7

8

9

10

36

9 13 11 16 26 27 22 23 4 5 7 615 3

Figure 1. DCT500 Control Panel.

01) Large Display

Eight digit multi use display composed of 7-segment LED’s.

02) Small Display

Three digit multi use display composed of 7-segment LED’s.

Displays

+

+

18 19 20 21 34 35

+

h

+

0

03) Ten segment bar graph display

The suction length display is a used to display the Suction Length as a percentage of Sheet

Length. This allows a range from 5% to 50%.

Machine Status Indicators

04) Suction Indicator

The suction indicator will track the suction output. The LED will turn on when the suction

output turns on.

05) Pile indicator

The indicator is lit when the feeder is in automatic feed mode. The indicator will flash if the

feeder is in reverse mode (Continuous Feeder) or moving down (Pile feeder).

06) Input Indicator

The input indicator shows the status of a user selected photo eye.

TP10476-1 PAGE 18

Page 19

07) Output Indicator

The output indicator lights when the Batch Preset PV is reached and the user has selected a

batching option. The output indicator is lit during the time the batching option is active.

Batching options are Feed interruption, Marking table, Speed up table or Kicker.

Machine Control Pushbuttons

08) Main Drive Start

09) Main Drive Stop

10) Pump Start

11) Pump Stop

12) Feeder Start

13) Feeder Stop

14) Pile Feeder Up, Continuous Feeder Start

15) Pile Feeder Stop, Continuous Feeder Stop

16) Pile Feeder Down, Continuous Feeder Reverse

17) Emergency Stop

Keypad Buttons for Selection Adjustments

18) Show Output Count

19) Show Batch Count and Number of Batches

20) Show Current Rate

21) Show Input Count

22) Learn Mode

23) Make Ready Mode

Keypad Buttons with Selection Indicators

24) Gap Minus

25) Gap Plus

26) Suction Length Minus

27) Suction Length Plus

28) Batch Preset Minus

29) Batch Preset Plus

30) Counter Setup Mode

31) Machine Setup Mode

32) Batching Time Minus

33) Batching Time Plus

34) Network Job Mode

35) Reset

36) Potentiometer Speed Adjust

PAGE 19 TP10476-1

Page 20

2. Run Mode Functions

When the folder is started with the RUN/MAINT jumper in the RUN position, the system is enabled for

the user to make machine setups and to fold paper. The counter will start up in production mode, the

normal operating mode of the counter. In this mode, various job parameters can be displayed on the large

display (1), and the small display (2) shows the gap length. The suction length display (3) is active in this mode

and shows the suction length as a percentage of sheet length.

The DCT500 mode select keys perform the same function in all modes, except Counter Setup. This

allows a user to quickly switch between the operating modes on the counter. Select Make Ready is not a

mode unto itself, but rather is a modifier to all modes.

2.1 Machine Setup and Diagnostic Mode

Pushing this key puts the controller in machine setup mode.

Machine setup mode provides a method to view and optionally change operating parameters for the

controller. The decimal points in the large display (1) will move from side to side to indicate that a parameter may be changed. In this mode, the small display gives the selected parameter number, while the

large display (1) shows a parameter value. The suction length display (3) is disabled.

Parameter Selection

+

The plus (25) and minus (24) keys are used to move through the list of available parameters.

Selected Parameter Adjustment

+

+

If the large display (1) decimal points are moving, the set of minus and plus buttons will move through

the set of values for the selected parameter, see table 3 and 4.

2.1.1 Machine Setup Parameters

Table 1. DCT 500 Machine Setup Parameter List

# Function Type Variable Displayed

P00 Input Counter Setup Variables adjustable 1-24 - Std setting 1

P01 Output Counter Setup Variables adjustable 1 to Input Factor SV

Standard setting 1

P02 Tremat Setup Variables adjustable Standard: none 0

Tremat available 1

P03 Knife Setup Variables adjustable Standard : none 0

Knife available 1

P0 4 Ergonomic pile Setup Variables adjustable Standard: none 0

Ergo. available 1

P05 Kicker Setup Variables adjustable Standard : none 0

Kicker available 1

TP10476-1 PAGE 20

Page 21

P00: Input Counter

The number of sheets sensed by the sheet count sensor is multiplied by the factor number displayed, but does not

effect the Batch Down Count, Number of Batches and the Rate.

The Factor can range from 1 to 24. If the Input Factor is changed, it also changes the value of the Output

Counter to the same setting.

P01: Output Counter

This number is added to the Total Output Count but does not effect the Batch Down Count, Number of Batches

and the Rate.

The Factor can range from 1 to Input Counter setting.

P02: Tremat

This selection allows pile feeder machines to switch the tremat function on (1) and off (0)

P03: Knife

The operator must indicate to the machine whether a single cross-fold or several cross-folds are in use in the

machine network. This is done by entering either "1" (Cross fold) or "0" (No cross fold).

Entering "1" (Cross fold) automatically sets the sheet spacing to 10 cm after a single learned sheet. If "0" (No

cross fold) is entered, the sheet spacing is automatically set to 4 cm after a single learned sheet.

P04:Ergonomic stacking

Select "1" to activate the Ergonomic stacking function. "0" indicates that the Ergonomic stacking function is

disabled or not available.

Note: This parameter is only displayed on machines configured with a horizontal pile feeder.

P05: Kicker

Select this parameter to activate/deactivate the kicker function.

0 = Kicker disabled (not available), 1 = Kicker enabled.

2.1.2 DCT 500 Diagnostic Parameters

# Function Type Variable Displayed

P10 Machine Speed Statistics Values Display only Meters per minute

P11 Production time Statistics Values Reset to zero Time in Hours (decimals)

P12 Production stoppage time Statistics Values Reset to zero Time in Hours (decimals)

P13 Setup time Statistics Values Reset to zero Time in Hours (decimals)

P14 Pause Statistics Values Reset to zero Time in Hours (decimals)

P15 Curent Job No. Disabled

P16 Personnel No. Disabled

Table 2 Statistics

P10:Machine Speed

Select this parameter to view the current machine speed expressed in meters per minute (m/min)

P11: Production Time

Select this parameter to view the length of time for which the machine drive is activated - shown in hours (decimals).

PAGE 21 TP10476-1

Page 22

P12: Production stoppage time

Select this parameter to view the time during which the machine is not operating. The Pause function and Sheet

feed are disabled. The time is shown in hours (decimals) and reset to zero for a new job.

P13: Setup Time

Select this parameter to view the Setup time in hours (decimals). The time indicator is reset to zero for a new

job.

P14: Pause Time

Select this parameter to view the time during which the machine is held by the Pause function (P23 enabled).

.

The time is shown in hours (decimals) and reset to zero when new operating data is entered.

P15: Current Job No.

Note: This parameter is only displayed when the network is activated in Service mode. Not available in Software Version 100.300.

P16: Personnel No.

This parameter is only displayed when the network is activated in Service mode. Not available in Software

Version 100.

# Function Operation Key Combin. Variable Displayed

P20 Units Adjustable with Standard Inches

P21 Language Adjustable with Standard English

P22 Network address Function not enabled

P23 Pause Time On/Off Adjustable with Standard - Disabled 0

Adjustable with Activated

Adjustable with Deactivated

P24 Network Function not enabled

P25 Easy Mode Adjustable with Default setting 0

P26 Software Version Automatic from RAM Fixed e.g. dCt 3.0.1

P27 Machine Type In Service mode Fixed e.g. P-36

P28 Serial Port type In Service mode Fixed e.g. off

Table 3Machine settings Network net

+

+

+

Release 1

+

only on C-2020, P-2020

Large contr. display dsP

Meters

German

Codes

P20:Units

Use this parameter to select the unit of measurement (meters or inches) for the values which appear in Displays

01 and 02.

P21: Language

Use this parameter to select the language (English, German or code) for the Display (01) messages.

P22:Network Address

Only indicated when the "Network" option is selected and enabled in the Service menu. Not available in Software Version 100.300.

TP10476-1 PAGE 22

Page 23

P23: Pause

This function is used to activate/deactivate a Pause counter. Select this parameter to display the period of time

for which the pause function was last engaged. It is not possible to feed in sheets when the Pause function is

activated.

P24: Network

Network is only displayed when "Network" is selected and enabled in the Service menu. Not available in

Software Version 100.300.

P25:Easy Mode

This function can only be used on machine types P-b20, C-b20, C-2020 and P-2020.

P26:Hardware and Firmware Version

Select this parameter to display the software installed in Service mode. The logic board type appears in the left

of the display. DCT displays a DCT 500 logic board.

P27:Machine Type

Select this parameter to view the Machine type specified in Service mode.

P28:Serial Port

Parameter setting in Service mode is displayed: dSp, nEt, Off

P30 Status Input Port 1

P30.1 P30.2 P30.3 P30.4 P30.5 P30.6 P30.7 P30.8

Pile Motor Function Pile Down Pile Stop Pile Up Compress. Compress. Drive Start

Energized Control K1 Button Button Button Stop Button Start Button Relay K3

P31 Status Input Port 2

P31.1 P31.2 P31.3 P31.4 P31.5 P31.6 P31.7 P31.8

Pile Sensor Double Pile Down Sheet Start Sheet Stop Thermal Wrong Sheet Emerg.Stop

Sheet Fault Limit Button Button Fault Fault Drive Stop

P32 Status Input Port 3

P32.1 P32.2 P32.3 P32.4 P32.5 P32.6 P32.7 P32.8

Ergonomic Jam on Knife in Jam on Jam on Suction Delivery Count sensor

Pile Load Knife 3 Manual Mode Knife 2 Knife 1 Controller Count Input Suction

Eye fail Wheel

P33 Status Input Port 4

P33.1 N P33.2 P33.3 P33.4 P33.5 P33.6 P33.7 P33.8

Board select Board select Not used Not used Not used Not used Not used Not used

P34 Status Input Port 5

A34.1 A34.2 A34.3 A34.4 A34.5 A34.6 A34.7 A34.8

External Setup LT folding External K2 Checkback Emerg. stop Emerg. stop Machine

Mis-feed sht. Station 2 station device signal station guard open Emerg. stop

P35 Status Output Port 1

P35.1 P35.2 P35.3 P35.4 P35.5 P35.6 P35.7 P35.8

Not used Controller Relief Not used Pile down Pile up Drive Stop Pump

drive valve/Tremat active is active function start (K4)

release ON (K6) Relay (K5)

Button

delivery protection activated

Table 4 Machine diagnostic mode parameters

PAGE 23 TP10476-1

Page 24

P30: Port 1 Inputs

P30 indicates Port 1 input status.

P31: Port 2 Inputs

P31 indicates Port 2 input staus

P32: Port 3 Inputs

P32 indicates Port 3 input status

P33: Port 4 Inputs

P33 indicates Port 4 input status

P34:Port 5 Inputs

P34 indicates Port 5 input status

P35: Port 1 Outputs

P35 indicates Port 1 output status

# Function Operation Key Combin. Variable Displayed

P60 Drive start key delay Adjustable with 0 - 13 secs.

P61 K2 release time Adjustable mit RP2 Adjuster- K2 Delayed release (sec)

(large display)

+

Table 5 Safety settings

P60: Drive Start Delay period (only when A02=0)

Entering the Drive Start Delay period for Station 1 (Settings: 0 to 13.0 sec.) ensures that the paper runs

smoothly after starting if there is any paper still inside the machine. (Station 1: approx. 0.6 sec.)

P61: Display of delayed release for the K2 guard (only when A02=0)

Adjuster for setting the K2 delayed release (Measuring time = 0 to 10 sec.). Adjust with the RP2 poti on the

SGM-3 board. Default setting = approx. 2.5 sec.

# Function Type Variable Displayed

P40 Mon. time for Knife 1 Variable function Input X26/1, P32.5 Time in milliseconds

P41 Mon. time for Knife 2 Variable function Input X26/2, P32.4 Time in milliseconds

P42 Folding station delivery Variable function Input X30/5, P34.3 Time in milliseconds

P43 Counting input Variable function Input X25/5, P32.7 Time in milliseconds

P44 Knife 1 strokes Variable function Input X26/2, P32.4 Time in milliseconds

P45 Knife 2 strokes Variable function Input X26/5, P32.2 Time in milliseconds

Table 6 Machine statistics

P40: Time: Knife 1

Knife 1: Light sensor cover time in milliseconds.

P41: Time: Knife 2

Knife 2: Light sensor cover time in milliseconds.

TP10476-1 PAGE 24

Page 25

P42: Folding station delivery

Display of the time registered by the photoelectric barrier on the folding station delivery.

P43:Counting input

Display of the time registered by the photoelectric barrier on the counting input.

Important:

The counting input is not monitored when Kicker batching is selected.

If the counting input is removed when the machine is activated, error message S-C 5 /B-C 5/STOP 13 is

displayed once and the drive is shut down. The error message is cancelled when the machine and the sheet feed

are restarted. The machine is reactivated by the rear edge at the counting input.

P44: Knife 1 strokes

Select this parameter to view the total number of strokes (in 1000s) for Knife 1.

P45: Knife 2 strokes

Select this parameter to view the total number of strokes (in 1000s) for Knife 2.

# Function Type Variable Displayed

P50 Main time switch ON Machine status Main switch ON Time in hours (decimals)

P51 Machine operating time Machine status Drive Start Time in hours (decimals)

P52 Total sheet feed Machine status Input X14/4, P31.1 Display x 1000 sheets

Table 7 Machine operating statistics

P50: Main time switch ON

Can only be reset in Service mode.

P51:Machine operating time

Can only be reset in Service mode.

P52:Total sheet feed

Select to view the total number of sheets fed in (in 1000s).

The total is reset to zero when new operating data is entered.

Exit Machine Setup Mode

0

Pressing any of these keys will cause the controller to change to a new mode.

h

PAGE 25 TP10476-1

Page 26

2.2 Counter Setup Mode

Batching Time Adjustment

+

Pushing this key puts the counter in counter setup mode.

Counter setup mode is used to prepare the controller to run

a job. The large display (1) shows the batch preset on the

left-hand side and the batching output time on the righthand side. The decimal points in the large display (1) will

move from side to side to indicate that a parameter may be

changed. The small display (2) shows the batching type.

The suction length display (3) is active.

Change Batching Type

+

The minus and plus buttons move through a list of four

output devices. The chosen Type is then activated when the

batch countdown goes to zero. Feed interruption stops the

feeding of sheets for the batching time setting. The speed

up table output activates the marking table output for the

batching time duration. The MKE mode delivers a 100 ms

pulse on the MKE output after awaiting the batching time.

The last, kicker, causes a 20 ms pulse on the kicker output

after the batching time expires. The kicker output may only

be selected if the Count Source is set to delivery. The

output types are represented by animated symbols. The

sequence of frames for the animations is shown in table 5.

Feed Interruption Speed Up Table MKE Table Kicker

Frame

1

Frame

2

Frame

3

Frame

4

Frame

5

Frame

6

Frame

7

Frame

8

The batching time adjustments allow the user to select the

time duration associated with the currently selected output

type. The DCT500 mode supports four output types and

times.

1. Feed interrupt has a range of 0.0 to 9.9

seconds.

2. Speed up Table has a range of 0.00 to 5.00

seconds.

3. MKE Table has a range of 0.000 to 1.000

seconds.

4. Kicker has a range of 0.000 to 1.000 seconds.

Select Count Source

The Input Count and Output Count keys select between

count at the feeder and delivery, respectively. One key

LED will always be lit in Counter Setup to show the

current count source, see table 6. If the output key is

pushed when it’s LED is on, the Batching Type is kicker,

then the DCT500 will activate chasing LEDs in the small

display signifying the start of kicker setup mode. The next

sheet fed through the kicker will be timed from leading

edge to the trailing edge and the kicker delay time will be

set to one half the sheet time. Please note, this must be

redone if the delivery speed is changed.

The batching count source will be the feeder

photoeye.

The batching count source will be whatever is

connected as the delivery photoeye.

Table 9. Count Source Selection

Exit Counter Setup Mode

0

Table 8. Output Type Animations

Suction Length Adjustment

+

This is the same as in run mode.

Batch Preset Adjustment

+

These buttons cause the batch preset to be incremented or

decremented. The preset will be reloaded after the user

leaves the setup mode only if the value has been changed.

TP10476-1 PAGE 26

Pressing any of these keys will cause the counter to

change to a new mode.

Page 27

2.3 Learn Mode

Select Suction Mode

+

This key places the counter in learn mode. Learn mode can

only be activated if the folder is idle.

The learn mode allows the user to setup the suction valve

controller. Both manual and automatic setup is accomplished in this mode. The large display (1) shows two

separate data items. On the left is the suction mode and the

right shows sheet length. The small display (2) shows the

current gap length. The suction length display is active.

During Learn Mode, the Learn Mode key LED indicates

whether a valid sheet has been learned. See table 15.

No valid sheet has been read yet, the system is in

Single Sheet mode.

A valid sheet has been read and the DCT500 has

been setup to run. Single Sheet mode is off.

Table 10. Learn Mode Status

When the LED is on, pushing the sheet start button will

feed a single sheet of paper. If the sheet is fed properly, the

indicator LED will go off. The suction mode will be set to

automatic. The length of the sheet will be set as the current

sheet length. The suction length will be set based on table 9

and the gap length will be set to 1.5 inches/4 cm if P06 is

set to 0 (no knife is active); the gap length will be 4.0

inches/10 cm if P06 is set to 1 (knifes are active).

Gap Length Adjustment

+

These keys toggle between automatic control and cycle

mode. In the cycle mode, the suction valve will be on for

the suction length and off for the remainder of the sheet

length plus the gap length. No adjustments are made for

slipped sheets or process changes. The automatic mode

corrects for process changes and controls the timing of the

suction valve to maintain the user selected gap. If the gap is

less than 2” (50 mm), the right hand decimal point of the

small display (2) will flash and the Leading edge control

will be active. If the gap is greater than or equal to 2.0” (50

mm), full Leading and Trailing edge control is maintained.

Refer to table 8 for suction mode symbol definitions.

TWT-180 Mode

Leading Edge Control

Leading and Trailing Edge Control

Table 11. Suction Mode Symbols

Sheet Length Adjustment

+

The minus and plus keys adjust the gap length. The gap

length range is 0.2” to 98.0” (0.5cm to 250cm).

Suction Length Adjustment

+

The suction length adjustment keys allow the user to

change the amount of suction applied to the current sheet

length. The display shows the percentage in 5% steps. All

of the bars must be totaled to get the value. The range of

adjustment is 5% to 50% of the current sheet length. If the

suction length is manually adjusted while the Learn Mode

LED is on, the suction length will no longer be the Single

Sheet suction length of 6.0 inches. The new suction length

will be based on the current sheet length and suction

setting.

PAGE 27 TP10476-1

The sheet length adjustment keys allow the user to

override the automatic Learn Mode. When the user

changes the sheet length, the suction length will be

adjusted according to table 9. If a different suction length

is desired, the value may be overridden with the suction

length adjustment keys. The sheet length range is 4

inches/10 cm to 98.5 inches/250 cm.

Page 28

Sheet Length Setting Resultant Suction Length Percentage.

Greater than or equal to 30 cm. 30% of Sheet Length

Less than 30 cm., and greater than or equal to 27 cm. 25% of Sheet Length

Less than 27 cm., and greater than or equal to 24 cm. 20% of Sheet Length

Less than 24 cm., and greater than or equal to 21 cm. 15% of Sheet Length

Less than 21 cm. 10% of Sheet Length.

Table 12. Suction Length Function

Exit Learn Mode

0

h

Pressing any of these keys will cause the controller to change

to a new mode.

2.4 Make Ready Mode

When this button is pushed, its LED toggles. When the LED

is on, the folder will only feed single sheets and a batching

output is issued for every two sheets fed. This allows the

operator to easily set up the batching time. Make ready is

deactivated when learn mode is started.

Pressing any of these keys will exit Make Ready Mode.

h

0

Select Job Number

+

+

This set of plus and minus keys step the large display (1)

through pause mode and a list of available job numbers.

While in network job mode, the folder is considered to be

paused.

Load Job and Return to Run Mode

2.5 Network Job Mode

Pushing this key puts the counter in network job mode

This mode is only available if a STA-NET adapter is

installed and activated through maintenance mode. In this

mode the small display (2) always shows the word ‘Job’. The

large display (1) shows either ‘Pause’ or a job number which

can be read from the network. The suction length display is

disabled.

TP10476-1 PAGE 28

When this button is pushed, the selected job will be loaded

into the counter and the counter will return to run mode. If

the large display (1) was showing the message ‘PauSE’, the

network job mode will end, but no job will be loaded.

Exit Network Job Mode

h

0

Pressing any of these keys will cause the counter to change

to a new mode.

Page 29

2.6 Production Mode

Suction Length Adjustment

Enter Run Mode and Select Large Display Content

h

These keys do not operate as mode select keys in counter

setup. In all other modes, the keys both select the large

display (1) contents and place the counter into run mode.

Pushing one of the buttons will light the button’s associated LED and cause the parameter to be displayed. If both

the input and output count keys are pressed simultaneously, then both LEDs go on and the waste count is

displayed.

Large Display Contents

h

h

h

h

Output Count

Batch Count Down

Number of Batches

Current Rate

Input Count

+

The suction length adjustment keys allow the user to change

the amount of suction applied to the current sheet length. The

display shows the percentage in 5% steps. All of the bars must

be totaled to get the value. The range of adjustment is 5% to

50% of the current sheet length.

Reset Function

0

Pressing and holding this key will result in a reset function

being activated after a 5 second countdown. The function is

based on the current large display selection, see table 11. The

large display (1) will show countdown to reset in this manner.

When the button is pressed the message ‘CLr In 5’ will show

on the large display (1). At one second intervals the display

will progress through ‘CLr In 4’, ‘CLr In 3’, ‘CLr In 2’, ‘CLr

In 1’, and finally will show ‘CLEArEd’ when the reset action

is complete.

h

Waste Count

Table 13. Determining the Large Display Contents

h

When the folder is started with the RUN/MAINT jumper

in the RUN position, the system is enabled to fold paper.

The counter will start up in run mode, the normal operating mode of the counter. In this mode, various job parameters can be displayed on the large display (1), and the small

display (2) shows the gap length. The suction length

display (3) is active in this mode and shows the suction

length as a percentage of sheet length.

Gap Length Adjustment

+

The gap length adjustment keys allow the user to change

the current gap length. The range of adjustment is 0.2

inches to 98.0 inches (0.5cm to 250mm).

Reset while showing Output Count will reset all job

variables.

Reset while showing batch data will reset Number

of Batches and reload the Batch Down Count.

Table 14. Reset mode Selection

Exit Run Mode

Pressing any of these keys will cause the counter to change to a

new mode.

PAGE 29 TP10476-1

Page 30

3. Controller Input Description

3.1 Table Inputs

Input Type Connector Point Indicator Name

DCI-1 NPN 24VDC X14/2 P31.1 Pile Sensor

DCI-2 NPN 24VDC X14/5 P14.8 Photoeye Suction Wheel

DCI-3 PNP 24 VDC X25/5 P32.7 Delivery Count Input

DCI-4 NPN 24VDC X15/2 LED 1 Encoder

DCI-5 NPN 24VDC X26/1 P32.5 Sheet Control Knife 1

DCI-6 NPN 24VDC X26/2 P32.4 Sheet Control Knife 2

DCI-7 NPN 24VDC X26/4 P32.3 Knife Manual

DCI-9 PNP 24 VDC X26/8 P32.1 Ergonomic Pile Make Ready

DCI-10 24VDC X30/5 P34.3 Light sensor - Folding station del.

DCI-11 24VDC X30/11 P34.2 Folding station - Make Ready

ACI-1 24VAC X21/1, X21/2, X23/3 P30.8 Drive is on

ACI-2 24VAC X11/3, X22/2, X23/4 P31.8 Emergency Stop/Drive Stop

ACI-3 24VAC X22/3 P31.7 Jammed Sheet

ACI-4 24VAC X22/4 P31.6 Drive Thermal Fault

ACI-5 24VAC X21/5, X23/9 P31.5 Sheet Stop Button

ACI-6 24VAC X21/6, X23/11 P31.4 Sheet Start Button

ACI-7 24VAC X11/2 P31.3 Pile is down

ACI-8 24VAC X11/6 P31.2 Double Sheet Fault

ACI-9 24VAC X23/5 P30.7 Compressor Start Button

ACI-10 24VAC X23/6 P30.6 Compressor Stop Button

ACI-11 24VAC X23/10 P30.4 Pile Stop Button

ACI-12 24VAC X23/12 P30.3 Pile Down (backward) Button

ACI-13 24VAC X23/14 P30.5 Pile Up (forward) Button

ACI-14 220VAC Internal P30.2 Function Control K1

ACI-15 220VAC Internal P30.1 Function Control Pile

ACI-16 24VAC X29/5 P34.5 K2 protective relay monitor

ACI-17 24VAC X29/7 P34.4 External device monitor

ACI-18 24VAC X29/1 P34.8 Emergency stop - control panel

ACI-19 24VAC X29/2 P34.7 Emergency stop - guard

ACI-20 24VAC X29/3 P34.6 Emergency stop - next stations

ACI-24 24VAC X19/2 P34.1 External mis-fed sheet

Table 15. Inputs

3.2 24VAC Inputs

Several mechanical switches are used to indicate machine

faults. These faults are described here. If these faults occur

when the machine is not running, they will display the

associated fault message until the fault is cleared. The only

exception is the Safety fault. The Safety fault always

requires removal of power before the machine can be used

again. If a fault occurs while the machine is running, the

method used to clear the fault varies from fault to fault.

TP10476-1 PAGE 30

Double Sheet

The Double Sheet switch is used to sense multiple sheets

being fed into the machine at the same time. If this fault occurs,

the message “2 Sheet” will be displayed and sheet feeding will

stop. The Drive and Compressor outputs will continue

unaffected. Once the fault has been cleared the machine can

start feeding sheets again by pressing the Sheet Start switch.

Page 31

Thermal

The Thermal input indicates that a motor is overheating. If

this fault occurs, the message “overload” will be displayed,

sheet feeding will stop, the Drive and Pile outputs will be

turned off. Once the fault has been cleared, the machine can

start feeding sheets again by pressing the Drive Start switch

followed by the Sheet Start switch.

Wrong Sheet

The Wrong Sheet switch is used to sense a jam in the

output register. If this fault occurs, the message “Wrng

Sht” will be displayed, sheet feeding will stop, the Drive,

Pile outputs, and RLY1 will be turned off. Once the fault has

been cleared, the machine can start feeding sheets again by

pressing the Drive Start switch followed by the Sheet Start

switch.

3.3 24VDC Inputs

Count

The DCT500 can have two Count inputs. The Count Inputs are

referred to as Feeder (FED) and Delivery (DEL). The Feeder

input is used to increment the Total Input Count. The Delivery

input is used to increment the Total Output Count. Some

machines will only use the Feeder input. Machines that use

both count inputs use a sensor at the input of the machine

(Feeder) to sense sheets feeding into the machine and a sensor

at the output of the machine (Delivery) to sense actual completed sheet output. The difference between the two counts is

called the Waste Count.

Tachometer

The Tachometer input is a high speed input that is used to

sense rotation of the Fold Roll. This input allows the unit to

calculate the speed of the machine, and allow the unit to

determine the length of a sheet being fed through the machine

by counting the number of Tachometer pulses received. Each

tachometer pulse represents a certain distance, see Table 1

Machine Types. The actual distance is dependent on the

machine type selected. The Tachometer Input starts when the

Drive Start switch is pressed. If the tachometer reading is

outside the range of 10 to 230 meters per minute, the unit will

display the message “NO TACH”, and prevent further operation of the machine. To restore operation, the Drive Start switch

must be pressed.

Four additional 24VDC inputs are provided on the DCT500. One

input is for the Tremat unit and two inputs are for the knifefolding unit. The remaining input is for the ergonomic pile load

sensor.

Ergonomic Pile Load Sensor

The Ergonomic Pile Load Sensor is an optional sensor that is

installed for special paper loading applications. If the input is

active and the Down Pile switch is pressed, the Pile Down

output will turn on. Once the Ergonomic Pile Load input

changes to the inactive state, the Down output will turn off. At

this time the operator will load paper onto the pile. Five seconds

after the Ergonomic Pile Load input senses the Pile, the Pile

Down output will turn on. This process will continue until the

operator presses the Pile Stop switch.

Knife unit in manual mode

If this input is active, the unit will operate in manual mode,

where only a single sheet will be fed into the machine each time

the Sheet Start switch is pressed. If this input is active, the LED

in the make ready key is blinking.

Paper under knife eye (1 to 3)

This input is the photo-eye for the knife unit. If the photo-eye is

covered for more than 1.5 times the last saved knife photo-eye

time, the message ‘KnIFE #’ appears on the large display (1)

and the machine stops.

PAGE 31 TP10476-1

Page 32

Reference Name Description

Designator

LED1 Encoder Indicator Encoder input

LED2 Batching Output Batching device pulse output activated. LED illuminated

LED3 Suction cycle valve Suction cycle valve activated, LED illuminated

LED4 K1 Illuminated when K1 relay is activated

LED5 Pile Down Output Down activated. LED illuminated

LED6 Pile Up Output Up activated. LED illuminated

LED7 Pile Controller Pile outputs Up/Down or Forward/Reverse activated, LED illuminated.

LED8 +5VDC Power Supply Power ON, LED illuminated

LED9 +5VDC Supply, grounded Power ON, LED illuminated

LED10 +24VDC Supply, groundedPower ON, LED illuminated

LED11 Kicker Kicker output activated, LED illuminated.

LED12 Regulator release Activated when regulator release is active.

Table 16. LED Status Indicators

4. Process Variables

4.4 Number of Batches

4.1 Total Input Count

Total Input Count PV increments by the factor setting each

time an input is received at the Input Count input. Total

Input Count can range from 0 to 99,999,999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

The Number of Batches is the number of times the Batch

Down Count has reached zero.

Number of Batches can range from 0 to 9999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

Reset batch will clear this process variable to zero.

4.2 Total Output Count

Total Output Count increments by the factor setting each

time an input is received at the Output Count input.

Total Output Count can range from 0 to 99,999,999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

4.3 Batch Down Count

The Batch Down Count is the number of remaining inputs

necessary to trigger a batch output. As input counts are

received, this value counts down to zero. Each input

decrements the Batch Count Down by one. The factor is not

used. When zero is reached, the Batch Down Count resets

to the Batch Preset. The Count input that is used by the