Page 1

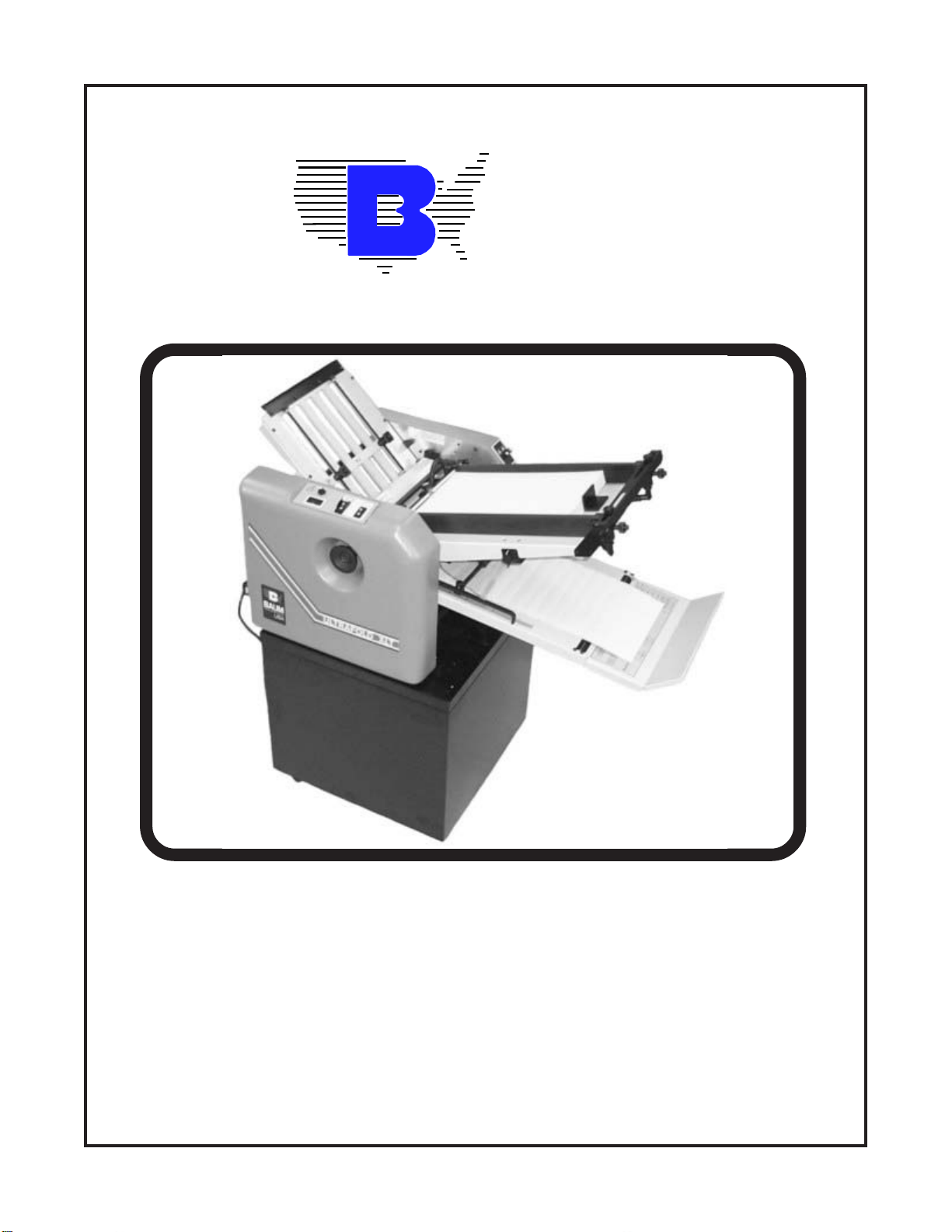

BAUMFOLDER

CORPORATION

Quality Bindery Equipment Since 1917

714XLT AIR FEED

FOLDER

INSTALLATION, OPERATION,

MAINTENANCE & PARTS MANUAL

© Baumfolder Corp., 2006 Printed in U.S.A. TP10289-3

PAGE 1 TP10289-3

Page 2

© 2006

All Rights Reserved

WARNING

• Do not operate this machine without all guarding in place.

• Do not make adjustments or perform maintenance on this machine with power on.

• Keep the machine and the work area clean and free of spills to prevent accidents.

• Be sure to replace any safety decals that may have been detached for any reason.

BAUMFOLDER reserves the right to make changes in design or to make additions or improvements

in its products without imposing any obligation upon itself to install them on its products previously

manufactured. It is recommended that modifications to this equipment not be made without the advice

and express written consent of BAUMFOLDER.

FOLDER IDENTIFICATION

MODEL NO: _______________________________ SERIAL NO: _____________________________

DEALER : __________________________________________________________________________

INSTALLED BY: _____________________________________________ DATE: ________________

PHONE NO: _______________________________

TP10289-3 PAGE 2

Page 3

Contents

1.0 INTRODUCTION..................................................................................................................................................... 4

2.0 SPECIFICA TIONS................................................................................................................................................... 4

3.0 INST ALLATION....................................................................................................................................................... 4

3.1 Unpacking & Inspection ............................................................................................................................................. 4

4.0 ASSEMBL Y ............................................................................................................................................................... 5

4.1 Main Unit .................................................................................................................................................................... 5

4.2 Pump Electrical Connections ...................................................................................................................................... 5

4.3 Pump Hose Connections ............................................................................................................................................. 5

4.4 Slitter Shaft Installation............................................................................................................................................... 5

4.5 Delivery Table ............................................................................................................................................................. 6

4.6 Feed Table Assembly Installation ............................................................................................................................... 6

4.7 Fold Plate Installation ................................................................................................................................................. 7

5.0 ELECTRICAL ACCESS .......................................................................................................................................... 7

6.0 FEED TABLE SETUP .............................................................................................................................................. 7

6.1 Setting the Controls..................................................................................................................................................... 7

6.2 Paper Size and Type of Fold ....................................................................................................................................... 7

6.3 Paper Stop Adjustment ................................................................................................................................................ 8

6.4 Gap Adjustment.......................................................................................................................................................... 8

6.5 Feed Table Adjustment................................................................................................................................................ 9

6.6 Air Blow Adjustment................................................................................................................................................... 9

7.0 OPERA TION............................................................................................................................................................. 9

7.1 Loading of Feed Table ................................................................................................................................................ 9

7.2 Starting the Vacuum/Air Feeder .................................................................................................................................. 9

7.3 Check Squareness of Fold........................................................................................................................................ 10

7.4 Use of Handwheel ..................................................................................................................................................... 10

8.0 PERFORA TING, SCORING & SLITTING......................................................................................................... 10

8.1 Perforating................................................................................................................................................................. 10

8.2 Scoring ....................................................................................................................................................................... 11

8.3 Slitting........................................................................................................................................................................ 11

9.0 MAINTENANCE .................................................................................................................................................... 12

9.1 Maintenance and Care of Autofold ........................................................................................................................... 12

9.2 Lubrication ................................................................................................................................................................ 12

9.3 Cleaning of Fold Rolls .............................................................................................................................................. 12

9.4 Cleaning Filters ......................................................................................................................................................... 12

9.5 Photo Eyes ................................................................................................................................................................ 12

9.6 Cleaning The Fold Stop Guides ................................................................................................................................ 12

9.7 Replacement Parts..................................................................................................................................................... 12

10.0 MATERIAL SAFETY DATA SHEET ................................................................................................................. 13

11.0 SPARE PARTS, SCHEMATICS & WARNING LABELS ................................................................................ 14

PAGE 3 TP10289-3

Page 4

1.0 INTRODUCTION

Your new 714XLT Air Feed Table Top Folder has been designed to give you many years of useful service provided

it is installed, maintained, and operated according to the instructions in this manual.

Your 714XLT Air Feed is a unique and versatile paper folding machine, capable of folding paper measuring

between 3 x 5 inches (7.6 x 12.7 cm) and 14 x 20 inches (35.5 x 50.8 cm), at speeds up to 35,000 sheets per hour of 8 1/2

x 11 (21.6 x 27.9 cm) and up to 65,000 sheets per hour of 3x5 (7.6x12.7 cm). The XLT will make six types of folds:

single fold, letter fold, fan fold, French fold, double-parallel fold and a double letter fold, with a few simple settings.

(Note: The French fold and double-letter fold requires either two passes or the use of a right-angle unit).

Your 714XLT is built rigid enough to ensure years of trouble-free performance, and at the same time, is compact

enough to fit on any table or desk. It is portable so it can be moved anywhere it is needed.

2.0 SPECIFICATIONS

Model No............................................................... 714XLT

Minimum Sheet Size ........................ 3 x 5" (7.6 x 12.7 cm)

Maximum Sheet Size ................. 14 x 20" (35.5 x 50.8 cm)

Minimum Size Fold .................................... 2 1/4" (5.7 cm)

Maximum Paper Weight ..................................65 lb. Cover

Stack Height...................................................... 2" (5.1 cm)

Fold Roll Speed ........................ Infinitely variable between

0"/min. and 7200"/min.

(18,288 cm/min. or 182 m/min.)

Fold Plate Depth ......................... #1 Plate, 13.5" (34.3 cm)

#2 Plate, 13.5" (34.3 cm)

Fold Roll Width ...................................... 14 1/8" (35.8 cm)

Fold Roll Diameter ..................................... 1 1/2" (3.8 cm)

Overall Physical Dimensions ................Height 26" (66 cm)

Length 34" (88 cm)

Width 23 1/2" (60 cm)

Operating Voltage ....................DOM. 110 VAC/1PH/60Hz

EXP. 220 VAC/1PH/60Hz

Power Consumption (folder) ...............................250 Watts

Power Consumption (pump) ..............................1500 Watts

Amperage (pump) .....................................DOM. 13.6 Amp

EXP. 6.8 Amp

3.0 INSTALLATION

3.1 Unpacking & Inspection

The 714XLT Air Feed is packaged in three cartons,

crated together as one package. It is broken down into 12

major assemblies for shipment. These are:

A) Main Folder Assembly

B) Pump Assembly

C) Feed T able Assembly (not shown)

D) Slitter Shaft Assembly

E) Stacker Wheel Assembly

F) Accessory Package (not shown)

G) Fold Roll Guards (2)

H) Stacker Tray

I) Fold Pans (2)

J) Hose Assembly (2)

K) Literature Package (not shown)

L) 1/2 Pint Surewash (not shown)

NOTICE

Immediately upon unpacking, carefully inspect each of the above assemblies for shipping damage. If any damage

is found, be sure to contact the delivery freight carrier to file a damage claim. Save all packaging material for the claims

adjustor to inspect.

TP10289-3 PAGE 4

Page 5

WARNING

4.3 Pump Hose Connections

Do not plug the power cord into an A Coutlet until

the 714XLT Air Feed is fully assembled, adjusted and

ready to use. Unplug the 714XLT any time disassembly is

required.

4.0 ASSEMBLY

4.1 Main Unit

T o assemble the 714XLT Air Feed unit, first remove

the four bolts holding it to the skid. Place the folder on the

stand (See Figure 4.1-1).

T wo hoses come with your 714XLT Air

Feed. (See Figure 4.3-1)

Air

Vacuum

For

Pump

Hoses

Figure

4.3-1

Figure 4.1-1

4.2 Pump Electrical Connections

The pump has a plug/cord set attached. This plug

fits directly into the rear of the lefthand side cover. (See

Figure 4.2-1)

Pump

Plug/Cord Set

4.4 Slitter Shaft Installation

T o install the slitter shaft, hold it with the grooves in

the boxings down. Be sure the slitter shafts are free

turning.

Insert the slitter shaft and seat the grooves in the

boxings on the lower locating pins in the side frames. (See

Figure 4.4-1)

Check for proper gear engagement between the upper

slitter shaft gear and the 19-tooth frame idler gear by

turning the handwheel.

Slitter Shaft Assembly

Figure 4.2-1

PAGE 5 TP10289-3

Page 6

4.5 Delivery Table

T o install the delivery table, loosen the knobs on

either side of the stacker table. Drop the tray over the

knobs and retighten.

Feed Table

Hoses

Air

Vacuum

Pump

Hoses

Figure

4.5-1

4.6 Feed Table Assembly Installation

Insert the feed table with the feed wheel toward the

fold rolls. Slide the paper feed table over both

sets of locating pins. (See Figure 4.6-1)

Figure 4.6-1

The first notch in the front part of the feed table

should rest on the pins. Then drop the rear notch down on

the upper dowel pins.

Figure

4.6-2

Rotate the handwheel to check that the gears are

properly meshed.

Connect the feed table hoses. Push the fittings into

the holes in the manifold block. (See Figure 4.6-2)

TP10289-3 PAGE 6

Page 7

4.7 Fold Plate Installation

5.0 ELECTRICAL ACCESS

WARNING

Unplug the AC power cord when installing or

removing fold plates.

The fold plates are marked #1 and #2 and are not

interchangeable. The #1 fold plate is installed in the top

position, the #2 fold plate in the lower position.

Each fold plate has an open end which faces toward

the fold rolls.

T o install the fold plates, pivot the fold plate holddowns out of the way and slide the fold plate in position

so that the slots in the leading edge of the fold plate

engage the two locating pins in the side frames.

Figure 4.7-1)

The center notches should seat on the second set of

locating pins. Pivot the fold plate hold-downs back into

position to secure the fold plates.

Turn the handwheel to be sure that the fold plates are

properly installed and not rubbing on the fold rolls.

(See

WARNING

Unplug the AC power cord before attempting any

electrical repair.

The motor speed control and counter control are

located under the left-hand side cover. The handwheel

must be removed for access to these controls.

The cover can be removed by taking out the four

screws located on the inside of the frame.

6.0 SETUP

6.1 Setting The Controls

The operator controls are conveniently located on a

control panel on the left-hand side of the 714XLT.

These controls consist of an On/Off power switch,

which is an overload reset, a speed control potentiometer,

a pump On/Off switch, and a counter with zero reset.

Set these initially at:

Holddown

#1 Fold Pan

A) Power Switch Off position

B) Speed Control “0” position

C) Pump Switch Off position

D) Counter “0” position

6.2 Determining Paper Size and Type of Fold

The next step is to determine the paper size and type

of fold to be made, following the steps below:

A) Measure a sample sheet of the job to be run to

determine its size. Retain this information for later use.

B) Refer to the printed chart on the stacker tray (See

Figure 6.2-1) and locate the type of fold that you want to

make. (Example: letter fold)

C) Locate on the chart the columns corresponding

to the sheet size measured in Step A. (Example: 8 1/

2x11)

Figure 4.7-1

PAGE 7 TP10289-3

Page 8

D) Locate the point on the chart where the columns

for the type of fold and the sheet size intersect. You will

notice that there are either two letters or a dash and a

letter. These letters and/or dash tell you where to set the

paper stop on the fold plate, and whether or not one of the

fold plates will be installed in the deflector position.

Example #1 ; To make a letter fold to an 8 1/2 x11

sheet, set the paper stops for the #1 and #2 fold plates on

the letter E. No dash appears, so neither fold plate is

installed in the deflector position.

Example #2: To make a single fold to an 8 1/2x11

sheet, install the #2 fold plate in the deflector position.

Set the paper stop for the #1 fold plate at the letter K.

6.3 Paper S top Adjustment

Figure 6.2-1

Figure 6.3-1

6.4 Gap Adjustment

To move the paper stops to the correct position as

determined in step #2, depress the coarse adjustment

knobs on the paper stop and slide the paper stop until the

indicating edge is aligned with the proper letter on the fold

plate. (See Figure 6.3-1)

T o obtain an exact setting on the paper stops, turn

the micro-adjustment knobs until the indicating edge of

the paper stop is perfectly aligned with the line adjacent to

the letter on the plate.

between the tab and the sucker wheel. Turn the gap knob

counterclockwise until there is a slight drag on the paper.

Remove the paper. The correct gap is now set. (See

Figure 6.4-1)

TP10289-3 PAGE 8

With the machine running, insert two sheets of paper

Gap Knob

Figure 6.4-1

Page 9

6.5 Feed Table Adjustment

6.6 Air Blow Adjustment

On the paper feed table there are two guides which

keep the stack of paper properly aligned for feeding into

the folder. Adjust these guides to correspond with the

different widths of paper being fed. (See Figure 6.5-1)

T o adjust the paper feed guides, loosen the two side

guide locking knobs on each guide. Slide the guides from

side to side until the insideedge of each guide is aligned

with the number corresponding to the width of the paper

being folded.

Example: For an 8 1/2-in wide sheet, move the side

guides until the inside edges align with the “8 1/2” on the

feed table.

An additional check is to lay a sheet of paper on the

feeder, close to but not touching the side guides. Push the

sheet down into the nip of the fold rolls. Then align the

guide by loosening the adjusting knobs and aligning the

guide so that it is parallel to the edge of the paper. When

one side is square, the other side can be moved into

position.

Tighten the locking knobs to secure the paper guides

in position.

When you load the actual job, you may have to

move these guides slightly to take care of variations in

sheet size. To feed properly, the paper must slide freely

between these guides.

Turn the air blow adjustment on the vacuum/aircontrol

panel fully counterclockwise to the + position. Except for

when very small sheets are being run, the air blow

adjustment is left adjusted for maximum air. (See Figure

6.6-1)

Once the amount of air blow has been selected using the

air blow adjustment, the feeder valve knob may be used to

direct the air (See Figure 6.5-1).

Turn the knob to the right to obtain more blow on the

right side and front of the feed table. Turn the knob to the

left to obtain more blow on the left side and

lessen the front blow.

Turn the vacuum adjustment clockwise all the way

down. This setting is used for most light and medium

papers. Heavy paper will require more vacuum.

+ttt--

Blow

+sss--

Vacuum

Figure 6.6-1

Side Guide

Locking Knobs

Side Guide Adjustment

Knobs

Figure 6.5-1

Feeder Valve Knob

(not shown)

Side Guides

7.0 OPERATION

7.1 Loading of Feed Table

Before you can load the paper on the feed table, you

must determine which way the paper is to be loaded by

running a few sample sheets. (Example: printing face up

or face down)

Then you can load a stack of paper no higher than

two inches between the paper feed guides. Let the stack

slide freely down into position between the side guides.

7.2 Starting the Vacuum/Air Feeder

After the vacuum and air adjustments have been

made, start the folder, then start the vacuum/pump.

PAGE 9 TP10289-3

Page 10

Additional paper can be loaded on top of the stack

of paper already in the feeder without stopping the

machine.

If the feeder runs out of paper or if youwant to stop

the machine for any reason, first turn off the vacuum

pump, then the folder.

7.3 Check Squareness of Fold

Examine the folded sheets on the stacker to make

sure that you are getting an even and square fold.

There is a skew adjustment on each plate to adjust

for a square fold on paper that is not cut square (See

figure 4.7-1).

7.4 Use of Handwheel

The handwheel is used to help clear jams and for

setup. To use the handwheel, shut off the folder, pull out

the handwheel and turn it in either direction.

TOP SHAFT

Figure 8.1-1

The perforating blade holder assembly is then slid

onto the upper slitter shaft along with the necessary pullout tire assemblies. Then tighten the screws holding the

perforator blade to the blade holder, aligning the blade to

the holder. This allows for free horizontal movement on

the shaft.

Slide the grooved perforator collar onto the lower

slitter shaft along with the other pull-out tire assemblies.

The flat side of the perforator blade should just touch the

side of the groove in the perforator collar. (See Figure

8.1-1)

8.0 PERFORATING, SCORING

& SLITTING

In addition to folding, your 714XLT Air Feed can

perforate, score and slit.

WARNING

Be careful when handling perforator and slitting

blades. They are extremely sharp.

8.1 Perforating

The 714XLT can be used to perforate either the

folded sheet (to assist in making a right-angle fold) or to

perforate sheets delivered flat. BAUMFOLDER supplies

one standard 41-tooth perforator blade. Additional

perforator blades are available through the

BAUMFOLDER Parts Department.

The perforator blade should be mounted loosely to

the blade holder with the retainer collar to give better

support to the perforator blade. Always be sure that the

flat side of the blade is against the blade holder. Loosen

the brass-tipped set screws in the perforator collar and

blade holder before attempting to place them on the slitter

shafts.

TOP SHAFT

Figure 8.1-2

Slide the perforator collar and blade holder to the

desired position on the slitter shaft. Then lock the blade

holder and perforator collar into position with the brasstipped set screw.

The perforator stripper fits onto the slitter shaft bar

in between or next to the perforating blade. (See Figure

8.1-2) This strips the paper off for delivery and prevents

it from wrapping around the perforator blade.

TP10289-3 PAGE 10

Page 11

8.2 Scoring

The 714XLT can be used to score a sheet and

deliver it flat, or to score a sheet after a fold or folds have

been made.

T o ensure accuracy in making right-angle folds,

always score the sheet where the fold is to be made. This

applies in all instances when a perforator cannot be used.

Attach the scoring blade loosely to the blade holder

for mounting on the slitter shaft. Scoring blades can be

mounted on either the upper or lower slitter shaft. Once

on the shaft, tighten the screws, aligning both the blade

and the collar. This allows free horizontal movement on

the shaft. Scoring blades should be placed so that the fold

will be made with rather than against the scoring, or, in a

continuing direction to the pressure of the crease that has

been applied by the scoring blade.

TOP SHAFT

TOP SHAFT

Figure 8.2-2

8.3 Slitting

NOTE: Slitting accessories are optional on your

714XLT and can be ordered from your BAUMFOLDER

Parts Department.

The 714XLT can be used to cut folded or flat sheets

apart. The general setup for blades and collars is shown in

(Figure 8.3.1). Two or more cuts may be made if duplicate sets of cutters are used.

Figure 8.2-1

For a wide, well-rounded score, use the two steel

scoring collars. (See Figure 8.2-1) Sharpness and the

depth of the score can be controlled by regulating the

distance the collars are placed away from the scoring

blade.

The scoring collars can also be placed on either side

of the rubber scoring collar. The two collars can be

compressed against the rubber collar, causing the rubber

to bulge up for a deeper score. (See Figure 8.2-2)

TOP SHAFT

Figure 8.3.-1

Use care in mounting slitter blades to the collars in

order to avoid ragged edges during slitting operations.

Ragged edges can be caused by two conditions:

1) Nicks or burrs on the collars or blades. Remove

carefully by filing or using a fine piece of emery cloth.

2) Incorrect mounting of blades caused by tightening

with the wrong type of screw. Always use flat head screws

on the side of the blade and blade holder collar, which are

countersunk.

PAGE 11 TP10289-3

Page 12

Before tightening the blade to the collar, slide the

blade with the collar loosely attached on the end of the

shaft. Then tighten securely , thus aligning both the blade

and collar, allowing free horizontal movement along the

shaft.

Place the blade, mounted on the collar, on the upper

shaft in the proper position where the cut is to be made.

Then move the blade and collar on the lower shaft so that

the two flat edges of the blades are pressed snugly together.

T oo much space between the blades will produce a ragged

cut.

9.6 Cleaning The Fold Stop Guides

The fold stop guides (See figure 4.7-1) should be

cleaned once a week with a dry cloth to keep the plate

moving properly.

9.7 Replacement Parts

To order replacement parts for your 714XLT Air

Feed, contact BAUMFOLDER Parts Department toll free,

800-543-6107.

Space the rubber pull-out tires to support the sheet.

9.0 MAINTENANCE

9.1 Maintenance and Care of your

714XLT

The 714XLT Air Feed has been designed to give

you years of useful service, provided you maintain it

according to these instructions.

9.2 Lubrication

Apply one or two drops of light machine oil at all

slitter shaft bearings and the feed table bearings and idler

gear once a week. Be sure to keep oil off any surface

which may contact the paper.

9.3 Cleaning of Fold Rolls

Periodically wipe off the rubber surface of the fold

rolls using an approved solvent such as Surewash or its

equivalent. Surewash is available from BAUMFOLDER

in 1-quart (P/N 24108-001) and 1-gallon (P/N 24108-002)

containers. A complementary bottle of Surewash is

included with your machine.

Always be sure to give the model number and serial

number of your 714XLT to ensure receiving the proper

parts.

9.4 Cleaning Filters

The filters on the pump should be checked periodically and cleaned as needed. The filters can be reached by

unscrewing the filter jars.

9.5 Photo Eyes

Occasionally wipe off the photo eye with a dry cloth.

TP10289-3 PAGE 12

Page 13

SUREWASH

10.0 MATERIAL SAFETY DATA

SHEET

irritation and may affect central nervous system. May cause

skin irritation. Chronic over-exposure to many petroleum

hydrocarbons may cause liver or kidney injury. May cause

eye irritation.

NOTICE: Surewash is a product of RBP Chemical

Corporation, 150 S. 118th St., P.O. Box 14069, Milwaukee,

Wisconsin 53214-0069. Tel. 414/258-0911, 800/558-0747.

H M I S RATING

Health: 1

Flammability: 2

Reactivity: 0

Personal Protection: 8

HAZARDOUS INGREDIENTS

Name: Medium Aliphatic Solvent Naptha

(Syn: 140 HF Mineral Spirits)

CAS#: 64742-88-7

ACGIH TLV: 100ppm

OSHA PEL: 500ppm

%: <95

PHYSICAL/CHEMICAL CHARACTERISTICS

Boiling Point: ND

Solubility in Water: Insoluble

% Volatiles (by vol.): 95

Specific Gravity: 0.786

Appearance and Odor: Clear, light blue liquid

with pleasant odor.

FIRE AND EXPLOSION HAZARD DATA

Flash Point: 140' F

Extinguishing Media: CO2, Dry chemical,

Foam

Special Fire Fighting Procedures: Wear selfcontained breathing apparatus for any fire

involving chemicals.

Unusual Fire and Explosion Hazards: None

REACTIVITY DATA

Stability: Stable

Incompatibility: Strong oxidizers

Hazardous Decomposition By-products: Carbon dioxide/monoxide

Hazardous Polymerization: Will not occur

Conditions to Avoid: Heat, Sparks, and Open

Flames

HEALTH HAZARD DATA

Routes of Entry: Inhalation, Primary; Skin,

Secondary; Ingestion, Unlikely

Health Hazards Acute and Chronic: Chronic Inhala-

tion of high concentrations may cause respiratory tract

Emergency & First Aid Prodedures:

Skin Contact: Wash affected area with soap and water.

Remove contaminated clothing.

Eye contact: Flush eyes with water for at least 15

minutes. Consult a physician.

Inhalation: Remove to fresh air. Restore breathing if

required. Get medical attention.

Ingestion: DO NOT induce vomiting. Get medical

attention.

Carcinogenicity: None of the ingredients in this prod-

uct are listed by IARC, NTP, or OSHA as carcinogenic.

Signs and Symptoms of Over-exposure: Headache,

dizziness, nausea, irritation of the mucous membranes, respiratory tract irritation or mild narcosis at high concentrations.

Medical Conditions Aggravated by Exposure: May

aggravate an existing dermatitis.

PRECAUTIONS FOR USE AND DISPOSAL

Spills: Small spills can be soaked up with suitable

absorbent. For large spills, dike the spill and pump to salvage

tank.

Waste Disposal: Incineration or absorbent disposal

according to local, state, or federal regulations.

Special Storage/Handling Precautions: None

CONTROL MEASURES

Respiratory Protection: Organic vapor respirator for

concentrations above the TLV.

Ventilation: Mechanical

Eye Protection: Recommended

Gloves: Recommended, butyl, rubber or neoprene.

Other: Eye bath or safety shower should be located in

the work place when working with chemicals.

*ND = No data found or not determined.

The information contained herein is furnished without

warranty of any kind. Users should consider this data a

supplement to other information gathered by them and are

responsible for completeness of information to assure proper

use of these materials and the safety and health of their

employees.

To order Surewash call toll free, 800/543-6107

Part numbers: 24108-001 (quart) & 24108-002 (gallon)

PAGE 13 TP10289-3

Loading...

Loading...