Page 1

BA U

M

BAUM 2020

1ST STATION FOLDER W/PILE FEED

INSTRUCTION MANUAL

©Baumfolder Corp., 2006 Printed in U.S.A. TP10243-5

PAGE 1 TP10243-5

Page 2

© 2006 BAUMFOLDER CORPORATION

All Rights Reserved

WARNING

• Do not operate this machine without all guarding in place.

• Do not make adjustments or perform maintenance on this machine with power on.

• Keep the machine and the work area clean and free of spills to prevent accidents.

• Be sure to replace any safety decals that may have been detached for any reason.

Baumfolder Corporation reserves the right to make changes in design or to make additions or

improvements in its products without imposing any obligation upon itself to install them on its

previously manufactured products. It is recommended that modifications to this equipment not be

made without the advice and express written consent of Baumfolder Corporation.

FOLDER IDENTIFICATION

MODEL NO: _______________________________ SERIAL NO: _____________________________

SALES AGENCY:____________________________________________________________________

INSTALLED BY: _____________________________________________ DATE: ________________

PHONE NO: _______________________________

TP10243-5 PAGE 2

Page 3

CONTENTS

DESCRIPTION PAGE

I.) Safety .................................................................................................................................................................. 6

II.) Introduction Overview ........................................................................................................................................ 7

III.) Transportation/Installation ................................................................................................................................7

IV.) Squaring the Machine ........................................................................................................................................ 7

V. ) Electrical Connections ....................................................................................................................................... 8

1.0 .Wiring the Pump (3 phase) ................................................................................................................... 8

1.1. Wiring the Pump (1 phase).................................................................................................................................8

1.2. Other Connections ............................................................................................................................... 8

1.3 .Tapping the Transformer ...................................................................................................................... 9

1.4 .Pump Connections ................................................................................................................................9

VI.) "QUICK START" INSTRUCTION'S .............................................................................................................. 10

V II .) Installing Fold Plates & Stacker Delivery ...................................................................................................... 21

VIII.) Operator Controls ............................................................................................................................................ 21

1.0 .Setting Folding Speed ......................................................................................................................... 21

1. 1 .Setting Stacker Belt Speed...................................................................................................................21

1.2 .Emergency Stop Button.......................................................................................................................21

1.0 Control Panel BAN-5................................................................................................................................ 22

1.1 .Displays...............................................................................................................................................22

1.2 . Machine Status Indicators .................................................................................................................. 22

1.3 . Machine Control Pushbuttons ............................................................................................................22

1.4 .Keypad Buttons with Selection Indicators .......................................................................................... 23

1.5 .Keypad Buttons for Selection Adjustments ........................................................................................ 23

2.0 RUN MODE FUNCTIONS ................................................................................................................................23

2.1 .Machine Setup and Diagnostic Mode................................................................................................. 23

2.2 .Counter Setup Mode ........................................................................................................................... 27

2.3 .Easy Mode and Continuous Cycle Mode ........................................................................................... 28

2.4 .Learn Mode ......................................................................................................................................... 28

2.5 .Make Ready Mode .............................................................................................................................. 29

2.6 .Network Job Mode .............................................................................................................................. 30

2.7 . Production Mode ................................................................................................................................ 30

3.0 LOGIC BOARD STATUS INDICATORS ............................................................................................................. 31

4.0 Process Variables Definitions.................................................................................................................. 32

4.1 .Total Input Count ................................................................................................................................ 32

4.2 .Total Output Count ............................................................................................................................. 32

4.3 .Batch Down Count .............................................................................................................................. 32

4. 4 .Number of Batches .............................................................................................................................. 32

4. 5 .Current Rate......................................................................................................................................... 32

4. 6 .Main Drive Run Time .......................................................................................................................... 32

4.7 .Main Drive Velocity.............................................................................................................................32

4. 8 .Waste Count (DCT500) ....................................................................................................................... 32

5.0 COUNTER SETUP VARIABLES ....................................................................................................................... 32

5.1 .Batch Preset.........................................................................................................................................32

5.2 .Batch Output Type .............................................................................................................................. 32

5. 3 .Batch Output Time .............................................................................................................................. 33

5.4 .Sheet Length ....................................................................................................................................... 33

5. 5 .Gap Length .......................................................................................................................................... 33

5.6 .Suction Length .................................................................................................................................... 33

6.0 SYSTEM MESSAGES AND RUN MESSAGES ....................................................................................................... 34

6.1 .Power-Up Fault Messages .................................................................................................................. 34

6.2 .Run Time Fault Messages ................................................................................................................... 35

6.3 .Machine Run Error Messages ............................................................................................................. 36

PAGE 3 TP10243-5

Page 4

CONTENTS

DESCRIPTION PAGE

IX.) Pile Feeder Operation ...................................................................................................................................... 37

1.0 .Loading ............................................................................................................................................... 37

1.1 .Hold-down Locations .......................................................................................................................... 37

1. 2 .Air and Vacuum Setting.......................................................................................................................37

1.3 .Front Blow Tube Settings....................................................................................................................38

1.4 .Vacuum Wheel .................................................................................................................................... 38

X.) Register Operation .......................................................................................................................................... 39

1.0 .Double Sheet Detector ........................................................................................................................ 39

XI. ) Baumset Adjustment ........................................................................................................................................ 40

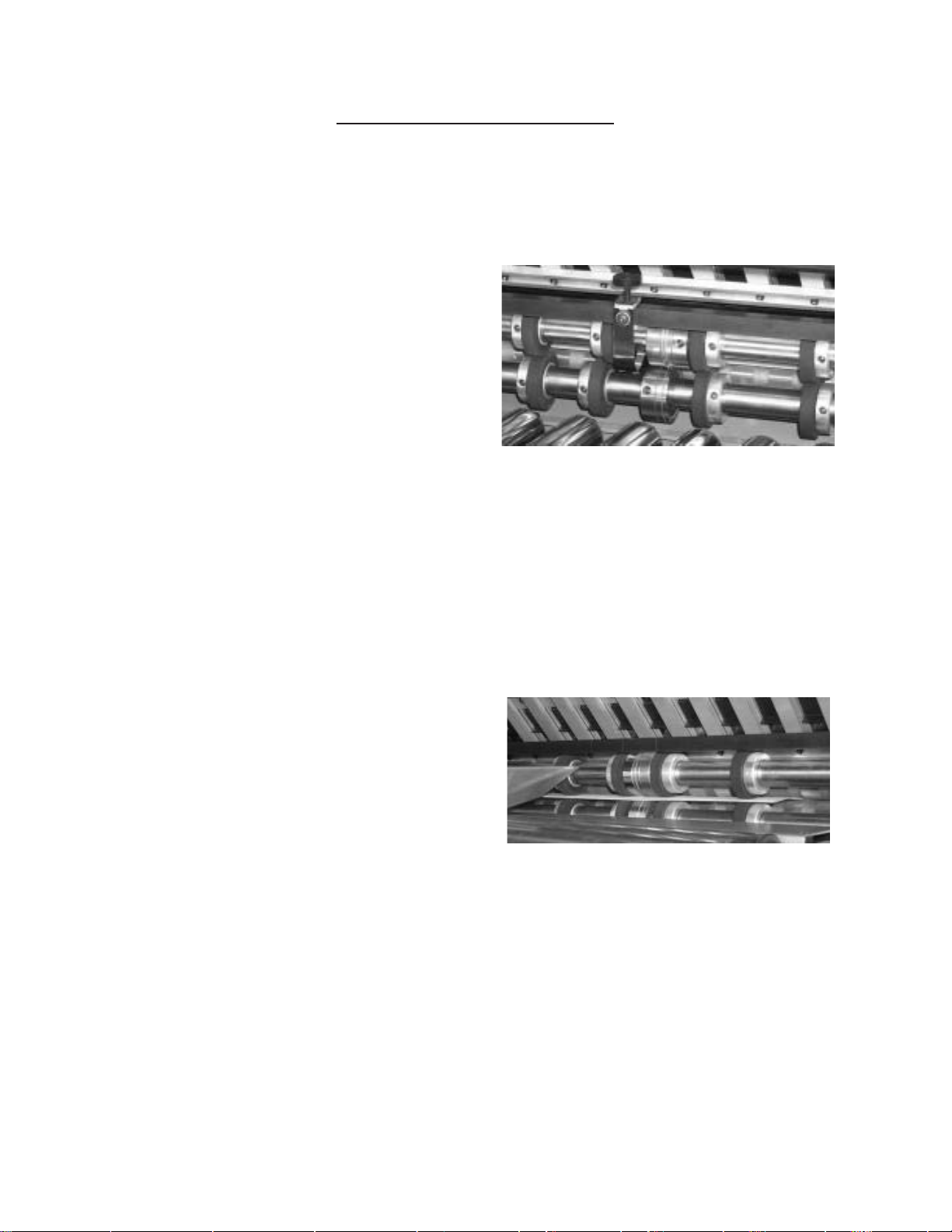

1.0 .Adjusting Folding Rollers ................................................................................................................... 40

XII.) Setting Fold Plates ........................................................................................................................................... 41

XIII.) Setting Deflectors ............................................................................................................................................ 41

XIV.) Stacker Operation ........................................................................................................................................... 42

XV.) Scoring/Slitting/Perforating........................................................................................................................... 43

1. 0 .Slitter Shaft Removal ........................................................................................................................... 43

1.1 .Scoring ................................................................................................................................................ 44

1.2 .Perforating ...........................................................................................................................................45

1.3 .Slitting ................................................................................................................................................. 46

1.4 . Trimming .............................................................................................................................................. 47

1. 5 .Trimming a Strip from Center of Sheet ................................................................................................. 48

1. 6 .Blade Installation................................................................................................................................. 48

XVI.) Lubrication/Maintenance ................................................................................................................................. 50

XVII.) Technical Specifications .................................................................................................................................. 51

XVIII.) Accessories ...................................................................................................................................................... 51

XIX.) Troubleshooting ............................................................................................................................................... 52

XX.) Operating Tips ................................................................................................................................................. 54

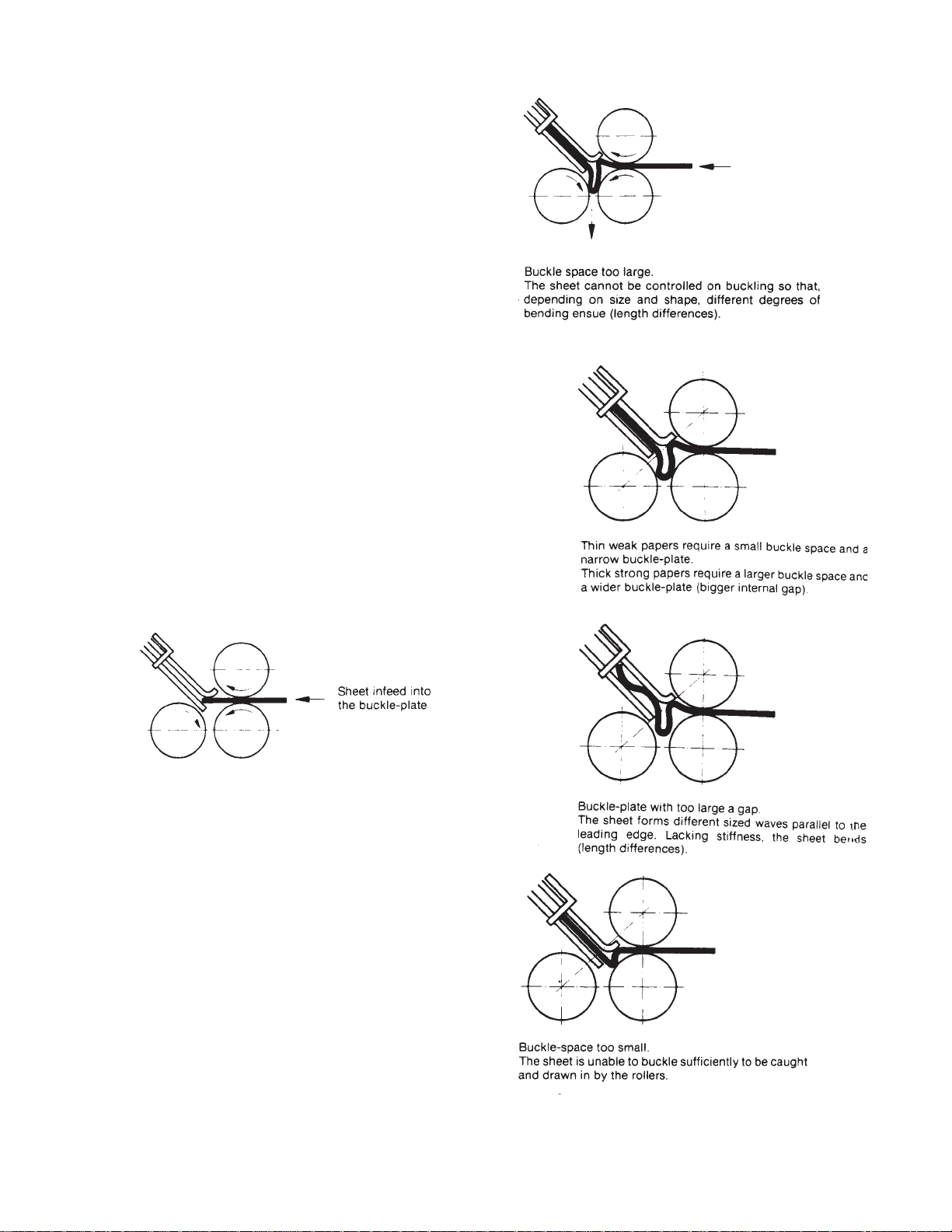

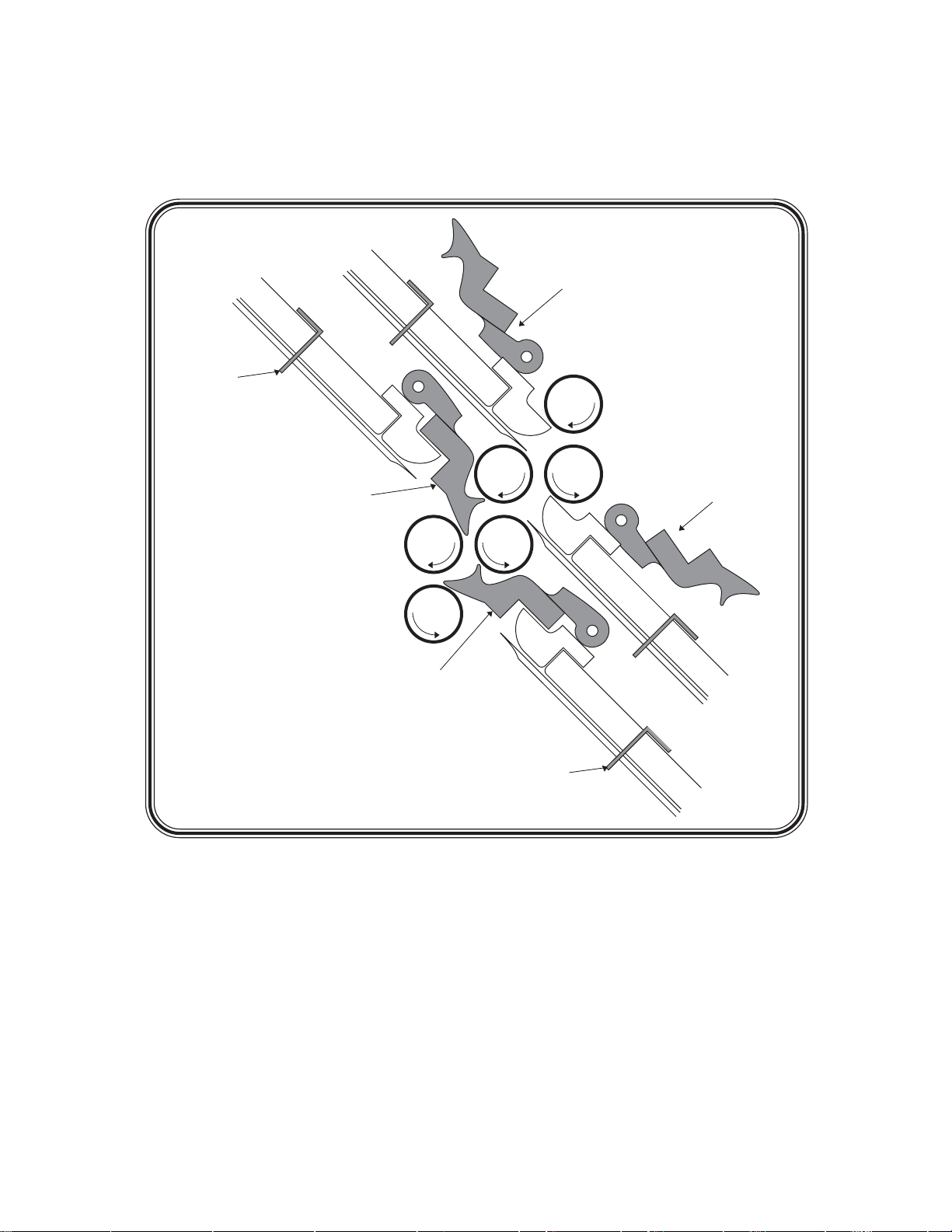

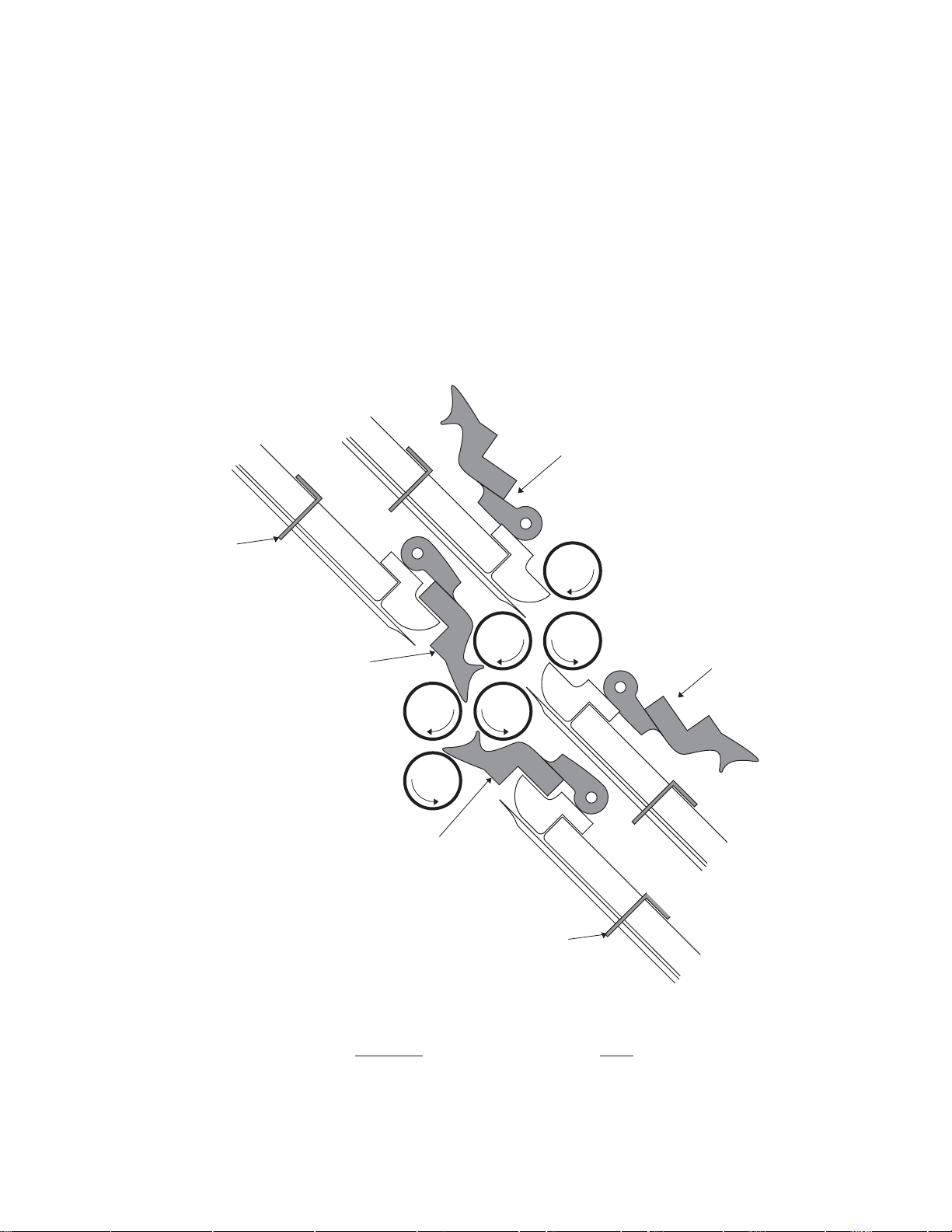

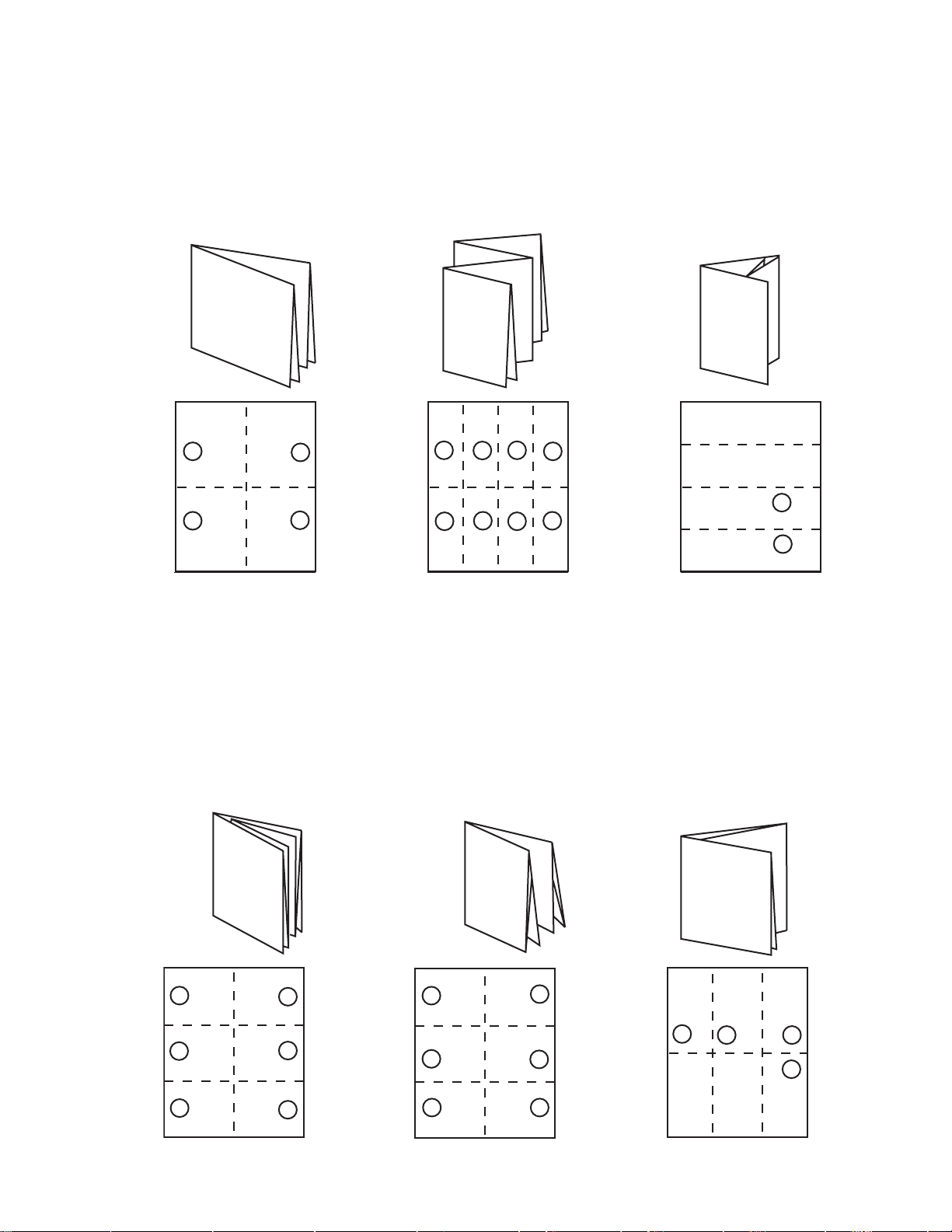

XXI.) Principles of Mechanical Folding .................................................................................................................... 56

XXII.) Job setup example ............................................................................................................................................. 57

XXIIi.) Folding Chart ................................................................................................................................................... 61

XXIV .) Manual Usage ................................................................................................................................................... 63

XX V.) T ypical Layout & Sheet Orientation ................................................................................................................ 64

XXVI.) Impositions ....................................................................................................................................................... 65

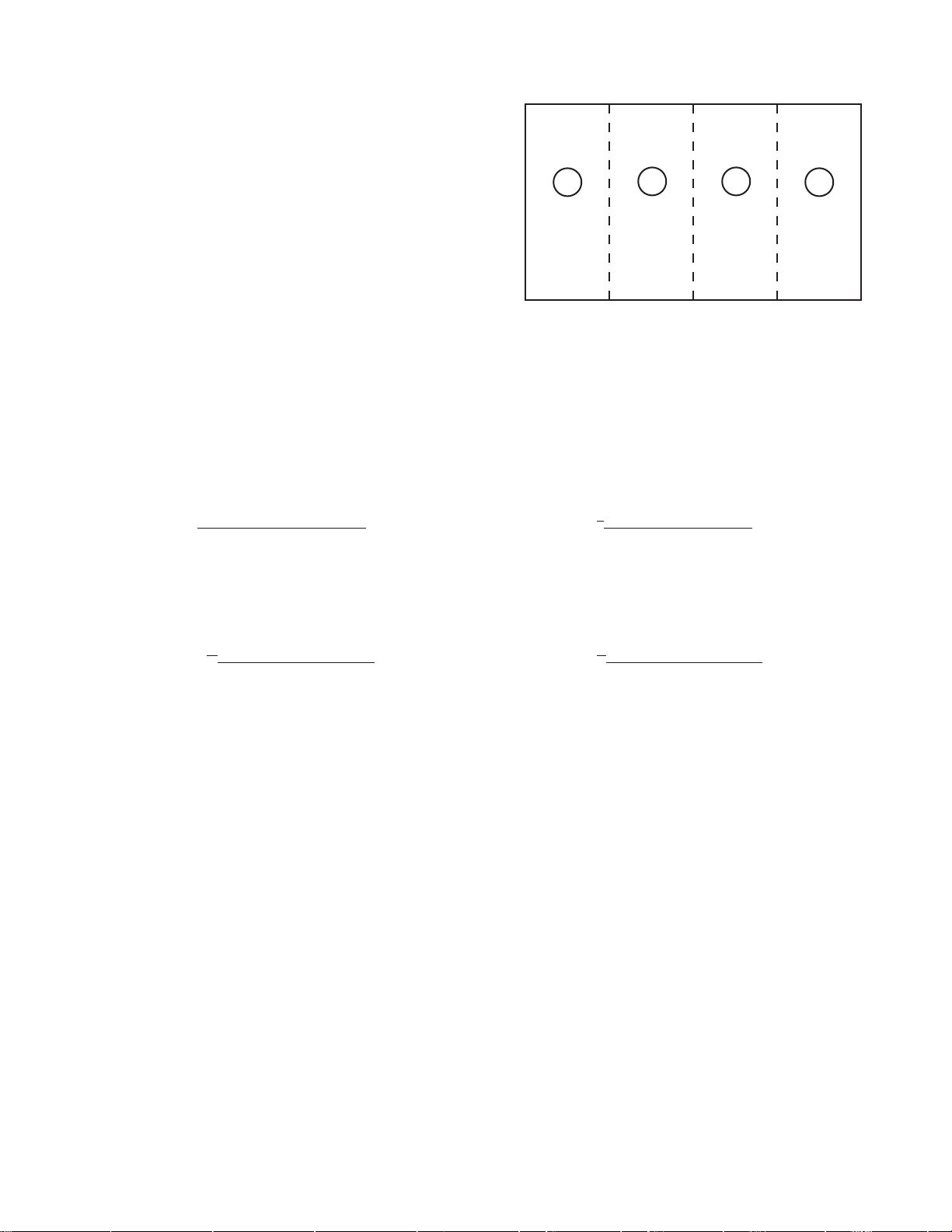

#1 4 - PAGE ............................................................................................................................................... 65

#2 4 - PAGE, DOUBLE IMPOSITION........................................................................................................65

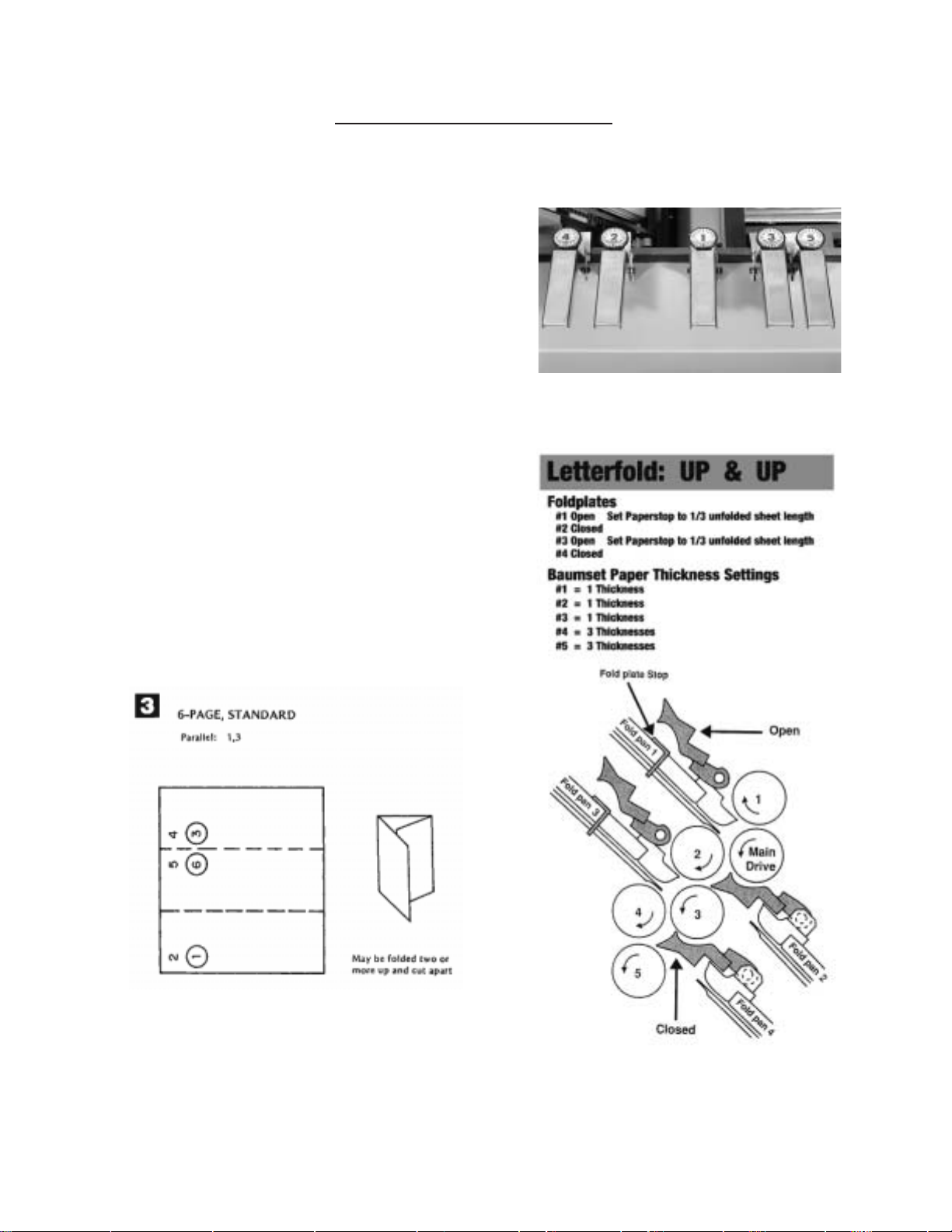

#3 6 - PAGE, ST ANDARD......................................................................................................................... 65

#4 6 - P AGE, ACCORDION ....................................................................................................................... 65

#5 8 - PAGE, P ARALLEL IMPOSITION .................................................................................................... 65

#6 8 - P AGE, RIGHT ANGLE ..................................................................................................................... 65

#7 8 - PAGE, RIGHT ANGLE OBLONG ..................................................................................................... 66

#8 8 - P AGE, RIGHT ANGLE DOUBLE IMPOSITION............................................................................... 66

#9 8 - P AGE, PARALLEL OVER & OVER .................................................................................................. 66

#10 12 - P AGE BOOK, SADDLE STITCH ................................................................................................... 66

#11 12 - P AGE BOOK, SADDLE STITCH ................................................................................................... 66

#12 12 - P AGE LETTER FOLD, HEADS OUT ............................................................................................. 66

#13 12 - P AGE LETTER FOLD, HEADS IN ................................................................................................. 67

#14 12 - PAGE LETTER FOLD, ACCORDION.............................................................................................67

#15 16 - PAGE, THREE RIGHT ANGLE BOOK IMPOSITION.................................................................... 67

#16 12 - P AGE FOLDER, HEADS OUT ....................................................................................................... 67

#17 24 - PAGE BOOKLET ........................................................................................................................... 67

#18 32 - PAGE BOOK..................................................................................................................................67

XXVII.) Service ............................................................................................................................................................ 68

TP10243-5 PAGE 4

Page 5

List of Tables

DESCRIPTION PAGE

Table 1. Machine Setup Parameter List "A" ........................................................................................................................ 24

Table 2. Machine Monitor Parameter List ............................................................................................................................ 24

Table 3. Machine Setup Parameter List "B" ......................................................................................................................... 25

Table 4. Machine Diagnostic Parameter List......................................................................................................................... 26

Table 5. Future Features List ................................................................................................................................................ 26

Table 6. Machine Usage Status Parameter List ..................................................................................................................... 27

Table 7. Output Type Animations ........................................................................................................................................ 27

Table 8. Count Source Selection ........................................................................................................................................... 28

Table 9. Learn Mode Status ................................................................................................................................................. 28

Table 10. Suction Mode Symbols ........................................................................................................................................ 29

Table 11. Suction Length Function ....................................................................................................................................... 29

Table 12. Determining the Large Display Contents............................................................................................................... 30

Table 13. Reset mode Selection............................................................................................................................................. 31

Table 14. LED Status Indicators............................................................................................................................................ 31

Table 15. Output Delay and Duration ................................................................................................................................... 33

Table 16. Power Up Fault Messages..................................................................................................................................... 34

Table 17. Run Time Fault Messages ..................................................................................................................................... 35

Table 18. Machine Run Error Messages ............................................................................................................................... 36

PAGE 5 TP10243-5

Page 6

SAFETY FIRST

10. Make sure that all safety devices are in place before

restarting the machine.

Your new Baum paper folding machine has been designed

in accordance with the latest safety specifications. The

warning and caution labels on the machine must remain in

place. Make sure all guarding provided is in place before

starting up and running the machine.

Due to the nature of the work process of paper folding

machines, there are parts and areas on the machine which

cannot be completely covered without interfering with the

operation of the machine. Therefore, sound personal work

habits and strict observance of all safety precautions is

required for the protection of the operator, co-workers, and

the machine.

Be sure to follow these

safety precautions:

1. Study the safety instructions at your plant and those

provided in this manual.

2. Study the operating instructions carefully before

operating the machine.

3. Make sure that your co-workers are familiar with the

work process, potential danger areas,

and all necessary safety measures.

11. Never clean moving parts of the machine (rollers,

shafts, etc.) or remove any test sheets or paper jams

while the machine is running.

12. Keep the floor around the entire machine clean.

Immediately clean up any oil, grease, or paint spills

from the floor. Remove tools, cleaning cloths, and

paper scraps from all work areas.

13. Never allow unauthorized personnel to make adjustments on the machine, remove problem sheets, or start

the machine.

14. Never climb over the machine or crawl into it while it is

turned on.

15. Immediately repair or replace any safety devices which

have become ineffective or are missing.

16. Report any exposed cables or exposed electrical

connections.

17. Always have a certified qualified electrician perform all

electrical maintenance.

18. Do not make adjustments or perform maintenance with

the power on.

4. Make sure that the machine is in good working order

before turning it on.

5. If the machine suddenly stops for whatever reason, do

not restart it right away. Someone may have stopped

the machine, but failed to press the emergency (Stop)

button. If the machine is restarted unexpectedly, your

co-worker could be seriously injured.

6. Always press the emergency (Stop) button first if you

stop the machine for adjustments or maintenance work

which must not be done while the machine is in

operation.

7. For extensive maintenance or repair work, turn off the

main power supply.

8. Never use improper or defective tools.

9. After making adjustments or after doing maintenance

or repair work, always make sure that all tools and

other objects are removed from the machine. Otherwise, they might fall into the machine, causing severe

damage or injuries.

19. Become familiar with and follow the safety labels on

the next page. Replace any of these labels that are

damaged or lost.

Additional Notes:

20. Do not attempt to remove a paper jam, no matter how

minor it may appear to be, while the machine is

running.

21. When cleaning the fold rolls, use the handwheel for

turning. Be sure the power to the machine is off.

22. Turn off the machine before making any adjustments to

the scoring, perforating, or slitting attachments. Keep

hands and clothing away from the slitter shafts when

the machine is running.

TP10243-5 PAGE 6

Page 7

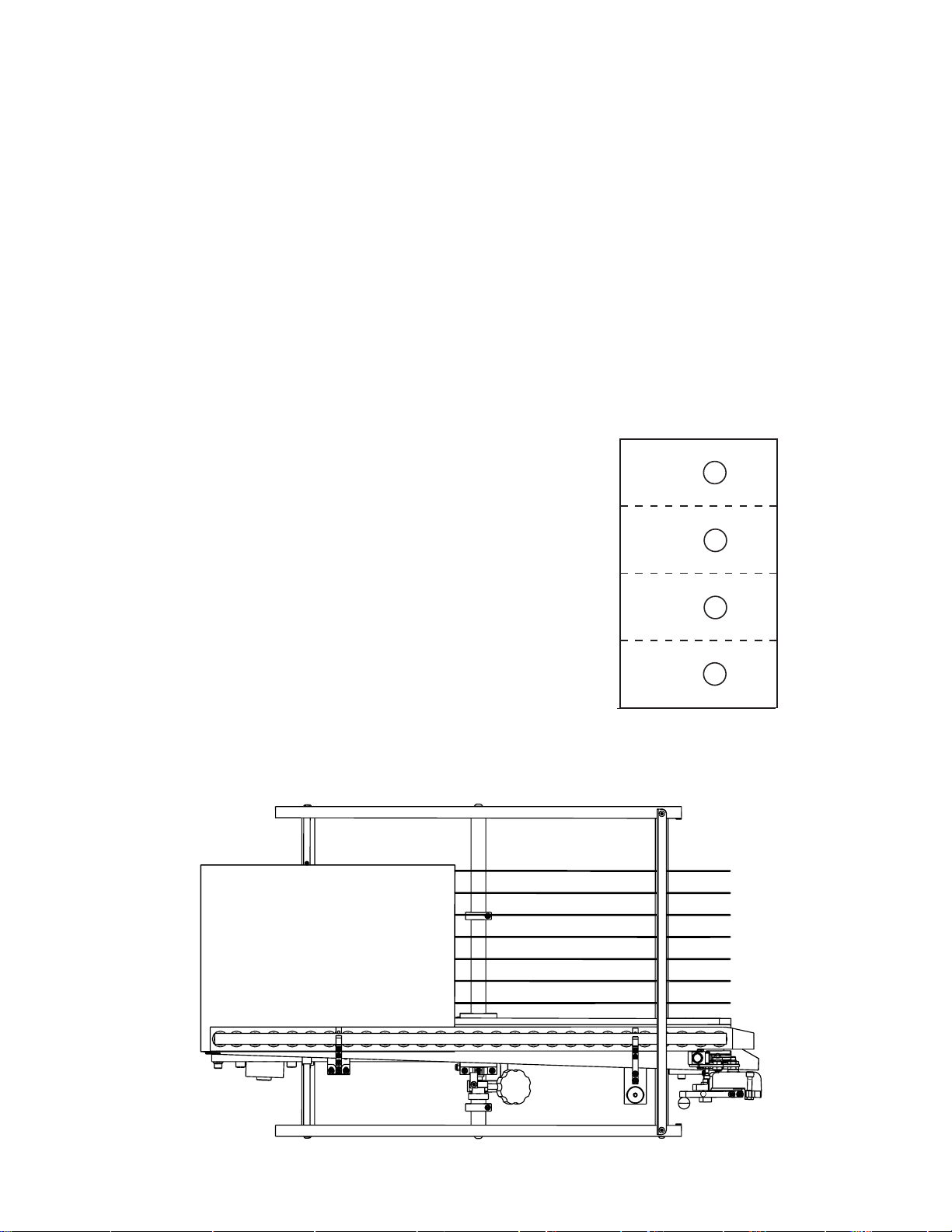

INTRODUCTION OVERVIEW

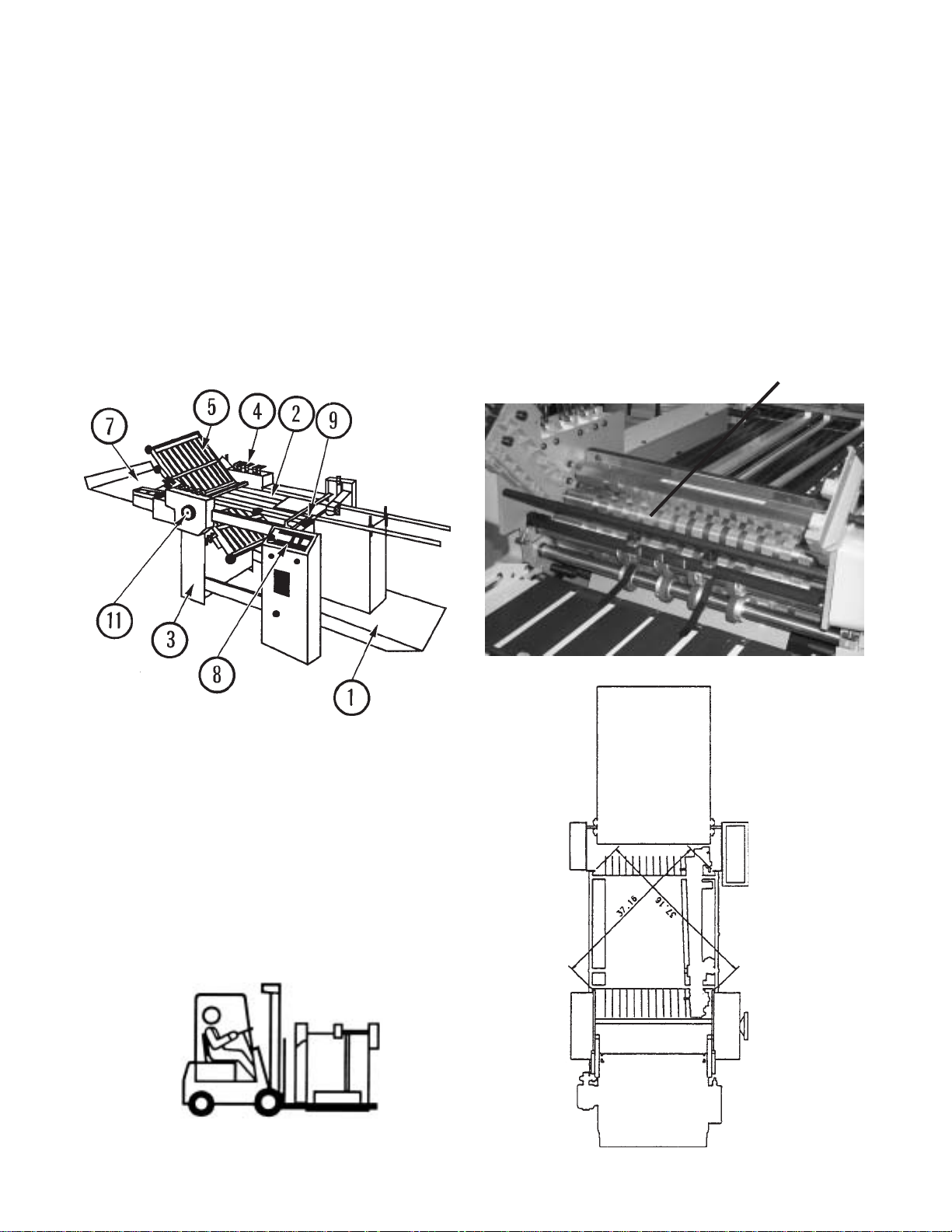

The 1st station [parallel] folder with pile feeder

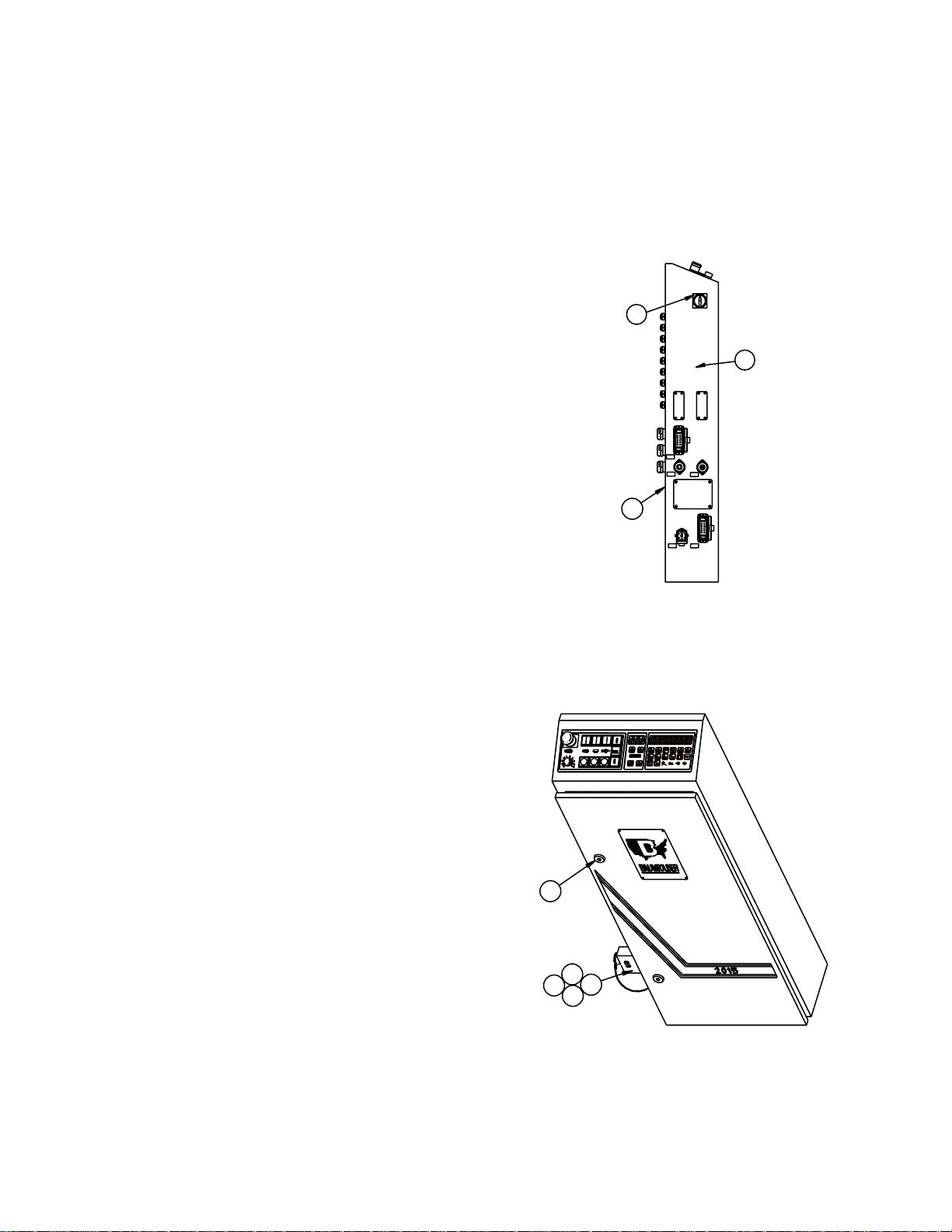

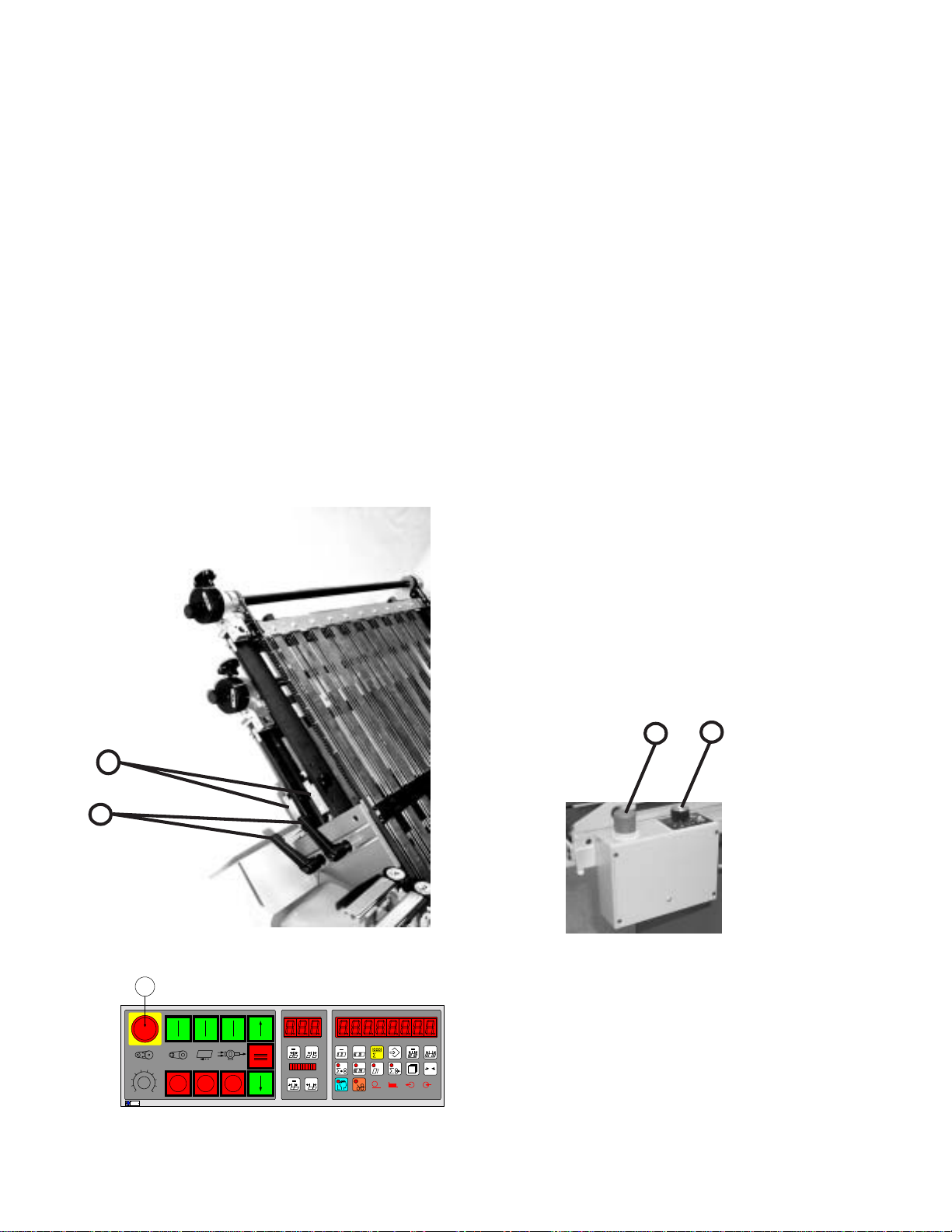

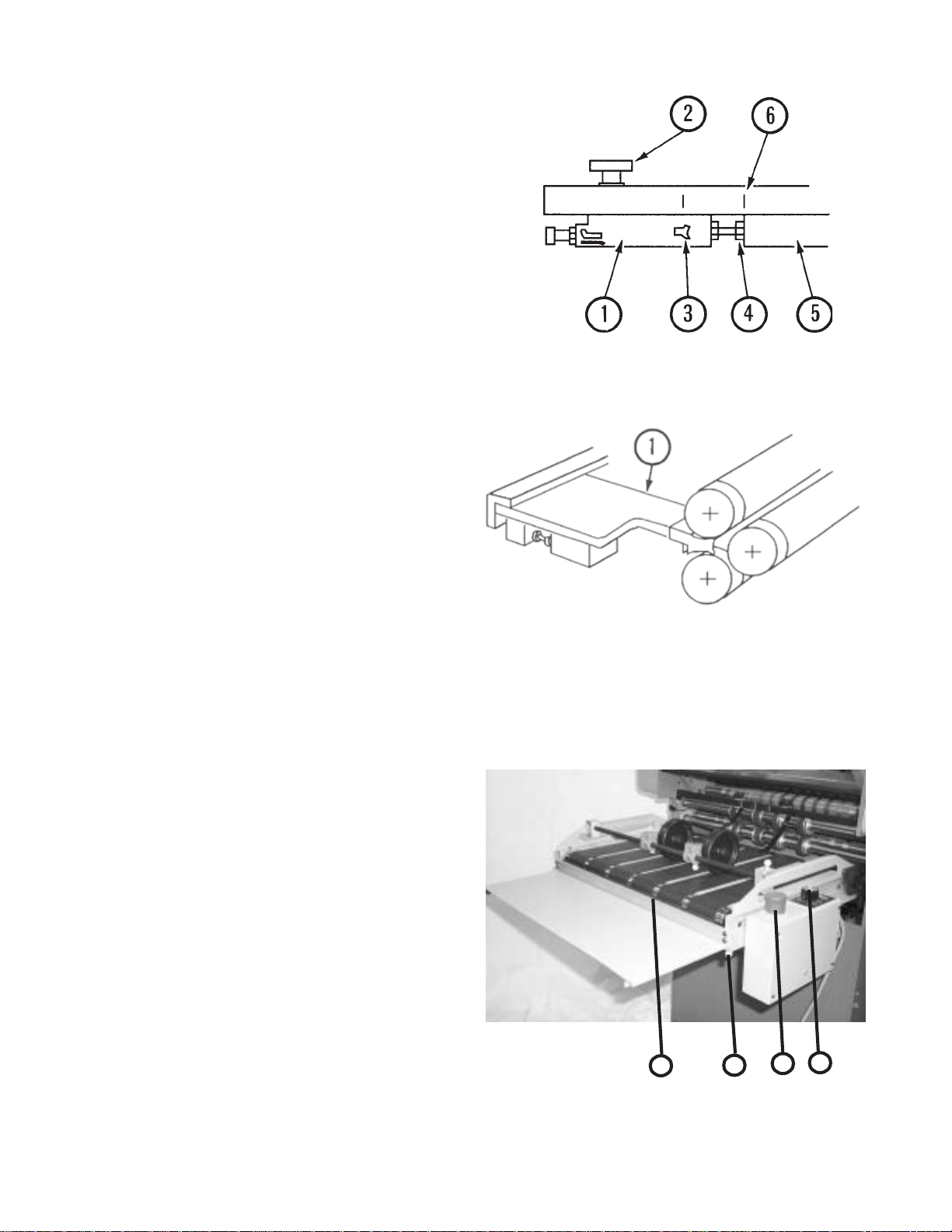

contains the following main components (Figure 1):

1. Pile Feeder

2. Register

3. 1st Station Folder (Parallel)

4. Fold Roller Gapsets

5. Fold Plates

6. Slitter Shafts (not shown)

7. Delivery (Stacker)

8. Operator Controls

9. Double Sheet Detector (Caliper)

10. Vacuum Pump (not shown)

11. Handwheel

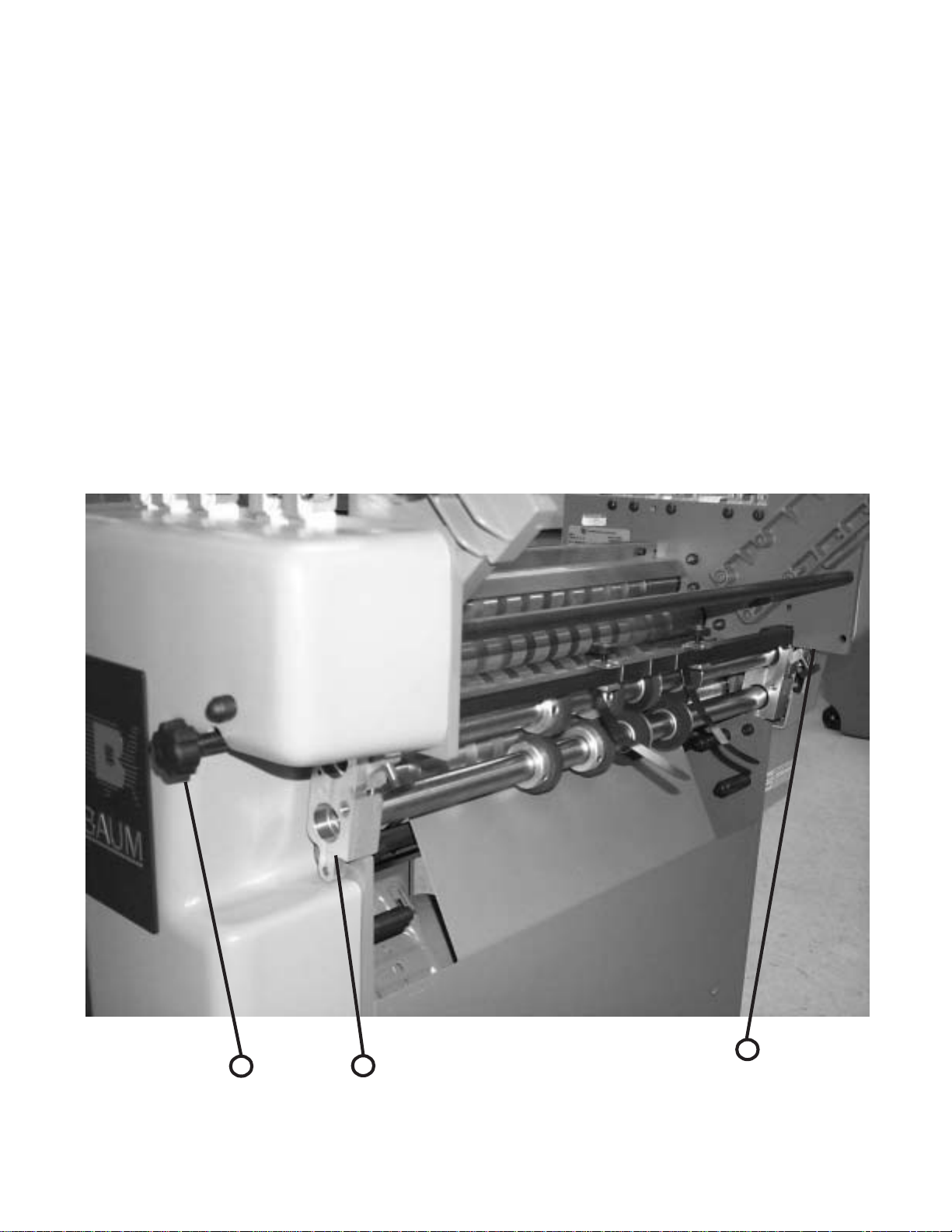

Level the machine on the floor. Place a spirit level on

the #2 fold roller (Figure 3) and on the feeder crossmembers.

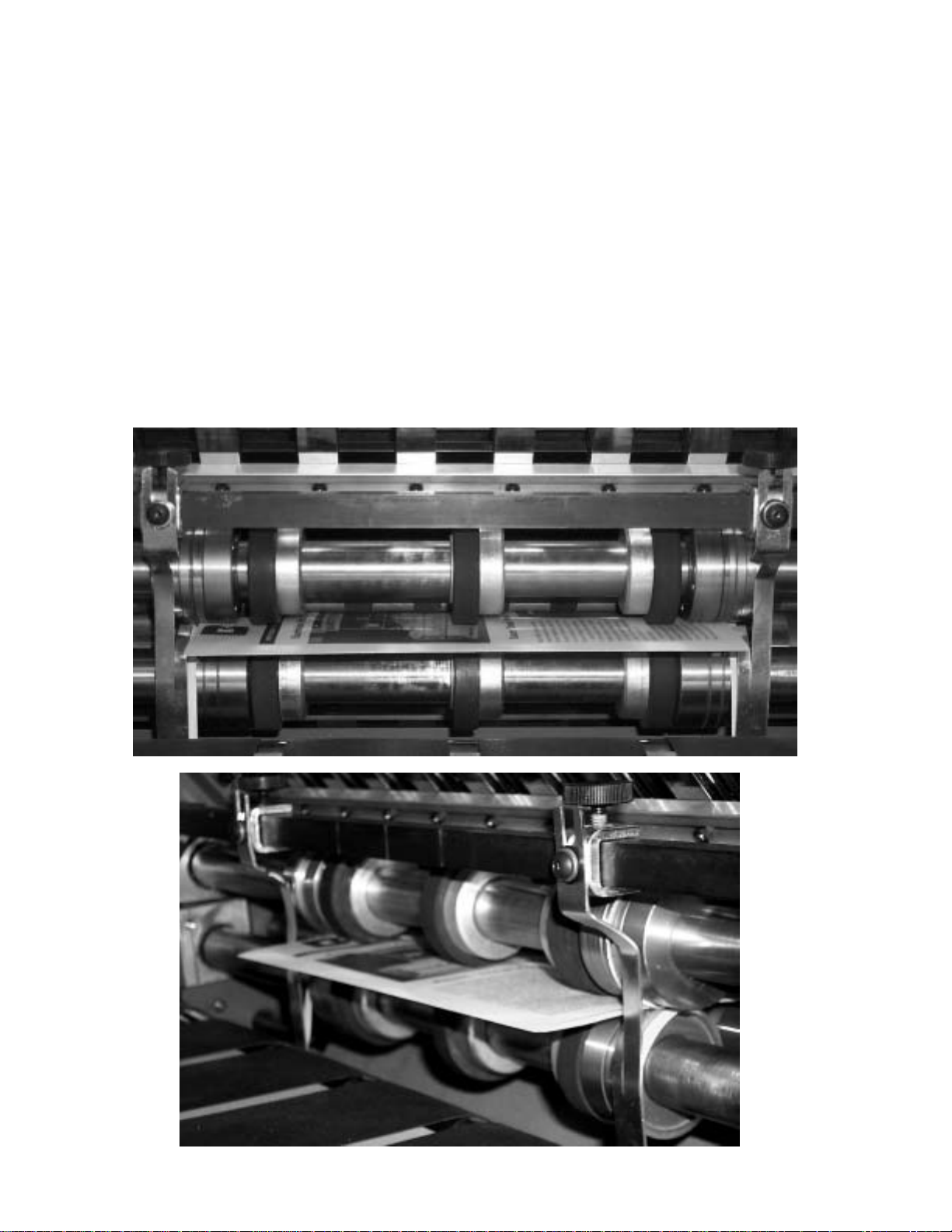

SQUARING THE MACHINE

It is essential that this folding machine is square in

order for it to work properly. To square the machine,

measure diagonally across corners from feeder frame to

folder frame (Figure 4). Dimensions shown are approximate. Be sure that the measurements taken are identical

within 1/16-inch. If the machine is out of square, shift the

frames in the direction needed until the proper squareness is

obtained.

#2 FOLD ROLL#2 FOLD ROLL

#2 FOLD ROLL

#2 FOLD ROLL#2 FOLD ROLL

Figure 1Figure 1

Figure 1

Figure 1Figure 1

TRANSPORTATION/INSTALLATION

As soon as you receive your new folder, and before

removing the machine from the skid, check carefully for any

damage to the shipments. If any damage is found, promptly

contact your Baumfolder sales representative.

To lift the folder from the skid, place the fork lift rails

under the lower rails as shown in Figure 2. Note that the

fork lift must have at least a 1500 lb. capacity.

Remove all rust protection coating after unpacking the

folder.

Figure 2Figure 2

Figure 2

Figure 2Figure 2

Figure 3Figure 3

Figure 3

Figure 3Figure 3

Figure 4Figure 4

Figure 4

Figure 4Figure 4

PAGE 7 TP10243-5

Page 8

#4

#5

U1

#1

W2

V1

#2

U2

W1

#3

V2

GND

G/Y

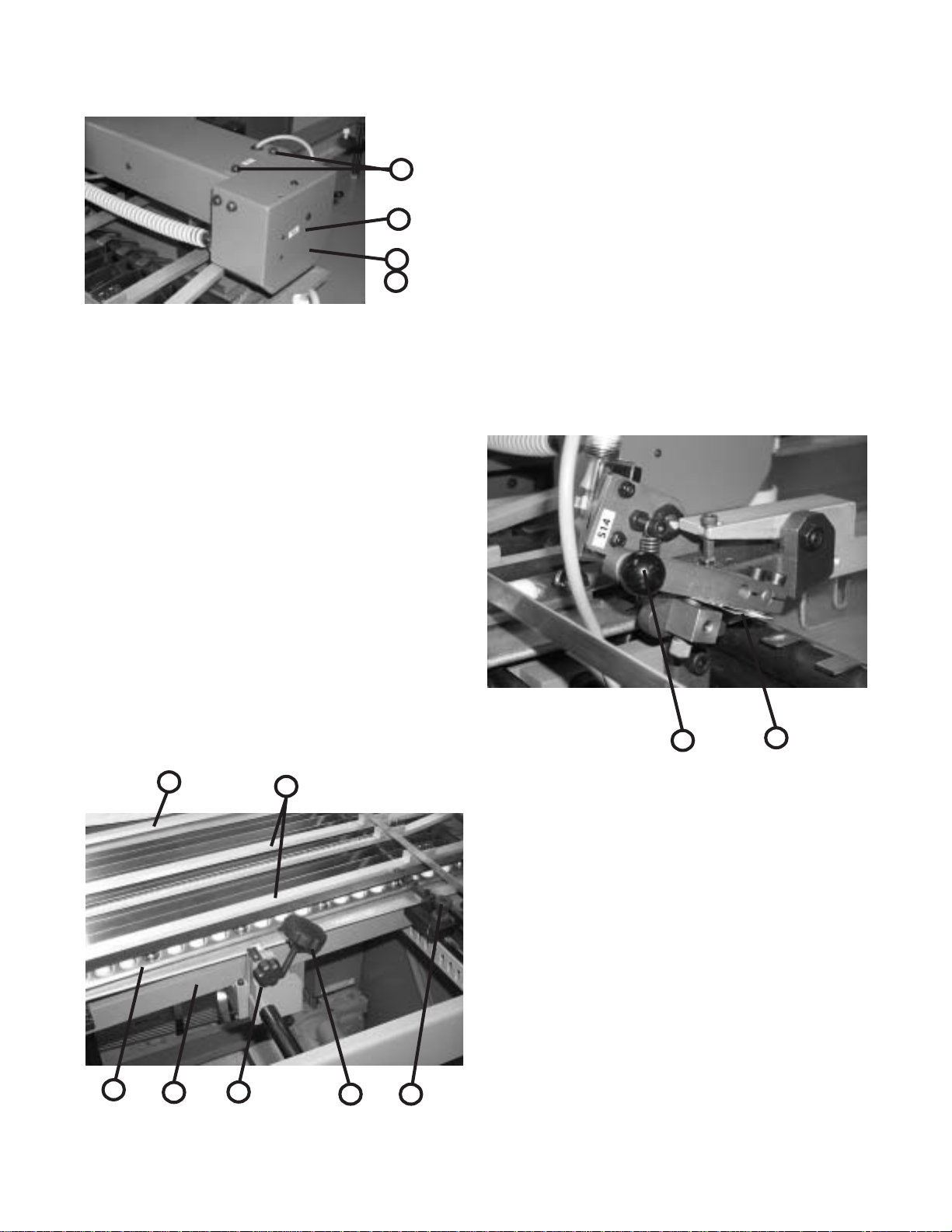

ELECTRICAL CONNECTIONS

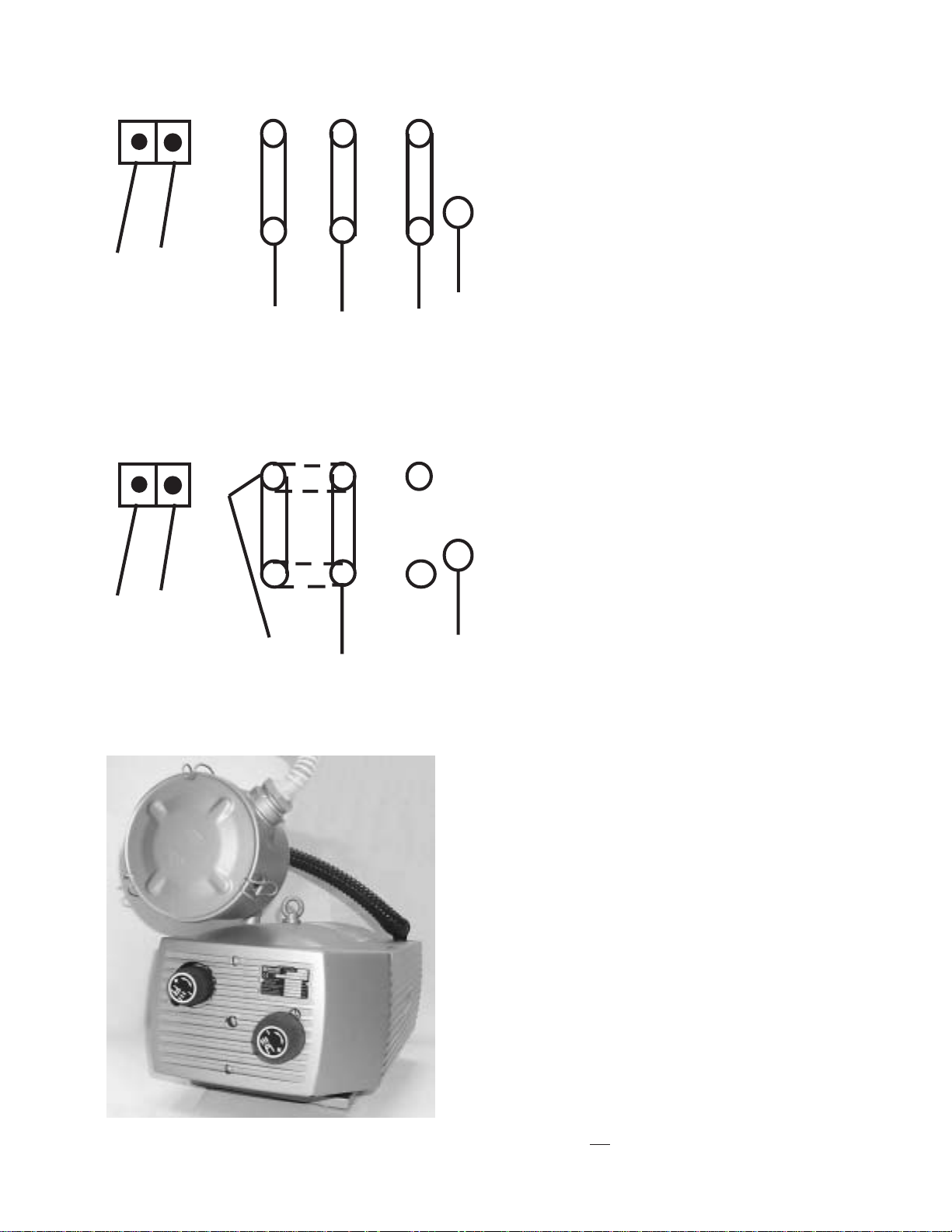

1.0 Wiring the Pump (2020 / 3 phase)

Connect the pressure/vacuum pump at the pump

junction box (Figure 5) using the attached cable. Follow

the instructions to the left for the proper connections.

Turn the main power switch to the "ON" position.

Switch the pump on momentarily and check for proper

pump rotation as indicated by the rotation arrow on the

pump. Immediately turn off the pump if the rotation is

wrong.

If the rotation is incorrect interchange any two of the

three wires #1, #2, or #3 in the pump motor terminal box.

W2

#4

#3

U1

#1

Note: Dotted line indicates the cnange

you need to make if the pump

is running backwards

1 PHASE ONLY

V1

#2

U2

W1

V2

GND

1.1 Wiring the Pump (2020 / 1 phase)

Connect the pressure/vacuum pump at the pump

junction box (Figure 5) using the attached cable. Follow

the instructions to the left for the proper connections.

G/Y

1.2 Other Connections

Refer to the serial number plate for electrical

requirements. The serial number plate notes the voltage,

phase and hertz, minimum time delay fuse, total machine

amperage, and minimum wire conductor size for the main

power connection.

The main power is connected directly to the line side of

the main power switch. In a (2020 / 1 phase) use L1 and L2

only. In a (2020 / 3 phase) use L1, L2, L3.

All electrical connections are to be made by a certified

electrician. Refer to local building electrical codes for proper

and safe connections.

For the following items, refer to Figure 6. Run a power

cable from your distribution box to the main control box on

the pile feeder. Turn the main power switch to zero. Using

the appropriate tool, open the latches on the control box

door and open the door.

Figure 5

TP10243-5 PAGE 8

NOTE: The door is connected to the main box by a ground

wire that should not be removed.

Page 9

1.3 Tapping the Transformer

Pass the power cable through the strain relief and the

hole provided in the control box. Connect the power cable to

the open terminals on the main disconnect in the control box.

The incoming ground wire should be attached to the ground

stud located in the lower right-hand corner of the control box.

To tap the transformer, read the incoming voltage at the

main disconnect. Then move the wire numbered 7L2 on the

transformer to the corresponding tap on the transformer.

Tighten all screw connections and close the door before

switching the machine on.

A connector is provided for power connection to the

stacker. The stacker must be plugged into the socket for the

machine to operate, if not, install the blind plug attached to

the box.

A connector is provided for power connection to the

second station (8-page) fold unit. If no additional folding

station is to be connected, the connector must be closed off

with a blind plug.

1.4 Pump Connections

Connect the air hoses to the pump. The small diameter

hose is connected to the vacuum side of the pump. Connect

it to the barbed fitting above the ball valve on one end and

the other end to the vacuum solenoid valve on the pile

feeder.

Connect the larger diameter hose to the remaining

outlet port on the pump and to the barbed fitting on the pile

feeder at the end of the blow bar.

Troubleshooting tips and actions required for the

display messages that may appear on the control readout

may be found the "Diagnostic Messages" section of the

manual.

3

2

1X7

1X10

1X12

1

1X1

1X2

4

6

5

8

7

Figure 6

PAGE 9 TP10243-5

Page 10

BAUMFOLDER 2000 Series “QUICK START” INSTRUCTIONS

TURNING THE MAIN SWITCH ON

When you turn on the Main Power Switch located on the side of the Control Box , you must let

the Control automatically run a self-test. During the self-test

a button will cause an Error Message to appear in the Main Display. To CLEAR Message turn Power

OFF at the Main Power Switch—WAIT

5 SECONDS, then turn Power back on.

1. Turn on Main Power Switch on left side of control enclosure.

- Wait until control finishes self-test.

2. Load paper on Pile Feed Table. Press Pile up GREEN Button

Pile will raise automatically to correct height.

NOTE: To STOP Pile—Press RED Button

3. To START Drive Motor & Pump—Press GREEN Button ABOVE the symbol.

DO NOT Press any buttons. Pressing of

To STOP Drive Motor —Press RED Button BELOW the symbol or Press EMER-

GENCY STOP BUTTON

RAISING AND LOWERING THE PILE FEEDER LIFT TABLE

1. After loading paper onto Pile Feeder Lift Table, Press the GREEN Button

This will raise the paper to the proper feeding height automatically. You

can stop the Pile Feeder Lift Table by Pressing the RED Pile Feeder

STOP Button

2.

To lower the Pile Feeder Table, you must first Press the RED Pile Feeder

STOP Button

TP10243-5 PAGE 10

Page 11

Then Press the GREEN Button to lower Pile Feed Table. The Table will lower and stop

automatically in its lowest position.

STARTING PRODUCTION WITH THE BAUM 2020

1. To START the Folder Drive, Press the GREEN Button on the Control Panel

just ABOVE the symbol, this will Start the Folder Drive and the Pump will automatically

come on.

2. To STOP the Folder Drive, Press the RED Button on the Control Panel just BELOW the

symbol or Press the RED EMERGENCY STOP Button on the Control Panel or on the

Stacker Control Panel. The Folder Drive will STOP, The Pump may continue to run for about 7

seconds. If you want to stop the pump at the same time as the folder drive press the Drive

STOP button twice within a 0.5 seconds.

The Pump circuit has a minimum ON time of 4 SECONDS. If the Pump is commanded OFF

within 4 seconds after it is started, it will continue run for the duration of the 4 seconds and then

shut OFF.

3. To Turn the Pump ON without the Folder Drive coming On, Press the GREEN Button ABOVE

the symbol

4. To Turn the Pump OFF, Press the RED Button BELOW the symbol NOTE: the Pump

will stay ON for at least 4 SECONDS before being able to shut off.

Easy Mode:

This mode is an automatic setup mode that sets the sheet gap to 1 inch and vacuum duration to 5

inches. Most jobs may be ran with this mode of operation. A Z-fold or a product with a window

will require the Continuous Mode of operation. You can not change the sheet gap or vacuum

duration settings manually using the Easy-Mode. Only the DCT500 mode or Continuous Cycle

mode allows adjustment of these settings.

PAGE 11 TP10243-5

Page 12

The Easy-Mode is used for folds that require half of the sheet length or less going into the

foldplate. These folding applications normally operate with a 1.0 Inch sheet gap. If you are folding

half of the sheet length or more into the foldplate you must have a greater gap.

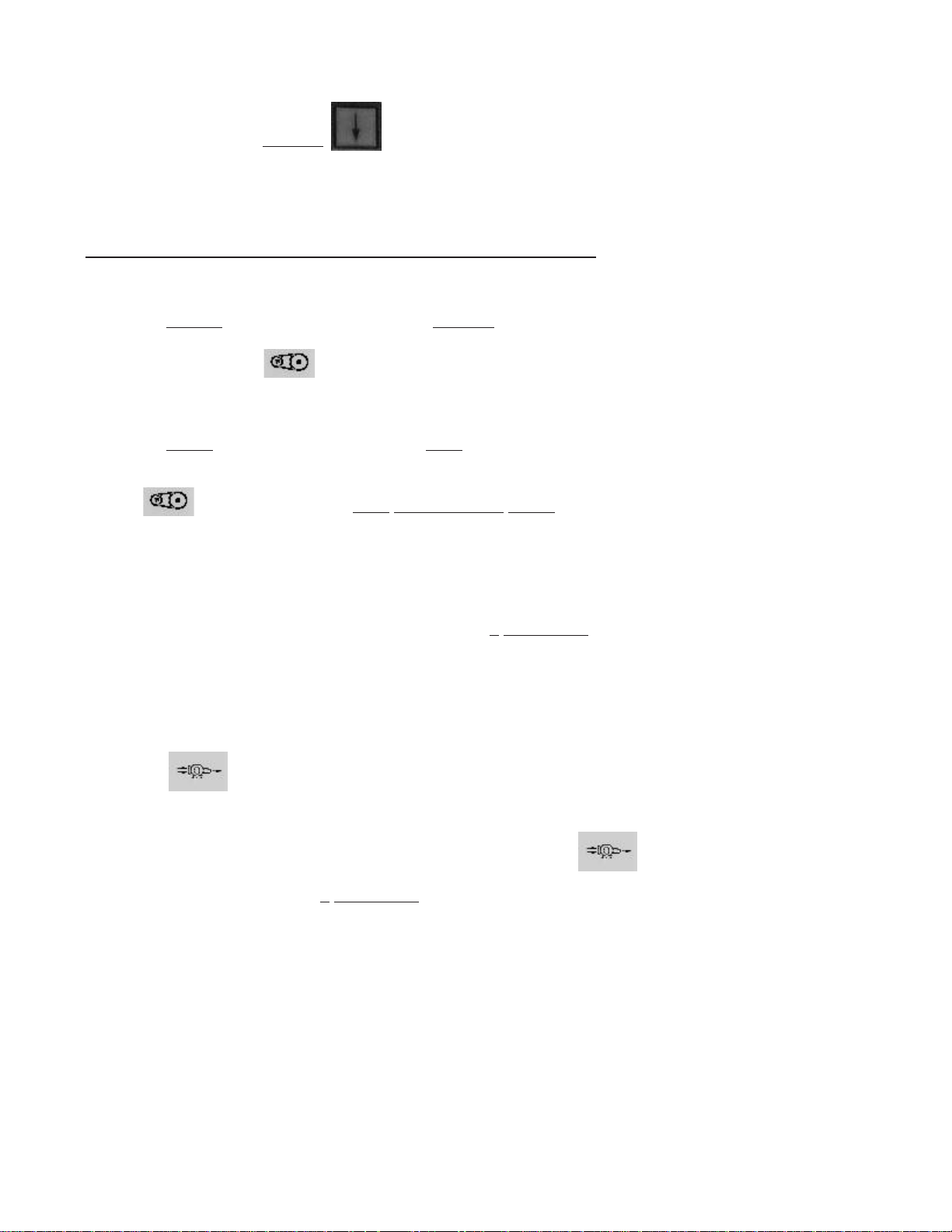

TURN THE EASY-PARAMETER ON/OFF

1. Press the Machine Setup button found in the top row.

..

2.

.Press the Sheet Gap

..

+ or - Buttons until P20 appears in the sheet gap display.

3. Press the Batch Count + Button until P25 appears in the sheet gap

display. You will now see the word “EASY” in the counter display

Batch Count + Button until P25 appears in the sheet gap display. You will now see the word “EASY”

in the counter display, see Figure E1.

Figure E1

TP10243-5 PAGE 12

Page 13

4. Look to the right hand end of the counter display. If an “ 1 “ appears in the display the Easy-

Parameter is turned on. If an “ 0 “ is displayed, the Easy-Parameter is turned off, see Figure E1.

To turn the Easy-Parameter on or off, Press the Plus (+) button for the batch

time delay setup. Pressing this button changes the “ 1 “ to an “ 0 “ and back. This button is found

at the far right side of the top row, see Figure E1.

5. Press the Machine Setup button again in the top row to confirm and exit pro-

gramming mode.

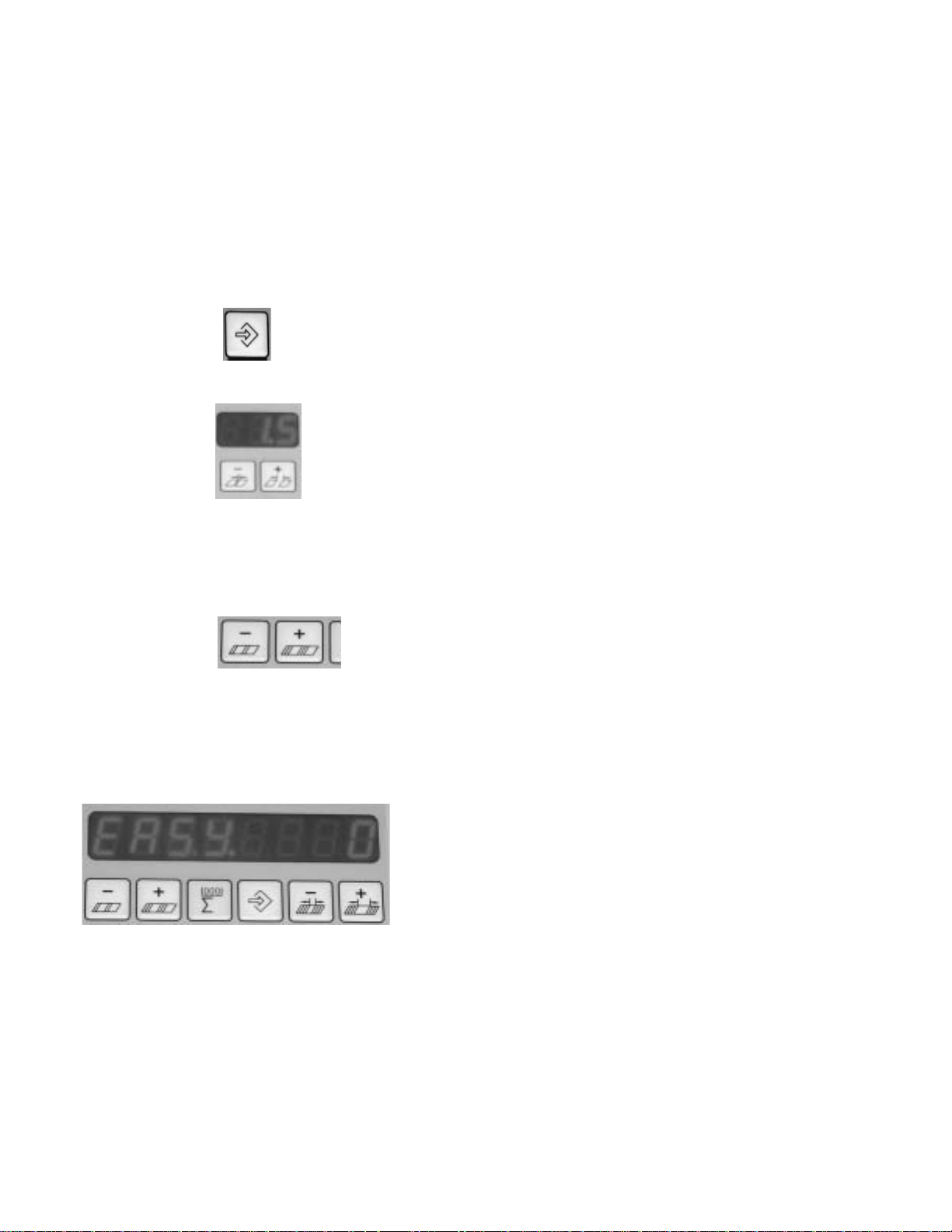

SELECT EASY MODE

Pressing this button enables the selection of either the EASY mode or cYcL mode

+

Pressing these buttons will toggle between the EASY mode or cYcL mode. Set EASY in

the large display. You will notice that the sheet gap display screen has (3) dashes when the

Easy Mode is on and a number when it is off.

Press the mode selection button again to exit mode selection.

PAGE 13 TP10243-5

Page 14

SELECT CONTINUOUS CYCLE MODE

It is recommended to use the continuous cycle mode when the job requires more than ½ of

the sheet length to go in the #1 fold plate or if the product has a window that will be sensed

as the trailing edge of the sheet.

The continuous cycle mode allows you to select the SHEET GAP, SHEET LENGTH and

the SUCTION LENGTH.

Pressing this button enables the selection of either the EASY mode or cYcL mode

+

Pressing these buttons will toggle between the EASY mode or cYcL mode. Set cYcL in the large

display (see figure E1).

SETTING THE SHEET GAP AND SHEET LENGTH

The small 3 digit display shows the current setting for the sheet gap. The number on the

right hand side of the large display (1) represents the current sheet length. Set the sheet

gap and sheet length for the current job.

SETTING THE SUCTION LENGTH

Use the + and – buttons under the 10 segment bar graph display to adjust the suction

length. Each segment represents 5% of sheet length. If 10 segments are illuminated 50%

of sheet length is selected. So, it is important that the sheet length is set properly for the

current job.

Press the mode selection button again to exit mode selection.

TP10243-5 PAGE 14

Page 15

TO START FEEDING

1. Press the GREEN Button to START the Folder Drive and the Pump.

2. Press the

Solenoid. The Sucker Wheel will pull a sheet from the Feeder onto the Register.

GREEN Button ABOVE the symbol to START the Vacuum

TO STOP FEEDING

1. Press the RED Button BELOW the symbol. This will turn the Vacuum

Solenoid OFF. The Sucker Wheel will STOP pulling sheets—BUT the Folder Drive and

the Pump will stay ON.

NOTE: You can also STOP feeding by Pressing the

RED PILE FEEDER STOP BUTTON.

CHANGE SPEED OF FOLDER DRIVE

To change the speed of the Folder Drive, just turn the Potentiometer Speed

adjust Knob on the Main Control Panel 1 thru 10, 10 being maximum speed

MACHINE PARAMETERS

Pressin Button allows access to the Machine Parameters. The Machine

Parameters may be monitored, some changed and various options (kicker, pile re-load,

etc.) enabled or disabled.

Navigation through the parameters is accomplished by using the following procedure:

1. Pressing and directly UNDER the 3 digit display will select

the various Parameters Groups by count of tens.

PAGE 15 TP10243-5

Page 16

EXAMPLE: Hold the MINUS Button, this will automatically count back to P00

(group P0). Now by Pressing the Button will take you to the next

Parameter Group P10 – P20 - P30 – P40 – P50 – P60

2. Pressing and directly UNDER the left 3 digits of the Large 8 digit

display, this will select the individual Parameters in a select group.

EXAMPLE: Start with the first Group of Parameters, the 3 digit

display reads P00. Pressing the this will take you to Parameters

P01 – P02 – P03 – P04 – P05

- To go to the next Group of Parameters Press

The display will show P10. Pressing the button

will take you to Parameters P11 – P12 –P13 – P14 (continue this sequence

to move thru the rest

of the Parameter Groups P20 – P30 – P40 – P50 – P60

3. To change one of the machines Parameter Settings Press or

Buttons UNDER the right most 2 digits of the large 8 digit display.

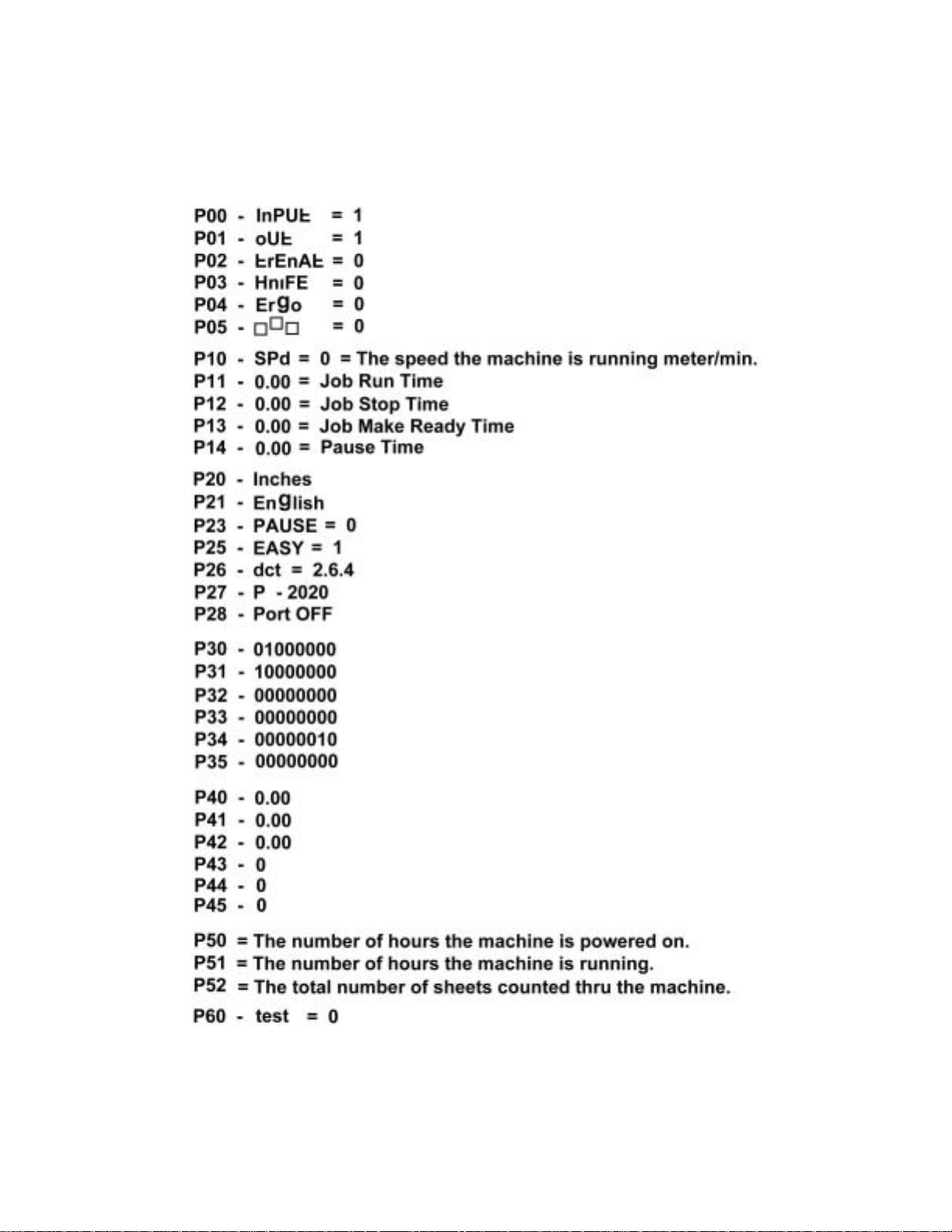

The following is a list of the available parameters. Please see the Operators Manual for a definition of each parameter.

TP10243-5 PAGE 16

Page 17

PAGE 17 TP10243-5

Page 18

To get out of the Machine Parameter Settings Mode, Press again. The displays will

ood

oo

o

return to normal operations.

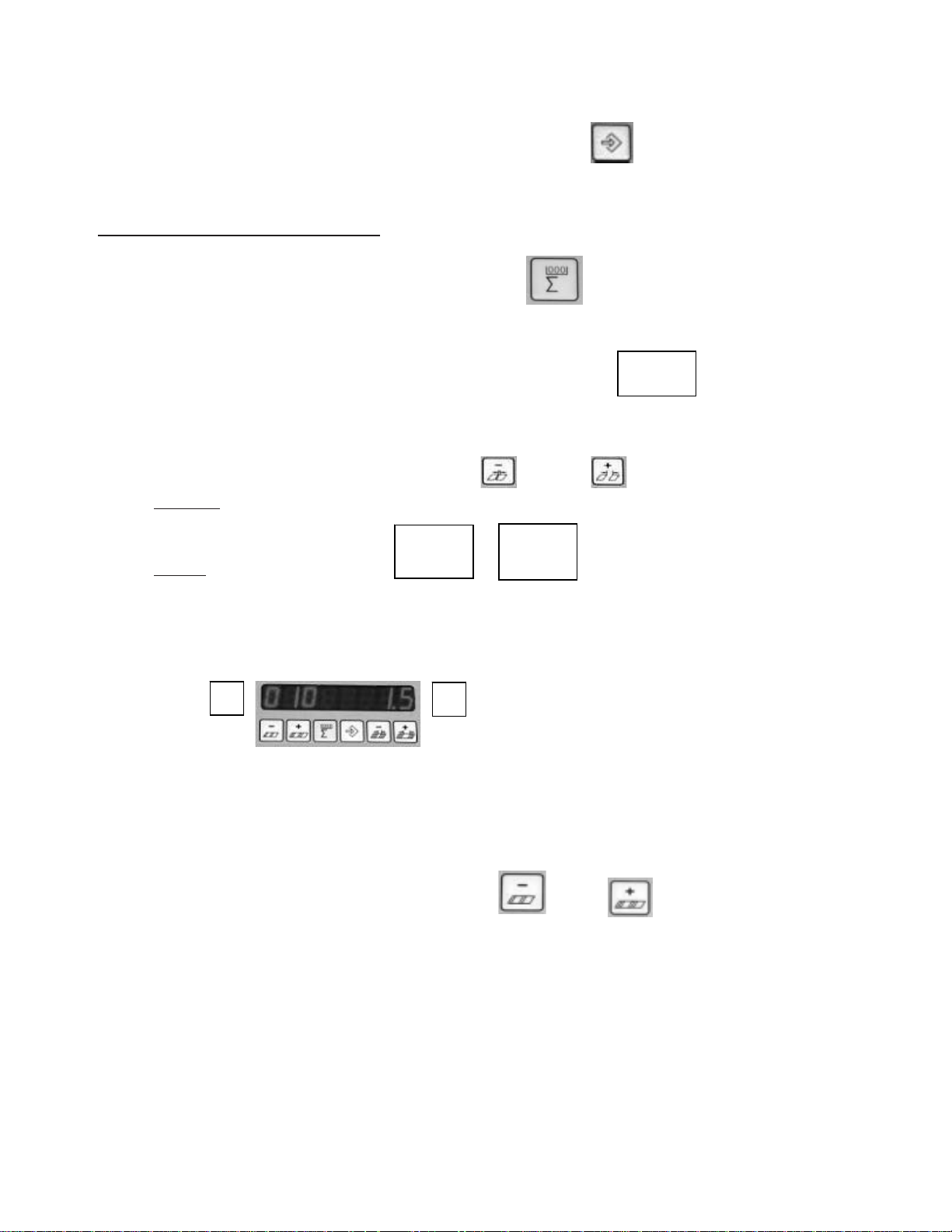

BA TCH COUNTING SETUP

To enter Batch Count Set-Up, Press

1. This will bring up 3 display functions on the Control Panel.

First is the Small 3 digit display – this display must show

If the display shows any other Mode, the Batch Counter

will not function. To change, Press the or Buttons directly

UNDER the 3 digit display to change this Mode of Operation.

NOTE: If the display shows or the wrong batching device is

ooo

selected. These batching devices are Options not sold as standard equipment.

2. In the Large 8 digit display you will see 2 display functions.

1. Is the number of sheets in the batch.

2. Is the time delay between batches.

A. In the first 3 digits of the 8 digit display, this is the number of Sheets in each batch.

To adjust the number, press the or Button directly UNDER

the display until the desired number is displayed.

B. In the last 2 digits of the 8 digit display, is the time between batches

setting. This setting moves in Tenth (10th) of Seconds, to adjust, Press

TP10243-5 PAGE 18

Page 19

th e or Buttons directly UNDER the 2 digit display until the

desired delay number is displayed.

EXAMPLE:

This is set-up for 10 pieces in a Batch with a 1.5 second

delay between Batches.

3. To return back to RUN mode, Press Button and set either the Batch Size or

Time Delay to Zero and the Folder will run continuously.

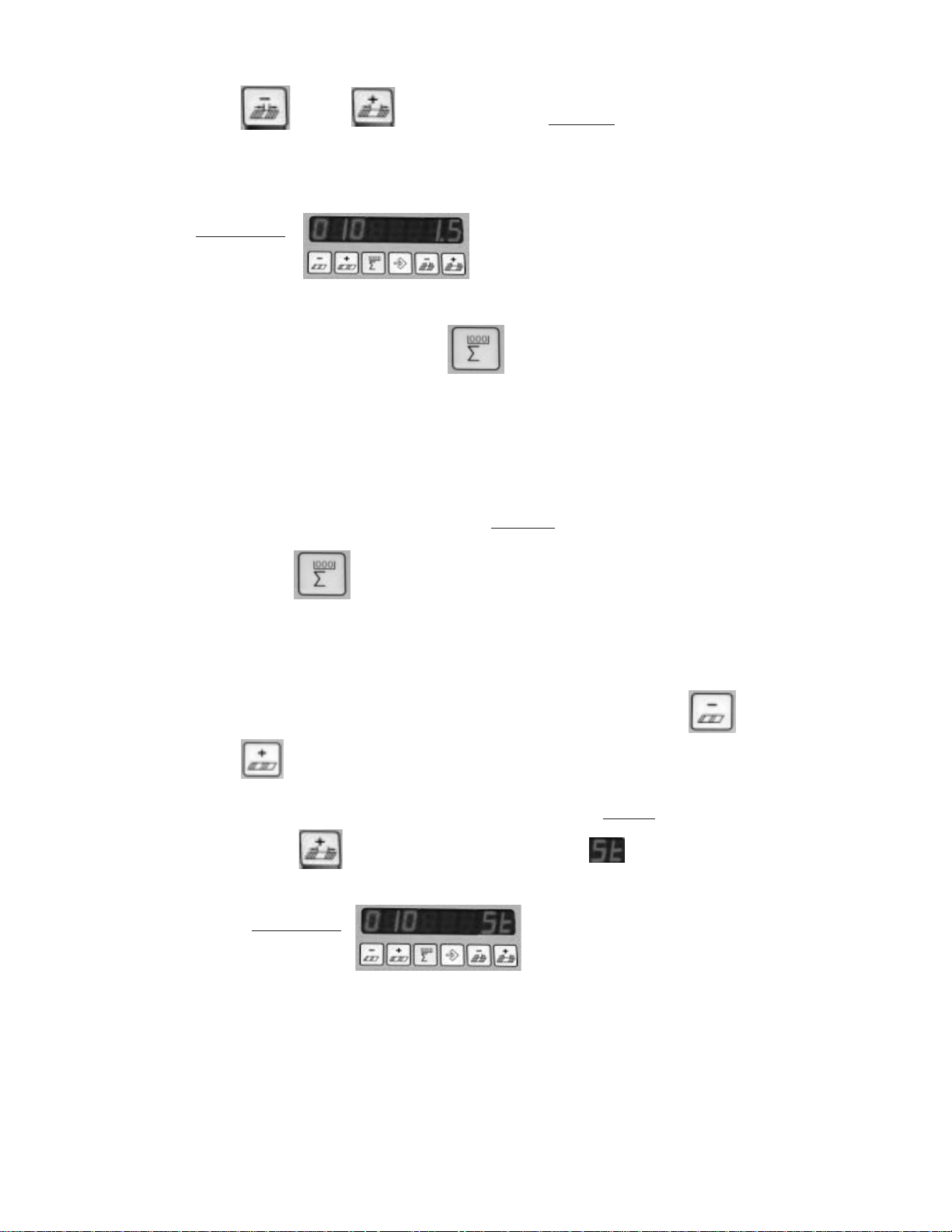

STOP FEED

In Batch Count Mode, you also can have the Feeder Set-Up for a Stop Feed Count. You can enter

the number of Sheets that you wish to Feed and the Feeder will Feed that number and STOP.

The feeder will not Re-Start until you Press SHEET START Button.

1. Press the Button on the Control Panel, the 3 display functions on the

Control Panelwill appear.

A. In the first 3 digits of the 8 digit display enter the Number of

Sheets that you wish the Feeder to Feed by Pressing either

or Buttons.

B. In the Last 2 digits of the 8 digit display, Press and HOLD

th e Button until the LETTERS appears – the machine will

now Feed only the Number of Sheets that you have entered.

EXAMPLE:

With this setting the Feeder will run 10 sheets

and Stop Feeding.

PAGE 19 TP10243-5

Page 20

RESETTING THE TOTAL COUNTER

To reset the Total Counter, Press Button ; ensure the red LED is illuminated.

Press Button and HOLD DOWN for 3 SECONDS,

The Large 8 digit display will begin to Count BACKWARDS from 5.4.3.2.1,

then display CLEARED, the Counter is then ZERO.

You MUST Press and HOLD Button as the display is counting

BACKWARDS, if at anytime the ZERO Button is released, the Counter will

display the Last Count Value

NOTE The Batch counte r will also be reset to 0 by this procedure.

RESETTING THE BATCH COUNTER

Press the Batch counter Button ; ensure the red LED is illuminated.

Press Button and HOLD DOWN for 3 SECONDS,

The Large 8 digit display will begin to Count BACKWARDS from 5.4.3.2.1,

then display CLEARED, the Counter is then ZERO.

NOTE The Total counter will not be reset to zero.

TURN OFF BATCH COUNTING:

Press the counter setup button and set either the batch size or time dwell to zero.

Exit the counter setup mode by pressing the counter setup button again or any button in the second row.

TP10243-5 PAGE 20

Page 21

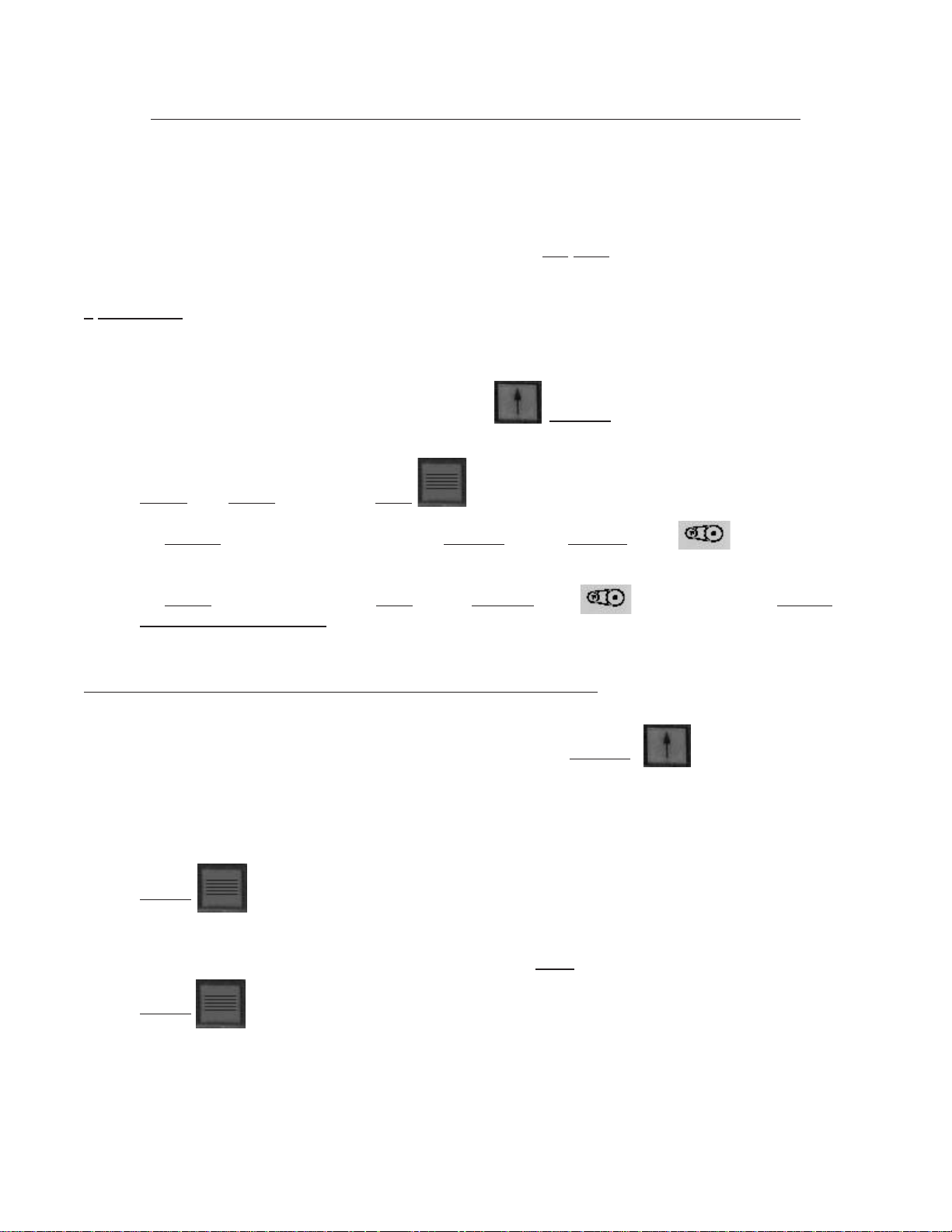

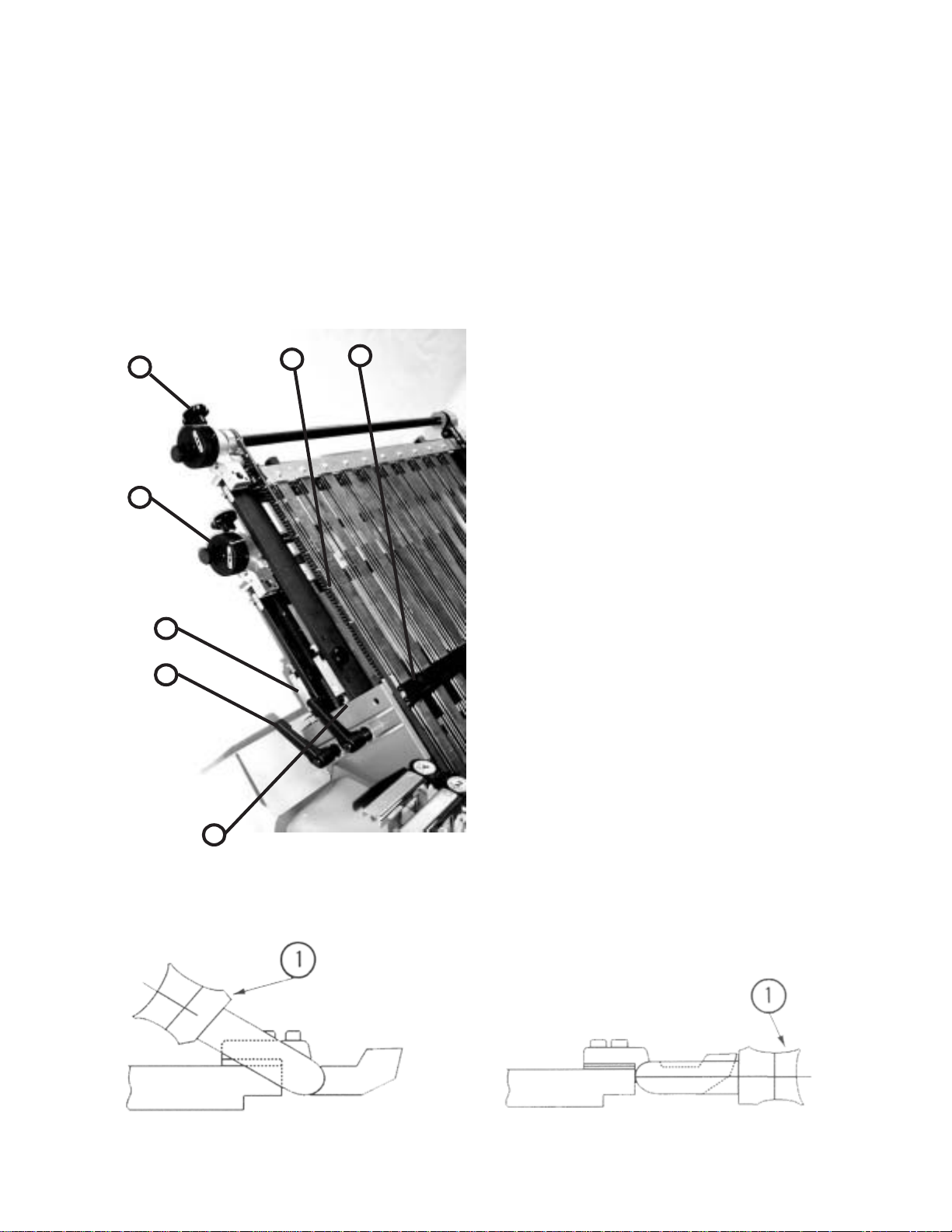

INSTALLING FOLD PLATES & STACKER

CORPORA

DELIVERY

Install the fold plates into the folder. When installing

the fold plates, take note of the symbol on the fold plate stop

(Figure 7-1). The swing deflector may only be brought

forward when the deflector symbol is also in the forward

position. Lock the fold plates in position with the clamp

levers (7-2). See "Fold Pan" section for fold plate setting

procedure.

Attach the delivery stacker (3-2) by hooking the hanger

brackets onto the round rods at the exit end of the folder.

Plug the stacker power cable into the corresponding outlet

on the main control enclosure on the pile feeder (Figure 6-

1).

Pull the handwheel (Figure 1-11) to manually turn the

fold rollers to be sure that they are operating smoothly.

Check for any foreign material, and be sure that the deflectors do not touch the fold rollers.

OPERATOR CONTROLS

The main operator control panel (Figure 8) is located at

the pile feeder. See the "Control Panel" section for a detailed

description of all the buttons.

1.0 Setting Folding Speed

The speed of the fold rollers may be set while the folder

is running! This is done by adjusting the speed control

potentiometer located on the top left side of the main control

panel. Clockwise rotation speeds the folder up; counterclockwise rotation slows the folder down.

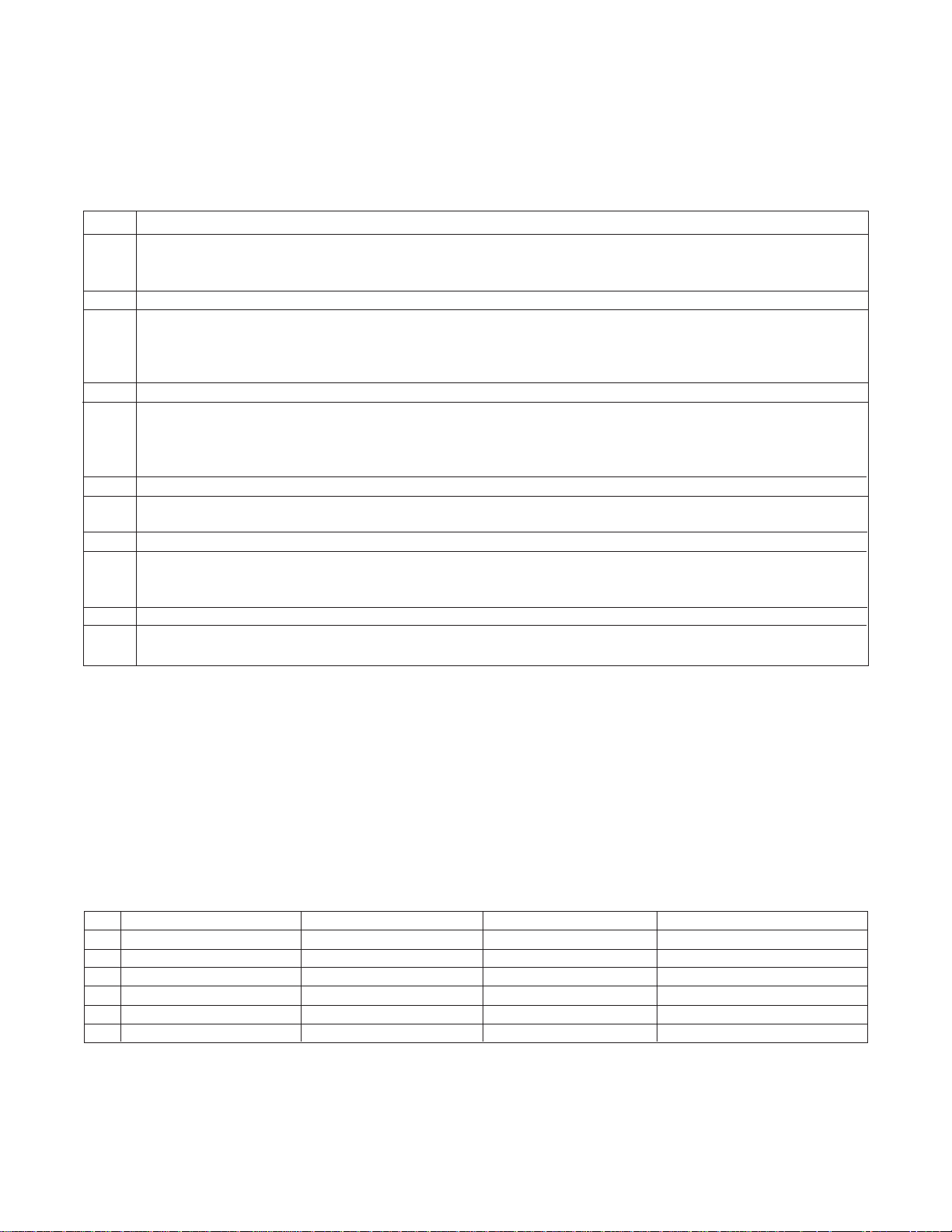

1.1 Setting Stacker Belt Speed

An infinite speed range between high and low is set by

turning the control knob (Figure 9-1).

1.2 Emergency Stop Button

When an emergency stop button (8-1 & 9-2) is pressed,

the result is:

Sheet feed - stop

Folder drive - stop

Pile lift - stop

The pressure/vacuum pump continues to operate. The

emergency stop button must be pulled to release before the

machine can be restarted. An error message "StoP" will

appear on the readout.

The emergency stop buttons are found at the main

operator control panel (8-1) and the delivery control (9-2).

1

2

Figure 7

1

56

4

7

3

8

2

9

1

10

BAUMFOLDER

CORPORA

TION

Figure 8

2

1

Figure 9

+

+

+

h

+

0

PAGE 21 TP10243-5

Page 22

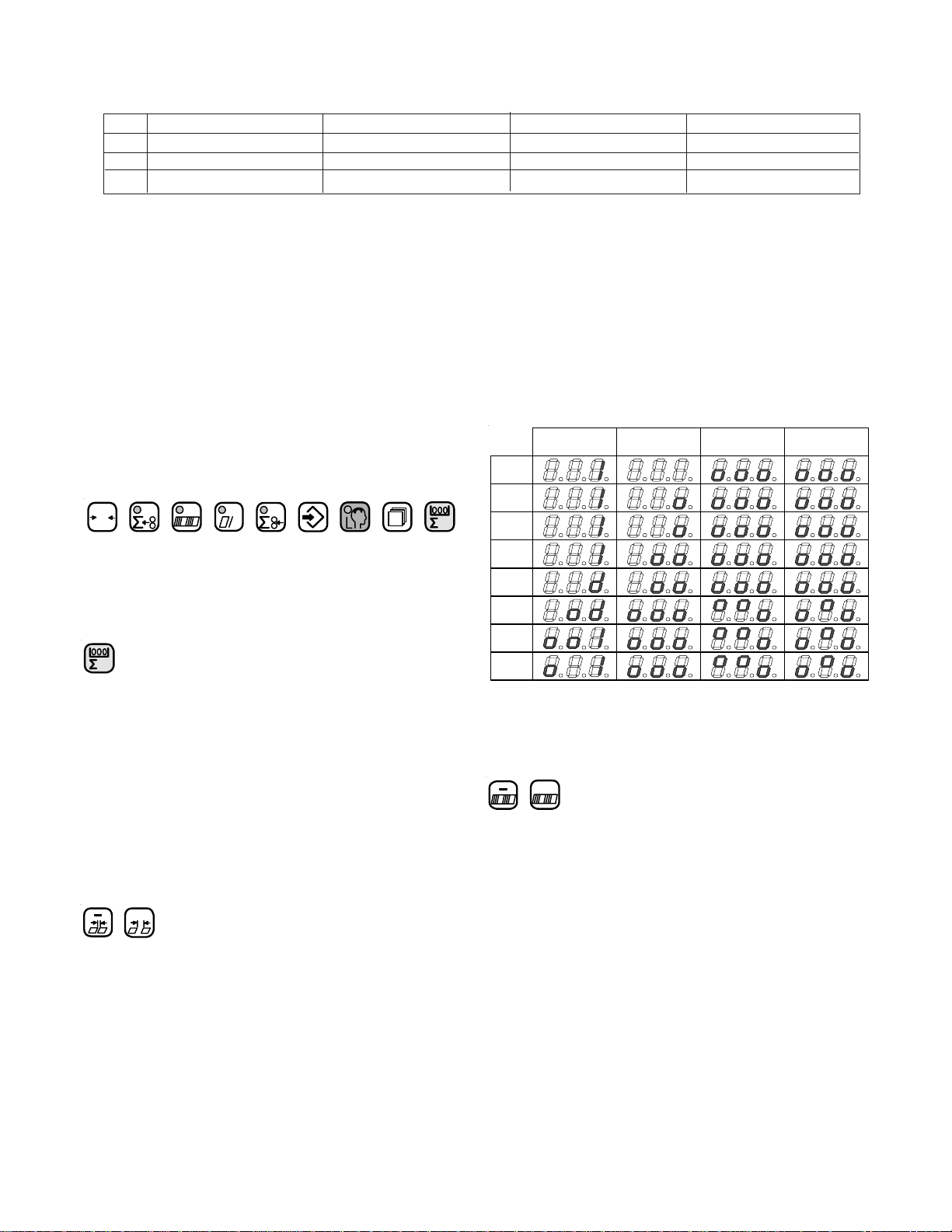

1. 0 Control Panel BAN-5

56

4

3

2

1

BAUMFOLDER

CORPORATION

7

8

9

10

36

9 13 11 16 26 27 22 23 4 5 7 615 3

Figure 1. Control Panel.

25 2824 28 12 10 1417

+

+

1 29 30 31 32 33

+

h

18 19 20 21 34 35

+

0

1.1 Displays

01) Large Display

Eight digit multi use display composed of 7segment LED’s.

02) Small Display

Three digit multi use display composed of 7segment LED’s.

03) Ten segment bar graph display

The suction length display is used to display the

Suction Length as a percentage of Sheet Length.

This allows a range from 5% to 50%.

1.2 Machine Status Indicators

04) Suction Indicator

The suction indicator will track the suction

output. The LED will turn on when the suction

output turns on.

05) Pile indicator

The indicator is lit when the feeder is in automatic feed mode. The indicator will flash if the

feeder is in reverse mode (Continuous Feeder) or

moving down (Pile feeder)

06) Input Indicator

The input indicator shows the status of the suction

photo-eye.

07) Output Indicator

The output indicator lights when the Batch Preset

is reached and the user has selected a batching

option. The output indicator is lit during the time

the batching option is active.

Batching options are Feed interruption, Speed up

table, Marking table or Kicker.

1.3 Machine Control Pushbuttons

08) Main Drive Start

09) Main Drive Stop

10) Pump Start

11) Pump Stop

12) Feeder Start

13) Feeder Stop

14) Pile Feeder Up, Continuous Feeder Start

15) Pile Feeder Stop, Continuous Feeder Stop

16) Pile Feeder Down, Continuous Feeder Reverse

17) Emergency Stop

TP10243-5 PAGE 22

Page 23

1.4 Keypad Buttons with Selection Indicators

18) Show Output Count

19) Show Batch Count and Number of Batches

20) Show Current Rate

21) Show Input Count

22) Learn Mode

23) Make Ready Mode

1.5 Keypad Buttons for Selection Adjustment

24) Gap Minus

25) Gap Plus

26) Suction Length Minus

27) Suction Length Plus

28) Batch Preset Minus

29) Batch Preset Plus

30) Counter Setup Mode

31) Machine Setup Mode

32) Batching Time Minus

33) Batching Time Plus

34) Network Job Mode

35) Reset

36) Potentiometer Speed adjustment

2. 1 Machine Setup/Diagnostic Mode

Pushing this key puts the controller in machine setup

mode.

Machine setup mode provides a method to view and

optionally change operating parameters for the controller.

The decimal points in the large display (1) will move from

side to side to indicate that various parameters may be

changed. In this mode, the small display gives the selected

parameter number, while the large display (1) shows a

parameter value. The suction length display (3) is disabled.

Parameter Group Selection

+

The plus and minus keys are used to select the various

parameter groups: machine setup parameters, machine

monitor parameters, machine diagnostic parameters, knife

status parameters, and machine usage parameters.

Parameter Selection within a Group

+

2.0 Run Mode Functions

After turning on the main switch, the control automatically runs a self test. During this self test all displays and

indicator lights come on for approxmately 4 seconds. After

a successful self test, the display reverts to the previous

count screen active before power shutdown. In this mode,

various job parameters can be displayed on the large display

(1) and the small display (2) shows the gap length. The

suction length display (3) is active in this mode and shows

the suction length as a percentage of sheet length.

The DCT500 mode select keys perform the same

function in all modes, except Counter Setup. This allows a

user to quickly switch between the operating modes on the

counter. Select Make-Ready is not a mode unto itself, but

rather is a modifier to all modes.

During the self test operation, do not press any

button. Pressing of a button will cause an error

message to appear in the main display.

!

If the large display (1) decimal points are moving, this

set of minus and plus buttons will select the machine

parameters within each group, see tables 1-6.

Select Parameter Adjustment

+

If the large display (1) decimal points are moving, this

set of minus and plus buttons will move through the set of

values for the selected parameter, see tables 1–6.

PAGE 23 TP10243-5

Page 24

2.1.1 Machine Setup Parameters

Parameter Function Type Variable Displayed

P00 Input Factor Setup Variables Adjustable 1-24

P01 Output Factor Setup Variables Adjustable 1 to Input Factor

P02 Tremat Setup Variables Adjustable 1 or 0

P03 Knife Setup Variables Adjustable 1 or 0

Table 1. Machine Setup Parameter List

P00: Input Factor

Each sheet sensed by the Sheet count sensor is multiplied by the Factor number and added to theTotal Input

Count, but does not effect the Batch Down Count, Number

of Batches or the Rate. The Factor can range from 1 to 24. If

the Input Factor is changed, it also changes the value of the

Output Factor to the same setting.

P01: Output Factor

This number is added to the Total Output Count but

does not effect the Batch Down Count, Number of Batches

and the Rate. The Factor can range from 1 to Input Factor

setting.

2.1.2 Machine Monitor Parameters

# Function Type Variable Displayed

P10 Machine Speed Process Variable Based on input Meters/Minute

P11 Job Run Time Process Variable Based on input Hours

P12 Job Stop Time Process Variable Based on input Hours

P13 Job Make Ready Time Process Variable Based on input Hours

P14 Pause Time Process Variable Based on input Hours

P15 Job Number Process Variable Based on Input Number 1 - 9999

P16 Employee’s Number Process Variable Based on input 1 - 255

P02: Tremat

This is an unavailable option.

P03: Knife

This is an unavailable option.

Table 2. Machine Monitor Parameter List

P10: Machine Speed (Velocity)

This selection shows the machine speed in meters/

minute.

P11: Job Run Time

Displays the time duration this job has ran. Time

displayed in .01 Hours. This information becomes part of the

job record.

P12: Job Stop Time

Display the time duration this job has been interrupted.

Time displayed in .01 Hours. This information becomes part

of the job record.

P13: Job Make Ready Time

Displays the length of time that the Make Ready

feature was enabled. Time displayed in .01 Hours. This

information becomes part of the job record.

TP10243-5 PAGE 24

P14: Pause Time

Display the length of time that the Job was Paused.

Time displayed in .01 Hours. This information becomes part

of the job record.

P15: Job Number

A Job Number may be entered so that production

data may be recorded against it. This is an operator entry.

This information becomes part of the job record.

P16: Employee’s Number

An Employee may be assigned a number. When

the employee operates the machine, his number may be

entered. This information becomes part of the job record.

Page 25

2.1.3 Machine Setup Parameters

# Function Type Variable Displayed

P20 Units of Measure Setup Variables Adjustable Inches, Meters

P21 Language Setup Variables Adjustable English, German, Codes

P22 Network Address Setup Variables Adjustable 0-255

P23 Pause Setup Variables Adjustable 1 or 0

P24 Network Setup Variables Adjustable 1 or 0

P25 Easy Setup Variables Adjustable 1 or 0

P26 Software Version Machine Configuration Fixed V X.X.X

P27 Machine Type Machine Configuration Fixed Set at Factory

P28 Serial Output Type Machine Configuration Fixed Off, Display, or Network

Table 3. Machine Setup Parameter List

P20: Units of Measurement

This selection specifies the unit of measurement used to

display all lengths. Inches (SAE) is the default selection.

Available choices are Meters (measurement displayed in cm)

and Inches (measurement displayed in inches and tenths of

inches).

P21: Language

This selection specifies the Language used to display

fault messages. Available choices are ENGLISH,

DEUTSCH, and CODES, see Tables 16–18, Error Message

Translation. English is the default selection.

P22: Network Address

This selection specifies the unit address used for

Network communication. Available choices are 0 through

255. Address 0 is the default selection. Network functions

are not available in software version 3.0.1

P23: Pause

P24: Network Enable

Network components must be installed and enabled in

Maintenance Mode. Enable Network by selecting “1”.

Disable network by selecting “0”.

P25: Easy Mode

Enable Easy Mode by selecting “1”. Disable Easy Mode

by selecting “0”.

Easy Mode has two sheet control methods, Easy setup or

Continuous cycle. Easy setup will run any job with a 1 inch

sheet gap. The sheet gap display contains 3 dashes and the

Suction Length bar graph is turned off.

In Continuous cycle setup, the suction cycle is determined by

the sheet gap setting, sheet length setting and the suction

length setting. Sheet error detection methods are turned off.

P26: Hardware and Firmware Version

This selection shows the hardware and firmware

versions of the unit. The left side of the display shows logic

board type. The right side of the display shows the firmware

version (3.X.X).

P27: Machine Type

This selection, in maintenance mode, shows the selected

machine configuration.

P28: Serial Output Type

This selection, in maintenance mode, shows selected

serial output type.

PAGE 25 TP10243-5

Page 26

P28: Serial Output Type

This selection, in maintenance mode, shows selected

serial output type.

2.1.4 Diagnostic Parameters

P30 Status Input Port 1

P30.1 P30.2 P30.3 P30.4 P30.5 P30.6 P30.7 P30.8

Pile Motor Function Pile Down Pile Stop Pile Up Compress. Compress. Drive Start

Energized Control K1 Button Button Button Stop Button Start Button Relay K3

P31 Status Input Port 2

P31.1 P31.2 P31.3 P31.4 P31.5 P31.6 P31.7 P31.8

Pile Sensor Double Pile Sheet Start Sheet Stop Thermal Wrong Sheet Emerg.Stop

Sheet Fault Bottom Button Button Fault Fault Drive Stop

P32 Status Input Port 3

P32.1 P32.2 P32.3 P32.4 P32.5 P32.6 P32.7 P32.8

Ergonomic Not used Not used Not used Not used Suction Delivery Photo eye

Pile Load Controller Count Input Suction

Eye Fail Wheel

P33 Status Input Port 4 (Extension Port)

P33.1 P33.2 P33.3 P33.4 P33.5 P33.6 P33.7 P33.8

Not used Not used Not used Not used Not used Not used Not used Not used

P34 Status Output Port 1

P34.1 N P34.2 P34.3 P34.4 P34.5 P34.6 P34.7 P34.8

Not used Not used Not used Not used Pile Down Pile up Release Compress

P35 Status Output Port 2 (Extension Port)

P35.1 P35.2 P35.3 P35.4 P35.5 P35.6 P35.7 P35.8

Not used Not used Not used Not used Not used Not used Not used Not used

Button

is active is active Drive Start Start (K4)

Table 4. Machine Diagnostic Parameter List

P30: Input Port 1 Status

P31: Input Port 2 Status

P32: Input Port 3 Status

P33: Input Port 4 Status (Extension)

This selection shows the inputs status(see table4).

P34: Output Port 1 Status

P35: Output Port 2 (Extension)

This selection shows the outputs status (see table 4).

2.1.5 Future Features

# Function Type Variable Displayed

P40 Last Knife Eye Time 1 Not used Not used Not used

P41 Last Knife Eye Time 2 Not used Not used Not used

P42 Last Knife Eye Time 3 Not used Not used Not used

P43 Strokes knife 1 Not used Not used Not used

P44 Strokes knife 2 Not used Not used Not used

P45 Strokes knife 3 Not used Not used Not used

Table 5. Future Features List

TP10243-5 PAGE 26

Page 27

2.1.6 Machine UsageStatus Parameters

# Function Type Variable Displayed

P50 Power on time Machine Status Based on Inputs Time in 1/100 Hours

P51 Machine run time Machine Status Based on Inputs Time in 1/100 Hours

P52 Total Input Sheets Machine Status Based on Inputs Number in 1000 Sheets

Table 6. Machine Usage Status Parameter List

P50: Power On Time

This selection shows the time in 1/100 hour during the

main switch of the machine is on.

P51: Machine Run Time

This selection shows the time in 1/100 hour during the

main drive contactor of the machine is on.

P52: Total Input Sheets

This selection shows the total input counts in 1000

sheets

Exit Machine Setup and Diagnostic Mode

0

h

Pressing any of these keys will cause the controller to

change to a new mode.

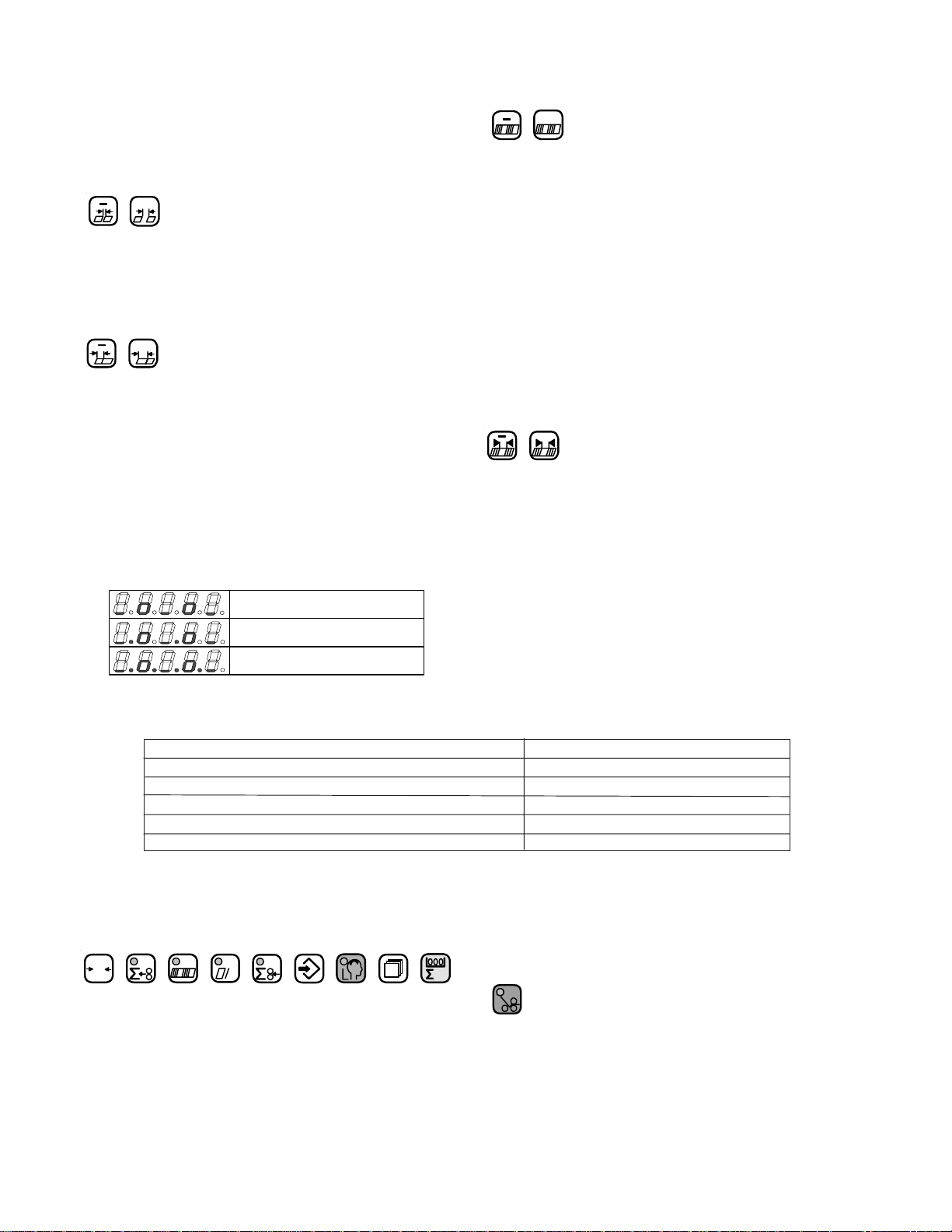

2.2 Counter Setup Mode

Pushing this key puts the counter in counter setup

mode.

The speed up-table output activates the marking table

output for the batching time duration.

The MKE mode is an unavailable option.

The kicker is a future feature.

The output types are represented by animated symbols.

The sequence of frames for the animations is shown in

table 7.

Feed Interruption Speed Up Table MKE Table Kicker

Frame

1

Frame

2

Frame

3

Frame

4

Frame

5

Frame

6

Frame

7

Frame

8

Not

Available

Future

Feature

Table 7. Output Type Animations

Counter setup mode is used to prepare the controller to

run a job. The large display (1) shows the batch preset on

the left-hand side and the batching output time on the right

hand side. The decimal points in the large display (1) will

move from side to side to indicate that a parameter may be

changed. The small display (2) shows the batching type. The

suction length display (3) is active.

Change Batching Type

+

The minus and plus buttons move through a list of four

output devices. The chosen Type is then activated when the

batch down-count goes to zero. Feed interruption stops the

feeding of sheets for the batching time setting.

Batch Preset Adjustment

+

These buttons cause the batch preset value to increment or

decrement. The preset will be reloaded after the user leaves

the setup mode only if the value has been changed.

PAGE 27 TP10243-5

Page 28

Batching Time Adjustment

+

The batching time adjustments allow the user to select

the time duration associated with the currently selected

output type. Two output types and times are available.

1. Feed interrupt has a range of 0.0 to 9.9 seconds.

2. Speed-up Table has a range of 0.00 to 5.00 seconds.

Select Count Source

The Output Count and Input Count keys select between

count at delivery and feeder, respectively. One key LED

will always be lit in Counter Setup to show the current

count source, see table 8. Chasing LEDs will activate in

the small display signifying the start setup mode. The next

sheet fed through will be timed from leading edge to

trailing edge and the delay time will be set to one half the

sheet time. Please note this must be redone if the delivery

speed is changed.

+

Pressing these buttons will toggle between the EASY

mode or cYcL mode. Set EASY in the large display and

press again.

Select Continuous Cycle Mode

Pressing this button enables the selection of either the

EASY mode or cYcL mode

+

Pressing these buttons will toggle between the EASY

mode or cYcL mode. Set cYcL in the large display and

.press again.

Exit Run Mode

The batching count source will be the feeder

photoeye.

The batching count source will be whatever is

connected as the delivery photoeye.

Table 8. Count Source Selection

Exit Counter Setup Mode

Pressing any of these keys will cause the counter to

change to a new mode.

0

2.3 Easy Mode and Continuous Cycle

Mode

2.3.1 Easy Mode and Continuous Cycle Mode

Pressing any of these keys will cause the counter to

change to a new mode.

2.4 Learn Mode

This key places the controller in learn mode. Learn

mode can only be activated if the folder is idle.

The learn mode allows the user to setup the suction

valve controller. Both manual and automatic setup is

accomplished in this mode. The large display (1) shows

two separate data items. The suction mode is shown on the

left and the sheet length is shown on the right. The small

display (2) shows the current gap length. The suction

length display is active. During Learn Mode, the Learn

Mode key LED indicates whether a valid sheet has been

learned.

No valid sheet has been read yet, t he system i s in

Single Sheet mode.

A vali d sheet has been read and the DCT500 has

been setup to run. Single Sheet mode is of f.

Job

Enable EASY mode at parameter P25, see Table 3.

Select Easy Mode

Pressing this button enables the selection of either the

EASY mode or cYcL mode.

TP10243-5 PAGE 28

Table 9. Learn Mode Status

When the LED is on, pushing the sheet start button will

feed a single sheet of paper. If the sheet is fed properly, the

indicator LED will go off. The suction mode will be set to

automatic. The length of the sheet will be set as the current

sheet length. The suction length will be set based on table

11 and the gap length will be set to 4 cm /1.50 inches.

Page 29

l

If P06 is set to 0 (no knife is active) and 10 cm /4.0 inches. If

P06 is setting to 1, knifes are active.

Gap Length Adjustment

+

The minus and plus keys adjust the gap length. The gap

length range is 0.2” to 98.0” (0.5cm to 250cm).

Suction Length Adjustment

+

This is the same as in run mode

Select Suction Mode

+

These keys toggle between automatic control and cycle

mode. In the cycle mode, the suction valve will be on for

the suction length and off for the remainder of the sheet

length plus the gap length. No adjustments are made for

slipped sheets or process changes. The automatic mode

corrects for process changes and controls the timing of the

suction valve to maintain the user-selected gap. If the gap

is less than 1.5” (4.0 cm), the right hand decimal point of

the small display (2) will flash and the Leading edge

control will be active. If the gap is greater than or equal to

1.5” (4.0 cm), full Leading and Trailing edge control is

maintained. Refer to table 10 for suction mode symbol

definitions.

The suction length adjustment keys allow the user to

change the amount of suction applied to the current sheet

length. The display shows the percentage in 5% steps. All

of the bars must be totaled to get the value. The range of

adjustment is 5% to 50% of the current sheet length. If the

suction length is manually adjusted while the Learn Mode

LED is on, the suction length will no longer be the Single

Sheet suction length of 6.0”. The new suction length will

be based on the current sheet length and suction setting.

TWT-180 Mode

Leading Edge Control

Leading and Trailing Edge Contro

Table 10. Suction Mode Symbols

Sheet Length Setting Resultant Suction Length Percentage

Greater than or equal to 30 cm. 30% of Sheet Length

Less than 30 cm., and greater than or equal to 27 cm. 25% of Sheet Length

Less than 27 cm., and greater than or equal to 24 cm. 20% of Sheet Length

Less than 24 cm., and greater than or equal to 21 cm. 15% of Sheet Length

Less than 21 cm. 10% of Sheet Length.

Table 11. Suction Length Function

Sheet Length Adjustment

+

The sheet length adjustment keys allow the user to

override the automatic Learn Mode setting. When the user

changes the sheet length, the suction length will be

adjusted according to table 11. If a different suction length

is desired, the value may be overridden with the suction

length adjustment keys. The sheet length range is 10 cm /4

inches to 250 cm / 98.5 inches.

Exit Learn Mode

0

h

Pressing any of these keys will cause the controller to

change to a new mode.

2.5 Make Ready Mode

This key places the controller in the make ready mode.

The key LED goes on. In this mode the folder will only

feed single sheets and a batching output is issued for every

two sheets fed. This allows the operator to easily set up the

batching time.

PAGE 29 TP10243-5

Page 30

Exit Make Ready Mode

2.7 Production Mode

Enter Run Mode and Select Large Display Content

h

Pressing any of these keys will cause the controller to

change to a new mode.

0

2.6 Network Job Mode

Pushing this key puts the counter in network job mode

+

This mode is only available if a STA-NET adapter is

installed and activated through maintenance mode. In this

mode the small display (2) always shows the word ‘Job’.

The large display (1) shows either ‘PAuSE’ or a job

number which can be read from the network. The suction

length display is disabled.

Select Job Number

+

This set of plus and minus keys step the large display

(1) through pause mode and a list of available job numbers.

While in network job mode, the folder is considered to be

paused.

Load Job and Return to Run Mode

When this button is pushed the selected job will be

loaded into the counter and the counter will return to run

mode. If the large display (1) was showing the message

‘PauSE’, the network job mode will end, but no job will be

loaded.

Exit Network Job Mode

+

+

h

These keys do not operate as mode select keys in

counter setup. In all other modes, the keys both select the

large display (1) contents and place the counter into run

mode. Pushing one of the buttons will light the button’s

associated LED and cause the parameter to be displayed. If

both the input and output count keys are pressed simultaneously, then both LEDs go on and the waste count is

displayed. See Process Variable Definitions.

Large Display Contents

h

h

h

h

h

Table 12. Determining the Large Display Contents

h

When the folder is started the counter will start up in

the run mode, the normal operating mode of the counter.

In this mode, various job parameters can be displayed on

the large display (1) and the small display (2) shows the

gap length. The suction length display (3) is active in this

mode and shows the suction length as a percentage of sheet

length.

Output Count

Batch Count Down

Number of Batches

Current Rate

Input Count

Waste Count

Gap Length Adjustment

+

h

Pressing any of these keys will cause the counter to

change to a new mode.

TP10243-5 PAGE 30

The gap length adjustment keys allow the user to

change the current gap length. The range of adjustment is

0.2” to 98.0” (0.5 cm to 250 cm).

Suction Length Adjustment

+

The suction length adjustment keys allow the user to

change the amount of suction applied to the current sheet

length. The display shows the percentage in 5% steps. All

of the bars must be totaled to get the value. The range of

adjustment is 5% to 50% of the current sheet length.

Page 31

Reset Function

0

Pressing and holding this key will result in a reset

function being activated after a 5-second countdown. The

function is based on the current large display selection, see

table 12. The large display (1) will show countdown to

reset in this manner. When the button is pressed the

message ‘CLr In 5’ will show on the large display (1). At

one second intervals the display will progress through ‘CLr

In 4’, ‘CLr In 3’, ‘CLr In 2’, ‘CLr In 1’, and finally will

show ‘CLEArEd’ when the reset action is complete.

3. 0 Logic Board Status Indicators

Several of the controller functions are monitored with

LED indicators located on the Logic Board (see Table 14).

The status of all other inputs are shown on the 8 Digit

display in Machine Setup mode (see Tables 1 - 6).

Reference Name Description

Designator

LED1 Tachometer Indicator Tracks the Tachometer input.

LED2 Not Used Turns on when MKE output is activated.

LED3 Suction Indicator Tracks the Suction output.

LED4 K1 Status of Relay K1

LED5 Pile Down Tracks the Pile down output.

LED6 Pile Up Tracks the Pile up output.

LED7 Pile Indicator Tracks the Pile outputs. If one of the Pile

LED8 Logic +5VDC Supply Shows status of Logic +5VDC Supply

LED9 Isolated +5VDC Supply Shows status of Isolated +5VDC Supply

LED10 Isolated +24VDC Supply Shows status of Isolated +24VDC Supply

LED11 Kicker Turns on when kicker output is activated.

Table 14. LED Status Indicators

Reset while showing Output Count will reset all job

variables.

Reset while showing batch data will reset Number

of Batches and reload the Batch Down Count.

Table 13. Reset mode Selection

outputs is on, this LED will be on.

PAGE 31 TP10243-5

Page 32

4.0 Process Variables Definitions

4.1 Total Input Count

The Current Rate is rounded to the nearest hundreds.

Current Rate can range from 0 to 99,999,900.

This process variable is not stored in memory.

Total Input Count increments by the factor setting each

time an input is received at the Input Count input. Total

Input Count can range from 0 to 99,999,999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

4.2 Total Output Count

Total Output Count increments by the factor setting

each time an input is received at the Output Count input.

Total Output Count can range from 0 to 99,999,999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

4.3 Batch Down Count

The Batch Down Count is the number of remaining

inputs necessary to trigger a batch output. As input counts

are received, this value counts down to zero. Each input

decrements the Batch Count Down by one. When zero is

reached, the Batch Down Count resets to the Batch Preset.

The Count input that is used by the Batch Down Count is

determined by the Batching Selection in Machine Setup. If

Feeder is the Batching Selection, the Batch Down Count

will be affected by the Input Count Input. If Delivery is the

Batching Selection, the Batch Down Count will be affected

by the Output Count Input.

Batch Down Count can range from 1 to 999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

Reset batch will load this process variable with the batch

preset.

4.4 Number of Batches

The Number of Batches is the number of times the

Batch Down Count has reached zero.

Number of Batches can range from 0 to 9999.

This process variable is stored in memory in case of a

power outage.

Reset job will clear this process variable to zero.

Reset batch will clear this process variable to zero.

4.5 Current Rate

The Current Rate is based on the number of Input

Count inputs received during the sample period.

The Current Rate is calculated every second.

The Current Rate is shown as rate per hour

4.6 Main Drive Run Time

The Main Drive Run Time is the amount of time the

Drive output has been on since the last Clear All Memory

Reset in Maintenance Mode.

This value is displayed in the format HHHHHH.HH.

Main Drive Run Time can range from 0.00 to 999,999.99.

This process variable is stored in memory in case of a

power outage.

Reset ALL in maintenance mode will clear this process

variable to zero.

4.7 Main Drive Velocity

The Main Drive Velocity is the speed of the Tachometer input.

This value is displayed in meters per minute.

This value is calculated every 300 milliseconds.

This process variable is not stored in memory.

4.8 Waste Count (Option)

The Waste Count is the difference between the Total

Input Count and the Total Output Count.

Waste Count is accessible by pressing and holding the Total

Count button followed by pressing the Total Output Count

button.

Waste Count can range from 0 to 99,999,999.

This process variable is not stored in memory.

Reset job will clear this process variable to zero.

5.0 Counter Setup V ariables

5.1 Batch Preset

This parameter, accessible in the Batch Setup mode,

specifies the batch count that will be used by the Batch

Count Down. Zero is the default setting.

This value can range from 0 to 999.

5.2 Batch Output T ype

This parameter, accessible in the Batch Setup mode,

specifies the batch output type that will be used when the

Batch Count Down reaches zero.

Available choices are Feed (FED), Delivery (DEL), Speed

(SPD), and Table (TBL).

TP10243-5 PAGE 32

Page 33

5.3 Batch Output Time

This parameter, accessible in the Batch Setup mode,

specifies the output duration or delay that will be used when

the Batch Count Down reaches zero.

Available ranges are determined by the Batch Output Type

selected. The Table below shows the ranges for each output

type.

Output Delay Duration

Type Min. Time Max. Time Min. Time Max. Time

Feed Not applicable 0.0 Sec. 9.9 Sec.

Table 0.000 Sec. 1.000 Sec. 100 ms

Delivery 0.000 Sec. 1.000 Sec. 25 ms

Speed Not applicable 0.00 Sec. 5.55 Sec.

Table 15. Output Delay and Duration

5.4 Sheet Length

This parameter, accessible in the Batch Setup mode,

specifies the length of the paper that will be fed into the

machine.

Available range is 6.0” to 59.0”. 6.0” is the default

selection.

5.5 Gap Length

This parameter is accessible in Run mode and Learn

mode and specifies the length of gap to use between sheets

of paper that are fed into the machine.

Available range is 0.2” to 98.0”. 2.0” is the default selection.

5.6 Suction Length

This parameter is accessible in Run mode and Learn

mode andspecifies the suction length used on a sheet of

paper that is fed into the machine.

Available range is 5% to 50% in 5% increments. 30% is the

default.

PAGE 33 TP10243-5

Page 34

6.0 System Messages and Run Messages

6.1 Power-Up Fault Messages

Messages that are displayed during power on self-test. If PLC System Errors are shown in the display, call service.

ENGLISH GERMAN CODES TYPE DESCRIPTION

88888 88888 88888 Information The controller is performing its lamp test.

MEM TEST MEM TEST MEM TEST Information The controller is performing its RAM test.

All Blank All Blank All Blank PLC System The display board is not functioning.

Error Cycle Power. If error persists, call service.

ID Fail ID Fail ID Fail PLC System System cannot recognize the controller board.

Error Action: Cycle Power, if error persists call service.

Error 1 Error 1 Error 1 PLC System The RAM test has found a bad memory location.

Error Action: Cycle Power, if error persists call service.

Error 2 Error 2 Error 2 PLC System The Pile Safety Relay is stuck on or there is no power supply to the

Error pile circuits. Action: Check the condition of Relay 1 (K1), Fuses

F1 and F2, and X18. Cycle Power. If error persists, call service.