OPERATOR MANUAL

Basil 4600 Cage and Rack Washer

Basil 4602 Cage and Rack Washer

(2008-06-12) P122997-341

A WORD FROM STERIS CORPORATION

This manual contains important information on proper use and main-

tenance of this equipment. Refer to S

NANCE, for instructions in routine care of this washer. All personnel

involved in the use and maintenance of this equipment must

carefully review and comply with the warnings, cautions and

instructions contained in this manual. These instructions are

important to protect the health and safety of personnel operating a

®

4600 Cage and Rack Washer or a Basil® 4602 Cage and

Basil

Rack Washer and should be retained in a conveniently accessible

area for quick reference.

This equipment is specifically designed only for the uses outlined in

this manual.

Complete instructions for uncrating and connecting utilities, as well

as equipment drawings, have been provided. If they are missing,

contact STERIS for replacement copies, providing the serial and

model numbers of the unit.

Advisory IMPORTANT: A listing of the Safety Precautions to be observed

when operating this washer can be found in S

ate the equipment until you have become familiar with this information.

Any alteration of this equipment not authorized or performed by

STERIS could void the warranty, adversely affect its efficacy and violate national, state and local regulations.

ECTION 6, ROUTINE MAINTE-

ECTION 1. Do not oper-

To help assure operators are adequately trained in the safe use of

the equipment, STERIS recommends that:

• all personnel who operate or maintain the equipment are trained

in its operation and in its safe use;

• personnel working with toxic chemicals and vapors (if

applicable) have comprehensive instructions in the unit, washing

process, relevant health hazards and methods to detect the

escape of toxic materials;

• there is regular training of all personnel concerned with the

operation and maintenance of the equipment; attendance

records are maintained; and the evidence of understanding is

demonstrated.

©2008, STERIS Corporation. All rights reserved. Printed in Canada.

Introduction Operator Manual 122997-341

i

Indications For Use The Basil 4600 Cage and Rack Washer and Basil 4602 Cage and

Rack Washer are heavy duty, large capacity hydrospray washers

designed for thorough, efficient cleaning of cages, racks, debris

pans and miscellaneous items used in the care of laboratory animals.

These units are specifically designed to only process goods as outlined in this manual. If there is any doubt about a specific material or

product, contact the manufacturer of the product for the recommended washing technique.

Service Information A thorough preventive maintenance program is essential to safe and

proper unit operation. This manual contains maintenance schedules

and procedures which should be followed for satisfactory equipment

performance.

Customers are encouraged to contact STERIS concerning extended

service maintenance agreements to give their equipment planned

maintenance assuring equipment performance according to factory

specifications.

A global network of skilled service specialists can provide periodic

inspections and adjustments to help ensure low-cost peak performance. STERIS representatives can provide information regarding

annual maintenance agreements. STERIS carries a complete line of

accessories for use with this washer. Please contact STERIS for

details.

Basil 4600 Cage and Rack Washer and Basil 4602 Cage and Rack

Washer meet the application requirements of the following standard:

• 61010-1 Electrical Equipment for measurement; control and

laboratory use; Part 1 General requirements as certified by

Underwriters Laboratories (UL).

Manufacturer:

Corporation STERIS

Canada

Beauport, Qc, CANADA

The base language of this document is

ENGLISH. Any translations must be made

from the base language document.

ISO 13485

ISO 9001

Certified

Facility

Sales and Service:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

440-354-2600 • 800-444-9009

www.steris.com

ii

122997-341 Operator Manual Introduction

TABLE OF CONTENTS

Section

Number Description Page

A WORD FROM STERIS CORPORATION................................................................. I

Advisory ........................................................................................................................................................... i

Indications For Use .........................................................................................................................................ii

Service Information .........................................................................................................................................ii

1 SAFETY PRECAUTIONS .....................................................................................1-1

2 INSTALLATION CHECKLIST ...............................................................................2-1

2.1 General .................................................................................................................................................. 2-1

2.1.1 Technical specifications ................................................................................................................. 2-1

2.1.2 Amperage and Power Consumption .............................................................................................. 2-1

2.1.3 Permissible Environmental Conditions ........................................................................................... 2-2

2.1.4 Noise Level ..................................................................................................................................... 2-2

2.1.5 Seismic Anchorage System ........................................................................................................... 2-2

2.2 Installation Checklist .............................................................................................................................. 2-2

2.3 Chemical Additives Specifications ........................................................................................................ 2-4

3 COMPONENT IDENTIFICATION ..........................................................................3-1

3.1 General .................................................................................................................................................. 3-1

3.2 POWER-OFF/STANDBY Switch ............................................................................................................. 3-2

3.3 Interior Light ........................................................................................................................................... 3-2

3.4 Control Panel ......................................................................................................................................... 3-3

3.4.1 Display Screen ............................................................................................................................... 3-3

3.4.2 Cycle Status Touch Pads ............................................................................................................... 3-3

3.4.3 Manual Control Touch Pads ........................................................................................................... 3-4

3.4.4 Program Touch Pads ..................................................................................................................... 3-4

3.5 Printer .................................................................................................................................................... 3-5

3.5.1 Printer Function Switch ................................................................................................................... 3-5

3.5.2 Sample Printout .............................................................................................................................. 3-6

3.6 Unload-Side Control Panel .................................................................................................................... 3-7

3.7 Oscillating Jet System ........................................................................................................................... 3-7

3.8 Safety System ........................................................................................................................................ 3-8

3.9 Heat Exchanger ..................................................................................................................................... 3-9

3.10 Automatic Detergent Injection System ................................................................................................ 3-9

3.11 Reusable-Throwaway Acid Detergent System ..................................................................................3-10

3.12 Non- Recirculated Final Rinse ........................................................................................................... 3-10

3.13 Feeder Bottle Washing System ......................................................................................................... 3-11

Continued...

122997-341 Operator Manual Table of Contents

iii

TABLE OF CONTENTS (Cont’d)

Section

Number Description Page

3 COMPONENT IDENTIFICATION (Cont’d)

3.14 Automatic Water Flush System for Two Racks .................................................................................. 3-11

3.15 Drain Discharge Cooldown with Side Tank and Temperature Guarantee ........................................ 3-12

3.16 Drain Discharge Cooldown System with Cold Water Injection Only ................................................. 3-13

3.17 Exhaust Fan ....................................................................................................................................... 3-13

4 WASHER OPERATION .........................................................................................4-1

4.1 Before Operating Washer ...................................................................................................................... 4-1

4.2 How to Load Washer ............................................................................................................................. 4-2

4.3 Cycle Operation ..................................................................................................................................... 4-4

4.4 Review and Print Specific Cycle Program ........................................................................................... 4-17

4.5 Stop Cycle Operation .......................................................................................................................... 4-19

4.6 Abort Cycle Operation ......................................................................................................................... 4-19

4.7 Extend Cycle Phase Time .................................................................................................................... 4-20

4.7.1 During a Cycle ............................................................................................................................. 4-20

4.7.2 Prior to Starting a Cycle ............................................................................................................... 4-20

4.8 Bypass Phase ...................................................................................................................................... 4-22

4.9 Shutdown Procedure ........................................................................................................................... 4-22

4.10 Manual Control Mode ........................................................................................................................ 4-23

4.10.1 Accessing Manual Control Mode ............................................................................................... 4-24

4.10.2 FILL Function .............................................................................................................................. 4-24

4.11 DRAIN Function ................................................................................................................................. 4-25

4.11.1 Draining Sump ........................................................................................................................... 4-25

4.11.2 Draining Alkaline Tank ............................................................................................................... 4-26

4.11.3 Draining Acid Tank ..................................................................................................................... 4-27

4.11.4 Draining Cooldown Tank ............................................................................................................ 4-27

4.12 PUMP/DRV Function .......................................................................................................................... 4-28

4.13 DRIVE Function .................................................................................................................................. 4-29

5 CYCLE PROGRAMMING ......................................................................................5-1

5.1 Program Touch Pads ............................................................................................................................. 5-1

5.2 Change Values Mode ............................................................................................................................ 5-1

5.3 Programming Cycle Values ................................................................................................................... 5-3

5.3.1 Pre-Wash ........................................................................................................................................ 5-4

5.3.2 Alkaline Wash ................................................................................................................................. 5-4

5.3.3 Acid Wash ...................................................................................................................................... 5-5

5.3.4 Rinse .............................................................................................................................................. 5-7

Continued...

iv

Table of Contents Operator Manual 122997-341

TABLE OF CONTENTS (Cont’d)

TABLE OF CONTENTS

Section

Number Description Page

5 CYCLE PROGRAMMING (Cont’d)

5.4 Programming Operating Values .......................................................................................................... 5-10

5.5 Programming Values with Access Code Enabled ............................................................................... 5-11

6 ROUTINE MAINTENANCE ...................................................................................6-1

6.1 General .................................................................................................................................................. 6-1

6.2 Preventive Maintenance Schedule ........................................................................................................ 6-2

6.3 Daily Cleaning Procedures .................................................................................................................... 6-4

6.4 Weekly Cleaning Procedures ................................................................................................................ 6-5

6.4.1 Clean Washer Exterior..................................................................................................................... 6-5

6.4.2 Clean Washer Interior ..................................................................................................................... 6-5

6.4.3 Clean Spray Jets and Headers ...................................................................................................... 6-6

6.4.4 Inspect Self-Cleaning Screen ........................................................................................................ 6-7

6.5 Monthly Cleaning Procedures ............................................................................................................... 6-8

6.5.1 Remove Hard Water Deposits From Chamber and Accessories .................................................. 6-8

6.6 Routine Maintenance ............................................................................................................................. 6-9

6.6.1 Grease Exhaust Fan Bearings ....................................................................................................... 6-9

6.6.2 Clean Drain Discharge Side Tank ................................................................................................ 6-10

6.6.3 Clean Drain Discharge Temperature Control Probe .................................................................... 6-12

6.6.4 Replace Detergent Squeeze Tube ............................................................................................... 6-13

6.6.5 Replacing Detergent Container ................................................................................................... 6-14

6.7 Printer Paper ........................................................................................................................................ 6-15

6.7.1 Printer Paper Roll Replacement ................................................................................................... 6-15

6.7.2 Storing Thermal Paper ................................................................................................................. 6-17

7 TROUBLESHOOTING .......................................................................................... 7-1

5.1 Test Procedure – Allen-Bradley Control ................................................................................................ 5-1

5.2 Test Procedure – Siemens Control ........................................................................................................ 5-7

122997-341 Operator Manual Table of Contents

v

TABLE OF CONTENTS (Cont’d)

LIST OF FIGURES

Section

Figure

Number Description Page

2 INSTALLATION CHECKLIST

2-1 Shutoff Valves and Disconnect switch ................................................................................................. 2-1

3 COMPONENT IDENTIFICATION

3-1 Washer Components - Basil 4600 (Typical) ........................................................................................ 3-1

3-2 Control Column ................................................................................................................................... 3-2

3-3 Control Panel ....................................................................................................................................... 3-3

3-4 Printer .................................................................................................................................................. 3-5

3-5 Sample Printout ................................................................................................................................... 3-6

3-6 Sample Alarm Printout ......................................................................................................................... 3-6

3-7 Unload-Side Control Panel .................................................................................................................. 3-7

3-8 Oscillating Jet System ......................................................................................................................... 3-7

3-9 Safety Cables ...................................................................................................................................... 3-8

3-10 Heat Exchanger .................................................................................................................................. 3-9

3-11 Non-Recirculated Final Rinse Spray Header .................................................................................... 3-10

3-12 Drain Discharge Side Tank (Typical) ................................................................................................ 3-12

3-13 Exhaust Fan ....................................................................................................................................... 3-13

4 WASHER OPERATION

4-1 Manual Drain Valve ............................................................................................................................. 4-1

4-2 Accessories ......................................................................................................................................... 4-3

4-3 Manual Control Mode Flow Chart ...................................................................................................... 4-23

5 CYCLE PROGRAMMING

5-1. Program Touch Pads ............................................................................................................................ 5-1

6 ROUTINE MAINTENANCE

6-1. Spray Header Flush Plug ..................................................................................................................... 6-6

6-2. Self-Cleaning Screen ............................................................................................................................ 6-7

6-3. Exhaust Fan Grease Fittings ................................................................................................................ 6-9

6-4. Manual Drain Valve ............................................................................................................................ 6-10

6-5. Replace Squeeze Tube ...................................................................................................................... 6-13

6-6. Replacing Detergent Container........................................................................................................... 6-14

6-7. Printer Paper Roll Replacement ......................................................................................................... 6-16

vi

Table of Contents Operator Manual 122997-341

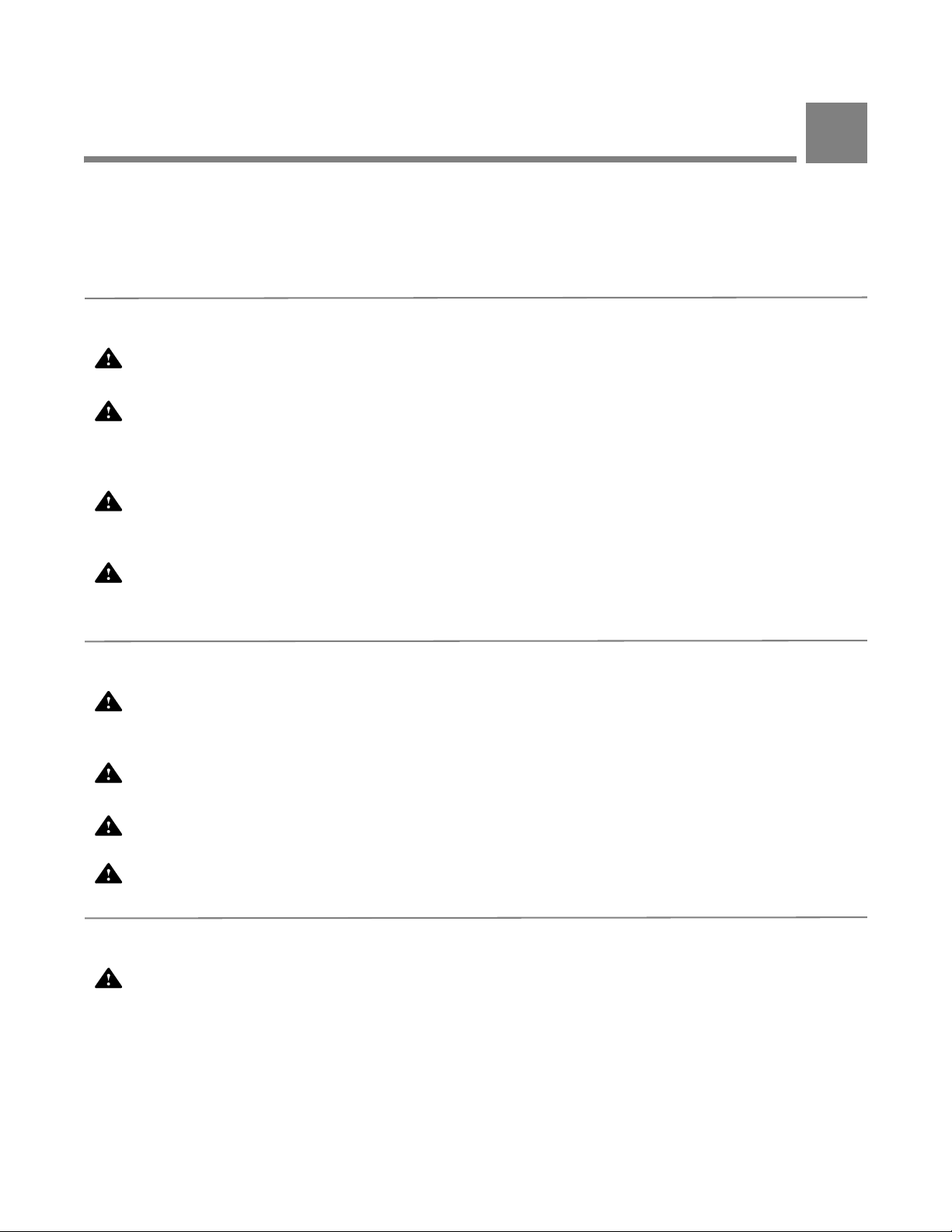

SAFETY PRECAUTIONS

The following Safety Precautions must be observed when operating or servicing this equipment. WARNING indi-

cates the potential for personal injury and CAUTION indicates the potential for damage to equipment. For empha-

sis, certain Safety Precautions are repeated throughout the manual. It is important to review ALL Safety

Precautions before operating or servicing the unit.

1

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Always wear appropriate Personal Protective Equipment (PPE) when cleaning or removing debris from

bottom of wash chamber and over suction plate.

Only STERIS or STERIS-trained service personnel should make repairs and adjustments to this equipment. Maintenance done by inexperienced, unqualified personnel or installation of unauthorized parts

could cause personal injur y, invalida te warranty, or result in costly damage. Contact STERIS regarding

Service options.

Regularly scheduled preventive maintenance, in addition to faithful performance of minor maintenance

described within this manual, is required for safe and reliable operation of this equipment. Contact

STERIS to schedule preventive maintenance.

To open doors from inside wash chamber, pull EMERGENCY STOP cables. Washer operation will

automatically stop. Then, push firmly on door panel using shoulder and u pper arm, applying upper bod y

force.

WARNING – PERSONAL INJURY HAZARD:

Items in washing cart may move du ring processing and be filled with residual hot w ater or protrude from

cart at the end of the cycle. Always wear appropriate personal protective equipment (PPE) and carefully

remove it ems from cart.

Never perform cleaning of wash chamber until full cycle has been completed. If cycle has not been

completed, contaminated debris or water may remain in the bottom of the wash chamber.

Keep fingers away from door hinges to prevent pinching.

To prevent tipping, place biggest and heaviest items on the lower levels of accessory cart.

WARNING – ELECTRIC SHOCK AND/OR BURN HAZARD:

Disconnect all utilities to washer before servicing. Do not service washer unless all utilities have been

properly locked out. Always follow local occupational health and safety regulations, as well as electric

and plumbing codes.

Safety Precautions Operator Manual 122997-341

1-1

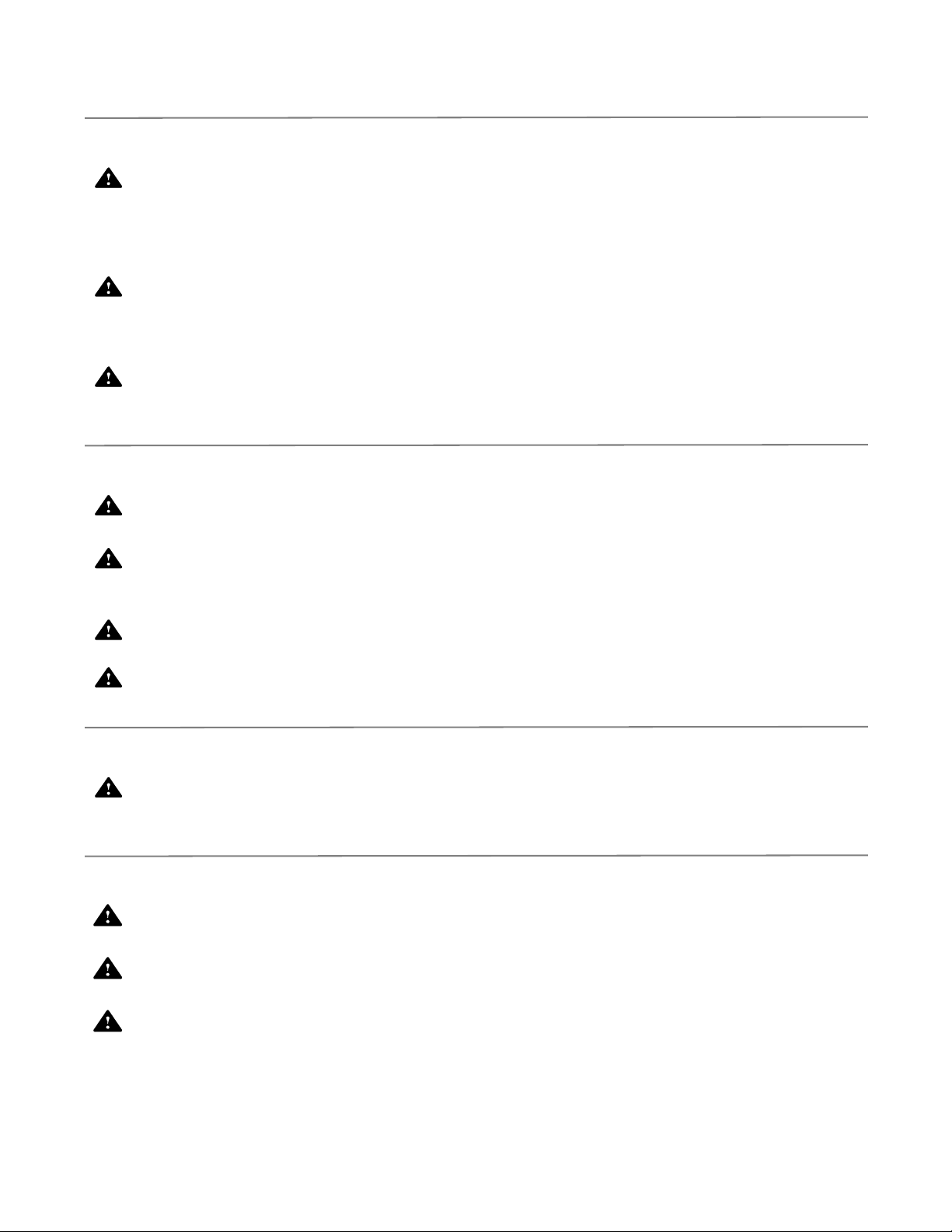

WARNING – CHEMICAL BURN AND/OR EYE INJURY HAZARD:

Washer chemicals are caustic an d can cause ad v erse ef f ect s to exposed tissues. Do not get in eyes , on

skin, or attempt to swallow. Read and follow precautions and instructions on chemical label and in

Material Safety Data Sheet (MSDS) prior to handling deter gen t conta iner s, or servicing detergent injection pumps, tank, and lines . W ear appropriate Personal Protective Equipment (PPE) whenever handling

chemicals or servicing chemical injection pumps, tank, and lines.

Wear appropriate Personal Protective Equipment (PPE) when removing clamps and replacing squeeze

tubes. Residual chemicals might remain in used squeeze tubes. If chemical contacts skin or eyes,

immediately flush with running water for at least 10 minutes. If contact was with eyes, seek medical

attention.

Wear gloves and eye protection when using a descaling product. Avoid contact with eyes or skin. If

spilled or splashed, flush with plenty of water for 15 minutes. If swallowed, DO NOT induce vomiting.

Administer an alkali with plenty of water. Seek medical attention immediately.

WARNING – BURN HAZARD:

Allow unit to cool down before performing any service on mechanical components and on piping. Components and piping become very hot during operation.

Inner surfaces of washer are very hot after cycle completion. Ope rator should wear appropriate Personal Protective Equipment (PPE) and avoid all contact with inner walls when entering chamber to

unload washer.

Pipes may be extremely hot.

When cycle is complete, partially open chamber door and allow chamber and load to cool. Hot steam

may escape through door opening if door is fully opened after a cycle.

WARNING – SLIPPING HAZARD:

To avoid slippery floor conditions, k eep floor d ry. Promptly wipe up any spilled liquids or condensation. If

spilled liquids are detergents or other chemicals, follow safety precautions and handling procedures set

forth on detergent or chemical label and/or Material Safety Data Sheet (MSDS).

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Always use non-foaming chemical for effective cleaning and proper pump and water lev el contr ol oper ation. Follow manufacturer’s recommendations for amount of chemical to be used.

Always use a silicone lubricant to lubricate squeeze tubes. Petroleum-based lubricants, such as

Vaseline

Avoid product damage. Always select a cycle appropriate for items being processed.

1

Vaseline is a trademark of Chesebrough Pond's Incorporated.

®1

or grease, will cause squeeze tubes to melt.

1-2

122997-341 Operator Manual Safety Precautions

CAUTION – POSSIBLE EQUIPMENT DAMAGE (Cont’d):

Before operating unit, always position manifolded Bottle Washing Cart over central water inlet connector. If manifolded accessory is not positioned correctly, damage may result and unit will be unable to

effectiv ely wash load.

Do not process load using Bottle Washing Cart when Automatic Floor Tiltin g o ption is act ivated. If Automatic Floor Tilting is used, manifolded water inlet and washer will be damaged.

Remove all cellulose-type bedding from cages and pans before processing. Cellulose bedding can clog

filters and piping.

Use nonabrasive cleaners when cleaning unit. Follow directions on containers and rub in a back-andforth motion (in same direction as surface grain). Abrasive cleaners will damage stainless steel. Cleaners rubbed in a circular motion applied with a wire brush or steel wool will scratch and dull stainless

steel. Do not use these cleaners on painted surfaces.

When choosing a detergent, select one with a low chloride conte nt. Detergents wi th a high chlo ride content can corrode stainless steel.

Safety Precautions Operator Manual 122997-341

1-3

The tables below contain symbols which may be on your Basil 4600 Cage and Rack Washer or 4602 Cage and

Rack Washer components:

Table 1-1. Definition of Symbols on Unit

Symbol Definition

Protective Earth (Ground).

Warning! Risk of Electrical Shock.

Attention! Refer to Manual for Further Instructions.

Fuse Identification.

Pump Rotation

Table 1-2. Definition of Symbols on Identification Nameplate

Symbol Definition

MODEL Model Number of the Unit.

S/N Serial Number of the Unit.

V 3

~ Volt, Number of the Phase (Three) Alternating Current.

WIRE Number of Wires of the Unit, Ground not Included.

YEAR Year of Manufacture of the Unit.

kW Power Rating of the Unit

A Amperage.

Hz Hertz – Frequency of the Unit.

1-4

122997-341 Operator Manual Safety Precautions

2

INSTALLATION CHECKLIST

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this Cage

and Rack Washer can be found in S

this information.

2.1 General An equipment drawing, showing all utility and space requirements,

ECTION 1. Do not install equipment until you have become familiar with

was supplied with the washer. Clearance space specified on equipment drawing is necessary for ease of installation and to assure

proper operation and maintenance of equipment. If documents are

missing or misplaced, contact STERIS giving unit serial, equipment,

and model numbers. Replacement copies will be sent to you

promptly.

2.1.1 Technical specifications

2.1.2 Amperage and Power Consumption

These specifications are intended to describe technical information

given on nameplate of your washer and to state other relevant information. Check equipment drawing or identification nameplate,

located inside control door, above main electrical box, for proper

voltage and amperage.

Basil® 4600 Cage and Rack Washer and Basil® 4602 Cage and

Rack Washer operate on:

• 208 V~, three-phase, 60 Hz

• 480 V~, three-phase, 60 Hz.

A protective ground conductor is required (Class 1 Equipment).

Installation Category is Overvoltage II.

Refer to equipment drawing (920-505-383 for Basil 4600; 920-505-

871 for Basil 4602 or custom equipment drawing) for proper connection.

IMPORTANT: Customer is responsible for compliance with

applicable codes and regulations.

Maximum currents and power consumptions, are indicated on

nameplate.

Installation Checklist Operator Manual 122997-341

2-1

2.1.3 Permissible

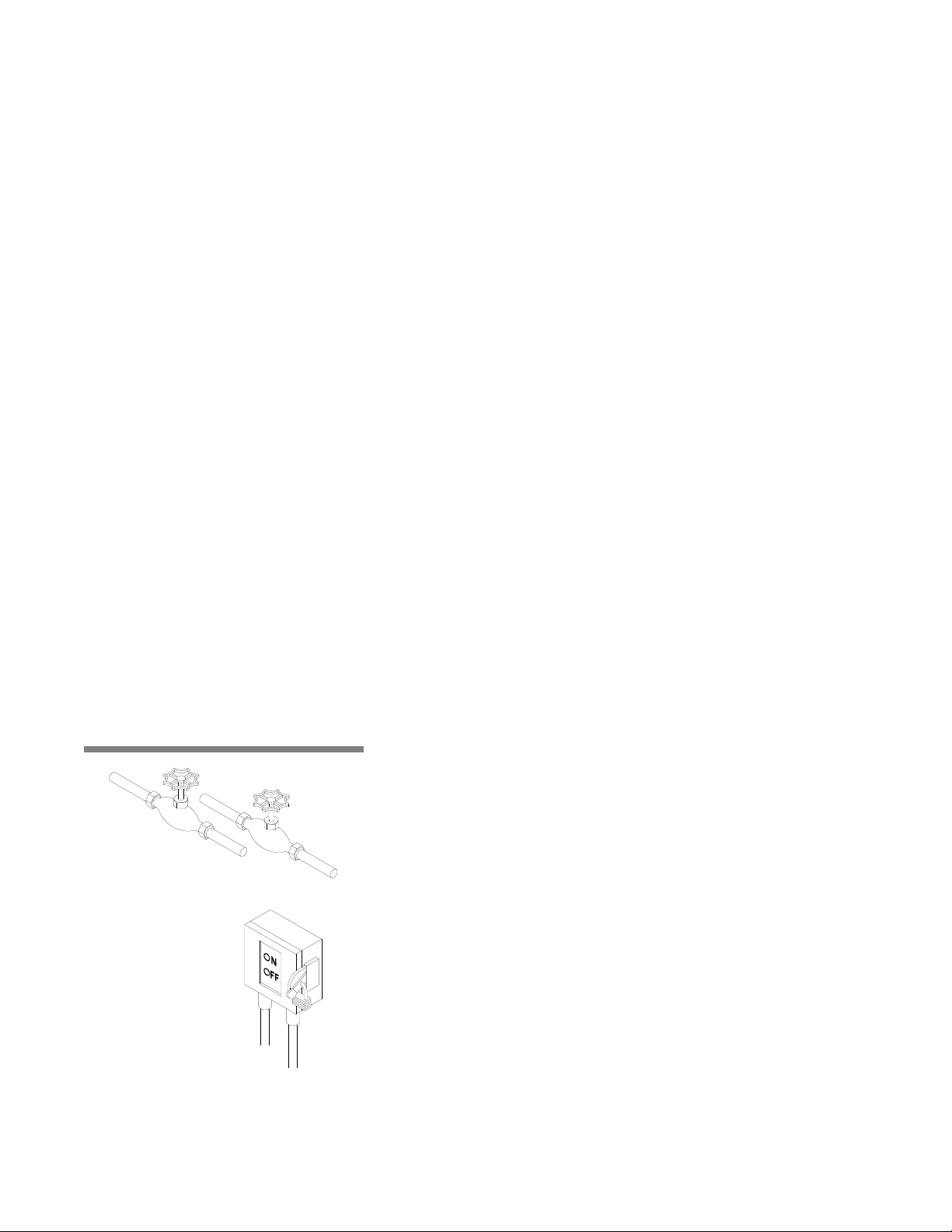

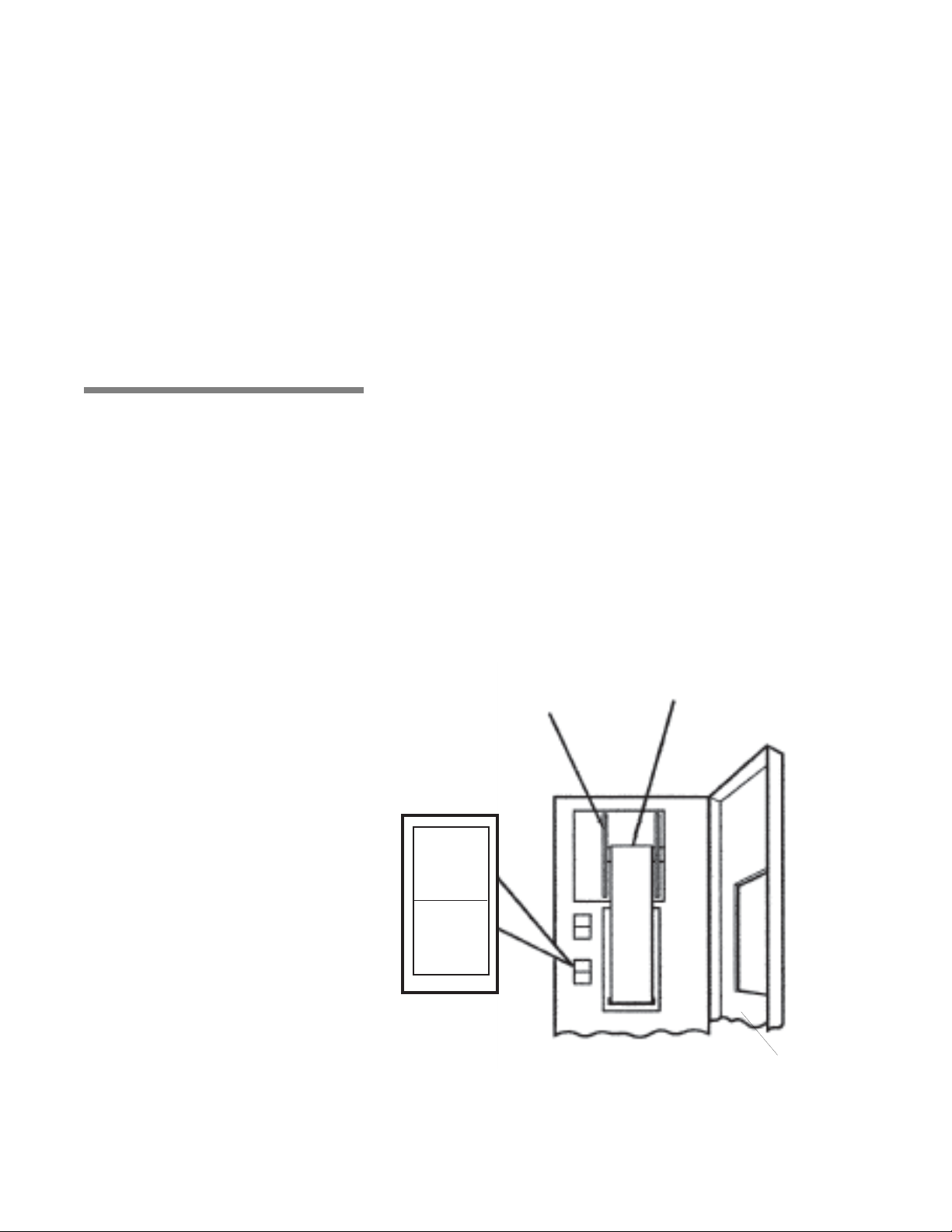

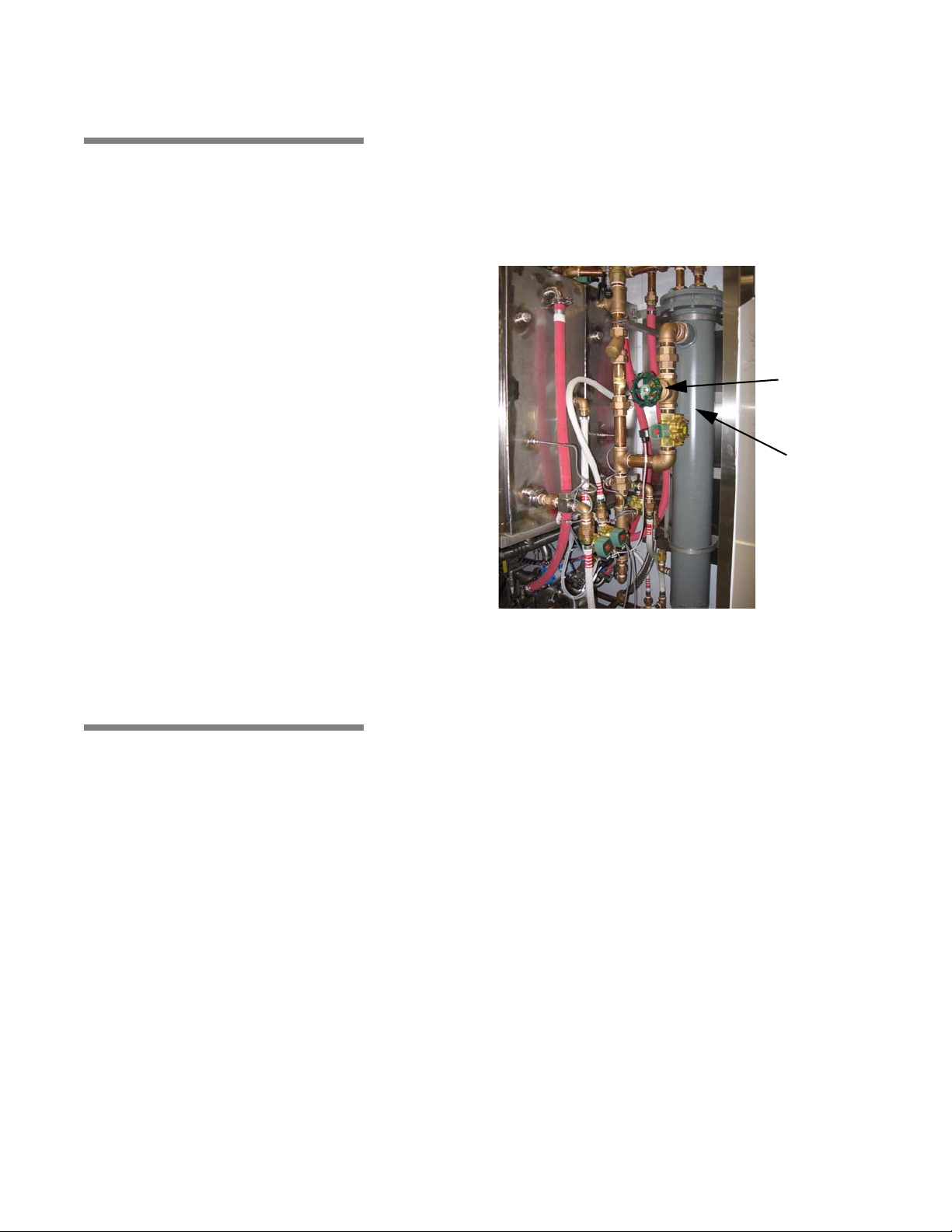

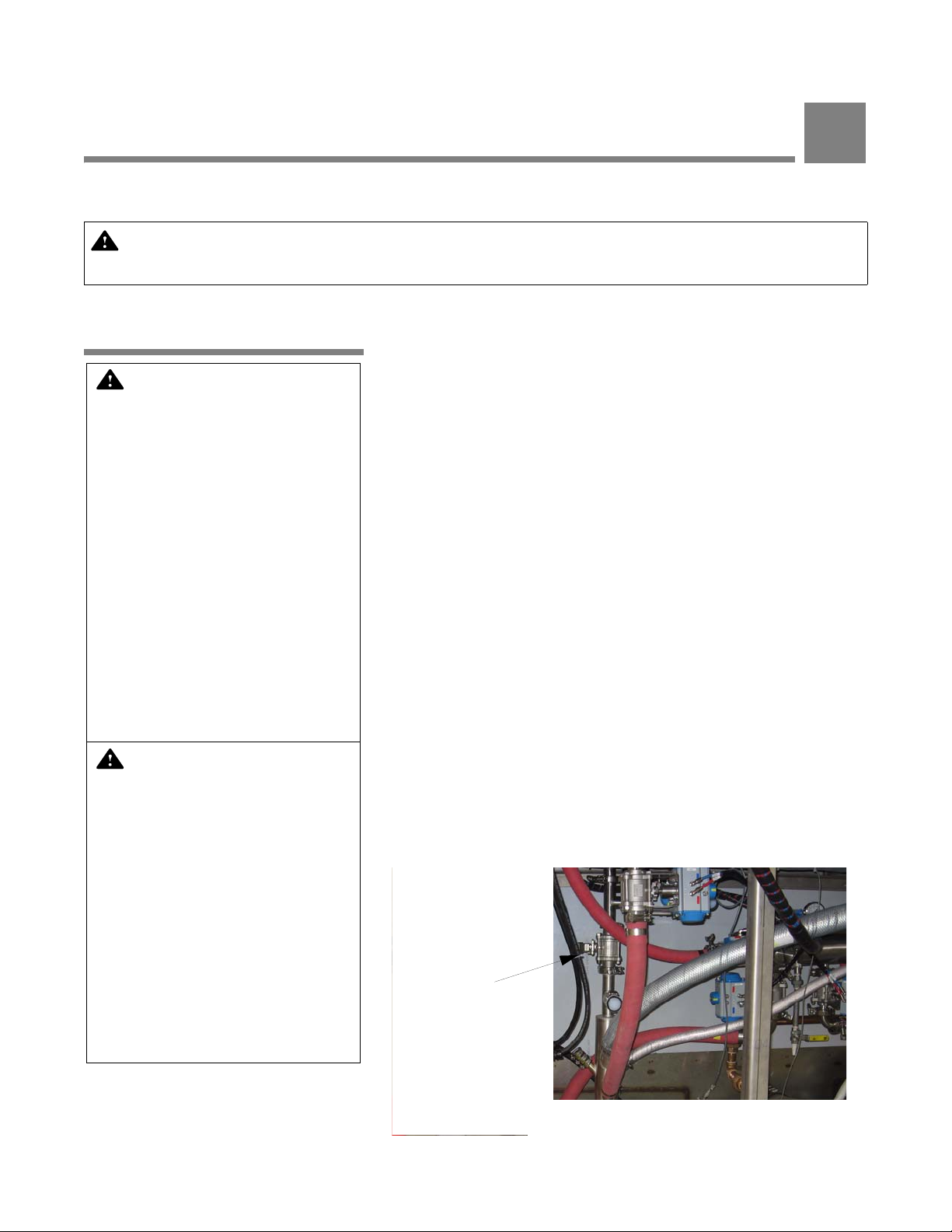

Figure 2-1. Shutoff Valves and

Disconnect Switch

Shutoff Valves

Disconnect Switch

Environmental Conditions

2.1.4 Noise Level Equivalent Sound Pressure Level: 84 dB (A). Results determined

This unit is designed to give optimal results under the following con-

ditions:

- Indoor use only;

- Altitude of operation up to 6562 ft (2000 m);

- Temperature 41°F to 104°F (5°C to 40°C);

- Maximum relative humidity is 80% for temperatures up to 88°F

(31°C) decreasing linearly to 50% relative humidity at 104°F

(40°C);

- Installation Category II;

- Pollution Degree 2.

according to ISO-3746: 1995 Standard: Acoustics Determination of

Sound Power Levels of Noise Sources Survey Method.

2.1.5 Seismic Anchorage

2.2 Installation Checklist

Washer can be built to seismic zone 3 and 4 requirements.

System

After installing washer according to Uncrating/Installation Instructions (P910000-015), complete the following checklist to assure

complete and correct installation. Contact STERIS to schedule a

technician to test your installation and demonstrate proper equipment operation.

❑ Shutoff valves (not provided by STERIS) should be installed on

steam and water supply lines to unit (see Figure 2-1). Shutoff

valves must be capable of being locked in OFF position only and

in compliance with occupational health and safety regulations,

as well as electric and plumbing codes for any special requirements that may pertain to installation of this unit.

❑ Disconnect switches (not provided by STERIS) should be

installed in electric supply lines near unit (see Figure 2-1). Disconnect switches must be capable of being locked in OFF position only. Disconnect switches must be installed in electric

supply line near unit (within 10' [3 m] of equipment) and in compliance with occupational health and safety regulations, as well

as electric and plumbing codes for any special requirements

that may pertain to installation of this unit.

2-2

122997-341 Operator Manual Installation Checklist

NOTE: If washer is installed next to other equipment, shutoff valves

and disconnect switch should be placed so that service can be shut

off to any one unit.

❑ Washer is positioned, as shown on equipment drawing, with

required service clearance space and in relation to building supply lines.

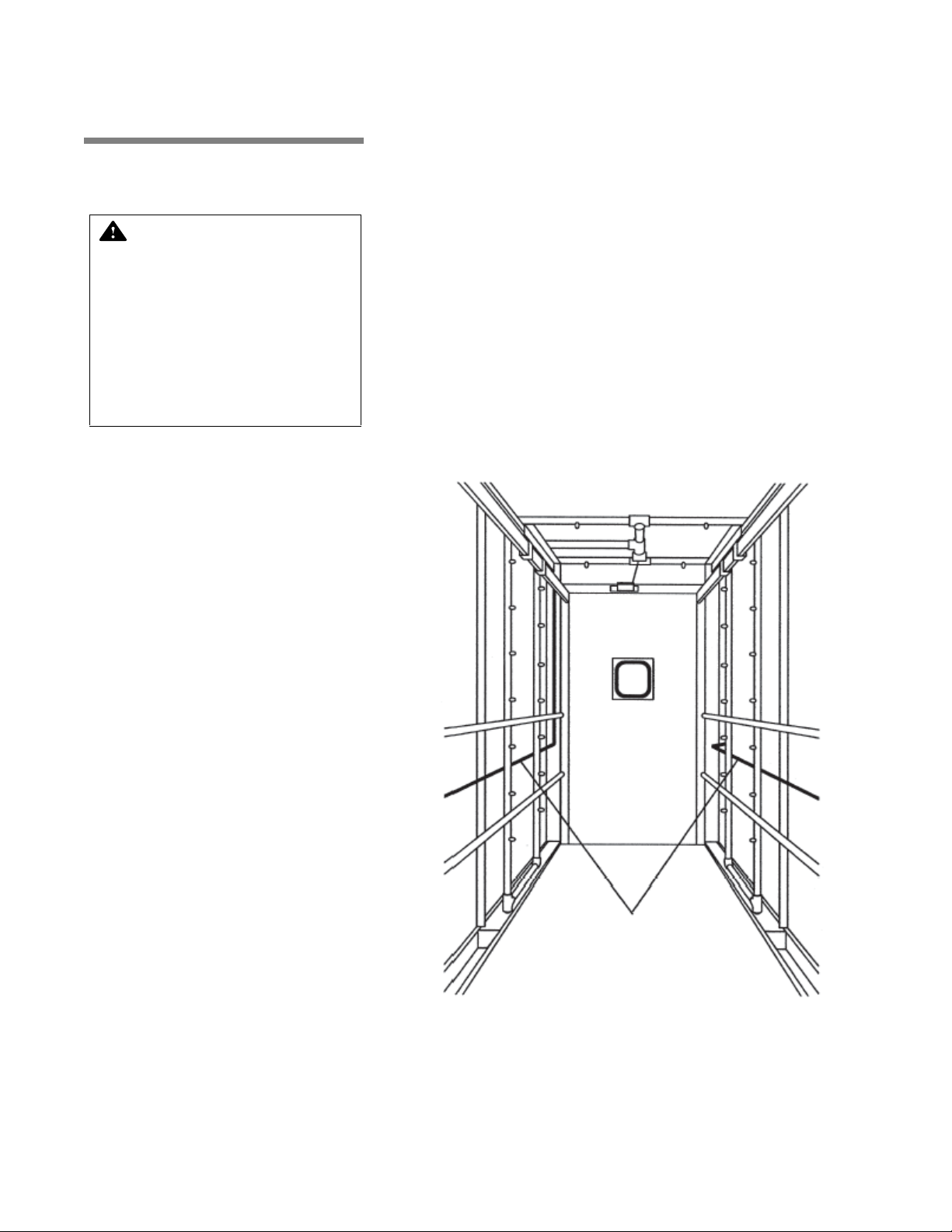

❑ Basil 4600 Cage and Rack Washer and Basil 4602 Cage and

Rack Washer must be installed between two walls, with a key-

locked service door, so washer service side is not accessible to

operator.

❑ Building steam line provides maximum dynamic steam pressure

and flow rate to washer as specified on equipment drawing.

❑ Drip leg with steam trap installed in steam supply line.

❑ Building hot water line supplies water to washer at pressure and

temperature specified on equipment drawing.

❑ Building cold water line supplies water to washer at pressure

specified on equipment drawing.

❑ Electrical supply for washer is as specified on equipment draw-

ing.

❑ Condensate returns are sized as specified on equipment draw-

ing.

❑ Vent connections are sized as specified on equipment drawing.

❑ Recirculation pump pressure is within 25 to 60 psig.

❑ Recirculation pump motor rotating in direction shown by arrow.

❑ Self-cleaning screen assembly functioning properly.

❑ Carriage drive motor rotating in direction shown by arrow.

❑ Carriage drive system functioning properly.

❑ Carriage drive motor amperage within rating indicated on the

motor.

❑ Optional exhaust fan rotating in direction shown by arrow.

❑ All piping is leak-free.

❑ Chamber sump steam coil functioning properly.

❑ Door safety switch(es) functioning properly.

❑ Cabinet joints are completely sealed, no leaks (for verification,

run machine for 1/2 hour).

❑ Door(s) easily opens from inside of chamber.

❑ Safety cables immediately stop washer operation when pulled.

❑ Each gear box plastic cap removed and replaced with air vent

provided.

❑ Floor surrounding unit has non-slip surface.

IMPORTANT: After a few weeks of operation, inspect unit for leaks.

Retighten all clamps and connections.

Installation Checklist Operator Manual 122997-341

2-3

2.3 Chemical Additives Specifications

The selection of chemical additives is open for customer preference;

however, in order to achieve optimal performance, the selected

chemical additives must meet as a minimum, the following specifications:

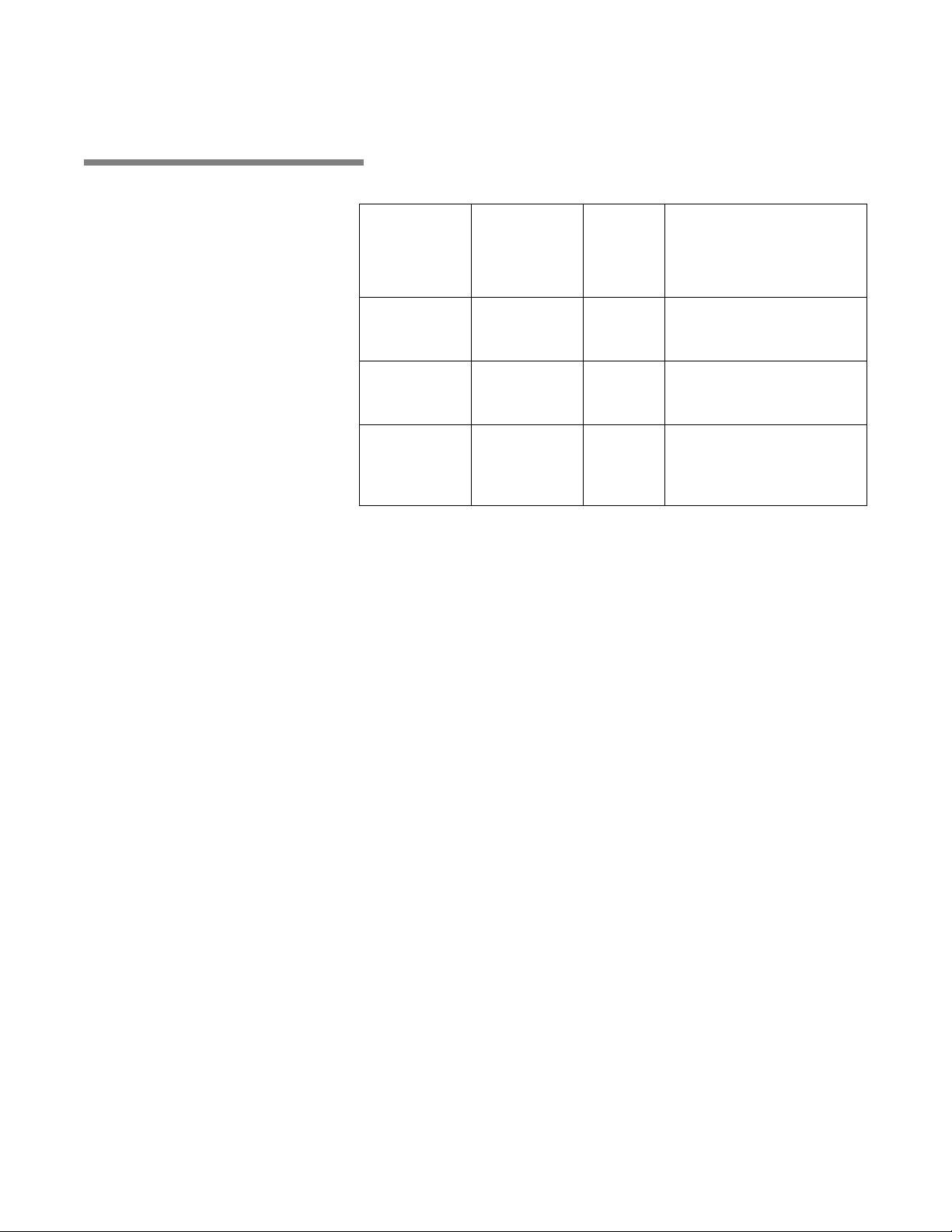

Use Dilution

Product

Description

Range oz/

gal (mL/L)

Dilution

Alkaline

Chemicals

Acidic

Chemicals

Descalers 1/2 -2 <2.5

1/4 - 4

(2-32)

1/4 - 4

(2-32)

pH

Range

at Use

9.0 - 12.0

3.0 - 6.0

Other Applicable

Requirements

Liquid, non-foaming, and viscosity below 200 SSU

(0.0004623 ft2/sec).

Liquid, non-foaming, free

rinsing, and viscosity below

200 SSU (0.0004623 ft2/sec).

Liquid, non-foaming, phosphoric acid-based, and viscosity below 200 SSU

(0.0004623 ft2/sec).

NOTE: When choosing and using chemicals, take note of the following:

1) Follow chemical label recommendations for concentration of

chemical to use.

2) Follow chemical manufacturer's recommendations to determine

the temperature of the WASH treatment .

3) Follow chemical manufacturer's recommendations for the amount

of chemical used according to water hardness.

To achieve maximum cleaning efficiency, select chemical appropriate to soil type being processed. STERIS recommends the following

chemicals:

®

• Cage-Klenz

100 Alkaline Cage Wash Detergent -

(Alkaline) formulated to remove urine, scale, animal fats, oils and

other organic soils from cage materials.

®

• Cage-Klenz

200 Acid-Based Cage Wash Detergent -

(Acidic) formulated to remove urine, scale, animal fats, oils and

other organic soils from cage materials.

• Liquid Descaler Acid-Based Scale Remover - for

removing scale and other hard water deposits. For use in animal

care centers.

NOTE: Certain products may not be available in your area. Contact

your STERIS representative for availability of these products and for

ordering information.

IMPORTANT: STERIS does not promote, recommend, nor endorse

the use of any other type of chemical additives in the processing of

articles in the Basil 4600/4602 Cage and Rack Washers, such as

drying agents, strong alkaline detergents (pH>12), alcohol rinses and

liquid germicides including hypochloric acid (bleach).

2-4

122997-341 Operator Manual Installation Checklist

3

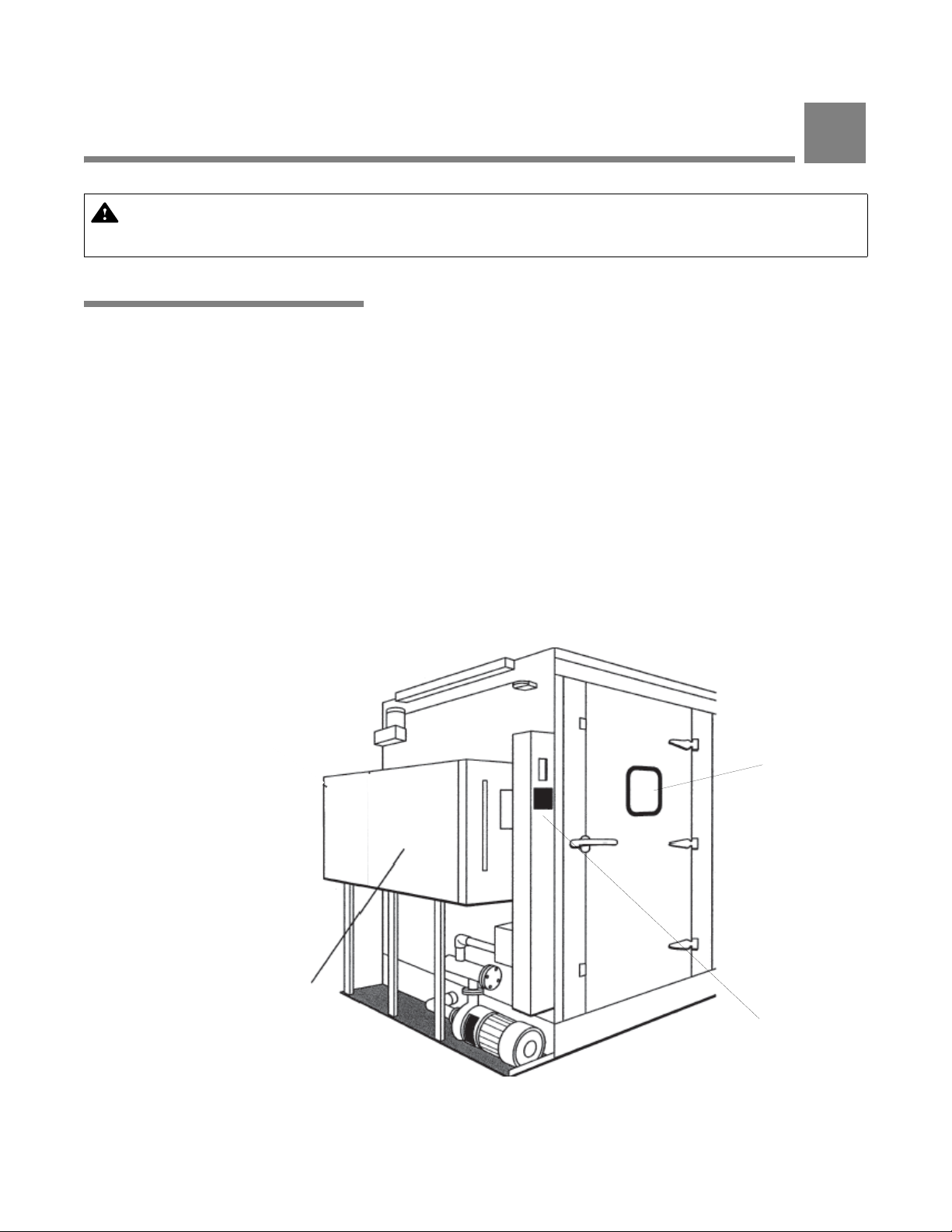

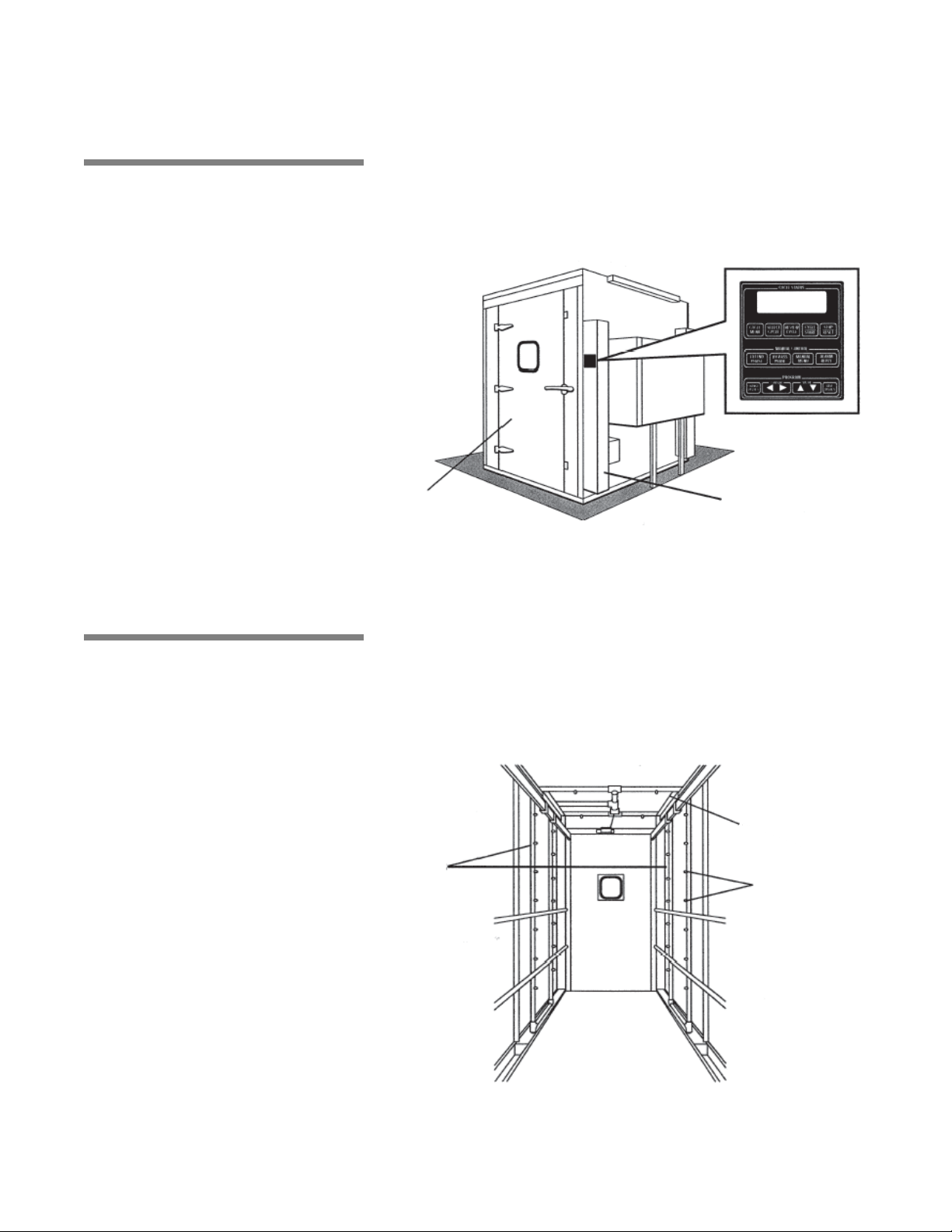

Figure 3-1. Washer Components - Basil 4600 (Typical)

Reusable-Throwaway

Detergent Tank

Chamber Door

and Viewing

Window

Control Console

COMPONENT IDENTIFICATION

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this Cage

and Rack Washer can be found in S

this information.

3.1 General Become familiar with location and function of all major components

ECTION 1. Do not install equipment until you have become familiar with

and controls, as well as their function before operating this unit (see

Figure 3-1).

Two models are available: Basil

®

4602 Cage and Rack Washer.

Basil

•Basil

4600:

Wash Chamber: 46" W x 85" H x 92" L (1168 x 2159 x 2336 mm)

Overall Unit: 82" W x 102" H x 99" L (2082 x 2590 x 2514 mm)

Equipped with Reusable - Throwaway Detergent Tank

• Basil 4602:

Wash Chamber: 46" W x 85" H x 188" L (1168 x 2159 x 4775 mm)

Overall Unit: 82" W x 102" H x 195" L (2082 x 2590 x 4953 mm)

Equipped with Reusable - Throwaway Detergent Tank

Each model is equipped with a user-programmable microcomputer

control system capable of storing up to twelve treatment cycles to

process a wide variety of loads. Computer control system monitors

and automatically controls all cycle operations.

®

4600 Cage and Rack Washer and

3-1

Component Identification Operator Manual 122997-341

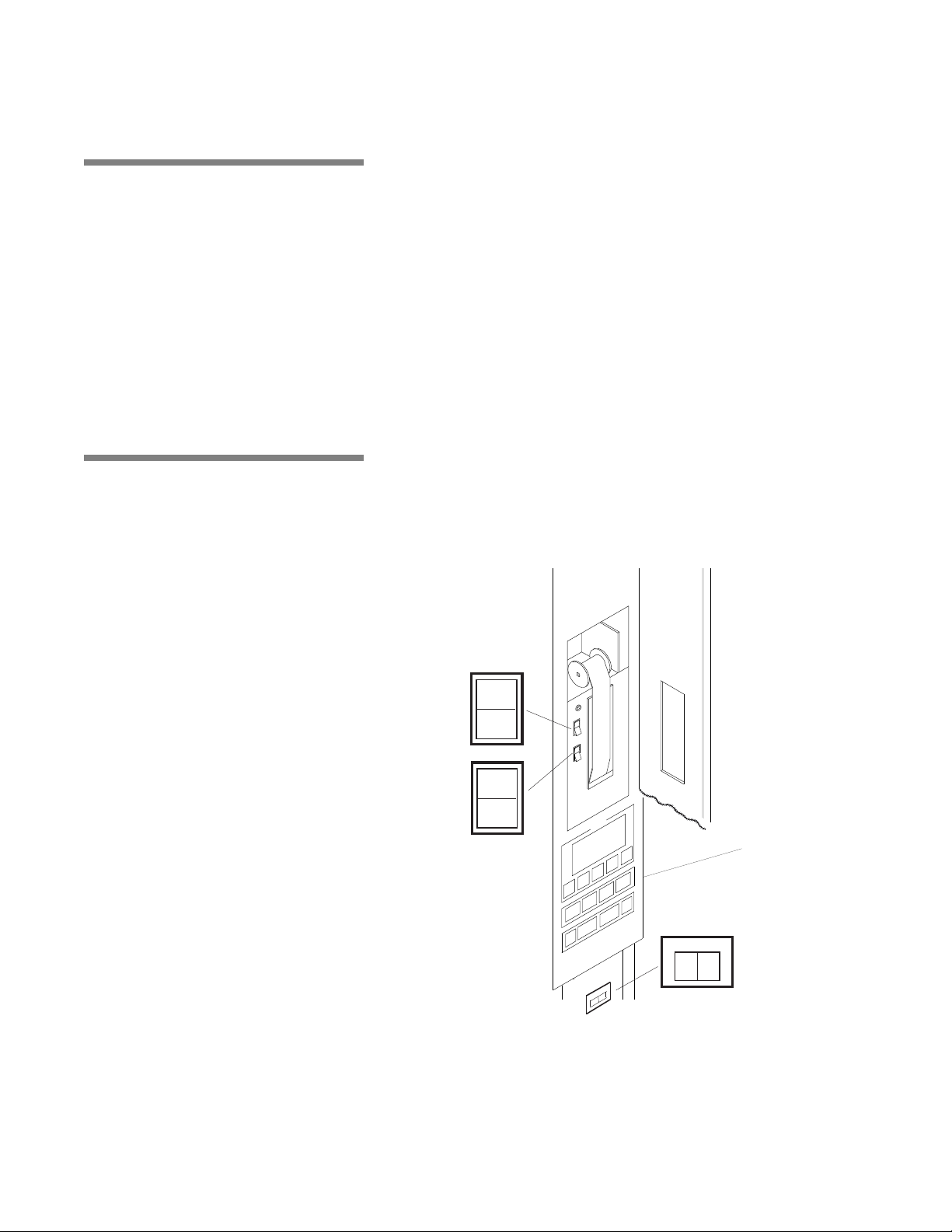

3.2 POWER-OFF/

POWER

OFF

STANDBY

PRINT

PRINT

VALUES

ON

OFF

INTERIOR LIGHT

Figure 3-2. Control Column

Control Panel

STANDBY Switch

POWER-OFF/STANDBY switch, located behind the printer door,

includes two settings which direct operation of control (see Figure 3-

2):

• POWER – Press top portion of POWER-OFF/STANDBY switch to

initialize control and place control in Ready Mode.

• OFF/STANDBY – Press bottom portion of POWER-OFF/

STANDBY switch to initiate Shutdown Cycle and place control in

Standby Mode.

NOTE: Control should be placed in Standby Mode for last cycle of th e

day and when washer is not in use for an extended peri od of time.

IMPORTANT: POWER-OFF/STANDBY switch does not turn off

electrical power to unit.

3.3 Interior Light Interior light, can be manually controlled by operator through a tog-

gle switch located behind printer door, below control panel, on load

side (see Figure 3-2). Interior light illuminates wash chamber when

loading or unloading washer, or it can left ON during a whole washing cycle to view washing process.

3-2

122997-341 Operator Manual Component Identification

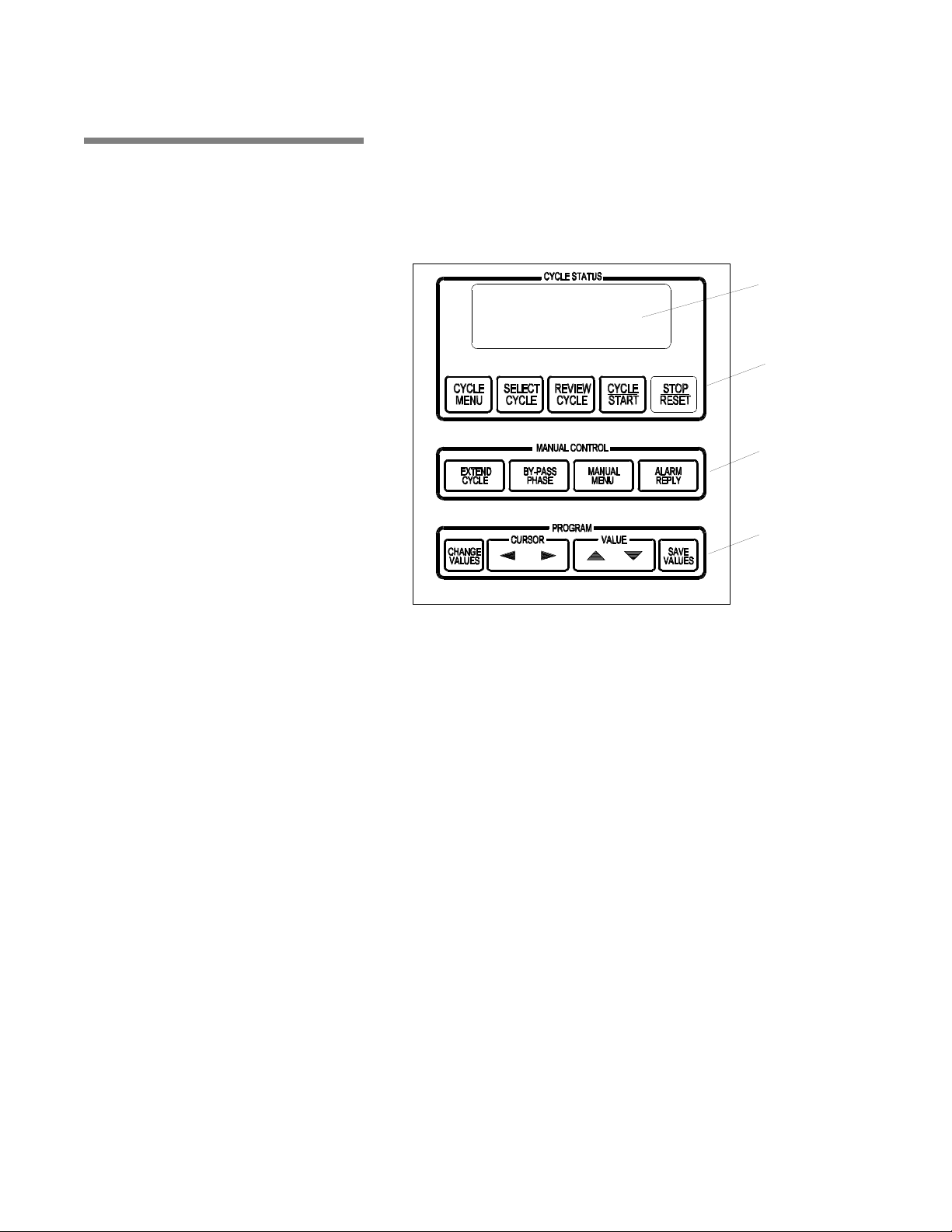

3.4 Control Panel Control Panel is used to direct all washer functions (see Figure 3-3).

Figure 3-3. Control Panel

Display Screen

Cycle Status

Touch Pads

Manual Control

Touch Pads

Program Touch

Pads

Operator may program specific cycles, review and select cycles,

start, stop or reset cycle operation, extend or bypass cycle phases,

and monitor cycle performance.

3.4.1 Display Screen Two line alpha-numeric screen displays cycle program data on

demand, in-cycle performance data and operator instructions. Display screen also indicates certain abnormal conditions that may

occur during a cycle.

3.4.2 Cycle Status Touch Pads

Component Identification Operator Manual 122997-341

• CYCLE MENU touch pad – press to view first cycle menu. Press

again to advance screen to next cycle menu. Three menus are

available, each with four cycles.

• SELECT CYCLE touch pad – press until desired cycle name

flashes.

NOTE: When a displayed cycle name or phase value is selected,

corresponding word or digit flashes.

• REVIEW CYCLE touch pad – press to review cycle phases and

values programmed for selected cycle.

• CYCLE/START touch pad – press once to display name of

selected cycle. Press a second time to start cycle.

NOTE: Selected cycle name remains on screen for 5 seconds

3-3

after pressing CYCLE/START touch pad once. To start a cycle,

CYCLE/START touch pad must be pressed a second time while

selected cycle name is displayed. If touch pad is not pressed

within 5 seconds, screen automatically returns to Cycle Menu.

• STOP/RESET touch pad – press once to stop cycle operation.

Press a second time to abort cycle and return screen to cycle

menu.

NOTE: When cycle is stopped, press Cycle/Start touch pad once to

resume cycle operation. Cycle operation resumes at beginning of

interrupted phase function (i.e., filling, recirculating, draining). When

cycle is aborted, cycle operation is discontinued and cycle must be

re-started from the beginning.

3.4.3 Manual Control Touch Pads

• EXTEND PHASE touch pad – press to temporarily increase

selected phase time. On completion of cycle, phase time returns

to programmed setpoint.

• BYPASS PHASE touch pad – press to bypass specific phase in

progress and advance cycle to next phase.

NOTE: Bypass Phase touch pad can only be used when a cycle

is in progress. During cycle, filling and draining functions can not

be bypassed. In addition, a phase can not be bypassed if

Temperature Guarantee feature is selected for that phase.

• MANUAL MENU touch pad – press to view washer functions

which can be controlled manually.

• ALARM REPLY touch pad – press to turn off alarm buzzer and

acknowledge displayed alarm message. Refer to S

ROUBLESHOOTING, for specific alarm conditions and corrective

T

ECTION 7,

actions.

3.4.4 Program Touch Pads Program touch pads allow programming of twelve distinct cycles

and changing of previously programmed cycle values to process

different types of loads. Cycle programming may be limited by

access code to ensure process integrity. Refer to S

PROGRAMMING, for details on cycle programming and access code

feature.

• CHANGE VALUES touch pad – press to access Change Values

mode. Change Values mode allows authorized operators to

change user-programmable items. Refer to S

PROGRAMMING, for details about Change Values Mode.

ECTION 5, CYCLE

ECTION 5, CYCLE

NOTE: Examples of user-programmable items include cycle

name, phase temperature, phase time, and questions regarding

phase options (e.g., retention of final rinse water).

3-4

122997-341 Operator Manual Component Identification

• CURSOR (left or right) touch pad – press until item to be

PRINT

PRINT

VALUES

Figure 3-4. Printer

Thermal Paper

Take-Up Spindle

Printer Door

changed (word, letter, or number) flashes.

• VALUE (up or down) touch pad – depending on item flashing

(selected), press to either toggle between answer selections or

scroll through alphabet and numbers 0 through 9.

NOTE: Alphabet includes characters for an underline (_) and a

space ( ).

• SAVE VALUES touch pad – press to save changes made, exit

Change Values mode and return screen to cycle menu.

3.5 Printer Printer records pertinent cycle data on 2-1/4" wide thermal paper

(see Figure 3-4). Refer to S

on changing paper roll and storing thermal paper.

3.5.1 Printer Function Switch Printer Function Switch controls the following two printer functions:

• PRINT – press top of Printer Function Switch to generate a print

of alkaline and acid detergent setpoints (if conductivity option)

and all RTD temperatures (actual water temperature).

• PRINT VALUES – press bottom of Printer Function Switch to

generate a complete printout of all cycle parameters.

ECTION 6.7, PRINTER PAPER, for information

Component Identification Operator Manual 122997-341

3-5

3.5.2 Sample Printout The following is an example of a typical cycle printout (see Figure 3-5):

Figure 3-5.Sample Printout

* CONTROL ON 8:32:31A

- - - - - - - - - - - - - - - - - - - - - - - CYCLE – CYCLE 1

- - - - - - - - - - - - - - - - - - - - - - - -

CYCLE START 8:37:33A

CYCLE DATE 4/24/05

CYCLE NUMBER 00000001

UNIT NUMBER 3600000000

PHASE TIME F

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PRE-WASH 8:38:03A 141.5

8:39:03A 135.0

DET-WASH 8:41:33A 146.3

8:46:33A 144.2

RINSE 1 8:49:10A 183.5

8:50:40A 182.7

RINSE 2 8:53:00A 184.0

8:54:30A 182.5

F. RINSE 8:57:20A 184.3

8:58:50A 183.8

EXHAUST 8:59:50A 183.8

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

CYCLE COMPLETE 9:01:20A

MAX WASH TEMP= 146.3F

MAX RINSE TEMP= 184.3F

CYCKE TIME= 0:23:27

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - READY TO UNLOAD

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

DOOR OPENED 9:03:42A

Cycle Start In-Cycle Performance

End-of Cycle Performance

Summary

Figure 3-6. Sample Alarm Printout

PHASE TIME F

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PREWASH 10:15:20A 163.5

10:17:02A 166.8

* ALARM 10:18:02A

SUMP

TOO LONG IN FILL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ALARM ACKNOWLEDGED

AT 10:18:15A

• POWER UP

When POWER-OFF/STANDBY switch is set to POWER,

generated printout lists time and date control was turned on and

unit’s serial number.

• CYCLE START

When CYCLE/START touch pad is pressed twice to begin

selected cycle, generated printout lists name of cycle started,

time and date cycle was started, cycle number, and unit

number.

• IN-CYCLE PERFORMANCE

During a cycle, generated printout lists start and end time of

each phase, along with actual temperature of solution/water in

chamber sump.

• END-OF-CYCLE PERFORMANCE SUMMARY

At end of a cycle, generated printout lists time cycle was

completed, maximum wash and rinse temperatures reached

during cycle, and total cycle processing time.

• ALARM CONDITION

When an alarm condition occurs, generated printout lists type of

alarm and time it occurred (see Figure 3-6). Once operator

presses Alarm Reply touch pad, generated printout lists time

alarm was acknowledged.

3-6

122997-341 Operator Manual Component Identification

3.6 Unload-Side

Figure 3-7. Unload-Side Control Panel

Second Control

Column

Additional Chamber

Door on Unload Side

Figure 3-8. Oscillating Jet System

Spray Jets

Spray

Headers

Oscillating

Carriage

Control Panel

An additional control column is installed on unload side of unit (see

Figure 3-7). The unload side control panel features same touch pads

and display screen as load end control panel.

All washer functions except POWER-OFF/STANDBY and PRINT/

PRINT VALUES can be directed from this control panel, and display

screen concurrently shows same cycle performance data as loadside control panel.

3.7 Oscillating Jet System

Oscillating jet system consists of two spray headers, one on each

side of wash chamber, suspended from an oscillating carriage (see

Figure 3-8). Each spray header is equipped with machined jets

angled to reach all surfaces of load.

Oscillating jet system travels back and forth along length of chamber

during recirculating/spraying phase function. Jet system is equipped

with a safety clutch that stops movement of oscillating carriage if an

obstruction is detected.

Component Identification Operator Manual 122997-341

3-7

3.8 Safety System Chamber doors are equipped with a safety switch to stop washer

WARNING – PERSONAL

INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

To open doors from inside

wash chamber, pull EMERGENCY STOP cables.

Washer operation will automatically stop. Then, push

firmly on door panel using

shoulder and upper arm,

applying upper body force.

Figure 3-9. Safety Cables

Safety

Cables

operation if door is opened during a cycle and to prevent start of

washer operation if door is not securely closed.

Chamber doors are also equipped with a spring-loaded, explosion

relief type safety latch. Door can be easily opened when pushed

from inside of wash chamber.

Two stainless-steel, red-coated safety cables are installed inside

wash chamber, one along each side (see Figure 3-9). If cable is

pulled, washer operation is immediately stopped.

Oscillating jet system is equipped with a mechanical clutch to disengage carriage drive if an obstruction is encountered, preventing

damage to spray headers and load items.

Load-side and unload-side control panels are equipped with STOP/

RESET touch pads. Press touch pad once to stop cycle operation,

and twice to abort cycle.

3-8

122997-341 Operator Manual Component Identification

3.9 Heat Exchanger Washer is equipped with a steam heat exchanger and valving sys-

Figure 3-10. Heat Exchanger

Heat

Exchanger

Heat

Exchanger

Steam

Throtling

Valve

tem to preheat incoming fill water, reducing normal water/solution

heat-up time (see Figure 3-10).

System is fully automatic and works during filling function of Prewash, optional Acid Wash (if acid tank is not available), and Rinse

phases. Heat exchanger steam valve is energized only if temperature is below 165°F (73.8°C).

3.10 Automatic

Detergent Injection

System

Automatic Detergent Injection System includes a peristaltic pump

mounted to washer exterior. System also includes a conductivity

probe located in chamber sump.

If using alkaline detergent with injection system, alkaline detergent is

automatically injected into chamber sump during Wash phase of a

cycle.

• Hot detergent solution from alkaline detergent tank fills sump

until required solution level is attained. Once sump is full, control

checks detergent concentration of solution in sump. Alkaline

detergent is then injected into sump until solution reaches set

concentration level. Alkaline detergent solution is monitored and

maintained at set concentration level while recirculating and

spraying over load.

If using acid detergent with injection system, acid detergent is automatically injected into chamber sump during Acid Wash phase of a

cycle.

• Hot detergent solution from acid detergent tank fills sump until

required solution level is attained. Once sump is full, control

checks detergent concentration of solution in sump. Acid

detergent is then injected into sump until solution reaches set

concentration level. Acid detergent solution is monitored and

maintained at set concentration level while recirculating and

spraying over load.

Component Identification Operator Manual 122997-341

3-9

3.11 Reusable-

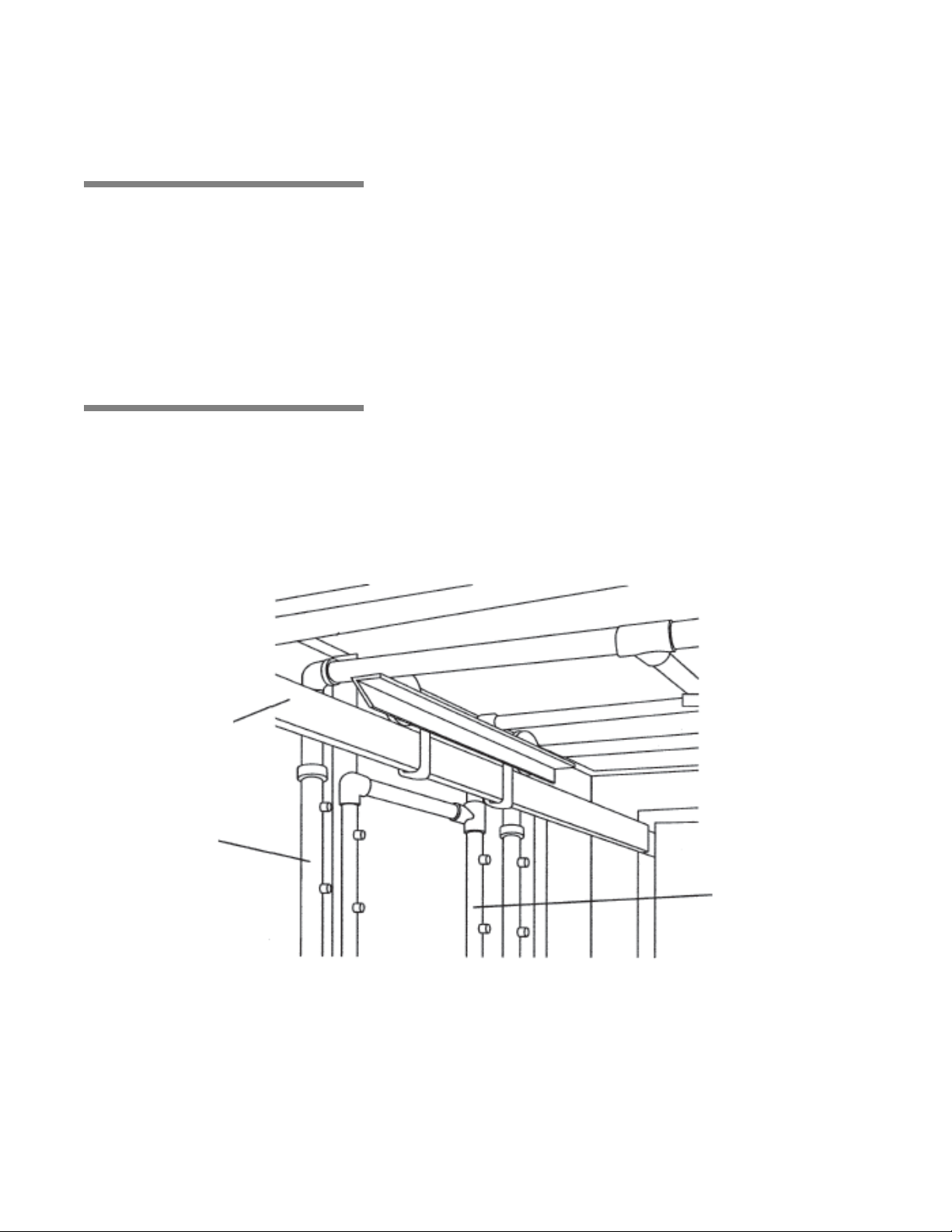

Figure 3-11. Non-Recirculated Final Rinse Spray Header

Separate Spray Header

for Fresh Water

Carriage Rail

Main Spray Header

Throwaway Acid

Detergent System

Washers equipped with Reusable-Throwaway Acid Detergent System can be programmed to process an Acid Wash phase after

Detergent Wash phase, and to either save or drain acid detergent

solution on completion of phase.

System includes a separate acid detergent tank and piping constructed of stainless steel. Acid detergent tank is equipped with a

steam coil to maintain acid detergent solution at programmed temperature.

3.12 Non- Recirculated Final Rinse

Washers equipped with Non-Recirculated Final Rinse System can be

programmed to spray load with fresh, non-recirculated water during

standard Final Rinse phase. System includes a separate spray

header mounted directly to each side of oscillating carriage, inside

of main spray headers (see Figure 3-11).

3-10

122997-341 Operator Manual Component Identification

3.13 Feeder Bottle Washing System

Feeder Bottle Washing System provides capability of processing a

loaded bottle cart during normal cycle operation. System includes a

quick disconnect coupler.

NOTE: Bottle washing cart is available as a separate accessory.

Cycle must be programmed to process bottle cart before starting

cycle operation.

3.14 Automatic Water

Flush System for Two

Racks

Automatic Water Flush System for two racks permits cleaning of

facility’s automatic watering system during normal cycle operation.

System includes a set of two hoses, each equipped with a quick disconnect fitting, mounted on service side carriage rail.

Hoses are manually connected to customer cage watering racks

moved into wash chamber. During Final Rinse filling, fresh hot water

is sent through heat exchanger and sprayed over cage watering

racks for programmed filling time interval.

Component Identification Operator Manual 122997-341

3-11

3.15 Drain Discharge

Figure 3-12. Drain Discharge Side Tank (Typical)

Drain Discharge Side

Tank

Cooldown with Side

Tank and Temperature

Guarantee

A separate tank is typically mounted along service side of washer to

temporarily retain and cool all drain discharges (see Figure 3-12).

NOTE: Location of drain discharge side tank may change depending

on other options ordered with washer.

During draining function of each phase, solution/water in sump is

automatically pumped to side tank where cold tap water is added.

Cold water remains on until water temperature in side tank reaches

programmed set point. Once cooled to set temperature, side tank

gravity drains to building drain system.

3-12

122997-341 Operator Manual Component Identification

3.16 Drain Discharge

Figure 3-13. Exhaust Fan

Cooldown System with

Cold Water Injection

Only

3.17 Exhaust Fan Exhaust Fan is mounted directly in washer exhaust line, on top of unit

Washer drain system is piped to automatically cool all drain discharges using building cold water supply.

During draining function of each phase, cold tap water is injected

into washer drain line as washer drain discharges are sent directly to

building drain system. Cold water remains on until sump drain valve

closes.

(see Figure 3-13).

During unit operation, exhaust fan removes residual vapors from

wash chamber and directs vapors to building exhaust duct.

Component Identification Operator Manual 122997-341

3-13

4

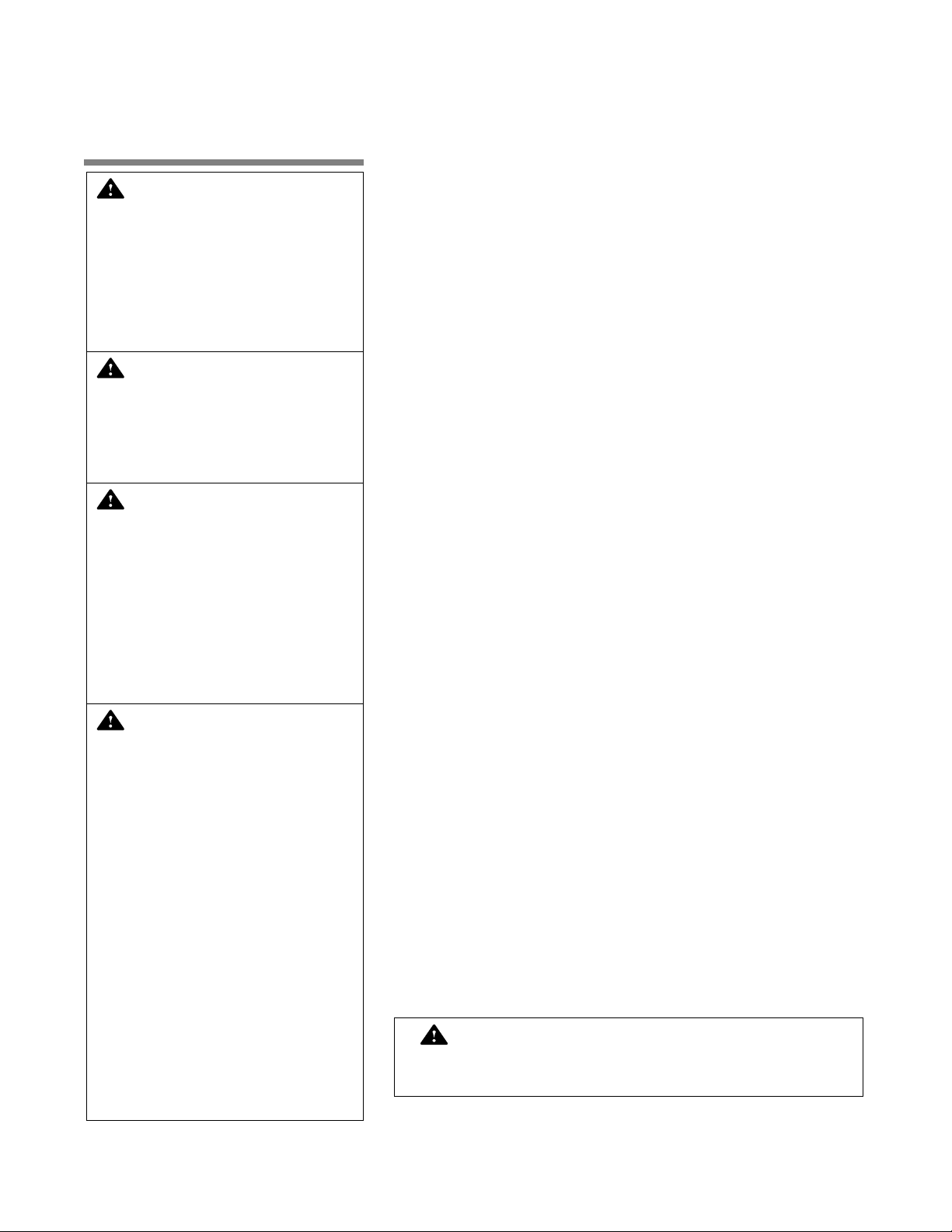

WARNING – CHEMICAL

BURN AND/OR EYE INJURY

HAZARD: Washer chemicals

are caustic and can cause

adverse effects to exposed

tissues. Do not get in eyes,

on skin or attempt to swallow. Read and follow precautions and instructions on

chemical label and in Material Safety Data Sheet

(MSDS) prior to handling

detergent containers, or servicing detergent injection

pumps, tank, and lines. Wear

appropriate Personal Protective Equipment (PPE) whenever handling chemicals or

servicing chemical injection

pumps, tank, and lines.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE:

• Always use non-foaming

chemical for effective

cleaning and proper pump

and water level control

operation. Follow manufacturer’s recommendations for amount of

chemical to be used.

• When choosing a detergent, select one with a low

chloride content. Detergents with a high chl oride

content can corrode stainless steel.

Figure 4-1. Manual Drain Valve

Manual Drain

Valve

WASHER OPERATION

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this Cage

and Rack Washer can be found in S

this information.

ECTION 1. Do not install equipment until you have become familiar with

4.1 Before Operating Washer

Become familiar with location and function of all major components

and controls, as well as their function before operating equipment.

1. Verify building electrical supply disconnect switch (circuit

breaker) is positioned to ON. Verify steam and water supply

valves are open.

2. Open chamber door. Verify chamber is empty and all material

has been removed.

3. Verify debris screens in bottom of sump are clean and properly

installed.

4. Open printer door and check sufficient amount of printer paper

is available.

NOTE: A colored warning stripe is visible when printer paper roll

is near the end. Refer to S

needed.

5. Ensure manual drain valves on bottom of detergent tanks and, if

applicable, optional acid detergent tank are closed (see Figure

4-1).

6. Verify detergent supply (provided by customer). Check sufficient

amount of detergent is available (Refer toS

ING DETERGENT CONTAINER). Ensure supply hose(s) is correctly

placed in detergent container(s) and detergent pump(s) is

turned on.

NOTE: Always use a non-foaming detergent for effective cleaning

and proper pump and water level control operation. To achieve

maximum cleaning efficien cy, sele ct det ergent appro priate to soil

type being processed.

ECTION 6.7, PRINTER PAPER, if paper is

ECTION 6.6.5, REPLAC-

Washer Operation Operator Manual 122997-341

4-1

4.2 How to Load

WARNING – PERSONAL

INJURY HAZARD:

• Keep fingers away from

door hinges to prevent

pinching.

• To prevent tipping, place

biggest and heaviest items

on the lower levels of accessory cart.

WARNING – BURN HAZARD:

When cycle is complete, partially open chamber door and

allow chamber and load to

cool. Hot steam may escape

through door opening if door

is fully opened after a cycle.

WARNING – SLIPPING HAZARD: To avoid slippery floor

conditions, keep floor dry.

Promptly wipe up any spilled

liquids or condensation. If

spilled liquids are detergents

or other chemicals, follow

safety precautions and handling procedures set forth on

detergent or chemical label

and/or Material Safety Data

Sheet (MSDS).

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

• Avoid product damage.

Always select a cycle appropriate for items being processed.

• Before operating unit,

always position manifolded

Bottle Washing Cart over

central water inlet connector. If manifolded accessory

is not positioned correctly,

damage may result and unit

will be unable to effectively

wash load.

• Do not process load using

Bottle Washing Cart when

Automatic Floor Tilting

option is activated. If Automatic Floor Tilting is used,

manifolded water inlet and

washer will be damaged.

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Remove all cellulose-type bedding from cages and

pans before processing. Cellulose bedding can clog

filters and piping.

Washer

To properly clean items and avoid personal injuries, always follow

these general guidelines:

1. Remove gross soil before processing in washer.

2. Use appropriate accessory racks within cart to load items such

as bottles.

3. Assure no items stick out or hang out of the accessory cart.

4. Place biggest and heaviest items on the lower levels of acces-

4-2

122997-341 Operator Manual Washer Operation

sory cart.

5. As an example, proper placement of items in Washing Cart

would be as follows, from the top down

Accessories (see Figure 4-2):

• Bottle Washing Cart – Used for processing up to six bottle

baskets. Requires Manifold Coupling System.

• Pan Cart – Used to wash pans, floor gratings, cage doors,

etc.

• Universal Cage and Wash Cart – Used to wash 54 stan-

dard mouse boxes or 36 standard rat boxes.

• Rodent Cage Rack – Used to hold up to 92 mouse cages or

32 rat cages, or shoe boxes, covers, and feeder tops.

IMPORTANT: Use baskets for handling and cleaning various

size bottles. Lightweight basket design provides easy

handling and simplifies transport and washing of bottles.

• 5 x 5 Bottle Basket – Used to wash 25,16 oz (454 mL) bottles.

• 4 x 6 Bottle Basket – Used to wash 24, 16 oz (454 mL) bottles.

• 5 x 5 Bottle Basket – Used to wash 25 short 4" (10 cm) bottles.

• 4 x 6 Bottle Basket – Used to wash 24 tall 5-1/2" (14 cm) bot-

tles.

6. Open chamber door and push loaded wash cart(s) into wash

chamber.

a. Ensure all cages, racks, etc. are correctly positioned on

wash cart(s).

b. Position cart(s) in center of wash chamber. Verify clearance

space on both sides of cart permits unobstructed movement

of oscillating jet system.

7. Close and latch chamber doors securely.

NOTE: Door safety switch prevents cycle operation unless

door(s) is closed.

8. Start desired cycle.

Washer Operation Operator Manual 122997-341

4-34

122997-341 Operator Manual Washer Operation

Rodent Cage Rack

Universal Cage and Pan Wash Cart

Bottle Washing Cart (Typical)

Pan Cart

Figure 4-2. Accessories

4-3

4.3 Cycle Operation Basil

Table 4- 1. Demo ns t rati o n Cycle

Phase Values

Cycle

Phase

Time

(minutes)

Temperature

Pre-

Wash

1:00 HTW

Wash 5:00 140ºF (60ºC)

Rinse 1 1:30 180ºF (82ºC)

Rinse 2 1:30 180ºF (82ºC)

Final

Rinse

1:30 180ºF (82ºC)

Exhaust 1:30 N/A

SELECT

CYCLE

CYCLE

START

CYCLE

START

Rack Washer are equipped with a microcomputer control capable

of storing parameters for twelve distinct cycles. Authorized operators

have capability of customizing/programming all cycles to meet specific washing needs. For instructions on cycle programming or

changing cycle parameters, refer to S

On initial receipt of washer, each cycle is set with a basic demonstration cycle consisting of six sequential phases – Pre-wash, Wash,

Rinse 1, Rinse 2, Final Rinse and Exhaust. Refer to Table 4-1 for

phase values of demonstration cycle.

To begin cycle operation:

1. Set POWER-OFF/STANDBY switch, located behind printer door,

®

4600 Cage and Rack Washer and Basil® 4602 Cage and

ECTION 5, CYCLE PROGRAMMING.

to POWER.

Unit name temporarily appears on screen, then screen displays

first cycle menu:

CYCLE 1

CYCLE 2

CYCLE 3 CYCLE 4

__indicates flashing position.

and printer records:

* CONTROL ON 8:32:31A

4/21/05

NOTE: If printer does not print when POWER-OFF/STANDBY

switch is set to POWER, press top of Printer Function Switch to

turn printer on.

2. Press CYCLE MENU touch pad until desired cycle menu

appears on screen. Display shows:

CYCLE 9

CYCLE 10

CYCLE 11 CYCLE 12

__indicates flashing position.

3. Press SELECT CYCLE touch pad until desired cycle name

flashes.

CYCLE 9 CYCLE 10

CYCLE 11 CYCLE 12

__indicates flashing position.

4. When desired cycle name is flashing, press CYCLE/START

touch pad. Name of selected cycle appears on screen and

remains displayed for five seconds.

PRESS START TO

PROCESS CYCLE 10

5. To start selected cycle, press CYCLE/START touch pad a sec-

ond time while selected cycle name is displayed on screen.

NOTE: If CYCLE/START is not pressed a second time while

selected cycle name is displayed, screen automatically returns to

cycle menu.

4-4

122997-341 Operator Manual Washer Operation

Once selected cycle is started, printer records:

CYCLE - CYCLE 10

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

CYCLE START 8:37:33A

CYCLE DATE 4/24/05

CYCLE NUMBER 00000001

UNIT NUMBER 3600000000

PHASE TIME F

6. Washer automatically progresses through selected cycle as follows:

NOTE: For cycle operation, note the following:

1) Time displayed on screen counts down time remaining for cycle

phase in progress. If Temperature Guarantee feature is selected,

time displayed for that phase only counts down when solution/

water temperature in chamber sump is equal to or greater than

setpoint.

2) Cycle operation may be halted at any time by pressing STOP/

RESET touch pad once. To resume cycle operation at be gin n ing

of interrupted phase function (i.e., fill, recirculate, drain), press

CYCLE/START. To abort cycle operation, press STOP/RESET a

second time.

• PRE-WASH PHASE

>> Hot water, from building supply, fills sump until required

water level is attained.

NOTE: Sump may contain rinse water retained from previous

cycle.

Display shows:

CYCLE 10 135.7f

PREWASH FILL T=2:00

>> Pre-wash water recirculates through oscillating jet system for

programmed time interval. Display shows:

CYCLE 10 139.5F

PREWASH T=1:00

Printer records time and water temperature in chamber sump at

beginning and end of recirculation:

PREWASH 10:18:15A 139.5

10:19:15A 135.0

• pH NEUTRALIZATION (Option)

>> pH analyzer is initialized. Display shows:

STANDBY NEUTRALIZING SUMP

Washer Operation Operator Manual 122997-341

4-5

>> pH analyzer checks to see if value is within limits. Display

shows:

CHECKING pH

pH = XX.XXX

>> If pH is too low while injecting, acid Neutralizer is injected

to compensate. Display shows:

pH TOO LOW

INJECTING ACID NEUT.

>> Water-Acid neutralizer solution is mixed. Display shows:

pH TOO LOW

MIXING WATER

>> If pH is too high while injecting, alkaline neutralizer is

injected to compensate. Display shows:

PH TOO HIGH

INJECTING ALK. NEUT.

>> Water-Alkaline neutralizer solution is mixed. Display shows:

pH TOO HIGH

MIXING WATER

>> Water contained in traveling spray header is sent to sump

(all units). Display shows:

CYCLE 10 128.5F

HEADER DRAIN T= 1:00

>> Sump water is pumped to drain. Display shows:

CYCLE 10 128.5F

PREWASHDRAIN T= 1:00

>> Water still present in sump is gravity-drained (option).

Displays shows:

CYCLE 10 128.5F

GRAVITY DRAIN T= 1:00

• ALKALINE WASH PHASE

>> Hot water, from alkaline wash tank, fills sump. If temperature

is guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=)137.4F

ALK. WASH FILL T= 2:00

NOTE: Control alternates between these display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than

setpoint.

>> Water is heated while recirculating (CONDUCTIVITY

OPTION ONLY). If temperature is guaranteed actual sump

temperature alternates with guaranteed set temperature.

Display shows:

4-6

122997-341 Operator Manual Washer Operation

CYCLE 10 (G=)141.5F

RECIRC./HEATING T= 5:00

NOTE: Control alternates between these display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than

setpoint.

>> Alkaline detergent is injected into sump. If temperature is

guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=)141.5F

INJECTING ALK. T= 5:00

NOTE: Control alternates between these display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than

setpoint.

>> Detergent solution is recirculated through oscillating jet

system for programmed amount of time. If temperature is

guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=)140.4F

ALKALINE WASH T= 5:00

NOTE: Control alternates between these display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than

setpoint.

Printer records time and solution temperature in chamber sump

at beginning and end of recirculation:

ALK. WASH 10:21:55A 141.5

10:26:55A 140.2

• TIME-BASED pH NEUTRALIZATION (Option)

Alkaline neutralizer is injected during programmed amount of

time. If temperature is guaranteed, actual sump temperature

alternates with guaranteed set temperature. Display shows:

CYCLE 10 (G=) 167.8

ALK.NEUTRALIZE T = 2:00

• CONTROLLER-DRIVEN pH NEUTRALIZATION (Option)

>> pH analyzer is initialized. Display shows:

STANDBY

NEUTRALIZING SUMP

>> pH analyzer checks to see if value is within limits. Display

shows:

CHECKING pH

pH = XX.XXX

Washer Operation Operator Manual 122997-341

4-7

>> If pH is too low while injecting, acid neutralizer is injected

to compensate. Display shows:

pH TOO LOW

INJECTING ACIDNEUT.

>> Water-Acid neutralizer solution is mixed. Display shows:

pH TOO LOW

MIXING WATER

>> If pH is too high while injecting, alkaline neutralizer is

injected to compensate. Display shows:

pH TOO HIGH

INJECTING ALK.NEUT.

>> Water-Alkaline neutralizer solution is mixed. Display shows:

pH TOO HIGH

MIXING WATER

>> Water contained in traveling spray header is sent to sump. If

temperature is guaranteed, actual sump temperature

alternates with guaranteed set temperature. Displays shows:

CYCLE 10 (G=) 128.5F

HEADER DRAIN T= 1:00

>> Sump water is pumped to drain. If temperature is

guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=)128.5F

ALK.DRAIN T= 1:00

>> Water still present in sump is gravity-drained (option). If

temperature is guaranteed, actual sump temperature

alternates with guaranteed set temperature. Display shows:

CYCLE 10 (G=)128.5F

GRAVITYDRAIN T= 1:00

>> If water saver is enabled, sump water is sent back to

alkaline tank. If temperature is guaranteed, actual sump

temperature alternates with guaranteed set temperature.

Display shows:

CYCLE 10 (G=)138.7F

ALK.SAVER T= 2:00

>> If sump flush option is available, water still present in

sump is gravity drained. If temperature is guaranteed, actual

sump temperature alternates with guaranteed set

temperature. Display shows:

CYCLE 10 (G=) 128.5F

FLUSH DRAIN T= 00:45

>> If sump flush option is available, water is injected in sump

to remove debris. If temperature is guaranteed, actual sump

temperature alternates with guaranteed set temperature.

Display shows:

CYCLE 10 (G=) 128.5F

FLUSHFILL T= 2:00

4-8

122997-341 Operator Manual Washer Operation

>> If sump flush option is available, refreshed water still

present in sump is gravity drained. If temperature is

guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=) 128.5F

FLUSHDRAIN T= 2:00

• ACID WASH PHASE

>> Hot water, from building supply (or from acid wash tank, if

option applies) fills sump. If temperature is guaranteed,

actual sump temperature alternates with guaranteed set

temperature. Display shows:

CYCLE 10 (G=) 137.4F

ACIDWASHFILL T= 2:00

NOTE: Control alternates between th ese display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than setpoint.

>> Water is heated while recirculating (CONDUCTIVITY

OPTION ONLY). If temperature is guaranteed, actual sump

temperature alternates with guaranteed set temperature.

Display shows:

CYCLE 10 (G=) 141.5F

RECIRC/HEATING T= 5:00

NOTE: Control alternates between th ese display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than setpoint.

>> Acid detergent is injected into sump. If temperature is

guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=) 141.5F

INJECTINGACID T= 5:00

NOTE: Control alternates between th ese display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than setpoint.

>> Detergent solution is recirculated through oscillating jet

system for programmed amount of time. If temperature is

guaranteed, actual sump temperature alternates with

guaranteed set temperature. Display shows:

CYCLE 10 (G=) 140.0F

ACIDWASH T= 5:00

NOTE: Control alternates between th ese display screens every

four seconds during recirculation. Displayed time only counts

down when solution temperature is equal or greater than setpoint.

Washer Operation Operator Manual 122997-341

4-9

Printer records time and solution temperature in chamber sump

at the beginning and end of recirculation:

ACID WASH 10:21:55A 141.5

10:26:55A 140.2

>> Load is soaked in Acid solution for programmed amount of

time. If temperature is guaranteed, actual sump temperature

alternates with guaranteed set temperature. Display shows:

CYCLE 10 (G=) 167.8F

ACIDSOAK T= 2:00

• TIME-BASED pH NEUTRALIZATION (Option)

>> Acid neutralizer is injected during programmed amount of

time. If temperature is guaranteed, actual sump temperature

alternates with guaranteed set temperature. Display shows:

CYCLE 10 (G=) 167.8F

ACIDNEUTRALIZ T= 2:00

• CONTROLLER-DRIVEN pH NEUTRALIZATION (Option)

>> pH analyzer is initialized. Display shows:

STANDBY

NEUTRALIZING SUMP

>> pH analyzer checks to see if value is within limits. Display

shows:

CHECKING pH

pH=XX.XXX

>> If pH is too low while injecting, acid neutralizer is injected

to compensate. Display shows:

pH TOO LOW

INJECTING ACIDNEUT