Page 1

1"

"

"The"new"BAUM"1620"folders"include"a"new"design"of"fold"roll"gap"adjusting"gapsets"that"only"require"

the"operator"to"turn"the"gapset"knob"to"th e"co rrect"n um b er"fo r"the"th ickne ss"an d"p rop er"nu m b er"of"

sheets"required"to"effectively"drive"the"signatures"through"the"fold"rolls."This"new"paperless"gapset"

design"does"not"require"the"operator"to"tear"strips"of"paper"and"place"them"into"the"gapsets."

!"#$%&'(

)* +%(,-(.$/011$23$ 3(% 0 (-45%(,2/01,26(708 $ .(0 # #(%0 (% 4 $ (#0 93 $ .(: & (5 - ,2 6 (%4 $ (1",2(708$.(

3,-/022$/%(90/"%$3(02(%4$(7"."99$9(52,%(0.(3,-/022$/%,26(708$.(%0(%4$(1"/4,2$(:&(5279566,26(,%(

#.01("2&;"99((708$.(-05./$<-=*(

(

2. >5$(%0(70--,:9$(,2?5.&@(2$A$.("%%$17%(0.("9908("2&02$(%0("%%$17%(%0(-$%(%4$(#093(.099(6"7-$%-(

84,9$(%4$(#093(.099-(".$(.522,26*"

"

"Critical"items"that"need"special"attention"during"initial"build/rebuild"of"gapsets:"to"ensure"proper"gapset"

operation:"

1. The"5/16H18"elastic"stop"nut"must"only"be"tightened"just"enough"to"where"it"touches"the"g ap s e t"

knob.""

"

B0%$'(C2&(%0.D5$(02(%4,-(25%(02%0(%4$(6"7-$%(E20:(8,99(/"5-$("2(,17.07$.(6"7-$%(/"9,:."%,02*(

"

2. The"gapset"rod/block"weldment"has"a"center"drill"spot"on"the"block."This"center"drill"spot"is"

placed"on"the"block"to"indicate"which"orientation"this"black"is"to"be"placed"in"reference"to"the"

foldhead"frame."

"

B0%$'"F4$(-,3$(0#(%4$(:90/E(8,%4(%4$(/$2%$.(3.,99(-70%(,-(%0(#"/$("8"&(#.01(%4$(#0934$"3(#."1$(

-5/4(%4"%(84$2(%4$(6"7-$%("--$1:9&(,-(/0179$%$@(&05(-40593(-$$(%4,-(/$2%$.(3.,99(-70%*(

(

"

"

"

"

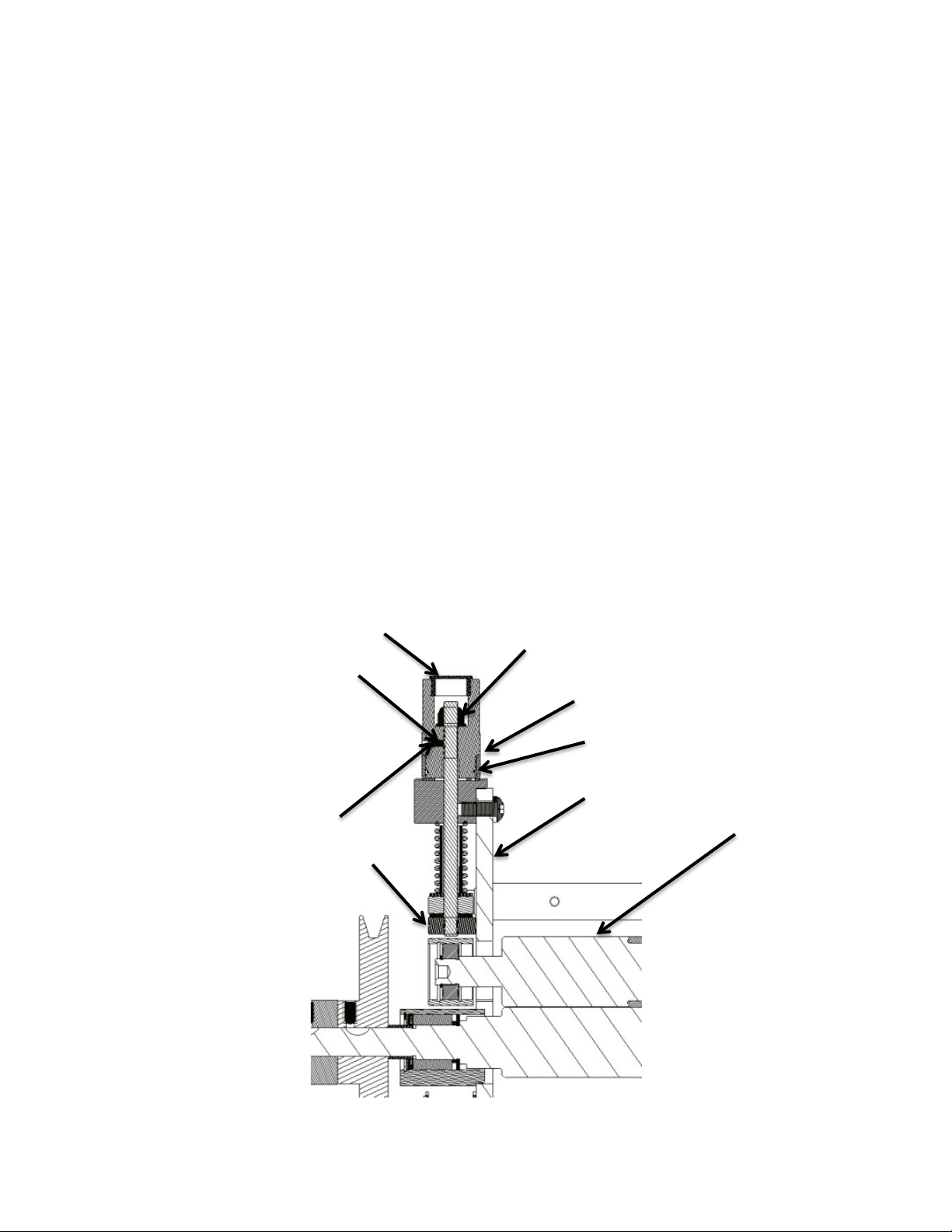

Gapset"block"

center"drill"points"

Page 2

2"

"

3. Due"to"tolerance"stackup"of"components"used"in"the"gapset"assemblies,"there"will"be"a"variation"

as"to"where"the"max"setting"of"each"gapset"knob"will"be."Some"gapset"knobs"may"not"rotate"a"

full"360"degrees"and"stop"at"a"setting"of"13."Some"gapset"knobs"may"rotate"beyond"360"degrees"

and"stop"at"a"setting"greater"than"the"intended"max"setting"of"15.""

"

B0%$'(>5$(%0(%4$(%09$."2/$(-%"/E57(0#(%4$(/01702$2%-(5-$3(,2(%4,-(6"7-$%("--$1:9&("23(%4$(

70--,:,9,%&(0#(%4$(6"7-$%(:$,26(.0%"%$3(10.$(%4"2(GHI(3$6.$$-("23(60,26(:$&023("(-$%%,26(0#(

)J(.$D5,.$3("(70,2%(0#(.$#$.$2 / $ (#0 . (%4 $ (0 7 $ . "% 0 .(% 0 (.$ % 5 .2 (% 4 $ (6 " 7 -$ % (: " /E (% 0 (" (-$ % %,2 6 (0 # () *(

F4,-(,-(%4$(029&(75.70-$(0#(%4$(J;)HK)L($9"-%,/(-%07(25%(,2(%4$(6"7-$%("--$1:9&*(

"

4. This"new"type"of"gapset"was"designed"around"20#"(0.0037”"thick)"bond"paper"being"the"most"

common"stock"folded"on"our"floor"model"folders.""This"factor"was"considered"in"both"the"pitch"of"

thread"used"on"the"gapset"knob/ro d"an d"a lso"the "des ign"of"th e"ga pse t"kno b"se tting"lab el.""With"

this"fact"in"mind,"each"full"graduation"on"the"gap set"kn ob "label"indicates"1"sheet"thickness"of"20#"

bond.""

"

B0%$'(>5$(%0(%4$(70--,:,9,%&(0#(%4$(6"7-$%(E20:(:$,26(":9$(%0(07$2$3(57(7"-%()J(02(%4$(6"7-$%((

E20:@(%4$(07$."%0.(-40593((20%(07$."%$(%4$(#093$.(8,%4("2&;"99(6"7-$%-("%("(-$%%,26(6.$"%$.(

%4"2()J*(+#(%4$(07$."%0.(30$-(07$."%$(%4$(#093$.(8,%4("2&(0#(%4$(6"7-$%-("%(-$%%,26-(6.$"%$.(

%4"2()J@(%4$2(%4$.$(,-("(70--,:,9,%&(0#(%4$(#093(.099-(.5::,26(%4 $(,2%" E$- ;3$ #9$/%0.- (0#(%4$ (#093(

7"2-*(F4,-(80593(/"5-$(7.$1"%5.$(8$".;3"1"6$(%0(%4$(#0937"2-;#093(.099-*(

(

"

Plastic"Binder"Plug"

Set"Screw

Cap"

Gapset"Knob"

Gapset"Setting"Dial"Indicator"w/"Label"

Foldhead"Frame"

Fold"Roll"

Elastic"Stop"Nut"

Gapset"Rod/Block"

Weldment"

Page 3

3"

"

Factory"Calibration"of"1620"Gapsets"&"Field/Service"Fold"Roll"Replacement:"

1. The"proper"fold"roll"gapset"calibration"sequence"is"as"follows:"

"

a) #1"fold"roll"to"main"fold"roll"

b) #2"fold"roll"to"main"fold"roll"

c) #3"fold"roll"to"#2"fold"roll"

d) #4"fold"roll"to"#3"fold"roll"

e) #5"fold"roll"to"#4"fold"roll"

This"sequence"of"setting"the"fold"rolls"must"be"followed,"as"not"doing"so"may"result"in"improper"

calibration"of"the"fold"rolls"causing"inaccurate/crooked"folds."

2. Ensure"that"there"is"an"equal"gap"on"both"the"operator"and"nonHoperator"sides"between"all"fold"

rolls."This"gap"only"needs"to"be"large"enough"to"allow"a"single"sheet"thickness"of"20#"bond"paper"

to"freely"be"slid"between"the"rolls."

"

H To"increase"the"gap"between"the"fold"rolls,"turn"the"gapset"knob"clockwise"

"

H To"decrease"the"gap"between"the"fold"rolls,"turn"the"gapset"knob"counterHclockwise."

"

3. Place"(1)"1”"wide"strip"of"20#"bond"paper"towards"the"outer"portion"of"the"main"and"#1"fold"rolls"

ensuring"that"the"paper"is"making"full"contact"with"the"urethane"bands"of"the"fold"rolls."

"

"

As"you"place"each"strip"of"paper"into"the"proper"fold"rolls"that"you"are"calibrating"the"gapsets"

for,"it"is"helpful"to"turn"the"gapset"knob"counte r Hclockwise"until"the"strip"of"paper"is"being"held"

lightly"by"the"fold"rolls.""

H While"placing"the"strip"of"paper"on"the"operator"side"of"the"fold"rolls,"adjust"the"#1"

gapset"knob"on"the"operator"side."

"

H While"placing"the"strip"of"paper"on"the"nonHoperator"side"of"the"fold"rolls,"adjust"the"#1"

gapset"knob"on"the"nonHoperator"side."

Page 4

4"

"

"

4. Setting"the"fold"roll"gap/pressure.""

Note:&The&proper&factory&calibration&of&the&gapsets&is&to&where&by&individually&pulling&on&each&

strip&of&paper&and&the&fold&rolls&just&starting&to&rotate.&&&

Not&enough&fold&roll&pressure&could&cause&the&folds&to&be&tight&and¬&provide&enough&

drive&for&the&sheets&to&flow&through&the&roll&bank.&

Too&much&fold&roll&pressure&can&cause&unnecessary&cracking,&especially&on&coated&

stocks,&and&could&cause&premature&wear&of&the&fold&rolls.&

"

a) To"do"this,"gently"pull"on"the"strip"of"paper"on"the"operator"side"and"feel"the"

amount"of"pressure"the"fold"rolls"are"applying."

"

o "If"pulling"on"this"strip "o f"p a p e r"fe lls"lik e "th e re "is"n ot"enough"pressure "a n d "d o e s"

not"cause"the"fold"rolls"to"start"rotating,"turn"the"gapset"knob"counterHclock"

wise"to"add"more"fold"roll"pressure."

"

o If"pulling"on"this"strip"o f"p a p e r"fe lls "like "th e re "is "to o "much"pressure"and "ca u s e"

the"strip"of"paper"to"tear"rotating,"turn"the"gapset"kno b "clock"w ise"to "redu ce "the"

amount"of"fold"roll"pressure."

"

"

b) After"feeling"the"pressure"on"the"strip"of"paper"on"the"operator"side,"gently"pull"

on"the"strip"of"paper"on"the"nonHoperator"side"and"feel"the"amount"of"pressure"

the"fold"rolls"are"applying."

"

o If"pulling"on"this"strip"o f"p a p e r"fe lls "like "th e re "is "n o t"e n o u g h "p re s su re "a n d "d o e s"

not"cause"the"fold"rolls"to"start"rotating,"turn"the"gapset"knob"counterHclock"

wise"to"add"more"fold"roll"pressure."

"

o If"pulling"on"this"strip"o f"p a p e r"fe lls "like "th e re "is "to o "much"pressure"and "ca u s e"

the"strip"of"paper"to"tear"rotating,"turn"the"gapset"kno b "clock"w ise"to "redu ce "the"

amount"of"fold"roll"pressure."

"

c) Now"that"you"have"initially"calibrated"the"fold"roll"pressures"on"the"operator"and"

nonHoperator"sides,"you"must"go"back"and"check"the"pressures"on"each"strip"of"

paper"again"to"ensure"the"pressures"remained"the"same."You"may"have"to"

readjust"the"pressure"on"each"side"to"ensu re"the "prop er"a m ou nt"o f"fold"roll"

pressure"is"maintained."

"

Page 5

5"

"

"

>5.,26(/"9,:."%,02(0#(%4$(#093(.099(7.$--5.$(-$%%,26-@(,%(,-(/.,%,/"9(%0($2-5.$(%4"%(

%4$("1052%(0#(3."6(02(:0%4(%4$ (07 $." %0.(" 23 (20 2K 07$."%0.(-,3$-(,-(%4$(-"1$M(

(

d) Repeat"steps"3"&"4"by"adjust"the"proper"gapset"knobs"for:"

#2"fold"roll"to"main"fold"roll(strips"of"paper"in"between"the"#2"and"m ain "fold "rolls"

&"adjusting"the"#2"gapset"knobs),"then"

#3"fold"roll"to"#2"fold"roll(strips"of"paper"in"between"the"#3"and"#2"fo l d"rolls"&"

adjusting"the"#3"gapset"knobs),"then"

"

#4"fold"roll"to"#3"fold"roll(strips"of"paper"in"between"the"#4"and"#3"fo ld"rolls"& "

adjusting"the"#4"gapset"knobs),"then"

"

#5"fold"roll"to"#4"fold"roll(strips"of"paper"in"between"the"#5"and"#4"fo ld"rolls"& "

adjusting"the"#5"gapset"knobs."

"

5. Now"that"all"of"the"fold"roll"pressures"have"been"set"properly,"while"holding"each"gapset"knob"so"

that"it"does"not"move(if"the"gapset"knob"tu rns,"the "fold"roll"pre ssure s"w ill"chang e),"turn "each "

gapset"indicator"dial"so"that"each"dial"is"set"at"1."

"

"

"

"

"

"

"

"

"

"

"

"

"

Page 6

6"

"

6. On"all"gapset"knobs,"using"a"2mm"allen"wrench,"tighten"the"set"screws"tha t "h o ld "t h e "p la s ti c"

binder"plug"so"that"the"binder"plug"applies"pressure"to"the"gapset"threaded"rod."Tighten"this"set"

screw"so"that"the"plastic"binder"plug"is"actually"“compressed”"on"the"threads"of"the"gapset"rod"

threads."This"step"will"ensure"that"the"gapset"kno b "doe s"no t"turn "as"the "rolls"ope n"an d"clo se"as "

the"sheets"are"passing"through"the"fold"roll"ban k."

"

"

"

7. Each"gapset"indicator"dial"has"a"label"with"indication"of"settings"from"1"–"15,"with"an"open"area"

in"which"the"label"doe s"n o t "w ra p "ar ou n d "th e "e n tire "rin g ."Tu rn "a ll" of"the"gapset"knob"counterH

clockwise"until"the"gapset"indicates"halfway"in"between"the"1"&"15"indicators.("

(

>0(20%(?5-%(%5.2(%4$(3,"9(,23,/"%0.(.,26@(029&(%5.2(%4$(6"7-$%(E20:-M(

"

"

"

"

"

"

"

"

"

"

Page 7

7"

"

8. While"holding"the"gapset"knob"so"it"does"not"turn,"tighten"the"elastic"stop"nut"located"in"the"

cavity"of"the"gapset"knobs"slowly"to"ensure"that"it"just"contacts"the"gapset"knob."This"is"done"

using"a"1/2”"or"13mm"nut"driver."Do"this"for"all"gapset"knobs."

"

">0(20%(%0.D5$(%4,-(25%(02%0(%4$(6"7-$%(E20:N(029&(%,64%$2(%4,-(25%(52%,9(,%(?5-%(%05/4$-(%4$(

6"7-$%(E20:M(

(

(

(

These"nuts"on"top"of"the"gapset"knobs"serve"2"purposes:"

"

a) With"the"nuts"just"tightened"until"they"are"just"touching"the"gapset"knobs"while"

the"gapset"is"set"in"between"1"&"15,"the"operator"can"now"adjust"the"fold"roll"

pressures"for"running"a"thinner"stock"than"20#"bond"such"as"Bible"paper,"etc."

"

b) If"the"operator"is"able"to"set"the"gapsets"t o "a "ga p s et "se tt in g"g re a te r"t h an"15,"the"

operator"can"just"turn"the"gapset"knob"counterHclockwise"until"it"contacts"this"

nut."The"operator"can"then"turn"the"knob"clockwise"until"a"gapset"setting"of"1."

The"fold"roll"pressure"for"this"roll"should"now"be"set"for"a"single"sheet"of"20#"

bond"paper."

(

9. Turn"all"of"the"gapset"knobs"back"to"1."It"is"recommended"that"you"check"the"fold"roll"pressures"

of"all"fold"rolls"by"using"1”"wide"strips"of"20#"bond"paper"ad"doing"the"pull"test."IF"the"fold"roll"

pressures"remained"the"same"with"all"gapset"knobs"set"at"1,"then"you"may"proceed"to"the"next"

step."If"the"fold"roll"pressures"do"not"feel"correct,"it"will"be"necessary"to"re pe at"ste ps"4 " H"6"to"

properly"set"the"fold"roll"pressures.""

"

10. The"gapset"knob"caps"can"now"be"pressed"into"the"top"of"the"gapset"knobs."

"

11. The"gapset"calibration"is"now"complete."

"

"

Page 8

8"

"

Recalibrating"Fold"Roll"Pressures"for"Fold"Roll"Wear:((

!"#$%&'(

)* +%(,-(.$/011$23$ 3(% 0 (-45%(,2/01,26(708 $ .(0 # #(%0 (% 4 $ (#0 93 $ .(: & (5 - ,2 6 (%4 $ (1",2(708$.(

3,-/022$/%(90/"%$3(02(%4$(7"."99$9(52,%(0.(3,-/022$/%,26(708$.(%0(%4$(1"/4,2$(:&(5279566,26(,%(

#.01("2&;"99((708$.(-05./$<-=*(

(

2. >5$(%0(70--,:9$(,2?5.&@(2$A$.("%%$17%(0.("9908("2&02$(%0("%%$17%(%0(-$%(%4$(#093(.099(6"7-$%-(

84,9$(%4$(#093(.099-(".$(.522,26*"

(

(

"

Adjusting"fold"rolls"due"to"normal"wear"and"tear"on"the"folder"is"common."Recalibrating"th e"fold "

rolls"for"this"is"very"easy."

1. Remove"plastic"caps"from"the"top"of"all"of"the"gapset"knobs."

"

2. Loosen"the"nuts"in"all"of"the"gapset"knob"cavity"using"a"½”"or"13mm"nut"driver."

"

3. Place"(1)"1”"wide"strip"of"20#"bond"paper"towards"the"outer"portion"of"the"main"and"#1"fold"rolls"

ensuring"that"the"paper"is"making"full"contact"with"the"urethane"bands"of"the"fold"rolls."

Plastic"Binder"Plug"

Set"Screw

Cap"

Gapset"Knob"

Gapset"Setting"Dial"Indicator"w/"Label"

Foldhead"Frame"

Fold"Roll"

Elastic"Stop"Nut"

Gapset"Rod/Block"

Weldment"

Page 9

9"

"

As"you"place"each"strip"of"paper"into"the"proper"fold"rolls"that"you"are"setting"the"gapsets"for,"it"

is"helpful"to"turn"the"ga ps e t"k no b "c o un t er Hclockwise"until"the"strip"of"paper"is"being"held"lightly"

by"the"fold"rolls.""

H While"placing"the"strip"of"paper"on"the"operator"side"of"the"fold"rolls,"adjust"the"#1"

gapset"knob"on"the"operator"side."

H While"placing"the"strip"of"paper"on"the"nonHoperator"side"of"the"fold"rolls,"adjust"the"#1"

gapset"knob"on"the"nonHoperator"side."

"

"

"

4. Calibrating"the"fold"roll"gap/pressure.""

Note:&The&proper&factory&calibration&of&the&gapsets&is&to&where&by&individually&pulling&on&each&

strip&of&paper&and&the&fold&rolls&just&starting&to&rotate.&&&

Not&enough&fold&roll&pressure&could&cause&the&folds&to&be&tight&and¬&provide&enough&

drive&for&the&sheets&to&flow&through&the&roll&bank.&

Too&much&fold&roll&pressure&can&cause&unnecessary&cracking,&especially&on&coated&

stocks,&and&could&cause&premature&wear&of&the&fold&rolls.&

"

a) To"do"this,"gently"pull"on"the"strip"of"paper"on"the"operator"side"and"feel"the"

amount"of"pressure"the"fold"rolls"are"applying."

"

o "If"pulling"on"this"strip "o f"p a p e r"fe lls"lik e "th e re "is"n ot"enough"pressure "a n d "d o e s"

not"cause"the"fold"rolls"to"start"rotating,"turn"the"gapset"knob"counterHclock"

wise"to"add"more"fold"roll"pressure."

"

o If"pulling"on"this"strip"o f"p a p e r"fe lls "like "th e re "is "to o "much"pressure"and "ca u s e"

the"strip"of"paper"to"tear"rotating,"turn"the"gapset"kno b "clock"w ise"to "redu ce "the"

amount"of"fold"roll"pressure."

"

Page 10

10"

"

"

b) After"feeling"the"pressure"on"the"strip"of"paper"on"the"operator"side,"gently"pull"

on"the"strip"of"paper"on"the"nonHoperator"side"and"feel"the"amount"of"pressure"

the"fold"rolls"are"applying."

"

o If"pulling"on"this"strip"o f"p a p e r"fe lls "like "th e re "is "n o t"e n o u g h "p re s su re "a n d "d o e s"

not"cause"the"fold"rolls"to"start"rotating,"turn"the"gapset"knob"counterHclock"

wise"to"add"more"fold"roll"pressure."

"

o If"pulling"on"this"strip"o f"p a p e r"fe lls "like "th e re "is "to o "much"pressure"and "ca u s e"

the"strip"of"paper"to"tear"rotating,"turn"the"gapset"kno b "clock"wise"to"reduce"the"

amount"of"fold"roll"pressure."

"

c) Now"that"you"have"initially"cailbrated"the"fold"roll"pressures"on"the"operator"and"

nonHoperator"sides,"you"must"go"back"and"check"the"pressures"on"each"strip"of"

paper"again"to"ensure"the"pressures"remained"the"same."You"may"have"to"

readjust"the"pressure"on"each"side"to"ens ure "the"p rop er"am o u nt"of"fo ld"roll"

pressure"is"maintained."

"

>5.,26(/"9,:."%,02(0#(%4$(#093(.099(7.$--5.$(-$%%,26-@(,%(,-(/.,%,/"9(%0($2-5.$(%4"%(

%4$("1052%(0#(3."6(02(:0%4(%4$ (07 $." %0.(" 23 (202K07$."%0.(-,3$-(,-(%4$(-"1$M(

(

d) Repeat"steps"3"&"4"by"adjust"the"proper"gapset"knobs"for:"

#2"fold"roll"to"main"fold"roll(strips"of"paper"in"between"the"#2"and"main"fold"rolls"

&"adjusting"the"#2"gapset"knobs),"then"

#3"fold"roll"to"#2"fold"roll(strips"of"paper"in"between"the"#3"and"#2"fold"rolls"&"

adjusting"the"#3"gapset"knobs),"then"

"

#4"fold"roll"to"#3"fold"roll(strips"of"paper"in"between"the"#4"and"#3"fold"rolls"&"

adjusting"the"#4"gapset"knobs),"then"

"

#5"fold"roll"to"#4"fold"roll(strips"of"paper"in"between"the"#5"and"#4"fold"rolls"&"

adjusting"the"#5"gapset"knobs."

"

5. Now"that"all"of"the"fold"roll"pressures"have"been"calibrated"properly,"while"holding"each"gapset"

knob"so"that"it"does"not"move(if"the"gapset"knob"turns,"the"fold"roll"pressures"will"change),"turn"

each"gapset"indicator"dial"so"that"each"dial"is"set"at"1."

Page 11

11"

"

"

"

It"is"possible"that"you "m a y "h ave"to"turn"the"gapset"knob"to"have"the"room"to"tighten"this"set"

screw"on"some"of"the"gapset"knobs."If"you"must"turn"the"gapset"knob"to"tighten"this"set"screw,"

after"you"tighten"this"set"screw"as"described,"ensure"that"you"turn"the"gapset"knob"back"to"a"

setting"of"1."

"

6. Each"gapset"indicator"dial"has"a"label"with"indication"of"settings"from"1"–"15,"with"an"open"area"

in"which"the"label"doe s"n o t "w ra p "ar ou n d "th e "e n tire "rin g ."T u rn"a ll"of"the"gapset"knob"counterH

clockwise"until"the"gapset"indicates"halfway"in"between"the"1"&"15"indicators.("

(

>0(20%(?5-%(%5.2(%4$(3,"9(,23,/"%0.(.,26@(029&(%5.2(%4$(6"7-$%(E20:-M(

(

"

"

"

"

"

"

"

"

"

"

Page 12

12"

"

7. While"holding"the"gapset"knob"so"it"does"not"turn,"tighten"the"elastic"stop"nut"located"in"the"

cavity"of"the"gapset"knobs"slowly"to"ensure"that"it"just"contacts"the"gapset"knob."This"is"done"

using"a"1/2”"or"13mm"nut"driver."Do"this"for"all"gapset"knobs."

"

">0(20%(%0.D5$(%4,-(25%(02%0(%4$(6"7-$%(E20:@(029&(%,64%$2(%4,-(25%(52%,9(,%(?5-%(%05/4$-(%4$(

6"7-$%(E20:M(

(

(

(

These"nuts"on"top"of"the"gapset"knobs"serve"2"purposes:"

"

a) With"the"nuts"just"tightened"until"they"are"just"touching"the"gapset"knobs"while"

the"gapset"is"set"in"between"1"&"15,"the"operator"can"now"adjust"the"fold"roll"

pressures"for"running"a"thinner"stock"than"20#"bond"such"as"Bible"paper,"etc."

"

b) If"the"operator"is"able"to"set"the"gapsets"t o "a "ga p s et "se tt in g"g re a te r"t h an"15,"the"

operator"can"just"turn"the"gapset"knob"counterHclockwise"until"it"contacts"this"

nut."The"operator"can"then"turn"the"knob"clockwise"until"a"gapset"setting"of"1."

The"fold"roll"pressure"for"this"roll"should"now"be"set"for"a"single"sheet"of"20#"

bond"paper."

"

8. Turn"all"of"the"gapset"knobs"back"to"1."It"is"recommended"that"you"check"the"fold"roll"pressures"

of"all"fold"rolls"by"using"1”"wide"strips"of"20#"bond"paper"ad"doing"the"pull"test."IF"the"fold"roll"

pressures"remained"the"same"with"all"gapset"knobs"set"at"1,"then"you"may"proceed"to"the"next"

step."If"the"fold"roll"pressures"do"n o t"fee l"co rr ec t,"it"w ill"be"necessary"to"repeat"steps"4"H"6"to"

properly"set"the"fold"roll"pressures.""

"

9. The"gapset"knob"caps"can"now"be"pressed"into"the"top"of"the"gapset"knobs."

"

10. The"gapset"calibration"is"now"complete."

"

Page 13

13"

"

Setting"of"Gapset"Knobs"for"the"operation"of"the"folder:"

Proper"setting"of"each"gapset"is"determined"by"the"least"amount"of"sheet"thicknesses"passing"

thru"each"nip"between"the"different"fold "rolls.""

For"instance,"if"you"are"folding"a"sheet"of"20#"bond,"and"the"least"amount"of"sheet"thicknesses"of"

passing"thru"the"#1,"#2"&"#3"rolls"was"1,"and"the"least"amount"of"sheet"thicknesses"of"passing"

thru"the"#4"was"2,"and"the"least"amoun t"of"she et"thick ne sses "of"pa ssing"th ru"#5 "wa s"4,"the n"yo u"

would"set"the"gapset"knobs"for"the"#1,"#2"&"#3"rolls"at"1,"the"#3"&"#4"rolls"at"2,"and"the"#5"roll""

at"4."

For"thicker"and"thinner"stocks"than"the"20#"bond,"set"the"gapsets"as"you"would"for"20#"bond."

a) If"you"notice"pressure"marks"or"sever"cracking"on"the"sheet,"reduce"the"amount"

of"fold"roll"pressure"of"the"proper"fold"roll"by"rotating"the"gapset"knob"

clockwise."

"

b) If"you"notice"that"the"sheet"is"stumblin g"a s "it"p a ss es "th r u "th e "fo ld "b a n k "o r"t h e"

fold"is"not"crisp/tight"enough,"increase"the "am o un t"of"fold "roll"pre ssu re"of"the"

proper"fold"roll"by"rotating"the"gapset"knobs"counterHclockwise."

"

"

"

"

Loading...

Loading...