Page 1

BAUMFOLDER

CORPORATION

Quality Bindery Equipment Since 1917

2020 KICKER ASSEMBLY

INSTALLATION INSTRUCTIONS

©Baumfolder Corp., 2000 Printed in U.S.A TP10324A

PAGE 1 TP10324A

Page 2

© 2000 Baumfolder Corporation

All Rights Reserved

WARNING

Do not operate this machine without all guarding in place.

Do not make adjustments or perform maintenance on this machine with power on.

Keep the machine and the work area clean and free of spills to prevent accidents.

Be sure to replace any safety decals that may have been detached for any reason.

BAUMFOLDER reserves the right to make changes in design or to make additions or improvements

in its products without imposing any obligation upon itself to install them on its products previously

manufactured. It is recommended that modifications to this equipment not be made without the advice

and express written consent of BAUMFOLDER.

FOLDER IDENTIFICATION

MODEL NO: ________________________________ SERIAL NO: ______________________________

DEALER : ___________________________________________________________________________

INSTALLED BY: _______________________________________________ DATE: ________________

PHONE NO: ________________________________

TP10324A PAGE 2

Page 3

CONTENTS

1.0 KIT INSTALLATION ............................................................................................................... 4

2.0 KICKER FUNCTION SETUP ................................................................................................. 7

3.0 PARTS ...................................................................................................................................... 12

4.0 SCHEMATIC ........................................................................................................................... 14

5.0 SERVICE/PARTS ..................................................................................................................... 15

PAGE 3 TP10324A

Page 4

1.0 KIT INSTALLATION

Note:

This Feature is applicable only on Folders with

the DCT500 Controller Installed.

CAUTION

ELECTRICAL SHOCK HAZARD PRESENT.

THIS KIT SHOULD ONLY BE INSTALLED

BY QUALFIED PERSONNEL.

Remove electrical power from the folder at the main

circuit breaker panel. This will ensure that the installer

will not come into contact with the main power leads at

the folder disconnect switch.

If the kicker device is not assembled to the bracket, do so

with the supplied hardware per drawing TP220-889-02-00

of this manual.

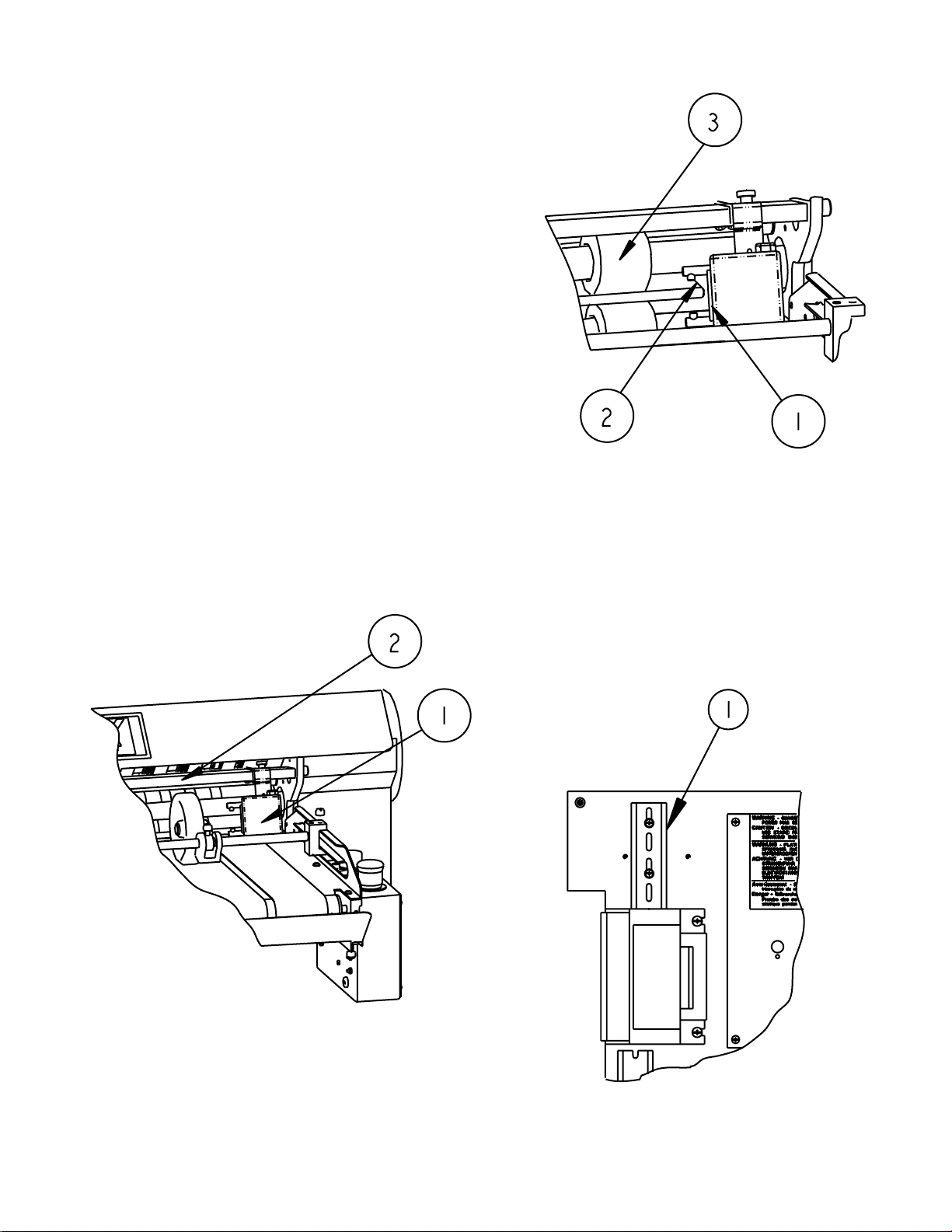

Install the assembled kicker device(Figure 1-1) on the

square slitter shaft accessory spreader bar(Figure 1-2).

The location of the kicker unit is dependent on the type

and size of fold that is being made.

Figure 2

After locating the kicker unit, plug the connector into the

1X12 connector located on the side of the main control

panel.

Open the door of the main control panel and find the DIN

rail located in the upper left hand corner above the blue

power transformer. Remove the hardware that attaches

the rail to the box and rotate the rail 90 degrees(Figure 3-

1).

Figure 1

The location of the kicker unit, along the tie bar, is set so

that the striker plate(Figure 2-1) of the plunger is

approximately 1/8 from the right edge of the

stock(Figure 2-2) as it exits the slitter assembly pullout

tires(Figure 2-3).

Figure 3

TP10324A PAGE 4

Page 5

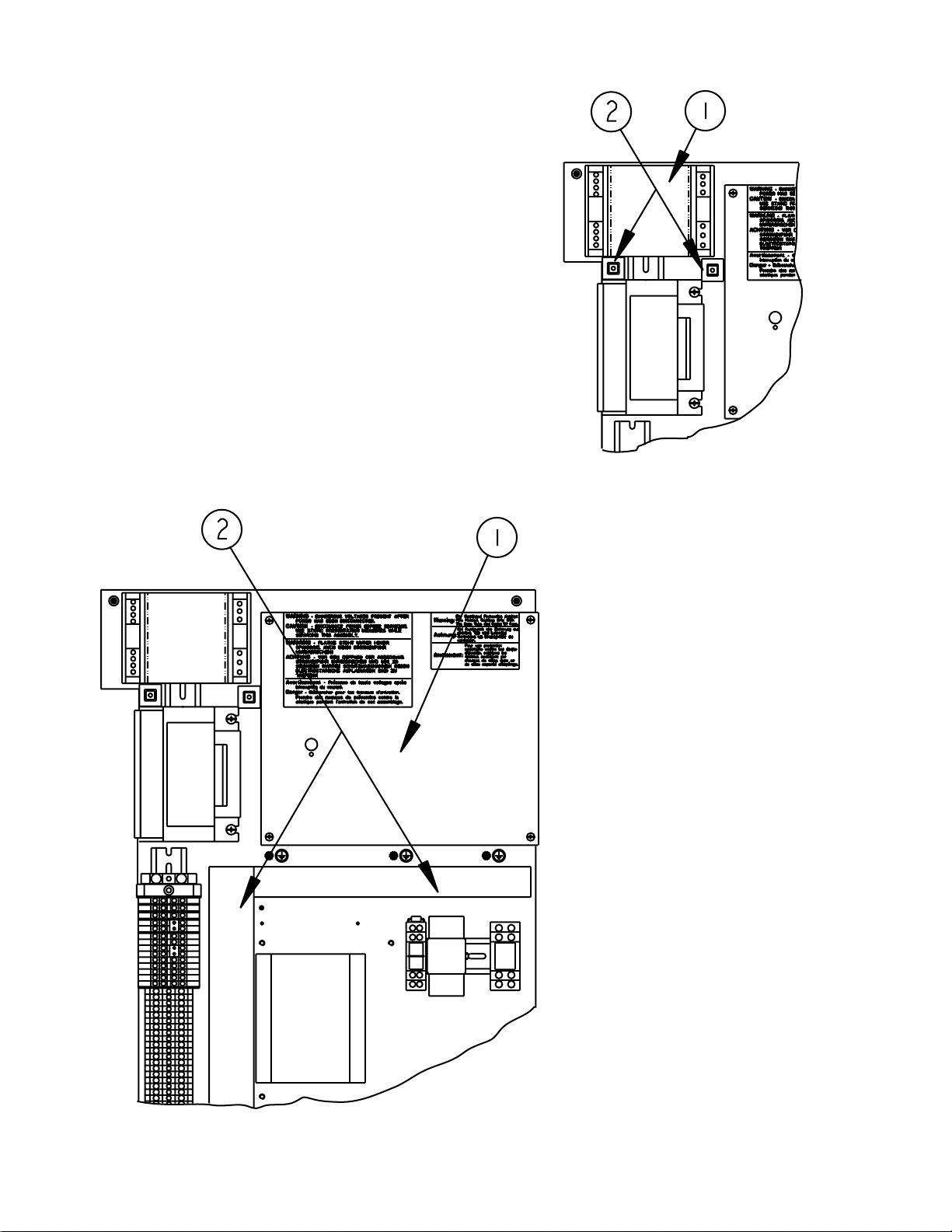

Install the kicker module, A20(Figure 4-1), on the DIN rail

in the upper left corner of the main electrical enclosure, as

shown. Place the two cable tie anchors in the approximate location show in Figure 4-2.

Remove the protective plexiglass cover(Figure 5-1) that

covers the main circuit board. Also remove the two

wireway covers(Figure 5-2).

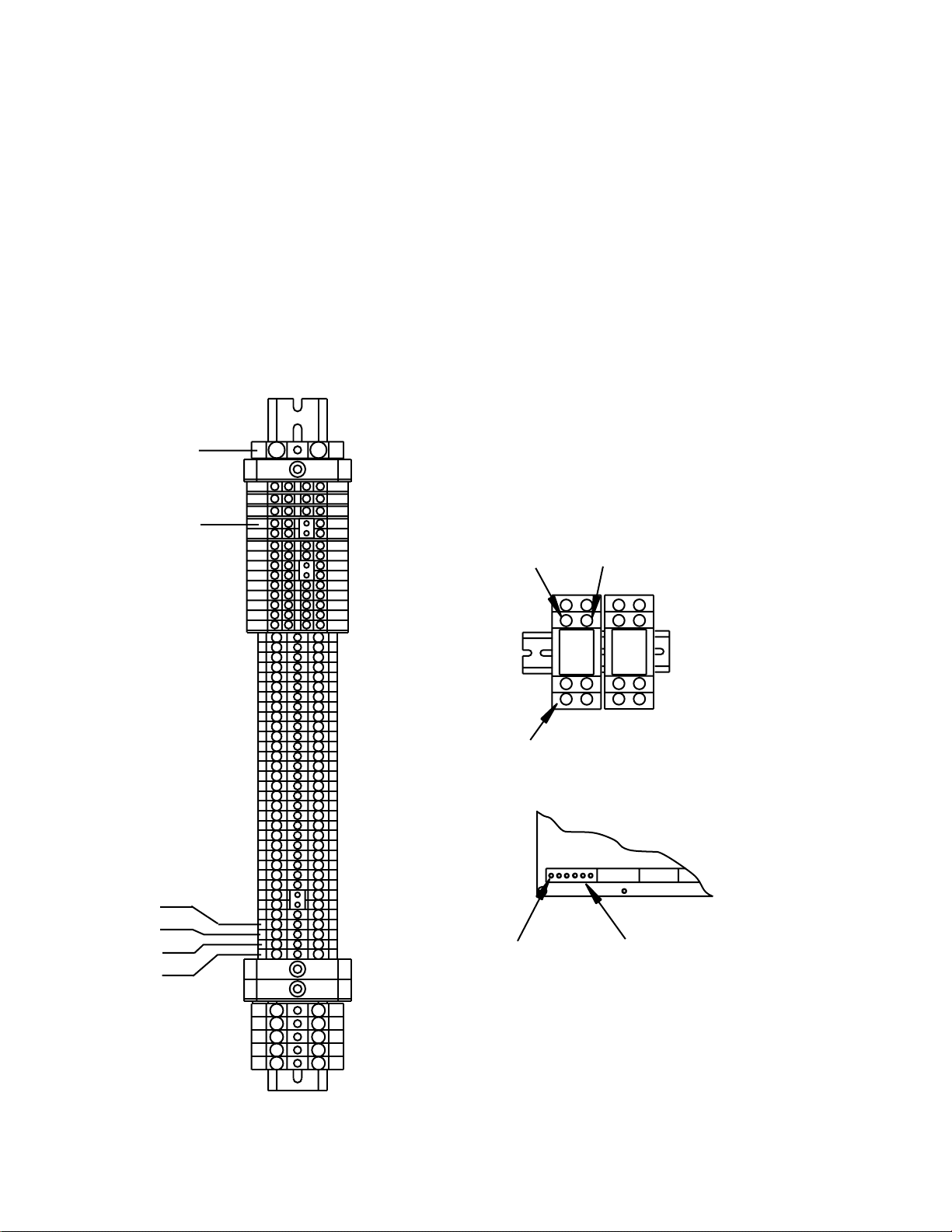

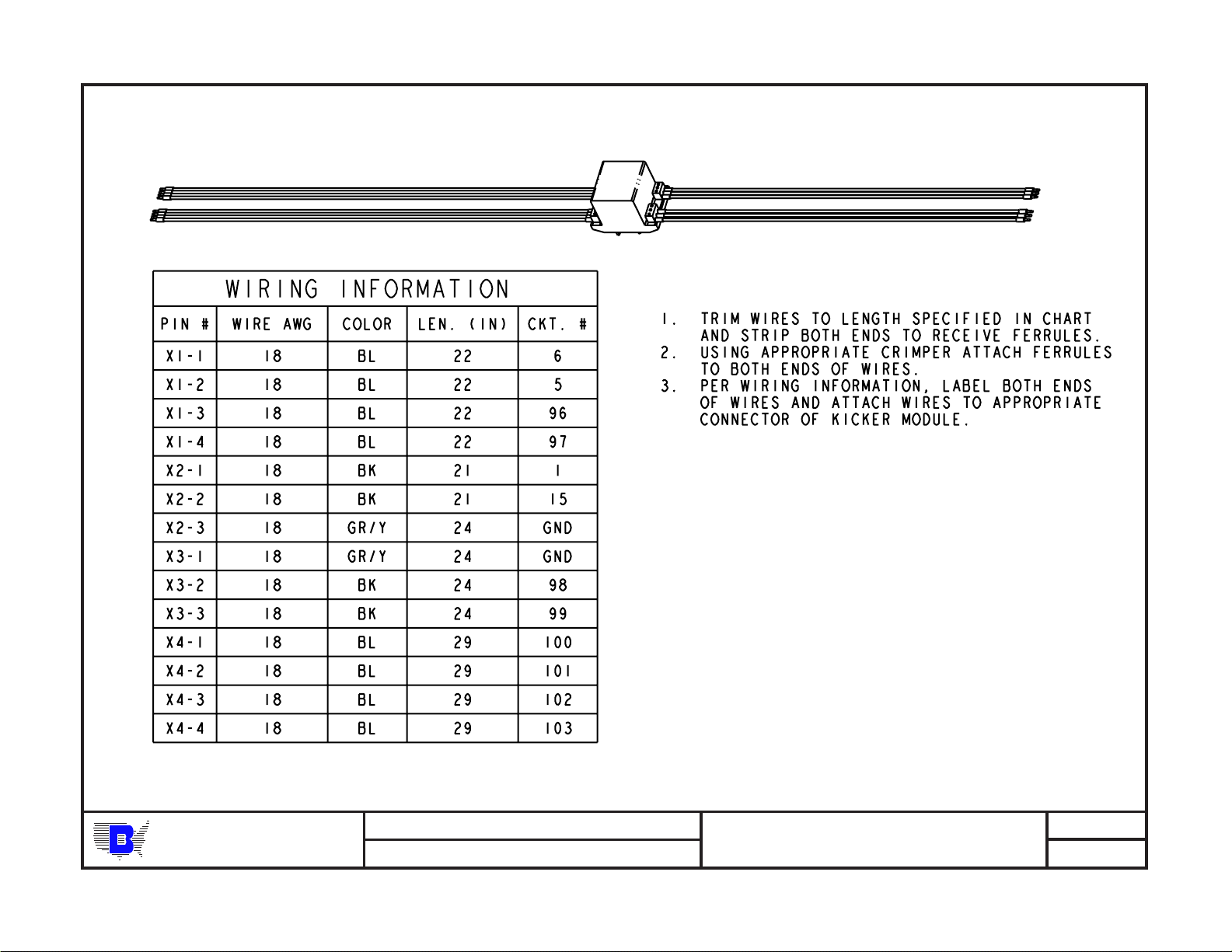

Install the wires from the kicker module, A20, per the

wiring instructions of Figure 6. After installation of wires,

replace plexiglass cover and two wireway covers. Cable

tie wire bundle to anchors and cable tie the rest of new

wiring to existing wires.

Close main electrical enclosure and reapply power to the

folder.

Figure 4

Figure 5

PAGE 5 TP10324A

Page 6

CKT NO. COLOR FROM TO

5 BL A20-X1-2 A1-2X25-4

6 BL A20-X1-1 A1-2X25-3

1 BK A20-X2-1 TB1-1

15 BK A20-X2-2 TB1-15

GND GR/Y A20-X2-3 TB1-PE

GND GR/Y A20-X3-1 TB1-PE

98 BK A20-X3-2 K3-4

99 BK A20-X3-3 K3-1

96 BL A20-X1-3 A1-2X25-5

97 BL A20-X1-4 A1-2X25-6

100 BL A20-X4-1 TB1-100

101 BL A20-X4-2 TB1-101

102 BL A20-X4-3 TB1-102

103 BL A20-X4-4 TB1-103

TB1-PE

F17

TB1-1

TB1-100

TB1-101

TB1-102

TB1-103

F15

F16

Pin 4

K3

Pin 1

Pin 1

A1-2x25

Figure 6

TP10324A PAGE 6

Page 7

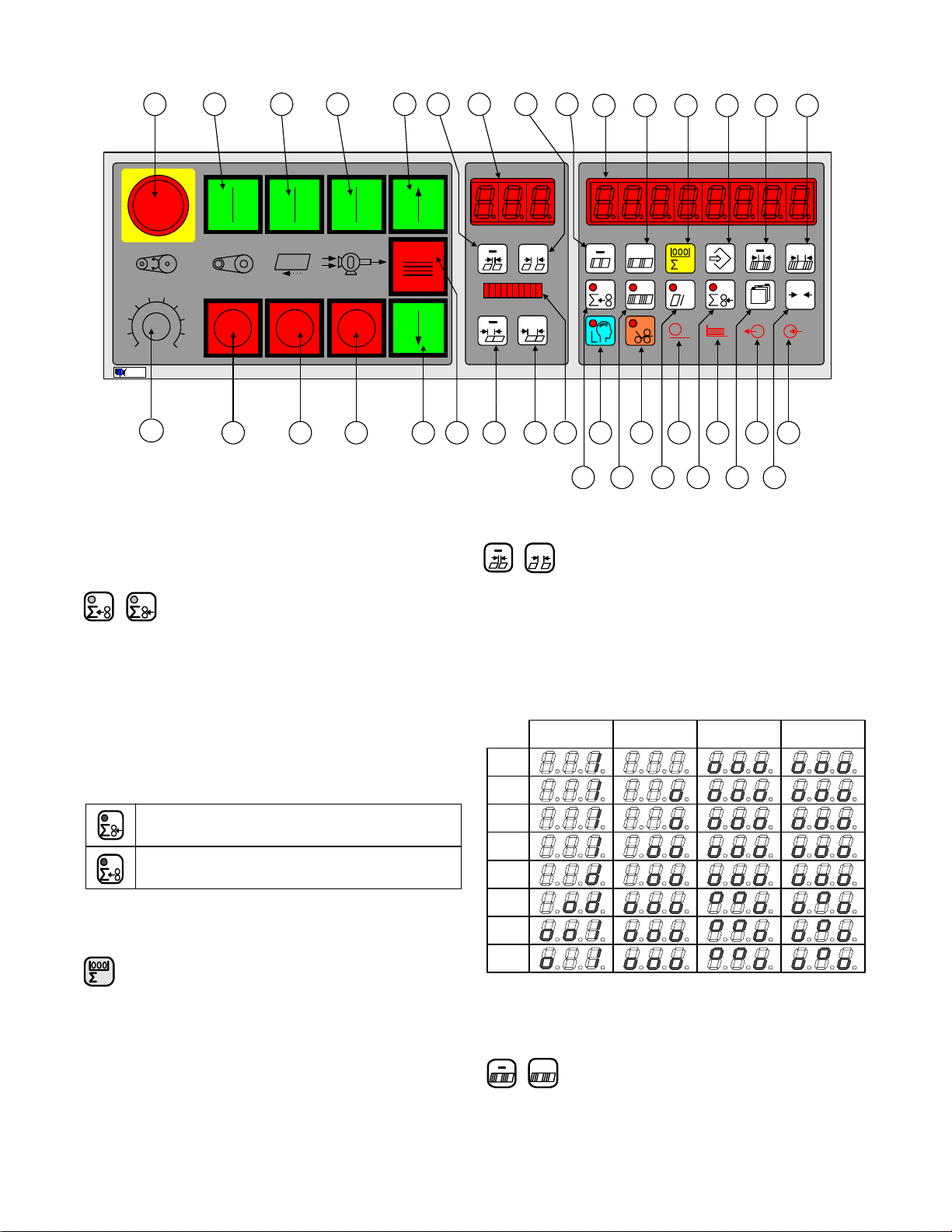

25 2824 28 12 10 1417

1 29 30 31 32 33

56

4

3

2

1

BAUMFOLDER

CORPORATION

7

8

9

10

36

9 13 11 16 26 27 22 23 4 5 7 615 3

2.0 KICKER FUNCTION SETUP

2.1 Select Count Source

The Output Count and Input Count keys select between

count at delivery and feeder, respectively. One key LED will

always be lit in Counter Setup to show the current count

source, see below. Chasing LEDs will activate in the small

display signifying the start setup mode. The next sheet fed

through will be timed from leading edge to trailing edge and

the delay time will be set to one half the sheet time. Please

note this must be redone if the delivery speed is changed.

Select the Output Count button #18.

The batching count source will be the feeder

photoeye.

The batching count source will be whatever is

connected as the del ivery photoey e.

2.2 Counter Setup Mode

+

+

18 19 20 21 34 35

+

h

+

0

Change Batching Type

+

The minus and plus buttons move through a list of four

output devices. The chosen type is then activated when the

batch down-count goes to zero. Select the MKE Table column

to kick the last sheet for the batching type setting.

The output types are represented by animated symbols.

The sequence of frames for the animations is shown below.

Feed Interruption Speed Up Table MKE Table Kicker

Frame

1

Frame

2

Frame

3

Frame

4

Frame

5

Frame

6

Frame

7

Frame

8

Future

Feature

Pushing this key puts the counter in counter setup mode.

Counter setup mode is used to prepare the controller to

run a job. The large display (1) shows the batch preset on the

left-hand side and the batching output time on the right hand

side. The decimal points in the large display (1) will move from

side to side to indicate that a parameter may be changed. The

small display (2) shows the batching type. The suction length

display (3) is active.

PAGE 7 TP10324A

Output Type Animations

Batch Preset Adjustment

+

These buttons cause the batch preset value to increment or

decrement. The preset will be reloaded after the user leaves

the setup mode only if the value has been changed.

Page 8

Batching Time Adjustment

+

The batching time adjustments allow the user to select the

time duration associated with the currently selected output

type. Two output types and times are available.

1. Feed interrupt has a range of 0.0 to 9.9 seconds.

2. Speed-up Table has a range of 0.00 to 5.00 seconds.

Set the range at approximately 0.5.

2.3 Make Ready Mode

This key places the controller in the make ready mode.

The key LED goes on. In this mode the folder will only feed

single sheets and a batching output is issued for every two

sheets fed. This allows the operator to easily set up the

batching time.

Press the make ready button.

Press the sheet feed button, one sheet will be fed. The

system will measure the sheet and automatically set some

tiking parameters.

After each second sheet the Kicker will activate. Adjust

the Kicker timing by changing thebatching time in the counter

setup mode. This will achieve the desired offset (index) for

the batch point.

Press the Make Ready button (#23). Its LED should go

out informing you that the system is ready for production.

TP10324A PAGE 8

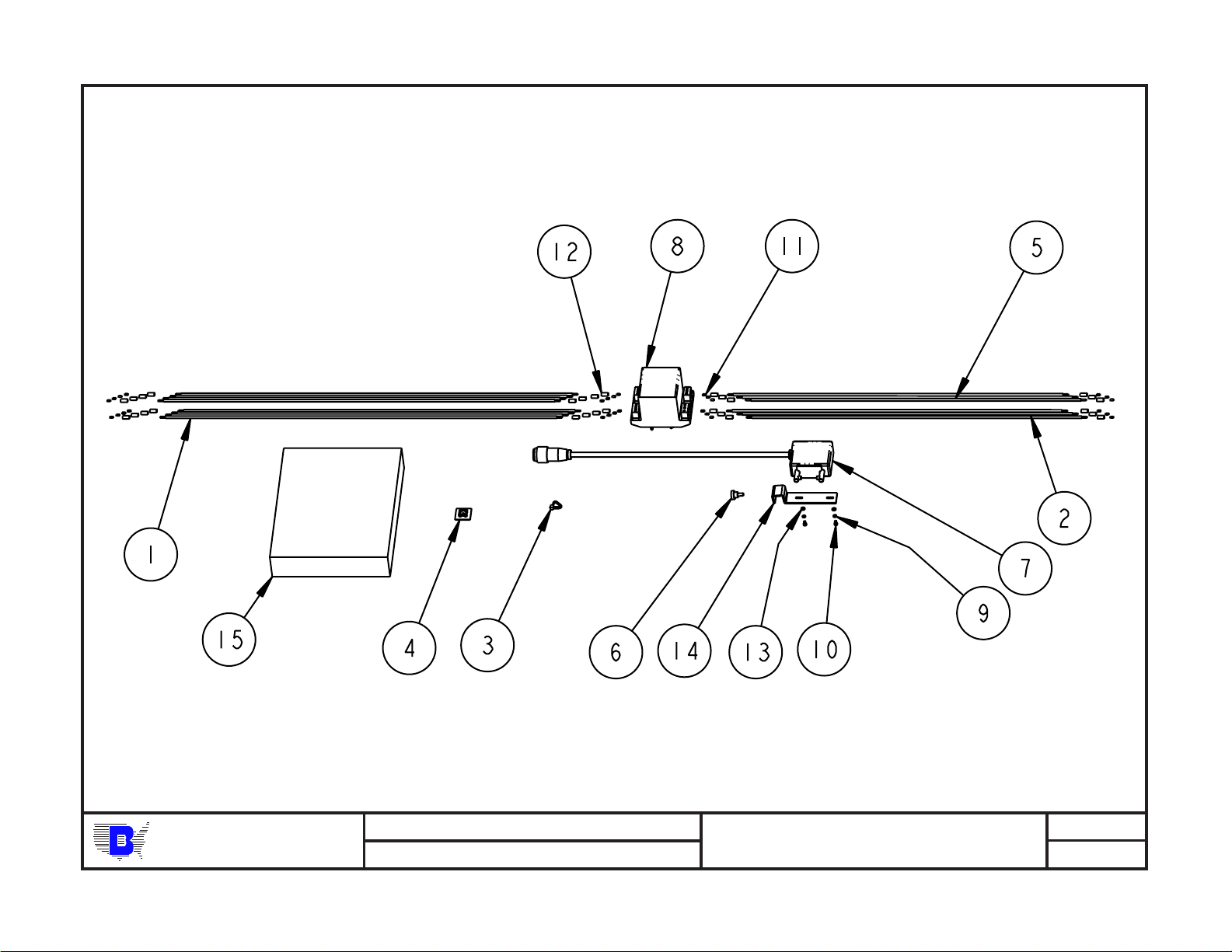

Page 9

1 2

REV:

SHEET OF

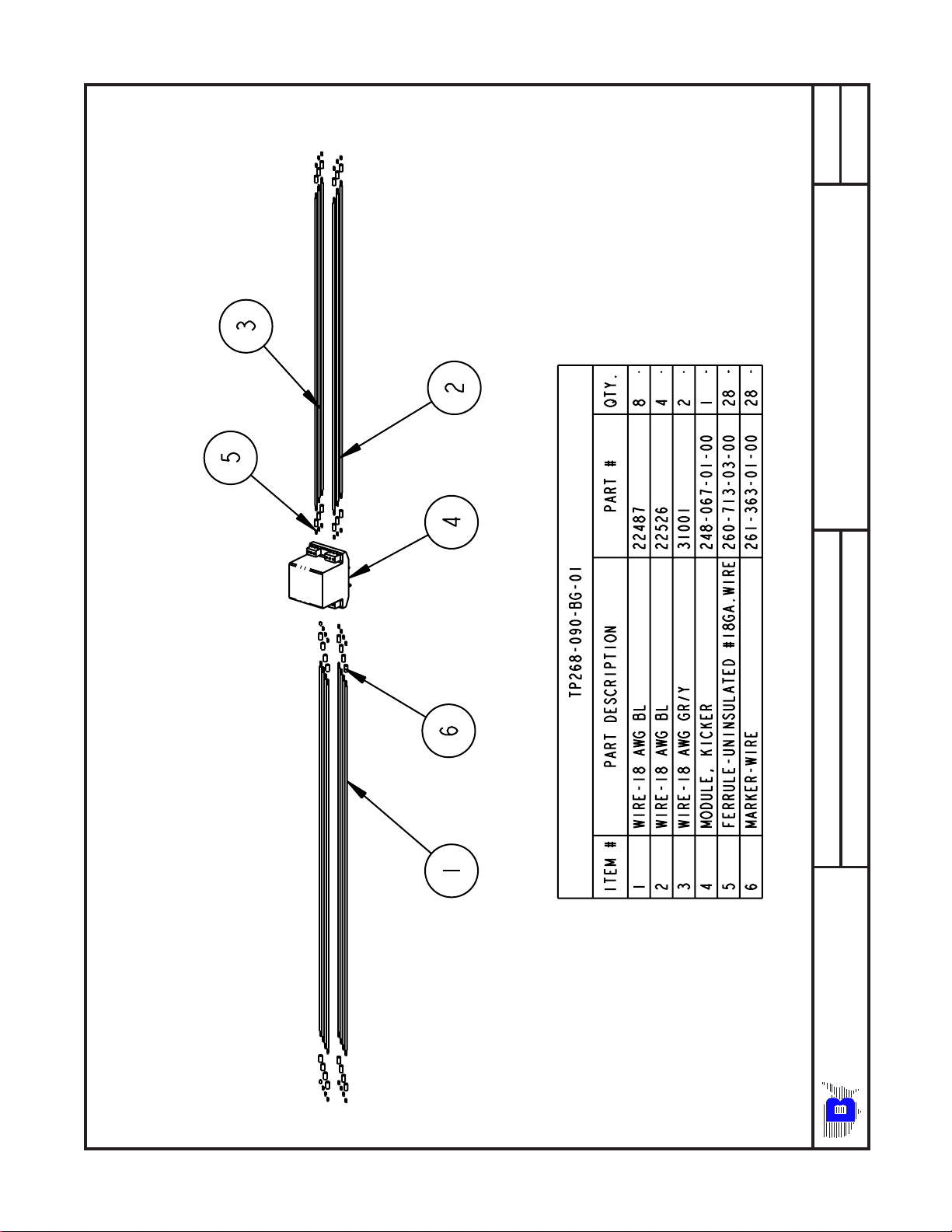

TP268-090-BG-01

ASSEMBLY NUMBER:

2020 KICKER MODULE ASSEMBLY

DESCRIPTION:

UNIT NAME:

BA UMFOLDER CORPORATION

PAGE 9 TP10324A

2020 KICKER KIT

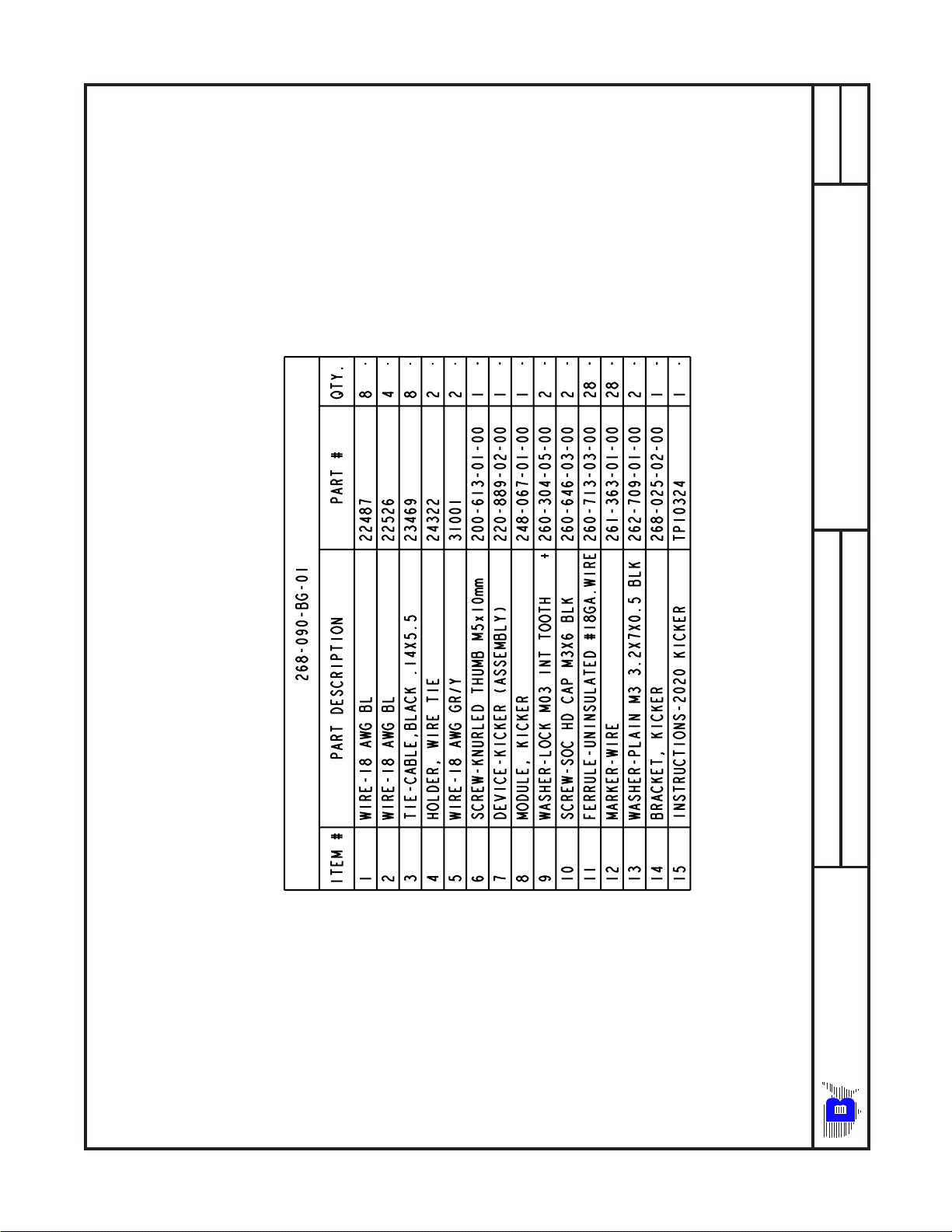

Page 10

TP10324A PAGE 10

BA UMFOLDER CORPORATION

DESCRIPTION:

UNIT NAME:

2020 KICKER MODULE ASSEMBLY

2020 KICKER KIT

ASSEMBLY NUMBER:

TP268-090-BG-01

REV:

SHEET OF

2 2

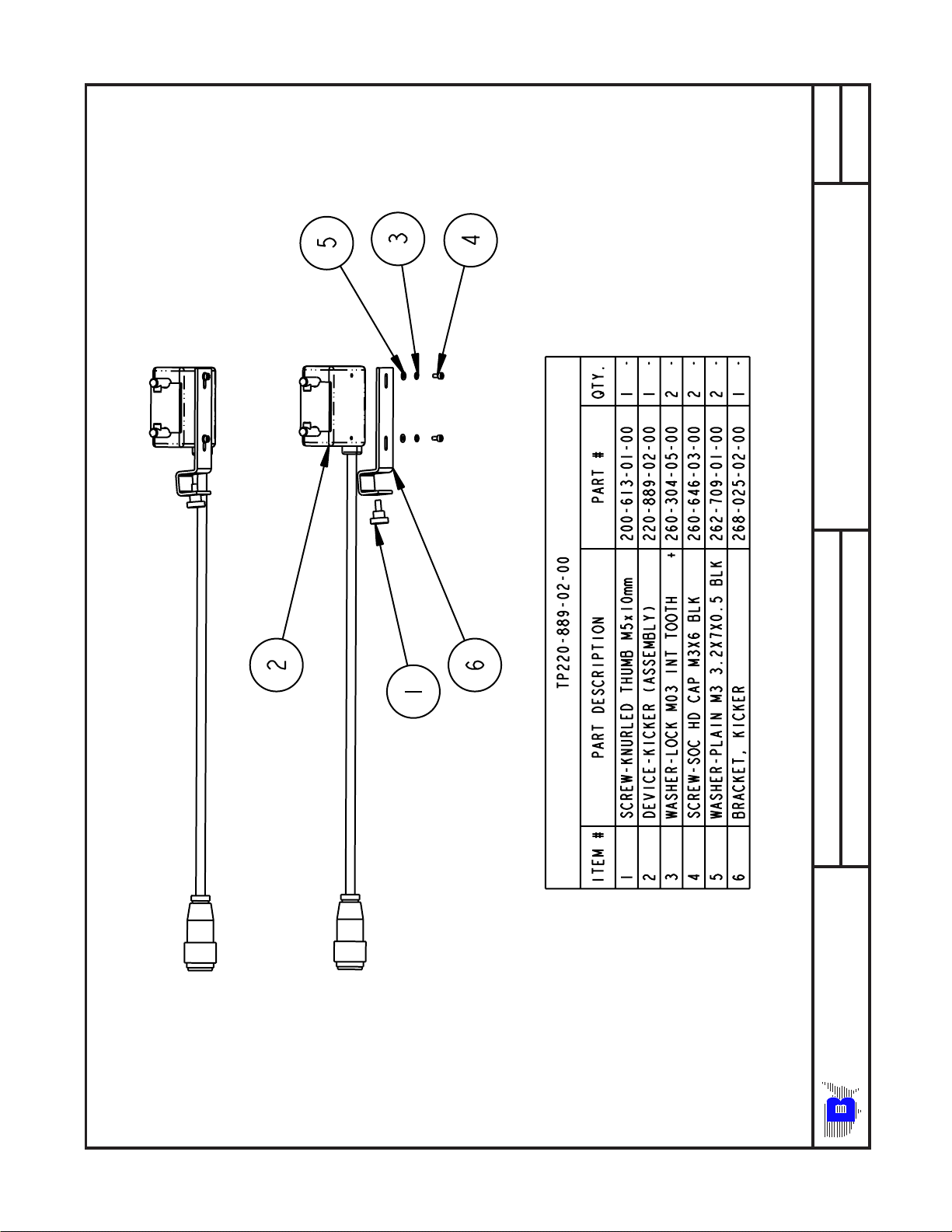

Page 11

1 1

REV:

SHEET OF

TP220-889-02-00

ASSEMBLY NUMBER:

2020 KICKER DEVICE ASSEMBLY

DESCRIPTION:

UNIT NAME:

BA UMFOLDER CORPORATION

PAGE 11 TP10324A

2020 KICKER KIT

Page 12

TP10324A PAGE 12

BA UMFOLDER CORPORATION

DESCRIPTION:

UNIT NAME:

2020 KICKER KIT ASSEMBLY

2020 KICKER KIT

ASSEMBLY NUMBER:

268-090-BG-01

REV:

SHEET OF

1 2

Page 13

2 2

REV:

SHEET OF

268-090-BG-01

ASSEMBLY NUMBER:

2020 KICKER KIT ASSEMBLY

DESCRIPTION:

UNIT NAME:

BA UMFOLDER CORPORATION

PAGE 13 TP10324A

2020 KICKER KIT

Page 14

TP10324A PAGE 14

BA UMFOLDER CORPORATION

DESCRIPTION:

UNIT NAME:

2020 KICKER KIT SCHEMATIC

2020 KICKER KIT

ASSEMBLY NUMBER:

267-385-00-11

REV:

1 1

SHEET OF

Page 15

Baumfolder has authorized dealers located throughout the United States.

Call toll free, 1-800/543-6107 for parts or the

number of your nearest authorized dealer.

BAUMFOLDER

C O R P O R A T I O N

Quality Bindery Equipment Since 1917

1660 Campbell Road

Sidney, Ohio 45365-0728

Phone: 937/492-1281 or 800/543-6107

Fax: 800/452-0947

Internet: www.baumfolder.com

E-mail: baum@bright.net

PAGE 15 TP10324A

Loading...

Loading...