barfield 1811D User Instruction Manual

1811D (SERIES)

PITOT-STATIC TEST SET

USER INSTRUCTION MANUAL

Doc. P/N: 56-101-00164

Revision F

April 19, 2013

____________________________________

M/N: 1811D, P/N: 101-00164-SERIES

BARFIELD, INC.

Corporate Headquarters

4101 Northwest 29th

Miami, Florida 33142

www.barfieldinc.com

Email: gsesales@barfieldinc.com

Barfield Inc. Confidential and Proprietary Information.

This document and all the information contained herein is the sole property of Barfield Inc.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This entire document is proprietary information and shall not be reproduced or disclosed to a third party without

the express written consent of Barfield Inc.

This document and its content shall not be used for any purpose other than that for which it is supplied.

Street

1811D INSTRUCTION MANUAL

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in

this manual. Inquiries should include specific questions and reference the publication title,

number, chapter, page, figure, paragraph, and effective date.

Please send comments to:

TECHNICAL CUSTOMER SUPPORT - GSTE

BARFIELD, INC.

P.O. BOX 025367

MIAMI, FL 33102-5367

USA

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Email gsesales@barfieldinc.com

56-101-00164 Rev. F Contact

Apr / 19 / 13 Page iii

1811D INSTRUCTION MANUAL

ATTENTION

Although every effort has been made to provide the end user of this equipment with the most

current and accurate information, it may be necessary to revise this manual in the future. Please

be sure to complete and return the enclosed OWNER WARRANTY REGISTRATION CARD to

Barfield in order to validate the warranty and to ensure that you will receive updated information

when published. You MUST

user of this equipment, to be able to obtain the service covered by the warranty.

Visit the company website, http://barfieldinc.com/

Please send the Registration Card to:

have your name and address on file at Barfield as a registered

, for publication updates.

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

56-101-00164 Rev. F Attention

Apr / 19 / 13 Page iv

1811D INSTRUCTION MANUAL

1811 SERIES

PITOT-STATIC TEST SET

INFORMATIONAL LETTER

The Barfield 1811 series Pitot-Static Testers are not advertised for use to comply with

FAR 91.411. The Test Sets do fully meet the requirements of DOT Advisory Circular 43-203B

for performing Altimeter and Static System Tests and Inspections. However, the personnel

requirements and some of the technical aspects of actual testing put a sizeable burden on the

person or persons performing the test.

Barfield advertises its 1811 series Test Sets as general-purpose trouble-shooting testers. With

respect to compliance with FAR 91.411, we feel that the customer should first be aware of all

requirements for performing test tests in the field. With this in mind, Barfield stands ready to

offer advice and assistance to its customers for accomplishing the required tests.

In conclusion, the Barfield 1811 Series Pitot-Static Testers meet the requirements for

compliance with FAR 91.411, but it is important that the customer be sure that the use of the

test set will be in compliance with the regulations.

Please note that a Barfield Altimeter and Static Test Procedure (Document number 60-101-

00150) is available to use in compliance with FAR 91.411.

56-101-00164 Rev. F Info

Apr / 19 / 13 Page v

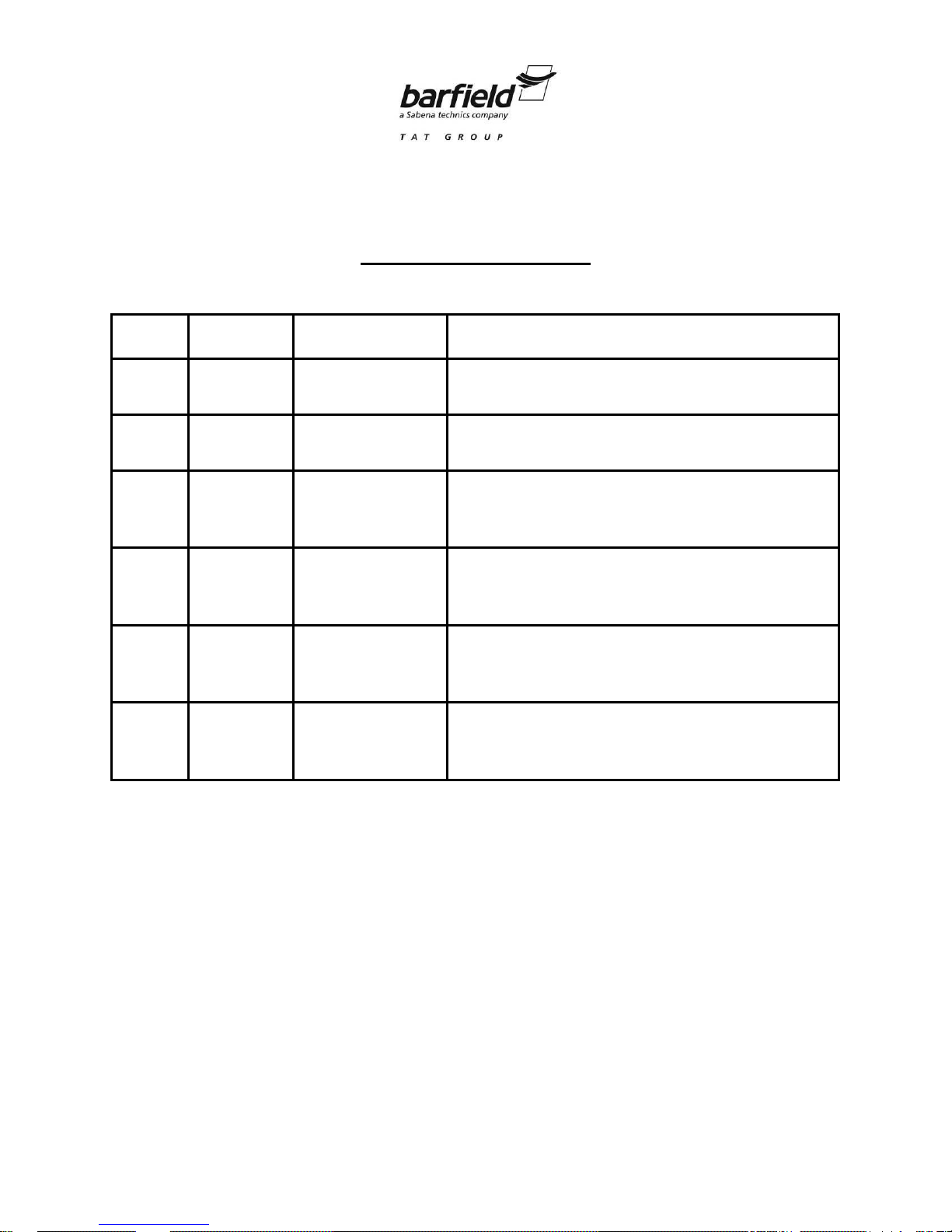

REV.

ECO #

1811D INSTRUCTION MANUAL

REVISION RECORD

REV. DATE

DESCRIPTION OF CHANGE

A N/A Mar / 11 / 2003

B 260-00729 Jul / 02 / 2008

C 260-00746 Dec / 16 / 2008

D 260-00779 Apr / 29 / 2010

E 260-00828 Mar / 25 / 11

F 260-00968 Apr / 19 / 13

Initial Release. This Instruction Manual replaces

TM1811D/E, dated 10/1/82.

Updated Company logo. Sections and page

numbering were reorganized.

A numeric code was added at the end of the

former P/Ns, to identify the instruments

configuration supplied with a particular unit.

Additional information was included in the

Certification paragraph (page 3)

Updated warranty; Table 5: Required Inspection

updated; shipping and storage information

Amended Static Preset information; updated

gauge information regarding inspection

56-101-00164 Rev. F Rev

Apr / 19 / 13 Page vi

1811D INSTRUCTION MANUAL

MAINTENANCE AND REPAIR INFORMATION

The manufacturer of this equipment does not recommend the user to attempt any maintenance

or repair. In case of malfunction, contact the manufacturer, to obtain the list of approved repair

facilities worldwide, ensuring that this equipment will be serviced using proper procedures and

certified instruments.

BARFIELD PRODUCT SUPPORT

DIVISION

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Shipping Address:

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

Mailing Address:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

56-101-00164 Rev. F Maint.

Apr / 19 / 13 Page vii

1811D INSTRUCTION MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

56-101-00164 Rev. F Blank

Apr / 19 / 13 Page viii

1811D INSTRUCTION MANUAL

TABLE OF CONTENTS

Contact Information

Attention Page

Informational Letter Page

Revision Record Page

Maintenance Information

Table of Contents

List of Figures and Tables

SECTION

INTRODUCTION

1. PUBLICATION BREAKDOWN ................................................................................... 1

2. INFORMATION PROVIDED WITH THE UNIT ........................................................... 1

PAGE

3. RECERTIFICATION ................................................................................................... 2

1. DESCRIPTION

1. GENERAL DESCRIPTION ......................................................................................... 5

2. PHYSICAL DESCRIPTION ........................................................................................ 6

2. SPECIFICATIONS

1 PHYSICAL DATA ....................................................................................................... 9

2. INPUT POWER .......................................................................................................... 9

3. OPERATION

1. THEORY OF OPERATION ....................................................................................... 11

2. 1811D OPERATIONAL SCHEMATIC DIAGRAM ..................................................... 11

3. 1811D PLUMBING SCHEMATIC DIAGRAM ............................................................ 12

4. PRELIMINARY .......................................................................................................... 12

5. PRETESTS ............................................................................................................... 13

6. PITOT SYSTEM TEST .............................................................................................. 15

56-101-00164 Rev. F TOC

Apr / 19 / 13 Page ix

1811D INSTRUCTION MANUAL

TABLE OF CONTENTS (Continued)

SECTION

3. OPERATION (continued)

7. STATIC SYSTEM TEST ............................................................................................ 16

8. STATIC LEAK TEST ................................................................................................. 16

9. COMBINED PITOT / STATIC TEST .......................................................................... 19

10. MACHMETER TEST ................................................................................................. 22

11. ENGINE PRESSURE RATIO TEST .......................................................................... 23

12. MANIFOLD PRESSURE GAUGE TEST ................................................................... 23

13. LOW PRESSURE TEST ........................................................................................... 24

14. VACUUM TEST ......................................................................................................... 26

4. VALVE LEAK TEST

1. METERING VALVE ADJUSTMENT PROCEDURE .................................................. 27

PAGE

2. RESETTING NEEDLE VALVE POSITIVE STOP ...................................................... 29

5. INSPECTION RECOMMENDATIONS ............................................................................ 31

6. SHIPPING ....................................................................................................................... 33

7. STORAGE ....................................................................................................................... 34

APPENDIX (ENGINEERING SPECIFICATIONS) ......................................................................... 35

1. ALTIMETER ............................................................................................................... A

2. AIRSPEED INDICATOR ............................................................................................. B

3. VERTICAL SPEED INDICATOR ................................................................................ C

56-101-00164 Rev. F TOC

Apr / 19 / 13 Page x

1811D INSTRUCTION MANUAL

LIST OF FIGURES AND TABLES

SECTION

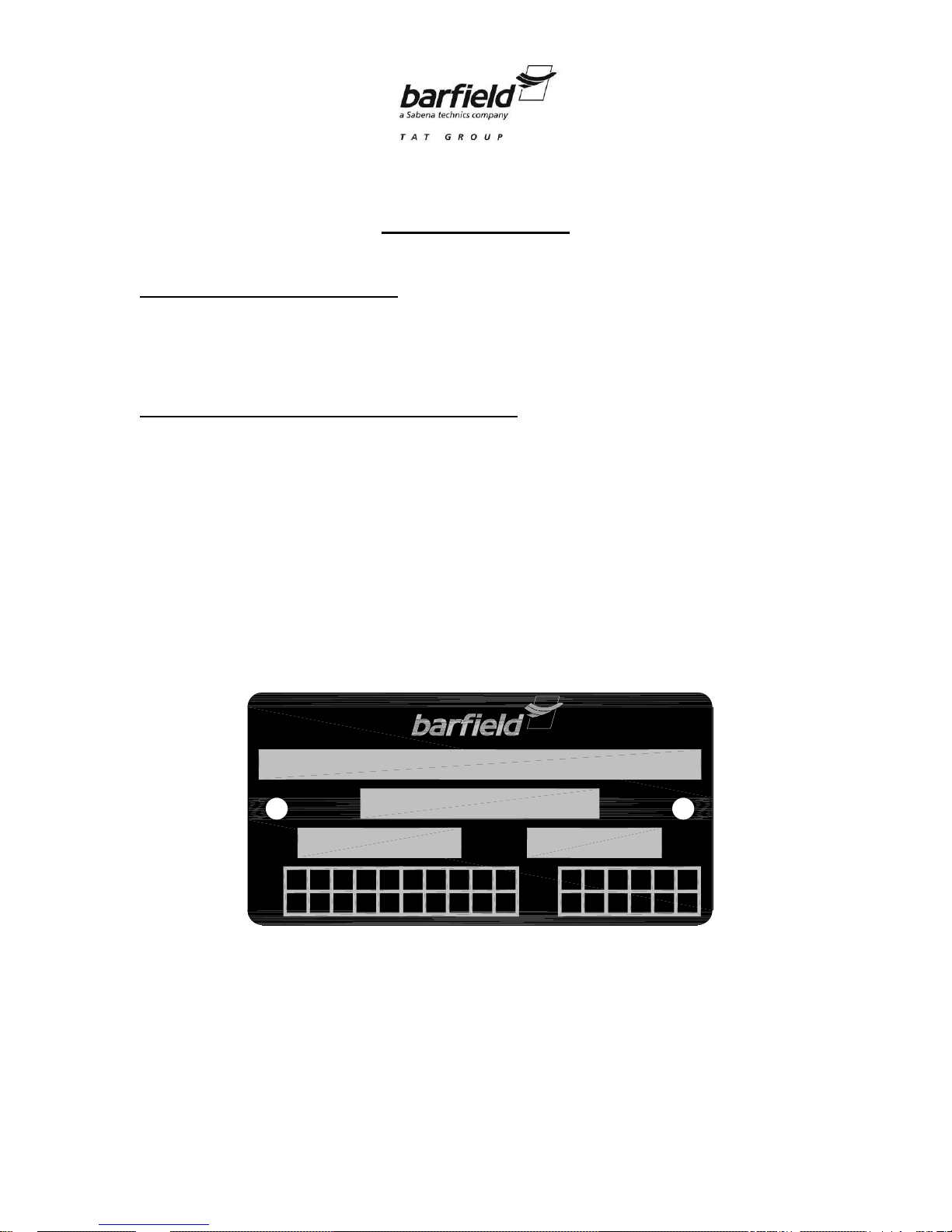

INTRO 1 Identification Label ............................................................... 1

INTRO 2 Limited One Year Warranty ................................................. 3

1 3 1811D Pitot-Static Test Set .................................................. 5

1 4 Leading Particulars ............................................................ 6, 7

3 5 1811D Operational Schematic Diagram .............................. 11

3 6 1811D Plumbing Schematic Diagram ................................. 12

3 7 1811D Panel Mounted Components ................................... 13

3 1 Airspeed vs. Mach Number Table ....................................... 22

3 2 EPR Test Table ................................................................... 23

3 3 Altitude vs. Manifold Pressure Table ................................... 24

3 4 Airspeed Equivalent for Differential Pressure Table ........... 25

5 5 Required Periodic Inspections ............................................ 31

FIGURE / TABLE TITLE PAGE

56-101-00164 Rev. F LOFT

Apr / 19 / 13 Page xi

1811D INSTRUCTION MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

56-101-00164 Rev. F Blank

Apr / 19 / 13 Page xii

1811D INSTRUCTION MANUAL

INTRODUCTION

1. PUBLICATION BREAKDOWN

This

2. INFORMATION PROVIDED WITH THE UNIT

Besides this User Instruction Manual, the 1811D Test Set is provided with the items

A. An identification label similar to Figure 1 and located on the front bulkhead of the Test

Equipment Model Number Equipment Serial Number

Equipment Modification (if applicable) Equipment Options (if applicable)

instruction manual establishes the operation standards for the 1811D Pitot-Static Test

Set.

described below.

Set, provides the following information:

Manufacturer Name

Designation of Equipment

Equipment Part Number

M/N

M

O

D

AB

L

MN

P/N

C

a Sabena technics company

PITOT STATIC TEST SET

101-00164-105

1811D

EDFG

OP RQ

S/N

H

S

K

T

U

O

P

AJ

G

T

459-00024 rev. F

MADE IN

THE USA

BF

CD

J

H

E

L

KM

56-101-00164 Rev. F INTRO

Apr / 19 / 13 Page 1 of 38

IDENTIFICATION LABEL

Figure 1

1811D INSTRUCTION MANUAL

B. Each new or re-certified unit is delivered with a Certificate that shows the date when the

unit was tested by the manufacturer, its serial number, and when the next certification is

due. This certificate confirms that the unit performed according to its design

specifications.

3. RECERTIFICATION

The Test Sets P/N 101-00184 and P/N 101-00185 have a 6-month recertification period

when analog instruments are installed. However, when digital instruments are installed the

recertification period is typically one year. For complete specifications on digital

instruments, refer to documents 61-101-02184 and 61-101-02194.

It is strongly recommended that the manufacturer, Barfield Inc., service the Test Set. This

will ensure that all applicable engineering change orders are incorporated during the

required maintenance or recertification processes, which are to be done following Barfieldapproved procedures. Additionally, at this time only Barfield technicians are qualified to

service the digital instruments.

Note

: It is important that the customer ensures the Test Set is in compliance with the

Recertification requirement

Note

: If the Test Set is to be used in compliance with F.A.R. 91.170 and Part 43, Appendix

E, "Altimeter System Tests and Inspections," refer to FAA Advisory Circular AC43-6B

(or subsequent) for approved inspection intervals and procedures.

.

56-101-00164 Rev. F INTRO

Apr / 19 / 13 Page 2 of 38

1811D INSTRUCTION MANUAL

56-101-00164 Rev. F INTRO

Apr / 19 / 13 Page 3 of 38

LIMITED ONE YEAR WARRANTY

Figure 2

1811D INSTRUCTION MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

56-101-00164 Rev. F Blank

Apr / 19 / 13 Page 4 of 38

1811D INSTRUCTION MANUAL

SECTION 1: DESCRIPTION

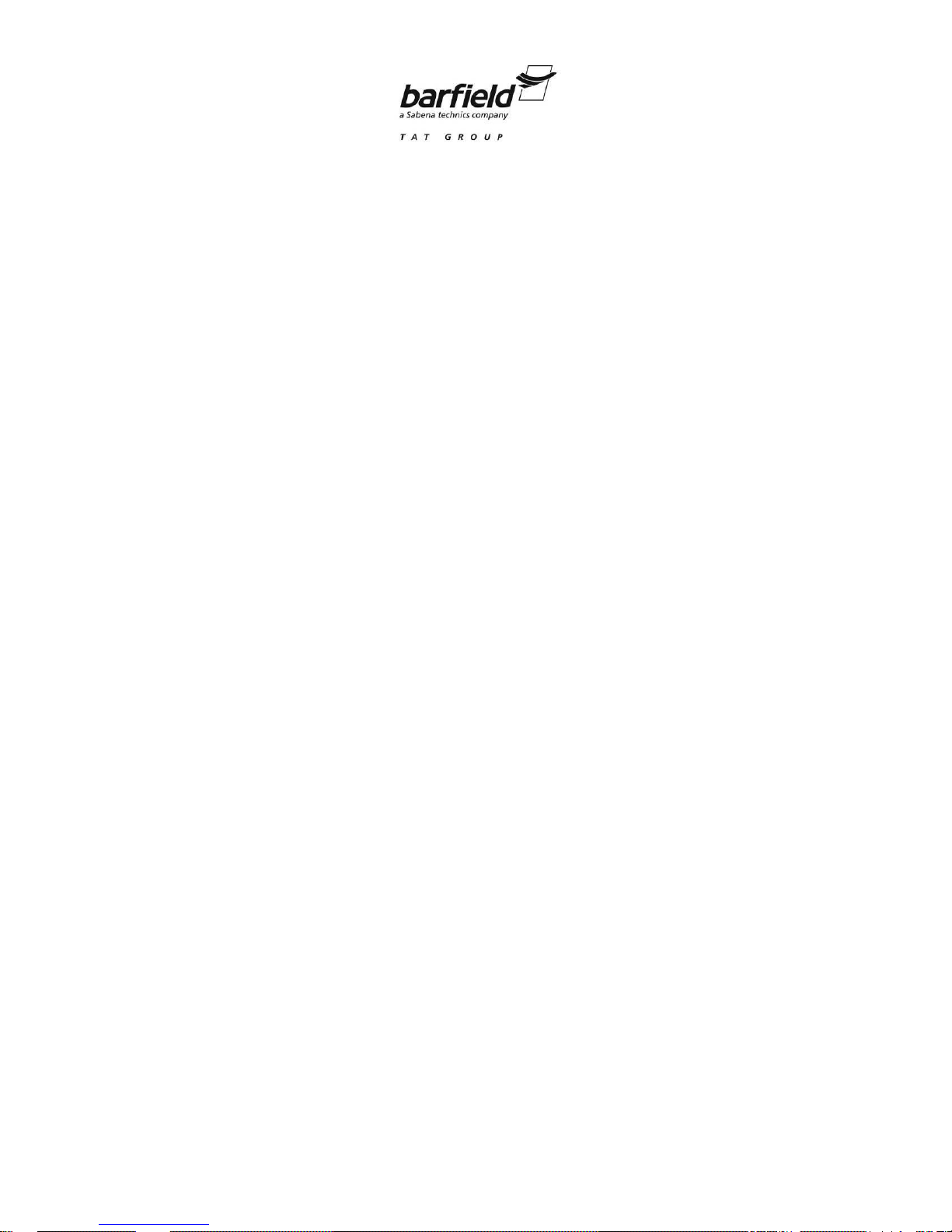

1. GENERAL DESCRIPTION

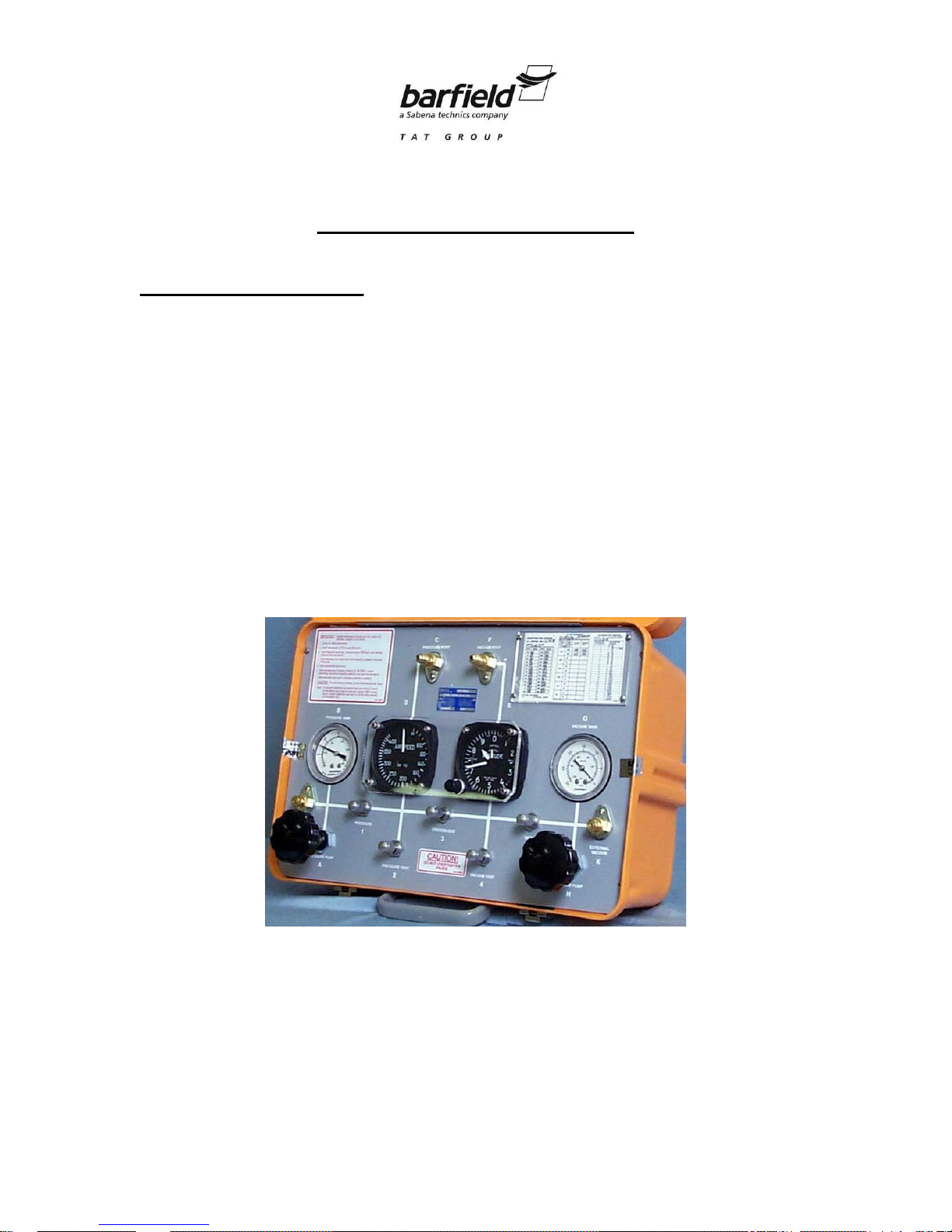

The Barfield 1811D Pitot Static Test Set (Fig. 3), housed in a plastic carrying case, is a

portable, self-contained field tester designed to test aircraft pitot and static systems for leaks

as well as the operation and calibration of airspeed, altimeter, engine pressure ratio,

manifold pressure indicators, and other vacuum or low pressure units.

Panel mounted hand pumps are equipped with reservoir tanks to supply pressure and vacuum.

Metering valves provide control of all pneumatic functions. External pressure ports supply the

necessary pressure and vacuum needed for on-board testing. The 1811D has a 50 to 650 knot

sensitive airspeed and is available with a 35, 000 or 50,000 ft altimeter.

The tester consists of a hand-operated vacuum pump, a hand-operated pressure pump vacuum

and pressure gauges, 5 control valves, an altimeter and an airspeed indicator. The package

accessories include two 25-foot hoses, a pitot mast adapter, and a static port adapter kit which

enable the user to connect the aircraft pitot and static lines.

Different alternatives are available for the altimeter and airspeed indicators that are installed

in the tester, so the three-digit code that follows the basic part number of the 101-00164,

identifies which combination of them is provided with a particular tester. The first digit

indicates the airspeed range; the last digit in the code identifies the altimeter range (the

middle digit is always zero). Possible

56-101-00164 Rev. F SECTION 1

Apr / 19 / 13 Page 5 of 38

1811D PITOT-STATIC TEST SET

Figure 3

alternatives for both indicators are shown in the

1811D INSTRUCTION MANUAL

following table. For example, P/N 101-00164-105 is identified as an 1811D tester with a 650

knot airspeed indicator and a 35,000 feet altimeter. (The 1811D is also available with the

Barfield DAS650 digital airspeed and DALT55 digital altimeter.)

Airspeed

Code

Airspeed Range

1 650 knots (50-650 kts) 2

Altimeter

Code

Altimeter Range

Precision dual diaphragm, 3

ptr. 80K range cal to 55k

4 420 knot (60-420 kts) 3 Sensitive, 3 ptr., 50,000 ft

6 250 knot (20-250 kts) 5 Sensitive, 3 ptr., 35,000 ft

9 SPECIAL 9 SPECIAL

A DALT650, 650 kt range A DALT55, Digital 55k feet

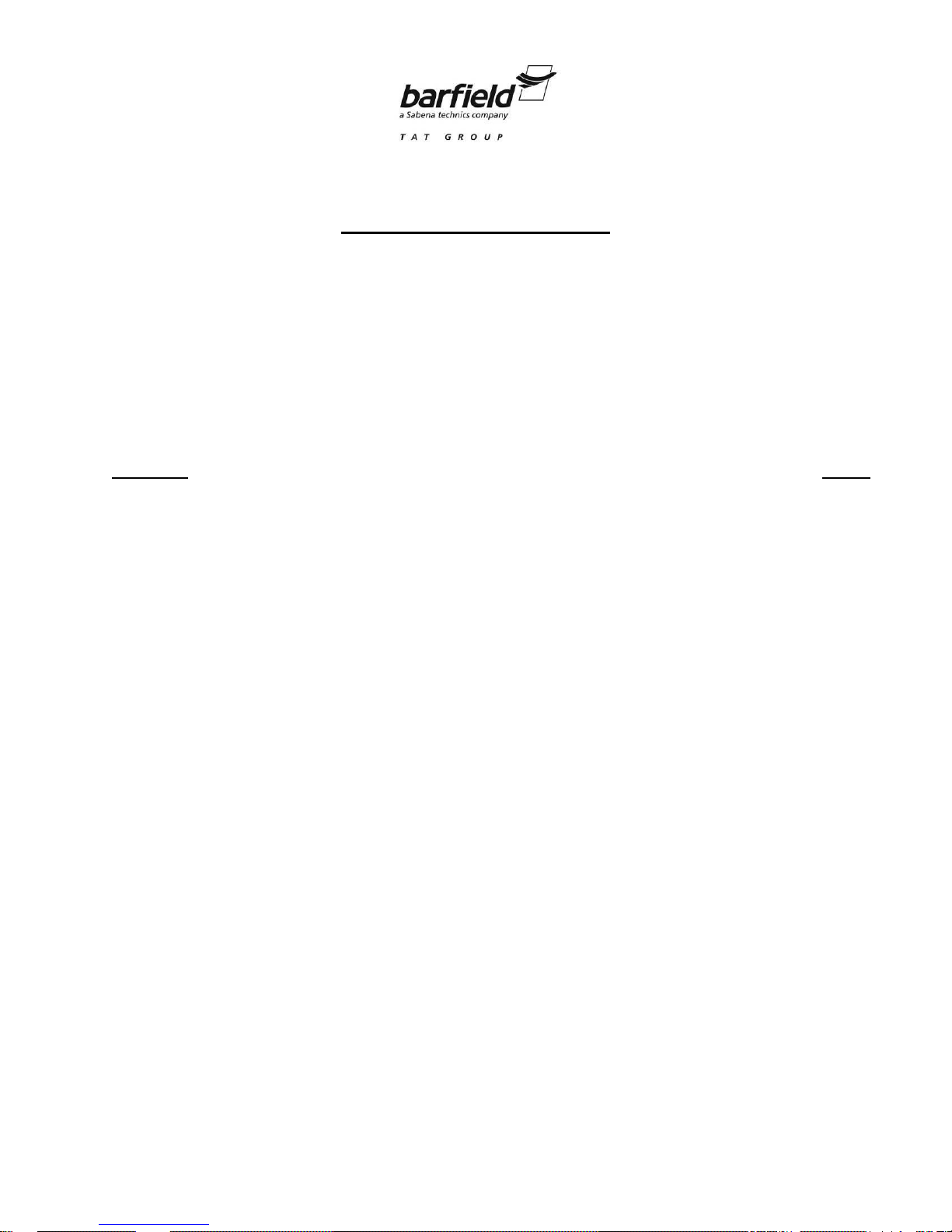

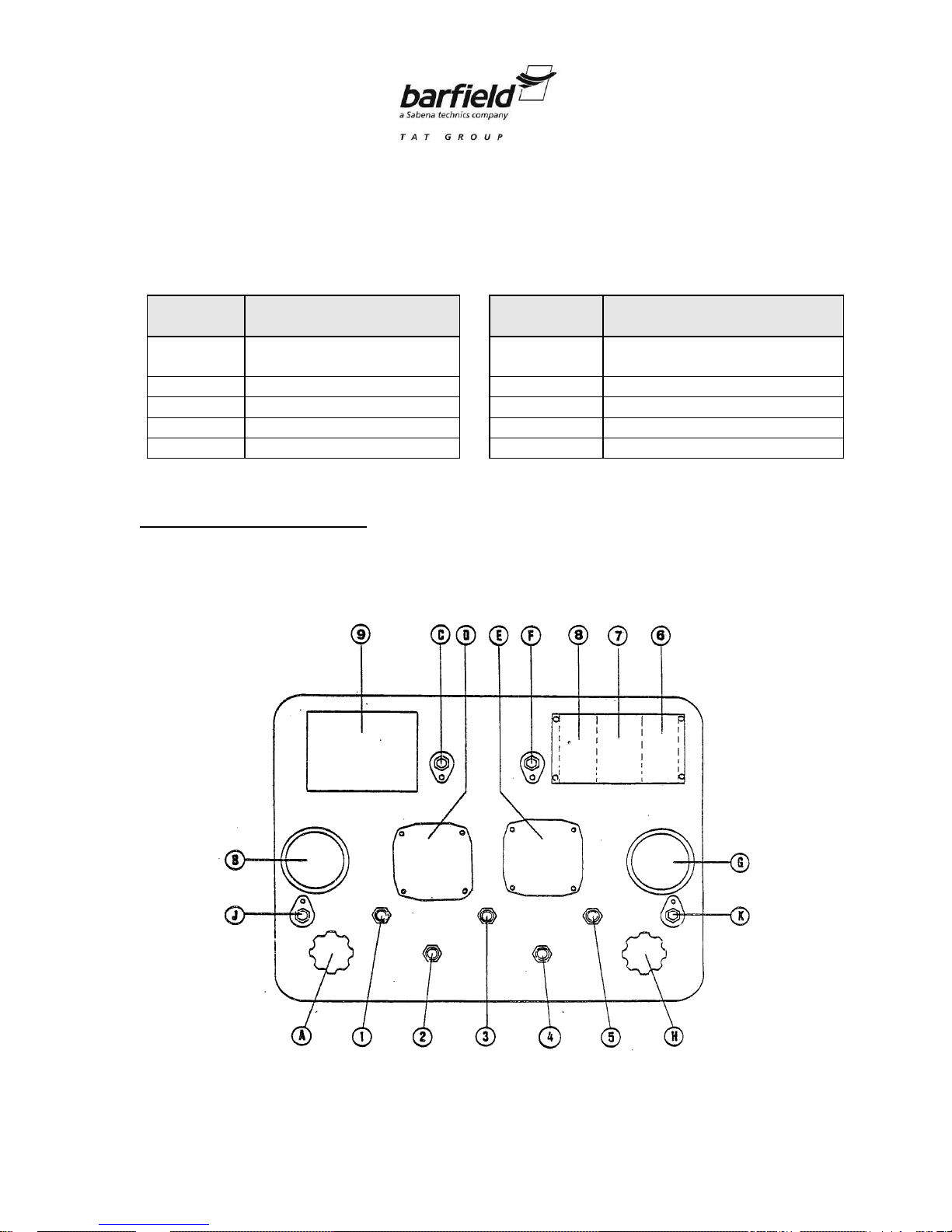

2. PHYSICAL DESCRIPTION

The controls, indicators, and other items located in the Front Panel of the Test Set, are

described in Figure 4 (this page and the next).

56-101-00164 Rev. F SECTION 1

Apr / 19 / 13 Page 6 of 38

1811D LEADING PARTICULARS

Figure 4

1811D INSTRUCTION MANUAL

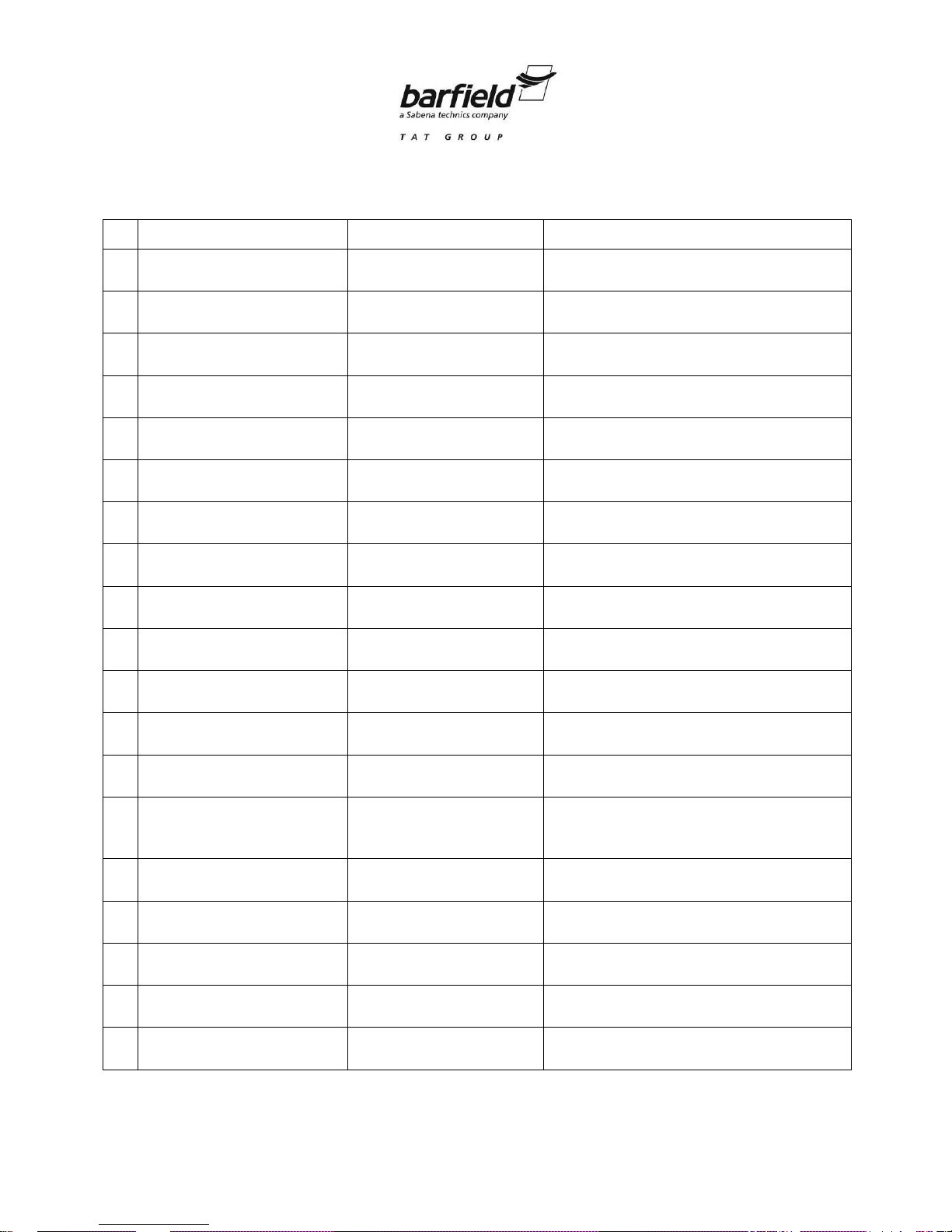

ID ITEM NAME DESCRIPTION FUNCTION

A PRESSURE PUMP

1 PRESSURE VALVE

2 PRESSURE VENT

3 CROSSBLEED VALVE

4 VACUUM VENT

5 VACUUM VALVE

H VACUUM PUMP

J EXTERNAL PRESSURE

G VACUUM TANK

Hand Operated Piston

Pump

Pressure Source

Needle Valve

Pressure Vent Needle

Valve

Crossbleed Needle

Valve

Vacuum Vent Needle

Valve

Vacuum Source

Needle Valve

Hand Operated Piston

Pump

1/8-27 NPT Female

Bulkhead Fitting

0-30 In Hg Vacuum

Gauge

E ALTIMETER --

CALIBRATION CARD

6

7

8

(ALTIMETER)

CALIBRATION CARD

(HYSTERESIS)

CALIBRATION CARD

(AIRSPEED)

F VACUUM PORT

C PRESSURE PORT

1/8-27 NPT Female

Bulkhead Fitting

1/8-27 NPT Female

Bulkhead Fitting

--

--

--

D AIRSPEED INDICATOR --

9 DECAL --

B PRESSURE TANK

K EXTERNAL VACUUM

0-30 PSI Pressure

Gauge

1/8-27 NPT Female

Bulkhead Fitting

Integral pressure source for all tests

Used to control pressure source

Used to release pressure to ambient

atmosphere

Used to control pressure difference

between pitot and static

Used to release vacuum to ambient

atmosphere

Used to control vacuum source

Integral vacuum source for all tests

Port for external pressure source

Used to monitor vacuum available in

vacuum reservoir tank

Monitors pressure altitude at vacuum

static side of Test Set

Provides altimeter calibration

correction (Only for Analog Indicators)

Lists altimeter hysteresis at selected

altitudes (Only for Analog Indicators)

Provides airspeed calibration

correction (Only for Analog Indicators)

Port for connection to aircraft Static

System or other vacuum test

application

Port for connection to aircraft Pitot

System or other application

Monitors differential pressure in terms

of airspeed between pitot and static

Provides instruction for pretesting

Test Set

Monitors pressure available from

pressure reservoir tank

Port for external vacuum source

56-101-00164 Rev. F SECTION 1

Apr / 19 / 13 Page 7 of 38

1811D LEADING PARTICULARS

Figure 4 (continued)

1811D INSTRUCTION MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

56-101-00164 Rev. F Blank

Apr / 19 / 13 Page 8 of 38

Loading...

Loading...