OPERATOR MANUAL

®

BASIL

Cage and Rack Washer

(2004-06-29) P920017-148

9502

A WORD FROM STERIS CORPORATION

This manual contains important information on the proper use of this equipment.

Refer to Section 6,

washer. All personnel and department heads are urged to carefully review and

become familiar with the

These instructions should be retained in a conveniently accessible area for quick

reference. This equipment is specifically designed only for the uses outlined in

this manual.

Routine Maintenance

Safety Precautions

, for instructions in routine care of this

and instructions contained herein.

Advisory

IMPORTANT: A listing of the

this washer can be found in Section 1. Do not operate the equipment until you have

become familiar with this information.

STERIS does not intend, recommend, or represent in any way that this

Basil® 9502 Cage and Rack Washer be used for the sterilization of any animal

care or other device which has been contaminated with pathogenic microorganisms.

Any alteration of the washer not authorized or performed by STERIS which could

affect its operation will void the warranty, could adversely affect washing efficacy,

could violate national, state, and local regulations, and could jeopardize your

insurance coverage.

To help assure operators are adequately trained in the safe use of the equipment,

STERIS recommends:

– all personnel who operate or maintain the equipment are trained in its

operation and in its safe use;

– personnel working with toxic chemicals and vapors (if applicable) have

comprehensive instructions in the washer disinfector process, relevant

health hazards, and methods to detect the escape of toxic materials;

– there is regular training of all personnel concerned with the operation and

maintenance of the equipment; attendance records are maintained; and

that evidence of understanding is demonstrated.

Safety Precautions

to be observed when operating

The Basil 9502 Cage and Rack Washer is intended for use in the sanitation of

Indications for Use

©2004, STERIS Corporation. All rights reserved. Printed in Canada

Table of Contents Operator Manual 920017-148

soiled, reusable animal care devices such as cages, racks, debris pans,

feeder bottles, and other miscellaneous items by providing thorough cleaning,

and optional drying.

This washer is specifically designed to only process goods as outlined in this

manual. If there is any doubt about a specific material or product, contact the

manufacturer of the product for recommended washing technique.

i

Service Information

Certification

A thorough preventive maintenance program is essential for safe and proper

equipment operation. You are encouraged to contact STERIS concerning

extended service maintenance agreements to give your equipment planned

maintenance.

A global network of skilled service specialists can provide periodic inspections

and adjustments to assure low-cost peak performance. STERIS can provide

information regarding the Annual Maintenance Agreements.

STERIS carries a complete line of accessories for use in this equipment. A STERIS

representative will gladly review these with you.

See inside back cover for contact information.

This Basil 9502 Cage and Rack Washer complies with the following

standards:

• Underwriters Laboratories (UL):

Standard 61010A-1.

• Canadian Standards Association (CSA):

Standard CAN/CSA C22.2 No. 1010.1.

Governing Directive for the Affixing of the CE Mark:

• Machinery Directive (98/37/CE).

Conformity to Other Applicable Directives:

• Low Voltage Directive (73/23/EEC) and amendment (93/68/EC).

• Electromagnetic Compatibility Directive (89/336/EEC) and amendments

(91/263/EEC, 92/31/EEC, and 93/68/EEC).

Standards applied to demonstrate conformity to the directives:

• EN/IEC-61010-1; EN/IEC-61010-2-045; EN/IEC-61326-1.

ii

920017-148 Operator Manual Table of Contents

TABLE OF CONTENTS

Section Title Page

A WORD FROM STERIS CORPORATION ............................................ i

Advisory ................................................................................................................................. i

Indications for Use ................................................................................................................. i

Service Information ................................................................................................................ ii

Certification ............................................................................................................................ ii

1 SAFETY PRECAUTIONS AND SYMBOLS ....................................... 1-1

1.1 Symbols on Unit ........................................................................................................... 1-4

1.2 Symbols on Nameplate ............................................................................................... 1-5

2 INSTALLATION VERIFICATION ...................................................... 2-1

2.1 Technical Specifications ............................................................................................... 2-1

2.1.1 Voltage and Amperage ........................................................................................ 2-1

2.1.2 Noise Level .......................................................................................................... 2-1

2.1.3 Permissible Environmental Conditions ................................................................. 2-1

2.2 Installation Checklist .................................................................................................... 2-2

2.3 Chemical Additives Specifications ............................................................................... 2-4

2.3.1 General ................................................................................................................ 2-4

2.3.2 Recommended Chemical Additives..................................................................... 2-4

3 COMPONENT IDENTIFICATION ...................................................... 3-1

3.1 General ........................................................................................................................ 3-1

3.2 Control Location ........................................................................................................... 3-2

3.2.1 LOCK/UNLOCK/INIT Key Switch ......................................................................... 3-2

3.2.2 POWER-OFF/STANDBY Switch ............................................................................ 3-2

3.3 Load-Side (Main) Control Panel ................................................................................... 3-3

3.3.1 Display Screen ..................................................................................................... 3-3

3.3.2 Touch Pads .......................................................................................................... 3-3

3.3.3 Printer ................................................................................................................... 3-4

3.4 Unload-Side (Remote) Control Panel ........................................................................... 3-8

3.5 Emergency Safety Features ........................................................................................ 3-8

3.5.1 Photoelectric Sensors .......................................................................................... 3-8

3.5.2 Emergency Exit Safety Doors .............................................................................. 3-9

3.5.3 Emergency Stop Cables ...................................................................................... 3-9

3.5.4 Emergency Stop Pushbuttons ............................................................................. 3-9

3.5.5 Interior Light ......................................................................................................... 3-9

3.5.6 Safety Delay ........................................................................................................ 3-9

3.5.7 LOCK/UNLOCK/INIT Key Switch ........................................................................3-10

4 OPERATING INSTRUCTIONS .......................................................... 4-1

4.1 Before Operating Washer............................................................................................ 4-1

4.2 Priming Procedure ....................................................................................................... 4-2

4.3 Doors .......................................................................................................................... 4-3

4.3.1 Door Operation ..................................................................................................... 4-3

4.3.2 Interlock Feature .................................................................................................. 4-4

4.3.3 Opening Doors during a Power Failure................................................................. 4-4

Table of Contents Operator Manual 920017-148

iii

TABLE OF CONTENTS (Cont'd)

Section Title Page

4.4 Accessories ................................................................................................................ 4-5

4.4.1 General ................................................................................................................ 4-5

4.4.2 How to Load Accessories Into Wash Chamber .................................................... 4-5

4.4.3 How to Load Central Header Manifold with Rodent Cage Racks (Accessory) ..... 4-7

4.4.4 How to Load Bottle Washing Cart or Universal Cage and Pan Wash Cart

(Accessory) ........................................................................................................ 4-9

4.5 Typical Cycle Operation .............................................................................................4-10

4.6 DRAIN Cycle ..............................................................................................................4-13

4.7 Pause Cycle Operation ............................................................................................. 4-15

4.8 Abort Cycle Operation ...............................................................................................4-16

4.9 Acknowledge Alarm Condition ................................................................................... 4-17

4.10 Shutdown ................................................................................................................. 4-18

4.10.1 Manual Shutdown ..............................................................................................4-18

4.10.2 Automatic Shutdown .........................................................................................4-19

5 CYCLE AND CONTROL VALUE PROGRAMMING ........................... 5-1

5.1 General ....................................................................................................................... 5-1

5.2 Change Values Mode .................................................................................................. 5-3

5.2.1 Sequence of Display Screens .............................................................................. 5-3

5.2.2 How to Modify a Cycle ......................................................................................... 5-3

5.3 Review Cycle Values .................................................................................................. 5-12

6 ROUTINE MAINTENANCE ............................................................... 6-1

6.1 Preventive Maintenance Schedule .............................................................................. 6-1

6.2 Cleaning Procedures ................................................................................................... 6-3

6.2.1 Daily Cleaning ...................................................................................................... 6-3

6.2.2 Weekly Cleaning .................................................................................................. 6-5

6.2.3 Horizontal Spray Headers and Spray Jets .......................................................... 6-7

6.2.4 Central Header Manifold (Option)......................................................................... 6-7

6.2.5 Rotary Spray Arms on Bottle Washing Cart (Option) ........................................... 6-9

6.2.6 Building Supply Line Strainers ............................................................................. 6-9

6.2.7 Vertical Self-Cleaning Filters................................................................................ 6-10

6.3 Descaler Cycle ..........................................................................................................6-12

6.3.1 Manual Descaler Cycle ....................................................................................... 6-12

6.3.2 Automatic Descaler Cycle (Option) .....................................................................6-15

6.4 Chemical Container Replacement .............................................................................. 6-18

6.5 Injection Pumps Lubrication and Squeeze Tube Replacement ..................................6-19

6.6 Printer Paper Roll Replacement .................................................................................6-20

6.6.1 Procedure ...........................................................................................................6-21

6.6.2 Thermal Paper Storage ........................................................................................6-22

7 TROUBLESHOOTING....................................................................... 7-1

8 REPLACEMENT PARTS AND PRODUCTS ...................................... 8-1

iv

920017-148 Operator Manual Table of Contents

SAFETY PRECAUTIONS AND SYMBOLS

1

The following

the potential for personal injury and CAUTION indicates the potential for danger to equipment. These

are repeated, where applicable, throughout the manual. It is important to review these

operating or servicing the unit.

Strictly following these

customer to avoid improper maintenance methods which could damage the unit or render it unsafe. It is important to

understand that these

policies and procedures to enhance and compliment these Safety Precautions.

Safety Precautions

Safety Precautions

Safety Precautions

mustmust

must be observed when operating and servicing this equipment. WARNING indicates

mustmust

Safety Precautions

Safety Precautions

enhances your ability to safely and effectively utilize the unit and allows the

are not exhaustive; customers are encouraged to develop their own safety

before

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Always wear appropriate Personal Protective Equipment (PPE) when cleaning or removing debris from bottom of

the wash chamber and over the suction plate.

Before servicing or cleaning exterior of unit, always turn LOCK/UNLOCK/INIT key selector to LOCK position to

de-energize unit. Keep the key on yourself.

Only fully qualified service personnel should make repairs and adjustments to this equipment. Maintenance done

by inexperienced, unqualified personnel or installation of unauthorized parts could cause personal injury,

invalidate the warranty, or result in costly damage. Contact STERIS regarding service options.

Regularly scheduled preventive maintenance, in addition to the faithful performance of the minor maintenance

described within this manual, is required for safe and reliable operation of this equipment. Contact STERIS to

schedule preventive maintenance.

To open doors from inside wash chamber, pull EMERGENCY STOP cables. Washer operation will automatically

stop. Then, push firmly between door panels using shoulder and upper arm, applying upper body force. Do not

push between the two doors, but between the door panels.

To test or demonstrate Emergency Exit Safety Doors, first press EMERGENCY STOP pushbutton (located under

control) or EMERGENCY STOP cables (inside wash chamber) to turn power OFF. If power is still on while adjusting

or servicing doors, the photoelectric sensor will detect the movement of the door panels and doors will open

automatically.

WARNING – PERSONAL INJURY HAZARD:

If doors are still slightly open (less than 2 inches [5 cm]) when power is restored after a power failure, control will

apply pressure to complete closing. Lock building electrical supply disconnect switch in OFF position and close

unit air supply when opening doors after a power failure.

Keep hands/fingers away from closing doors to prevent crushing between the two doors.

Never perform cleaning of wash chamber until full cycle has been completed. If cycle has not been completed,

contaminated debris or water may remain in the bottom of the wash chamber

When doors are closing, a pinch point is created at the hinges. Keep fingers away from door hinges to prevent

pinching.

(See next page for additional Safety Precautions)

Safety Precautions and Symbols Operator Manual 920017-148

1-1

WARNING – ELECTRICAL SHOCK AND/OR BURN HAZARD:

Disconnect all utilities to washer before servicing. Do not service washer unless all utilities have been properly

locked out. Always follow local occupational health and safety regulations, as well as electric and plumbing codes.

WARNING – BURN HAZARD:

After pressing STOP/RESET touch pad, wait until water flow stops before opening doors. Hot water/steam may

be sprayed through door opening if doors are opened too soon.

Except for emergency, do not open door when cycle is in progress. In an emergency, first stop cycle by pressing

the EMERGENCY STOP pushbutton and wait for water flow to stop. Wear appropriate Personal Protective

Equipment (PPE) whenever reaching into or entering wash chamber.

Inner surfaces of washer are very hot after cycle completion. Operator should wear appropriate Personal Protective

Equipment (PPE) and avoid all contact with inner walls when entering chamber to unload washer.

WARNING – SLIPPING HAZARD:

To avoid slippery floor conditions, immediately wipe up any spilled liquids or condensation.

WARNING – CHEMICAL BURN AND/OR EYE INJURY HAZARD:

Always use non-foaming chemical for effective cleaning and proper pump and water level control operation. Follow

manufacturer's recommendations for amount of chemical to be used.

Detergents are caustic and can cause adverse effects to exposed tissues. Do not get in eyes, on skin or attempt

to swallow.

• Read and follow the precautions and instructions on the detergent label and in the Material Safety Data Sheet

(MSDS) prior to handling detergent containers, or servicing the detergent injection pumps and lines.

• Wear appropriate Personal Protective Equipment (PPE) whenever handling chemicals or servicing chemical

injection pumps and lines.

Wear appropriate Personal Protective Equipment (PPE) when using a descaling product. Avoid contact with eyes

or skin. If spilled or splashed, flush with water for 15 minutes. If swallowed, DO NOT induce vomiting. Administer

an alkali with plenty of water. Seek medical attention immediately.

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Always leave plenty of space between load and doors. Leaning load against doors will damage doors and also

prevent them from opening or closing.

Always use a silicone lubricant to lubricate squeeze tubes. Petroleum-based lubricants, such as Vaseline or

grease, will cause squeeze tubes to melt.

Avoid product damage. Always select a cycle appropriate for the items being processed.

Before operating the unit, always position manifolded Bottle Washing Cart and/or Central Header Manifold over

central water inlet connector. If manifolded accessory is not positioned correctly, damage may result and unit will

be unable to effectively wash load.

(See next page for additional Safety Precautions)

1-2

920017-148 Operator Manual Safety Precautions and Symbols

CAUTION – POSSIBLE EQUIPMENT DAMAGE (Cont'd):

Do not process load using Central Header Manifold or Bottle Washing Cart in a chamber where Automatic Floor

Tilting option is activated. If Automatic Floor Tilting is used, manifolded water inlet and washer will be damaged.

Keep away from doors to prevent load detection sensor from stopping doors from closing.

Remove all cellulose-type bedding from cages and pans before processing. Cellulose bedding can clog filters

and piping.

Use non-abrasive cleaners when cleaning unit. Follow directions on containers and rub in a back-and-forth motion,

in same direction as surface grain. Abrasive cleaners will damage stainless steel. Cleaners rubbed in a circular

motion or applied with a wire brush or steel wool on door and chamber assemblies can be harmful to stainless steel.

Do not use these cleaners on painted surfaces.

When choosing a chemical, select one with a low chloride content. Chloride is harmful to stainless steel and will

deteriorate washer.

Safety Precautions and Symbols Operator Manual 920017-148

1-3

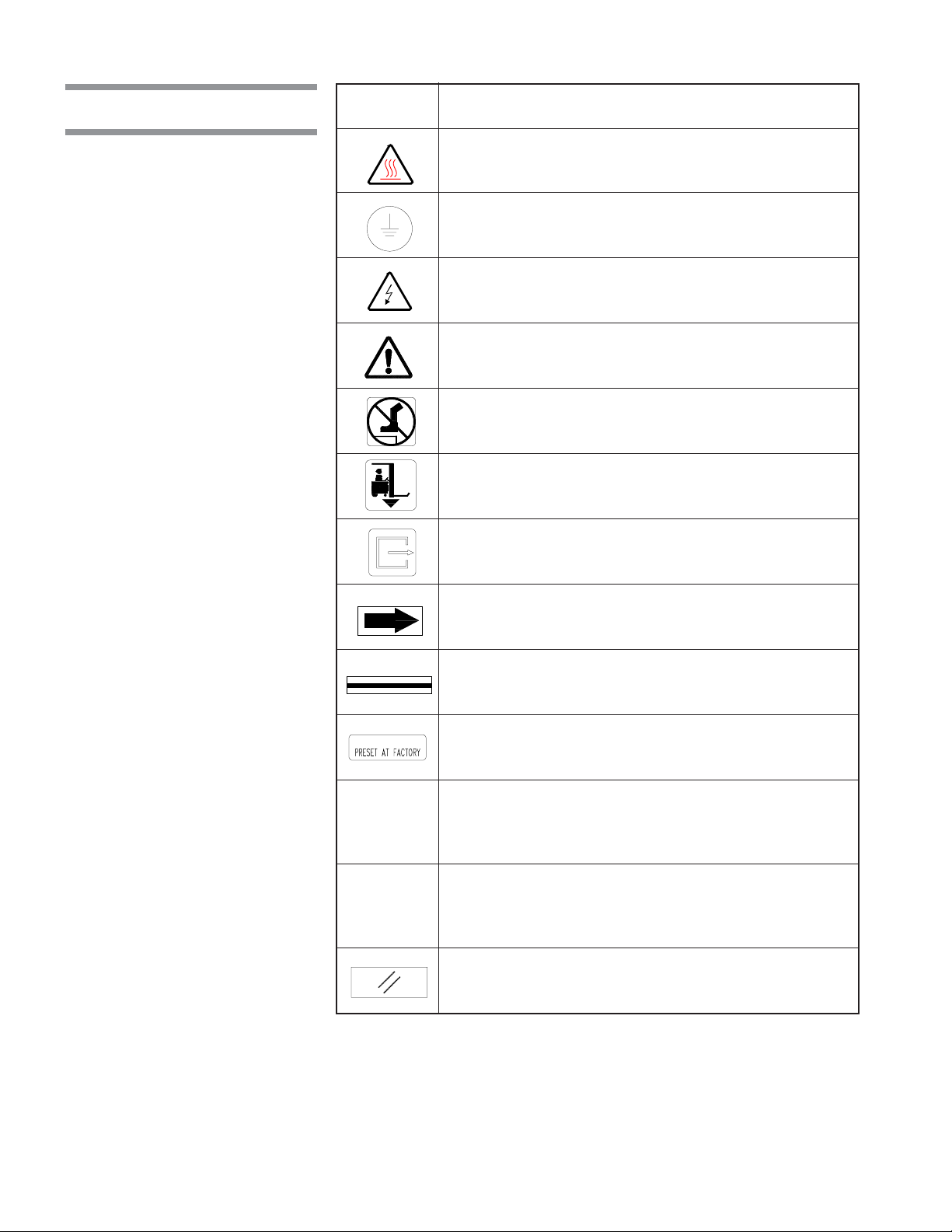

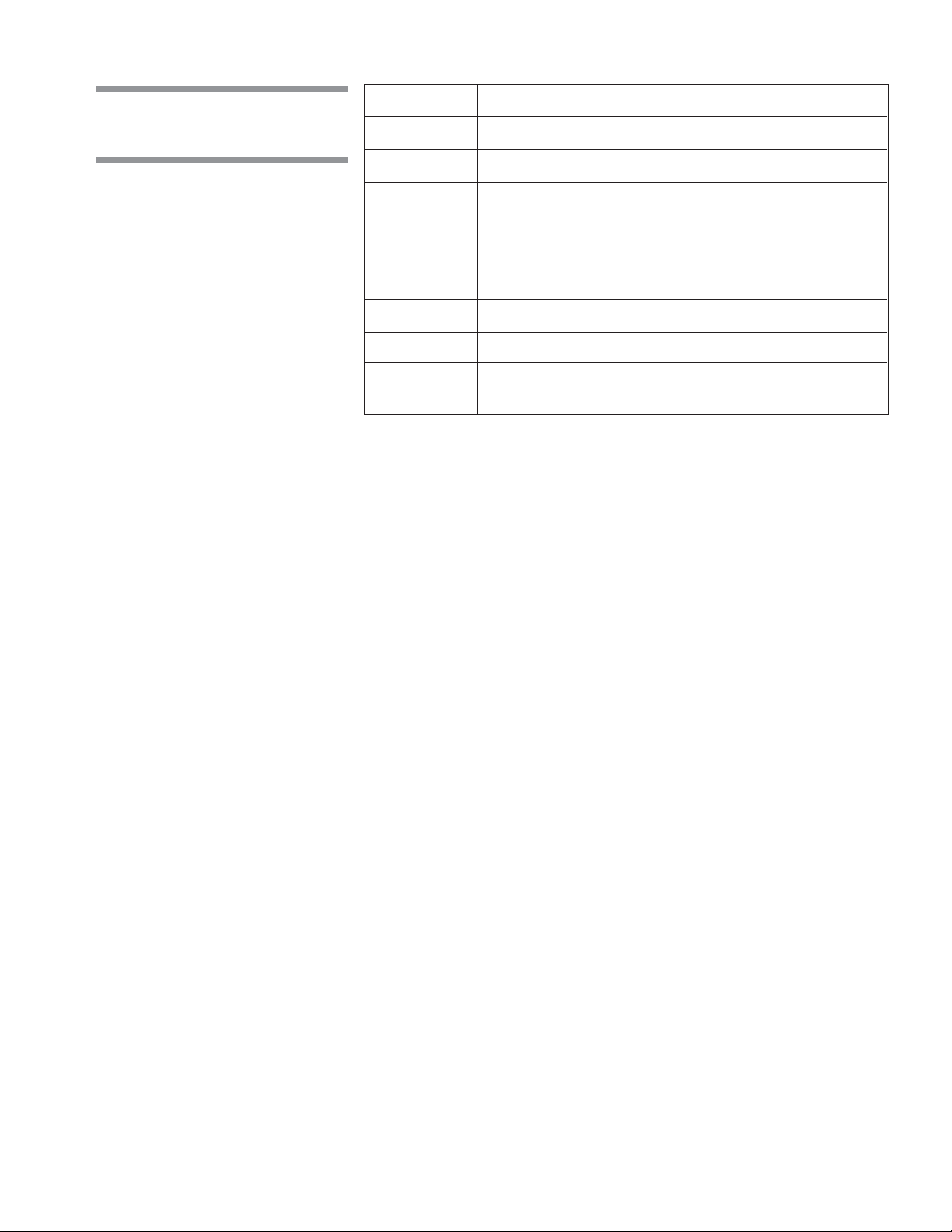

1.1 Symbols on Unit

Symbol Definition

Transfer of Heat, Hot Surface.

Protective Earth (Ground).

Warning! Risk of Electrical Shock.

Warning. Refer to Manual for Further Instructions.

Warning! Do Not Step Here.

Fork Lift: Place Forks of The Fork Lift Here.

Safety Exit: Push Here in Case of an Emergency.

Rotation: Direction of the Rotating Device.

Load Delimitation: Do Not Place Load Over These Marks.

Factory Adjustment: Do Not Adjust.

² Unlock and Energize Unit.

± Lock and De-Energize Unit.

Initialize/Reset Unit.

1-4

920017-148 Operator Manual Safety Precautions and Symbols

1.2 Symbols on Nameplate

Symbol Definition

MODEL Model Number of the Unit.

S/N Serial Number of the Unit.

kVA Kilovolt-Ampere.

V__~ Volt, Number of Phase (3 or 1 [blank]),

Alternate Current.

A Ampere.

YEAR Year of Manufacture of the Unit.

Hz Hertz – Frequency of the Unit.

WIRE Number of Wires in the Electrical Cable

(Ground Not Included).

Safety Precautions and Symbols Operator Manual 920017-148

1-5

INSTALLATION VERIFICATION

2

2.1 Technical

Specifications

2.1.1 Voltage and Amperage

IMPORTANT: A listing of the

and servicing this equipment can be found in Section 1 of this manual. Do not

operate or service the equipment until you have become familiar with this

information.

These specifications are intended to describe the technical information given

on the nameplate of your washer and to state other relevant information. Check

Equipment Drawing or Identification nameplate, located on frame of mobile

mechanical core, below main electrical box, for proper voltage and amperage.

This unit operates on:

• 380/400/415 V~, 3-phase, 50 Hz

• 480 V~, 3-phase, 60 Hz.

• 208 V~, 3-phase, 60 Hz (with the optional transformer).

A protective ground conductor is required (Class 1 Equipment). Installation

Category is Overvoltage II.

Refer to

Uncrating/Installation Manual

Safety Precautions

(P920017-147) for proper connection.

to be observed when operating

2.1.2 Noise Level

2.1.3 Permissible

Environmental Conditions

IMPORTANT: Customer responsible for compliance with applicable codes and

regulations.

The maximum currents and power consumptions, for units with or without

drying, are:

kW A

• 380/400/415 V 18,6 26

• 480 V 28,3 34

Equivalent Sound Pressure Level at work station (measured 3 ft. [1 m] away from

equipment and at 5 ft [1.6 m] from ground): 76.6 dB (A) for a freestanding unit

with side panels (Results determined according to

Acoustics Determination of Sound Power Levels of Noise Sources Survey

Method

This washer is designed to give optimal results in an environment where

maximum relative humidity is less than 85% and maximum operating temperature is 104°F (40°C).

).

ISO-3746: 1979 Standard:

2-1

Installation Verification Operator Manual 920017-148

2.2 Installation Checklist

An Equipment Drawing, showing all utility and space requirements, was sent to

you after the order for this equipment was received. The clearance space,

specified on Equipment Drawing (P920502-212), is necessary for proper

installation, operation, and maintenance.

(P920017-147) were provided with the washer. If any of these documents are

missing or misplaced, contact STERIS giving the serial, equipment, and model

numbers of the unit. Replacement copies will be sent to you promptly.

Uncrating/Installation Instructions

After installing the washer according to the

tions

(P920017-147), complete the following checklist to assure complete and

correct installation, or contact STERIS to schedule a technician to test your

installation and demonstrate proper equipment operation.

❑ Shutoff valves (not provided by STERIS), for maintenance purposes and

capable of being locked in OFF position only, are installed on steam, air, and

water lines and are in compliance with local occupational health and safety

regulations, as well as plumbing codes.

❑ Disconnect switches (not provided by STERIS), for maintenance purposes

and capable of being locked in OFF position only, are installed on electrical

supply lines near the unit and are in compliance with local occupational health

and safety regulations, as well as electric codes. Disconnect switches must

bear the identification of the equipment to which they are connected.

Uncrating and Installation Instruc-

NOTE: If unit is installed next to other equipment, shutoff valves and disconnect

switches should be located so that service can be shut off to one piece of

equipment at a time.

❑ Washer positioned as shown on Equipment Drawing and with required

clearance space and in relation to building supply lines.

❑ Washer and two mechanical cores are level. Use shims or Leveling Legs (if

accessory is present) if necessary.

❑ If Drain Discharge Cooldown System or pH Neutralizing System option is

present, building cold water line supplies water to unit as specified on

Equipment Drawing.

❑ Building hot water line supplies water to unit as specified on Equipment

Drawing.

❑ Building steam line provides steam to unit as specified on Equipment

Drawing.

❑ Building condensate return line is connected to washer as specified on

Equipment Drawing.

❑ Building air line supplies air to unit as specified on Equipment Drawing.

❑ Building waste line is connected to washer as specified on Equipment

Drawing.

❑ Building ventilation system is connected to washer as specified on Equip-

ment Drawing.

❑ Electrical supply for unit is as specified on Equipment Drawing.

❑ Piping connections between washer, main mechanical core, and secondary

mechanical core are as specified in Section 3 of

Instructions

(P920017-147).

Uncrating/Installation

2-2

920017-148 Operator Manual Installation Verification

❑ Electrical connections between washer, main mechanical core, and second-

ary mechanical core are as specified in Section 3 of

Instructions

(P920017-147).

Uncrating/Installation

❑ Air line connections between washer, main mechanical core, and secondary

mechanical core are as specified in Section 3 of

Instructions

(P920017-147).

Uncrating/Installation

❑ If Drying System option is present, drying connections between washer, main

mechanical core, and secondary mechanical core are as specified in Section

3 of

Uncrating/Installation Instructions

(P920017-147).

❑ If Floor Ramp accessory is present, floor ramp is correctly attached to washer

as specified in Section 3 of

Uncrating/Installation Instructions

(P920017-147).

❑ If Service Side Access Panels accessory is present, service side access

panels are correctly attached to washer as specified in Section 3 of

Installation Instructions

(P920017-147).

Uncrating/

❑ Floor surrounding unit has nonslip surface.

IMPORTANT: After a few weeks of operation, inspect units for leaks. Retighten

all clamps and connections.

2-3

Installation Verification Operator Manual 920017-148

2.3 Chemical

Additives

Specifications

2.3.1 General

The selection of chemical additives is open for customer preference. However,

in order to achieve optimal performance, the selected chemical additives must

meet as a minimum, the following specifications:

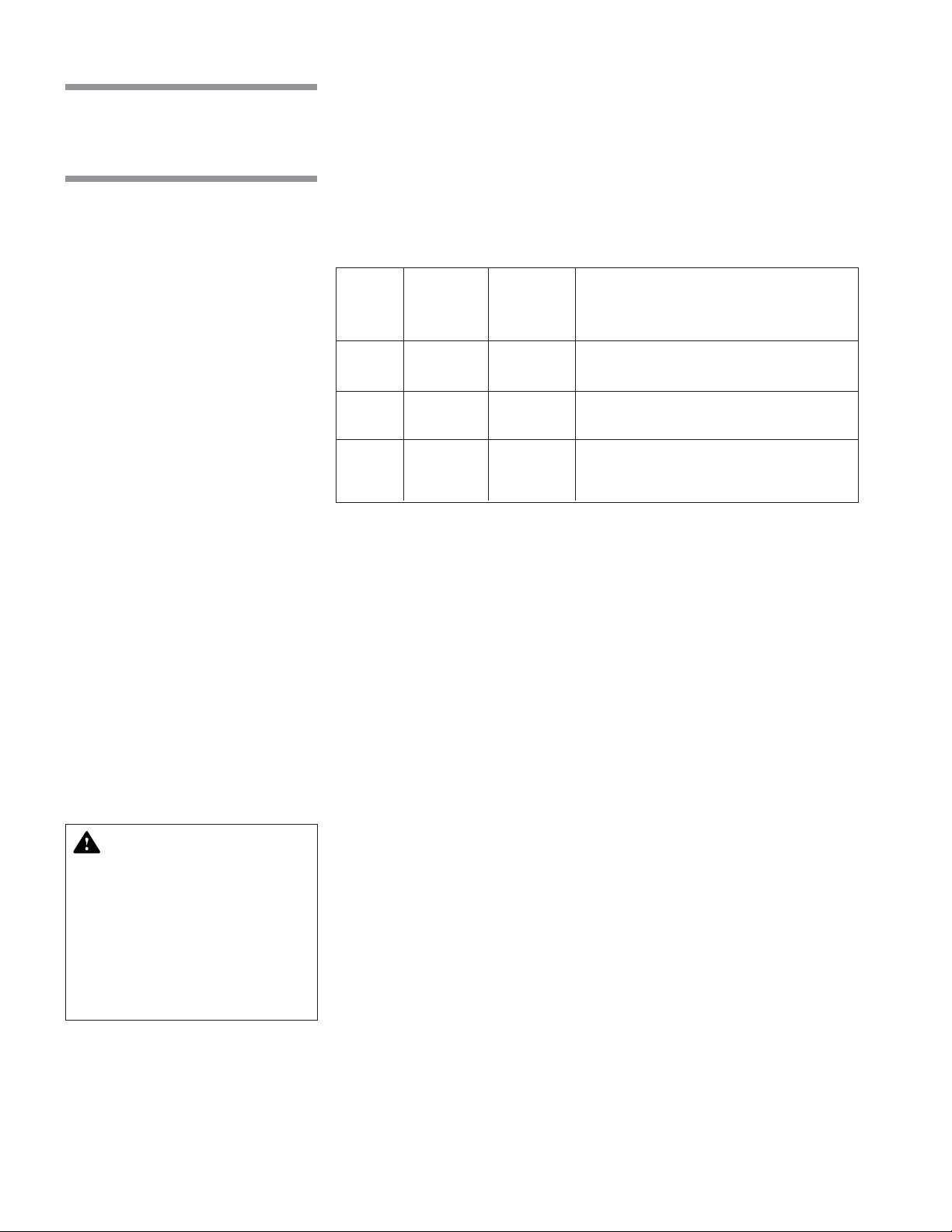

Product Use Dilution pH Range Other Applicable

Description Range oz/gal at Use Dilution Requirements

(mL/L)

Alkaline 1/4 - 4 9.0 - 12.0 Liquid, non foaming, and viscosity below 200 ccsu.

Chemicals (2 - 32)

Acidic 1/4 - 4 3.0 - 6.0 Liquid, non foaming, free rinsing, and viscosity

Chemicals (2 - 32) below 200 ccsu.

Descalers 1/2 - 2 < 2.5 Liquid, non foaming, phosphoric acid-based, and

(4 - 16) viscosity below 200 ccsu.

NOTE: When choosing and using detergents, note the following:

1) Follow chemical label recommendations for concentration of chemical to use.

2) Follow chemical manufacturer's recommendations to determine the temperature of the WASH treatment.

3) Follow chemical manufacturer's recommendations for the amount of chemical

used according to water hardness.

2.3.2 Recommended Chemical Additives

WARNING – CHEMICAL

BURN AND/OR EYE INJURY

HAZARD: Always use nonfoaming chemical for effective cleaning and proper

pump and water level control operation. Follow

manufacturer's recommendations for amount of

chemical to be used.

2-4

920017-148 Operator Manual Installation Verification

To achieve maximum cleaning efficiency, select chemical appropriate to soil

type being processed. STERIS recommends the following chemicals:

• Cage-Klenz® 100 Alkaline Cage Wash Detergent – (Alkaline) formulated to

remove urine, scale, animal fats, oils, and other organic soils from cage

materials.

• Cage-Klenz® 200 Acid-Based Wash Detergent – (Acidic) formulated to

remove urine, scale, animal fats, oils, and other organic soils from cage

materials.

• LIQUID DESCALER LIQUID SCALE REMOVER – for removing scale and

other hard water deposits. For use in animal care centers.

NOTE: Certain products may not be available in your area. Contact STERIS for

availability of these products and for ordering information.

IMPORTANT: STERIS does not promote, recommend, or endorse the use of any

other type of chemical additives in the processing of articles in the Basil® 9502

Cage and Rack Washer, such as drying agents, strong alkaline detergents

(pH>12), alcohol rinses, and liquid germicides including hypochloric acid

(bleach).

COMPONENT IDENTIFICATION

3

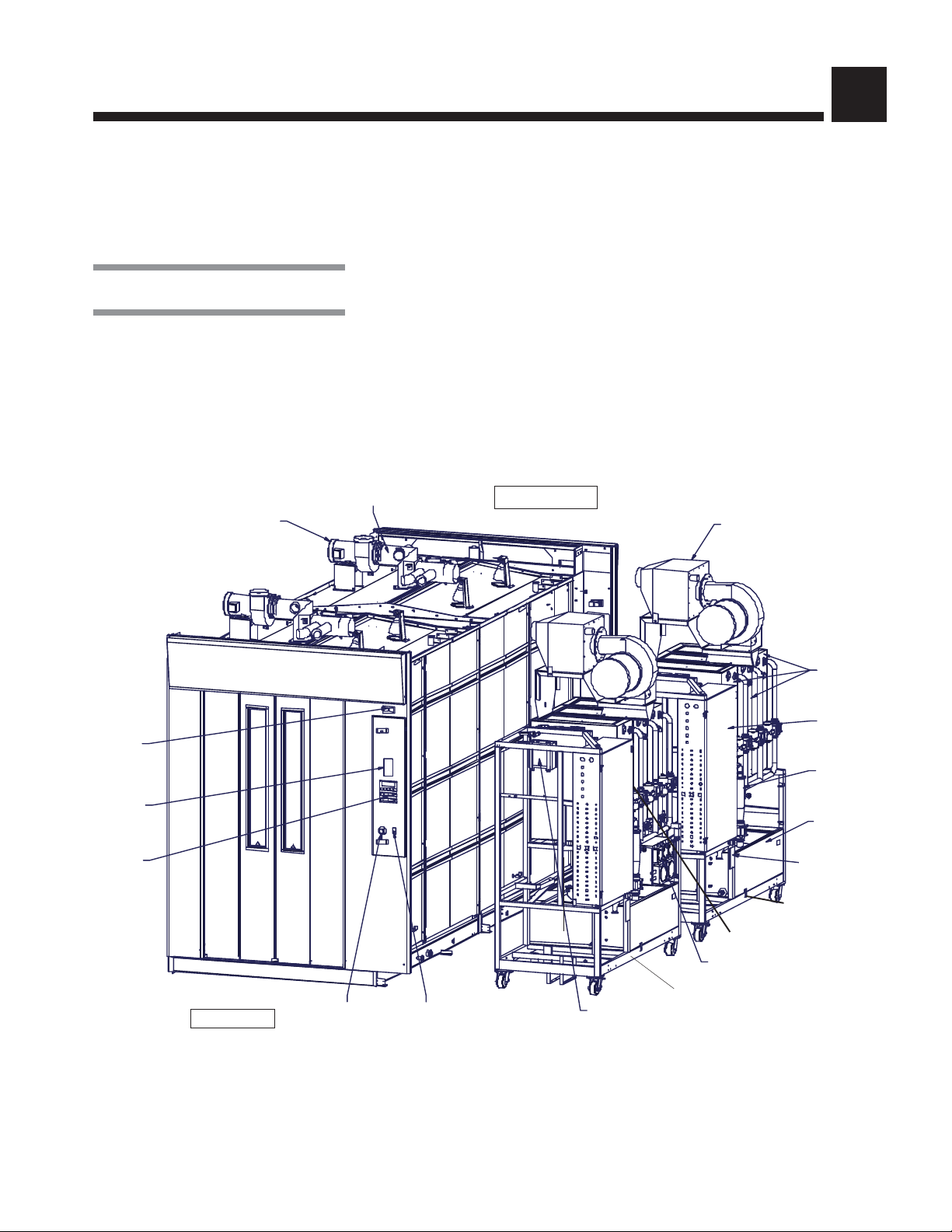

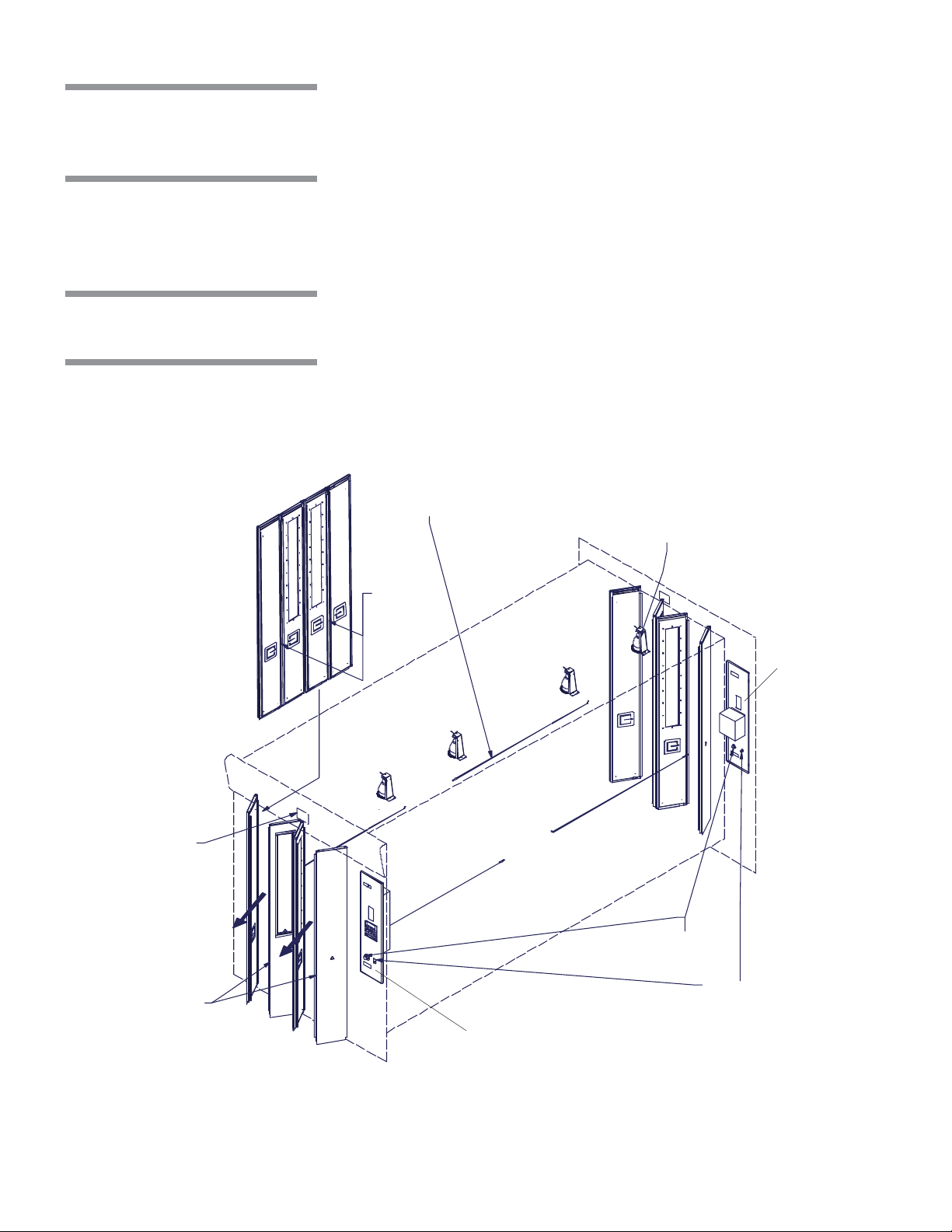

3.1 General

Exhaust

Fan

IMPORTANT: A listing of the

Safety Precautions

to be observed when operating

and servicing this equipment can be found in Section 1 of this manual. Do not

operate or service the equipment until you have become familiar with this

information.

Become familiar with the location and function of all major components and

controls, as well as their function before operating this unit (see Figure 3-1).

Damper

UNLOAD SIDE

Drying

Option

Indicator

Lights

Printer

Control

Panel

Side

Tanks

Secondary

Electrical

Box

Vertical Self-

Cleaning

Filter

Cool Down

Tank

Identification

Nameplate

SECONDARY

MECHANICAL

CORE

Flowmeters

Main Electrical Box

MAIN MECHANICAL CORE

(Always on left when facing

service side)

Ref: # 920-501-294

LOAD SIDE

EMERGENCY

STOP

Pushbutton

Lock /

Unlock/Init

Switch

Electrical

Supply Box

Figure 3-1. Basil® 9502 Cage and Rack Washer (Typical)

3-1

Component Identification Operator Manual 920017-148

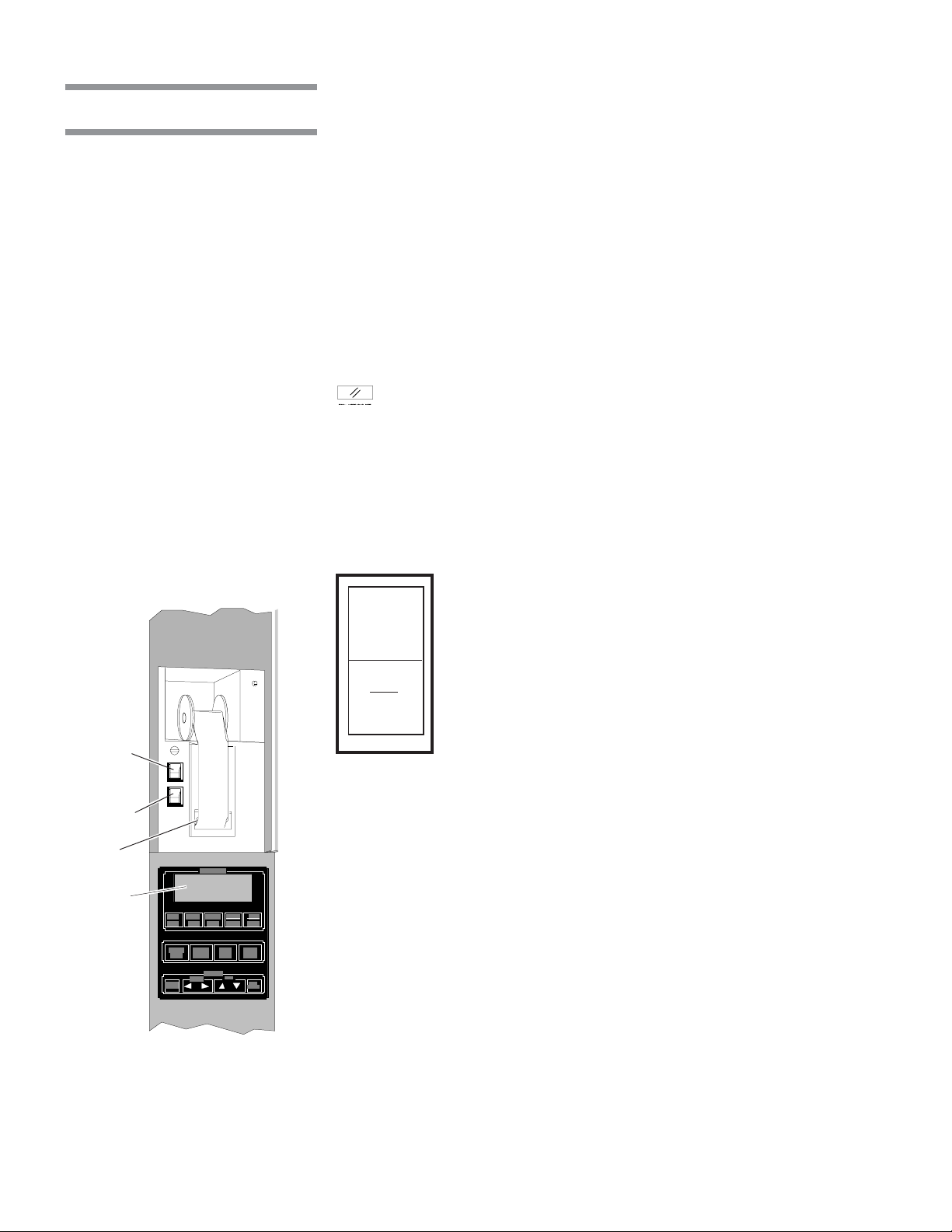

3.2 Control Location

Become familiar with all control locations and functions before operating the unit

(see Figures 3-1 and 3-2).

3.2.1 LOCK/UNLOCK/INIT Key Switch

3.2.2 POWER-OFF/ STANDBY Switch

LOCK/UNLOCK/INIT key switch is located on both control panel doors and

includes three positions :

± • LOCK – To lock washer for maintenance purposes, use key to turn

selector switch to the left. Positioning selector switch to LOCK position

places the washer in locked mode. The operator cannot start a new

cycle or enter into the Service mode.

² • UNLOCK

washer. Positioning switch to UNLOCK enables the washer to function

normally.

••

• INITIALIZATION

••

normal operation after Emergency Stop Cables or Emergency Stop

Button were activated, after a power up, or a power failure.

NOTE : Selector returns automatically from reset to UNLOCK position when key

is released.

The POWER-OFF/STANDBY switch, located behind the printer door, includes

two settings which direct operation of the control (see Figure 3-1 and 3-2):

POWER

– Use key to turn selector switch to central position to unlock

– Use key to turn selector to the right to reset washer

• POWER – Press top portion of POWER-OFF/STANDBY

switch to initialize control and place control in Ready Mode.

POWER-

OFF/

STANDBY

Switch

PRINT/PRINT

VALUES

Switch

Printer

Display

Screen

Figure 3-2. Load End

Control Panel and Printer

OFF

• OFF/STANDBY – Press bottom portion of POWER-OFF/

STANDBY switch to initiate Shutdown Cycle and place

STANDBY

control in Standby Mode.

NOTE: Control should be placed in Standby Mode for last cycle of the day and

when washer is not in use for an extended period of time.

IMPORTANT: POWER-OFF/STANDBY switch does not turn off electrical power

to the unit.

3-2

920017-148 Operator Manual Component Identification

3.3 Load-Side

(Main) Control Panel

The Basil 9502 Cage and Rack Washer is equipped with a fully-programmable

microprocessor control system capable of storing up to 12 cycles for processing a wide variety of loads. The control system monitors and automatically

controls all cycle operations and functions.

The main control panel is used to direct all washer functions. It can be placed

on either the load side or the unload side (see Figures 3-1 and 3-3). The operator

may select and review cycles and treatments, start, stop, or reset cycle

operation, and monitor cycle performance and washer status from the control

panel.

3.3.1 Display Screen

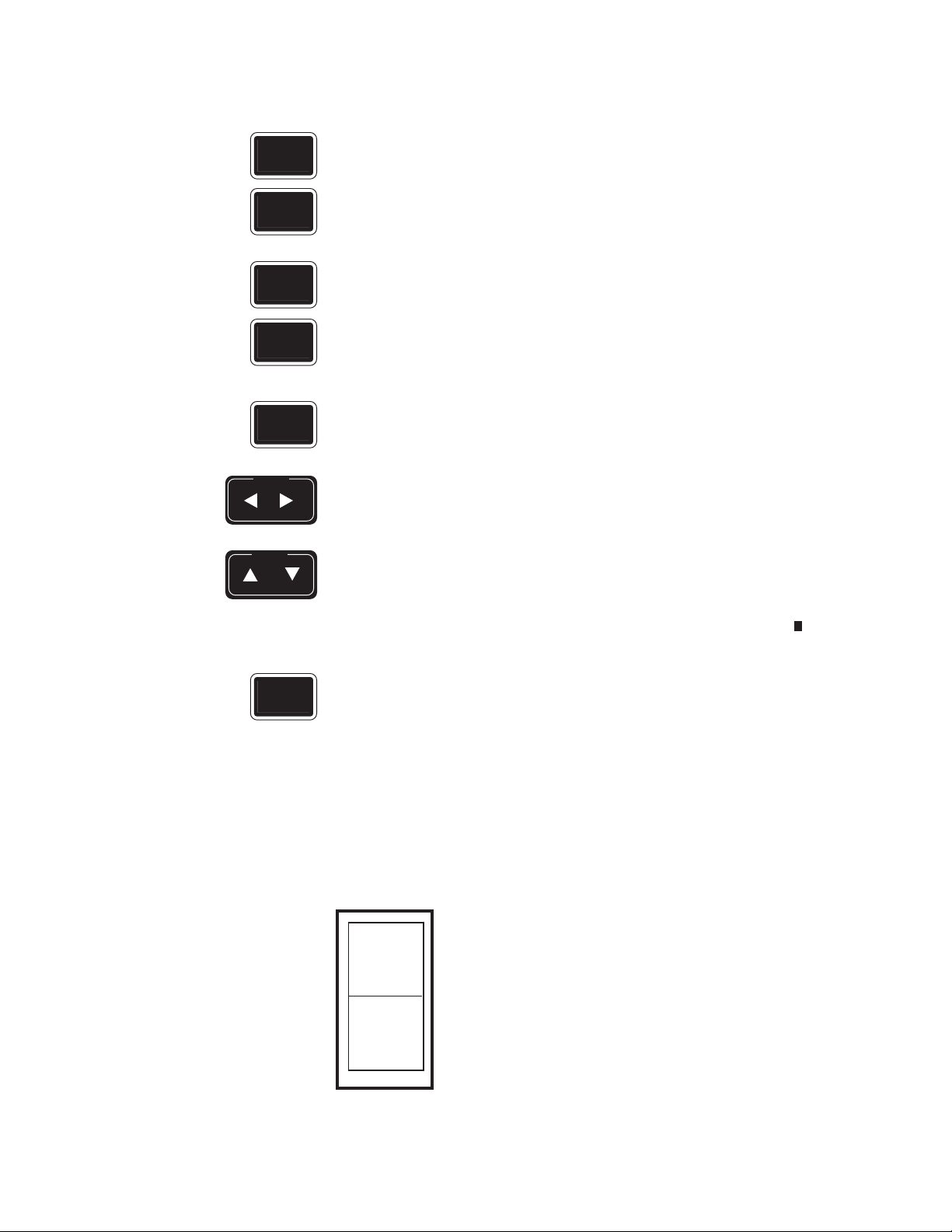

3.3.2 Touch Pads

CYCLE

MENU

SELECT

CYCLE

REVIEW

CYCLE

CYCLE

START

The two-line, alphanumeric screen displays cycle program data on demand,

cycle performance data and operator instructions. Display screen also indicates certain abnormal conditions that may occur during a cycle.

• Cycle Status Touch Pads:

CYCLE MENU Touch Pad – Press to view the cycle menus. Three cycle menus

are available.

SELECT CYCLE Touch Pad – Press to select one of the four cycles available

from each cycle menu.

NOTE: When a displayed cycle or treatment value is selected, the corresponding word or digit flashes.

REVIEW CYCLE Touch Pad – Press to review treatments and values programmed for a selected cycle.

CYCLE/START – Press to start selected cycle.

STOP

RESET

STOP/RESET – Press once to stop cycle operation. Press a second time to

abort cycle or to interrupt opening or closing of doors.

CYCLE STATUS

Display

Screen

CYCLE

CYCLE

MENU

EXTEND

CYCLE

CHANGE

VALUES

SELECT

CYCLE

ALARM

REPLY

CURSOR

REVIEW

CYCLE

PROGRAM

DOOR

OPEN

START

VALUE

STOP

RESET

DOOR

CLOSE

VALUES

Touch

Pads

SAVE

Figure 3-3. Control Panel

3-3

Component Identification Operator Manual 920017-148

• Manual Operation Touch Pads:

EXTEND

CYCLE

ALARM

REPLY

DOOR

OPEN

DOOR

CLOSE

CHANGE

VALUES

CURSOR

VALUE

EXTEND CYCLE Touch Pad – Available in Service Mode only.

ALARM REPLY Touch Pad – Press to stop intermittent alarm buzzer and

acknowledge the displayed alarm message.

DOOR OPEN Touch Pad – Press to automatically open door(s).

DOOR CLOSE Touch Pad – Press to automatically close door(s).

• Program Touch Pads:

CHANGE VALUES (CVTP) Touch Pad – Press to modify treatments from

programmed cycles and to confirm selected values from programmed cycles.

CURSOR (left or right) Touch Pad- Press to move left or right on the display

screen.

VALUE (up or down) Touch Pad – Press to move up or down on the display

screen and, depending on selected item, press to either toggle between answer

selections or to scroll through the alphabet, numbers 0 through 9, and symbols.

SAVE

VALUES

3.3.3 Printer

NOTE: Alphabet includes characters for an underline and a space ( ).

SAVE VALUES (SVTP) Touch Pad – Press to store all treatment values and

cycle changes.

The printer, located on the right side of the load end, records all cycle data on

57 mm (2-1/4 inch) wide single-ply thermal paper. See Section 6,

Maintenance,

for paper changing and paper ordering information.

Routine

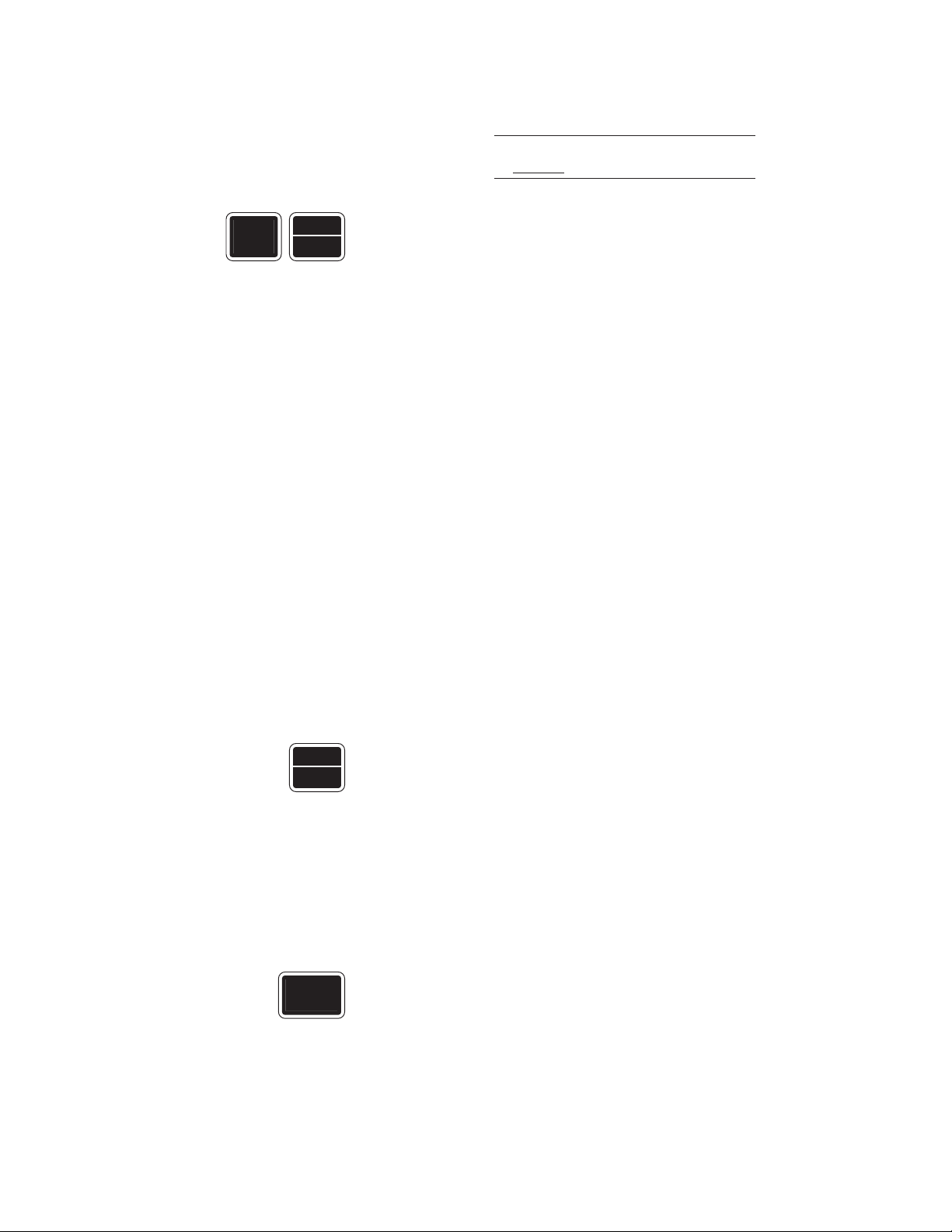

Printer Function Switch

The Printer Function Switch controls two printer functions, PRINT and PRINT

VALUES:

• •

• PRINT

• •

– Pressing the top portion of the rocker switch

generates a complete printout of the current water tempera-

PRINT

PRINT

ture of sump, and air temperature in drying chamber.

• •

• PRINT VALUES

• •

– Pressing the bottom portion of the rocker

switch generates a complete printout of all cycle values,

VALUES

including all treatments values, of selected cycle (cycle

flashing in Cycle Menu when PRINT VALUES was pressed)

(see Figure 3-6).

3-4

920017-148 Operator Manual Component Identification

Press the PRINT portion of the rocker switch to display print menu. Display

shows:

ANALOG CONSUMP.

CYCLE DUPLICATE

__ indicates flashing position

SELECT

CYCLE

CYCLE

START

Press SELECT CYCLE touch pad to select a function and CYCLE/START

touch pad to generate the selected printout.

• ANALOG

– Generates a printout of the actual in-line heat exchanger water

temperature, current air temperature at the exhaust (Drying System option),

current solution temperature in cooldown tank (Drain Discharge Cooldown with

Guaranteed Cooldown System with Side Tank or pH Neutralizing System

options), current water pressure and current solution pH in the cooldown tank

(pH Neutralizing System option) (see Figure 3-4).

• CONSUMP – Generates a printout of the water and chemical consumption

over a determined period of time. Report can be either in gallons or in liters

(see Figure 3-5).

• CYCLE – Generates a complete printout of all programmed cycles and

treatment values (see Figure 3-6).

• DUPLICATE – Generates a second printout of last cycle, with or without cycle

validation according to the cycle configuration.

Typical Printouts

Figure 3-7 is an example of a typical cycle printout without cycle validation for

Reliance 9502 Cage and Cart Washer. Figure 3-8 is an example of a printout with

cycle validation.

• Power Up - When POWER-OFF/STANDBY switch is set to POWER, the

generated printout lists time and date the control was turned on, model and

unit number (see Figure 3-9).

CYCLE

START

• Cycle Start – When CYCLE/START touch pad is pressed to begin selected

cycle, the generated printout lists name of selected cycle, time and date cycle

was started as well as cycle number and unit serial number.

• Cycle Performance – During a cycle, the generated printout indicates

beginning and end of each treatment.

• End-of-cycle Performance Summary

– At the end of a cycle, the generated

printout lists time the cycle was completed, total cycle processing time, and

time the door was opened.

ALARM

REPLY

• Alarm Printout

the type of alarm and time it occurred. Once the operator presses ALARM

REPLY touch pad, the generated printout lists the time the alarm was

– When an alarm condition occurs, the generated printout lists

acknowledged (see Figure 3-10).

NOTE : Refer to Section 7, Troubleshooting, for listing of possible alarm

conditions.

3-5

Component Identification Operator Manual 920017-148

LOAD BST = 88.1F

UNLOAD BST = 89.2F

DRYING = 80.1F

COOL DOWN = 78.2F

Figure 3-4. Typical Printout

if ANALOG is Selected

=========================

= CYCLE PROGRAM REVIEW =

= CYCLE - RABBITS =

=========================

REVIEW TIME 9:28:23A

REVIEW DATE 0/02/05

UNIT NUMBER 3633900006

CYCLEAUTHORIZED: YES

========================

CYCLE - RODENTS

========================

CYCLE START 4:45:04P

CYCLE DATE 99/09/24

CYCLE NUMBER 000000003

UNIT NUMBER 3600000000

=========================

CONSUMPTION

REPORT

8:16:26P 99/09/23

UNIT S/N 36XXXXXXXX

=========================

CYCLE CNT= 00000002

WATER: 1197 gal

LAST RESET: 0/00/00

ALKALINE: 0.625 gal

LAST RESET: 0/00/00

ACIDIC: 0.000 gal

LAST RESET: 0/00/00

Figure 3-5. Typical Printout

if CONSUMP is Selected

PRE-WASH

DURATION = 00:20

FINAL R.

DURATION = 08:00

TEMP. = 185.0F

EXHAUST

DURATION = 01:00

DRYING

DURATION = 05:00

TEMP. = 180.0

F ALKALINE REFRESH 15%

ACID REFRESH 15%

LOAD FLOOR TILT= YES

UNLOAD FLOOR TILT = YES

LOAD MANIFOLD = NO

UNLOAD MANIFOLD = NO

Figure 3-6. Typical Printout

if CYCLE is Selected

TREATMENT TIME

------------------------

PRE-WASH 4:45:27 PM

4:46:19 PM

WASH 1 4:46:19 PM

WATER TEMP. = 99.6 F

4:50:18 PM

FINAL R. 4:50:18 PM

WATER TEMP. = 107.9 F

5:00:05 PM

EXHAUST 5:00:05 PM

5:01:07 PM

DRYING 5:01:07 PM

5:16:08 PM

COMPLETED 5:16:08 PM

TOTAL CYCLE = 0:31:04

========================

= READY TO UNLOAD =

========================

Figure 3-7. Typical Cycle

Printout, Without Cycle

Validation

3-6

920017-148 Operator Manual Component Identification

* CONTROL ON 6:41:57P

99/09/24

*****************************

STERIS

BASIL 9502

S/N 36XXXXXXXX

*****************************

========================

CYCLE - RODENTS

========================

CYCLE START 6:41:57 P

CYCLE DATE 99/09/24

CYCLE NUMBER 000000003

UNIT NUMBER 3600000000

TREATMENT TIME

--------------------------------------PRE-WASH 6:43:51 PM

DURATION = 00:20

6:45:52 PM

WASH 1 6:45:52 PM

DURATION = 02:00

TEMP. = 130.0 F

CHEMICAL = ALKALINE

RATE = 1 oz/gal

6:51:31 PM

FINAL R. 6:51:31 PM

DURATION = 03:00

TEMP. = 185.0 F

7:00:17 PM

EXHAUST 7:00:17 PM

DURATION = 01:00

7:01:19 PM

DRYING 7:01:19 PM

DURATION = 15:00

TEMP. = 180.0F

7:16:20 PM

COMPLETED 7:16:20 PM

TOTAL CYCLE = 0:34:25

Power Up

Cycle Start

Cycle

Performance

* CONTROL ON 8:20:05 P

99/09/23

******************************

BASIL 9502

S/N 36XXXXXXXX

*****************************

Figure 3-9. Typical

POWER UP Printout

========================

= CYCLE — RODENTS =

========================

CYCLE START 8:22:41P

CYCLE DATE 99/09/23

CYCLE NUMBER 00000001

UNIT NUMBER 3600000000

TREATMENT TIME

------------------------------------PRE-WASH 8:23:05 PM

* STOP PRESSED 8:23:40 P

* ALARM:

ALKALINE INJ

NOT REACHED

8:23:45P 99/09/23

-----------------------* ALARM ACKNOWLEDGED

AT 8:23:50P

* ABORT 8:23:57P

------------------------

PUMP PRESSURE SET

POINTS LOW = 70 PSIG

HIGH = 140 PSIG

========================

= READY TO UNLOAD =

========================

End-of-Cycle

Performance

Summary

Figure 3-10. Typical Alarm

Printout

Figure 3-8. Typical Cycle

Printout, with Cycle

Validation

3-7

Component Identification Operator Manual 920017-148

3.4 Unload-Side

(Remote) Control

Panel

3.5 Emergency

Safety Features

An additional control panel is installed on the unload end of the washer (see

Figure 3-11). The unload side control panel features the same touch pads and

display screen as the load end control panel (see Figure 3-3).

All washer functions except POWER-OFF/STANDBY and PRINT/PRINT VALUES

can be directed from the unload end control panel, and the display screen

concurrently shows the same message as displayed on the operating end

control panel. There is no printer on the unload end control panel.

See Figure 3-11.

3.5.1 Photoelectric Sensors

Photoelectric

Sensor

Photoelectric sensors, located under Upper Service Panel, are installed to

detect obstructions when doors are closing. Doors will automatically depressurize and stop if any obstruction is detected by the photoelectric sensors.

EMERGENCY STOP

Cable

Interior Light

Push here

Unload-Side (Remote)

Control Panel

Pushuttons

LOCK/UNLOCK/INIT

Switch

REF: # 920-501-293

Emergency Exit

Safety Doors

EMERGENCY STOP

Load-Side (Main)

Control Panel

Figure 3-11. Emergency Safety Features

3-8

920017-148 Operator Manual Component Identification

3.5.2 Emergency Exit Safety Doors

WARNING – PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

• To open doors from inside

wash chamber, pull EMERGENCY STOP cables.

Washer operation will automatically stop. Then, push

firmly between door panels

using shoulder and upper

arm, applying upper body

force. Do not push between

the two doors, but between

the door panels.

• To test or demonstrate

Emergency Exit Safety

Doors, first press EMERGENCY STOP pushbutton

(located under control) or

EMERGENCY STOP cables

(inside wash chamber) to

turn power OFF. If power is

still on while adjusting or

servicing doors, the photoelectric sensor will detect

the movement of the door

panels and doors will open

automatically.

Door panels can be pushed out in case of an emergency, offering four

emergency exit points (see Figure 3-11).

3.5.3 EMERGENCY STOP Cables

3.5.4 EMERGENCY STOP

Pushbuttons

Four EMERGENCY STOP cables, located on each side of wash chamber,

instantly stop washer operation when pressed (see Figure 3-11).

Two EMERGENCY STOP pushbuttons located under each control panel,

instantly stop washer operation when pressed.

NOTE: EMERGENCY STOP pushbuttons will cut off electrical power to control

only and completely depressurize unit.

3.5.5 Interior Light

3.5.6 Safety Delay

Component Identification Operator Manual 920017-148

Interior light flashes once prior to cycle start, warning the operator that a cycle

is about to begin.

An adjustable Safety Delay (15 to 60 seconds), during which the washer will

sound an alarm signal, has been provided to warn operator to leave the wash

chamber before the cycle starts. Safety Delay is adjustable in Service Mode

(see Section 4 of

15 seconds.

Maintenance Manual

[P764330-842]). Default Safety Delay is

3-9

3.5.7 LOCK/UNLOCK/INIT

Key Switch

±

²

Includes three settings. Positioning switch to LOCK places washer in locked

mode for maintenance purposes. When switch is in LOCK position, the operator

cannot start a cycle or enter into the Service mode.

1. When key is turned to LOCK position, display shows:

WASHER LOCK

... and printer records:

WASHER LOCK

HH:MM:SS YY/MM/DD

2. As an additional safety measure, key should be removed from switch and

kept by the operator until ready to unlock the washer.

3. To unlock washer, insert key in LOCK/UNLOCK/INIT switch and turn to

UNLOCK position to resume normal operation.

3-10

920017-148 Operator Manual Component Identification

OPERATING INSTRUCTIONS

4

4.1 Before

Operating Washer

IMPORTANT: A listing of the

and servicing this equipment can be found in Section 1 of this manual. Do not

operate or service the equipment until you have become familiar with this

information.

1. Verify building electrical supply disconnect switch (circuit breaker) is

positioned to ON. Verify unit supply valves are open.

2. Verify EMERGENCY STOP pushbuttons are pulled out on Load and Unload

sides of washer.

3. Verify wash chamber is empty and all material has been removed.

4. Verify debris screen in bottom of sump is clean and properly installed.

5. Open printer door and verify sufficient amount of printer paper is available.

Safety Precautions

to be observed when operating

NOTE: A colored warning stripe is visible when paper roll is near the end. See

Section 6.6, Printer Paper Roll Replacement, if paper roll needs to be replaced.

6. Put POWER-OFF/STANDBY switch to POWER position. Display shows:

* STERIS *

* BASIL 9502 *

... and printer records:

* CONTROL ON HH:MM:SSX

YY/MM/DD

Current Time

Current Date

*********************************

Unit Serial

Number

7. Side tanks fill with water (if not already full). Display screen automatically

advances to the first Cycle Menu of factory-set cycles. Display shows:

***** BASIL 9502 **********

**** S/N 3600000000 ****

*********************************

RODENTS BOTTLES

RABBITS PRIMATES

___indicates flashing position.

4-1

Operating Instructions Operator Manual 920017-148

4.2 Priming Procedure

WARNING – CHEMICAL

BURN AND/OR EYE INJURY

HAZARD:

• Always use non-foaming

chemical for effective cleaning and proper pump and

water level control operation. Follow manufacturer's

recommendations for amount

of chemical to be used.

• Detergents are caustic and

can cause adverse effects to

exposed tissues. Do not get

in eyes, on skin or attempt

to swallow. Read and follow

the precautions and instructions on the detergent label

and in the Material Safety

Data Sheet (MSDS) prior to

handling detergent containers, or servicing the detergent injection pumps and

lines. Wear appropriate personal protective equipment

(PPE) whenever handling

chemicals or servicing

chemical injection pumps

and lines.

The system is self-priming and requires no specific operation. At the beginning

of the cycle, display shows for example:

PRIMATES STARTING

PRIMING

If chemical flowmeters detect no detergent is being injected, an alarm buzzer

sounds and display shows:

ALARM: (CHEM NAME) INJ

NOT REACHED

See Section 6.4,

replace chemical containers.

To achieve maximum cleaning efficiency, select chemical appropriate to soil

type being processed. See Section 2.3,

Chemical Container Replacement

Chemical Additives Specifications

, for procedure on how to

.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

When choosing a chemical,

select one with a low chloride content. Chloride is

harmful to stainless steel

and will deteriorate washer.

4-2

920017-148 Operator Manual Operating Instructions

4.3 Doors

Inward sliding doors provide access to the wash chamber. Door movement is

power controlled. When a load is placed in front of the doors, a photoelectric

sensor will detect the load and doors will automatically open when washer is

ready.

NOTE: The Photoelectric Sensor may be disabled in Service Mode. Refer to

Section 4 of Maintenance Manual (P764330-842).

4.3.1 Door Operation

DOOR

OPEN

DOOR

CLOSE

STOP

RESET

WARNING – PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

To open doors from inside

wash chamber, pull EMERGENCY STOP cables.

Washer operation will automatically stop. Then, push

firmly between door panels

using shoulder and upper

arm, applying upper body

force. Do not push between

the two doors but between

the door panels.

Power doors are controlled by touch pads located on the control panel (see

Figures 4-1 and 3-3).

• Press DOOR OPEN touch pad to automatically open doors or place load under

photoelectric sensor beam. Load must remain under photoelectric sensor

beam for at least three seconds before doors will open.

• Press

DOOR CLOSE touch pad to automatically close doors. Doors will not

close if any obstruction is detected in front of washer or in doorway.

• Press STOP/RESET

touch pad to interrupt opening or closing of doors.

IMPORTANT: Keep chamber doors closed between cycles and when washer is

not in use.

WARNING – PERSONAL

INJURY HAZARD:

• Keep hands/fingers away

from closing doors to prevent crushing between the

two doors.

• When doors are closing, a

pinch point is created at

the hinges. Keep fingers

away from door hinges to

prevent pinching.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Keep away from doors to

prevent load detection sensor from stopping doors

from closing.

4-3

Operating Instructions Operator Manual 920017-148

4.3.2 Interlock Feature

A door interlock feature prevents cross contamination by allowing only one door

to be opened at a time. Doors can be opened one at a time when green light is

on.

Load end control will energize load end doors only. Unload end control will

energize unload end doors only.

NOTE: It is possible to bypass the interlock system in Service Mode (see

Section 4 of Maintenance Manual P764330-842), if opening of both doors at the

same time is more practical for operator.

DOOR

OPEN

DOOR

CLOSE

4.3.3 Opening Doors

during a Power Failure

WARNING – PERSONAL

INJURY HAZARD: If doors

are still slightly open (less

than 2 inches [5 cm]) when

power is restored after a

power failure, control will

apply pressure to complete

closing. Lock building electrical supply disconnect

switch in OFF position and

close unit air supply when

opening doors after a power

failure.

NOTE: If operator chooses to deactivate interlock feature, pressing DOOR

CLOSE or DOOR OPEN touch pads on either side of washer will automatically

open or close doors on both the load and unload side.

1. Lock building electrical supply disconnect switch on OFF position and close

unit air supply valve before opening doors manually. If not, when the power

returns, doors could close automatically.

2. Wearing gloves, slide fingers between doors and slowly push the doors

apart.

NOTE: If operator is inside wash chamber during a power failure, it is possible

to exit through the Emergency Exit Safety Doors or by opening the doors

manually.

4-4

920017-148 Operator Manual Operating Instructions

4.4 Accessories

To properly clean items and to avoid personal injuries, always follow the loading

guidelines. Always use a rack designed to handle the appropriate type of items

to be processed.

4.4.1 General

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Remove all cellulose-type

bedding from cages and

pans before processing. Cellulose bedding can clog

filters and piping.

1. Use specific accessories designed to handle cages, bottles, pans, floor

grids, and cage doors:

IMPORTANT: Remove as much debris as possible from cages and pans before

loading accessories

••

• Bottle Washing Cart

••

Requires Manifolded Coupling System (option).

••

• Pan Cart – Used to wash pans, floor gratings, cage doors, etc.

••

••

• Central Spray Header Manifold – Used to clean and sanitize up to

••

200 standard mouse cages per load.

••

• Rodent Cage Rack – Used to hold up to 92 mouse cages or 32 rat cages,

••

or shoe boxes, covers, and feeder tops.

2. Use baskets for handling and cleaning various size bottles. The lightweight

basket design provides easy handling and simplifies transport and

washing of bottles.

••

• 5 x 5 Bottle Basket, 16 oz (454 mL) bottles – Used to wash 25 bottles

••

(16 oz [454 ml]).

••

• 4 x 6 Bottle Basket, 16 oz (454 mL) bottles – Used to wash 24 bottles

••

(16 oz [454 ml]).

••

• 5 x 5 Bottle Basket, 8 oz (236 mL) bottles – Used to wash 25 short

••

4" (10 cm) bottles.

– Used for processing up to six bottle baskets.

4.4.2 How to Load

Accessories Into Wash

Chamber

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Always leave plenty of

space between load and

doors. Leaning load against

doors will damage doors

and also prevent them from

opening or closing.

••

• 4 x 6 Bottle Basket, 8 oz (236 mL) bottles – Used to wash 24 tall

••

5-1/2" (14 cm) bottles.

3. Assure all items to be treated are correctly positioned on accessory and no

items stick out or hang out of the rack.

Washer chamber is composed of two sections. The section closer to the load

side, is called the "load chamber". The section closer to the unload side is called

the "unload chamber".

The accessories must be installed correctly in the corresponding sections of the

chamber, especially accessories that need to be connected to the manifold

coupling system or used with the floor tilt (see Figure 4-1).

1. Place the correctly loaded accessory cart in front of unit, on the load side

under photoelectric sensor beam. Load must not touch doors, inside or

outside wash chamber.

NOTE: Photoelectric sensor located above doors, under upper front access

panel, must be able to detect cart. Assure cart is positioned under photoelectric

sensor beam.

4-5

Operating Instructions Operator Manual 920017-148

Left Configuration

Load Chamber

Printer

Control Panel

Unload Chamber

Unload Side

Load Side

Right Configuration

Unload Side

Unload Chamber

Load Side

Load Chamber

Printer

Control Panel

REF:# 920-501-297

Figure 4-1. Washer Configurations

4-6

920017-148 Operator Manual Operating Instructions

2. Wait for chamber doors to open and push loaded accessory cart into wash

chamber.

-- or --

DOOR

OPEN

4.4.3 How to Load

Central Header Manifold

with Rodent Cage Racks

(Accessory)

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

• Always position manifolded Bottle Washing Cart

and/or Central Header

Manifold over central water inlet connector. If manifolded accessory is not

positioned correctly, damage may result and unit

will be unable to effectively

wash load.

If photoelectric sensor is disabled, press DOOR OPEN touch pad to open

door and push cart into wash chamber. For procedure on how to disable

photoelectric sensor in Service Mode, see Section 4 in

Maintenance Manual

(P764330-842).

IMPORTANT: If the Central Header Manifold is used, assure Floor Tilting option

IS NOT ACTIVATED in the wash chamber where it is positioned (see Section 5,

Cycle and Control Value Programming

).

1. When doors are open, enter wash chamber and roll Central Spray Header

Manifold and Support (see Figure 4-2) along central rails until top of header

is aligned with roof locking support.

2. Unlock safety locking pin retaining Central Header Manifold to support.

3. Align manifold at the bottom of the accessory with the water inlet connector

at the bottom of the wash chamber.

4. Push up locking handle towards roof locking support and turn clockwise to

secure header into position.

5. Roll Support out from wash chamber.

6. Roll Rodent Cage Racks (see Figure 4-3) along Central Spray Header

Manifold inside wash chamber.

• Do not process load using

Central Header Manifold or

Bottle Washing Cart in a

chamber where Automatic

Floor Tilting option is activated. If Automatic Floor

Tilting is used, manifolded

water inlet and washer will

be damaged.

4-7

Operating Instructions Operator Manual 920017-148

Locking

Handle

Safety

Locking Pin

Central Header

Manifold

Figure 4-2. Central Header Manifold and Support

Support

Figure 4-3. Rodent Cage Rack

4-8

920017-148 Operator Manual Operating Instructions

4.4.4 How to Load

Bottle Washing Cart or

Universal Cage and Pan

Wash Cart (Accessory)

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

• Always position manifolded Bottle Washing Cart

and/or Central Header

Manifold over central water inlet connector. If manifolded accessory is not

positioned correctly, damage may result and unit

will be unable to effectively

wash load.

• Do not process load using

Central Header Manifold

or Bottle Washing Cart in a

chamber where Automatic

Floor Tilting option is activated. If Automatic Floor

Tilting is used, manifolded

water inlet and washer will

be damaged.

IMPORTANT: If the manifolded Bottle Washing Cart is used, assure Floor Tilting

option IS NOT ACTIVATED in the wash chamber where it is positioned (see

Section 5,

1. When doors are open, roll correctly loaded Bottle Washing Cart (see

2. Push until wheels are positioned between stoppers on rails.

3. Assure water inlet connector at bottom of wash chamber is aligned with

Cycle and Control Value Programming

Figure 4-4) or Universal Cage and Pan Wash Cart (see Figure 4-5) along

guiding rails.

manifold on bottle washing cart.

).

Figure 4-4. Bottle Washing Cart

Figure 4-5. Universal Cage and Pan

Wash Cart

4-9

Operating Instructions Operator Manual 920017-148

4.5 Typical Cycle

Operation

The Basil® 9502 Cage and Rack Washer is pre-programmed at factory with four

processing cycles and two maintenance cycles, and is capable of retaining up

to six additional cycles (see Table 5-1). Each cycle can be customized to

include up to seven different treatments. For instructions on programming, refer

to Section 5,

Cycle and Control Value Programming

.

The following cycle description is based on the pre-programmed PRIMATES

cycle. See Table 4-1 for default treatment values of the PRIMATES cycle.

NOTE: Note the following regarding the typical cycle:

STOP

RESET

CYCLE

START

DOOR

CLOSE

CYCLE

MENU

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

Avoid product damage. Always select a cycle appropriate for the items being

processed.

1) Washer operation can be interrupted at any time by pressing STOP/RESET

touch pad. To resume cycle, press CYCLE/START touch pad. To abort cycle,

press STOP/RESET touch pad a second time.

2) After washer operation has been interrupted, a 60-second delay will prevent

doors from opening before it is safe to do so. Operator must wait until the end

of the delay before opening doors.

3) If unit fails or if any abnormal condition occurs during a cycle, see Section 7,

Troubleshooting, to identify the possible cause and corrective action.

1. Once washer is properly loaded, press DOOR CLOSE touch pad to close

doors. The first Factory-set Cycle Menu appears on the screen. Display

shows:

RODENTS BOTTLES

RABBITS PRIMATES

___ indicates flashing position

NOTE: To access one of the other two cycle menus, press CYCLE MENU touch

pad.

SELECT

CYCLE

CYCLE

START

2. Press SELECT CYCLE touch pad to select PRIMATES cycle from the

displayed menu.

3. When desired cycle is selected (cycle name is flashing on display screen),

press

CYCLE/START touch pad. The name of the selected cycle appears

on the screen and remains displayed during the safety delay. Display

shows:

PRIMATES STARTING

PRIMING

... then:

Name of

Cycle Started

Safety Delay

Countdown

PRIMATES STARTING

MM:SS

4-10

920017-148 Operator Manual Operating Instructions

Treatment Time Water/Air

Name (min:sec) Temp.

Pre-wash 00:20 N/A

Wash 1 06:00 130°F/54°C

Rinse 00:00 N/A

Wash 2* 06:00 160°F/71°C

Rinse 00:00 N/A

Final Rinse 02:00 185°F/71°C

Exhaust 01:00 N/A

Drying* 10:00 180°F/82°C

*Option

Table 4-1. Default Treatments

and Settings for PRIMATES

Cycle

4. After the safety delay has elapsed (15 seconds default, adjustable in Service

Mode, see Section 4 in

Maintenance Manual

P764330-842), washer auto-

matically progresses through the following programmed treatments.

• PRE-WASH: Solution from Tank 2 is sprayed over load for 20 seconds

(factory set) and sent directly to drain (or to Drain Discharge Cooldown

Tank if option is present). Pre-wash is non-recirculated.

• WASH 1: Load is washed with 130°F (54°C) heated solution from Tank 1

for 6 minutes (factory set).

• RINSE: Water from Tank 2 is sprayed over load and sent directly to drain

(or to Drain Discharge Cooldown Tank if option is present). Rinse is nonrecirculated.

• WASH 2 (Option): Load is washed with 160°F (71°C) heated solution from

Tank 3 (factory set) for 6 minutes (factory set).

• RINSE: Water from Tank 2 is sprayed over load and sent directly to drain

(or to Drain Discharge Cooldown Tank if option is present). Rinse is nonrecirculated.

NOTE: Not available in PRIMATES Cycle (factory set).

• FINAL RINSE: Load is rinsed with 185°F (85°C) heated water from Tank 2

for 2 minutes (factory set).

NOTE: RINSE phase timer will be started only when 185°F (85°C) is reached.

• VAPOR EXHAUST: Residual vapor is removed from chamber for 1 minute

(factory set).

• DRYING (Option): Load is dried at 180°F (82°C) (factory set) for 10 minutes

(factory set). Drying is non-recirculated.

5. The following is an example of the sequence of displays while a treatment

is in progress:

PRIMATES WASH 1

FILLING

.. then:

PRIMATES WASH 1

INJECTING

Detergent Injection

Phase

.. then:

Name of Cycle

Started

Phase in

Progress

PRIMATES WASH 1

CIRCULATE MM:SS*

Treatment in

Progress

Phase Countdown

NOTE: During Final Rinse treatment, countdown will start only when temperature

set point is reached.

... alternating with:

PRIMATES WASH 1

SET POINT XXX.X F

Temperature Setpoint

4-11

Operating Instructions Operator Manual 920017-148

... alternating with:

DOOR

OPEN

Current Temperature

in Load Chamber

PRIMATES WASH 1

XXX.X F XXX.X F

Current Temperature

in Unload Chamber

...then:

PRIMATES EXHAUST

VAPOR REM MM:SS

...then, if Drying System option is present, display shows:

PRIMATES DRYING

MM:SS

When cycle treatments are completed, display shows:

PRIMATES COMPLETED

Beep sounds and display shows:

PLEASE OPEN DOOR

AND REMOVE THE LOAD

6. Open chamber door by pressing on DOOR OPEN

touch pad or by simply

stepping in front of doors. Leave doors open and allow load to cool before

removing accessory headers. Display screen returns to cycle menu.

Display shows:

WARNING – BURN HAZARD:

Inner surfaces of washer are

very hot after cycle completion. Operator should wear

appropriate personal protective equipment (PPE) and

avoid all contact with inner

walls when entering chamber.

WARNING – SLIPPING

HAZARD: To avoid slippery

floor conditions, immediately wipe up any spilled

liquids or condensation.

RODENTS BOTTLES

RABBITS PRIMATES

___ indicates flashing position

IMPORTANT

: :

: When cycle is completed, unload door must be opened and then

: :

closed before another cycle may be started.

4-12

920017-148 Operator Manual Operating Instructions

4.6 DRAIN Cycle

DRAIN cycle can be performed whenever necessary, after each cycle, between

different load types, or at the end of a work session.

CHANGE

VALUES

CYCLE

MENU

SELECT

CYCLE

CYCLE

START

SAVE

VALUES

1. Press

CYCLE MENU

touch pad to scroll to appropriate cycle menu. Display

shows:

CYCLE 9 CYCLE 10

DRAIN DESCALER

___ indicates flashing position

2. Press

SELECT CYCLE

touch pad to select DRAIN Cycle. Display shows:

CYCLE 9 CYCLE 10

DRAIN DESCALER

___ indicates flashing position

3. Press CYCLE/START

touch pad to confirm. Display shows:

PURGE TRAVELERS?

CVTP=YES SVTP=NO

NOTE: Purging travelers will also purge Rinse Tank (Tank 2).

4. Press CHANGE VALUES

touch pad to purge travelers or press

VALUES touch pad to skip to the next question. Display shows:

DRAIN ALL TANKS?

CVTP=YES SVTP=NO

SAVE

CHANGE

VALUES

CHANGE

VALUES

CHANGE

VALUES

SAVE

VALUES

SAVE

VALUES

SAVE

VALUES

5. Press

CHANGE VALUES

touch pad to select YES and drain all tanks. Control

will automatically move to Step 9.

-- or --

Press SAVE VALUES

touch pad to select

NO

and choose which tanks to

drain. Display shows:

DRAIN ALKALINE

CVTP=YES SVTP=NO

6. Press CHANGE VALUES

touch pad to drain Alkaline Tank (Tank 1), or press

SAVE VALUES touch pad to keep tank filled. Display shows:

DRAIN RINSE?

CVTP=YES SVTP=NO

NOTE: The display is only shown if NO has been selected in answer to PURGE

TRAVELERS?

7. Press

CHANGE VALUES touch pad to drain Rinse Tank (Tank 2), or press

SAVE VALUES touch pad to keep tank filled. Display shows:

DRAIN ACID?

CVTP=YES SVTP=NO

NOTE: The display appears only if Additional Wash Tank option is present.

4-13

Operating Instructions Operator Manual 920017-148

CHANGE

VALUES

SAVE

VALUES

8. Press CHANGE VALUES

SAVE VALUES

touch pad to keep tank filled. Display shows:

REFILL AFTER DRAIN?

CVTP=YES SVTP=NO

touch pad to drain Acid Tank (Tank 3), or press

CHANGE

VALUES

SAVE

VALUES

9. Press

CHANGE VALUES

touch pad to select YES to refill selected tanks

after draining is completed.

-- or --

Press SAVE VALUES

touch pad to select

NO

and leave selected tanks

empty after draining is completed.

10. Washer drains selected tanks.

IMPORTANT: At the end of a work session, the washer should be completely

drained.

4-14

920017-148 Operator Manual Operating Instructions

4.7 Pause Cycle Operation

STOP

RESET

WARNING – BURN HAZARD:

• After pressing STOP/RESET touch pad, wait until

water flow stops before

opening doors. Hot water/

steam may be sprayed

through door opening if

doors are opened too soon.

• Except for emergency, do

not open door when cycle

is in progress. In an emergency, first stop cycle by

pressing the EMERGENCY

STOP pushbutton and wait

for water flow to stop. Wear

appropriate Personal Protective Equipment (PPE)

whenever reaching into or

entering wash chamber.

1. Press STOP/RESET touch pad once to interrupt cycle operation. Pressing

STOP/RESET touch pad once interrupts cycle and removes remaining water

and vapor from wash chamber. Display shows:

VAPOR EXHAUST

PLEASE WAIT

... and printer records:

*STOP PRESSED HH:MM:SSXM

IMPORTANT: Unit has a built-in 60-second (approximately) delay to prevent

doors from opening before washer is in a safe state. Operator must wait until

the end of the delay before opening doors. Display shows:

CYCLE IS PAUSED

START TO CONTINUE OR

... alternating with:

CYCLE IS PAUSED

PRESS STOP TO ABORT

• Inner surfaces of washer

are very hot after cycle

completion. Operator

should wear appropriate

personal protective equipment (PPE) and avoid all

contact with inner walls

when entering chamber.

CYCLE

START

STOP

RESET

2. Press CYCLE/START touch pad to resume cycle operation. Treatment

resumes where it was interrupted. Printer records:

*CYCLE RESUME HH:MM:SSXM

-- or --

Press STOP/RESET touch pad to abort cycle (see Section 4.8,

Operation

).

Abort Cycle

4-15

Operating Instructions Operator Manual 920017-148

4.8 Abort Cycle Operation

STOP

RESET

WARNING – BURN HAZARD:

• After pressing STOP/RESET

touch pad, wait until water

flow stops before opening

doors. Hot water/steam may

be sprayed through door

opening if doors are opened

too soon.

• Inner surfaces of washer are

very hot after cycle completion. Operator should wear

appropriate personal protective equipment (PPE) and

avoid all contact with inner

walls when entering chamber.

When cycle is in progress, press STOP/RESET touch pad twice to abort cycle.

Display shows:

ABORTING

IN PROGRESS

..and printer records:

*STOP PRESSED HH:MM:SSXM

*ABORT HH:MM:SSXM

IMPORTANT: Unit has a built-in 60-second (approximate) delay to prevent

doors from opening before it is safe. Operator must wait until the end of the delay

before opening doors.

4-16

920017-148 Operator Manual Operating Instructions

4.9 Acknowledge Alarm Condition

If an alarm condition occurs during cycle operation, an alarm buzzer sounds to

notify operator (see Section 7,

Troubleshooting

, for a list of alarm conditions and

their possible solution).

An alarm message appears on the display screen. Display shows, for example:

ALARM: WATER

TOO LONG TO HEAT

... and the printer lists the type of alarm and time it occurred:

*ALARM:

WATER

TOO LONG TO HEAT

HH:MM:SSX YY/MM/DD

ALARM

REPLY

1. Press ALARM REPLY touch pad to silence alarm buzzer and acknowledge