Page 1

INSTALLATION INSTRUCTIONS

Partial Flow

Commercial Room Ventilator

24 Volt On/Off

with Spring Return and Exhaust

Models:

CRV-F2 CRV-F3

For Use with Bard Single Stage Wall Mount

Air Conditioner and Heat Pump Models:

CRV-F2

CRV-F3

: W18A/LB, W24A/LB, W18HB, W24HB

: W30A/LB, W36A/LB, W30HB, W36HB

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-691

Supersedes: NEW

Date: 3-1-19

Page 1 of 15

Page 2

CONTENTS

General Information ...............................................3

Commercial Room Ventilator Model Nomenclature ...

Unpacking .......................................................... 3

General ..............................................................3

Description .........................................................3

Application .........................................................3

Installation of Field-Installed CRV-F* .................4

Basic Installation .................................................4

Preparing Unit for CRV-F Installation ................. 4

Commercial Room Ventilator (CRV) No Hood

Installation .....................................................7

Blade Adjustment for Desired Ventilation Air ........11

3

Figures

Figure 1 Wall Mount Unit Access Panels ............. 4

Figure 2 Condenser Exhaust Plate with Screen..... 5

Figure 3 Filter Bracket and Filter Bracket

Fill Plate Installation ............................ 6

Figure 4 Extension Cable Installation .................. 7

Figure 5 Damper Assembly Installation ............... 8

Figure 6 Vent Door Assembly .............................. 8

Figure 7 Required Control Connections for CRV

with Air Conditioners ............................ 9

Figure 8 Required Control Connections for CRV

with Heat Pumps ............................... 10

Figure 9 Blade Adjustment For Desired

Ventilation Air .................................... 11

Figure 10 Call for Ventilation With or Without

Compressor Operation ........................ 14

Figure 11 Call for Compressor or Fan Only with

Ventilation Off ................................... 15

Graphs

Graph 1 W18 Ventilation Delivery ...................... 12

Graph 2 W24 Ventilation Delivery ...................... 12

Graph 3

Graph 4 W36 Ventilation Delivery ...................... 13

W30 Ventilation Delivery ....................... 13

CRV FEATURES

• One piece construction – easy to install with no

mechanical linkage adjustment required.

• Exhaust air damper – built in with positive closed

position. Provides exhaust air capability to prevent

pressurization of tight buildings.

• Actuator motor – 24 volt, power open, spring

return with built in torque limiting switch.

Manual 2100-691

Page 2 of 15

Page 3

GENERAL INFORMATION

Commercial Room Ventilator Model Nomenclature

CRV – F 2

COMMERCIAL ROOM VENTILATOR

FIXED (24V ON/OFF)

CHASSIS SIZE

2 – 1.5 & 2 Ton Models

3 – 2.5 & 3 Ton Models

Unpacking

Upon receipt of the equipment be sure to compare the

model number found on the shipping label with the

accessory identification information on the ordering and

shipping document to verify that the correct accessory

has been shipped.

Inspect the carton housing of each ventilator as it is

received, and before signing the freight bill, verify that

all items have been received and that there is no visible

damage. Note any shortages or damage on all copies

of the freight bill. The receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent. Concealed

damage not discovered until after loading must be

reported to the carrier within 15 days of its receipt.

General

The ventilator should only be installed by a trained

heating and air conditioning technician. These

instructions serve as a guide to the technician installing

the ventilator package. They are not intended as a stepby-step procedure with which the mechanically inclined

owner can install the package.

The ventilator housing is shipped in one carton which

contains the electrical harness, miscellaneous hardware

and installation instructions.

Description

Commercial room ventilators CRV-F2 and CRV-F3 are

designed to be used with the specific models with

"letter" revision codes as designated on the front page

of this installation instructions manual.

The CRV-F ventilator is an electromechanical vent

system designed to provide fresh air to meet indoor air

quality standards.

Commercial room ventilators CRV-F2 and CRV-F3 are

internally mounted dampers with exhaust designed

to provide up to 50% fresh air. The damper blade

is powered by a 24 VAC motor with spring return on

power loss. The damper is powered open anytime A

is energized. Blade stop screws are located under the

fresh air blade and will provide 10 different airflow

settings.

When installed in the models listed on the front page,

the CRV-F provides built-in exhaust provisions. When

the damper blade opens to bring fresh air in, the

damper also opens an exhaust relief. The exhaust air

will flow into the condenser section of the unit. The

condenser fan will help draw exhaust air out when it

is operating with compressor in cooling or heat pump

mode.

Application

The amount of outside fresh air brought into the

structure is dependent on the supply and return duct

static pressure present in the duct system. Refer to

Graphs 1-4 on pages 12-13 for ventilation air that

will be supplied at different blade settings and duct

static pressures. For duct-free applications with return

air filter grilles and supply grilles, use 0.00 supply air

static pressure.

Manual 2100-691

Page 3 of 15

Page 4

INSTALLATION OF FIELD-INSTALLED CRV-F*

Basic Installation

!

WARNING

Electrical shock hazard.

Disconnect remote electrical power supply

or supplies before servicing.

Failure to do so could result in electric

shock or death.

Preparing Unit for CRV-F Installation

1. Disconnect power to unit.

2. Unpack the CRV-F assembly, which includes the

integral controls and electrical harness, body

panels, miscellaneous hardware and installation

instructions.

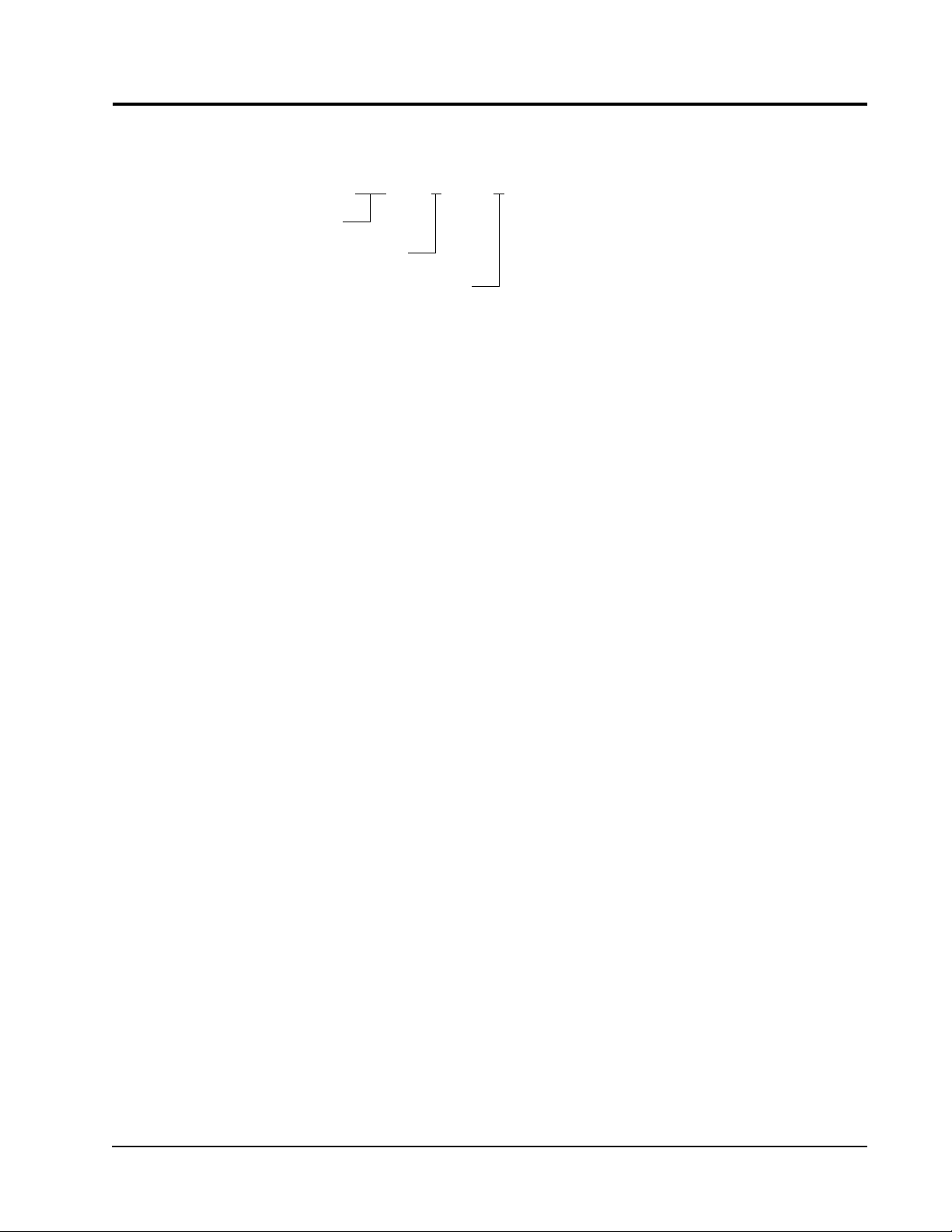

Wall Mount Unit Access Panels

3. From existing wall mount unit, remove and save (or

discard) as directed (see Figure 1):

• Blower access panel (save)

• Vent option panel (save)

• Filter access panel (save)

• Filter (save)

• Outer and inner control panel doors (save)

• Filter tray (discard, if applicable)

• Exhaust cover plate (discard)

4. Install new condenser exhaust plate with screen

over opening into condenser section (see Figure 2).

5. Remove filter brackets, if necessary. Two types

of filter brackets have been used with these wall

mount units. If the filter brackets are mounted

flat, they can be used with the commercial room

ventilator (CRV). If the brackets are set at a 30°

angle, they must be removed and discarded. The

circuit breaker offset plate must be loosened and

moved slightly to gain access to several of the

screws holding the filter brackets in place. Tighten

the screws holding control panel after the filter

brackets have been removed.

FIGURE 1

BLOWER ACCESS PANEL

FILTER ACCESS PANEL

VENT OPTION PANEL

FILTER TRAY

EXHAUST COVER PLATE

(THIS PLATE IS DISCARDED)

FILTER

SCREW

CIRCUIT BREAKER

ACCESS DOOR

CONTROL

PANEL DOOR

MIS-3987

Manual 2100-691

Page 4 of 15

Page 5

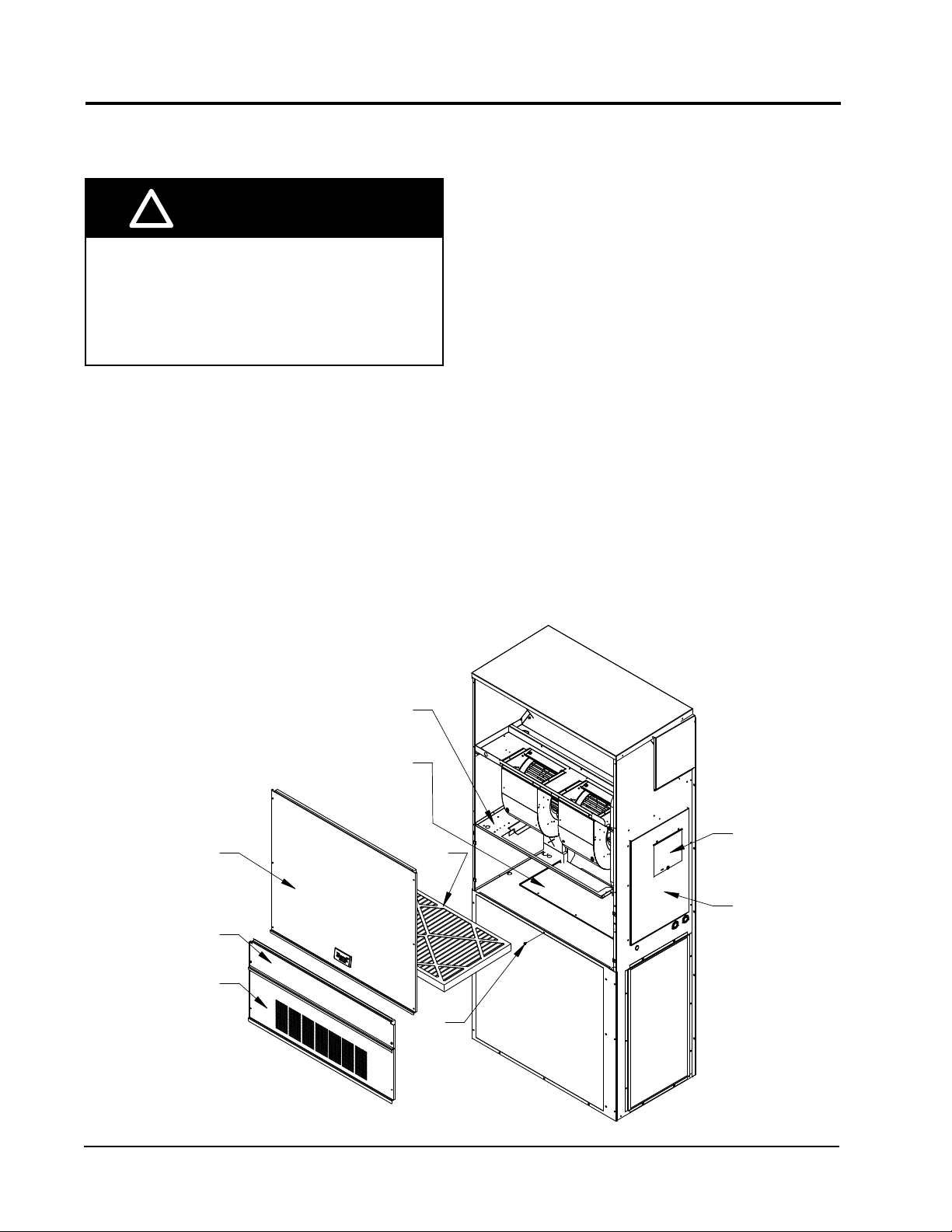

FIGURE 2

Condenser Exhaust Plate with Screen

Condenser Exhaust Plate with Screen

PARTITION COVER

INSTALL COVER PLATE

SCREEN MEDIA FACING

PARTITION

CONDENSER PARTITION

4 SCREWS

PLATE

PARTITION SUPPORT ANGLE

SHOWN FACING DOWN

(HIDDEN)

MIS-3633

If filter brackets were removed in Step 5, proceed

to Step 6. If the brackets were not removed,

proceed to Commercial Room Ventilator (CRV) No

Hood Installation on page 7.

6. Install filter bracket fill plate (if applicable) as

shown in Figure 3 on page 6.

7. Install provided filter brackets on CRV-F assembly

(see Figure 3).

Manual 2100-691

Page 5 of 15

Page 6

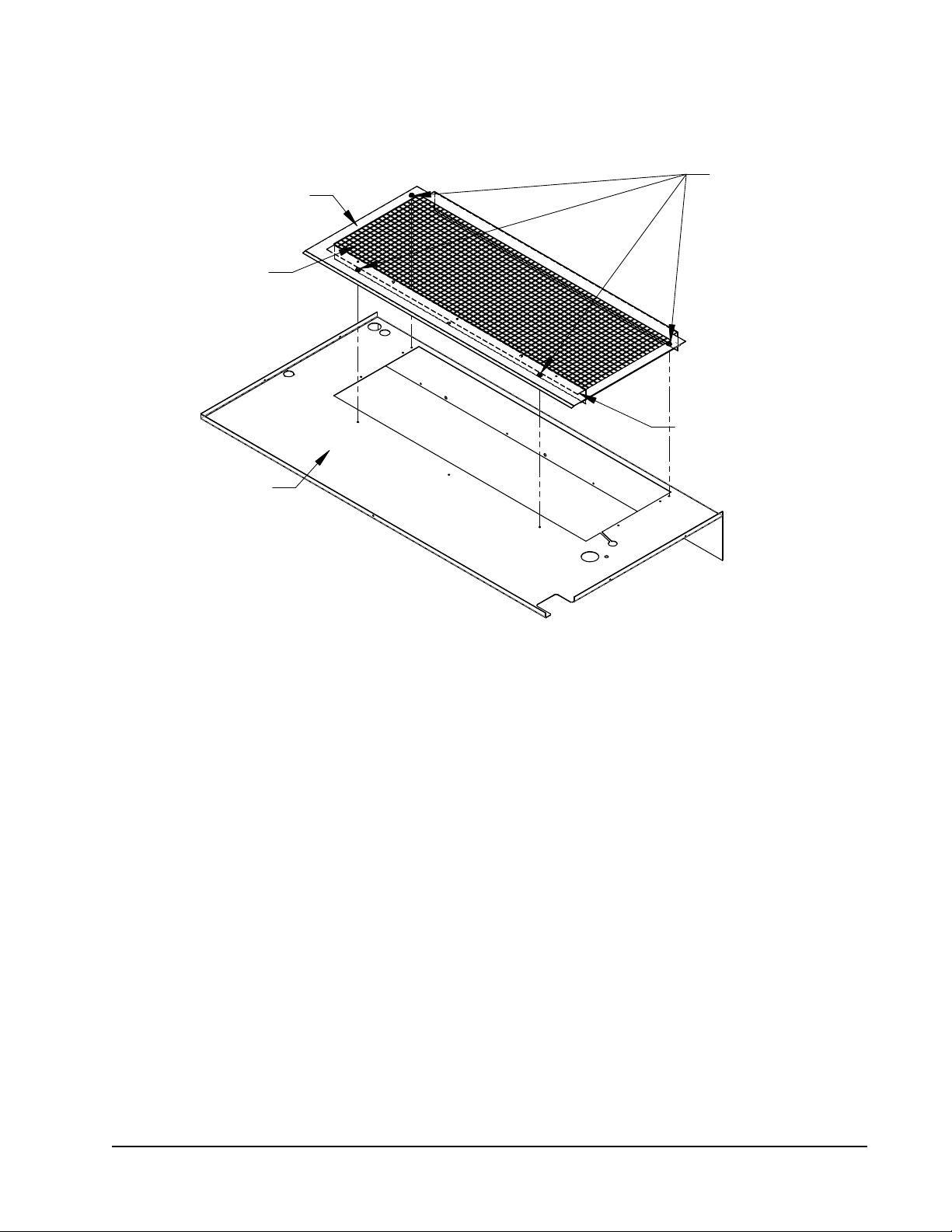

FIGURE 3

Filter Bracket and Filter Bracket Fill Plate Installation

INSTALL FILTER BRACKET

FILL PLATE WITH (2) SCREWS

(ONLY FOR 2-3 TON UNITS)

RIGHT HAND UNIT

LONG FILTER

BRACKET

Manual 2100-691

Page 6 of 15

(4) REGULAR SCREWS

(4) REGULAR SCREWS

SHORT FILTER

BRACKET

LEFT HAND UNIT

LONG FILTER

BRACKET

MIS-3988

Page 7

Commercial Room Ventilator (CRV) No Hood

Installation

1. Insert CRV into opening in the wall mount unit

between the filter rack and the condenser section,

being careful not to tear the unit insulation. Fully

seat CRV assembly to rear of the cavity. Slide the

CRV toward the control panel so that it lines up

with the return air opening in the rear of the wall

mount unit (see Figure 5 on page 8).

2. Insert and lock in the 12-pin plug end of the wire

assembly into the front side of the unit’s control

panel (see Figure 5).

Extension Cable Installation

3. Replace the air filters if they were removed (airflow

direction is up).

4. Put mist eliminator filter into place (as shown in

Figure 6 on page 8), then install the unit filter

door.

5. Make all the required thermostat connections per

the applicable connection diagram found on pages

9 or 10, and restore power to the unit.

6. Replace the lower vent option door with the four

(4) screws provided as shown in Figure 6.

FIGURE 4

NOTE: Incorporated with the CRV-F is one piece of 20˝ split

tubing. The tubing will cover the wire assembly routed to

the actuator. The tubing and wires will be routed under the

actuator assembly.

MIS-3989

FOR LEFT HAND MODELS, ROUTE ACTUATOR

WIRES TO THE LEFT SIDE

Manual 2100-691

Page 7 of 15

Page 8

FILTER/FILTER RACK

TOP OF OUTDOOR

COIL

FIGURE 5

Damper Assembly Installation

CONTROL PANEL

(RH SHOWN)

THE WIRE HARNESS

WILL PLUG INTO THE

FRONT SIDE OF THE

CONTROL PANEL.

POSITION SO THAT HOLE FROM LIP IS

WHEN INSTALLING CRV-F

CENTERED OVER HOLE IN CONDENSER

GRILLE TO INSERT A SELF DRILLING SCREW.

FILTER DOOR

ALUMINUM 8 MESH

SCREEN MATERIAL

FILTER

VENT DOOR

AFTER SLIDING THE VENT PACKAGE

INTO THE WALL MOUNT, SLIDE IT

TOWARD THE CONTROL PANEL SIDE

ALIGNING IT WITH THE RETURN AIR

OPENING IN THE REAR.

MIS-3999

FIGURE 6

Vent Door Assembly

INSERT (4) SCREWS

TO HOLD DOOR IN

PLACE.

Manual 2100-691

Page 8 of 15

MIS-3865

Page 9

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

SC

24V

FIGURE 7

Required Control Connections for CRV with Air Conditioners

SC

SC

COM

G

Y1 Y2 O/B L DA GND

W2

W1/E

Thermostat

Bard #8403-060

Unit Low

Voltage

Term. Strip

1

Vent Plug

Factory installed jumper. Remove jumper and connect

1

to N.C fire alarm circuit if emergency shutdown required.

2 Not needed below 15KW.

Additional wire required for dehumidification models.

3

6 1012119 412-Pin

23 5 7

2

W1/E

LO/BY2Y1R GC W2

2

B/W1

W2C GRT Y1 Y2

CRV-F* PLUGS IN HERE

CRV-F PLUGS IN HERE

4

L/1 DA 4

W3/8

Demand ventilation control, which could include switched CO2 control, or secondary

motion activated switch.

3

YO/D

A

3

76532R

MIS-4000

Manual 2100-691

Page 9 of 15

Page 10

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

SC

24V

SC

COM

FIGURE 8

Required Control Connections for CRV with Heat Pumps

SC

W1/E

G

Y1 Y2 O/B L DA GND

W2

Thermostat

Bard #8403-060

Unit Low

Voltage

Term. Strip

1

Vent Plug

Factory installed jumper. Remove jumper and connect

1

to N.C fire alarm circuit if emergency shutdown required.

2 Not needed below 15KW.

Additional wire required for dehumidification models.

3

6 1012119 412-Pin

23 5 7

2

W1/E

LO/BY2Y1R GC W2

2

B/W1

W2C GRT Y1 Y2

CRV-F* PLUGS IN HERE

CRV-F* PLUGS IN HERE

4

L/1 DA 4

W3/8 76532R

Demand ventilation control, which could include switched CO2 control, or secondary

motion activated switch.

3

YO/D

A

3

MIS-4001

Manual 2100-691

Page 10 of 15

Page 11

Blade Adjustment for Desired

Ventilator Air

The amount of ventilation air supplied by the

commercial room ventilator is dependant on four

factors.

1. Return air duct static pressure drop.

2. Supply air duct static pressure drop.

3. Indoor blower motor speed.

4. Damper blade open position setting.

Refer to the appropriate graph on the following pages

to determine the blade setting needed for required

airflow. Adjust blade stop screws accordingly (see

Figure 9).

Blade Adjustment for Desired Ventilation Air

FIGURE 9

BLADE STOP SCREW

BLADE STOPS

BLADE STOP SCREW

MIS-4002

Manual 2100-691

Page 11 of 15

Page 12

GRAPH 1

W18 Ventilation Delivery

GRAPH 2

W24 Ventilation Delivery

Manual 2100-691

Page 12 of 15

Page 13

GRAPH 3

W30 Ventilation Delivery

GRAPH 4

W36 Ventilation Delivery

Manual 2100-691

Page 13 of 15

Page 14

FIGURE 10

Call for Ventilation With or Without Compressor Operation

COOLING COIL

AIR FILTER

MIST

ELIMINATOR

OUTDOOR AIR

SUPPLY AIR

RETURN AIR

EXHAUST AIR

Manual 2100-691

Page 14 of 15

CONDENSER AIR

CONDENSER COIL

MIS-3866

Page 15

FIGURE 11

Call for Compressor or Fan Only with Ventilation Off

COOLING COIL

AIR FILTER

MIST

ELIMINATOR

OUTDOOR AIR

DAMPER BLADE

SUPPLY AIR

100% RETURN AIR

CONDENSER AIR

CONDENSER COIL

MIS-3867

Manual 2100-691

Page 15 of 15

Loading...

Loading...