Page 1

INSTALLATION INSTRUCTIONS

Partial Flow

Commercial Room Ventilator

24 Volt On/Off

with Spring Return and Exhaust

Model: CRV-F5

For Use with Bard Single Stage Wall Mount

Air Conditioner and Heat Pump Models:

W42AC, W48AC, W60AC, W72AC

W42HC, W48HC, W60HC

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-696A

Supersedes: 2100-696

Date: 9-16-19

Page 1 of 17

Page 2

CONTENTS

General Information ...............................................3

Commercial Room Ventilator Model Nomenclature ...

Unpacking .......................................................... 3

General ..............................................................3

Commercial Room Ventilator Features ....................3

Description .........................................................3

Models ...............................................................3

Installation of Field-Installed CRV-F5 .................4

Basic Installation .................................................4

Control System Notes ...........................................8

Blade Adjustment for Desired Ventilation Air ..........8

Sequence of Operation ....................................... 16

3

Figures

Figure 1 Disconnect Power ................................ 4

Figure 2 Remove Side Grilles ............................. 4

Figure 3 Remove Blower Door and Control Panel

Cover .................................................. 4

Figure 4 Remove Blank Off Plates (Both Sides) .... 5

Figure 5 Remove Exhaust Blank Off Plate ........... 5

Figure 6 Install Gasket ...................................... 5

Figure 7 Install Exhaust Blade Assembly ............. 5

Figure 8 Remove Air Filters and Low Voltage

Control Panel Cover .............................. 5

Figure 9 Connect 3000-1622 Wire Assembly ...... 6

Figure 10 Install Vent .......................................... 6

Figure 11 Control Plug Centered in Plug Access

Opening .............................................. 6

Figure 12 Connect CRV Power Plug to Control

Panel Plug........................................... 6

Figure 13 Remove Blade Shipping Screws ............. 6

Figure 14 Set Blade Stop to Adjust Fresh Air ......... 7

Figure 15 Install Intake Sealing Frame and

Lower Block Off Plates ......................... 7

Figure 16 Install Mist Filters ................................ 7

Figure 17 Install Bug Screen and Gaskets ............. 7

Figure 18 Programmable Thermostat Connections

for CRV with Air Conditioners .............. 11

Figure 19 Programmable Thermostat Connections

for CRV with Heat Pumps.................... 12

Figure 20 Non-Programmable Thermostat

Connections for CRV with

Air Conditioners ................................. 13

Figure 21 Non-Programmable Thermostat

Connections for CRV with Heat Pumps . 14

Figure 22 CRV-F* Wiring Diagram ....................... 15

Figure 23 Call for Ventilation With or WIthout

Compressor Operation ........................ 17

Figure 24 Call for Compressor or Fan Only with

Ventilation Off ................................... 17

Manual 2100-696A

Page 2 of 17

Graphs

Graph 1 W42AC CRV-F5 Ventilation Delivery ....... 9

Graph 2 W48AC CRV-F5 Ventilation Delivery ....... 9

Graph 3

Graph 4 W72AC CRV-F5 Ventilation Delivery ..... 10

Table

Table 1

(On/Off CRV)....................................... 16

W60AC

Unit Operation with M Ventilation Option

CRV-F5

Ventilation Delivery ...... 10

Page 3

GENERAL INFORMATION

Commercial Room Ventilator Model Nomenclature

CRV – F 5

Commercial Room Ventilator

Fixed 24 Volt On/Off

Chassis Size

5 – 4, 5 & 6 Ton Models

Unpacking

Upon receipt of the equipment be sure to compare the

model number found on the shipping label with the

accessory identification information on the ordering and

shipping document to verify that the correct accessory

has been shipped.

Inspect the carton housing of each ventilator as it is

received, and before signing the freight bill, verify that

all items have been received and that there is no visible

damage (check parts list below). Note any shortages or

damage on all copies of the freight bill. The receiving

party must contact the last carrier immediately,

preferably in writing, requesting inspection by the

carrier’s agent. Concealed damage not discovered until

after loading must be reported to the carrier within 15

days of its receipt.

General

The ventilator should only be installed by a trained

heating and air conditioning technician. These

instructions serve as a guide to the technician installing

the ventilator package. They are not intended as a stepby-step procedure with which the mechanically inclined

owner can install the package.

The ventilator housing is shipped in one carton which

contains the electrical harness, miscellaneous hardware

and installation instructions.

Ventilator kit includes:

(1) CRV-F5 ventilator

(2) 7003-084 mist filters

(1) 7003-083 exhaust bug screen

(2) 539-405 intake sealing frames

(1) 3000-1622 wire assembly

(2) 1913-002-0808 8-1/2" foam strips

(4) 1913-002-0708 7-1/2" foam strips

(1) 1913-013-2708 foam gasket

(2) 543-223 lower block off plates

(12) 1012-086 screws

(1) 539-414 exhaust damper assembly

(1) 2100-696A installation instructions

Commercial Room Ventilator Features

• Exhaust air damper – built in with positive closed

position. Provides exhaust air capability to prevent

pressurization of tight buildings.

• Actuator motor – 24 volt, power open, spring return

with built in torque limiting switch.

Description

The CRV-F5 ventilator is designed to be used with

the specific models with "letter" revision codes as

designated on the front page of this installation

instructions manual.

The ventilator is an electromechanical vent system

designed to provide fresh air to meet indoor air quality

standards.

Models

When installed in the models listed on the front page,

the CRV-F5 provides built-in exhaust provisions. When

the damper blade opens to bring fresh air in, the

damper also opens an exhaust relief. The exhaust air

will flow into the condenser section of the unit. The

condenser fan will help draw exhaust air out when it

is operating with compressor in cooling or heat pump

mode.

Manual 2100-696A

Page 3 of 17

Page 4

INSTALLATION OF FIELD-INSTALLED CRV-F5

Basic Installation

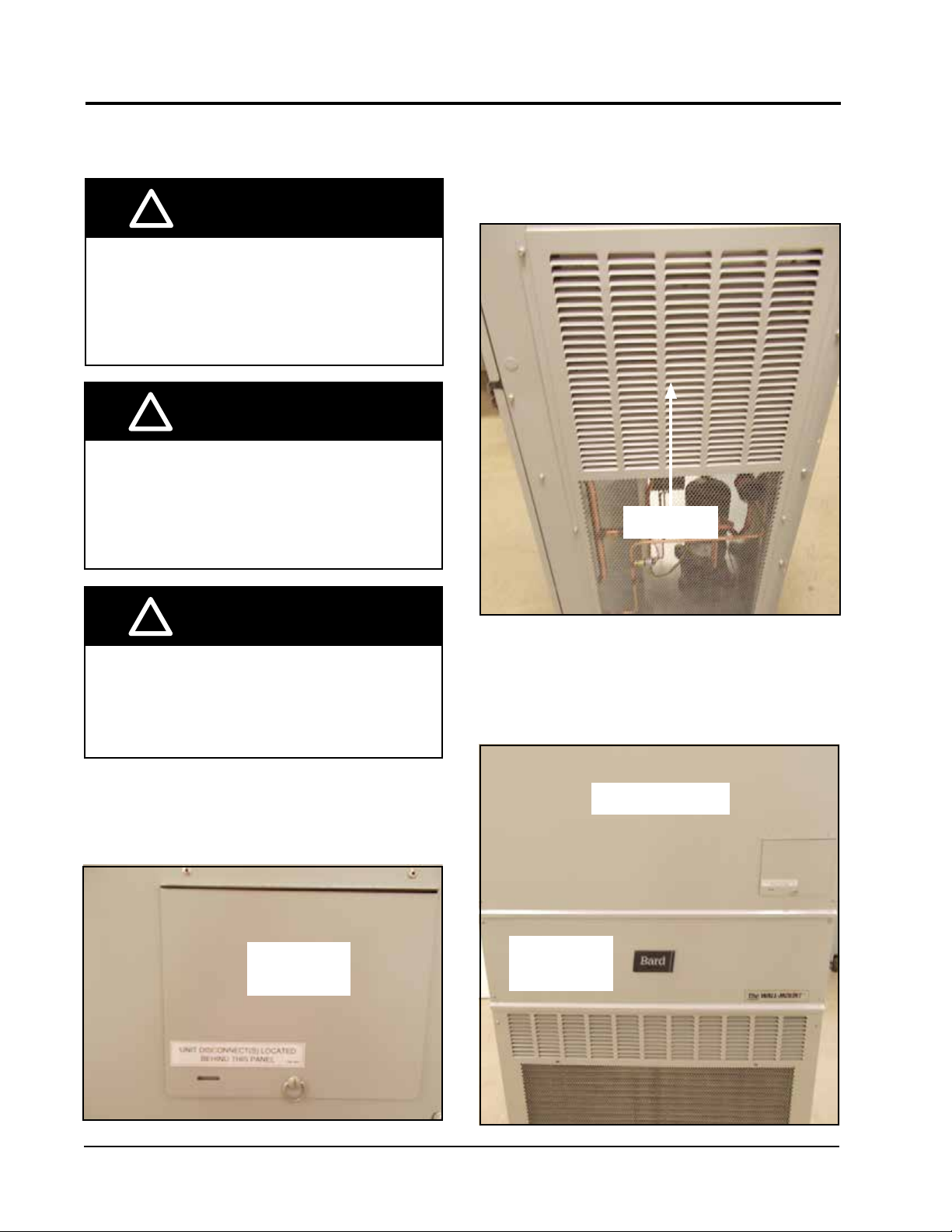

!

WARNING

Electrical shock hazard.

Disconnect remote electrical power supply

or supplies before servicing.

Failure to do so could result in electric

shock or death.

!

WARNING

Exposed moving parts.

Disconnect electrical power before

servicing.

Failure to do so could result in severe

injury or amputation.

Remove both side grilles (see FIgure 2).

FIGURE 2

Remove Side Grilles

Side Grille

!

CAUTION

Cut hazard.

Wear gloves to avoid contact with sharp

edges.

Failure to do so could result in personal injury.

Disconnect all power to unit (see Figure 1).

FIGURE 1

Disconnect Power

Disconnect

Access Door

Remove upper blower door and outer control panel

cover (see Figure 3).

FIGURE 3

Remove Blower Door and Control Panel Cover

Upper Blower Door

Outer

Control Panel

Cover

Manual 2100-696A

Page 4 of 17

Page 5

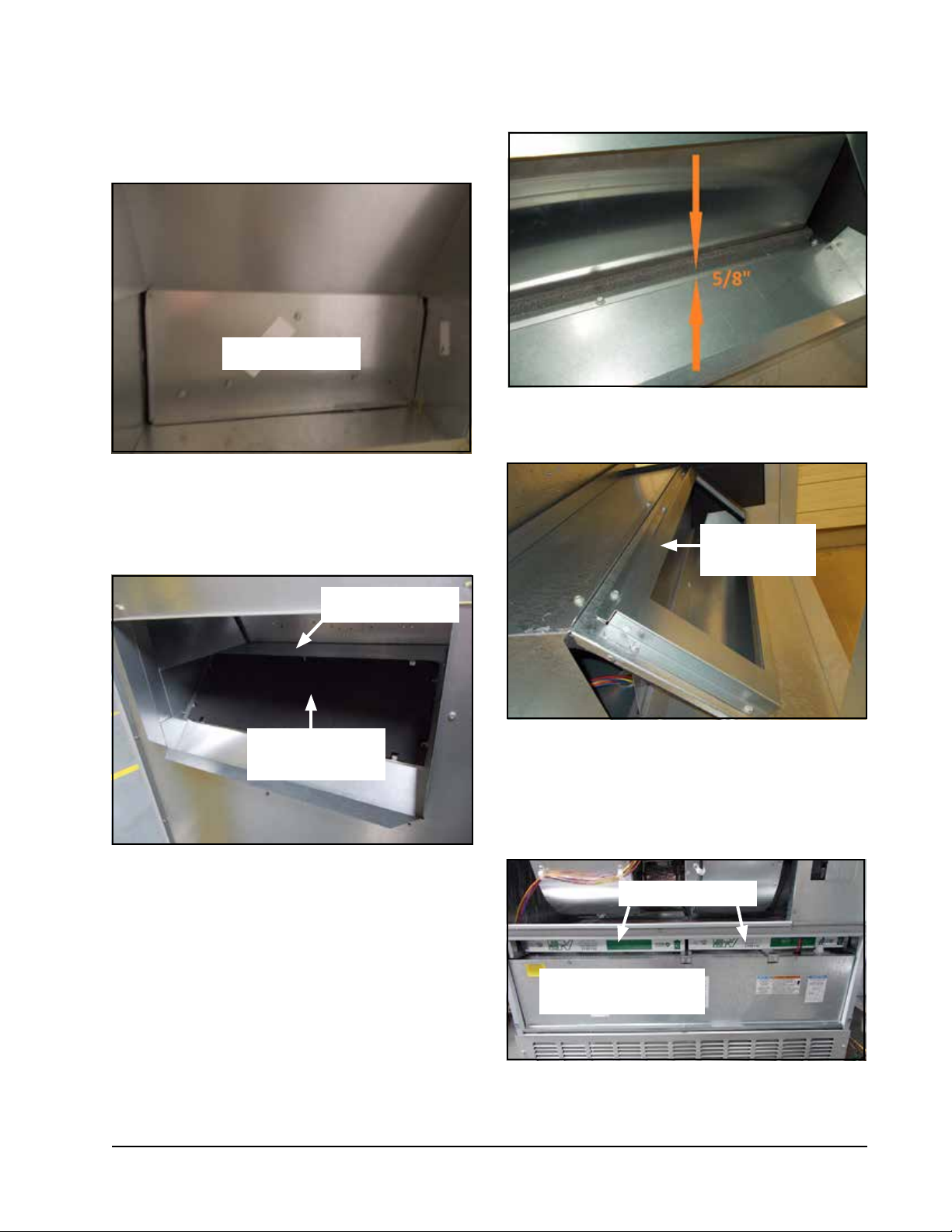

Remove blank off plates on both sides (behind side

grilles) and discard (see Figure 4).

FIGURE 4

Remove Blank Off Plates (Both Sides)

Blank Off Plate

Remove exhaust blank off plate through return or

through side intake openings (see Figure 5).

FIGURE 6

Install Gasket

FIGURE 7

Install Exhaust Blade Assembly

FIGURE 5

Remove Exhaust Blank Off Plate

Exhaust Partition

Exhaust Blank Off

Plate

Install 1913-013-2708 gasket 5/8" from bend as

shown in Figure 6. Then install exhaust blade assembly

using 10 screws (see Figure 7).

Exhaust Blade

Assembly

Remove both air filters and the low voltage inner control

panel cover (see Figure 8).

FIGURE 8

Remove Air Filters and

Low Voltage Inner Control Panel Cover

Air Filters (2)

Low Voltage Inner

Control Panel Cover

Manual 2100-696A

Page 5 of 17

Page 6

Connect 3000-1622 wire assembly (see Figure 9).

Snap the 4 pin connector into the opening next to the

low voltage box and plug the 12 pin male connector

into the female plug in the low voltage box.

FIGURE 9

Connect 3000-1622 Wire Assembly

4 Pin

Connector

12 Pin Male

Connector

FIGURE 11

Control Plug Centered in Plug Access Opening

From the front, through the filter opening, plug the CRV

power plug into the control panel plug (see Figure 12).

IMPORTANT: Sharp edges--PPE required.

Before installing vent, remove CRV from packaging

and verify there is no damage.

the side as shown in Figure 10. CRV can be installed

from either side.

Set CRV on the exhaust partition (see Figure 5 on page

5) and slide in until flush with the side of the wall

mount.

Install the vent from

FIGURE 10

Install Vent

FIGURE 12

Connect CRV Power Plug to Control Panel Plug

The CRV exhaust blade is fixed in the shipping position

by two (2) screws, one on each side (see Figure 13).

Remove screws to release the blade.

FIGURE 13

Remove Blade Shipping Screws

When the CRV is fully installed, the control plug should

be centered in the plug access opening on the front

panel of the CRV as shown in Figure 11.

Manual 2100-696A

Page 6 of 17

Page 7

Set blade stop (see Figure 14) using airflow charts

found on pages 9 and 10.

To adjust fresh air amount, loosen set screw two turns

on actuator stop. Slide stop to desired setting by

putting pressure toward the center drive shaft with

screwdriver while moving up and down. Use the marks

on the acuator to correlate with the airflow settings as

shown.

FIGURE 14

Set Blade Stop to Adjust Fresh Air Amount

Bend the two (2) sheet metal tabs in the condenser

partition up to hold the bottom of the mist eliminator

in place.

Install 7003-084 mist filters on both sides (see Figure

16). Then re-install the side grilles removed earlier.

FIGURE 16

Install Mist Filters

Mist Filter

Install the 539-405 intake sealing frame and the 543223 lower block off plates (both sides) as shown in

Figure 15. Install two (2) 1913-002-0708 7-1/2" foam

gaskets below the intake sealing frame (both sides).

FIGURE 15

Install Intake Sealing Frame and

Lower Block Off Plates

Intake Sealing

Frame

Lower Block

Off Plate

Remove the front lower (condenser) grille and bend the

two (2) sheet metal tabs in the condenser partition up

to hold the bottom of the bug screen in place. Install

two (2) 1913-002-0808 8-1/2" foam gaskets to sides

of cabinet (see Figure 17). Install the 7003-083

exhaust bug screen. Re-install grille.

FIGURE 17

Install Bug Screen and Gaskets

Foam Gaskets

Exhaust Bug

Screen

Install Gaskets Here

Restore power to unit. The "A" terminal can now be

energized to test blade operation. When blade testing is

complete, disconnect power.

Install both filters, then re-install the inner control panel

cover, outer control panel cover and upper blower door.

Restore power to unit.

Manual 2100-696A

Page 7 of 17

Page 8

Control System Notes

This ventilation package is capable of being set to

meet the current ASHRAE specifications for minimum

occupied airflow rates.

On/Off Operation

Energizing the A terminal in the low voltage connection

box during occupied conditions will drive the fresh

air damper to the fixed position selected as shown in

Figure 14 on page 7.

Blade Adjustment for Desired

Ventilator Air

The amount of ventilation air supplied by the

commercial room ventilator is dependant on four

factors.

1. Return air duct static pressure drop.

2. Supply air duct static pressure drop.

3. Indoor blower motor speed.

4. Damper blade open position setting.

Refer to the appropriate graph on pages 9 and 10 to

determine the blade setting necessary to achieve the

ventilation air required.

Manual 2100-696A

Page 8 of 17

Page 9

GRAPH 1

W42AC CRV-F5 Ventilation Delivery

GRAPH 2

W48AC CRV-F5 Ventilation Delivery

Manual 2100-696A

Page 9 of 17

Page 10

GRAPH 3

W60AC CRV-F5 Ventilation Delivery

GRAPH 4

W72AC CRV-F5 Ventilation Delivery

Manual 2100-696A

Page 10 of 17

Page 11

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

SC

24V

FIGURE 18

Programmable Thermostat Connections for CRV with Air Conditioners

SC

SC

COM

G

Y1 Y2 O/B L DA GND

W2

W1/E

6

Thermostat

Bard #8403-060

Unit Low

Voltage

Term. Strip

1

12-Pin

Vent Plug

Factory installed jumper. Removejumper andconnect

1

to N.C fire alarm circuitif emergency shutdown required.

Wire not needed below15KW.2

Wire required for dehumidification modelsonly.

3

4

Do not connect "A" from thermostat ifoptional CO2controller is used

0-10 VDC modulating C02control signal formodulating ventilation

5

control (optional for ECON only- see vent instruction manuals)

6

9

23 5 7

ALL VENT OPTIONS PLUG IN HERE

If not equipped with a ventilation option to plug in, a jumper plug must be installed.

B/W1

119

2

W1/E

2

7

W2C GRT Y1 Y2

W3

A

LO/BY2Y1R GC W2

4

L DA 3

Change model configuration from heat pump to heat/cool.Must beconfigured to programmable

and fan set to be programmed fan for the "A"output to function duringscheduled occupied

6

periods. Must be configured formulti-stage for Y1output to beactive 1st stage cooling. For

dehumidification, must be configured for "No Economizer" for YO/D tobe active for humidity

control.

7

Install jumper for 1 stageelectric heaton unitswith less than15KW

Do not add these wiresif settingup for modulating control. See note 7.

8

Factory installed jumper. Removejumper to activateBalanced Climate

9

A 2-stage thermostat is recommended forBalanced Climatemode.

3

4

YO/D

5

Optional CO2 Controller

3

65421R

4

1012

Bard Part#8403-067

1

2

3

4

5

6

8

™

24VAC

CO2 OUT

TEMP-OUT

mode.

MIS-3974

A

Manual 2100-696A

Page 11 of 17

Page 12

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

6

Thermostat

Bard #8403-060

SC

24V

FIGURE 19

Programmable Thermostat Connections for CRV with Heat Pumps

SC

SC

COM

G

Y1 Y2 O/B L DA GND

W2

W1/E

W1/E

3

2

4

YO/D

A

LO/BY2Y1R GC W2

Unit Low

Voltage

Term. Strip

1

12-Pin

Vent Plug

Factory installed jumper. Removejumper andconnect

1

to N.C fire alarm circuitif emergency shutdown required.

Wire not needed below 15KW.

2

Wire required for dehumidification modelsonly.

3

Do not connect "A" from thermostat ifoptional CO2controller is used

4

0-10 VDC modulating C02control signal formodulating ventilation

5

control (optional for ECON only- see vent instruction manuals)

6

8

23 5 7

ALL VENT OPTIONS PLUG IN HERE

If not equipped with a ventilation option to plug in, a jumper plug must be installed.

B/W1

119

2

4

3

W2C GRT Y1 Y2

L DA 3

W3

4

Ensure model configuration isheat pumpand notheat/cool. Must be configured to programmable

and fan set to be programmed fan for the "A"output to function during scheduled occupied

6

periods. Must be configured formulti-stage for Y1 output to beactive 1ststage cooling. For

dehumidification, must be configured for "No Economizer" for YO/D tobe active forhumidity

control.

7

Do not add these wiresif settingup for modulatingcontrol.

Factory installed jumper. Removejumper to activateBalanced Climate

8

A 2-stage thermostat is recommended forBalanced Climatemode.

5

Optional CO2 Controller

Bard Part#8403-067

1

24VAC

2

CO2 OUT

3

TEMP-OUT

65421R

1012

4

5

6

7

mode.

™

MIS-4063 A

Manual 2100-696A

Page 12 of 17

Page 13

8403-057

9

(TH311OD1040)

or T4 Pro 8403-089

8403-058

(TH522OD1151)

8403-059

(TH522OD1219/U)

or T6 Pro 8403-090

7

FIGURE 20

Non-Programmable Thermostat Connections for CRV with Air Conditioners

Units With Dehumidification

WCRc YR G

WRc CR G Y Y2

B

O

8

W2

6

35

8403-038

Mechanical Humidist at

8403-047

4

Electronic H umidistat

10

Unit Low

Voltage

Term. Strip

1

12-Pin

Vent Plug

Factory installed jumper. Remove jumper and connect

1

to N.C fire alarm circuit if emergency shutdown required.

2A

Wire not needed below 15KW.

Install Jumper for 1 stage electric heat on units with more

2B

than 10KW.

Wire required for dehumidification models only.

3

For vent operation, add jumper if optional CO2 controller is not used.

4

Vent will run while blower is energized.

For ECON & CRV-V an additional wire change is required

See install Manual.

5

Do not add these wires if setting up for modulating control. See note 7.

6

23 5 7

ALL VENT OPTIONS PLUG IN HERE

If not equipped with a ventilation option to plug in, a jumper plug must be installed.

119

B/W1

2A

3

6

2B

W3

W2C GRT Y1 Y2

L DA 3

4

4

0-10 VDC Modulating CO2 control signal for modulating ventilation control

6

(Optional for ECON Only) - See vent installation manual.

For 8403-058, change "system type", set up Function 1, From 5 (2 Heat/ 1 Cool heat Pump)

7

to 6 (2 Heat / 2 Cool Conventional). For 8403-059, No change required.

Jumper needs added.8

Thermostat will not work with units equipped with economizers.9

Factory installed jumper. Remove jumper to activate Balanced Climate™ Mode.

10

A 2-stage thermostat is recommended for Balanced Climate mode.

Optional CO2 Controller

Bard Part #8403-067

1

24VAC

2

3

CO2 OUT

4

65421R

5

TEMP-OUT

5

6

1012

MIS-3975 A

Manual 2100-696A

Page 13 of 17

Page 14

8403-057

9

(TH311OD1040)

or T4 Pro 8403-089

8403-058

(TH522OD1151)

8403-059

(TH522OD1219/U)

or T6 Pro 8403-090

7

Non-Programmable Thermostat Connections for CRV with Heat Pumps

R G Y Y2

C

FIGURE 21

Units With Dehumidification

8403-038

BCRc YR G

W

O

8

E

AUX

O/BRc

6

35

Mechanical Humidist at

8403-047

4

Electronic H umidistat

10

Unit Low

Voltage

Term. Strip

1

12-Pin

Vent Plug

Factory installed jumper. Remove jumper and connect

1

to N.C fire alarm circuit if emergency shutdown required.

Wire not needed below 15KW.

2

Wire required for dehumidification models only.

3

For vent operation, add jumper if optional CO2 controller is not used.

4

Vent will run while blower is energized.

For ECON & CRV-V, an additional wire change is required.

See install manual

5

Do not add these wires if setting up for modulating control. See note 6.

6

23 5 7

ALL VENT OPTIONS PLUG IN HERE

If not equipped with a ventilation option to plug in, a jumper plug must be installed.

119

B/W1

2

3

W3

W2C GRT Y1 Y2

L DA 3

6

4

4

0-10 VDC Modulating CO2 control signal for modulating ventilation control

6

(Optional for ECON Only) - See vent installation manual.

For 8403-058, change "system type", set up Function 1, From 5 (2 Heat/ 1 Cool heat Pump)

7

to 6 (2 Heat / 2 Cool Conventional). For 8403-059, No change required.

Jumper needs added.8

Thermostat will not work with units equipped with economizers.9

Factory installed jumper. Remove jumper to activate Balanced Climate™ Mode.

10

A 2-stage thermostat is recommended for Balanced Climate mode.

Optional CO2 Controller

Bard Part #8403-067

1

24VAC

2

3

CO2 OUT

4

65421R

5

TEMP-OUT

5

6

1012

MIS-4064 A

Manual 2100-696A

Page 14 of 17

Page 15

FIGURE 22

CRV-F* Wiring Diagram

FEMALE END

26

12 PIN

VENT PLUG

18

BLACK/WHITE

BLACK/WHITE

6

7

BLACK

BROWN/WHITE

PURPLE

9

3

1

17

5

Damper

Motor

16

21 3 4

2

8

17

YELLOW

4

MALE ENDMALE END

RED

BROWN/WHITE

4-Pin

Plug

10

1211

FEMALE END

18

ON/OFF CRV WIRING DIAGRAM

4056-244

Manual 2100-696A

Page 15 of 17

Page 16

Sequence of Operation

On/Off ventilation options energize when the “A” low

voltage strip terminal is energized signaling occupancy,

and de-energize when “A” terminal is no longer

receiving a 24VAC signal. The “G” low voltage strip

terminal is used to operate the indoor blower for unit

airflow.

The M On/Off CRV vent option is a damper blade

operated by a 24VAC motor that when energized opens

to a pre-adjusted setting. The airflow amount being

brought in will be dependent on the blower speed

during unit operation.

Unit Operation with M Ventilation Option (On/Off CRV)

TABLE 1

Unit

Operation

Occ.

Signal

G Y1 Y2 W1 W2 A D 1 2 3-4-5

Low Voltage 24VAC Speed Taps

Fan Speed

1

Comp.

Oper.

Damper

Fan Only Yes X X X Vent Off Open

Fan Only No X X Vent Off Closed

BC Cooling Ye s X X X X B Climate On Open

BC Cooling No X X X B Climate On Closed

Full Load Cool Ye s X X X X X X Lo/Med/Hi On Open

Full Load Cool No X X X X X Lo/Med/Hi On Closed

1st Stage Heat Yes X X X Lo/Med/Hi Off Open

1st Stage Heat No X X Lo/Med/Hi Off Closed

2nd Stage Heat Ye s X X X X Lo/Med/Hi Off Open

2nd Stage Heat No X X X Lo/Med/Hi Off Closed

Dehumidify

Dehumidify

2

2

Yes X X X X B Climate On Open

No X X X B Climate On Closed

BC and B Climate − Balanced Climate

¹ Fan speed is selectable through the blower speed control terminal block. LO (default), MED or HI speeds can be used.

2

Dehumidification operation is disabled when a call for heating or cooling occurs. Unit runs at Balanced Climate speed

during dehumidification operation.

Manual 2100-696A

Page 16 of 17

Page 17

FIGURE 23

Call for Ventilation With or Without Compressor Operation

FIGURE 24

Call for Compressor or Fan Only with Ventilation Off

Manual 2100-696A

Page 17 of 17

Loading...

Loading...