Page 1

714XAB-2-P-1

714XA A-2-P-1

714XAB-2-P-4

TABLE TOP FOLDER

TABLE TOP FOLDER

INSTRUCTION MANUAL

FOR INSTRUCTION MANUALS IN SPANISH, FRENCH, AND GERMAN

GO TO WWW.BAUMFOLDER.COM

©Baumfolder Corp., 2010 Printed in U.S.A. TP10583

INS

TRUCTION MANUAL

PAGE 1 TP10583

Page 2

© 2010 BAUMFOLDER CORPORATION

All Rights Reserved

WARNING

• Do not operate this machine without all guarding in place.

• Do not make adjustments or perform maintenance on this machine with power on.

• Keep the machine and the work area clean and free of spills to prevent accidents.

• Be sure to replace any safety decals that may have been detached for any reason.

Baumfolder Corporation reserves the right to make changes in design or to make additions or

improvements in its products without imposing any obligation upon itself to install them on its

previously manufactured products. It is recommended that modifications to this equipment not be

made without the advice and express written consent of Baumfolder Corporation.

FOLDER IDENTIFICATION

MODEL NO: _______________________________ SERIAL NO: _____________________________

SALES AGENCY:____________________________________________________________________

INSTALLED BY: _____________________________________________ DATE: ________________

PHONE NO: _______________________________

PAGE 2 TP10583

Page 3

DESCRIPTION PAGE

CONTENTS

INTRODUCTION

SAFETY FIRST.........................................................................................................6

INTRODUCTION OVERVIEW.................................................................................... 7

1.0 ASSEMBLY INSTRUCTIONS ................................................................................ 7

1.1 INSTALL FEED TABLE ................................................................................................................................. 8

1.2 INSTALL BOTH PANS ................................................................................................................................. 8

1.3 INSTALL STACKER TRAY...............................................................................................................................9

1.4 PUMP CONNECTIONS ................................................................................................................................9

1.5 INSTALL SLITTER SHAFT ASSEMBLY ............................................................................................................. 9

1.6 OTHER ELECTRICAL CONNECTIONS ............................................................................................................ 9

2.0 SETUP..................................................................................................................9

2.1 GAP ADJUSTMENT .................................................................................................................................... 9

2.2 FEED TABLE ADJUSTMENT .......................................................................................................................... 9

2.3 AIR FLOW ADJUSTMENT .......................................................................................................................... 10

3.0 OPERATION.....................................................................................................10

3.1 LOADING THE FEED TABLE ...................................................................................................................... 10

3.2 CHECK SQUARENESS OF FOLD ............................................................................................................... 10

3.3 USE OF HANDWHEEL .............................................................................................................................. 10

4.0 PERFORATING, SCORING & SLITTING ....................................................... 11

4.1 PERFORATING ........................................................................................................................................11

4.2 SCORING ...........................................................................................................................................................................12

4.3 SLITTING .............................................................................................................................................. 12

5.0 MAINTENANCE ....................................................................................................13

5.1 MAINTNANCE AND CARE OF YOUR 714XA...............................................................................................13

5.2 LUBRICATION..........................................................................................................................................13

5.3 CLEANING OF FOLD ROLLS.......................................................................................................................13

5.4 CLENINING FILTER ...................................................................................................................................13

5.5 PHOTO SENSORS.....................................................................................................................................13

TP10583 PAGE 3

Page 4

CONTENTS

DESCRIPTION PAGE

6.0 BAUMFOLDER 714XA “QUICK START” INSTRUCTIONS....................... 14

TURNING THE MAIN SWITCH ON .................................................................................................................... 14

CURRENT JOB OR SETUP NEW JOB ............................................................................................................... 14

FOLD CHOICE SCREEN .................................................................................................................................. 14

PAPER LENGTH SCREEN ................................................................................................................................. 14

SELECTING UNITS ......................................................................................................................................... 14

MOVING PANS (INITIALIZING OR MOVING TO FOLD POSITION) ........................................................................ 15

PAN MOVING STATUS IMAGE .......................................................................................................................... 15

COUNT SETUP SCREEN :BATCH OR NO BATCH ................................................................................................ 15

COUNT SETUP SCREEN :RUN BATCH-SIMPLE .................................................................................................... 16

COUNT SETUP SCREEN: RUN BATCH-VARIABLE ................................................................................................ 17

VARIABLE BATCH SETUP SCREEN .................................................................................................................... 17

VARIABLE BATCH DATA ENTRY SCREEN ......................................................................................................... 17

PRODUCTION SCREEN ICONS ........................................................................................................................ 18

CURRENT FOLD TYPE .................................................................................................................................... 18

PAN 1 AND PAN 2 CURRENT POSITIONS .......................................................................................................... 18

TURNING ON MAIN ROLLS, DELIVERY, AND PUMP ............................................................................................ 19

SINGLE SHEET MODE/ CONTINUOUS FEED MODE .............................................................................................. 19

PAPER FEED ON/ OFF.......................................................................................................................................20

TOTAL COUNT INDICATOR AND RESET COUNT BUTTON ..................................................................................... 20

BATCH COUNT INDICATORS............................................................................................................................20

PREVIOUS SCREEN REQUEST BUTTON ............................................................................................................. 20

MAIN SCREEN REQUEST BUTTON .................................................................................................................... 20

PRODUCTION SCREEN REQUEST BUTTON ........................................................................................................ 20

FOLD PA N ADJUSTMENT SCREEN .................................................................................................................... 21

FOLD PAN DIRECT ENTRY SCREEN.................................................................................................................. 21

SETUP PREFERENCES SCREEN ......................................................................................................................... 22

LANGUAGE SELECTION ................................................................................................................................. 22

SENSOR BYPASS OPTIONS ............................................................................................................................. 22

MEMORY SCREEN ......................................................................................................................................... 23

SAVE TO MEMORY SCREEN .......................................................................................................................... 24

RELOAD FROM MEMORY SCREEN .................................................................................................................. 24

FAULT STATES.................................................................................................................................................24

NON-FAULT STAUS INDICATORS..................................................................................................................... 25

ERROR SCREENS .......................................................................................................................................... 26

7.0 OPERATOR CONTROLS .................................................................................... 27

7.0 SETTING FOLDING SPEED ........................................................................................................................ 27

7.1 SETTING STACKER BELT SPEED .............................................................................................................. 27

7.2 EMERGENCY STOP BUTTON ...........................................................................................................................................27

PAGE 4 TP10583

Page 5

CONTENTS

8.0 BASIC MACHINE SETUP ..................................................................28

UNITS OF MEASURE ................................................................................................................................. 28

8.1

8.2 LANGUAGES ...................................................................................................................................................................... 28

8.3 HARDWARE AND SOFTWARE VERSIONS ....................................................................................................................28

9.0 DIAGNOSTICS ....................................................................................................... 28

10.0 CALIBRATION OF FOLD PANS ...................................................................... 29

TECHNICAL SPECIFICATIONS..........................................................................43

TROUBLESHOOTING ...........................................................................................44

INSTALLATION OF ANTISTATIC......................................................................45

TP10583 PAGE 5

Page 6

SAFETY FIRST

10. Make sure that all safety devices are in place before

restarting the machine.

Your new Baum paper folding machine has been designed

in accordance with the latest safety specifications. The

warning and caution labels on the machine must remain in

place. Make sure all guarding provided is in place before

starting up and running the machine.

Due to the nature of the work process of paper folding

machines, there are parts and areas on the machine which

cannot be completely covered without interfering with the

operation of the machine. Therefore, sound personal work

habits and strict observance of all safety precautions is

required for the protection of the operator, co-workers, and

the machine.

Be sure to follow these

safety precautions:

1. Study the safety instructions at your plant and those

provided in this manual.

2. Study the operating instructions carefully before

operating the machine.

3. Make sure that your co-workers are familiar with the

work process, potential danger areas,

and all necessary safety measures.

4. Make sure that the machine is in good working order

before turning it on.

5. If the machine suddenly stops for whatever reason, do

not restart it right away. Someone may have stopped

the machine, but failed to press the emergency (Stop)

button. If the machine is restarted unexpectedly, your

co-worker could be seriously injured.

6. Always press the emergency (Stop) button first if you

stop the machine for adjustments or maintenance work

which must not be done while the machine is in

operation.

11. Never clean moving parts of the machine (rollers,

shafts, etc.) or remove any test sheets or paper jams

while the machine is running.

12. Keep the floor around the entire machine clean.

Immediately clean up any oil, grease, or paint spills

from the floor. Remove tools, cleaning cloths, and

paper scraps from all work areas.

13. Never allow unauthorized personnel to make adjustments on the machine, remove problem sheets, or start

the machine.

14. Never climb over the machine or crawl into it while it is

turned on.

15. Immediately repair or replace any safety devices which

have become ineffective or are missing.

16. Report any exposed cables or exposed electrical

connections.

17. Always have a certified qualified electrician perform all

electrical maintenance.

18. Do not make adjustments or perform maintenance with

the power on.

19. Become familiar with and follow the safety labels on

the next page. Replace any of these labels that are

damaged or lost.

Additional Notes:

20. Do not attempt to remove a paper jam, no matter how

minor it may appear to be, while the machine is

running.

21. When cleaning the fold rolls, use the handwheel for

turning. Be sure the power to the machine is off.

7. For extensive maintenance or repair work, turn off the

main power supply.

8. Never use improper or defective tools.

9. After making adjustments or after doing maintenance

or repair work, always make sure that all tools and

other objects are removed from the machine. Otherwise, they might fall into the machine, causing severe

damage or injuries.

22. Turn off the machine before making any adjustments to

the scoring, perforating, or slitting attachments. Keep

hands and clothing away from the slitter shafts when

the machine is running.

PAGE 6 TP10583

Page 7

LA SEGURIDAD ES

LO PRIMERO

10. Asegúrese de que todos los dispositivos de seguridad

estén colocados en su lugar antes de volver a encender la

máquina.

Su nueva máquina plegadora de papel Baum ha sido

diseñada de acuerdo con las más recientes especicaciones

de seguridad. Las etiquetas de advertencia y precaución en la

máquina deben mantenerse colocadas en su lugar. Asegúrese

que todos los elementos protectores suministrados estén

colocados en su lugar antes de encender y usar la máquina.

Debido a la naturaleza del proceso de trabajo de las

máquinas plegadoras de papel, hay partes y áreas en la

máquina que no se pueden cubrir totalmente sin interferir con

el funcionamiento de la máquina. Por lo tanto, los buenos

hábitos de trabajo personales y el estricto cumplimiento

de todas las precauciones de seguridad son necesarios para

la protección del operador, los compañeros de trabajo y la

máquina.

Asegúrese de seguir estas

precauciones de seguridad:

1. Estudie las instrucciones de seguridad de su planta y

aquellas suministradas en este manual.

2. Estudie detenidamente las instrucciones de operación

antes de utilizar la máquina.

3. Asegúrese de que sus compañeros de trabajo estén

familiarizados con el proceso de trabajo, las áreas

posiblemente peligrosas y todas las medidas de

seguridad necesarias.

4. Asegúrese de que la máquina esté en buenas condiciones

de funcionamiento antes de encenderla.

5. Si la máquina se apaga repentinamente por cualquier

razón, no la encienda de nuevo inmediatamente. Alguien

podría haber apagado la máquina, pero no pulsó el botón

(de parada) de emergencia. Si se vuelve a encender la

máquina inesperadamente, su compañero de trabajo

podría sufrir una lesión grave.

6. Presione siempre primero el botón (de parada) de

emergencia si detiene la máquina para realizar ajustes o

tareas de mantenimiento, ya que este tipo de trabajo no

debe hacerse con la máquina en funcionamiento.

7. Para los trabajos de mantenimiento o reparación

extensivos, apague el interruptor principal de la

alimentación eléctrica.

11. Nunca limpie piezas móviles de la máquina (rodillos,

ejes, etc.) ni quite hojas de prueba ni elimine atascos de

papel en dichas áreas.

12. Mantenga limpio el suelo alrededor de toda la máquina.

Limpie inmediatamente los derrames de aceite, grasa

o pintura del suelo. Retire las herramientas, los trapos

de limpieza y los trozos de papel de todas las áreas de

trabajo.

13. Nunca permita que personal no autorizado haga ajustes

en la máquina, retire hojas que causen problemas o

encienda la máquina.

14. Nunca se suba a la máquina ni se meta en ella mientras

está encendida.

15. Repare o sustituya inmediatamente los dispositivos de

seguridad que falten o no sean ecaces.

16. Informe de cualquier cable expuesto o conexión

eléctrica expuesta.

17. Deje siempre en manos de un electricista cualicado

todas las tareas de mantenimiento eléctrico.

18. No realice ajustes ni tareas de mantenimiento con la

alimentación eléctrica conectada.

19. Familiarícese con las etiquetas de seguridad de la página

siguiente y siga sus recomendaciones. Sustituya las

etiquetas que falten o estén dañadas.

Notas adicionales:

20. No intente eliminar un atasco de papel, aunque

parezca algo fácil de hacer, mientras la máquina esté

funcionando.

21. Cuando limpie los rodillos plegadores, utilice la rueda

de mano para girar. Asegúrese de que la alimentación

eléctrica para la máquina esté desconectada.

22. Apague la máquina antes de hacer ningún ajuste a los

accesorios de hendido, perforación o corte. Mantenga

las manos alejadas de los ejes de la cortadora cuando la

máquina esté funcionando.

8. Nunca utilice herramientas inadecuadas o defectuosas.

9. Después de realizar los ajustes o después de terminar

las tareas de mantenimiento o el trabajo de reparación,

compruebe siempre que se hayan retirado de la máquina

todas las herramientas u otros objetos. De lo contrario,

esas herramientas u objetos podrían caer en la máquina y

causar daños o lesiones graves.

TP10583 PÁGINA 6

Page 8

LA SÉCURITÉ AVANT TOUT

10. Assurez-vousquetouslesdispositifsdesécuritésonten

placeavantderedémarrerlamachine.

VotrenouvellemachineBaumfolderàplierlepapieraété

conçueconformémentauxspécicationsdesécuritélesplus

récentes.Lesétiquettesd'avertissementetd'attentionsur

lamachinedoiventresterenplace.Assurez-vousquetous

lesdispositifsdeprotectionfournissontenplaceavantde

démarreretdefairefonctionnerlamachine.

Enraisondelanatureduprocessusdestravauxdesmachines

àplierlepapier,certainespiècesetautreszonesdela

machinenepeuventpasêtrecomplètementprotégéessans

interféreravecsonfonctionnement.C'estpourquoides

habitudespersonnellessainesdetravailetl'observation

strictedetouteslesprécautionsdesécuritésontnécessaires

àlaprotectiondel'opérateur,descollèguesdetravailetdela

machine.

Veuillez observez ces

précautions de sécurité :

1. Consultezlesinstructionsdesécuritédevotreusine

ainsiquecellesfourniesdanscemanuel.

2. Consultezlesinstructionsdefonctionnementavec

attentionavantdefairefonctionnerlamachine.

3. Assurez-vousquevoscollèguesdetravailsont

familiarisésaveclesméthodesdetravail,leszones

dedangerpotentielettouteslesmesuresdesécurité

nécessaires.

11. Nenettoyezjamaisdespiècesenmouvementdela

machine(rouleaux,axes),nineretirezaucunefeuille

detestoubourragedepapierlorsquelamachineesten

fonctionnement.

12. Lesoltoutautourdelamachinedoitêtrepropre.

Nettoyezimmédiatementl’huile,lagraisseoula

peintureencasdedéversementsurleplancher.Retirez

lesoutils,leschiffonsoulespapiersdenettoyagede

toutesleszonesdetravail.

13. Nelaissezjamaisunpersonnelnonautoriséprocéderà

desréglagessurlamachine,retirerdesfeuillesdepapier

avecdesproblèmesoudémarrerlamachine.

14. Nemontezjamaissurlamachinenin'ypénétrez

lorsqu'elleestsoustension.

15. Réparezouremplacezimmédiatementtoutdispositifde

sécuritéinefcaceoumanquant.

16. Signalezdescâblesoudesconnexionsélectriques

exposées.

17. Ayeztoujoursunélectricienqualiéetcertiéenmesure

deréaliserlamaintenanceélectrique

18. Neprocédezàaucunréglageouàunemaintenanceavec

latensionappliquée.

4. Assurez-vousquelamachineestenbonétatde

fonctionnementavantdelamettresoustension.

5. Silamachines'arrêtesoudainementpouruneraison

inconnue,nelaredémarrezpasimmédiatement.

Quelqu'unpeutavoirarrêtélamachinesansavoir

appuyésurleboutond'arrêtd'urgence.Silamachineest

inopinémentredémarrée,votrecollèguedetravailpeut

êtresérieusementblessé.

6. Vousdeveztoujoursappuyerd’abordsurlebouton

d'arrêtd’urgencesivousinterrompezlefonctionnement

delamachinepourdesréglagesoupourune

maintenancequinedoitpasêtreréaliséependantquela

machineestenfonctionnement.

7. Pourunemaintenanceoudesréparationsimportantes,

l’alimentationsecteurdoitêtreinterrompue.

8. N'utilisezjamaisdesoutilsinadéquatsoudéfectueux.

9. Aprèsavoirprocédéauréglage,àlamaintenanceouà

desréparations,assurez-voustoujoursquelamachine

estdébarrasséedetouslesoutilsetautresobjetsutilisés.

Danslecascontraire,ilspourraienttomberdansla

machineetprovoquerdesdétériorationsouunaccident

grave.

19. Familiarisez-vousaveccelle-cietappliquerles

consignesdesétiquettesdesécuritésurlapagesuivante.

Remplacezcesétiquettessiellessontendommagéesou

absentes.

Remarques supplémentaires :

20. N'essayezpasd'intervenirsurunbourragedupapier,

aussiinsigniantqu'ilpuisseparaître,lorsquela

machineestenfonctionnement.

21. Lorsdunettoyagedesrouleauxdepliage,utilisez

levolantmanuelàceteffet.Assurez-vousque

l'alimentationdelamachineestdéconnectée.

22. Mettezd'abordlamachinehorstensionavantde

procéderàdesréglagessurlesoutilsdedécoupe,

deperforationetderefente.Éloignezvosmainset

vosvêtementsdesarbreslorsquelamachineesten

fonctionnement.

TP10583 PAGE 6

Page 9

SICHERHEIT HAT VORRANG

Ihre neue Baum-Papierfalzmaschine wurde in

Übereinstimmung mit den neuesten Sicherheitspezikationen

konstruiert. Die Warn- und Vorsichtsaufkleber auf der

Maschine müssen angebracht bleiben. Vergewissern Sie sich,

dass alle Schutzvorrichtungen angebracht sind, bevor Sie die

Maschine starten und in Betrieb nehmen.

Wegen der Art des von Papier-Falzmaschinen ausgeführten

Arbeitsprozesses gibt es Komponenten und Bereiche an

der Maschine, die nicht ganz abgedeckt werden können,

da sie ansonsten den Betrieb der Maschine stören. Daher

sind gute Arbeitsgewohnheiten und eine strenge Einhaltung

aller Sicherheitsmaßnahmen erforderlich, um den Schutz

des Bedieners, der Mitarbeiter und der Maschine zu

gewährleisten.

Befolgen Sie stets die folgenden

Sicherheitsmaßnahmen:

1. Die Sicherheitsanweisungen in Ihrem Werk und in

diesem Handbuch lesen.

2. Vor der Inbetriebnahme der Maschine die

Bedienungsanweisungen genau durchlesen.

3. Sicherstellen, dass Ihre Mitarbeiter mit dem

Arbeitsprozess, möglichen Gefahrenbereichen und allen

erforderlichen Sicherheitsmaßnahmen vertraut sind.

4. Sicherstellen, dass die Maschine funktionsfähig ist,

bevor sie eingeschaltet wird.

5. Wenn die Maschine plötzlich aus irgendeinem Grund

stoppt, darf sie nicht sofort wieder in Betrieb genommen

werden. Es könnte sein, dass jemand die Maschine

angehalten hat, jedoch nicht die Notstopptaste gedrückt

hat. Wenn die Maschine unerwartet neu gestartet wird,

könnte Ihr Mitarbeiter ernsthaft verletzt werden.

6. Immer zuerst die Notstopptaste drücken, wenn die

Maschine für Einstellungen oder Wartungsarbeiten

angehalten werden muss, die nicht während des Betriebs

vorgenommen werden dürfen.

7. Bei ausgedehnten Wartungs- oder Reparaturarbeiten die

Hauptstromzufuhr ausschalten.

8. Auf keinen Fall falsche oder defekte Werkzeuge

verwenden.

9. Nachdem Einstellungen vorgenommen oder Wartungsbzw. Reparaturarbeiten ausgeführt wurden, muss

stets sichergestellt werden, dass alle Werkzeuge und

sonstigen Objekte von der Maschine entfernt werden.

Ansonsten könnten sie in die Maschine hineinfallen und

ernsthafte Schäden oder Verletzungen verursachen.

10. Vergewissern Sie sich, dass alle

Sicherheitsvorrichtungen angebracht sind, bevor die

Maschine wieder in Betrieb genommen wird.

11. Auf keinen Fall bewegliche Teile der Maschine (Walzen,

Wellen usw.) reinigen bzw. keine Testbögen oder

Papierstaus beseitigen, während die Maschine läuft.

12. Den Boden um die gesamte Maschine herum sauber

halten. Verschüttungen von Öl, Fett oder Farbe sofort

aufwischen. Werkzeuge, Reinigungstücher und

Papierreste aus allen Arbeitsbereichen entfernen.

13. Auf keinen Fall zulassen, dass nicht befugtes

Personal Einstellungen an der Maschine vornimmt,

problematische Bögen entfernt oder die Maschine

startet.

14. Auf keinen Fall über die Maschine klettern oder in sie

kriechen, während sie eingeschaltet ist.

15. Alle Sicherheitsvorrichtungen, die nicht mehr wirksam

sind oder fehlen, sofort reparieren oder ersetzen.

16. Alle freiliegenden Kabel oder elektrischen Anschlüsse

melden.

17. Alle Wartungsarbeiten an der Elektrik müssen

von einem zertizierten, qualizierten Elektriker

durchgeführt werden.

18. Keine Einstellungen oder Wartungsarbeiten vornehmen,

wenn die Stromzufuhr eingeschaltet ist.

19. Machen Sie sich mit den Sicherheitsaufklebern auf der

nächsten Seite vertraut machen und befolgen Sie sie.

Beschädigte oder verloren gegangene Aufkleber müssen

ersetzt werden.

Zusätzliche Hinweise:

20. Auf keinen Fall versuchen, einen Papierstau zu

beseitigen, während die Maschine läuft, ganz gleich, wie

geringfügig das Problem zu sein scheint.

21. Während der Reinigung der Falzwalzen das Handrad

zum Drehen verwenden. Sicherstellen, dass die

Stromzufuhr zur Maschine ausgeschaltet ist.

22. Die Maschine ausschalten, bevor Sie irgendwelche

Einstellungen an den Ritzungs-, Perforier- oder

Längsschneidegeräten vornehmen. Hände und Kleidung

von den Messerwellen entfernt halten, während die

Maschine läuft.

TP10583 SEITE 6

Page 10

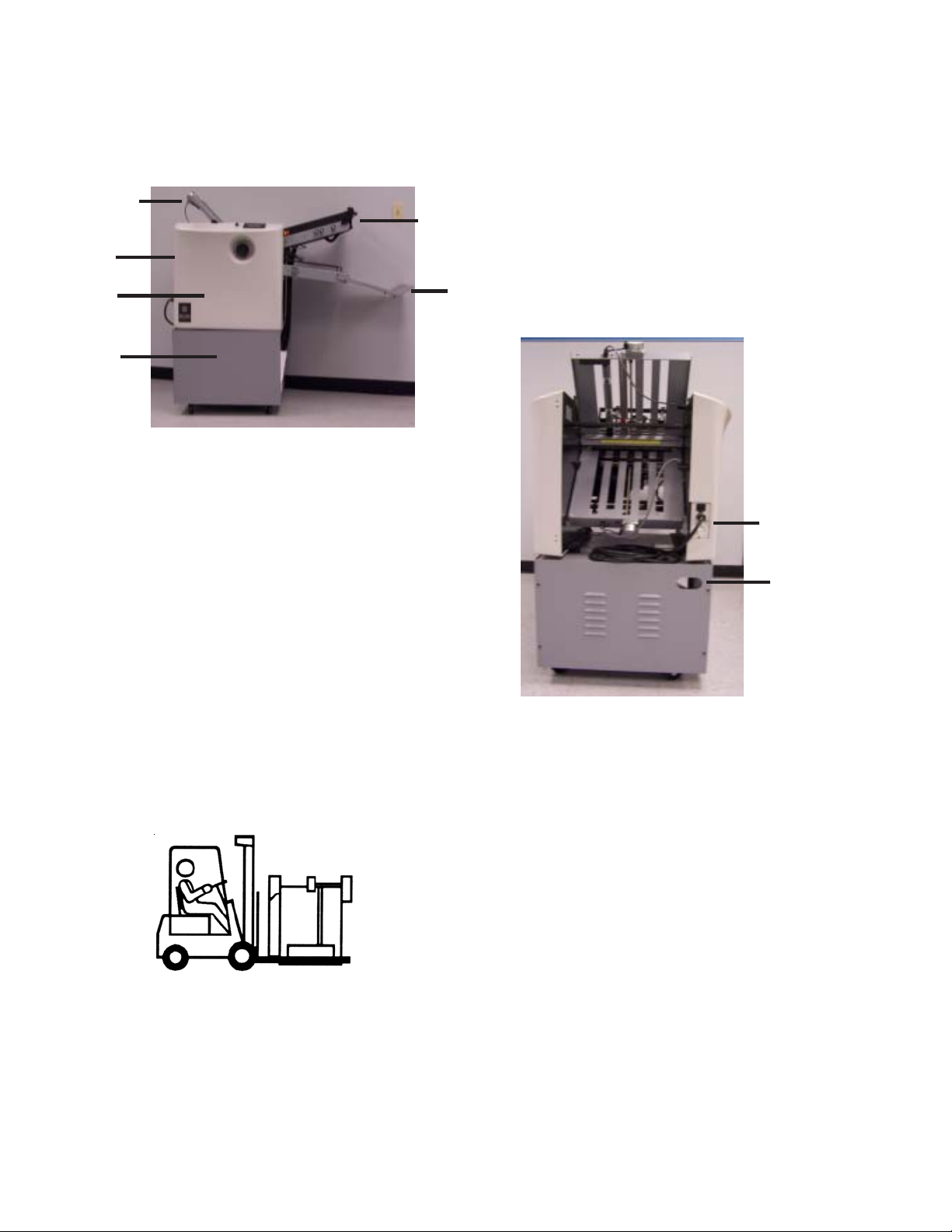

INTRODUCTION OVERVIEW

ASSEMBLY INSTRUCTIONS

nents:

4

5

1

2

Figure 1

The 714XA consists of the following major compo-

3

1 main unit w delivery table

2 cart w pump

3 feed table

4 pan 1

5 pan 2

6 stacker tray

7 accessories kit

1.0 SET MAIN UNIT ON TOP OF CART ASSY

Note orientation in Figure 3. The covered end of the

cart with the oval cut out for the pump power cord should be

directly below the power entry bracket mounted in the left

lower edge to the front guard.

Align inside of each frame to the four brackets on top

of the cart assembly and attach with (8) M6 internal tooth

lock washers (260-304-09-00) and (8) socket head M6x10

screws (262-320-04-00).

6

BRACKET

CUTOUT

TRANSPORTATION/INSTALLATION

As soon as you receive your new folder, and before

removing the machine from the skid, check carefully for any

damage to the shipments. If any damage is found, promptly

contact your Baumfolder sales representative.

To lift the folder from the skid, place the fork lift rails

under the lower rails as shown in Figure 2. Note that the

fork lift must have at least a 1500 lb. capacity.

Remove all rust protection coating after unpacking the

folder.

Figure 2

WARNING

Do not plug the power cord into an AC outlet until the

714XA is fully assembled, adjusted and ready to use. Unplug

the 714XA an time disassembly is required.

Figure 3

TP10583 PAGE 7

Page 11

1.1 INSTALL FEED TABLE

See Figure 4. Place feed table with feed wheel toward

the rolls. Slide the front knotch onto locating pins (1) and

rotate the back end of the table downward to rest on upper

dowel pins (2). Identical pins on both frames.

Rotate the handwheel to make sure the gears mesh.

Identify cable connected to the bottom of the feed table.

Engage the other end of this cable to the mating circular din

connector mounted in front frame. Turn rotating collar CW to

lock in place.

1 2

1.2 INSTALL BOTH FOLD PANS

The fold pans are identical.

See Figure 5 for positioning:

Pan 1 sets on pins 1 and 2

Pan 2 sets on pins 5 and 6

Rubber hold downs 3 and 7

Pan 1's mating connector is 4

Pan 2's mating connector is 8

Insert one pan into pan 1 position. With motor end of

pan towards the person installing the pan, angle front end

down and set onto locating pins (1). Rotate back end down

until center knotch is seated onto second set of locating pins

(2). Two rubber hold downs on top of the pan now need to

be rotated into position to hold the pan (3). Locate a cable

attached to the back end of the pan and engage the opposite

end into the mating circular din connector near the top of

the front frame (4). Rotate this collar CW to lock in place.

Repeat for pan 2 execept angle front end of this pan

upward. Engage its cable connector into mating connector

about half way down the left edge of the front frame (8).

Figure 4

3

Figure 5

2

1

4

5

7

6

8

MANUALLY TURN THE HAND WHEEL AFTER INSTALLING

BOTH

PANS TO MAKE SURE NEITHER PAN IS RUBBING

AGAINST

PAGE 8 TP10583

THE ROLLS.

Page 12

1.3 INSTALL STACKER TABLE TRAY

To install the stacker table tray, loosen the knobs on

either side of the tray. Drop the tray over the knobs and

retighten.

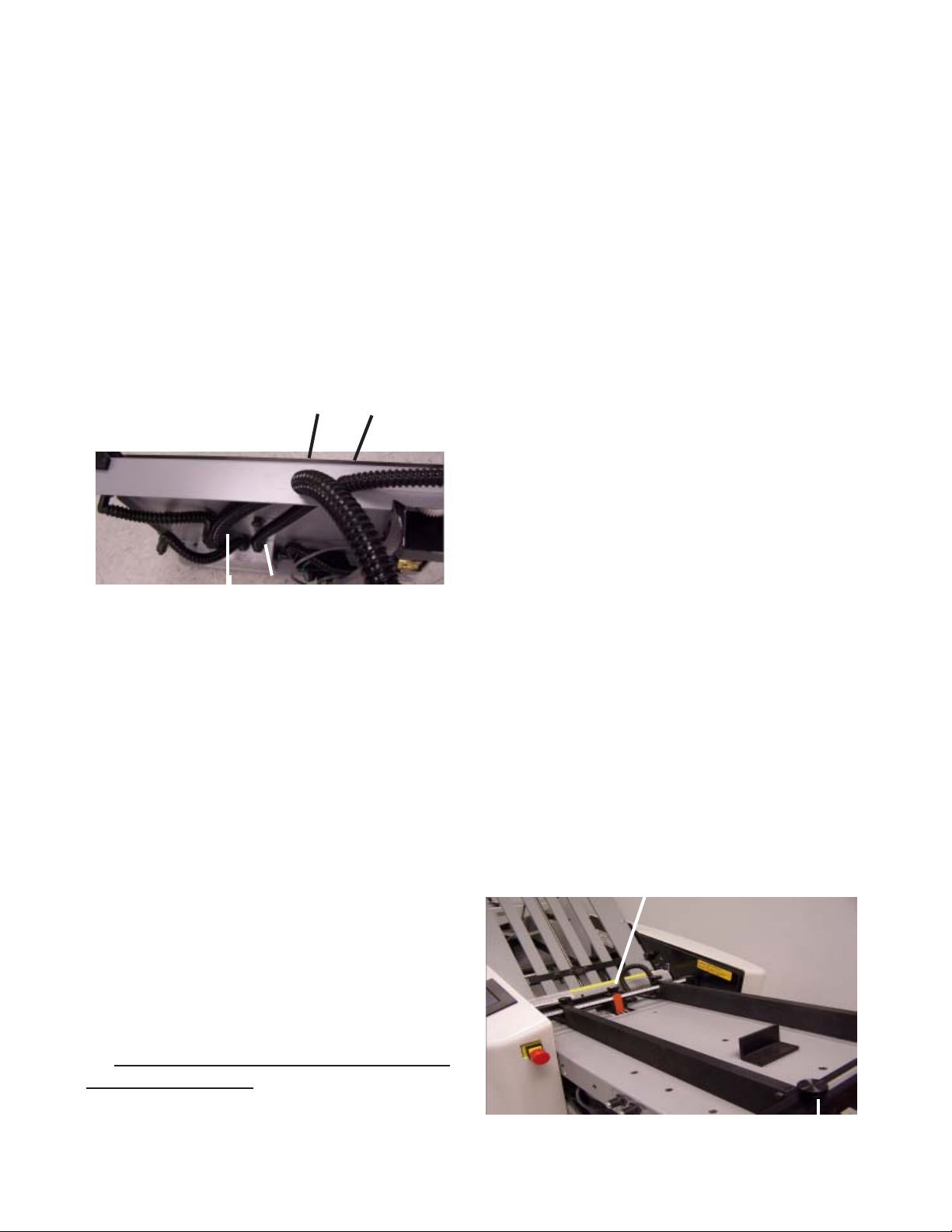

1.4 PUMP CONNECTIONS

1.41 PNEUMATIC CONNECTIONS

SEE FIGURE 7

Attach the vacuum side of the pump to the white elbow

at (1A). A second 1" hose should connect from the white

connect (1B).

The blow hose from the pump should connect to the

black connector at (2A). A second 1" hose should connect

from black connector to fitting on the solenoid manifold (2B).

2A

2B

Figure 7

1.42 ELECTRICAL CONNECTIONS

The pump has a plug/cord set attached. This plug fits directly

into the receptacle mounted in a bracket with a cut out in the

lower left side of the front guard. See figure 3.

1.5 SLITTER SHAFT INSTALLATION

To Install the slitter shaft, hold it with the grooves in the

boxing down. Be sure the slitter shafts are free turning.

Insert the slitter shaft and seat the grooves in the boxings

on the lower locating pins in the side frames.

Check for proper gear engagement between the upper

slitter shaft gear and the 19-tooth frame idler gear by turning

the hand wheel.

1B

1A

2.0 SETUP

2.1 GAP ADJUSTMENT

The orange tab above the sucker wheel assembly on the

feed table must be adjusted for each new weight of paper

See Figure 8.

Slide two sheets of paper between the tab and the

sucker wheel (or fold a single sheet and use the double

thickness). Turn the gap knob (1) counter clockwise to

tighten until there is a slight drag on the paper when you

pull the double thicknes of paper away from the orange tab.

Remove the paper. The correct gap is now set.

2.2 FEED TABLE ADJUSTMENT

On the paper feed table there are two guides which keep

the stack of paper properly aligned for feeding into the

folder. Adjust these guides to correspond with the different

widths of paper being fed. See black bars in Figure 8.

To adjust the paper feed guides, loosen the two side

guide locking knobs on each guide (2). Slide the guides

from side to side until the inside edge of each guide is

aligned with the number correponding to the width of the

paper being folded.

Square the guides to the rolls using a sheet of paper.

Lay a sheet of paper in the feeder, close to but not touching

the side guides. Push the sheet down just to the nip of the

rolls. Then align the guide by loosening the adjusting

knobs and aligning the guide so that it is parallel to the edge

of the paper. When one side is square, the other side can be

moved into position.

Tighten the locking knobs to secure the paper guides

into position.

When you load the actual job, you may have to move

these guides slightly to take care of variations in sheet size.

To feed properly, the paper must slide freely between these

guides.

1

1.6 OTHER CONNECTIONS

Refer to the serial number plate for electrical

requirements. The serial number plate notes the voltage,

phase and hertz, total machine amperage, and minimum wire

conductor size for the main power connection.

For the 110VAC 60 Hz version a 20A dedicated line is required.

All electrical connections are to be made by a certified

electrician. Refer to local building electrical codes for proper

and safe connections.

TP10583 PAGE 9

Figure 8

2

Page 13

2.3 AIR FLOW ADJUSTMENTS

3.0 Operation

There are three knobs on the side of the feed table. See

Figure 9. Two knob have nintey degrees of rotation. Clockwise movement of each valve these two values decreases the

settings.

The one closest to the main unit is the vacuum control

adjustment (1). Adjust the vacuum to draw the sheet down

toward the sucker wheel assembly. Heavier paper weights will

require more suction. Full CCW is the maximum vacuum

setting.

1

2

3.1 Loading of Feed Table

Before running a batch, determine which way to load

the paper: print side up or print side down. Use the single

sheet mode to run sample sheets to determine the correct

orientation.

Then you can load a stack of paper no higher than two

inches between the paper guides. (Please note for larger

sheets or heavier bonds, the stack will be shorter.) To feed

properly, the paper must "float" ( See Air Flow Adjustment)

and slide freely beween the guides. Switch to the continuous mode to run the batch when ready. See Quick Start

instruction for complete explaination page 14.

Figure 9

The middle knob (2) controls volumn of air blown onto the

feed table. The maximum setting is again full CCW. The knob

furthest away from the main unit not shown in figure 9 is a

directional value. It balances air flow to the feed table from the

left to right side. This valve has one hundred and eighty

degrees of adjustment. The center of this adjustment should

create equal flow to both sides of the feed table. Turning it to

the left or right of this position should create more air flow to

one side of the feed table. Adjust these two knobs to create lift

within the paper stack. "Floating" the stack correctly allows the

lowest sheet to be drawn into the sucker wheel assembly.

3.2 Check Squareness of Fold

Examine the folded sheets on the stacker to make sure

you are getting an even and square fold.

There is a skew adjustment on each pan to adjust for a

square fold on paper that is not cut perfectly square. There

is a large black thumbscrew mounted to the deflector bar for

this adjustment. There is also a scribe mark on the brace

behind the deflector bar. This scribe is intended for a

reference when making this adjustment. Please make sure

paper guides are adjusted to feed paper squarely with

respect to the rolls before making this adjustment.

3.3 Use of Handwheel

The handwheel is used to help clear jams and for

setup. To use the handwheel, shut off the main fold

rolls, pull out on the handwheel, and turn in either direction.

PAGE 10 TP10583

Page 14

4.0 PERFORATING,

SCORING & SLITTING

In addition to folding, your 714XA can perforate, score

and slit.

WARNING

Be careful when handling perforator and slitting

blades. They are extremely sharp.

4.1 Perforating

The 714XA can be used to perforate either

the folded sheet (to assist in making a right-angle

fold) or to perforate sheets delivered flat.

BAUMFOLDER supplies one standard 41-tooth

perforator blade. Additional perforator blades are

available through the BAUMFOLDER Parts

Department.

The perforator blade should be mounted

loosely to the blade holder with the retainer collar to

give better support to the perforator blade. Always

be sure that the flat side of the blade is against the

blade holder. Loosen the brass-tipped set screws

in the perforator collar and blade holder before

attempting to place them on the slitter shafts.

The perforating blade holder assembly is then

slid onto the upper slitter shaft along with the

necessary pull-out tire assemblies. Then tighten the

screws holding the perforator blade to the blade

holder, aligning the blade to the holder. This allows

for free horizontal movement on the shaft.

Slide the grooved perforator collar onto the

lower slitter shaft along with the other pull-out tire

assemblies. The flat side of the perforator blade

should just touch the side of the groove in the

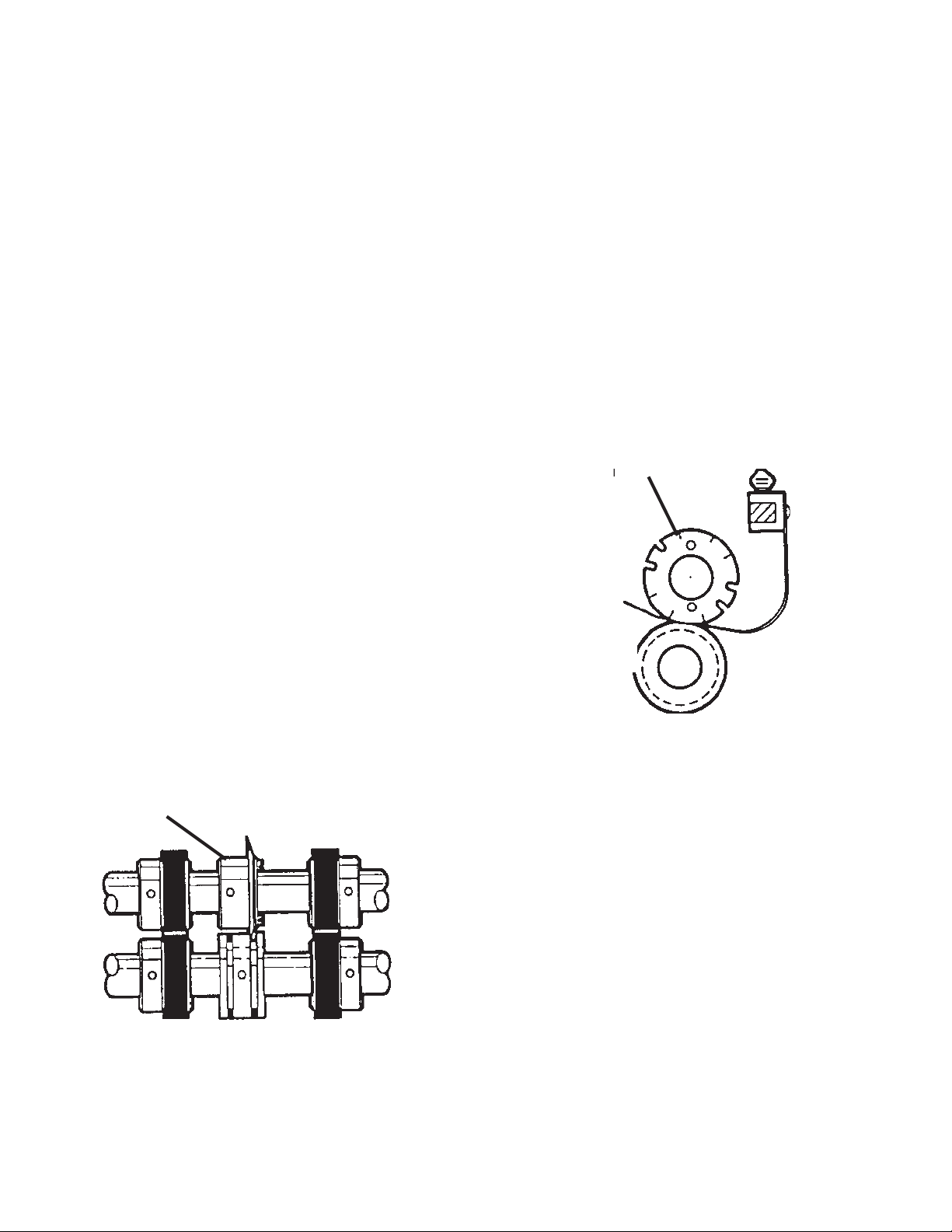

perforator collar. (See Figure 4.1-1)

TOP SHAFT

TOP SHAFT

Figure 4.1-1

TP10583 PAGE 11

Figure 4.1-2

Slide the perforator collar and blade holder to

the desired position on the slitter shaft. Then lock

the blade holder and perforator collar into position

with the brass-tipped set screw.

The perforator stripper fits onto the slitter shaft

bar in between or next to the perforating blade.

(See Figure 4.1-2) This strips the paper off for

delivery and prevents it from wrapping around the

perforator blade.

Page 15

4.2 Scoring

The 714XA can be used to score a sheet and

deliver it flat, or to score a sheet after a fold or folds

have been made.

To ensure accuracy in making right-angle

folds, always score the sheet where the fold is to be

made. This applies in all instances when a perforator cannot be used.

Attach the scoring blade loosely to the blade

holder for mounting on the slitter shaft. Scoring

blades can be mounted on either the upper or lower

slitter shaft. Once on the shaft, tighten the screws,

aligning both the blade and the collar. This allows

free horizontal movement on the shaft. Scoring

blades should be placed so that the fold will be

made with rather than against the scoring, or, in a

continuing direction to the pressure of the crease

that has been applied by the scoring blade.

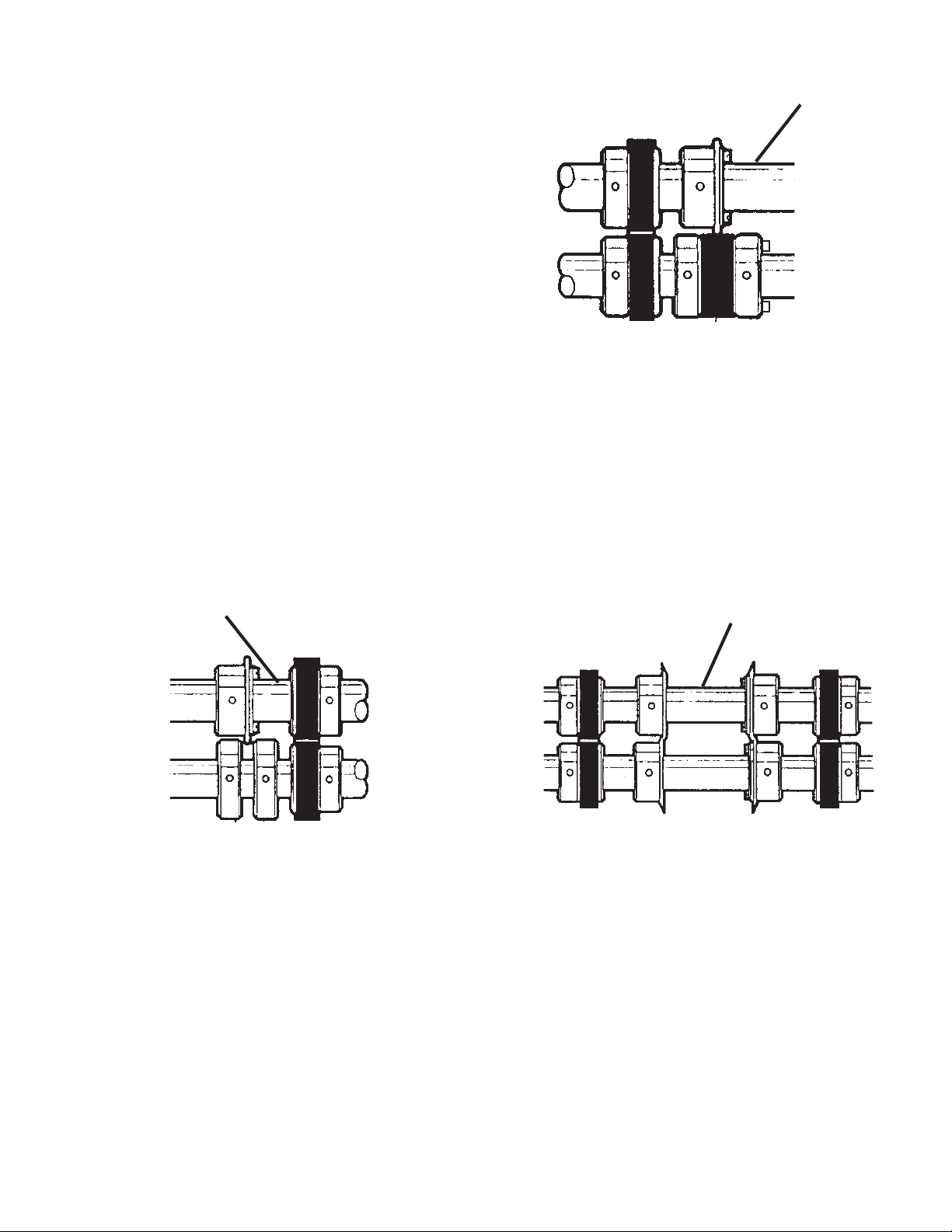

TOP SHAFT

TOP SHAFT

Figure 4.2-2

4.3 Slitting

NOTE: Slitting accessories are optional on

your 714XA and can be ordered from your

BAUMFOLDER Parts Department.

The 714XA can be used to cut folded or flat

sheets apart. The general setup for blades and

collars is shown in (Figure 4.3.1). Two or more

cuts may be made if duplicate sets of cutters are

used.

TOP SHAFT

Figure 4.2-1

For a wide, well-rounded score, use the two

steel scoring collars. (See Figure 4.2-1) Sharpness

and the depth of the score can be controlled by

regulating the distance the collars are placed away

from the scoring blade.

The scoring collars can also be placed on

either side of the rubber scoring collar. The two

collars can be compressed against the rubber collar,

causing the rubber to bulge up for a deeper score.

(See Figure 4.2-2)

Figure 4.3.-1

Use care in mounting slitter blades to the

collars in order to avoid ragged edges during slitting

operations. Ragged edges can be caused by two

conditions:

1) Nicks or burrs on the collars or blades.

Remove carefully by filing or using a fine piece of

emery cloth.

2) Incorrect mounting of blades caused by

tightening with the wrong type of screw. Always use

flat head screws on the side of the blade and blade

holder collar, which are countersunk.

PAGE 12 TP10583

Page 16

Before tightening the blade to the collar, slide

the blade with the collar loosely attached on the end

of the shaft. Then tighten securely, thus aligning both

the blade and collar, allowing free horizontal movement along the shaft.

Place the blade, mounted on the collar, on the

upper shaft in the proper position where the cut is to

be made. Then move the blade and collar on the

lower shaft so that the two flat edges of the blades

are pressed snugly together. Too much space

between the blades will produce a ragged cut.

Space the rubber pull-out tires to support the

sheet.

5.0 MAINTENANCE

5.1 Maintenance and Care of your

714XA

The 714XA Air Feed has been designed to

give you years of useful service, provided you

maintain it according to these instructions.

5.2 Lubrication

Apply one or two drops of light machine oil at

all slitter shaft bearings and the feed table bearings

and idler gear once a week. Be sure to keep oil off

any surface which may contact the paper.

5.3 Cleaning of Fold Rolls

Periodically wipe off the rubber surface of the

fold rolls using an approved solvent such as

Surewash or its equivalent. Surewash is available

from BAUMFOLDER in 1-quart (P/N 24108-

001) and 1-gallon (P/N 24108-002) containers. A

complementary bottle of Surewash is included with

your machine.

5.4 Cleaning Filters

The filters on the pump should be checked

periodically and cleaned as needed. The filters can

be reached by unscrewing the filter jars.

5.5 Photo Sensors

Occasionally wipe off the photo sensor with a

dry cloth.

TP10583 PAGE 13

Page 17

4.0 BAUMFOLDER 714XA “QUICK START” INSTRUCTIONS

1. Turn on Main Power switch on left side of the enclosure.

The display should show a Baumfolder information screen for 15 seconds and then automati

cally switches to the

Production Screen:

Production Screen with NO BATCH Production Screen with Batch

2. The Active fold type is shown in the upper left corner of the screen of the production screen. Press this

image to change to a different fold type. This changes to the Fold Choice screen. The selected

fold choice will be in color. Press a different icon to change. If the half fold is chosen, there will be a

choice of pan 1 or pan 2.

3. The NEXT button changes the screen to the Length screen. The active units will have a blue

background. Press the units with the gray backgroud to change units. The standard sizes for

metric will be shown when mm is shown in blue; the standard inch sized paper will be shown

when the inch has the blue background. The blue background indicates currently selected size.

To change to a different size, press a new standard size with a gray back gound or if you would

prefer a non-standard size, enter the value directly into the bottom numeric entry.

PAGE 14 TP10583

Page 18

Here is an example of the Length Screen:

After selecting the units and the paper size, Press the NEXT button to change to the

INITIALIZATION SCREEN:

4. After changing to the initialization screen, both pans will move into the deflect position then

back out to the fold position. While the pans are moving the status icon for

the pans moving will display:

After the pans have reached the requested fold positon, the PANS AT FOLD POSITION

message will appear. You then have a choice of returning to the production screen to

run the job using the or chosing the COUNT SETUP button to change the

batch count or mode.

5. There are several ways to get to the BATCH COUNT screen. From the

production screen, press the Batch Screen button if the mode is currently set for NO BATCH.

(See the picture labeled NO BATCH on page 14 item one). If the current mode is set for BATCH

then press any of the numbers to the right of the blue batch icons:

OR

PAGE 15 TP10583

Page 19

6. The first choice on the BATCH SCREEN is for BATCH or NO BATCH. The

active choice will have a blue background.

If NO BATCH is chosen there are no other choices except to return

to the production screen using

NO BATCH

The mode can be CHANGED TO BATCH by pressing the batch button with the gray

background changing it to a blue background:

SIMPLE BATCH

For SIMPLE BATCH there will be choices of time DELAY between batches or an automatic

STOP after the batch is complete, batch QUANTITY, and counting either UP or DOWN.

Each active choice will have a blue background. Use the button to return to the

production screen after the selections are made.

SIMPLE BATCH can be changed to VARIABLE BATCH by pressing the Simple

button in the upper right of the batch screen. Each time it is pressed it will switch back and forth

between SIMPLE and VARIABLE.

PAGE 16 TP10583

Page 20

After Selecting the VARIABLE batch:

VARIABLE BATCH

Press the V. SETUP button to continue.

VARIABLE BATCH SETUP

Enter the number of variable batches in this run. Then Press the V-Batch button to enter the values

in each batch.

VARIABLE BATCH DATA ENTRY

Only the number of variable batches requested in Variable batch setup will be displayed (up to 10).

Enter each batch value by pressing the corresponding blue numeric input area. If Needed, return

to change the number of batches using the V-Batch Setup or just use the arrow with the double bar

to return to the production screen when ready to run the job.

PAGE 17 TP10583

Page 21

23. Sample Production Screen:

Units:

The IN or MM is the unit indicator.

CURRENT FOLD TYPE:

This is the current fold indicator. In this case it is an engineering fold. If you press this button while

on the production screen, it takes you to the Fold Selection Screen.

PAN 1 AND PAN 2 POSITIONS:

The numbers on the left side of the screen below the units display show the current position of pan 1 and pan 2.

Pan 1 is on the top and Pan 2 is on the bottom.

TP10583 PAGE 18

Page 22

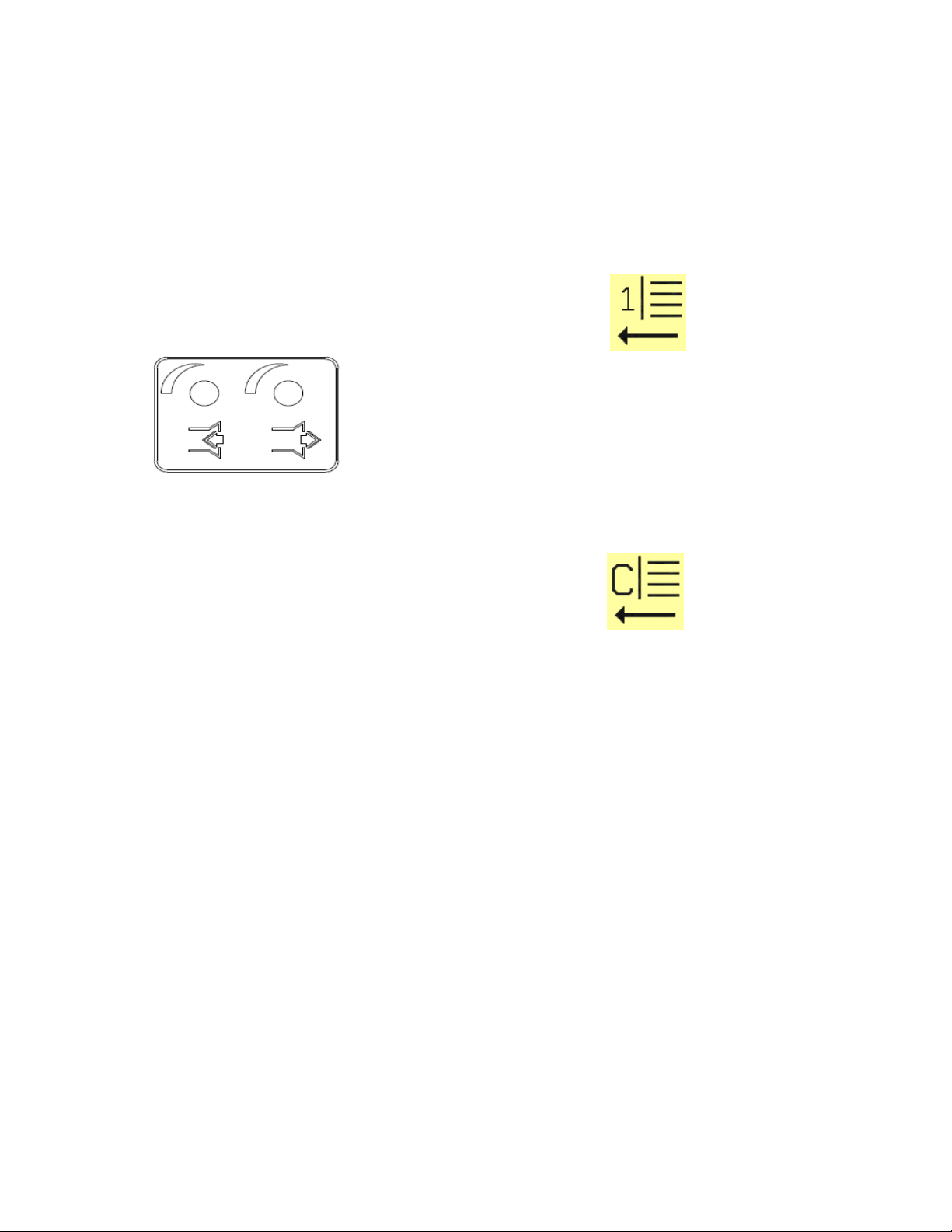

STATUS INDICATOR AND START BUTTON:

At the bottom left is the status indicator in the “ready” state.

The status indicator on the production screen is also the button to turn the machine ON

or OFF. Pressing the status indicator when it is in the “ready state” for half a second turns ON the main rolls,

the pump, and the delivery.

or The 1 indicates single sheet mode and the C indicates continuous feed mode.

Pressing this button toggles between the two options.

This indicates paper is not being released (fed) into the rollers.

To feed paper in continuous mode, press this button to toggle feed on or off.

In the single sheet mode, one sheet will be released each time this button is pressed.

In Continuous mode this indicates paper is being released (fed).

In Continuous mode, pressing this button will turn the feed back off and return the button

to the yellow state.

In Single Sheet mode, this state triggers only when the sheet is released, then returns to

the yellow 0 image automatically.

PAGE 19 TP10583

Page 23

To the right of this button is the total count. It can reset to zero if the button is held for 3

To the right of this icon is total requested in the current batch.

To the right of this icon is the current number run in this batch.

To the right of this icon is the number of batches. This is also a reset button to reset the

number of batches run back to zero.

seconds.

This button moves the display to the Previous Screen.

24. Main Screen:

This button moves the display to the Main Screen. On the main screen there are selections to

move directly to most available screens.

This button is not on the production screen. When available, it changes the display to the Produc-

tion Screen.

TP10583 PAGE 20

Page 24

25. Fold Pan Adjustment Screen:

To access the adjustment screen, start from the production screen. Press either of the numbers on the left side

of the screen that indicate current position of pan 1 and pan 2.

On the adjustment screen pressing either the “+ “or “– “button should move the pan immediately by .01”.

The status indicator will change to the pan moving status while the pan is moving and return to the “ready status”

after the movement is complete. The adjustment screen is meant to correct for small changes in the pans position. A double move is required to move small distances. You can watch the pan move towards the fold roll,

then away from the fold rolls. The + and - buttons will disappear while the pans are moving and then reappear

after the second move is complete.

26. Fold Pan Direct Entry Screen:

To access the direct entry screen, start from the production screen, press either one of the numbers on the left

side of the screen that show the current position of pan 1 and pan 2.

That should move to the adjustment screen. From the adjustment screen, press the direct entry button:

This screen will only move the pans if the movement requested is at least 0.1 inch or greater. Enter the new

numeric value, then press the pan number below the new value to initiate the movement.

If less than 0.1 movement is required, press the blue button to return to the adjustment screen.

PAGE 21 TP10583

Page 25

Repeat as desired for each pan. Use the button to go to the production screen when ready.

27. Setup Preferences Screen:

To access the Setup Preferences Screen, first use the button from any screen to access the Main

Screen (shown below):

Then select the

The two lower buttons toggle the sensors into and out of bypass when they are pressed. The Input Sensor is

used to count, so the counts will not be correct when bypassed. The Exit Sensor triggers the jam error, so there

will be no warning for a jam when this is bypassed. This option is intended to be used when a sensor is bad and

a replacement is on order.

Setup Preferences button to display Setup Preferences Screen (shown below):

TP10583 PAGE 22

Page 26

28. The Memory Screen (SAVE and RELOAD)

Before using either the Save to store a job or the Reload to recall

job, check what is currently saved in the

screen use the to get to the main screen:

From the production

Use the JOB MEMORY button to see memory 1-4.

Before choosing either to save or reload, enter the selected memory value into the upper

right box, while you can still see the options. Then use the SAVE SCREEN to save a fold into that

location or the RELOAD SCREEN to recall the fold saved in that location. Alternatively, the arrow

with the double lines can be used to exit this screen and go back to the production screen.

PAGE 23 TP10583

Page 27

29. The Save Screen

Use the Job Memory to select a location first (See 28.) On the save screen enter the speed the job was run

before saving.

Pressing the save button:

memory location.

moves the current pan locations, fold type, and speed into the selected

30. The Reload Screen

Use the Job Memory to select a location first (See 28). Press the reload button: to move data from

memory to current active values on the production screen. Please remember to manually set the pot to the saved

speed shown on the reload screen before returning to the production screen.

31. Status States:

Fault states include:

This indicates the emergency stop button is triggered and needs to be pulled to reset.

This indicates an AC drive fault. Turn power "off", allow the power to discharge, and

then turn it back "on".

This indicates a paper jam on the delivery table. The jam must be removed before this fault

can be cleared. Then go to the production screen and press this image on the lower left corner of the

screen to reset.

PAGE 24 TP10583

Page 28

Non- fault status states:

This indicates that the paper length and the fold choice are not compatible. Go to the

choice screen or the paper length screen and change one of the selections.

This state shows the machine is in the paper clear mode. After a regular

This state shows the machine is “ready” to start. On the production

screen pressing the status button in this state will start the machine.

This state shows the machine is currently running. Pressing the status button in

this state will request the machine to stop.

stop is requested, this 3 second delay allows the paper in the fold pans to move through

to the delivery before it stops.

This state shows the fold pans are moving.

This shows the machine has reached a requested stopping

point. This state triggers after the summation stop on a single batch is complete or the

requested grouping of variable batches is completed. The operator acknowledges

ready to continue by pressing this button on the production screen. Then it will return

to the ready status (partial green circle).

PAGE 25 TP10583

Page 29

32. Error Screens:

If the choice of fold or paper length created a fold lenghth either over maximum or 14 inches or under minimum

of 2 inches, instead of movement to the new position the Over limits Error screen will be the result. Use the

orange buttons to change to a selection within limits.

If the pans are overcycle moving to home without getting a instruction complete the Rehome pans Screen will

appear. Push the Move Pans Home button to try again. If this doesn't correct the problem there is something

impeding the process.

1. CHECK THAT THE COMMUNICATION CABLE TO THE PAN IS ENGAGED.

2. CHECK THAT THE HOME SWITCH FOR THE PAN IN QUESTION IS ACTIVATING CORRECTLY. ( USE THE TROUBLE

SHOOTING

NOT

POWER. IF THE POWER IS CORRECT, REPLACE THE HOME SWITCH.)

SCREEN TO MONITOR INPUTS. X3= P2 HOME AND X5=P1 HOME. IF THE HOME SWITCHES ARE

ACTIVATING CHECK THE POSITION OF THE HOME SWITCH. IF THE POSITION IS CORRECT, CHECK THE 24V

3. CHECK SETSCREW ON COLLAR CONNECTING THE PAN MOTOR TO THE LEAD SCREW . IF LEAD SCREW IS

MISALIGNED

LOOSEN THE SET SCREW, MOVE LEAD SCREW UNTIL ALIGNED, THEN RETIGHTEN.

4. IF NONE OF THESE HELP, CHECK THE 12V POWER SUPPLY. CEHCK F12. THE POWER LED ON THE A1

STEPPER BOARD. THEN CHECK THE CONNECTIONS ARE GOOD ON THE A1 SLEW CONNECTION AND THE

OUTPUTS

Y OF THE PLC. CHECK THE A1 Y CONNECTOR FOR PAN 2 AND THE A1 X CONNECTOR FOR PAN 1.

IF ALL OF THESE ARE GOOD, THE PAN MOTOR NEEDS TO BE REPLACED.

TP10583 PAGE 26

Page 30

7.0 OPERATOR CONTROLS

The main operator control panel is located at the top

right of the front guard. See Figure 10. The "Control

Panel"(1) is a full color touch sensitive screen. See Quick

Start Instructions for detailed explainations (Page 14).

7.0 Setting Folding Speed

The speed of the fold rolls may be set while the folder is

running! This is done by adjusting the speed control potentiometer located on the top of the front guard (2). Clockwise

rotation speeds the folder up; counter-clockwise rotation

slows the folder down.

7.1 Setting Stacker Belt Speed

An infinite speed range between high and low is set by

turning the speed control potentiometer mounted on the side

of the stacker (3). For shingling purposes use range

2 - 4. Higher speeds may be selected for use as a transfer

table.

7.2 Emergency Stop Button

When an emergency stop button is pressed,

the result is:

Sheet feed - stop

Folder drive - stop

Delivery feed - stop

Pump - stop

2

Figure 10

1

4

3

The emergency stop button must be pulled to release before

the machine can be restarted. The status indicator will change

to an exclaimation point inside of a red triangle inside a red

circle with a yellow background when the estop is active.

The emergency stop button is found on the right side of the

front guard (4).

PAGE 27 TP10583

Page 31

8.0 BASIC MACHINE SETUP

8.1: Units of Measurement

Toggles between metric and english units ( mm or inches).

See Quickstart Instructions page 14.

8.2: Language

This selection specifies the Language. Available choices

are ENGLISH, GERMAN, SPANISH and FRENCH. Use the

Setup Preferences Screen to change languages. See

Quickstart Instructions page 22.

8.3: Hardware and SoftwareVersion

This hardware versions are shown on the serial number

plate. This is located on the inside of the front frame between

pan 1 and pan 2.

The software loaded into each programmable component

is indicated by a label stuck onto each component: PLC, HMI,

and VFD.

9.0 DIAGNOSTICS

The inputs and output of the PLC can be monitored using the

HMI. Access the main screen using one of the orange

buttons with the upward arrow.

From the main screen select the Troubleshooting screen.

Green indicators show "on" states for all inputs X0-X7 and

outputs Y0-Y5. The encoder counts can also be monitored

here. There is also a button to force the solenoid "on."

PAGE 28 TP10583

Page 32

10. CALIBRATION OF FOLD PANS

1.) Ensuring that #1 pan deflector does not rub the rolls:

A.) Either use the HALF FOLD IN PAN 2 only fold choice to send pan 1

into the deflect position or temporarily disconnect the 9 pin connector

from the pan 1 to the frame and manually move pan 1 to the deflect

position.Then reattach the connector. Make sure Pan 2 is not in deflect

position.

B.) Turn the handwheel of the machine and listen and feel for any rubbing

of the #1 pan’s deflector on the rolls.

C.) If you do not feel or hear any rubbing then proceed to Step 2.

D.) If you do feel or hear any rubbing, then you will need to slightly adjust

the position of the #1 pan deflector.

E.) Turn power off to the machine.

F.) Remove the #1 fold pan from the machine.

G.) On top of the paper stop assembly, there is a deflector pusher that has

a curved surface that pushes a bar with a series of pins connected to

it. This curved piece has 2 slots in it that allows for the position of

the deflector to be adjusted. See Figure #3. This adjustment should

only have to adjusted a few thousandths of an inch from the factory

setting. This is due to tolerance stackups within the machine.

DEFLECTOR PUSHER PINS

Figure #3

DEFLECTOR PUSHER

DEFLECTOR

PAGE 29 TP10583

Page 33

H.) Loosen the 2 screws that are holding the deflector pusher in position

on the paper stop assembly with a 2.5 allen wrench.

I.) Move the deflector to the desired position to prevent the deflector

from rubbing the rolls. This should only be moved enough to not

allow the deflector to rub the rolls. This should be treated as a fine

adjustment and not adjust the deflector to much as the paper may be

able to enter the fold pan when the paper stop is in deflect, or if the

deflector is moved to close to the rolls, the paper will not properly

pass over the deflector and jam up in the fold rolls.See Figure #4 for

the dimension used in the factory setting and also the maximum and

minimum dimensions for this setting from lip of pan to outer edge of the deflector.

0.180”(4.58mm) FACTORY SETTING

0.173”(4.40mm) MINIMUM SETTING

0.185”(4.70mm) MAXIMUM SETTING

Figure #4

J.) Retighten screws retaining the deflector pusher screws on to paper

stop assembly. Be sure to not allow the deflector pusher to pivot as

you are tightening these screws up, as this may cause the deflector to

not be in the intended position.

K.) Recheck the position of the deflector as described by the dimension

called out in Step 1.I.

L.) Reinstall the fold pan into the folder and connect the plug.

M.) Turn the main power back on the machine.

N.) After power up, press the current fold icon in the upper left hand

corner of the production screen. Pick half fold P2 . Choose any paper

length. Next will send both fold pans to home position and then reset

their location according to the sheet length and type of fold currently

selected. "At Fold Position" message indicates the movement is done.

Note: The postion of the deflector will need to be adjusted in this

same manner any time the home position of the paper stop is

changed by making adjustments to the paper stop screws. If

this is not corrected each time these screws are adjusted,

serious damage to the folder or fold pans may occur!

TP10583 PAGE 30

Page 34

O.) Turn the handwheel of the machine and listen and feel for any rubbing

of the #1 pan’s deflector on the rolls. If there is not any rubbing of the

deflector on the fold rolls proceed to Step 2.

2.) Ensure that #2 pan deflector does not rub the rolls:

A.) Either use the HALF FOLD IN PAN 1 only fold choice to send pan 2

into the deflect position or temporarily disconnect the 9 pin connector

from the pan 2 to the frame and manually move pan 2 to the deflect

position.Then reattach the connector. Make sure Pan 1 is not in deflect

position.

B.) Turn the handwheel of the machine and listen and feel for any rubbing

of the #2 pan’s deflector on the rolls.

C.) If you do not feel or hear any rubbing then proceed to Step 3.

D.) If you do feel or hear any rubbing, then you will need to slightly adjust

the position of the #2 pan deflector.

E.) Turn power off to the machine.

F.) Remove the #2 fold pan from the machine.

G.) On top of the paper stop assembly, there is a deflector pusher that has

a curved surface that pushes a bar with a series of pins connected to

it. This curved piece has 2 slots in it that allows for the position of

the deflector to be adjusted. See Figure #5. This adjustment should

only have to adjusted a few thousandths of an inch from the factory

setting. This is due to tolerance stackups within the machine.

DEFLECTOR PUSHER PINS

DEFLECTOR PUSHER

DEFLECTOR

Figure #5

PAGE 31 TP10583

Page 35

H.) Loosen the 2 screws that are holding the deflector pusher in position on the paper

stop assembly using a 2.5 allen wrench.

I.) Move the deflector to the desired position to prevent the deflector

from rubbing the rolls. This should only be moved enough to not allow

the deflector to rub the rolls. This should be treated as a fine adjustment and not

adjust the deflector to much as the paper may be able to

enter the fold pan when the paper stop is in deflect, or if the deflector

is moved to close to the rolls, the paper will not properly pass over the

deflector and jam up in the fold rolls. See Figure #6 for the dimension

used in the factory setting and also the maximum and minimum dimensions for this

setting from the lip of the pan to the outer edge of the deflector.

0.180”(4.58mm) FACTORY SETTING

0.173”(4.40mm) MINIMUM SETTING

0.185”(4.70mm) MAXIMUM SETTING

Figure #6

J.) Retighten screws retaining the deflector pusher screws on to paper

stop assembly. Be sure to not allow the deflector pusher to pivot as

you are tightening these screws up, as this may cause the deflector to

not be in the intended position.

K.) Recheck the position of the deflector as described by the dimension

called out in Step #2.I.

L.) Reinstall the fold pan into the folder and connect the plug.

M.) Turn the main power back on the machine.

N.) After power up, press the current fold icon in the upper left hand

corner of the production screen. Pick half fold P1 . Choose any paper

length. Next will send both new fold pans to home position and then reset

their location according to the sheet length and type of fold currently

selected. "At Fold Position" message indicates the movement is done.

TP10583 PAGE 32

Page 36

Note: The postion of the deflector will need to be adjusted in this

same manner any time the home position of the paper stop is

changed by making adjustments to the paper stop screws. If

this is not corrected each time these screws are adjusted,

serious damage to the folder or fold pans may occur!

R.) Turn the handwheel of the machine and listen and feel for any rubbing

of the #2 pan’s deflector on the rolls. If there is not any rubbing of the

deflector on the fold rolls proceed to Step #3.

Before proceeding with calibration of the fold pans, you must ensure that the sheets are

being fed into the fold rolls squarely and that the sheets are hitting both paper stops of the

new fold pans squarely. These new pans are calibrated with

8 1/2 x 11” 20# Bond copier paper. We use this stock since it is a common stock used in

the tabletop folders.

3.) Ensure the paper is being fed into the fold rolls squarely:

A.) Turn power off to the machine.

B.) Remove the #1 fold pan.

C.) Place a single sheet of paper into the feeder.

D.) Move the non-operator side guide away from the sheet.

E.) Manually feed the single sheet of paper by hand until it enters the nip

of the fold rolls. Make sure that the sheet does not pull away from the

operator side guide.

F.) At this point you should be able to turn the handwheel and the sheet

should become visible on the exit side of the Main and #1 fold rolls.

G.) Compare the amount of paper now sticking out of the fold rolls on

both the operator and non-operator sides.

-If the amount is equal, then this means that the operator side guide

of the feeder is feeding the sheet square to the fold rolls. Proceed to

Step #3.N.

-If the amount is not equal, then this means that the operator side

guide of the feeder is not feeding the sheet square to the fold rolls

and the operator side guide will need to be adjusted. Proceed to

Step #3.H.

PAGE 33 TP10583

Page 37

H.) Loosen both front and rear thumb screws on the operator side guide.

I.) Push in and rotate the operator side guide skew adjust knob so that the

side guide skews in the direction the sheet was being off square to the

fold rolls.

J.) Now repeat steps #3.E - #3.G until the sheet is square to the fold rolls.

K.) Once the sheet is square to the fold rolls, hold the skew adjust knob in

place and loosen the set screw for the operator side guide skew adjust

knob.

L.) Now rotate the collar so that the slot in the collar slips over the nipple

on the operator side guide skew adjust knob.

M.) Tighten set screw in the collar.

N.) Place a stack of 10 sheets into the feeder.

O.) While holding the non-operator side of the stack of paper up, move

the non-operator side guide so that the clear mylar plastic piece on

the side guide is under the stack.

P.) Now adjust the non-operator side guide up to the stack of paper so

that side guides do not allow the sheet to move side to side, but not so

tight that the stack of paper is pinched by the side guides.

-If the side guides are to loose, the side guides will not properly

register the sheets and the folds will not be consistently square.

-If the side guides are to tight, the side guides will prevent the

sheets from being fed into the fold rolls.

Q.) Adjust the skew of the non-operator side guide, so that the side guide

is parallel to the stack of paper.

-If you have to adjust the skew of the non-operator side guide,

follow the same procedure for adjusting the side guide skew adjust

knob and collar on the operator side guide.

4.) Ensure the fold pan paper stops are square to the sheets:

A.) Using the Operator Control panel, select a half fold and enter proper

sheet length.

B.) Handfeed a sheet into the nip of the fold rolls.

C.) Turn the handwheel until the sheet is just shy of touching the paper

stop of the #1 fold pan.

D.) Adjust the skew of the #1 fold pan paper stop by turning the skew

adjust thumb screw on the paper stop until it is parallel with the sheet.

TP10583 PAGE 34

Page 38

E.) Now turn the handwheel, and make sure that the edge of the paper hit

at all points on the paper stop simultaneously.

F.) Confirm the squareness of the side guides to the fold rolls and the

sheet to the paper stop by turning the handwheel so that the sheet is

folded. Sheet should be folded straight.

G.) Using the Operator Control panel, select a double parallel fold and

enter proper sheet length.

H.) Handfeed a sheet into the nip of the fold rolls.

C.) Turn the handwheel until the sheet is just shy of touching the paper

stop of the #2 fold pan.

D.) Adjust the skew of the #2 fold pan paper stop by turning the skew

adjust thumb screw on the paper stop until it is parallel with the sheet.

E.) Now turn the handwheel, and make sure that the edge of the paper hit

at all points on the paper stop simultaneously.

F.) Confirm the squareness of the side guides to the fold rolls and the

sheet to the paper stop by turning the handwheel so that the sheet is

folded. Sheet should be folded straight.

5.) Confirming the calibration of the #1 Fold Pan:

All though a set of calipers is not a requirement, they are recommended to

measure the fold lengths of the sheet and to aid you in adjusting the

position of the paper stop’s home position. They will give you a more

accurate measurement.

A.) Load a stack of test paper into the feeder.

Note: Using stock that has print on it, or has been marked in some

way will aid you in determining which edge is the leading edge of the

sheet and which direction the paper stop needs to be adjusted.

B.) Using the Operator Control Panel, select a half fold and enter the

proper sheet length when prompted to do so.

C.) Run a single test sheet. If the sheet is folded exactly in half then

proceed to Step #6. If the sheet is not folded exactly in half, then

proceed to Step #5.D.

D.) Measure how much the folded length is off and note this for the

adjustment later. Also note if the fold is to long or short.

E.) Remove the #1 fold pan from the folder.

PAGE 35 TP10583

Page 39

F.) Run the paper stop to it’s home position by rotating the paper stop

lead screw by hand.

G.) Carefully rotate the deflector up so that you may get the calipers or

scale into the pan.

H.) In the center of the fold pan, take a measurement from the edge of the

lower half of the pan to the paper contact surface of the paper stop

and note this. See Figure #7.

PAPER CONTACT SURFACE

OF PAPER STOP

FRONT SURFACE OF

LOWER HALF PAN

MEASUREMENT NEEDED

Figure #7

I.) Using half of the measurement determined that the fold was off from

being folded in half in Step #5.D will either be added to or subtracted

from the measurement taken in Step #5.H.

-If the fold was to long, then half of the measurement taken in Step

#5D will be subtracted from the measurement in Step #5.H. This

will become the new measurement for the home position of the paper

stop.

-If the fold was to short, then half of the measurement taken in Step

#5D will be added to the measurement in Step #5.H. This will

become the new measurement for the home position of the paper

stop. Take note of this new home position for the paper stop.

TP10583 PAGE 36

Page 40

J.) Manually move the paper stop away from home position enough so

that you may use a 4mm allen wrench in the flat head screws on the

paper stop. These screws will be adjusted to position the paper stop

correctly for the new home position. See Figure #8 on page 37.

K.) Use a 10mm wrench to loosen up the nuts on the flat head screws.

See Figure #8 on page 37.

L.) Turn flat head screws further into the paper stop assembly.

M.) Manually move the paper stop until the paper stop is in the correct

position as determined in Step #5.I.

N.) Run the flat head screws out of the paper stop assembly until the

heads of the screws come in contact with the lower half pan brace.

See Figure #8 on page 37.

O.) Tighten the nuts on the flat head screws against the paper stop

assembly.

P.) Re-check that the paper stop is still positioned correctly by

making sure it is at the dimension determined in Step #5.I.

PAGE 37 TP10583

Page 41

HOME POSITION

SCREW JAM NUTS

HOME

POSITION

SCREWS

LOWER

HALF

PAN

BRACE

Figure #8

TP10583 PAGE 38

Page 42

Q.) Loosen nuts holding the home position switch to it’s bracket.

R.) Manually move the paper stop assembly away from home position so

that you have 0.25”(6.35mm) gap between the heads of the home

position screws and the lower half pan brace. A 1/4” allen wrench

may be used to aid in getting the proper distance.

Note: This dimension is critical. The software is programmed so that

the paper stop must travel 0.25”(6.35mm) from the time when the

home position switch is tripped until the paper stop reaches home.

Any variation in this distance may cause the fold lengths to be off.

S.) Move the home position switch so that the paper stop assembly trips

at the position described in Step #5.R and tighten nuts holding

switch.

T.) The deflector pusher will now need to be reset as described in Steps

#1.I - 1.O.

U.) Place pan back into machine.

V.) Turn power off and back on.

W.) Choose to initialize the folder when prompted to do so by the

Operator Panel Display.