Page 1

Baum 2015/2018/2020 Floor Model Folders

Job Setup

This sheet is only a guide to setup

and operation of the Baum

2015/2018/2020 Pile feed folders.

Jobs will vary and procedures will

need to be modified.

1. Hand fold a sample as close as possible of the

job to be run. Mark the sample so that it is not

lost during setup. Measure the overall length and

width of the sheet if you do not already know

them, using the scale located on the holddown in

the center of the register table.

2. Start with the feeder and move in progression

to the exit end of the last fold section to complete

the setup of the folder. There is no need to turn

the power on until the setup is complete.

3. Set the sideguide on the pile feeder to half of the

width of the sheet width using the scale on the

frame. Remove the LH sideguide for easy access

to load paper. See Fig. 1.

4. Set the double front blow bar to the proper air

settings referring to the chart on the side of the

control cabinet. See Figures 2 and 3.

5. Set the double sheet detector using (2)

thicknesses of the stock being fed and insert into

the lever and clip.

6. Load paper onto the pile feed platform. Be sure

to fan the paper before loading to add air in

between the sheets for easier feeding. Also note

that the loading of the paper must be positioned

to correspond to the folding imposition that you

want to achieve in the folding unit(s). You must

determine if you want the paper face up, or face

down, or head first, or tail first. Refer to your

hand folded sample to determine which

foldplates you will be using and the loading of

the paper.

7. Install LH see-thru sideguide and position

register guide approximately 1/16 to 1/8” away

from LH side of paper on pile feeder to insure

that paper can slide freely during feeding. See

figure 4.

8. Install the small metal clip that fastens to the

end of the register guide to keep an up-curl from

riding over the end of the register guide.

9. Check register marble configuration to make

sure that it matches the job that you are running.

At least (1) to (2) steel marbles are

recommended at the end of the register closest to

the pile feeder and (2) more at the end closest to

the fold rollers. The marble configuration in

between depends upon the weight of stock and

whether the feeding is landscape or portrait. To

Fig 1

Fig 2

Fig 3

Fig 4

Page 2

Baum 2015/2018/2020 Floor Model Folders

Job Setup

many steel marbles can drive the sheet too hard

and causing feeding problems.

10. Place register holddowns in proper locations

for the sheet width being fed. Note that for

11x17 sheets being fed in the 11 inch width,

place a register holddown between the LH seethru guide and the vacuum wheel to keep air

from cupping the sheet and causing stumbling.

Note that the register holddown with the scale is

always located in the center of the register in

front of the vacuum. Be careful when placing the

holddown on the right hand edge of the sheet to

angle the holddown slightly to prevent the right

hand edge from curling up inside and stumbling.

11. Set the Baumsets by inserting strips of paper of

the job that is being run. Only insert the

thickness that corresponds to the tailing or

minimum thickness that the roller must drive

without loosing control of the paper. You need to

refer to your hand-folded sample to follow the

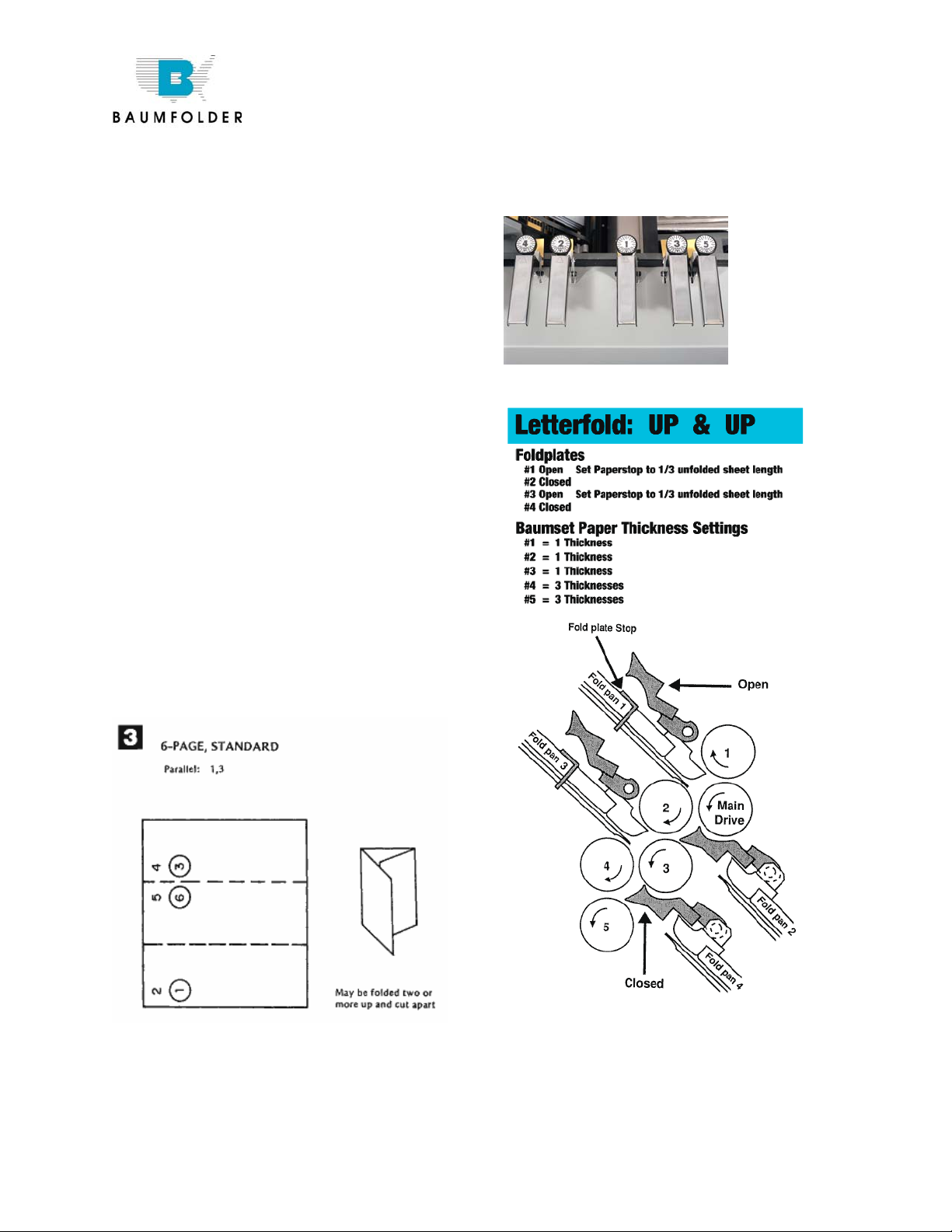

paper path See fig 5. Refer also to the example

fold given in Fig. 6 that shows a cut-away

section of the folder and notes the proper

foldplate and Baumset settings for the imposition

shown.

Fig. 5

Page 3

Baum 2015/2018/2020 Floor Model Folders

12. Set the foldplates to the proper open and closed

positions by rotating the stop blocks and placing

the correct symbol for either open of closed to

the position closest to the fold rollers. Then set

the desired fold depths using the scale on the belt

and reading at the yellow mark on the indicator.

13. Setup the slittershafts using the proper

perforating scoring or slitting accessories. If just

a parallel folder is being used an perforating,

scoring or slitting is not required, pullout tires

must still remain on the slittershafts to properly

eject the sheets. Note that a good setup procedure

is to have all the setscrews facing outward at the

same clock position. This eliminates a lot of

handwheel turning to get to the setscrews during

job changes. See Fig. 7

14. Setup Delivery Stacker Wheels to the expected

position of the paper as it ejects the folder. The

independent speed control will need to be set

during the initial fold operation to insure proper

shingling. Note that the exit holddown straps

must also be installed to kick the sheet down

onto the delivery stacker.

Right angle Folding

When adding an 8-page or 16-page folder to a

parallel unit it is highly recommended that the stock

must be either perforated or scored as it exits the

previous fold unit. The perforating or scoring is to be

performed at the line of the fold that is to be folded in

the next fold section. This weakens the grain of the

stock so that a consistent, quality fold can be

achieved. Perforating is also needed to relieve air that

can become trapped in the folding process and create

wrinkles in the paper. The size of the perforator tooth

can make a difference in the amount of air that can

escape and remove the wrinkle problem. Failure to

score or perforate a sheet going into a right angle

folder will result in inconsistent fold quality.

Refer to your operator’s manual for scoring,

perforating and slitting information.

Marbleholder Setup

Note that marble placement can be critical on some

jobs and not on others. You may want to remove

some marbles that are in the end that accepts the

sheets at a right angle so that the sheets do not

bounce back when trying to get under the marbles. At

least (2) steel marbles are recommended at the end

closest to the fold rollers to maintain sheet control

against the guide.

Job Setup

Fig. 7 Perforating on 1-1/8” slittershaft

Scoring with 1-1/8” slittershafts

Scoring on a 7/8” slittershaft

Perforating on a 7/8” Slittershaft

Page 4

Baum 2015/2018/2020 Floor Model Folders

Job Setup

Loading...

Loading...