barfield DC400, DC400A User Instruction

DC400/A

USER INSTRUCTION SUPPLEMENT

M/N DC400/A, P/N 101-00802

Doc. P/N: 61-101-00802.EF2

Revision G

January 7, 2015

_________________________________________

Adapter Module

MOD C, used with

DC400 OR DC400A

Corporate Headquarters

4101 Northwest 29th Street

Miami, Florida 33142

www.barfieldinc.com

Email: gsesales@barfieldinc.com

P/N’s 101-00800 or 101-00850

Digital DC Fuel Quantity Test Sets

For

BEECHCRAFT MODELS

1900/1900C, UA and UB

and

1900C/1900D, UC and UE

Barfield Inc. Confidential and Proprietary Information.

This document and all the information contained herein is the sole property of Barfield Inc.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This entire document is proprietary information and shall not be reproduced or disclosed to a third party without

the express written consent of Barfield Inc.

This document and its content shall not be used for any purpose other than that for which it is supplied.

Copyright © 2015 Barfield Inc. All Rights Reserved.

THIS PAGE INTENTIONALLY LEFT BLANK

APPLICABILITY

This manual is one of a family of manuals, each developed to address an individual

Adapter Module especially designed for the DC-400 / DC-400A Digital Fuel Quantity Test

Sets. It contains complete instructions for the maintenance, inspection, testing,

troubleshooting, and calibration of the Gull Airborne and Ragen Data Fuel Quantity

Systems.

These aircraft include (at the time of this writing):

1900 ............................... S/N UA

1900C ............................. S/N UB

1900C ............................. S/N UC

1900D ............................. S/N UE

61-101-00802.EF2 (REV. G) APP

January 7, 2015 Page iii

THIS PAGE INTENTIONALLY LEFT BLANK

REVISION RECORD

REV.

A

B

C

D

E

F

G

260-00678

260-00729

260-00779

260-01003

260-01076

ECO #

N/A

260-00617

REV. DATE

Mar/17/03

May/20/03

Sep/15/06

Jan/23/09

Apr / 29 / 10

Apr/29/14

Jan/07/15

First Issue. This supplement replaces

56-101-00802 manual and covers MOD B (or

earlier) releases of 101-00802.

For Mod C or later releases of adapter module.

Modifications to the company logo, company

contact information and listed part 101-00814

were implemented. Beech probe adapter cable

101-00829 is a reflection of the said changes to

adapter cable 101-00814.

Updated Company Logo

List of Approved Repair Facilities and

Recertification Information were added (page iv)

Revised per feedback from Beech and added

section 7. System Wiring Integrity Test.

Updated Barfield logos.

DESCRIPTION OF CHANGE

61-101-00802.EF2 (REV. G) REV

January 7, 2015 Page v

THIS PAGE INTENTIONALLY LEFT BLANK

r

LIST OF APPROVED REPAIR FACILITIES

The manufacturer of this equipment does not recommend the user to attempt any maintenance

or repair. In case of malfunction, contact the manufacturer, to obtain the list of approved repai

facilities worldwide, ensuring that this equipment will be serviced using proper procedures and

certified instruments. A Return Maintenance Authorization (RMA) number will be assigned

during this call, to keep track of the shipment and the service.

BARFIELD PRODUCT SUPPORT DIVISION

Telephone: (305) 894-5400 Shipping Address:

(800) 321-1039

Barfield, Inc.

Fax:

Miami, Florida 33142

Email:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

(305) 894-5401 4101 NW 29th Street

gsesales@barfieldinc.com USA

Mailing Address:

Barfield Adapter Module, P/N 101-00802, has a one-year recertification requirement.

Qualified technicians in a shop equipped with the necessary tooling, facilities, and

Barfield-approved procedures must perform the maintenance required by this unit.

61-101-00802.EF2 (REV. G) LOARF

January 7, 2015 Page vii

RECERTIFICATION

THIS PAGE INTENTIONALLY LEFT BLANK

CONTACT INFORMATION

USERS ARE REQUESTED TO

NOTIFY THE MANUFACTURER OF

ANY DISCREPANCY, OMISSION OR

ERROR FOUND IN THIS SUPPLEMENT.

PLEASE SEND YOUR COMMENTS TO:

BARFIELD, INC.

ATTN: GSTE

4101 NORTHWEST 29TH STREET

MIAMI, FL 33142

USA

TELEPHONE (305) 894-5400

(800) 321-1039

FAX (305) 894-5401

EMAIL ADDRESS: gsesales@barfieldinc.com

61-101-00802.EF2 (REV. G) CONTACT INFO

January 7, 2015 Page ix

THIS PAGE INTENTIONALLY LEFT BLANK

TABLE OF CONTENTS

Applicability

Revision Record

List of Approved Repair Facilities / Recertification

Contact Information

Table of Contents

List of Tables

PAGE

1. Description ........................................................................................................ 1

2. Operation

1. System Insulation Test ................................................................................. 3

2. Insulation Test (Individual Probes) ............................................................... 8

3. System Capacitance Test ........................................................................... 12

4. Capacitance Test (Individual Probes) ......................................................... 15

5. Indicator Test ............................................................................................... 21

6. Preferred Calibration Test (with Dry Tanks) ................................................ 26

7. System Wiring Integrity Test ....................................................................... 29

3. Alternate Tests

1. Probes Bench Test ...................................................................................... 34

2. Indicator Bench Test ................................................................................... 37

3. Alternate Calibration (Wet Tanks) ............................................................... 41

61-101-00802.EF2 (REV. G) TOC

January 7, 2015 Page xi

THIS PAGE INTENTIONALLY LEFT BLANK

LIST OF TABLES

PAGE

1. Conductance to Megaohm Conversion ...................................................................... 6

2. Tank Capacitance Empty ........................................................................................... 14

3. Tank Capacitance Full ............................................................................................... 14

4. Probe Capacitance Empty (1900/1900C, UA and UB) .............................................. 18

5. Probe Capacitance Empty (1900C/1900D, UC and UE) ........................................... 18

6. Probe Capacitance Full (1900/1900C, UA and UB) .................................................. 19

7. Probe Capacitance Full (1900C/1900D, UC and UE) ............................................... 19

8. Add for Full .................................................................................................... 27

61-101-00802.EF2 (REV. G) LOT

January 7, 2015 Page xiii

THIS PAGE INTENTIONALLY LEFT BLANK

CHAPTER 1 DESCRIPTION

A. Capabilities

(1) Complete testing of fuel quantity system.

(2) Testing of individual fuel tanks.

(3) Testing of indicators.

(4) Dry and wet tank calibration.

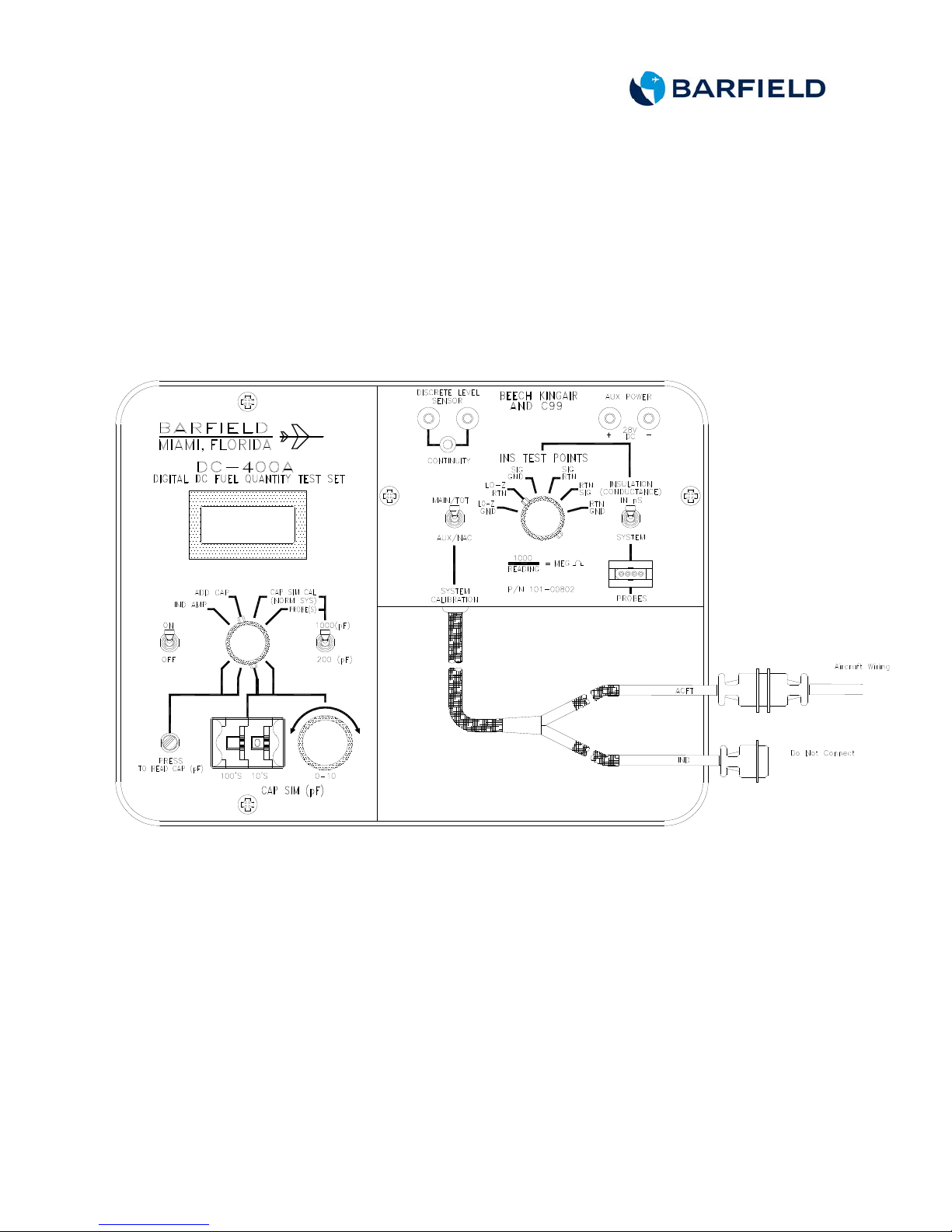

B. Panel Controls

(1) See Instruction Manual 56-101-00850 for details on the DC400A Fuel

Quantity Test Set. See Technical Manual 57-101-00800 for information

on the DC400 Digital Fuel Quantity Test Set.

(2) Refer to Aircraft Maintenance Manual for description of the aircraft fuel

quantity system.

C. Aircraft System Description

(1) Refer to the Aircraft Maintenance Manual for specific procedures and

maintenance practices.

D. Equipment Required (or equivalent)

(1) DC400A Digital Fuel Quantity Test Set, P/N 101-00850 or the DC400

Digital Fuel Quantity Test Set, P/N 101-00800

(2) Barfield Instruction Manual 56-101-00850 (DC400A) or Barfield

Technical Manual 57-101-00800 (DC400)

(3) Fuel Quantity Adapter Module, P/N 101-00802

(4) Probe Adapter Cable, Barfield P/N 101-00829 or 101-00814

(5) Test leads, banana plug to alligator clip, P/N 101-01012

(6) 15-pin adapter cable, Barfield P/N 101-00831 or 101-00817

NOTE: Barfield adapter cables are available as a separate

purchase.

(7) A 1900/1900C/1900D Beech Probe adapter pin

(8) A 28 VDC Power Supply

(9) A Probe Selector Unit:

For 1900/1900C, UA and UB: P/N 114-389001/935

For 1900C/1900D (UC, UE): P/N 118-389004/935

61-101-00802.EF2 (REV. G) CH. 1

January 7, 2015 Page 1 of 44

E. Precautions

(1) Refer to Aircraft Maintenance manual for proper fueling and defueling

procedures. Observe all safety precautions.

(2) Refer to the Aircraft Maintenance manual for location of the system

components and instructions for removal and replacement.

(3) Insure fuel quantity circuit breakers are open and they remain open

while aircraft and test set connections are broken or made.

(4) Insure power remains OFF unless otherwise specified.

F. Preliminary

(1) To insure the integrity of all system components, perform the

Insulation, Capacitance tests first. Then, perform one of the Indicator

tests (System or Bench) and, if necessary, the Probe Bench test.

These tests will provide an effective means for troubleshooting the

system.

(2) After performing an indicator test and before returning the aircraft to

service, calibrate the aircraft fuel quantity system using the Preferred

(or Alternate) Calibration Test.

(3) Failure to calibrate the system could result in an inaccurate fuel

quantity indication.

G. Disclaimer

(1) BARFIELD, INC., neither a vendor nor supplier of fuel quantity systems

or an airframe manufacturer, has no control over calibration figures or

procedures. A variant between actual values and those recommended

may exist. However, the information presented is correct to the best of

our knowledge at time of publication and is presented for reference

only.

61-101-00802.EF2 (REV. G) CH. 1

January 7, 2015 Page 2 of 44

CHAPTER 2 OPERATION

1. SYSTEM INSULATION TEST

Note: Refer to PRECAUTIONS and PRELIMINARY sections (Chapter 1).

Note: This test may be performed with either wet or dry tanks.

A. Aircraft Preparation

(1) Disconnect the aircraft battery.

Caution: When lowering or raising pilot fuel panel, insure aircraft

battery is disconnected.

(2) Access the indicator.

(3) Open the circuit breakers.

Caution: When breaking or making indicator connections, insure that

the applicable circuit breaker(s) are open.

(4) Disconnect the aircraft wiring plug at the indicator.

B. Test Set Preparation

(1) Set the ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to IND AMP.

(3) Set the INSULATION/SYSTEM switch to INSULATION.

(4) Rotate the INS TEST POINTS switch to LO-Z/GND.

(5) Set the AUX/MAIN switch to MAIN/TOT.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 3 of 44

C. Connecting Test Set

(1) Set up the test set (T/S) as shown in Figures 1 and 2.

(2) Connect the test set ACFT connector to the aircraft wiring plug

removed from the indicator.

(3) Connect the test set ACFT connector to the ACFT connector of the

adapter cable.

(4) Do not connect the test set IND connector of the adapter cable.

(5) Do not connect the test set IND connector.

Figure 1 Insulation Test Connector Setup

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 4 of 44

Loading...

Loading...