Page 1

TP10497

IFOLD

SERVICE

MANUAL

Page 2

TABLE OF CONTENCE

TP10497

IFOLD ELECTRICAL INSTALATION……......................PAGE 3

IFOLD MACHINE CONFIGURATION….........................PAGE 12

IFOLD STARTUP PROCEDURES………................…...PAGE 17

IFOLD SHUTDOWN PROCEDURES…………..............PAGE 17

SCREEN MAINTAINENCE………………...................….PAGE 17

WARRANTY NOTE……………………………….............PAGE 17

MAIN SCREEN HELP…………………........................…PAGE 18

FOLD SELECT HELP………………………….................PAGE 21

PAPER SELECT HELP……………………................…..PAGE 22

SUMMARY PAGE HELP………………………................PAGE 25

ADJUST PARALLEL HELP……………….......................PAGE 29

MAINTENANCE HELP…………………...............………PAGE 32

JOB CALCULATOR HELP…………………............…….PAGE 33

IFOLD PARTS MANUAL……………………............……PAGE 34

IFOLD SCHEMATIC……………………………….......….PAGE 47

Page 3

Page 1 of 45

TP10497

1

I-FOLD ELECTRICAL INSTALLATION

location (See Page 33). Note: Before tightening the (4) socket head screws, locate display mount so that a gap

between the top of the register frame and the display mount is at maximum clearance, so that the register guard

can be re-installed.

1. WARNING: Power MUST BE DISCONNECTED from the machine before starting this procedure.

2. Remove the back feeder, parallel & register guards.

3. Install I-fold display mount (See Assy. Drawing FK2001426) onto register frame as shown in I-fold display mounting

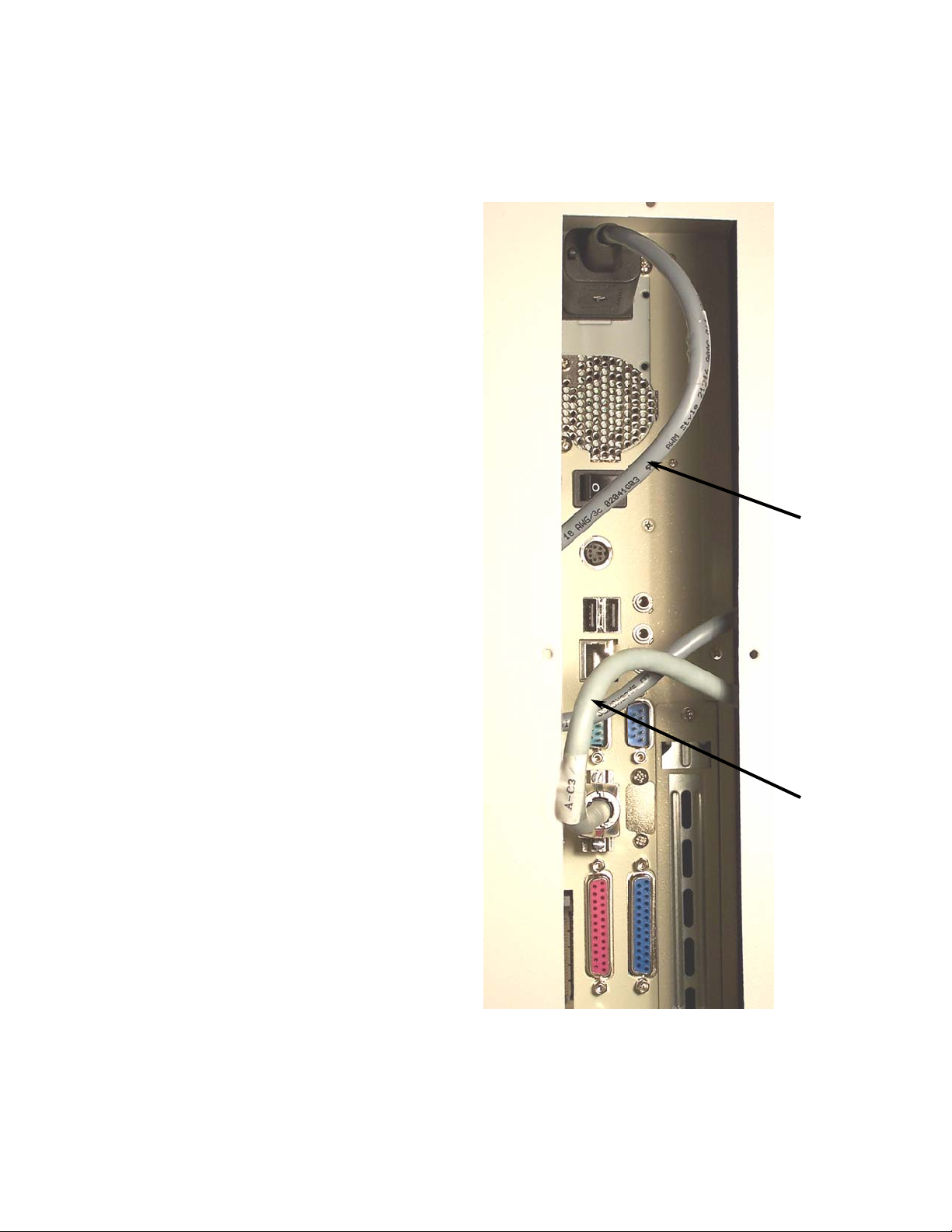

Figure 1

COM 2 Power Switch Power Socket

Page 4

2

Page 2 of 45

TP10497

receptacle “COM 2”, see Figure 2.

4. Install mounting arm into display mount.

5. Mount computer and enclosure onto mounting arm as shown in figure 3.

6. Remove Bottom cover plate from I-fold computer enclosure, to expose computer’s connectors, see Figure 1.

7. Install power cable FK201500 into computers power socket. Install communication cable FK2001501 into computer

computer’s enclosure, until both cables have a 3” to 4” service loop on the cable between the connectors and the

strain relief’s. Tighten outer strain relief nut to hold cables securely, see Figure 3.

8. Run both the power and communication cable through a cable strain relief located in a plate on the back side of the

the goose neck mounting arm tube and pull cables out the bottom of the mounting block, as shown in Figure 3.

9. Run both power and communication cable up into the hole of the enclosure mounting bracket and down through

Figure 2

Communication Cable Power Cable

Page 5

3

Page 3 of 45

TP10497

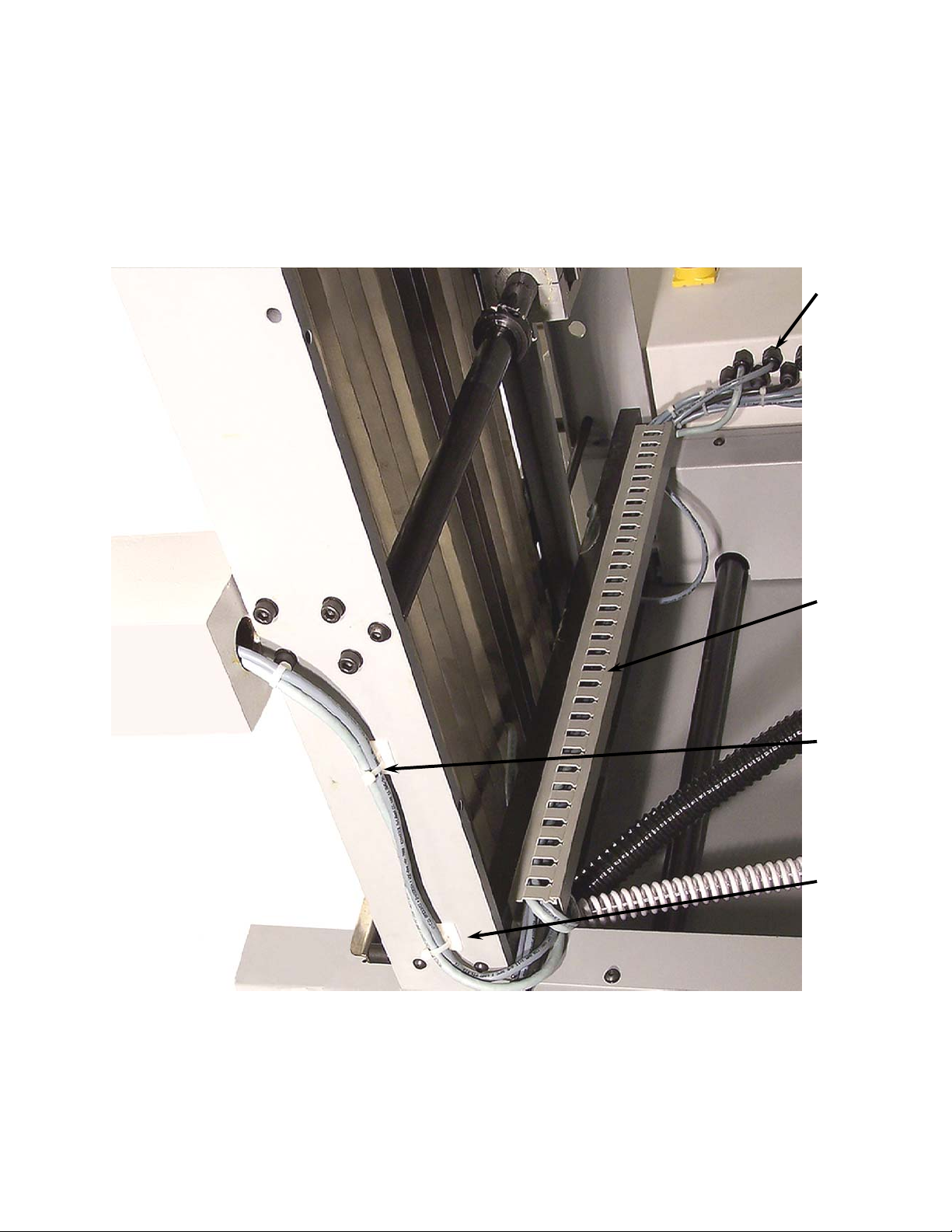

Figure 3

through the wire channel across the register. Remove two hole plugs in the back of the electrical enclosure and

install two cable strain reliefs. Run the two cables through the strain reliefs. Install folder guarding and wire

channel cover. Tighten the two strain relies to secure the cables.

10. Mount the 2 cable anchors, as shown in Figure 4. Mount cables with wire ties to the anchors as shown, run

Page 6

4

Page 4 of 45

TP10497

Figure 4

Cable Anchor Wire Tie Wire Channel Strain Reliefs

Page 7

Page 5 of 45

TP10497

5

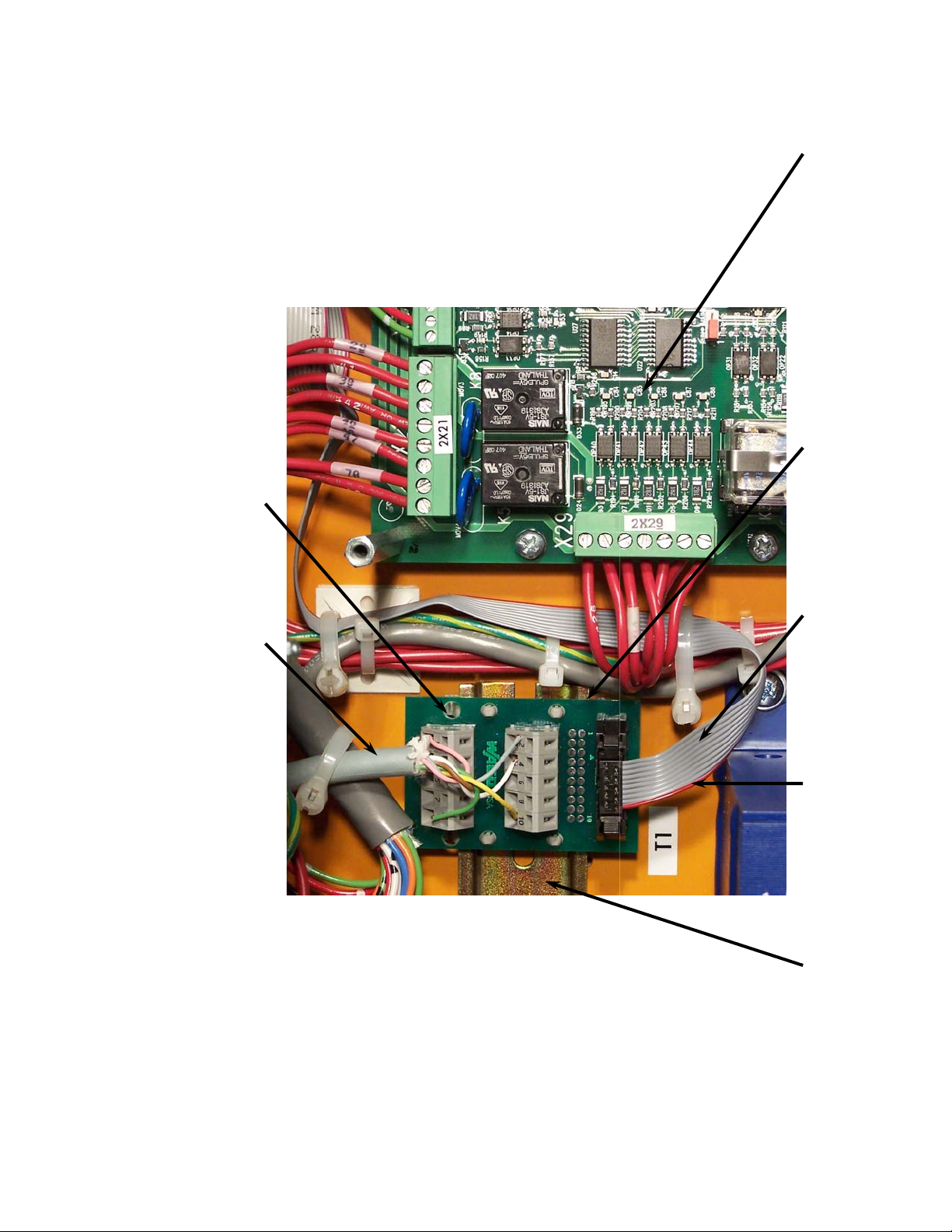

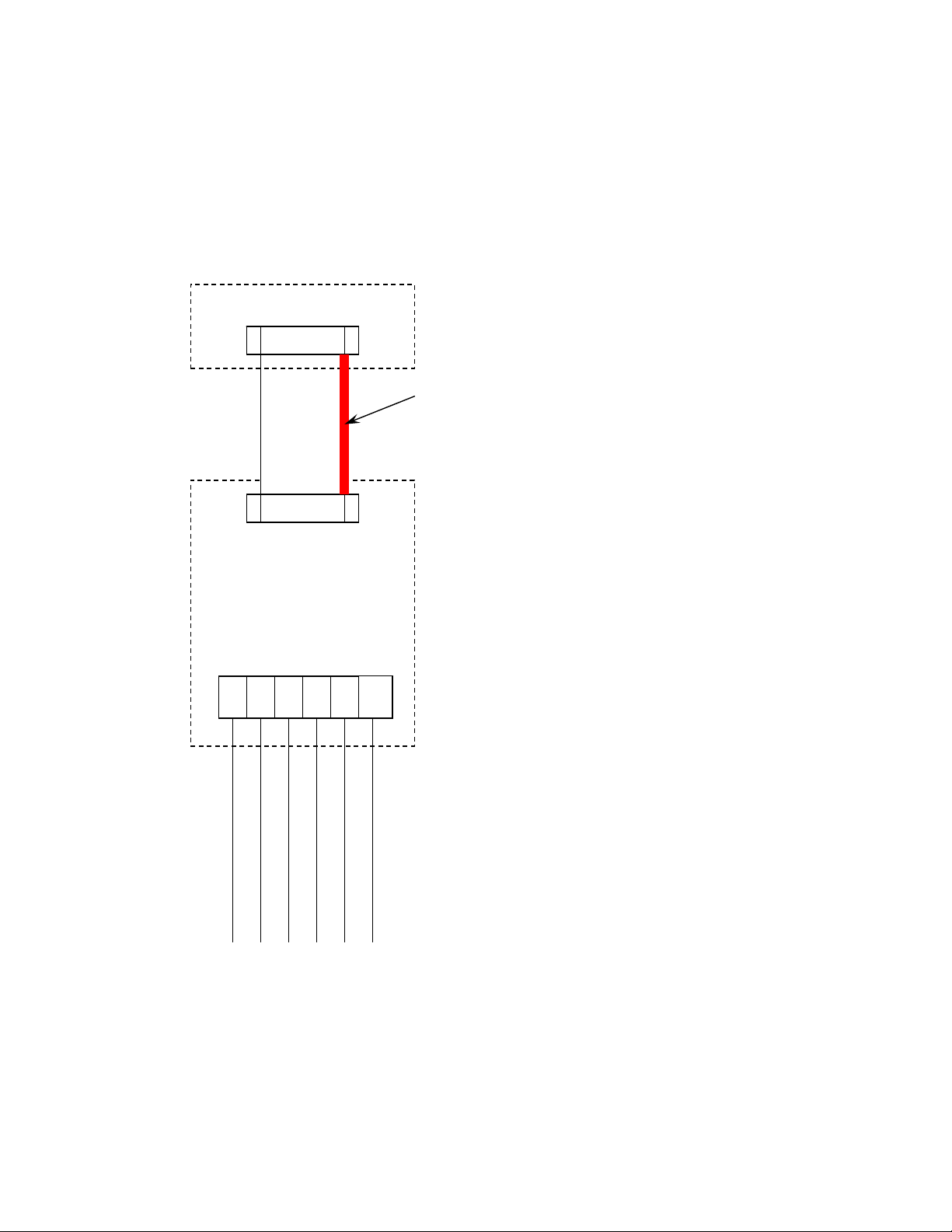

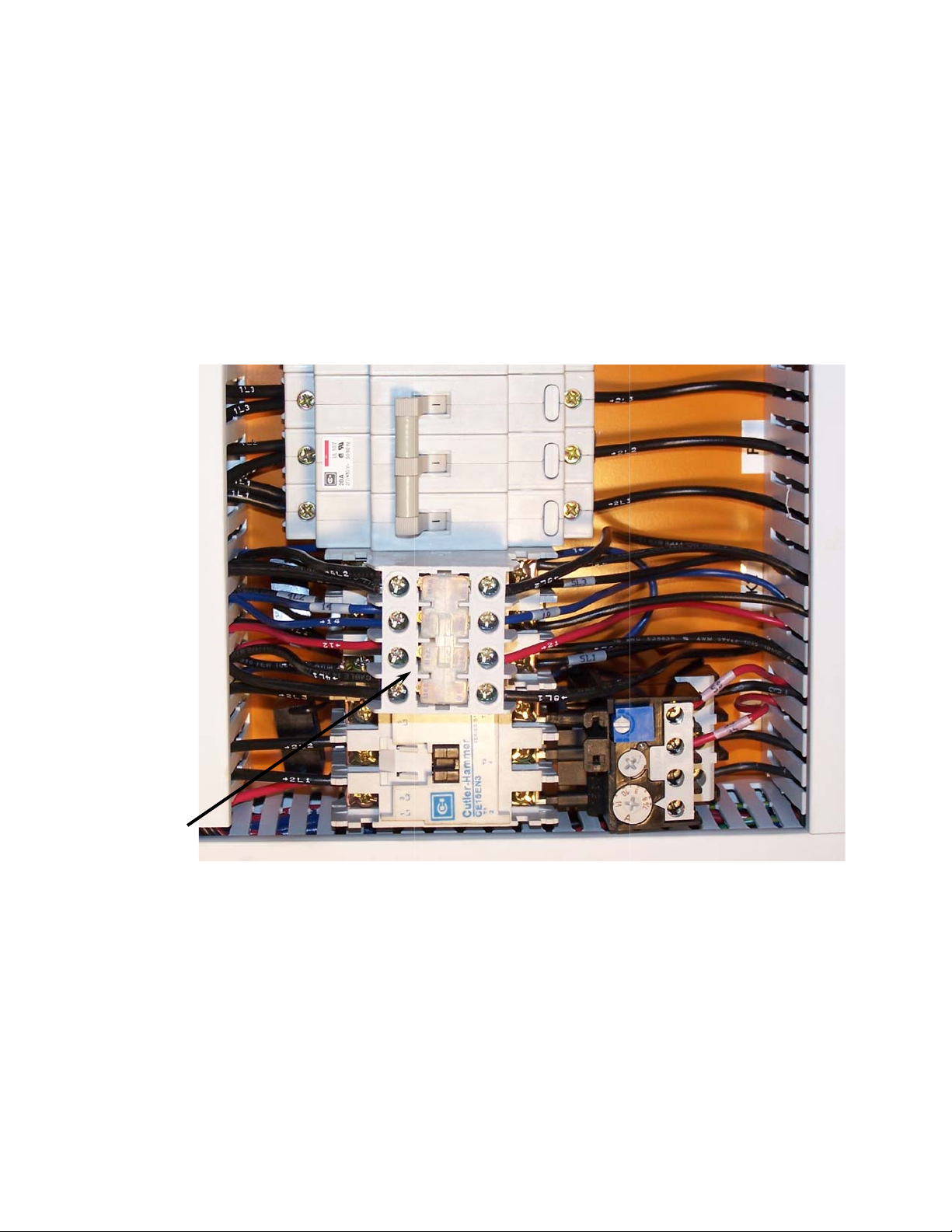

Run the communication cable to the top of the communication board and will wire into the two rows of terminals.

Add an extra 2” to 3” of cable, and then cut cable to that length. Strip back 4” of cable jacket and shielding to

expose conductors. Cut pink, brown & green conductors 1” shorter than the other three conductors. Strip

approximately 5/16” of wire insulation from each conductor. Wire communication cable into the communication

board terminal block as shown in figure 6.

Din Rail Cable Orientation Stripe Ribbon Cable Communication Board DCT500 Board

11. The communication board will sit on the right side of din rail that sits above the transformer, as shown in Figure 5.

Figure 5 Communication Cable Terminal Block

Page 8

12349

Pink

X27

Page 6 of 45

TP10497

Ribbon

Cable

Board

DCT500

Communication

6

Terminal Block

Gray

Figure 6

Brown

White

Cable

10

Yellow

Green

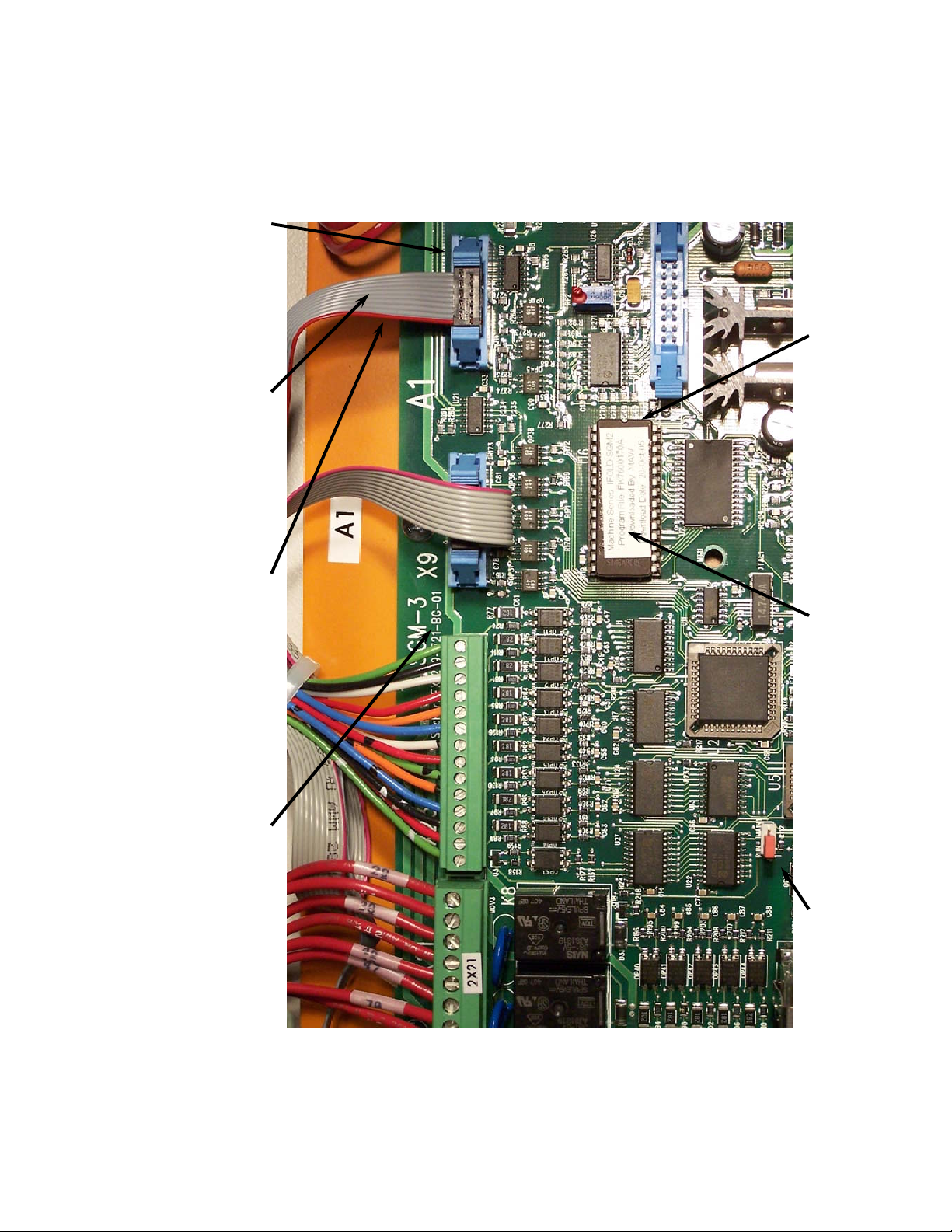

Communication

the ribbon cable, this must be on the left side of connector as shown. The connector can be installed backwards.

Run cable and connect to the X27 connector on the DTC500 board, see Figure 9. Note orientation stripe on the

ribbon cable, this must be on the left side of the X27 connector as shown. The connector can be installed

backwards. Secure the ribbon cable with wire ties, NOTE: do not over tighten or crush the ribbon cable with the

wire ties.

12. Add ribbon cable. Connect one end to the communication board as shown in Figure 5. Note orientation stripe on

must be tied together with a tie pin, this will insure that both fuse holders will open at the same time. Label fuse

13. Add new fuse blocks to the din rail to the right of the existing fuse blocks as shown in Figure 7, The fuse blocks

blocks as A-F1 and A-F2. NOTE: DO NOT INSTALL FUSES AT THIS TIME. Run I-fold power cable between

transformer and the terminal blocks and into the wire channel. Run cable to the bottom side of fuses. Add an

extra 2” to 3” of cable, and then cut cable to that length. Strip back approximately 8” of cable jacket. Strip

approximately 5/16” of wire insulation from each conductor. Add ring terminal to the green \ yellow conductor

and mount to ground lug shown in Figure 7. Wire conductor 1 to bottom of fuse block A-F1 and wire conductor 2

to bottom of fuse block A-F2.

Orientation Stripe

Page 9

7

Page 7 of 45

TP10497

Figure 7 A-F1 4L1 A-F2 4L2

Fuse Block Ground Lug

both ends. Label one conductor 4L1 and the other conductor 4L2 at both ends. Wire 4L1 to the top of fuse block

A-F1, and wire 4L2 to the top of fuse block A-F2, as shown in Figure 7.

14. Take wire and cut into two equal lengths. Strip approximately 5/16” of wire insulation from each conductor at

Page 10

8

Page 8 of 45

TP10497

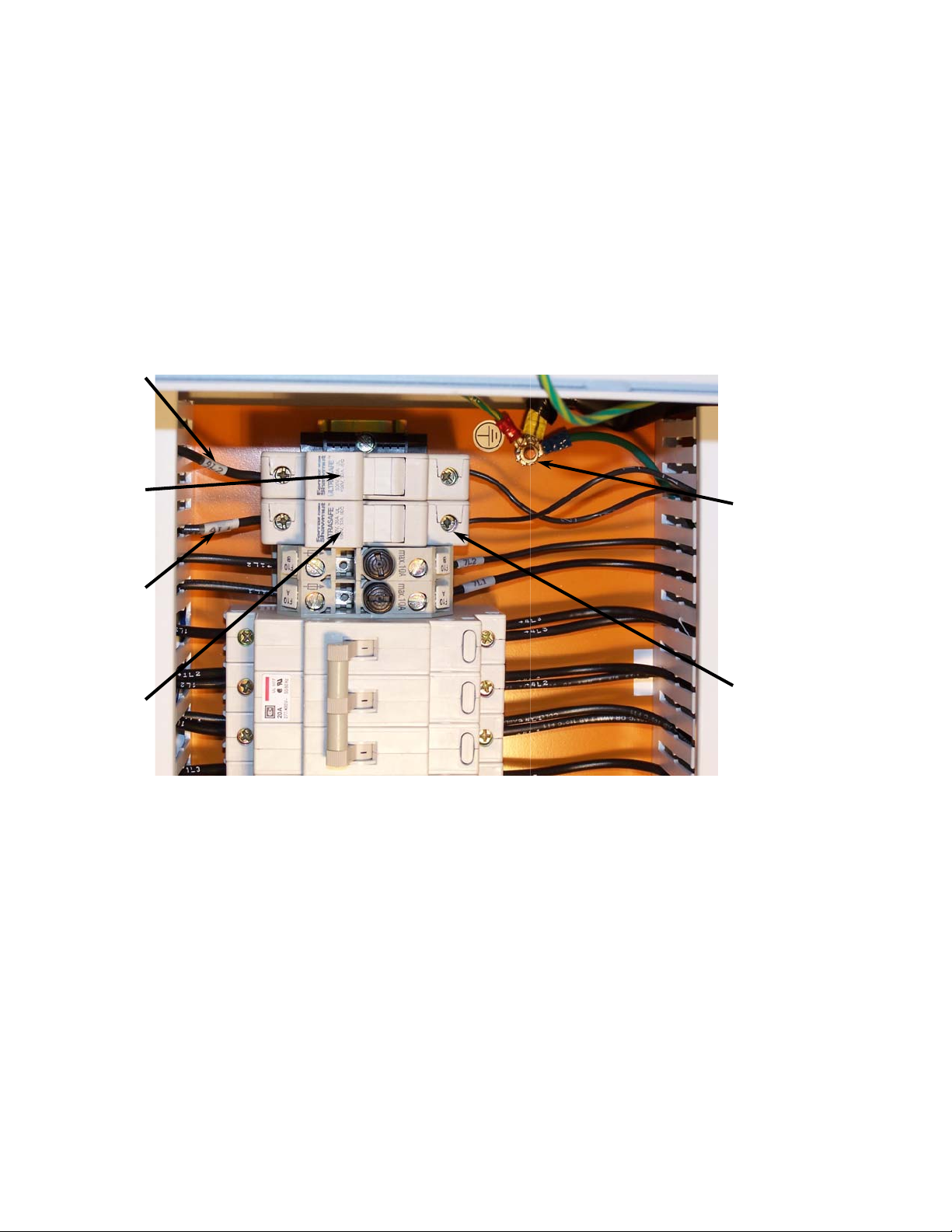

is a 15” or 18” model or to K2-63 if folder is a 20” model, as shown in Figure 8.

15. Run wire 4L1 to K2-53 if folder is a 15” or 18” model or to K2-53 if folder is a 20” model. Run 4L2 toK2-83 if folder

Figure 8 K2

Page 11

Page 9 of 45

TP10497

9

chip at both ends and out of the U6 socket. Do not handle the chip by the legs, only by the sides of the chip. Note

the orientation of the chip notch, the new chip must be installed in the same direction. Care must be taken not to

touch the legs of the chip. Carefully install new chip into the U6 socket.

16. Cleanup wiring and reinstall all wire channel covers that were removed.

17. Replace DCT500 software chip, shown in Figure 9. Carefully do this by using a small screw driver and lifting the

Figure 9 DCT500 Board Orientation Stripe Ribbon Cable X27 Connector

Run/Maintenance jumper Software chip Notch end

Page 12

pins; this will place the machine

Page 10 of 45

TP10497

rd

and 3

nd

pins) to the 2

nd

and 2

st

10

in maintenance mode at power up. See jumper location in Figure 9.

18. Move the run/main jumper (currently on the 1

THIS TIME. Turn on main power switch.

19. Reconnect power to the machine, NOTE: I-FOLD COMPUTER FUSES A-F1 and A-F2 ARE NOT INSTALLED AT

message will display in display 2. Then the new software version will display in display 2, “dct 9.9.b”. Then the

machine will switch to maintenance mode, display will display ether “oFF” or “dSP” and display 2 will display the

machine model i.e. (P-2020).

20. Folder will wake up in maintenance mode. Both displays will light up with “8” in each segment. Then a diagnostic

modes by pressing button 1, or button 2, until “nEt” is displayed.

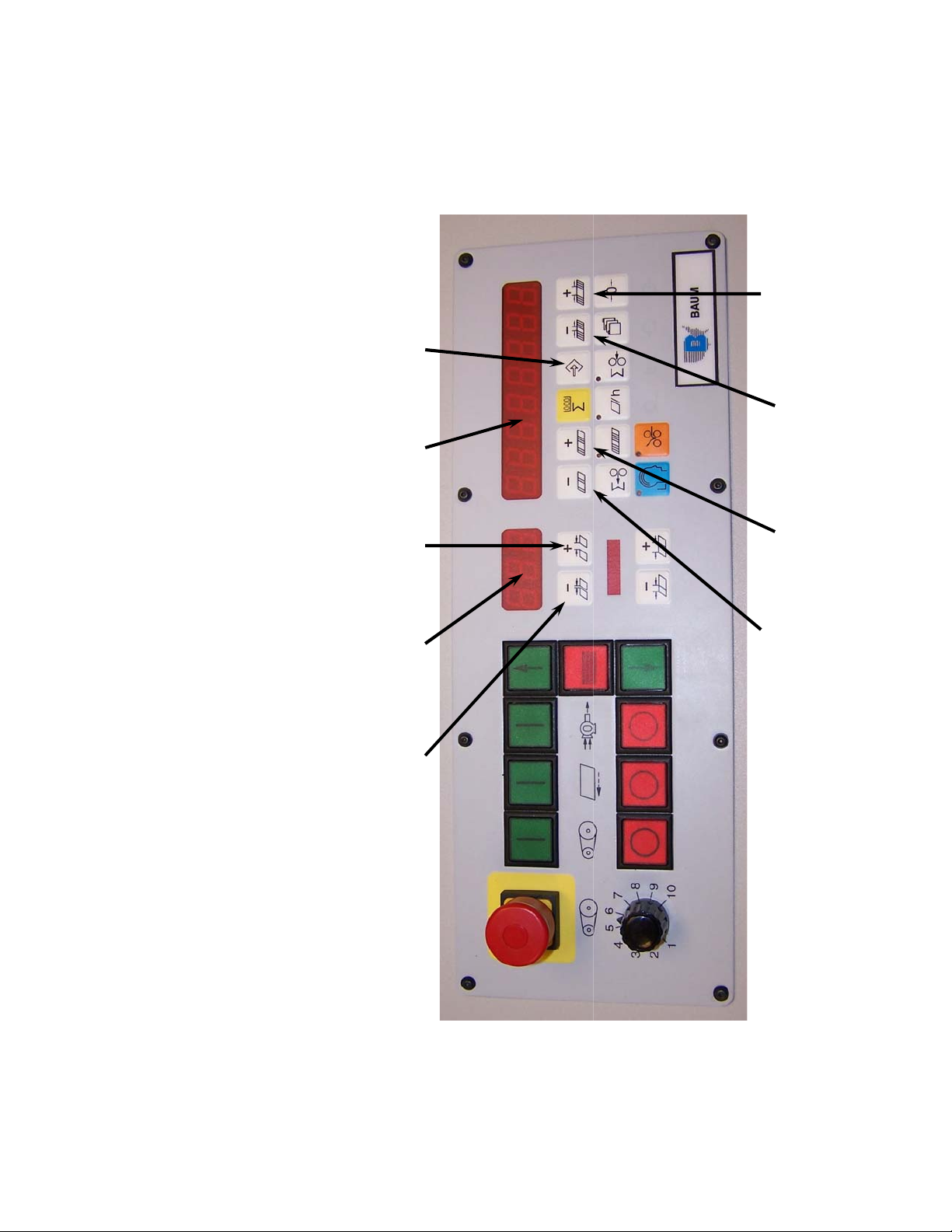

21. Set Serial Port operating mode. Note display 1, Figure 10, this display needs to display “nEt”. To toggle between

Figure 10 Button 1 Display 1 Button 2 Display 2 Button 3

Button 4 Button 5 Button 6 Button 7

Page 13

nd

Page 11 of 45

TP10497

11

pins; this will place the machine back in run mode at power up. See jumper

nd

and 2

st

pins) back to the 1

rd

BAUMFOLDER CORP.

ATTN. MARK WALKER

1660 Campbell Road

Sidney, Ohio 45365

button 4 and button 5 to change the value of display 1. By pressing button 5 the value increases, set value to

“A03”. A value of “0” should now be displayed in display 2. Use button 6 and button to change its value to “1”.

Next value “A04” must be displayed in display 1, use button 5. The value of A04 is displayed in display 2 and must

be change to “nEt 1”. Press button 6 or 7 to change the value. Press button 3 times to exit program mode.

22. Go to the advance settings by pressing button 3, Figure 10. Value A00 should now be displayed in display 1. Use

across the top of the new fuse blocks A-F1 and A-F2. The reading should be between 200 to 244 Volts. If not, go

back and troubleshoot power circuit, before fuses are installed.

23. Check the voltage to the I-fold computer by taking a voltmeter, setting it to VOLTS AC and look at the voltage

and 3

location in Figure 9.

24. Power down the machine by switching off main power switch. Move the run/main jumper (currently on the 2

and close up enclosure.

25. Install .5 amp fuses into fuse blocks A-F1 and A-F2. Reinstall cover over the DCT500 board. Cleanup enclosure

26. Turn on main power switch and let the machine wake up normally.

display in display 1. Use button 4, or button 5, to display “P22” in display 1, Display 2 should now read “Addr 1”.

Use button 4, or button 5. to change display 1 to read “P24”, Display 2 will read “nEt 0”. Use button 6, or button

7, to change display 2 so it reads as “nEt 1”. Press button 1 once then button 3 once to leave setup mode.

27. Go into the machine setup mode by pressing button 3, see Figure 9. Use button 1, or button 2, to get “P20” to

28. If I-fold computer is not up at this time check power switch on the computer, it must be switched on, see Figure 1.

Baumfolder for reprogramming.

29. Place the removed chip, from instruction 13 back into the box the new chip came in and please send it back to

Page 14

Page 12 of 45

TP10497

instructions

For service technicians use only

ifold machine configuration

Page 15

Page 13 of 45

TP10497

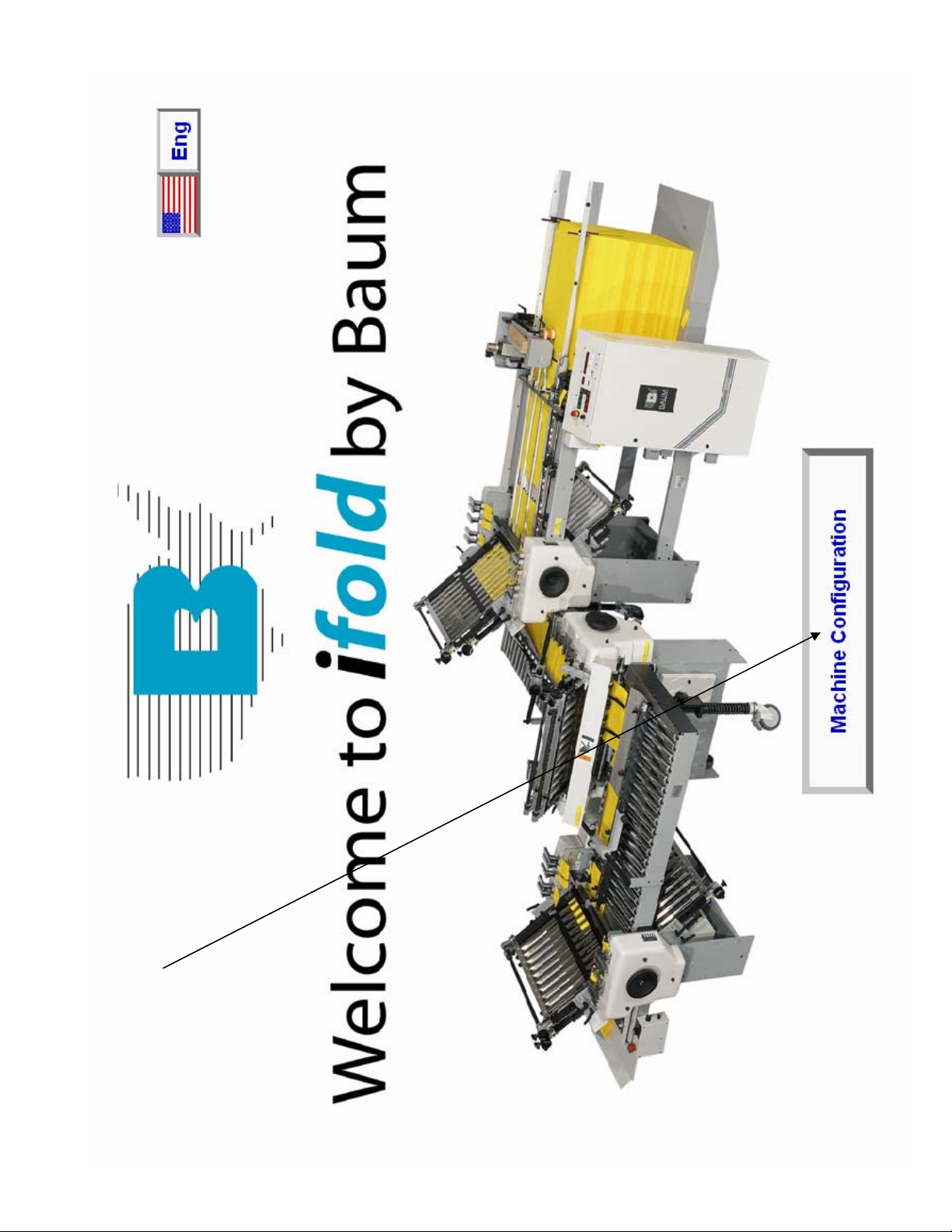

The first time ifold is powered up the Machine

Configuration button will appear on the start up

screen. Touch this button to configure for your

machine.

Page 16

This should be set from the factory.

Page 14 of 45

TP10497

0 = Autoset

1 = 2015

2 = 2020 pile

3 = 2020 continuous

4 = 1526 or 1530

This will only appear if the machine type is

4. It should be set from the factory to the

width of your machine.

Once the number of plates in the Parallel

are set these boxes will disappear. Verify

the settings are correct before setting the

number of plates in the parallel.

Touch this box to tell Ifold how many plates

you have in the parallel unit. It will

increment thru 0 2 3 4 6 each time you touch

this box.

Touch this box to tell Ifold how many plates you

have in the 8page unit. It will increment thru 0 2

3 4 6 each time you touch this box. If you do not

have an 8page unit leave it set to 0

Touch this box to tell Ifold how many plates you

have in the 16page unit. It will increment thru 0

2 3 4 6 each time you touch this box. If you do

not have a 16page unit leave it set to 0

Once you have completed the configuration

touch this button to go to the main page.

Page 17

Touch this box to tell Ifold if you have the

Page 15 of 45

TP10497

optional Gatefold plate. It will toggle between

yes and no each time it is touched.

Touch this box to tell Ifold if you want to display

the optional exit sensor count in place of the

standard infeed count. It will toggle between yes

and no each time it is touched.

Touch this box to tell Ifold if you are using the

standard hang on stacker. It will toggle between

yes and no each time it is touched. This is very

important if this is an Autoset.

Touch this box to tell Ifold if you have the

optional Presser Stacker. It will toggle between

yes and no each time it is touched.

Touch this box to shut down Ifold but not the

computer. This should only be used when

DO NOT TOUCH THIS BUTTON. This button

is for factory use only.

updating the program

Page 18

This will bring up a keypad asking you to enter

Page 16 of 45

TP10497

the password. Enter the password 4921281 then

touch the enter button.

Once in the Maintenance screen touch the

Machine Set-up button.

You can get back into the Machine

Configuration screen at anytime by going to the

main page then touching the Maintenance button

Page 19

Page 17 of 45

TP10497

Start up procedures

The I-Fold software should start-up automatically when the

machine is turned on. If for any reason it does not start up properly

cycle power to the machine. If the I-Fold software still will not start up

contact your local dealer for support.

Shut down procedures

It is very important to shut down the I-Fold properly before

turning off the machine. Before powering down the machine press the

button to start the power down procedure. A pop up box will

appear asking if you are sure you want to power down. Press OK.

From this point the power down is automatic. Once the screen reads it

is OK to turn off your computer you can shut down the machine.

Cleaning Touch Screen computer

It is very important to shut down the I-Fold computer before

cleaning the computer screen. Use a CRT screen cleaner ONLY on the

interface touch screen.

Warranty Note

WARNING – Damage to the computer screen will occur if

any instrument other than the operator’s finger is used to navigate

the I-Fold screens. NOTE: Warranty on the computer will be void

if this is found to be the case for computer failure.

Page 20

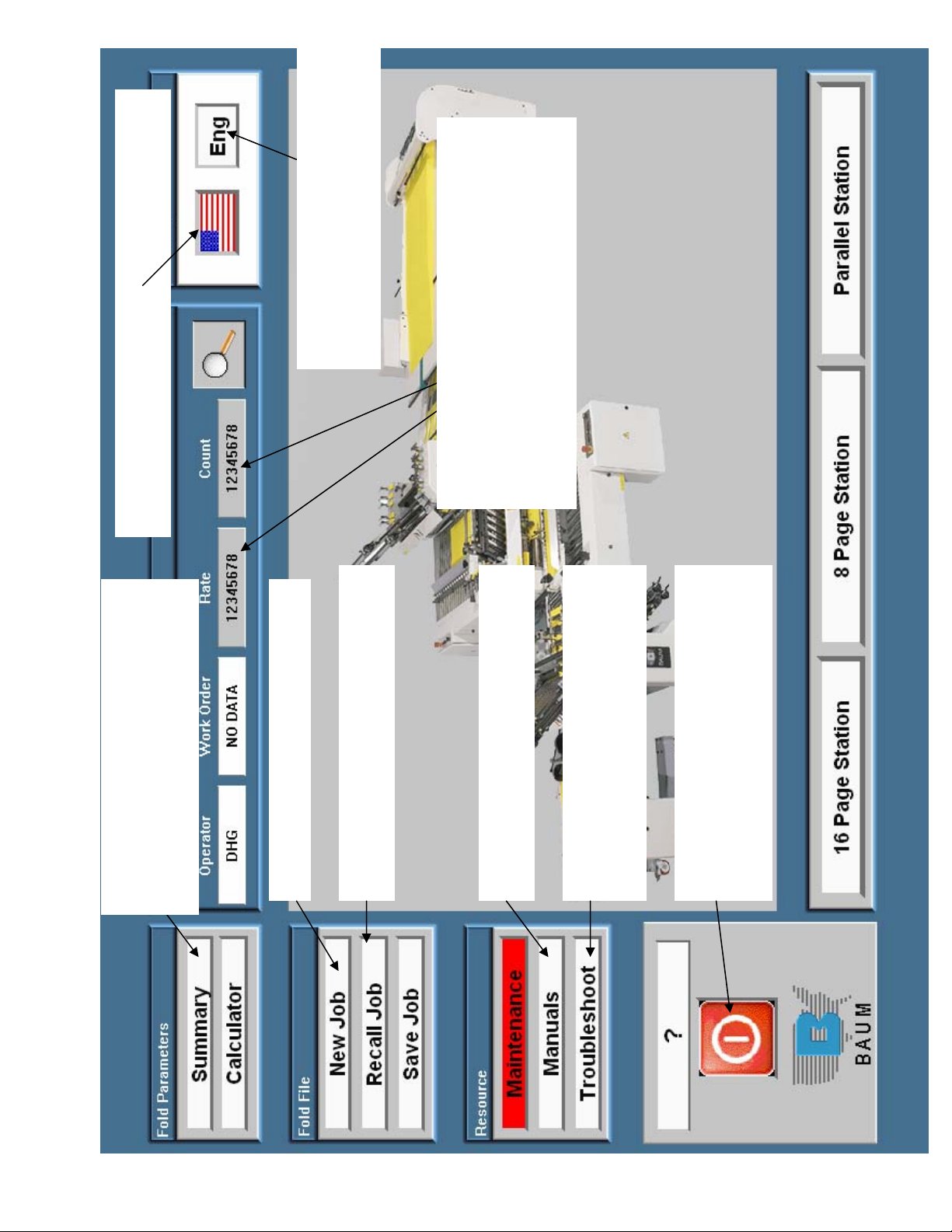

Touch this button to change from

Page 18 of 45

TP10497

standard, decimal, standard fractional

or metric.

This shows the count and rate from the

machine display. This is reset from the

machine control panel (see the operators

manual for instructions). Touch the numbers

in the count box to make the count display

larger and touch it again to change it back.

Touch this button to change the language. English,

Spanish, German or French.

Touch this button to go to the

summary screen for the current job.

The summary screen shows all of your

settings and any notes you want to add

Touch this button to setup a new job

Touch this button to recall a previously

saved job

Touch this button to see parts and

operators manuals for your machine.

Touch this button for troubleshooting

help with any problems you may be

having

Touch this button before turning off

the machine. Once the screen says it is

safe to turn off your computer then

you can turn off the machine

Page 21

nd

Page 19 of 45

TP10497

Touch this button to bring up

a job calculator that will help

you determine how long a job

will take.

When this box is red it indicates

you have made a change to the

setup. This change will be lost if the

system is powered down. If you

would like to save this change touch

this button

When this box is red it indicates

there is a maintenance item that

needs your attention. You can

touch this button anytime to see

recommended maintenance items

and how to do them.

station) the buttons will not be displayed.

rd

station) or a 16 page(3

section. You can also make changes to these settings if necessary. If you do not have an 8 page(2

Touch these buttons to see the current settings for the fold plates and Baumsets for the indicated fold

Page 22

Page 20 of 45

TP10497

This box contains the current work order.

Touch the box to enter a new work order.

When you touch the box a keyboard will pop

up, Just enter the work order and touch enter.

This box contains the initials of the operator

currently logged on. ??? indicates no

operator is currently logged on. Touch the

box to log on. A keyboard will pop up.

If this is the first time you have logged on touch the

NEW button then type your name and touch enter. It

will ask for a password, if you do not enter a password

at this time you will never be ask for one in the future.

If you type a password and touch enter you will need

to enter this password every time you log in. If you

have logged in before just type in your initials and

touch enter then type in a password and touch enter if

necessary.

Page 23

Page 21 of 45

TP10497

in the box to the left.

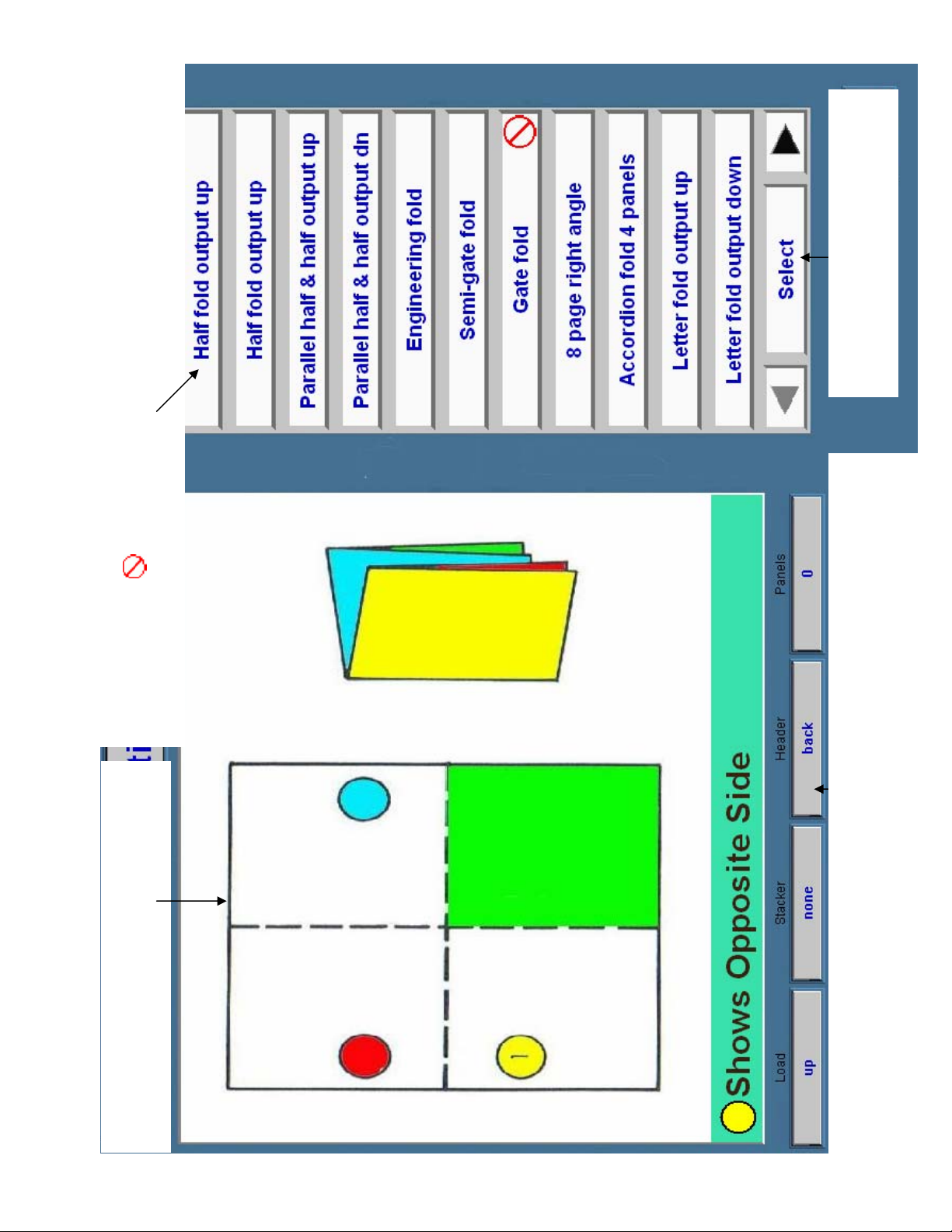

Press here to select the fold displayed

This box show the available folds. Touch a button to see the fold in the box on the left.

Touch the ► Arrow at the bottom of the page to see the next pages. Press the ◄ to come

back to this page. A on the button indicates the fold is not possible with you current

configuration.

circle indicates the opposite side

This box shows the selected fold. A color in a

determine for the selected fold.

and the label will come out face up on the stacker. Panels indicates the number of panels in a

Paper orientation shows how to load the paper and how the address or label will come out on

the stacker. Example: Load the address or label down and forward (toward the sucker wheel)

roll or accordion fold. If the stacker display shows none, the output on the stacker is difficult to

Page 24

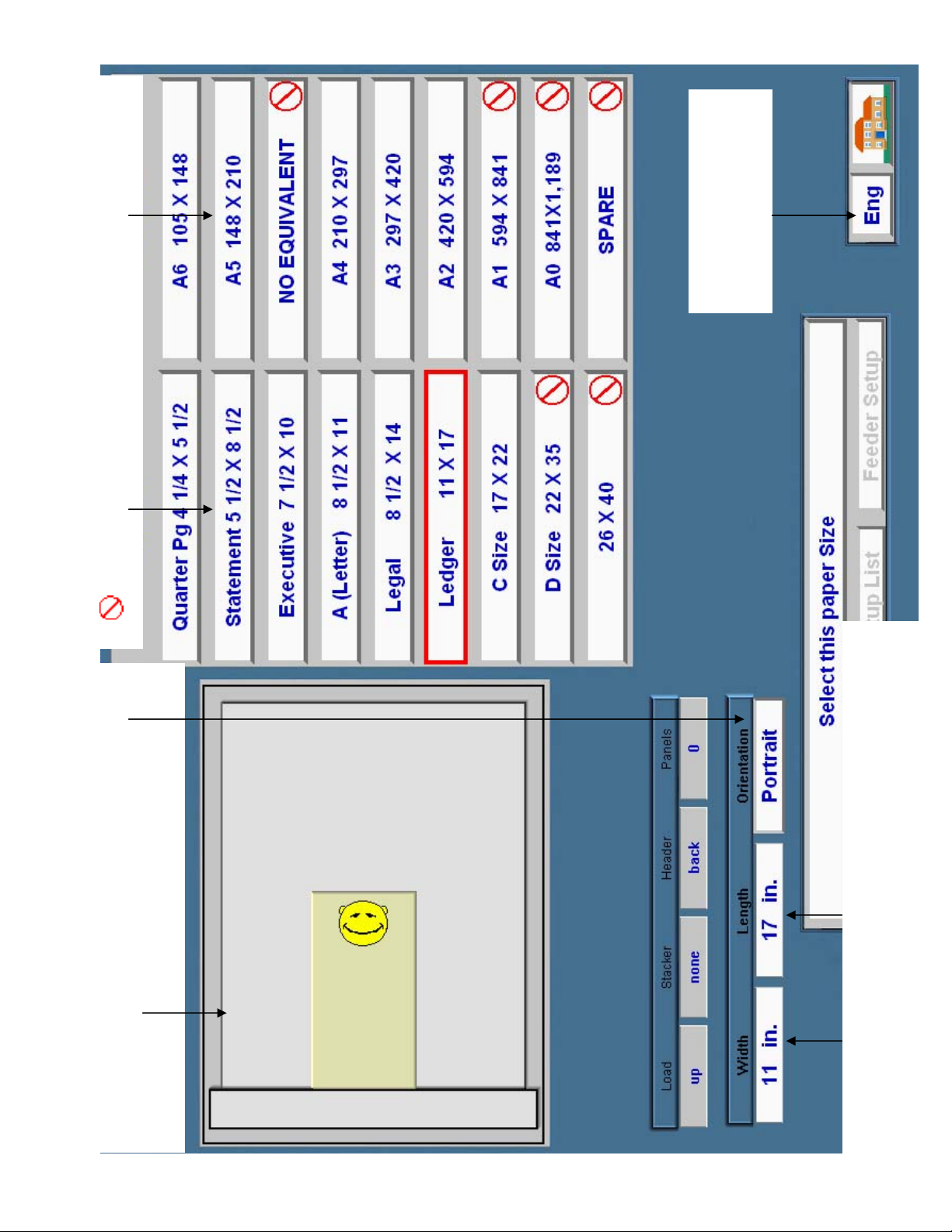

Touch one of these boxes to select a paper size.

Page 22 of 45

TP10497

A on the button indicates that paper size will not run on your machine

from inch to metric

Touch this box to change

button.

down and forward). You can change this from portrait

(shown) to Landscape and back by touching the orientation

This box shows how the paper is loaded (label or address face

size. Do this for both the width and length.

a keypad will pop up. Using the keypad enter the paper custom paper

Touch these boxes to enter a custom paper size. When you touch a box

Page 25

the main screen.

Page 23 of 45

TP10497

Touch this button to go to

feeder setup screen.

Touch this button to go to the

activate the see setup list and to feeder setup buttons.

and orientation to fold/paper setup completed. This will also

been selected. The text will change from select this paper size

Touch this box once the desired paper size and orientation have

setup list is explained on the next page.

Touch this button to see the setup list. The

the summary screen.

Touch this button to go to

Touch this button to go back

to the fold select screen.

Page 26

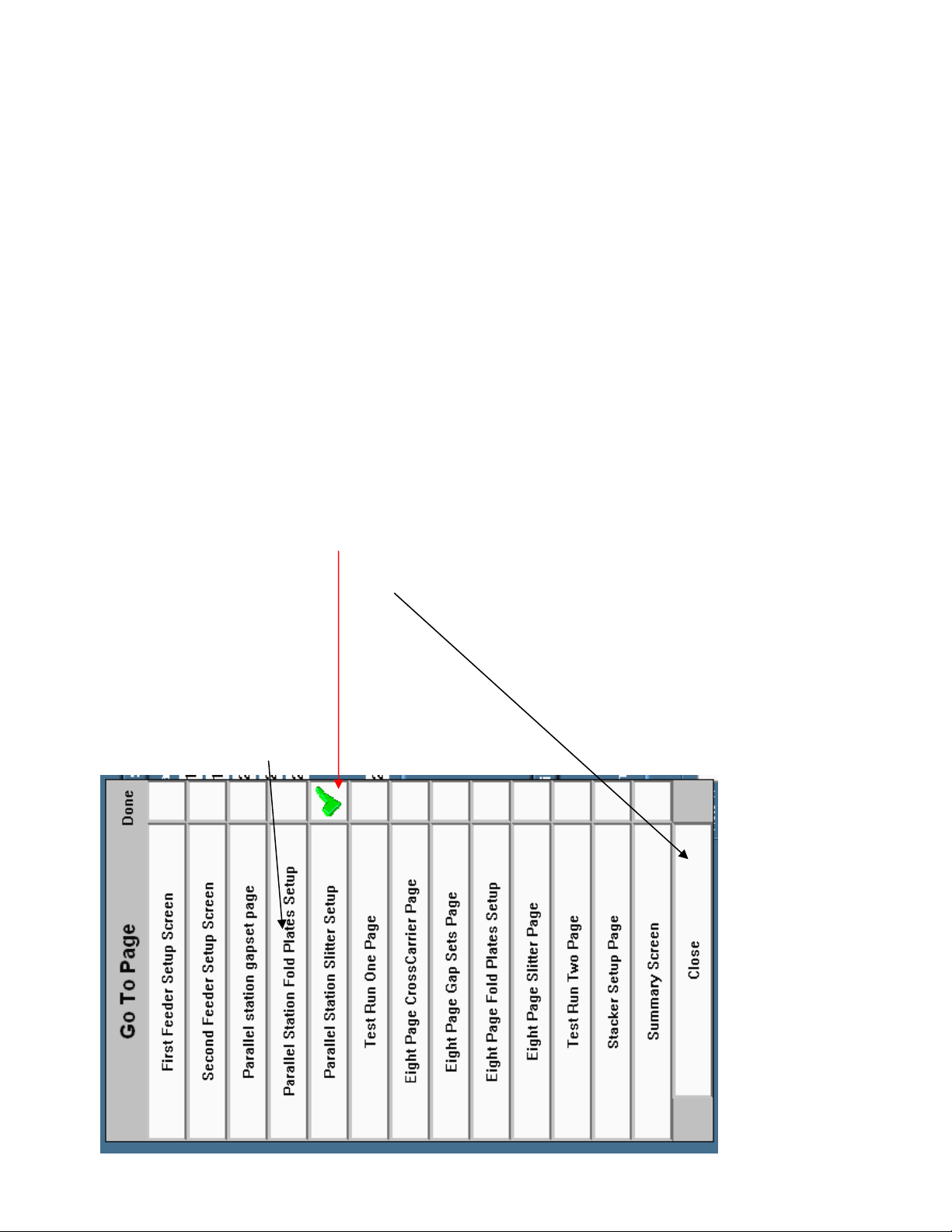

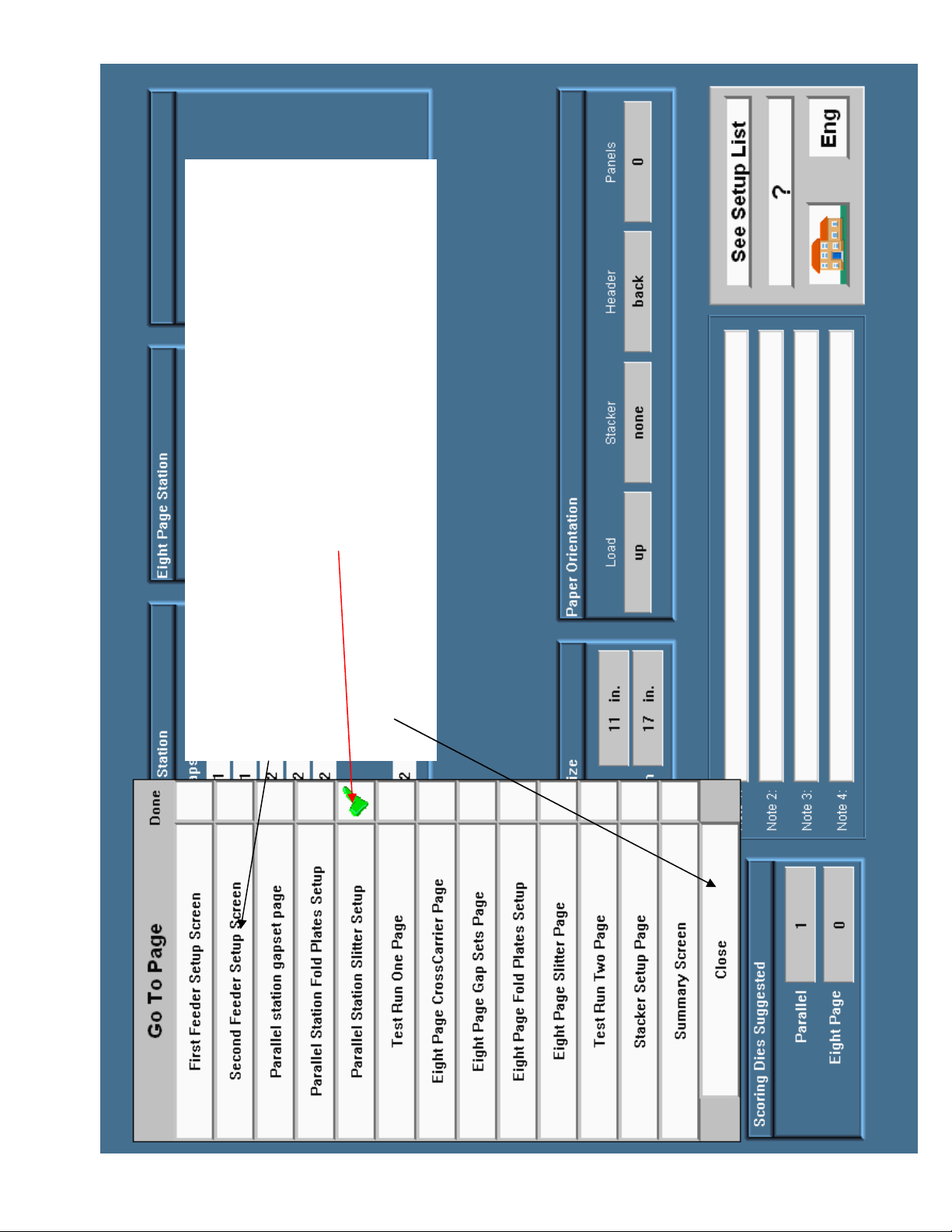

This will come up on the left of any setup screen when the see setup list

Page 24 of 45

TP10497

button is touched. This list shows all of the setup screens needed for the

selected fold. You can go to any screen on the list just by touching the

corresponding button. The done button shows a green checkmark when the

page is completed and the press when setup complete button has been

touched. This can help you keep track of where you are in the setup of the

job. You can also set the done button to a green checkmark by touching it

when this list is up. To close the setup task list without going to a different

page just touch the close button.

Page 27

save job screen.

Page 25 of 45

TP10497

the setup list. The setup

Touch this button to see

list is explained on page 4.

needs 1 sheet of paper and fold plate number 1 is set to 8 ½ inches to do the selected fold. Touch

blue or gray boxes indicate the fold plate setting. Example: On the parallel station gapset number 1

station required to do the selected fold. The black boxes indicate the gapset and fold plate numbers,

These areas show the number of sheets that go under each gapset and the fold plate settings for every

the dark blue boxes indicate the number of sheets that go under the corresponding gapset and the light

you can make any changes needed to the number of sheets in the gapsets or the fold plate settings.

anywhere in each area and it will take you to the corresponding adjustment screen, from that screen

This area shows the feeder settings.

Where to set the non-operator side paper

guide and the blow tube settings.

This area shows the suggested scoring

dies for each station to run the selected

fold.

blue box under the fold saved name to go to the

is saved what name it is saved under. Touch the

This area shows the current fold selected and if it

Page 28

Page 26 of 45

TP10497

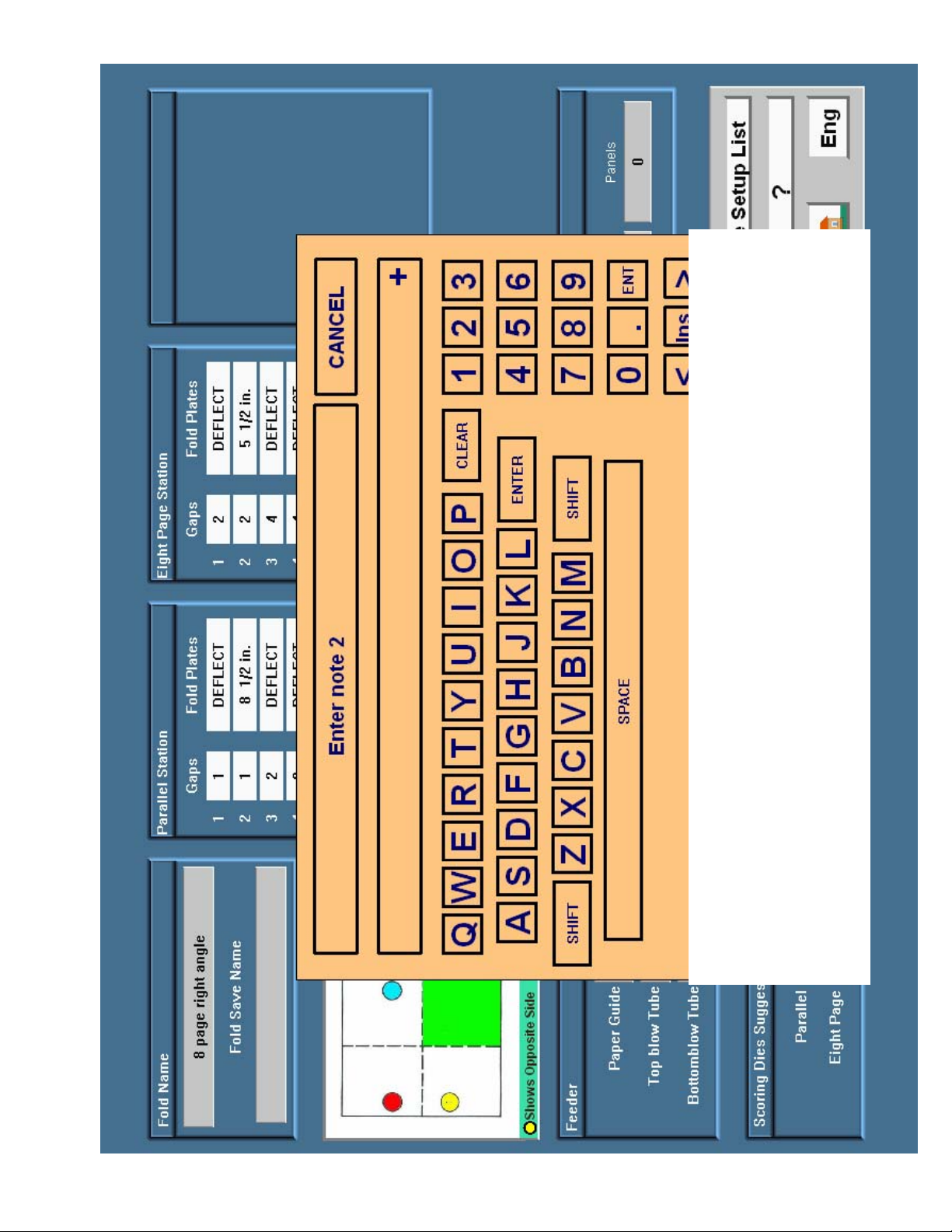

In this area you can enter up to 4 notes with up to 55 characters per note to be saved with a fold job. These

could contain information like what speed it ran best at if it needed a slit or a perf and what type of perf. To

enter a note just touch one of the gray lines next to a note: and a keypad will pop up (see the next page).

Page 29

r

Page 27 of 45

TP10497

button or the Ent button.

Use the keypad to enter a note, the clear button will clear everything in the display, this is

recommended if you are entering a new note. The Ins/Del button is used to control what happens

when you touch the arrow buttons. If the button displays Ins you are in insert mode the < and >

buttons will move the curser left or right then anything you type will be inserted where ever the

curser is located. If you Touch the button it will change to Del now you are in delete mode, if you

touch the < button it will delete the character to the left of the curser and if you touch the >

button it will delete the character to the right of the curser. After you are finished typing your note

touch the Ente

Page 30

Page 28 of 45

TP10497

This will come up on the left of any setup screen when the see setup list

button is touched. This list shows all of the setup screens needed for the

selected fold. You can go to any screen on the list just by touching the

corresponding button. The done button shows a green checkmark when the

page is completed and the press when setup complete button has been

touched. This can help you keep track of where you are in the setup of the

job. You can also set the done button to a green checkmark by touching it

when this list is up. To close the setup task list without going to a different

page just touch the yellow close this window button.

Page 31

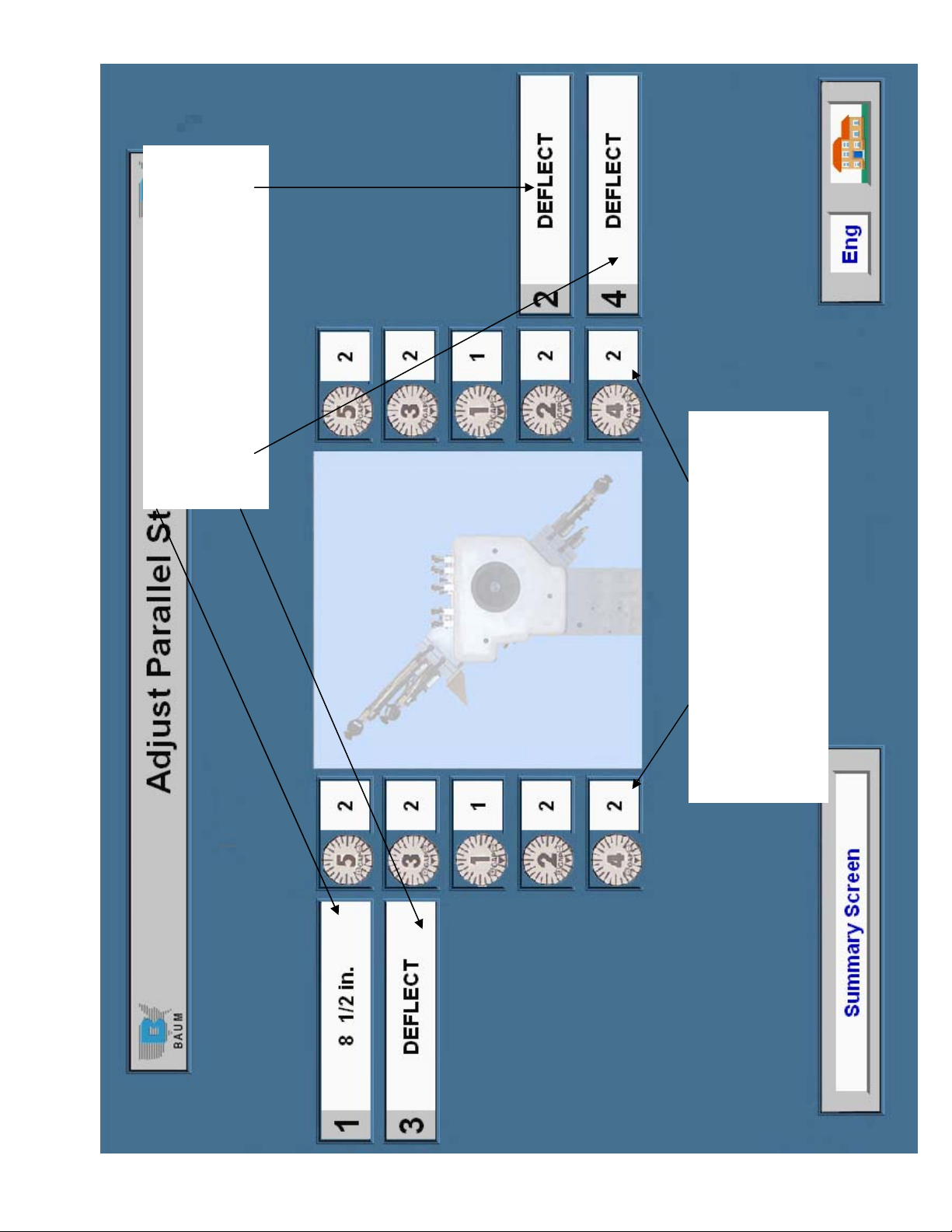

4 boxes show the settings for the fold plates.

Page 29 of 45

TP10497

To make a change to one of the settings just

touch the box you wish to change and a

keypad will pop up. This is shown and

explained on page 2.

These rows of boxes shows the number of sheets

to be placed under the gapsets. In this example

gapset 4 gets 2 sheets. To make a change to one

of the settings just touch the box you wish to

change and a keypad will pop up. This is shown

and explained on page 3.

Page 32

This line indicates the fold plate you are

Page 30 of 45

TP10497

making a change to

This is the current setting (0 or blank =

deflect). If a number is displayed touch the C

to clear it then enter the desired number. The

BK SP button will clear the last number

entered. Touch done when you have finished.

Page 33

This line indicates the gapset you are making

Page 31 of 45

TP10497

a change to.

This is the current setting touch the C to clear

it then enter the desired number. Touch done

when you have finished.

Page 34

These boxes tell you how many

Page 32 of 45

TP10497

days are left until the maintenance

item needs done. The grease

canister is fixed all the others can

be set as desired.

After the maintenance is

preformed touch the box to reset

the timer.

Press this to return to the main

screen

Use the numbers to enter the time interval

for the selected maintenance item then

press done. Enter zero to turn off the

selected timer.

Touch one of these boxes to set the timer for the maintenance item to the

right of that box. When you touch the box a keypad will pop up.

Click on any of these boxes to see how to

perform a maintenance item

Page 35

Page 33 of 45

TP10497

or metric.

decimal inch, fractional inch

Touch this box to change the

sheet separation display from

sheet gap.

Touch this box to enter the

per minute.

or metric.

sheet length display from

decimal inch, fractional inch

Touch this box to change the

Touch this box to enter the

current selected sheet length.

sheet length. The default is the

other down time.

Not including setup or any

will take to run the entire job.

This box displays how long it

Touch here to change the

folder speed display from

meters per minute to inches

out how to read the current folder speed.

speed. Touch the SEE HOW button to find

Touch this box to enter the folder speed you

plan to run the job. The default is 60% of full

per hour.

This box displays the sheets

total job size.

Touch this box to enter the

per minute.

This box displays the sheets

Page 36

1 1

Page 34 of 45

TP10497

REV:

SHEET OF

ASSEMBL Y NUMBER:

IFOLD DISPLAY MOUNTING LOCATION

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 37

1 2

Page 35 of 45

TP10497

REV:

SHEET OF

FK2001484

ASSEMBL Y NUMBER:

IFOLD DISPLAY ADAPTOR KIT

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 38

2 2

Page 36 of 45

TP10497

REV:

SHEET OF

FK2001484

ASSEMBL Y NUMBER:

IFOLD DISPLAY ADAPTOR KIT

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 39

1 2

Page 37 of 45

TP10497

REV:

SHEET OF

FK2001485

ASSEMBL Y NUMBER:

IFOLD DISPLAY MOUNT

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 40

2 2

Page 38 of 45

TP10497

REV:

SHEET OF

FK2001485

ASSEMBL Y NUMBER:

IFOLD DISPLAY MOUNT

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 41

1 2

Page 39 of 45

TP10497

REV:

SHEET OF

FK2001370

ASSEMBL Y NUMBER:

DISPLAY-ENCLOSURE

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 42

2 2

Page 40 of 45

TP10497

REV:

SHEET OF

FK2001370

ASSEMBL Y NUMBER:

DISPLAY-ENCLOSURE

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 43

1 2

Page 41 of 45

TP10497

REV:

SHEET OF

FK2001426

ASSEMBL Y NUMBER:

IFOLD DISPLAY MOUNT

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 44

2 2

Page 42 of 45

TP10497

REV:

SHEET OF

FK2001426

ASSEMBL Y NUMBER:

IFOLD DISPLAY MOUNT

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 45

1 1

Page 43 of 45

TP10497

REV:

SHEET OF

FK2001500

ASSEMBL Y NUMBER:

CABLE ASSY. POWER

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 46

1 1

Page 44 of 45

TP10497

REV:

SHEET OF

FK2001501

ASSEMBL Y NUMBER:

CABLE ASSY. COMMUNICATIONS

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Page 47

1 1

Page 45 of 45

TP10497

REV:

SHEET OF

FK7600179

ASSEMBL Y NUMBER:

SCHEMATIC-IFOLD

IFOLD DISPLAY

DESCRIPTION:

UNIT NAME:

BAUMFOLDER

CORPORATION

Loading...

Loading...