Page 1

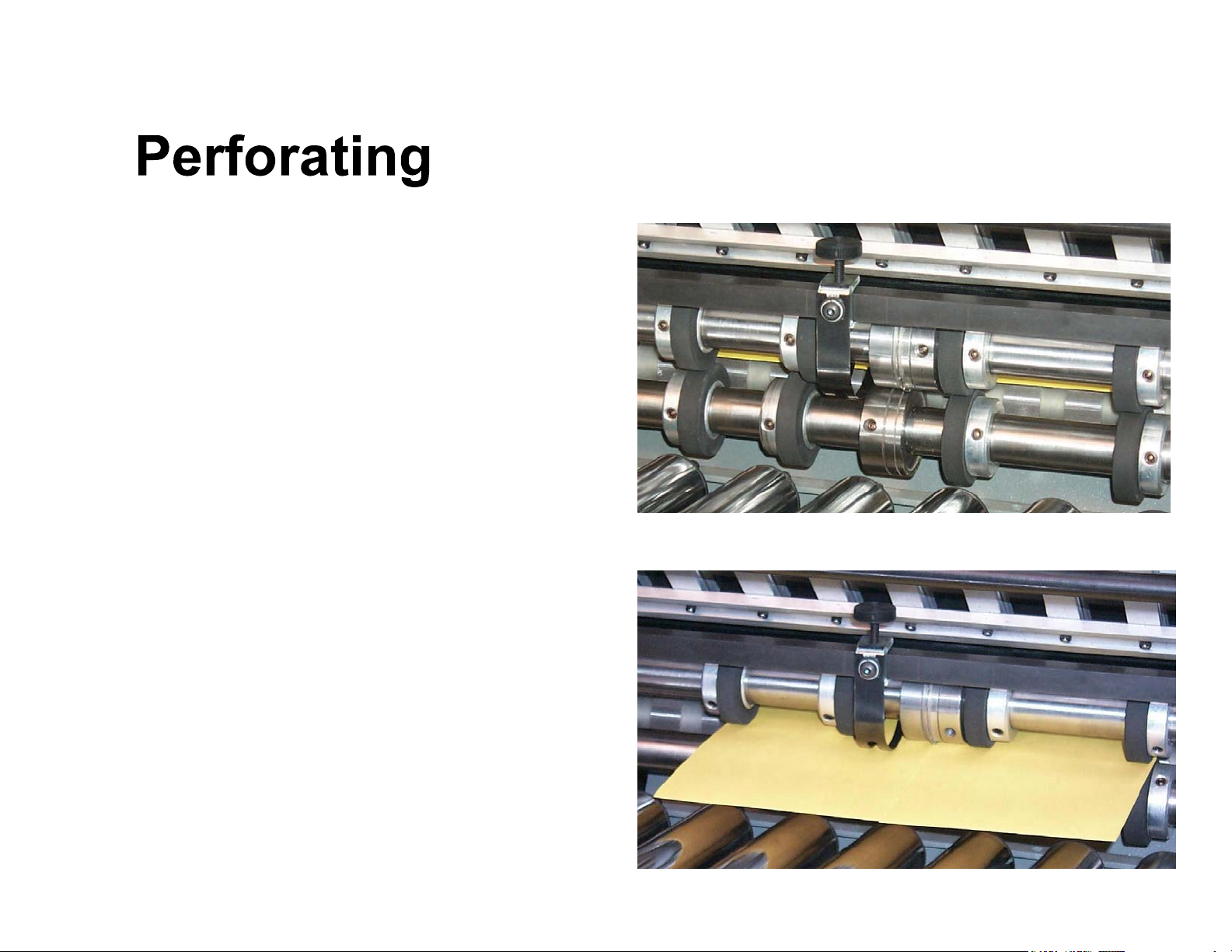

When folding right angle folds for book signatures it is

recommended to perforate the paper as it exits the

previous folding station. Perforating the paper creates

consistent, quality folds in the right angle folder.

Perforating creates a weakness or definition in the

paper that assists in folding multiple thicknesses or

against grains in the paper and more importantly

makes air passages in the paper to allow air to escape

during the folding process and eliminate wrinkles and

creases that occur from air pockets. When perforating

you must determine the next application in the

finishing process or the usage of the printed material

by the end recipient. If you are perforating signatures

for books that are to be gathered and stitched on a

saddlestitcher, you will want to use a course

perforating blade that has fewer number of teeth and

creates large slits for the air to escape. If you are

creating mailing pieces with coupons or reply sections

you will want to use a finer tooth perforator blade that

has several perforations per inch.

If you are folding 17x22” sheet in half in the first station

folder and then in half again in the right angle to make

standard 8-page signatures, you will need (1) line of

perforation on the slittershafts on the first station

folder. You will find (3) yellow scribe lines on the tie

bar at the exit of the first station folder. The yellow line

in the center is the approximate center of the folder

and the sheet and is where you can approximate the

location of the perforating accessories for this job.

Page 2

Perforating Continued:

To install the perforating accessories, first remove the

slittershaft housing on the non-operator side of the

folder. Loosen the holding knob and remove it from the

housing. Insert the holding knob into the tapped hole in

the side of the housing and screw it into the tapped

hole completely. Pull out on the holding knob and

remove the housing from the slittershafts. The

slittershafts stay in the folder. Use the 4mm hex allenkey ball driver to loosen the brass tip setscrews that

are holding existing accessories in place. Slide the

accessories that need removed off of the slittershafts.

Install the perforating blades onto the blade holder.

Note that there are multiple spacers of different

thicknesses on the blade holder. These are for

mounting multiple blades at incremental center

distances on the same blade holder. These are helpful

for perforations that are close together.

When installing the perforating blades onto the blade

holders, be sure to mount the blade holders so that the

rotation of the shaft will not loosen the locking nut.

Use the “Y” spanner wrench that is included with the

tools for the folder to loosen and tighten the blade

holder nut.

The perforating blade is to have the flat side running

against the sharp side of the female scoring collar and

the bevel side is to be pointing toward the next folder.

The (2) grooves in the collar are for scoring only. The

flat, sharp side of the collar acts as an anvil just like a

pair of scissors. If the perforating blade is not against

the anvil side the perforations will be ragged and of

poor quality.

Page 3

Perforating Continued:

Slide all accessories onto the slittershaft and leave all

items loose. Use the yellow scribe marks on the exit tie

bar to line up the perforating blades or pull up on the

#1 and #3 foldplates and roll a marked sheet of paper

through the folder and line up the perforating blades

with the marks on the lead edge of the paper and

place the pullout tires close to the perforating blades

and at the edges of the sheet. Reinstall the slittershaft

housing and tighten the holding knob back into the

upper position.

Line up all the accessories and rotate them so that all

of the setscrews are at the same position facing

outward and tighten the setscrews. This reduces setup

time for the next job having all of the setscrews at the

same position.

Mount the springsteel stripper assembly onto the exit

tiebar that has the yellow scribe marks as shown. The

stripper is to be mounted beside the perforating blade.

It does not straddle the blade. YOU MUST USE THE

STRIPPER TO PERFORATE!

Set the adjustable depth to the nominal center position

using the micrometer adjustment knobs at each end of

the slittershafts. The milled notch at the center of the

aluminum block is the nominal center adjustment.

To adjust the perforation position, you can use the

microadjustment knob on the register table. This is

only effective when one perforation is being adjusted.

It will not adjust multiple perforations.

Loading...

Loading...