UNCRATING/INSTALLATION INSTRUCTIONS

®

Basil

3500 Cage and Bottle Washer

(2006-06-14) P122996-977

A WORD FROM STERIS CORPORATION

Follow each step of UNCRATING/INSTALLATION INSTRUCTIONS in the

order presented. Open crate(s) carefully to avoid damage to equip-

ment inside. If you find any indication of damage to equipment (no

matter how slight), show it to your supervisor.

To properly install this unit, you will need equipment drawings (previously furnished), showing all utility service and space requirements.

If drawings cannot be located, replacement copies may be obtained

by writing, faxing or telephoning STERIS, giving serial and model

numbers of your unit.

Once installed, unit operation should be tested by a STERIS-trained

service technician prior to your equipment usage.

Advisory IMPORTANT: Basil

®

3500 Cage and Bottle Washer is specifically

designed to only process goods as outlined in this manual.

A listing of Safety Precautions to be observed when uncrating,

installing and testing this equipment can be found in S

ECTION 1 of

this manual. Do not begin uncrating/installing equipment until you

have become familiar with this information.

Any alteration of this equipment not authorized or performed by

STERIS could void the warranty, adversely affect its efficacy, and

violate national, state, and local regulations.

STERIS supervision is recommended for installing and starting up

this equipment. Contact STERIS for information on this service.

IMPORTANT: Be sure to verify the Occupational Health and Safety

Act, as well as local electric and plumbing codes, for any special

requirements that may pertain to installation of this unit.

Indications for Use Basil 3500 Cage and Bottle Washers are specifically designed for

thorough, efficient cleaning of cages, bottles, debris pans and miscellaneous items used in the care of laboratory animals.

This washer is specifically designed to only process goods as outlined in Operator Manual (P122998-741). If there is any doubt about

a specific material or product, contact product manufacturer for recommended washing technique.

©2006, STERIS Corporation. All rights reserved. Printed in Canada.

Introduction Uncrating/Installation Instructions 122996-977

i

Service Information A thorough preventive maintenance program is essential to safe and

proper unit operation. Customers are encouraged to contact STERIS

concerning extended service maintenance agreements to give their

washer planned maintenance ensuring equipment performance

according to factory specifications.

A global network of skilled service specialists can provide periodic

inspections and adjustments to help ensure low-cost peak performance. STERIS representatives can provide information regarding

annual maintenance agreements.

STERIS carries a complete line of accessories for use in this equipment. Please contact STERIS for details.

Man uf ac tu re r:

Corporation STERIS

Can ad a

Beauport, Qc, CANADA

The base language of this document is

ENGLISH. Any translations must be made

from the base language document.

ISO 13485

ISO 9001

Certified

Facility

EC Authorized Representative:

STERIS Limited

STERIS House

Jays Close

Viables

Basingstoke

Hampshire

RG22 4AX

Sales and Service:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

440-354-2600 • 800-444-9009

www.steris.com

ii

122996-977 Uncrating/Installation Instructions Introduction

TABLE OF CONTENTS

Section Title Page

A WORD FROM STERIS CORPORATION .................................................. i

Advisory .................................................................................................................................. i

Indications for Use .................................................................................................................. i

Service Information ................................................................................................................ ii

1 SAFETY PRECAUTIONS .................................................................... 1-1

2 UNCRATING INSTRUCTIONS ........................................................... 2-1

2.1 Open Crates .................................................................................................................2-1

2.2 Disassembled Unit Assembly .......................................................................................2-3

2.3 Move Washer and Remove Skid................................................................................... 2-5

2.4 Prepare Washer for Installation .....................................................................................2-8

3 INSTALLATION INSTRUCTIONS ....................................................... 3-1

3.1 Technical Specifications ...............................................................................................3-1

3.1.1 Voltage, Amperage and Power Consumption .......................................................3-1

3.1.2 Permissible Environmental Conditions .................................................................. 3-1

3.1.3 Seismic Anchorage System ..................................................................................3-1

3.2 Installation Requirements .............................................................................................3-2

3.3 Installation .....................................................................................................................3-3

3.4 Connect Utilities ............................................................................................................3-3

3.5 Cleanup ........................................................................................................................3-4

4 INSTALLATION VERIFICATION ........................................................ 4-1

4.1 General .........................................................................................................................4-1

4.2 Installation Checklist .....................................................................................................4-1

5 OPERATIONAL TEST ........................................................................ 5-1

Table of Contents Uncrating/Installation Instructions 122996-997

iii

SAFETY PRECAUTIONS

The following Safety Precautions must be observed when uncrating, installing and testing this Basil® 3500 Cage

and Bottle Washer. WARNING indicates potential for personal injury and CAUTION indicates potential for damage to equipment. For emphasis, certain Safety Precautions are repeated throughout the manual. It is important

to review ALL Safety Precautions before uncrating and installing the unit.

1

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Use a forklift to move unit.

WARNING – LACERATION HAZARD:

Wear gloves to protect your hands when removing bolts.

WARNING – BURN HAZARD:

Allow piping to cool before inspecting piping and/or cleaning supply line strainers or valves.

Except for an emergency, do not open door when cycle is in progress. In a emergency, first stop cycle

by pressing STOP touch pad and wait for water flow to stop. Wear appropriate Personal Protective

equipment (PPE) whenever reaching into chamber.

When checking automatic stop feature, wear appropriate Personal Protective equipment (PPE) and

open chamber door slowly. Hot water/steam may be sprayed through door opening if door is opened

during a cycle.

WARNING – SLIPPING HAZARD:

To prevent slips, keep floor dry. Promptly clean up any spills or condensation. If spilled liquids are detergents or other chemicals, follow safety precautions and handling procedures set forth on detergent or

chemical label and/or Material Safety Data Sheet (MSDS).

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Once three-phase power is connected, check pump for correct rotation. Incorrect pump rotation may

result in pump damage and improper cleaning action.

When removing adhesives from stainless steel, use a solvent specially formulated for that purpose. Rub

in a back-and-forth motion (in same direction as surface grain). Solvent rubbed in a circular motion or

applied with a wire brush or steel wool on door and chamber assemblies can be harmful to stainless

steel. Do not use solvents on painted surfaces.

Safety Precautions Uncrating/Installation Instructions 122996-977

1-1

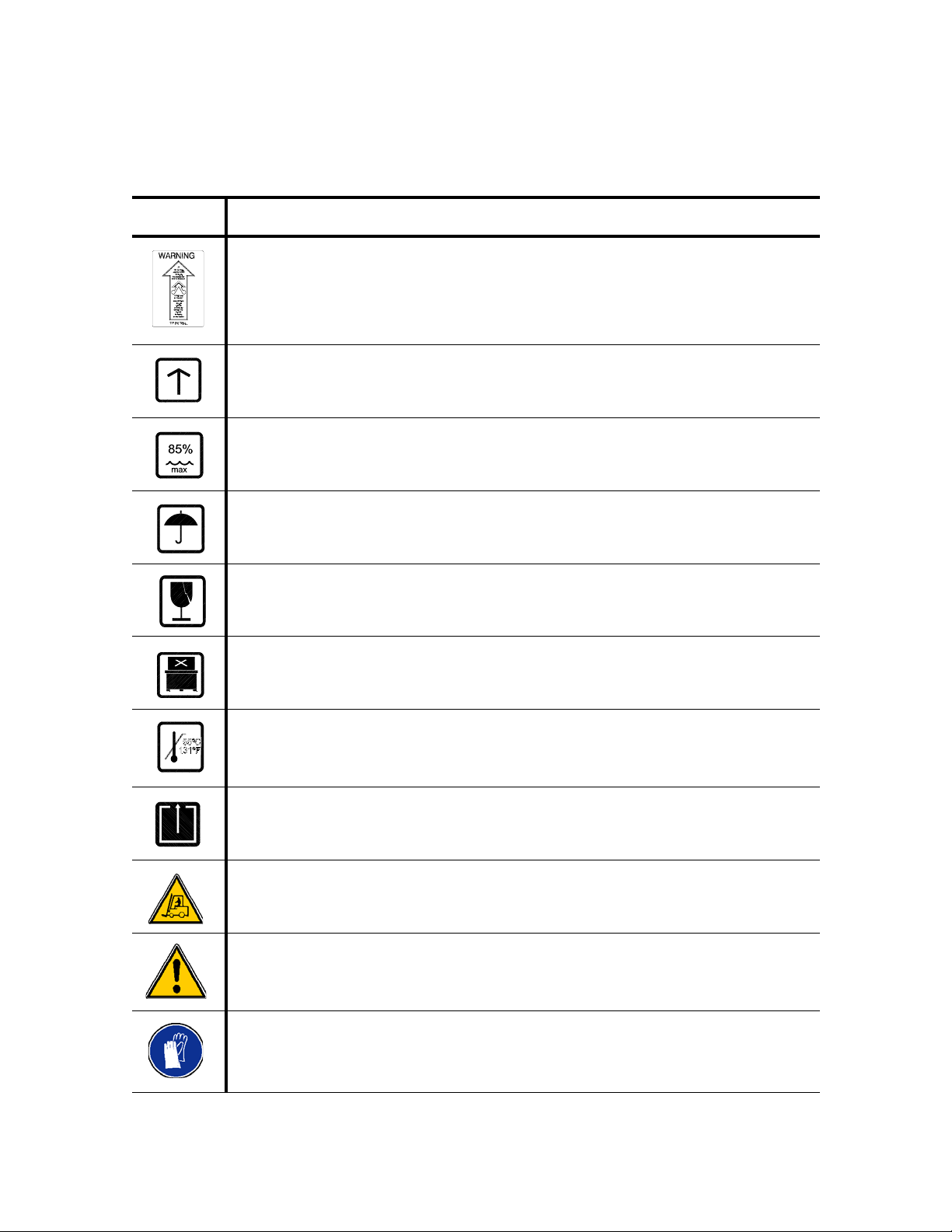

The tables below contain symbols which may be on your Basil 3500 Cage and Bottle Washer components:

Table 1-1. Symbols on Crate

Symbol Definition

Tip Indicator.

"If TIP 'N TELL arrow point is blue, this package has been on its side or tipped over

in transit. Make note on the bill of lading and check for damage. Any claims for tipping will be based on this notation."

This Side Up.

Maximum Relative Humidity.

Keep Dry.

Fragile.

Do Not Stack.

Maximum Temperature.

Open This Side.

Equipment contained in this crate is very heavy. Use a lift truck to move. Uncrate on

a level floor, as near as possible to the final installation location.

Personal injury and/or equipment damage hazard.

Always use tools appropriated for the task to be performed.

1-2

122996-977 Uncrating/Installation Instructions Safety Precautions

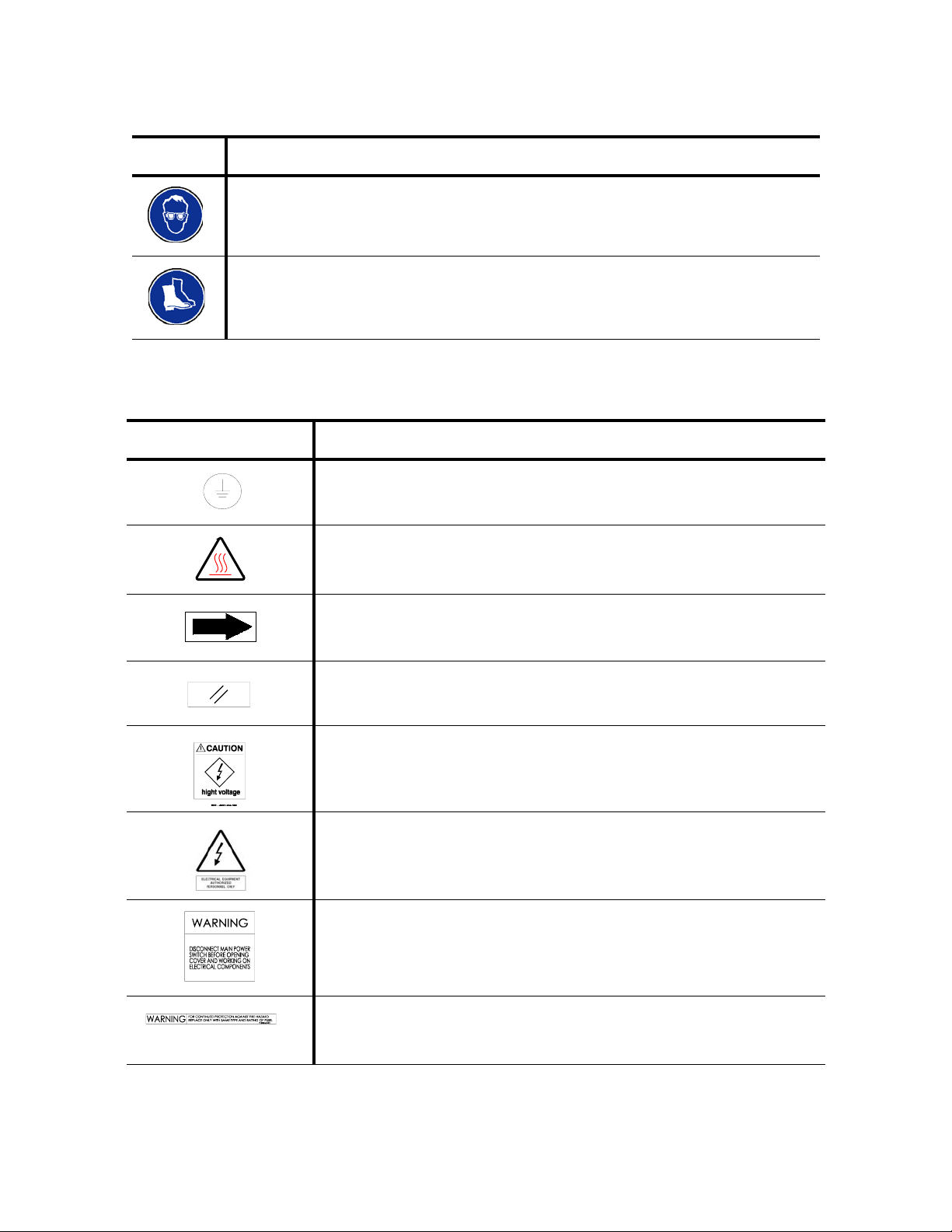

Table 1-1. Symbols on Crate (Cont’d)

Symbol Definition

Always use tools appropriated for the task to be performed.

Always use tools appropriated for the task to be performed.

Table 1-2. Definition of Symbols on Unit

Symbol Definition

Protective Earth (Ground).

Transfer of Heat, Hot Surface.

Rotation: Direction of Rotation Device.

Reset.

CAUTION. High Voltage.

ELECTRICAL EQUIPMENT.

Authorized Personnel Only.

WARNING.

Disconnect Main Power switch before opening cover and working on

electrical components.

WARNING.

For continued protection against fire hazard replace only with same

type and rating of fuse.

Safety Precautions Uncrating/Installation Instructions 122996-977

1-3

Table 1-2. Definition of Symbols on Unit (Cont’d)

Symbol Definition

DANGER.

Do not Operate Without Guards in Place.

WARNING! Chemical Burn Hazard:

Washer detergents are caustic...

Read and follow the precautions...

Wear protective gloves...

WARNING. Burn Hazard.

Surface May Be Hot

CAUTION

Always Cut OFF Electrical Supply Before Doing Any Repair.

Table 1-3. Definition of Symbols on Identification Nameplate

Symbol Definition

MODEL Model Number of The Unit.

S/N Serial Number of The Unit.

YEAR Year of Manufacture of The Unit.

kVA Kilovolt-Ampere.

V_~ Volt, Number of Phase (3 or 1[blank]), Alternate Current.

A Amperage.

Hz Hertz – Frequency of The Unit.

WIRE Number of Wires In The Electrical Cable (Ground Not Included).

PE Protective Ground Wire.

1-4

122996-977 Uncrating/Installation Instructions Safety Precautions

UNCRATING INSTRUCTIONS

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating and installing this Cage

and Bottle Washer can be found in S

this information.

2.1 Open Crates NOTE: When opening crate, note the following:

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD:

move unit.

WARNING – LACERATION

HAZARD:

tect your hands when removing bolts.

Use a forklift to

Wear gloves to pro-

ECTION 1. Do not install equipment until you have become familiar with

1) Use a forklift to move equipment.

2) Uncrate on level floor as close to installation site as possible.

IMPORTANT: Become familiar with components and installation

instructions before installing washer.

NOTE: Bring in and uncrate only one crate at a time.

1. Check tip indicator, located on upper left side of crate. Tip

Indicator contains a blue compound at bottom of indicator. If unit

has been tipped, residue from blue compound will be found

higher up in indicator. If unit has been tipped, notify STERIS. A

service technician will review equipment and determine if unit

was damaged.

2. Position unit to open crate from top. Provide a clear work area on

all sides.

3. Remove and discard wooden panels from top and sides of unit.

4. Remove and discard wooden frame from around unit.

2

5. Remove and discard polystyrene wrap from around unit.

6. For an assembled unit, go to S

REMOVE SKID.

ECTION 2.3, MOVE WASHER AND

Tip N-Tell

Indicator

2

1

Skid

Figure 2-1. Crate(s)

Uncrating Instructions Uncrating/Installation Instructions 122996-977

2-1

• Disassembled Unit:

NOTE: When uncrating unit, note the following:

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD:

Use a forklift to move

unit.

WARNING – LACERATION

HAZARD: Wear gloves to protect your hands when removing bolts.

1) Bring in and uncrate only one crate at a time.

2) Major components in crates are numbered to assist in inventory

and assembly of unit. Review crate contents by matching numbers on components to numbers in parenthesis ( ).

3) Bolts, washers, nuts, and other items needed for the assembly of

unit are in a box labeled HARDWARE, inside Crate 2.

A fully equipped, disassembled unit should consist of two crates:

• Crate 1 contents:

- Frame and sump assembly (corners 1-4 and 2-3);

- Top assembly (20)

• Crate 2 contents:

- Two side panels: load side (6) unload side (7);

- Control panel (5);

- Control box (8);

- Two stainless piping and two brass piping (9, 10, 11, 12);

- Frame supports (21) [for 1, 2, 3, 4];

- Six guides (22) for oscillating spray header;

- Counterweights (23), two for single door units, four on double

door units;

- Door(s): load-side [for single door unit] (24), unload-side (25)

[or back panel for single-door unit];

- Service panels: service-side (26), nonservice-side (27);

- Side panels (1, 4 and 2, 3);

- Oscillating Spray header (28);

- Flexible hose (29);

- Two brackets (30) [for control box and side panels]

- Guides taped on hardware box;

- Envelope taped on hardware box containing:

Manuals, Warranty Card, and Pre-In-Service form. Ensure

appropriate person receives documentation.

- Hardware box (P117942-853):

Screws, bolts, washers, spring washers, wire connectors,

silicone tubes, sealant gun, etc.

- Insulating wool.

2-2

122996-977 Uncrating/Installation Instructions Uncrating Instructions

2.2 Disassembled Unit Assembly

NOTE: Before uncrating washer, take note of the following:

1) Uncrate washer as close as possible to installation site.

2) Refer to equipment drawing and seismic anchorage report, for

complete installation details.

1. Use a forklift to move top of unit from crate and set aside.

WARNING – PERSONAL

INJURY AND/OR EQUIPMENT

DAMAGE HAZARD: Use a

forklift to move unit.

Apply Silicone Here

2. Use a forklift to move frame assembly (bottom part of washer).

Remove four lag bolts securing washer base to skid. Install

frame assembly in place. Each corner is numbered 1, 2, 3, and 4

to ease frame support installation.

3. Using a spirit level, level frame assembly (end-to-end and sideto-side). If necessary, lift assembly and adjust four leveling legs

(one on each bottom corner of assembly). Lower assembly and

verify level.

4. Cut tie-wraps to remove floor grate from sump and set aside.

5. Install unit sides as follows (see Figure 2-2):

a. Install frame supports (1,4). Match support numbers with

those on frame assembly.

b. Apply a generous coat of silicone over sump walls, as shown

on Figure 2-2

c. Install left side panel. Secure left side panel to unit sump

using four 5/16-18 x 3/4 bolts,

6. Repeat Step 5 for right side wall. Use (2, 3) supports.

20

Apply Silicone Here

4

1/4-20 x 1/2" Flat

Head Screws

Apply Silicone Here

1/4-20 Bolts and Nuts

Apply Silicone Here

3

1/4-20 Bolts and Nuts

1/4-20 x 1/2" Flat Head Screws

2

1

Figure 2-2. Sides and Top Installation

Uncrating Instructions Uncrating/Installation Instructions 122996-977

2-3

IMPORTANT: Install oscillating spray header (28) into wash

chamber before installing door(s) and/or back panel.

7. Secure side walls to front and back of unit using sixteen 1/4-20 x

1/2 flat head screws, sixteen 1/4-20 bolts, and twelve 1/4-20 nuts

provided.

8. Install unit top (20) as follows (see F

IGURE 2-2).

NOTE: A forklift is required to install top.

a. Apply a generous coat of silicone on each side of top, before

bolting it.

b. Install top of unit, over sides. Secure with twenty-four 1/4-20

x 1/2" bolts and 1/4" flat washers provided.

9. Install oscillating spray header guides (22) inside wash chamber.

10. Install oscillating spray header (28).

11. Install unit door(s), chains, and counterweights (two for single

door unit, four for double door unit) as follows (see F

IGURE 2-3):

a. From top of unit, slide door(s) into position.

b. Remove tape securing chain over door slide edge.

c. Position chain over gear; then on mounting bracket, tighten

two bolts on gear to secure gear in place (see F

IGURE 2-3).

d. Repeat for each chain and gear.

e. Lift door and secure open using a 2 x 4" piece of wood.

f. Attach each chain to its counterweight, using chain link

provided.

g. Secure each counterweight sliding guide in position, using

eight 10-32 x 1/4" screws and 1/4" lockwashers provided.

h. Remove piece of wood and verify door for smooth operation.

12. Install piping (9-12). Match numbers on piping ends.

13. On exterior of unit, install load (6) and unload side panels (7).

14. Install control box (8) and control panel (5).

15. Connect flexible hose (29) from sump to oscillating spray

header.

16. Install service panels (26, 27) (and back panel, if option applies).

17. Go to S

2-4

122996-977 Uncrating/Installation Instructions Uncrating Instructions

ECTION 3, INSTALLATION INSTRUCTIONS.

10-32 x 1/4" Bolts

and 1/4"

Lockwashers

Bolt Chain Gear

Counterweight

Door

Figure 2-3. Install Chains and Counterweights

2.3 Move Washer and Remove Skid

TOP VIEW

• Assembled units:

NOTE: A fully equipped, assembled unit weighs approximately

2020 lb (916 kg).

1. With washer still mounted on skid, use a forklift to move washer

to installation site.

2. Open lower service access doors (see F

IGURE 2-4).

3. Verify tip indicator, located inside washer service compartment

(bottom left side). If unit has been tipped, notify STERIS.

4. Remove four lag bolts securing washer base to skid.

5. Remove and discard skid from under washer. If necessary, use

a piece of plywood as a small ramp to slide washer from skid to

floor. See F

IGURE 2-5.

6. Position washer in final location. Use tubing as rollers and roll

washer into position.

7. Go to S

ECTION 3, INSTALLATION INSTRUCTIONS.

Uncrating Instructions Uncrating/Installation Instructions 122996-977

2-5

and Viewing Window

Service Access

Door

Figure 2-4. Basil 3500 Cage and Bottle Washer

Control PanelVertical Sliding Door

2-6

122996-977 Uncrating/Installation Instructions Uncrating Instructions

TOP VIEW

Center of Gravity

FRONT VIEW

SIDE VIEW

Center of Gravity

Anchorage Point

Anchorage Point

Figure 2-5. Center of Gravity

Uncrating Instructions Uncrating/Installation Instructions 122996-977

2-7

2.4 Prepare Washer for Installation

1. Remove all tape from washer.

2. Locate electrical box compartment keys (taped inside Main Control Panel). Give keys to department supervisor.

3. Operator Manual, Warranty Card, and pre-in-service form are

enclosed in an envelope inside wash chamber. Ensure appropriate person receives documentation.

4. Before opening door(s), remove 1/4 - 20 x 4" counterweight

retaining bolts (two on each door) to unlock counterweight (see

F

IGURE 2-6) and allow operation of door(s).

5. Discard all packing material removed during uncrating procedures.

Counterweight Retaining Bolts

(1/4-20 x 4")

Counterweight

TOP VIEW

DOOR

Figure 2-6. Remove Counterweight Retaining Bolts

2-8

122996-977 Uncrating/Installation Instructions Uncrating Instructions

INSTALLATION INSTRUCTIONS

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating and installing this Cage

and Bottle Washer can be found in S

this information.

ECTION 1. Do not install equipment until you have become familiar with

3

3.1 Technical

Specifications

3.1.1 Voltage, Amperage and Power Consumption

These specifications are intended to describe technical information given on nameplate of your washer and to state other relevant information.

Basil® 3500 Cage and Bottle Washer operates on:

• Steam-Heated units:

208 V, 60 Hz, 3-phase;

480 V, 60 Hz, 3-phase.

• Electric-Heated units:

480 V, 60 Hz, 3-phase.

A protective ground is required (Class 1 Equipment).

Maximum currents and power consumptions are indicated on nameplate.

Main supply voltage not exceeding ± 10% of nominal voltage.

Installation category: Overvoltage category II.

Always follow local electrical installation codes.

3.1.2 Permissible

Environmental Conditions

3.1.3 Seismic Anchorage System

Installation Instructions Uncrating/Installation Instructions 122996-997

This equipment is designated to give optimal results under the following conditions:

• Indoor use only;

• Altitude of operation up to: 6,265 ft (2,000 m);

• Maximum relative humidity is 80% for temperatures up to: 88ºF

(31ºC) decreasing linearly to 50% relative humidity at 104ºF

(40ºC);

• Pollution degree 2.

A Seismic Anchorage System is available for high risk seismic

zones.

3-1

3.2 Installation Requirements

Review installation requirements:

1. Clearance space shown on equipment drawing is necessary for

easy installation, proper operation and maintenance of washer.

2. Refer to equipment drawing for barrier wall flange(s) installation.

3. Utility service lines:

• To allow service of unit without shutting off building supply

lines, shutoff valves (not provided by STERIS) should be

installed on steam and water lines to unit. Shutoff valves

must be capable of being locked in OFF position only.

• Disconnect switches (not provided by STERIS) should be

installed in electric supply lines near washer

(see F

IGURE

3-1).

Disconnect switches must be capable of being locked in

OFF position only.

• If this machine is installed next to other equipment, shutoff

valves and disconnect switches should be located so that

service can be shut off to one piece of equipment at a time.

• Utility service requirements are shown on equipment drawing. This machine requires either 208 volts, 60 Hz, 3-phase,

3-Wire; or 480 volts, 60 Hz, 3-phase, 3-wire.

• Check equipment drawing or nameplate for proper voltage

and amperage.

• A protective conductor terminal is required (Class 1 Equipment).

Shut Off Valves

4. Floor under unit is a noncombustible surface.

5. Wall behind unit (if applicable) is a noncombustible surface.

6. Always follow local electrical codes and safety-related work

practices for wiring. Wire gauge should be appropriate to rating

of disconnect switch.

DisconnectSwitch

Figure 3-1. Utility Service Connections

3-2

122996-997 Uncrating/Installation Instructions Installation Instructions

3.3 Installation 1. Place washer, as shown on equipment drawing, in correct

relation to building supply lines. If unit is not at installation site,

refer to S

ECTION 2, UNCRATING INSTRUCTIONS, for proper moving

instructions.

2. Verify washer is level:

• Place a spirit level inside washer chamber.

• Level washer, end-to-end and side-to-side, using leveling

legs located at base of washer.

3. Open lower access panels.

3.4 Connect Utilities 1. COLD WATER (Option) - Purge building cold-water supply line

to remove chips, scale, etc. Connect line to washer. Cold-water

line is required for cold water pre-wash option and drain

discharge cool down.

2. HOT WATER - Purge building hot-water supply line to remove

chips, scale, etc. Connect line to washer, at top of unit.

3. STEAM (Option) - Purge building steam supply line to remove

chips, scale, etc. Connect line to washer, at top of unit. Steam

line is required for wash chamber.

4. STEAM RETURN (Option)- Connect washer steam return line to

building steam condensate return piping.

5. WASTE - Connect washer drain line to building waste line.

6. VENTILATION (Option) - Connect washer ventilation to a dedicated building exhaust.

7. COMPRESSED AIR - Connect unit air connection to building air

supply line.

8. ELECTRIC - Connect washer to building electrical supply. Verify

tight electrical connections.

9. Open building supply valves and check for leaks. Correct if necessary.

Installation Instructions Uncrating/Installation Instructions 122996-997

3-3

3.5 Cleanup 1. Remove any adhesive found on panels and inside chamber with

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

ing adhesives from stainless

steel, use a solvent specially

formulated for that purpose.

Rub in a back-and-forth

(in same direction as surface

grain). Solvent rubbed in a

circular motion or applied

with a wire brush or steel

wool on door and chamber

assemblies can be harmful to

stainless steel. do not use

solvents on painted surfaces.

When remov-

motion

a suitable solvent. Keep solvents away from all painted surfaces

or damage may result.

2. Inspect work area to ensure all materials used during installation

have been removed.

THIS COMPLETES THE INSTALLATION. Contact STERIS to

schedule a service technician to test your installation and show persons designated how to operate equipment. Refer to O

PERATOR

MANUAL (P122998-741).

3-4

122996-997 Uncrating/Installation Instructions Installation Instructions

INSTALLATION VERIFICATION

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating and installing this Cage

and Bottle Washer can be found in S

this information.

4.1 General An equipment drawing, showing all utility and space requirements,

ECTION 1. Do not install equipment until you have become familiar with

was supplied with washer. Clearance space specified on equipment

drawing is necessary for ease of installation and to ensure proper

operation and maintenance of equipment. If documents are missing

or misplaced, contact STERIS giving serial, equipment, and model

numbers of the unit. Replacement copies will be sent to you

promptly.

4

4.2 Installation Checklist

After your washer has been installed by qualified service technicians, complete the following checklist to ensure installation is complete and correct. If you desire, contact STERIS and schedule a

technician to test installation and demonstrate proper equipment

operation.

❑ Lockable shut-off valves (not provided by STERIS), for mainte-

nance purposes, are installed in steam and water lines in compliance with local occupational health and safety regulations, as

well as electric and plumbing codes.

❑ Disconnect switch (not provided by STERIS), for maintenance

purposes and capable of being locked in OFF position only,

installed in electric supply line in same room as washer, and in

compliance with local occupational health and safety regulations, as well as electric and plumbing codes.

NOTE: If unit is installed next to other equipment, shutoff valves

and disconnect switches should be located so that service can be

shut off to one piece of equipment at a time.

❑ Washer is positioned, as shown on equipment drawing, with

required service clearance space and in relation to building supply lines.

❑ Washer is installed between two walls with a key-locked service

door so service side is not accessible to operators.

❑ Building steam line provides maximum dynamic steam pressure

and flow rate to washer as specified on equipment drawing.

❑ Drip leg with steam trap installed in steam supply line.

❑ Building hot water line supplies water to washer at pressure and

temperature specified on equipment drawing.

❑ If applicable, building cold water line supplies water to washer at

pressure specified on equipment drawing.

❑ If applicable, building steam line supplies steam to washer at

pressure specified on equipment drawing.

Installation Verification Uncrating/Installation Instructions 122996-977

4-1

❑ Electrical supply for washer is as specified on equipment draw-

ing.

❑ Condensate return (if applicable) is sized as specified on equip-

ment drawing.

❑ Vent connection (if applicable) is sized as specified on equip-

ment drawing.

❑ Recirculation pump pressure is within 25 to 60 psig. Pump

rotates in direction shown by arrow.

❑ Self-cleaning screen assembly functioning properly.

❑ Header drive system functioning properly.

❑ All piping is leak-free and cabinet joints are completely sealed,

no leaks. (Check by running machine for 1/2 hour.)

❑ Door safety switch(es) functioning properly.

IMPORTANT: After a few weeks of operation, inspect units for leaks.

Retighten all clamps and connections.

4-2

122996-977 Uncrating/Installation Instructions Installation Verification

OPERATIONAL TEST

IMPORTANT: A listing of the Safety Precautions to be observed when uncrating and installing this Cage

and Bottle Washer can be found in S

this information.

ECTION 1. Do not install equipment until you have become familiar with

5

WARNING – BURN HAZARD:

• When checking automatic

stop feature, wear appropriate Personal Protective

Equipment (PPE) and open

chamber door slowly. Hot

water/steam may be

sprayed through door

opening if door is opened

during a cycle.

• Except for an emergency,

do not open door when

cycle is in progress. In an

emergency, first stop cycle

by pressing STOP touch

pad and wait for water flow

to stop. Wear appropriate

Personal Protective equipment (PPE) whenever

reaching into chamber.

• Allow piping to cool before

inspecting piping and/or

cleaning supply line strainers or valves.

CAUTION – POSSIBLE EQUIPMENT DAMAGE: Once threephase power is connected,

check pump for correct rotation. Incorrect pump rotation

may result in pump damage

and improper cleaning action.

WARNING – SLIPPING HAZARD:

To prevent slips, keep floor

dry. Promptly clean up any

spills or condensation. If

spilled liquids are detergents

or other chemicals, follow

safety precautions and handling procedures set forth on

detergent or chemical label

and/or Material safety Data

Sheet (MSDS)

Test procedure included in this section should be performed by a

STERIS or STERIS-trained service technician prior to normal operation of equipment.

1. Open chamber door.

2. Verify wash chamber is empty and all packing material has been

removed.

3. Close door, ensure POWER OFF/STANDBY rocker switch is in

POWER position.

4. Press SELECT CYCLE touch pad, then press START touch

pad. Let cycle run approximately 15 seconds to clear piping system of any foreign matter.

5. Verify pump rotation. Pump should turn in direction shown by

arrow. If pump is rotating in wrong direction, disconnect main

power, reverse any two 3-phase wires and recheck shaft rotation.

6. Wear appropriate Personal Protective Equipment (PPE), verify

automatic stop feature.

a. Being careful of hot water escaping, open front (load-side)

chamber door. Automatic Stop should shut off all service to

chamber. Press ALARM REPLY touch pad to silence

buzzer.

b. If double-door unit, close door and press START. Open

back (unload-side) chamber door (if option applies).

Automatic Stop should shut off all service to chamber. Press

ALARM REPLY touch pad to silence buzzer.

7. Remove four bolts securing self-cleaning filter flange in position.

Remove filter cartridge and clean under water. Replace filter cartridge inside self-cleaning filter and secure flange with four bolts

removed previously.

8. Close door and press START touch pad to resume cycle.

Inspect piping assembly for leaks. If any leaks occur, press

STOP touch pad, tighten hose connections and press START

again.

9. Allow cycle to run to completion. Verify that display shows:

PLEASE OPEN DOOR

AND REMOVE LOAD

10. Open door and unload chamber.

WASHER IS NOW READY FOR NORMAL OPERATION.

Operational Test Uncrating/Installation Instructions 122996-977

5-1

Loading...

Loading...