UNCRATING/INSTALLATION INSTRUCTIONS

®

Basil

4600 Cage and Rack Washer

Basil® 4602 Cage and Rack Washer

(2004-02-13) P910000-015

A WORD FROM STERIS CORPORATION

Advisory

Follow each step of these

presented. To avoid damage to the equipment inside, open the carton

carefully

slight), show it to your supervisor.

To properly install this unit, you will need the Equipment Drawings provided,

showing all utility service and space requirements. If drawings cannot be

located, replacement copies may be obtained by writing, faxing, or telephoning STERIS, giving the serial number and model of your unit.

Once installed, unit operation should be tested by a STERIS-trained service

technician prior to your equipment usage.

If STERIS supervision is desired for installing and starting up this equipment,

contact STERIS for pricing and availability of this service in you region.

IMPORTANT: This unit is specifically designed to only process goods as

outlined in

A listing of the

and testing this equipment can be found in Section 1 of this manual. Do not

begin uncrating/installing the equipment until you have become familiar with

this information.

Any alteration of this equipment not authorized or performed by STERIS which

could affect equipment operation will void the warranty, could adversely affect

cleaning efficacy, could violate national, state, and local regulations, and could

jeopardize your insurance coverage.

. If you find any indication of damage to the equipment (no matter how

Operator Manual

Safety Precautions

Uncrating/Installation Instructions

(P122997-341).

to be observed when uncrating, installing,

in the order

To assure operators are adequately trained in the safe use of the equipment,

STERIS recommends that:

• all personnel who operate or maintain the equipment are trained in its

operation and in its safe use;

• personnel working with toxic chemicals and vapors (if applicable) have

comprehensive instructions in the unit, process, relevant health hazards,

and methods to detect the escape of toxic materials;

• there is regular training of all personnel concerned with the operation and

maintenance of the equipment; attendance records are maintained; and the

evidence of understanding is demonstrated.

©2004, STERIS Corporation. All rights reserved. Printed in Canada

Table of Contents Uncrating/Installation Instructions 910000-015

i

Indications for Use

Service Information

The Basil® 4600 Cage and Rack Washer and Basil® 4602 Cage and Rack

Washer are heavy duty, large capacity hydrospray washers designed for

thorough, efficient cleaning of cages, racks, debris pans and miscellaneous

items used in the care of laboratory animals.

These units are specifically designed to only process goods as outlined in the

Operator Manual. If there is any doubt about a specific material or product,

contact the manufacturer of the product for the recommended washing

technique.

A thorough preventive maintenance program is essential to safe and proper

unit operation. You are encouraged to contact STERIS concerning our comprehensive Annual Maintenance Agreements. Under the terms of these agreements, preventive maintenance, adjustments, and replacement of worn parts

are done on a scheduled basis to help assure equipment performance at peak

capability and to help avoid untimely or costly interruptions. STERIS maintains

a global staff of well equipped, factory-trained technicians to provide this

service, as well as expert repair services. Please contact STERIS for details.

For contact information, see inside back cover.

Certification

The Basil 4600 Cage and Rack Washer and Basil 4602 Cage and Rack

Washer meet the applicable requirements of the following standards:

• Underwriters Laboratories (UL) Standard 1262, as certified by ITS Testing

Laboratories, Inc.

ii

910000-015 Uncrating/Installation Instructions Table of Contents

TABLE OF CONTENTS

Section Title Page

A WORD FROM STERIS CORPORATION ............................................ i

Advisory ................................................................................................................................. i

Indications for Use ................................................................................................................. ii

Service Information ................................................................................................................ii

Certification ............................................................................................................................ii

1 LISTING OF SAFETY PRECAUTIONS ............................................. 1-1

Definition of Symbols ......................................................................................................... 1-2

2 INSTALLATION REQUIREMENTS ................................................... 2-1

3 ASSEMBLY INSTRUCTIONS ........................................................... 3-1

3.1 General Guidelines ...................................................................................................... 3-1

3.2 Base ........................................................................................................................... 3-1

3.3 Cabinet ...................................................................................................................... 3-4

3.4 Chamber (Inner Cabinet) ............................................................................................ 3-11

3.5 Service Side of Cabinet.............................................................................................. 3-15

3.6 Top of Cabinet ............................................................................................................3-19

3.7 Final Assembly/Clean-up ........................................................................................... 3-20

4 INSTALLATION CHECKLIST .......................................................... 4-1

5 OPERATIONAL CHECKLIST ........................................................... 5-1

Table of Contents Uncrating/Installation Instructions 910000-015

iii

LISTING OF SAFETY PRECAUTIONS

1

The following listing of

potential for danger to personnel, and CAUTIONS indicate the potential for damage to equipment. These

Precautions

are repeated, where applicable, throughout the manual.

Safety Precautions

must be observed when installing this equipment. WARNINGS indicate the

WARNING – PERSONAL INJURY HAZARD:

When handling cabinet panels, use extreme care and wear protective gloves. Panels are heavy and may have

sharp edges.

When positioning cabinet panels two people are required to lift and support each panel because of weight and

size. One person must support panel while the other person installs the nuts and bolts.

Before placing any weight on the roof panel, secure panel on top of cabinet by installing bolts and nuts, finger tight,

in all four corners of roof panel.

When installing doors, more than one person is required to lift doors because of weight and size.

When installing control column(s), more than one person is required to lift control column in place because of weight

and size.

When installing detergent tank, more than one person is required to lift tank because of weight and size.

When moving sump coil, more than one person is required to lift coil because of weight and size.

Safety

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

When checking rotation of drive motor, use extreme caution. If rotation is incorrect, carriage will run directly into

the door header.

Listing of Safety Precautions Uncrating/Installation Instructions P910000-015

1-1

Definition of

Symbols

Symbol Definition

Protective Earth (Ground)

Warning! Risk of Electrical Shock

1-2

P910000-015 Uncrating/Installation Instructions Listing of Safety Precautions

INSTALLATION REQUIREMENTS

NOTE: Please review these instructions carefully prior to installing equipment.

Follow instructions in the sequence given.

1. Review installation site and room layout drawings provided with Installation

Kit. It may be necessary to vary the actual installation from the drawings due

to space limitations or existing obstructions.

2. If necessary, unload, uncrate and move equipment to installation site. Refer

to

Uncrating / Utility Connection Instructions

unit.

3. If handling disposal of debris, ensure customer signs off on the disposition

of trash left on the job site.

4. Check the Occupational Health and Safety Act as well as local electrical and

plumbing codes for any special requirements that may pertain to the

installation of this equipment.

5. Recommend to customer that shutoff valves be installed at readily

accessible locations in steam and water supply lines near the equipment.

6. Recommend to customer that disconnect switch (with OFF position lockout

only) be installed in electric supply line within 10 feet of the equipment.

2

(P910000-016) shipped with

NOTE: If washer is installed next to other equipment, shutoff valves and

disconnect switch must be placed so that service can be shut off to any one piece

of equipment at a time.

2-1

Installation Requirements Uncrating/Installation Instructions P910000-015

INSTALLATION INSTRUCTIONS

1. All mounting hardware necessary for complete installation is shipped with

3.1 General Guidelines

3.2 Base

the unit. Not every piece of mounting hardware will be utilized; ample

amounts are provided.

2. If necessary, use 6'' X 6'' X 1/8'' thick stainless-steel shims to level

equipment. Do not exceed 3/4-inch shim height. If equipment requires more

than 3/4" shimming material, use square tubing to level equipment.

3. Use silicone (RTV) provided in Installation Kit to seal all panel joints to

assure water tightness. When caulking, silicone bead should be a minimum

of 1/4 inch wide and completely circle all bolt holes. When in doubt, use

silicone liberally. It is easier to prevent a leak during assembly than to fix

a leak once equipment is in use.

4. All bolts going to atmosphere (from inside of chamber to outside of cabinet)

require sealing washers.

5. All bolts require lockwashers, except the welded nuts along the non-service

side of the washer.

1. Lift door grating and remove sump coil from base. Replace floor grating in

base.

3

2. Position base according to room layout drawings, either in a pit or on the

floor. It pit mounted, make sure face of surface is parallel to pit wall (within

two to thee inches from the non-service side wall) or positioned as specified

in the room layout drawings.

3. Check base height (see Figure 3-1). Ensure the door threshold is at least 1/4"

higher than the highest spot on the floor, along the netire door swing (four

feet from base). If necessary, position shims under corners of base.

Door Threshold

1/4"

Four Feet

Door Swing

1/4"

Add shims here, if

necessary, to achieve

proper height and level

Base

Pit Pad

Figure 3-1. Check Base Height

3-1

Installation Instructions Uncrating/Installation Instructions 920000-015

If pit mounted, use a four-foot level to check the door swing (see

Figure 3-2). Hold one end of level on door threshold and place two 1/8-inch

shims under the opposite end. Check door swing at 90°, 45°, and 15°.

NOTE: When shimming, ensure shim is placed under corner of base with part of

the shim exposed.

Door Threshold

Foor-Foot Level

Figure 3-2. Check Door Swing

4. Check level of base along face and length. If necessary, position shims

under corners of base. If shims are used to level base, base height must

be re-checked once the base is level.

5. In some instances, the base may be shipped in two or three pieces. If base

is split, assemble base pieces as follow:

a. Position base pieces, next to one another, close to the final location

indicated on the room layout drawings.

b. Connect the base pieces by installing the floor grating supports down the

center of the base and on either side of the door threshold (see Figure 3-3).

Floor Grating Supports

Door Threshold

Base

Figure 3-3. Install Floor

c. Align the base pieces by stretching a string across the four alignment

marks located on the side of each piece (see Figure 3-4). If necessary,

position shims under corners of base piece(s).

Alignment

Mark

Alignment

Mark

Alignment

Mark

Base Pieces

Figure 3-4. Align Base Pieces

3-2

910000-015 Uncrating/Installation Instructions Installation Instructions

d. Check base height and level of base as explained in Steps 3 and 4.

e. Once base is level, spot weld a series of one-inch welds along the base

seams to maintain the established position.

NOTE: The heat generated by most welding operations will damage epoxy/vinyl

flooring. Take appropriate precautions to protect floor from heat and welding arc.

f. Completely weld all base pieces together from the inside.

g. Check for pin holes and incomplete welds. All welds must be water tight.

h. Clean up welds using a wire brush.

6. If shims were used, weld shims in place to form a solid foundation (see

Figure 3-5).

Base

Weld

Shims

Pit Pad

Figure 3-5. Weld Shims

7. Attach pump plate to service side of washer (see Figure 3-6). Ensure

brackets are facing up and plate does not cover drain hole.

Pump

Plate

Brackets

(Facing Up)

Service Side

of Washer

Drain Hole

Figure 3-6. Install Pump Plate

8. Check level of pump plate along the plate width and length. If necessary,

position shims under the brackets attached to pump plate. Silicone shims

in place, using a heavy bead of silicone between the shims, between the

pump plate and shims and between the shims and floor.

If pit mounted, ensure shims are flush with the pit wall.

9. Re-tap threads on all welded nuts (along the non-service side of the washer)

with 5/16''-18 threads/inch tap.

3-3

Installation Instructions Uncrating/Installation Instructions 920000-015

3.3 Cabinet

WARNING–PERSONAL

INJURY HAZARD:

• When handling cabinet panels, use extreme care and

wear protective gloves. Panels are heavy and may have

sharp edges.

• When positioning cabinet

panels, two people are required to lift and support

each panel because of

weight and size. One person must support the panel

while the other installs the

nut and bolts.

NOTE: Cabinet must be completely assembled and tightened within the same

day, before silicone hardens.

1. Remove paper from all cabinet panels.

2. Select any corner panel to begin cabinet assembly.

3. Count the number of bolts holes along side of corner panel (e.g. six bolt

holes). Do not count bolt holes along face (load/unload side) of corner panel.

NOTE: When caulking, fully open caulk nozzle to allow for a heavy silicone bead.

4. On inside of base, silicone around and between the number of bolt holes

counted plus one (e.g. seven bolt holes; see Figure 3-7). Do not silicone

along face of unit

..

. Make sure to silicone in a consistent line.

..

NOTE: Only silicone around and between the base bolt holes needed to install

one panel at a time.

DO NOT Silicone

Face of Cabinet

Silicone

Bolt Holes

Figure 3-7. Silicone Around and Between Bolt Holes

5. Position bottom of corner panel on base lip. Using your foot, hold bottom

of panel on the lip and raise panel up into place. Insert alignment pins, one

on either end, to align panel and base bolt holes (see Figure 3-8).

NOTE: All bolts going to atmosphere (from inside of chamber to outside of

cabinet) require sealing washers. All bolts require lockwashers, except the

welded nut along the non-service side of the washer.

Alignment

Pin

Corner

Panel

Alignment

Pin

Base Lip

Figure 3-8. Insert Alignment Pins

3-4

910000-015 Uncrating/Installation Instructions Installation Instructions

6. Attach panel to base. Ensure bolts along face of base are installed with the

bolt heads located on outside of base, and bolts along side of base are

installed with the bolt heads located on inside of base (see Figure 3-9).

NOTE: During panel assembly, all bolts are installed snug (tight enough to flatten

the silicone). Once cabinet is completely assembled, bolts will be securely

tightened.

Bolt and Sealing

Washer

Nut and

Lockwasher

Nut and

Lockwasher

Side of Base

Face of Base

Bolt and Sealing

Washer

Figure 3-9. Bolt Positions for Corner Panel

7. Locate next panel to be installed. Each panel is numbered and installed in

sequential order, starting with the number assigned to the first corner panel

installed.

8. Count the number of bolt holes along bottom of panel.

9. Starting from top of installed panel, silicone around and between bolt holes

along the vertical panel joint and along inside of base (see Figure 3-10).

When caulking base, ensure to silicone around the number of bolt holes

counted plus one.

NOTE: Critical Leak areas are at the top and bottom of vertical panel joints, and

along base seams if base was split. Use silicone liberally in these areas.

Bolt Holes

Silicone

Figure 3-10. Silicone Vertical Panel Joint and Base

3-5

Installation Instructions Uncrating/Installation Instructions 920000-015

10. Position bottom of panel on base lip, with the panel tilted toward inside of

base and two inches away from installed panel (see Figure 3-11). Using your

foot, hold bottom of panel on the lip and slide panel over to within 1/2 inch

of the installed panel. Raise panel up into place; avoid smearing the

silicone. Insert alignment pins through farthest holes, one along horizontal

joint and one along vertical joint as high as possible.

Panel Tilted

Toward Base

Silicone

Base

Lip

Figure 3-11. Install Side Panel

11. Install sealing strip over vertical joint (see Figure 3-12). Ensure numbers on

sealing strip match the connecting panels.

NOTE: When installing sealing strip, ensure panel is supported while alignment

pin is temporarily pulled from the vertical joint.

Sealing Strip

Vertical Joint

Figure 3-12. Install Side Panel

3-6

910000-015 Uncrating/Installation Instructions Installation Instructions

12. Attach panel to base and adjacent panel. Make sure bolts along vertical

joint are installed with the bolt heads facing toward center of cabinet (see

Figure 3-13).

Side Panels

Nut and

Lockwasher

Bolt &

Sealing

Washer

Roof Panel

Nut and

Lockwasher

Bolts

Nut and

Lockwasher

Figure 3-13. Bolt Positions for Side and Roof Panels

13. Install remaining side and corner panels following Steps 3 through 12.

14. Locate door header(s). If pass-through unit, door headers are labelled

according to where the header should be mounted (i.e., load or unload end

of cabinet).

15. Silicone both ends of door header and the mounting area on each corner

panel.

16. Position door header between corner panels using alignment pins to align

header and panel bolt holes (see Figure 3-14). Attach door header to corner.

Door

Header

Control Panel

Silicone

Alignment Pin

Figure 3-14. Position Door Header

17. Verify door header is flush with front (face) of cabinet. Securely tighten bolts

attaching door header to corner panels.

18. Along top of cabinet, fill each joint between the connected panels with

silicone. Run a continuous line of roof gasket along top of each panel. Center

gasket over bolt holes. Silicone between any gasket seams.

3-7

Installation Instructions Uncrating/Installation Instructions 920000-015

19. Working from the top of the cabinet, punch bolt holes through the roof gasket

using alignment pin.

20. Install a continuous line of roof gasket along both sides of the center roof

panel (see Figure 3-15). Start end of gasket along edge of roof panel, below

first bolt hole. Bend gasket up and run gasket over center of the bolt holes.

Before last bolt hole, bend gasket down and finish by running gasket along

edge of roof panel, below last bolt hole. Using an alignment pin, punch bolt

holes through the roof gasket.

Gasket

Bolt Hole

Center Roof

Panel

Side Cabinet

Panel

Figure 3-15. Install Gasket on Center Roof Panel

WARNING–PERSONAL

INJURY HAZARD: Before

placing any weight on the

roof panel, secure panel on

top of cabinet by installing

bolts and nuts, finger tight,

in all four corners of roof

panel.

21. Attach roof panels starting from one end of the cabinet. Panels are labelled

indicating which end is attached to the service side of the cabinet. Use

alignment pins to align bolt holes and install bolts finger tight. Ensure bolts

are installed with the bolt heads located on inside of cabinet (see

Figure 3-13).

NOTE: When lifting roof panels to top of cabinet, do not slide panels over the roof

gasket.

22. Once cabinet is assembled, place a 1/4-inch shim on either side of door

opening.

23. Locate chamber door(s) and verify door latches are open. When open, tooth

is visible; when closed, solid block is visible (see Figure 3-16).

Door Latch

1/4'' Shim

Tooth Visble; Door

Latch Is Open

Figure 3-16. Verify Door Latch is Open

3-8

910000-015 Uncrating/Installation Instructions Installation Instructions

WARNING–PERSONAL

INJURY HAZARD: When installing doors, more than

one person is required to

lift doors because of it

weight and size.

24. Position bottom of door on shims and raise door up into place (see

Figure 3-16). Push door closed.

25. For each door hinge, insert alignment pin through hinge (from the bottom)

to align door and cabinet hinges (see Figure 3-17). Place four-inch door pin

in top of hinge.

26. Using an alignment pin, raise hinges enough to insert first bushing (see

Figure 3-17). Hammer door pin partially down through first bushing. Insert

second bushing and hammer door pin down completely.

Door Pin

Door Hinge

Alignment Pin

Bushing

Figure 3-17. Align Door and Cabinet Hinges

NOTE: It may be necessary to hammer bushing in place between door and

cabinet hinges.

27. Once all door pins and bushings are installed, open door and check door

swing.

28. Verify cabinet is in final position. Verify face of cabinet (load end) is aligned

with face of customer wall. If cabinet position must be adjusted, check level

of cabinet along face and lenght of roof after moving cabinet.

29. To prevent chamber door(s) from sagging while tightening the cabinet

bolts, place a 1/8-inch shim between door header and the non-hinged side

of the door (see Figure 3-18). Using a pry bar between the door threshold

and bottom of door, raise non-hinged side of door and tightly pack the

opening with shims.

1/8'' Shim

PryBar

Figure 3-18. Raise Non-Hinged Side of Chamber Door

3-9

Installation Instructions Uncrating/Installation Instructions 920000-015

30. Securely tighten cabinet bolts in the order listed below (see Figure 3-19):

a. Bolts along vertical joints (sealing strips) connecting cabinet side and

corner panels together.

b. Bolts along cabinet sides and face connecting the base to the cabinet side

and corner panels.

c. Bolts along inner roof panel joints connecting the roof panels together.

d. Bolts along outside of roof panels connecting the roof panels to the cabinet

side and corner panels.

NOTE: If using an impact gun to tighten bolts, do not use the impact gun on

welded nuts located along non-service side of cabinet.

Inner Roof

Panel Joints

Outside Roof

Panel Joints

Vertical Joints

Cabinet Sides and Face

Figure 3-19. Tighten Cabinet Bolts

31. Weld base to face of corner panels using three 1-inch welds on both sides

of door opening (see Figure 3-20).

1-Inch

Welds

Base

1-Inch

Welds

Figure 3-20. Weld Base

32. Attach high voltage electrical box to service side of cabinet. Open electrical

box door and verify that adequate space is available for service access.

3-10

910000-015 Uncrating/Installation Instructions Installation Instructions

WARNING–PERSONAL

INJURY HAZARD: When installing control column(s),

more than one person is

required to lift control column in place because of

weight and size.

33. Attach control column(s) to cabinet. Control column, containing printer, is

mounted on load end of cabinet. If pass-through unit, additional control

column is mounted on unload end of cabinet.

If unit is pit mounted, use a 2 X 4 to balance control column over pit while

attaching column to cabinet (see Figure 3-21).

NOTE: When attaching control column to cabinet, lower door on control column

must be opened to access bolt holes.

Control Column

Cabinet

2" X 4"

Figure 3-21. Attach Control Column

3-11

Installation Instructions Uncrating/Installation Instructions 920000-015

3.4 Chamber (Inner Cabinet)

1. Loosely attach U-bolts to cabinet, two on each side of door opening(s) at

waist height (see Figure 3-22).

U-Bolt

Safety

Cable

Guide

Bracket

U-Bolt

Safety Cable

Socket

Figure 3-22. Attach U-Bolts

2. Install drive cable roller brackets with roller facing up. Attach two brackets

to service side of cabinet exterior, one at each end and two brackets to

cabinet interior, one at either end of chamber centered above door opening

(see Figure 3-23). Ensure outer brackets are installed with open side facing

center of cabinet, and inner brackets are installed with the open side facing

service side of cabinet.

Drive Cable

Roller Brackets

Service Side

of Cabinet

Figure 3-23. Install Drive Cable Roller Brackets

3. Install carraige rails to inside of the brackets located one inch from top of

door opening(s), on both sides of the chamber. Completely attach both

ends of the first carriage rail, and attach only one end of the second rail.

Allow second rail to hang from bracket.

3-12

910000-015 Uncrating/Installation Instructions Installation Instructions

4. Position one side of the carriage on top of the fixed carriage rail (see

Figure 3-24). Ensure eye bolts in center of carriage are facing down and the

carriage hose connector is located on the same side as the cabinet hose

connector.

Carriage

Fixed Carriage

Rail

Figure 3-24. Position Carriage on

Top of Fixed Carriage Rail

5. While supporting the carriage, raise second carriage rail up into position

and attach loose end of rail to inside of bracket (see Figure 3-25). Tighten

bolts at both ends of second rail.

Bracket

Carriage

Carriage Rail

Figure 3-25. Attach Second Carriage Rail

6. Verify carriage rides smoothly along the rails.

7. Rotate the spray header connectors, two on either side of carriage, down

to 90°. Connect the U-shaped spray headers to the connectors on the

carriage.

NOTE: U-shaped spray headers and header connectors are labelled. Connect

appropriate spray header to corresponding connectors.

3-13

Installation Instructions Uncrating/Installation Instructions 920000-015

8. Attach safety hold-down brackets (J-brackets) to the carriage, two on eachside. Position bracket between the carriage and carriage rail, just inside of

the carriage wheel toward the center of the chamber (see Figure 3-26).

Mount brackets directly onto the carriage at a 90° angle to the carriage rail.

Carriage

Wheel

Carriage

Rail

Hold-Down

Carriage

Safety

Brackets

Figure 3-26. Attach Safety Hold-Down Brackets

9. Install hose by connecting one end to the carriage hose connector and the

other end to the cabinet hose conncector, located along bottom center of

chamber wall. If necessary, rotate hose (not nipple) to center it in space

between chamber wall and U-shaped spray header. Do not allow hose to rub

against chamber wall, spray headers, or safety cable.

10. Install two guide rails along each side of chamber. Insert guide rail (one-inch

pipe) into U-bolts (see Figure 3-27). Tighten U-bolts and trim excess bolt,

leaving 1/2 inch from nut.

NOTE: If using vice grips to trim excess bolt, grab bolt 1/2 inch away from nut

and bend bolt up and down until excess breaks off.

Guide Rail

U-Bolt

Trim

Excess

Bolt

Guide

Rail

Figure 3-27. Install Guide Rails

3-14

910000-015 Uncrating/Installation Instructions Installation Instructions

11. Using a 3/8-inch stainless-steel back-up nut, install safety cable along

service side of chamber by attaching bolted end of the cable to bracket

located along service side, on opposite end from main control panel (see

Figure 3-28).

Bracket

Back-Up

Nut

Safety

Cable

Figure 3-28. Attach Bolted End of Safety Cable

12. Feed non-bolted end of the service-side cable through socket into the main

control panel (see Figure 3-29). Ensure cable is positioned around guide

bracket.

Guide Bracket

Socket

Safety

Cable

Figure 3-29. Feed Service-Side Safety

Cable Through Socket

3-15

Installation Instructions Uncrating/Installation Instructions 920000-015

13. Insert end of service-side cable through collar of the microswitch lever,

located in main control panel (see Figure 3-30). Tighten collar.

Collar

Safety Cable

Microswitch

Lever

Microswitch

Figure 3-30. Connect Safety Cable to Microswitch

14. Using a 3/8-inch satinless-steel back-up nut, install safety cable along nonservice side of chamber by attaching bolted end of cable to bracket located

along non-service side.

15. Feed non-bolted end of the non-service side cable through socket into the

microswitch box mounted on top of the cabinet. Ensure cable is positioned

around both guide brackets (see Figure 3-31).

Safety Cable

Guide Brackets

Figure 3-31. Position Non-Service Side Safety Cable

Around Guide Brackets

16. Insert end of non-service side cable through collar of the microswitch lever,

located on top of cabinet. Tighten collar.

3-16

910000-015 Uncrating/Installation Instructions Installation Instructions

17. From inside chamber, pull on each safety cable to verify microswitch

engages and connection tight. Verify each microswitch resets after pulling

the appropriate cable.

If microswitch fails to reset (microswitch lever does not return to neutral

position), loosen retaining bolt connecting the lever to the microswitch.

Allow the spindle, inside of the microswitch, to return to the neutral (nonactivated) position and retighten the retaining bolt.

NOTE: The should be a minimum of one to two inches slack in each safety cable.

If cable is too tight, heat generated during cycle(s) will expand the cabinet and

inadvertently engage the microswitch.

3-17

Installation Instructions Uncrating/Installation Instructions 920000-015

3.5 Service Side of Cabinet

1. Attach tank stand to brackets on pump plate and cabinet exterior. Install

bolts finger tight.

2. Ensure electrical door switch wires on both ends of service side (waist

height on cabinet exterior) are pushed into sockets.

3. Remove three top plates from detergent tank. Two plates are attached with

screws and center plate lifts out.

NOTE: Center plate is shipped upside down.

WARNING–PERSONAL

INJURY HAZARD: When installing detergent tank, more

than one person is required

to lift tank because of weight

and size.

4. Position detergent tank on tank stand by rotating and sliding tank up onto

the stand. Use care when positioning tank; do not rest piping connections

on the stand. Position tank with finished side facing out.

5. Attach top of detergent tank to cabinet by installing three bolts (finger tight)

along back of tank (see Figure 3-32). Attach bottom of detergent tank to

cabinet and stand (four mounting bolts).

Service Side

of Cabinet

Bolts

Detergent

Tank

Figure 3-32. Install Detergent Tank

6. Once all mounting bolts are installed on tank and stand, completely tighten

bolts.

7. Ensure coil unions, along inside of tank, are tight. Replace tank covers.

8. Place recirculation pump on pump plate with motor fan facing pit wall

(opposite load-end of cabinet). Do not bolt pump to pump plate; piping will

hold pump in place.

9. Loosely attach suction pick-up pipe (90° elbow) to front of pump with two

bolts. Slide gasket between pick-up pipe and pump, and securely fasten

pipe to pump (see Figure 3-33). Connect other end of pick-up pipe to threeinch nipple in center of base (see Figure 3-34).

Recirculation Pump

Suction Pick-Up Pipe

Gasket

Figure 3-33. Attach Suction Pick-Up Pipe

3-18

910000-015 Uncrating/Installation Instructions Installation Instructions

10. Attach the self-cleaning screen assembly to top of recirculation pump with

four bolts. Ensure to insert Teflon gasket between self-cleaning screen

assembly and pump. Connect other end of screen assembly to two-inch

union on side of cabinet (see Figure 3-34).

NOTE: Each machine is piped differently. There is only one place for each pipe.

Follow general guidelines listed in Step 11 to install piping.

Self -Cleaning Screen

Assembly

Recirculation

Pump

2'' Union

Suction

Pick-Up

Pipe

3'' Nipple

Figure 3-34. Install Self-Cleaning Screen Assembly

11. Install all piping using guidelines listed below:

a. Prep all male piping connections. Use pipe dope on threads and face of

all unions. STERIS recommends use of a liquid Teflon pipe dope, similar to Permalok.

b. Attach black pipe to black pipe. Black pipe is used for steam supply and

condensate. Condensate pipes normally have a steam trap (thermodisk

type) attached on the exit side of the steam coil.

c. Attach brass pipe to brass pipe. Brass pipe is use for water supply and

alkaline detergent return lines.

d. Attach stainless-steel pipe to stainless-steel pipe. Stainless-steel pipe is

used for spray header system, drain, and optional acid detergent return

lines.

e. Attach galvanized pipe to galvanized pipe. Galvanized pipe is used for

drain or overflow.

f. Install support brackets as required.

3-19

Installation Instructions Uncrating/Installation Instructions 920000-015

12. Attach upper and lower wireways to cabinet (see Figure 3-35). Upper

wireway is located near top of cabinet. Lower wireway is located on side of

detergent tank.

Upper Wireway

Lower Wireway

Figure 3-35. Attach Upper and Lower Wireways

13. Connect all conduit, switches, and solenoids from wireways to the appropriate locations.

NOTE: Each motorized ball valve is equipped with two loose linkage connectors.

Ensure connectors do not fall out when installing valves.

14. Attach drive motor with capstan to top left corner of cabinet (see Figure 3-36).

Capstan

Drive Motor

Figure 3-36. Install Drive Motor with Capstan

15. Terminate all wires. Match numbers from wireways to corresponding

terminals in electrical box or control column.

NOTE: Ensure all electrical conduit and cables are clear of hot pipes and moving

parts.

3-20

910000-015 Uncrating/Installation Instructions Installation Instructions

16. Remove first layer of tape from drive motor capstan. Unwind cable and feed

cable through limit switches (rabbit ears) and outer roller bracket (see Cable

#1 in Figure 3-37).

17. Insert cable through opening in cabinet and feed cable through inner roller

bracket (see Cable #1 in Figure 3-37).

NOTE: It may be necessary to remove brass cap from opening inside the

chamber before inserting cable through cabinet.

Cable #1

(Rabbit Ears)

Inner Roller

Bracket

Limit Switch

Carriage

Eye Bolts

Outer Roller

Inner Roller

Bracket

Brass Cap

Bracket

Outer Roller

Bracket

Cable #2

Drive Motor

with Capstan

Brass Cap

Limit Switch

(Rabbit Ears)

Figure 3-37. Attach Drive Cables to Carriage

18. Attach cable to eye bolt in center of carriage (see Figures 3-37 and 3-38).

NOTE: Cable may be crimped in correct position from the factory testing. Attach

cable to eye bolt in same position.

Clamp

Eye Bolt

Cable Guard

Cable

Figure 3-38. Connect Cable to Eye Bolt

19. Push carriage to opposite end of chamber until the cable is tight.

20. Remove remaining tape from drive motor capstan. Unwind and feed cable

through other set of outer and inner roller brackets (see Cable #2 in

Figure 3-37). Attach cable to eye bolt in center of carriage (see Figure 3-38).

3-21

Installation Instructions Uncrating/Installation Instructions 920000-015

21. From inside the chamber, pull down on the cable and verify carriage only

moves slightly. There should be no slack in the cable and a minimum of one

to two inches free play. If necessary, adjust cable tension using the eye

bolts. Ensure to adjust eye bolts evenly to maintain a centered carriage.

NOTE: Do not overtighten cable. Immediate damage or accelerated wear may

occur.

22. Once cable tension is adjusted, remove brass caps from the outer roller

bracket openings inside the chamber. Fill each cap with silicone and

replace.

23. If applicable, install sight glass on side of detergent tank. Completely

install top and bottom fittings. Angle bottom fitting 45° from vertical. Insert

sight glass into fittings and rotate bottom fitting into position. Tighten

fittings finger tight.

NOTE: Verify O-rings are situated in fittings before installing sight glass.

3-22

910000-015 Uncrating/Installation Instructions Installation Instructions

3.6 Top of Cabinet

1. If optional automatic damper is provided, install damper as follows:

a. Verify motor linkage on damper is tight by manually moving the damper

blade before installation. Motor shaft should rotate when damper blade is

moved. If shaft does not rotate, remove motor and tighten screw on motor

linkage (see Figure 3-39).

Optional

Automatic

Damper

Screw

Motor Shaft

Damper Blade

Motor

Figure 3-39. Tighten Motor Linkage on

Optional Automatic Damper

b. Silicone around and between damper bolt holes. Securely attach damper

to top of cabinet with motor (electrical connection down) pointing toward

service side of cabinet (see Figure 3-40).

Optional

Automatic

Damper

Motor

Figure 3-40. Position Optional Automatic

Damper on Top of Cabinet

c. Connect damper to appropriate wire(s) on upper wireway.

2. If optional exhaust fan is provided, install fan as follows:

a. Silicone around and between bolt holes on exhaust fan. Securely attach

exhaust fan to top of cabinet with motor pointing toward service side of

cabinet.

3-23

Installation Instructions Uncrating/Installation Instructions 920000-015

b. Attach a remote bracket (supplied by others) and grease fittings to an

easily accessible location on the washer exterior. Run a separate copper

line from each remote grease fitting to the grease bearings located at top

of exhaust fan housing (see Figure 3-41).

Grease

Bearings

Figure 3-41. Optional Exhaust Fan Grease Bearings

c. Purge both lines with a high temprature, water-resistant grease

(P117951-457) up to the bearing connection points. Attach purged lines

to the exhaust fan grease bearings.

d. Connect exhaust fan to appropriate wire(s) on upper wireway.

3. Install insulation on top of entire cabinet, except around the optional

automatic damper (if applicable). Insulation must be cut to fit.

4. Install roof covers on top of cabinet by bowing the cover and sliding cover

under lip of roof panels.

3-24

910000-015 Uncrating/Installation Instructions Installation Instructions

3.7 Final Assembly/ Clean-Up

1. If pit-mounted unit, fit edge of transition plate(s) over lip of the drip gutter

(see Figure 3-42). Slide transition plate as far away from the unit as the interlocked surfaces will allow. Secure transition plate to floor with 1/4-inch drive

rivets and weld transition plate to drip gutter, maintaining the maximum

allowable opening for the drip gutter.

Transition Plate

1/4'' Drive Rivet

Drip Gutter

WARNING–PERSONAL

INJURY HAZARD: When

moving sump coil, more

than one person is required

to lift coil because of weight

and size.

Figure 3-42. Install Transition Plate

2. Trim excess silicone and remove any paper or tape from the cabinet interior

and exterior.

3. Lift off floor grating and trim any excess silicone around chamber sump.

4. Sweep up all debris from sump and chamber interior.

5. Replace sump coil in chamber sump (see Figure 3-43). Reattach coil to

piping connection.

NOTE: The 5/16-inch shipping bolt(s), previously removed from opposite side of

piping connection, remains off.

Sump Coil

Figure 3-43. Replace Sump Coil

NOTE: Use pipe dope on threads and face of sump coil connection before

replacing.

6. Wipe down cabinet exterior with WD-40.

7. If customer is connecting utilities, mark all service connections for customer's

convenience.

3-25

Installation Instructions Uncrating/Installation Instructions 920000-015

8. Recommend to customer that building exhaust system be all male

connections. All washer exhaust connections are female to allow any

condensate contained in the building exhaust system to flow into the

washer.

9. Recommend to customer that all pressurized drain pipes be centered over

the drain hole. All drain holes should be 1-1/2 times larger than the size of

the drain pipe.

10. Recommend to customer that sprinkler heads be mounted at least 10 feet

away from the unit and be able to withstand temperatures of at least 190°F

(88°C).

3-26

910000-015 Uncrating/Installation Instructions Installation Instructions

INSTALLATION CHECKLIST

NOTE: Installation checklist must be completed after washer is assembled and

prior to start-up procedures.

Complete the following checklist to assure washer is correctly assembled:

❑ Control voltage (120 VAC) verified.

❑ Pump and motor voltages (3-phase) verified.

❑ Optional exhaust fan amperage within rating indicated on fan motor.

❑ Optional exhaust fan belt tension correctly adjusted.

❑ Grease lines equipped with grease fittings and mounted to washer

exterior for convenient maintenance access.

❑ Grease lines purged and connected to optional exhaust fan bearings.

❑ Recirculation pump amperage within rating indicated on pump motor.

❑ Cable tension correctly adjusted.

❑ U-shaped spray headers square to washer.

❑ Each gear box plastic cap removed and replaced with provided air vent.

❑ Spray header connectors tight.

❑ Cabinet-to-carriage hose connection located away from cables, spray

headers, and cabinet wall.

4

❑ All steam coil unions tightened.

❑ All other unions tightened.

❑ Chamber door(s) square to washer.

❑ Chamber door(s) latch functioning properly.

❑ Gray silicone used for exterior cabinet gaps.

❑ Excess silicone trimmed off.

❑ All sharp edges deburred.

❑ Base welded to face of cabinet on both sides of door opening(s).

❑ Transition plate(s) welded in correct position.

❑ All welds polished.

❑ Electrical connections tight.

❑ All wires wire tied.

❑ 5/16" shipping bolt(s), securing sump coil during transportation, has

been removed.

❑ Lockable shut-off valves installed in steam and water lines within 10 feet

of the equipment.

❑ Disconnect switch (with OFF position lockout only) installed in electric

supply line in the same q Washer positioned as shown on the equipment drawing with required service clearance space and in relation to

building supply lines.

4-1

Installation Checklist Uncrating/Installation Instructions P910000-015

❑ Building steam line provides maximum dynamic pressure and flow rate

as specified on the equipment drawing.

❑ Drip leg with steam trap installed in steam supply line.

❑ Building hot water line supplies water to washer at the pressure and

temperature specified on the equipment drawing.

❑ If applicable, building cold water line supplies water to washer at the

pressure specified on the equipment drawing.

❑ Electrical supply for washer is as specified on the equipment drawing.

❑ Customer condensate returns are sized as specified on the equipment

drawing.

❑ Customer vent connections are sized as specified on the equipment

drawing.

❑ Recirculation pump pressure is within 25 to 60 psig.

❑ Recirculation pump motor rotating in direction shown by arrow.

❑ Self-cleaning screen assembly functioning properly.

❑ Carriage drive motor correctly rotating.

❑ Carriage drive system clutch correctly adjusted.

❑ Carriage drive motor amperage within rating indicated on the motor.

❑ Optional exhaust fan rotating in direction shown by arrow.

❑ All piping is leak-free.

IMPORTANT: After a few weeks of operation, inspect unit for leaks. Retighten

all clamps and connections.

4-2

P910000-015 Uncrating/Installation Instructions Installation Checklist

START-UP PROCEDURES

NOTE: Start-up procedures are to be performed after utility connections and

installation chekclist are completed and prior to unit operation by the customer.

1. Adjust spray jets along top and sides of chamber as follows:

a. Using a flat surface (e.g., credit card), determine where each spray jet is

directed.

b. Roughly position the four carriage spray jets (top of chamber) straight

down by rotating the main pipe.

c. Roughly position spray jets on both U-shaped headers (both sides of

chamber) to direct water straight across from each header.

NOTE: Jets must be positioned so that spray is 6'' away from the door when

carriage is at end of the chamber.

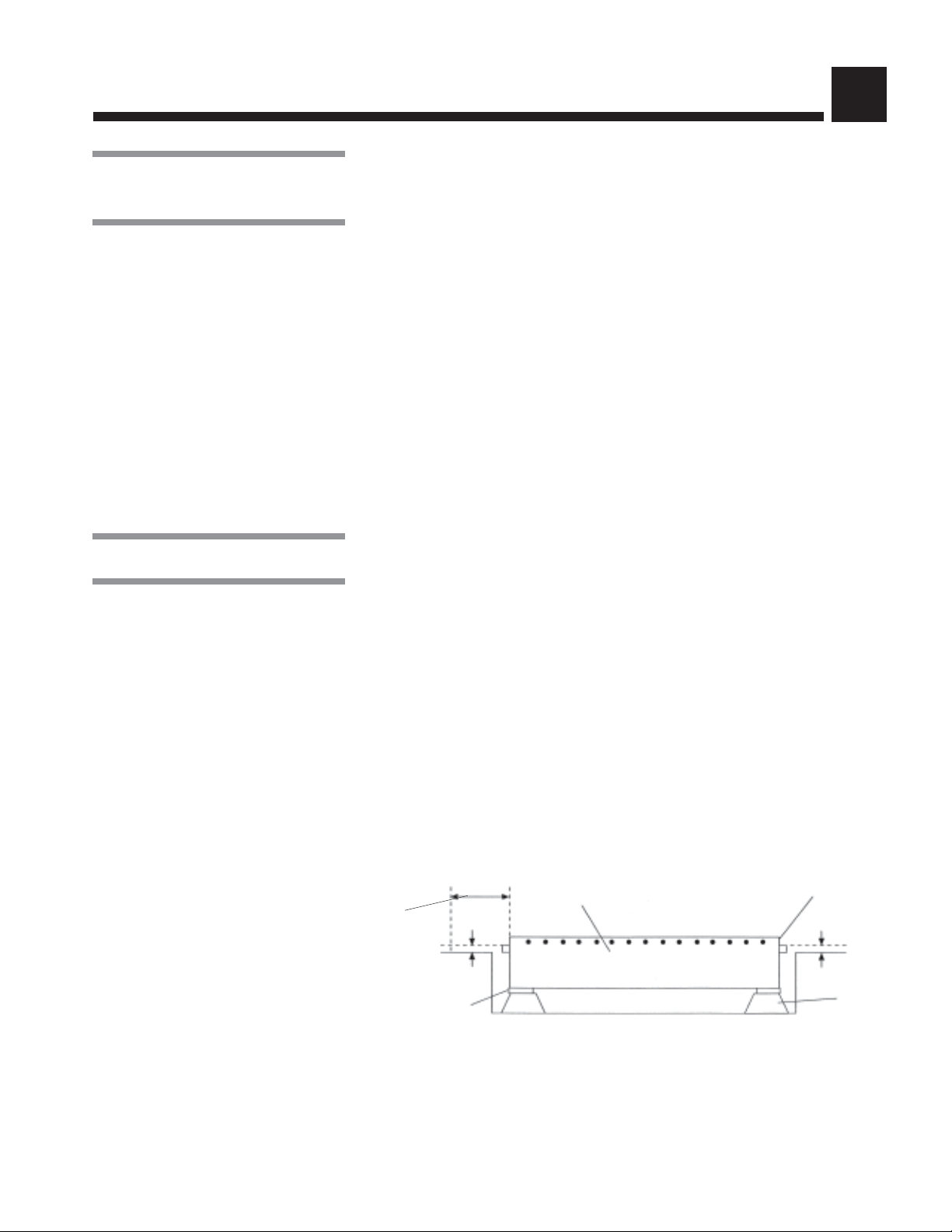

d. Individually adjust the bottom header spray jets to direct water 45° inward

(see Figure 5-1).

e. Individually adjust the corner header spray jets to direct water 45° inward

(see Figure 5-1).

5

Corner Header

Spray Jet

Bottom

Header

Spray Jet

Figure 5-1. Adjust Header Spray Jets

f. Individually adjust the remaining header spray jets to direct water

straight out.

g. Securely tighten all spray jets. Do not leave spray jets finger tight.

2. Close manual drain valve and turn main disconnect switch on. Ensure

control displays time of day when unit is powered up.

3. Check rotation of recirculation pump(s). Bump the motor starter and watch

the pump shaft to see if it is rotating in correct direction. If pump shaft is

rotating in wrong direction, disconnect main power, reverse any two high

voltage wires and recheck pump rotation.

4. If applicable, check rotation of optional exhaust fan. Bump the exhaust fan

motor starter. From top of cabinet, light a match and verify the smoke is

being drawn into the exhaust fan. If exhaust fan is rotating in wrong

direction, disconnect main power, reverse any two high voltage wires and

recheck fan rotation.

5-1

Start-Up Procedures Uncrating/Installation Instructions P910000-015

5. Adjust drive system clutch. Remove safety cover from top of the drive

motor capstan. Loosen the setscrews on the 3/4-inch adjusting nut located

in the center of the capstan. Torque the adjusting nut to 35 ft/lb. When

properly adjusted, clutch prevents damage to equipment and load if

carriage assembly becomes obstructed.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

When checking rotation of

drive motor, use extreme

caution. If rotation is incorrect, carriage will run directly into the door header.

6. Verify rotation of drive motor and direction of carriage assembly as follows:

a. Press

MANUAL MENU touch pad to access the Manual Control Mode (see

Figure 5-2).

b. Press SELECT CYCLE touch pad to access the Manual Control Mode

(see Figure 5-2).

c. Press CYCLE/START touch pad to initiate the drive motor.

SELECT CYCLE

Touch Pad

STOP/RESET

Touch Pad

CYCLE/START

Touch Pad

MANUAL MENU

Touch Pad

Figure 5-2. Control Panel

NOTE: Keep your finger on the STOP/RESET Touch pad while visually chekcing

the drive motor. It may be necessary to immediately stop the drive function.

d. As the drive motor is rotating, watch the actuator block located on the

cable. Once the actuator block strikes the limit switch (rabbit ears), drive

motor should stop and reverse rotation, and carriage assembly should

reverse direction.

e. If the actuator block pulls the limit switch (rabbit ears) past 90°,

immediately press STOP/RESET touch pad. Disconnect main power and

switch any two incoming high voltage wires on the motor starter. Re-check

drive motor rotation.

NOTE: DRIVE function is the only manual function that can be operated while

the chamber door is open.

7. Turn on building water supplies and check for piping leaks. Wait for

detergent tank to fill and check for tank leaks.

8. Access the manual control mode and individually test each manual

function.

a. Select FILL function and press CYCLE/START

touch pad.

Looking

through the door window, check for incoming water flow. Once fill function

automatically stops, open chamber door and check that float switch is

engaged (sump is full).

5-2

P910000-015 Uncrating/Installation Instructions Start-Up Procedures

b. Select DRAIN function and press CYCLE START touch pad. Once drain

function automatically stops, open chamber door and one to two inches

of water remains in the chamber sump.

c. Select PUMP/DRIVE function and press CYCLE/START touch pad.

During pump/drive function, check for proper operation of recirculation

pump and carriage drive system; water should spray from the carriage

and header spray jets as the carriage assembly moves back and forth.

d. Exit manual control mode by pressing STOP/RESET touch pad.

9. Select any pre-programmed cycle and press CYCLE/START touch pad.

Run one complete cycle and check mechanical operation of washer.

10. Check operation of each emergency safety cable. Actuate the traveller

drive system in the manual control mode. Pull on emergency cable by

reaching cable from outside of the washer. Verify all washer operations

immediately stop. Press ALARM REPLY touch pad.

11. Run several cycles, testing all the available options. Ensure washer

functions properly and is leak-free.

5-3

Start-Up Procedures Uncrating/Installation Instructions P910000-015

OPERATIONAL CHECKLIST

NOTE: Operational checklist must be completed prior to unit operation by the

customer.

Complete the following checklist to assure washer is correctly operating:

Chamber sump steam coil functioning properly.

Detergent tank filling to required level.

Detergent tank steam coil functioning properly.

Reusable-throwaway detergent system functioning properly.

Spray jets aimed correctly.

Pre-wash phase functions as programmed during entire specified time

period.

Alkaline wash phase functions as programmed during entire specified

time period.

Optional acid wash phase functions as programmed during entire

specified time period.

Optional acid soak timer functions properly.

Rinse phase(s) functions as programmed during entire specified time

period.

6

Final rinse phase functions as programmed during entire specified time

period.

Carriage drive system functioning properly during all cycles.

Each cycle is functioning as specified by customer order.

Cabinet joints are completely sealed, no leaks. (For verification, run

machine for 1/2 hour.)

Door(s) easily opens from inside of chamber.

Safety cables immediately stop washer operation when pulled.

Washer is now ready for customer operation.

6-1

Operational Checklist Uncrating/Installation Instructions P910000-015

Contact Information:

Sales and Service:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

Tel.: 440 354 2600

Fax : 440 639 8199

Manufacturer:

Corporation STERIS Canada

490 boul. Armand-Paris

Beauport (Québec)

Canada G1C 8A3

Tel.: 418 664 1549

Fax: 418 664 0188

Technical Assistance:

STERIS Engineering Services

2424 West 23rd Street

Erie, PA 16506

Tel.: 814 452 3100

Fax: 814 870 8400

Authorized EU Representative:

STERIS Limited

STERIS House

Jays Close

Viables

Basingstoke

Hampshire RG22 4AX

United Kingdom

Tel.: 44 1256 840400

Fax: 44 1256 866502

Web Site: www.steris.com

Loading...

Loading...