Page 1

Bardº

CritiCore”

Monitor

Service

Model

Number:

Manual

000002

Issued:

Pl

3336

[BANA

Covington,

June

1,

GA

1997

30014

C.R.

Bard,

Inc.

Page 2

Copyright

©

1997

C.

R.

Bard,

Bard

and

CritiCore

or

an

affiliate.

This

document

information

to

which

dissemination,

this

document

disclosed

U.S.

Patent

to

others

Nos.

agrees

inc.

All

rights

are

registered

and

subject

C.R.

reproduction,

without

4,448,207,

it

shail

matter

Bard,

written

manufacture,

4,658,834.

reserved.

trademarks

enclosed

Inc.

not

be

consent

Printed

herein

retains

the

and

duplicated

of

Other

of

C.R.

are

exclusive

sale.

in

whole

C.R.

Bard,

patents

in

the

U.S.A.

Bard,

Inc.

proprietary

right

Any

party

or

in

Inc.

applied

of

accepting

part,

nor

for.

Notice

to

Service

Personnel

This

manual

Monitor.

Operators

Be

sure

before

Please

contraindications,

The

attempting

consult

Bard

credentials

equivalent

Caution:

Caution: - The

РР

will

help

Use

this

manual

Manual.

to

read

these

to

product

hazards,

CritiCore

of a Certified

only.

Federal

of

physician.

Bard

devices.

proper

to

properly

result

in

you

troubleshoot

in

conjunction

Manuais

disassemble

labels

warnings,

Monitor

should

Biomedical

(USA)

law

CritiCore

Do

not

attempt

personal

and

ground

damage

to

and

become

or

repair

and

inserts

cautions

be

Equipment

restricts

Monitor

to

work

both

your

the

Bard

and

service

with

the

familiar

the

Bard

for

any

and

serviced

this

by

device

contains

disassemble

station

grounding

body

and

CritiCore

the

Bard

Bard

CritiCore

with

their

CritiCore

indications,

directions

individuals

Technician

to

sale

by

static

sensitive

the

Monitor

apparatus.

your

work

Monitor.

CritiCore

Monitor

contents

Monitor.

for

use.

with

the

(CBET)

or

on

or

the

electronic

without

station

order

the

Failure

could

Page 3

Tabie

of

Contents

NOS

Product

Description

Communications

NY

2

Module.

Functional

Troubleshooting

Mechanical

Bezel

Bezel

Membrane

Display

Temperature

Liquid

Front

Attraction

Rear

Battery

Details

Fluid

Temperature

Microcontroller

Display

Keyboard

Power

Checkout...

Testing

Enclosure

Top

Switch..

PCB

Crystal

Enclosure

Plates

Enclosure

Assembly...

of

Electrical

Output

Electronics

Electronics

Management

information „13

and

Repair

Jack

Display

Electronics

Measurement

(LCD)

Assembly

and

Magnets

seen

Operation.

Details

..

Procedures.........

.

..

..

Electronics

mens

sie

…

20

20

Electronic

Power

Transducer

Phototransistor

Tilt

Temperature

Main

CritiCore

Main

Replacement

Product

Measurement

Instrument

index

CritiCore

Testing

Modules

Sensor

PCB.

Communications

PCB

Component

Specifications

Monitor

and

Calibration

.

..

Electronics

Parts

List.

Ranges

Specifications

Schematics.……....

Map

..

and

....

...

Module

......

Limits.

"eos

Procedures...

73

Bard

CritiCore

Monitor

Service

Manual

Page

1

Page 4

Page 5

Introduction

This

manual

satisfactory

qualified

particular,

personnel

microprocessor-controlled

conjunction

The

contents

1.

Product

specifications,

2.

Functional

*

operation

the

CBET

turther

the

testing.

Functional

returning

3.

Troubleshooting

predetermined

isolate

4.

Mechanical

to

(by

verify

general

5.

Electronic

the

test,

disassemble

either

correct

procedures

repair

is

operation

6.

Replacement

parts.

provides

operation

with

of

who

the

this

the

technical

of

the

are

Bard

CrítiCore

manual

service

Bard

CritiCore

familiar

with

Monitor

are

summarized

Description—Description

and

product

Checkout—Use

of

the

Monitor.

will

be

referred

After

Checkout

the

Bard

CritiCore

information.

If

the

to

repair

is

procedure

this

Monitor

the

necessary

made

Monitor

Information—For

failure,

use

this

guide

problem.

Testing

Bard

use,

Testing

to

made,

before

operation

test

and

and

or

the

and

and

use

the

returning

Parts

Kit

Repair

reassemble

CBET),

before

use

returning

Calibration

calibrate

Functional

the

Bard

List—Listing

the

information

Monitor.

It

electro-mechanical

patient

monitors.

Operator's

below.

ot

Bard

CritiCore

test

procedure

fails

(by

either

to

verify

for

general

monitors

to

identify

to

any

test

sections

Bard

correct

use.

with

the

Procedures—Use

the

Monitor.

the

Functional

the

Bard

Procedures—Use

electronics

Checkout

CritiCore

of

available

of

procedure

Monitor

necessary

is

intended

devices,

Use

this

Manual.

Monitor

verify

correct

within

of

this

or

the

CBET),

operation

an

obvious

necessary

these

After

repair

Checkout

CritiCore

these

the

Monitor.

to

for

general

Bard

replacement

to

maintain

for

use

and

manual

functions,

the

checkout,

manual

for

use

before

or

tests

to

procedures

is

made

procedure

Monitor

for

After

verify

correct

use.

by

in

in

to

Warranty

Repairs

Note:

The

Bard

and

electronic

operation

specified

7.

Product

instrument

8.

Schematics—Schematic

control

Bard

provides a 90-day

repairs

repair

facility.

may

forfeit

to

return

To

obtain

contact

Specifications—Measurement

specifications.

block

diagrams

on

products

If

there

any

warranty

the

Monitor

technical

Bard

Customer

CritiCore

components.

of

the

in

the

replacement

and

limited

under

warranty

is

any

provisions

to

its

original

support,

Service

Monitor

Monitor,

diagrams

timing

warranty

must

evidence

and

condition.

product

at

1-800-526-4455.

contains

To

use

only

parts

many

ensure

Bard

kit

ranges

for

the

CritiCore

charts.

on

each

Bard

be

performed

of

unauthorized

may

be

billed

information,

and

custom

safe

and

replacement

list.

and

limits

Monitor.

CritiCore

at a Bard

service

for

the

for

placing

mechanical

proper

parts

along

Includes

Monitor.

designated

the

customer

repairs

orders

as

with

・

All

required

Bard

CritiCore

Monitor

Service

Manual

Page

2

Page 6

Non-Warranty

Repairs

Monitors

no

longer

constraints:

1.

Only

components

the

repair.

2.

No

component

component

3.

Each

repaired

(see

page

Call

Bard

Customer

components

under

has

is

specified

Bard

7)

before

Service

necessary

warranty

included

been

in

CritiCore

it

is

may

in

the

removed

the

replacement

Monitor

returned

Department

to

complete a repair.

be

repaired

replacement

from

the

parts

Monitor

paris

for

general

passes

the

use.

(1-800-526-4455)

within

the

list

are

unless

list.

Functional

to

following

used

to

that

Checkout

order

make

Contacting

Bard

For

orders

and

1-800-526-4455

through

supply

*

*

«+

*

+

*

*

+

‚

If

Return

and

Customer

To

Friday.

the

Your

Name

Hospital

Address

Telephone

Unit

Model

Unit

serial

Description

Was

ihe

Paiient

you

are

advised

Authorization

address

return

the

following

Name

Monitor

status

of

Service

Bard

technical

between

When

calling

information:

Number

Number

number

of

the

reported

used

and

type

to

return

Label

the

repair

Representative.

CritiCore

support,

8:30AM

and

for

technical

problem

contact

on a patient

of

intervention

the

Monitor

or

detailed

facility,

will

Monitor

for

Bard

Customer

4:30PM

when

eastern

support,

the

problem

required

time,

please

(if

applicable).

to a Bard-designated

mailing

be

instructions,

supplied

to

you

service:

Service

Monday

be

prepared

occurred?

repair

with

the

by

your

at

facility,

name

Bard

to

a

1.

Remove

2.

Package

original

8.

Include a brief

number

Note:

3.

Ship

your

4.

If

requested,

before

’

Bard

CritiCore

and

dispose

the

Monitor

materials

of

the

person

Apply a label

shipping

the

Monitor

Bard

Customer

Bard

any

repairs

Monitor

of 6 D-cell

with

adequate

in

which

the

description

to

be

with

of

the

carton.

Transportation

Service

will

evaluate

are

made.

Service

Manual

batteries.

protection.

Monitor

the

contacted

return

was

problem

for

authorization

Prepaid

as

additional

to

Representative.

the

Monitor

if

available,

shipped.

well

as

the

information.

number

the

location

and provide

use

name

and

to

the

specified

an

estimate

the

phone

by

Page

3

Page 7

Product

Description

The

Bard

CritiCore

monitor, a disposable

System

(temperature-sensing

consists

collection

Foley

catheters).

of a fluid

system,

output

and

disposable

and

core

temperature

temperature

probes

Temperature

Fluid

Ouput

Measurement

Note:

Consult

Monitor

The

Bard

CritiCore

utilizing

rests

Underneath

periodically

container.

towards

functions

microcontroller

burst

container

Bladder

The

thermistor.

the

any

400-Series

ultrasound

within

the

the

transmit a controlled

Ultrasonic

the

transducer

as

receiver,

within

took

to

make

volume.

Temperature

temperature

As

the

thermistor.

change

in

the

thermistor

Monitor and

silicone

sensor

Sensitive

reading.

the

Operators

functions.

Monitor

electronically

technology.

sits

rubber

energy

at

the

detecting

the

CritiCore

the

round-trip.

is

measured

integral

Bladder

Temperature

electronics

resistance

is

converted

Manual

for

details

measures

During

on

cap

will

fluid/air

the

top

is

the

burst

of

travel

interface.

return

Monitor

This

information

operation,

of a silicone

transducer

ultrasonic

through

the

The

of

the

transmitted

will

measure

by a temperature-sensing

to

the

disposable

changes,

in

the

Bard

CritiCore

of

the

thermistor.

The

into a corresponding

on

all

-

fluid

output

the

disposable

rubber

element,

energy

fluid

and

transducer

the

is

then

converted

catheter

so

does

resistive

relative

Bard

CritiCore

volume

container

transducer

which

up

through

reflect

cap.

will

the

back

also

burst.

time

The

the

energy

into

Foley

catheter.

is a “400-Series”

the

resistance

Monitor

vaiue

will

detect

of

the

temperature

of

Figure

1

The

CritiCore

+ | Present

+ © Prior

+

»

*

Interval

Cumulative

Container

Flow

Rate

Monitor

Interval

incorporates

Output

Output

Output

Volume

Calculation

Calculation

Calculation

Calculation

Measurement

the

following

features:

Bard

CritiCore

Monitor

Service

Manual

Page

4

Page 8

i

/

i

fee

i

ο

i

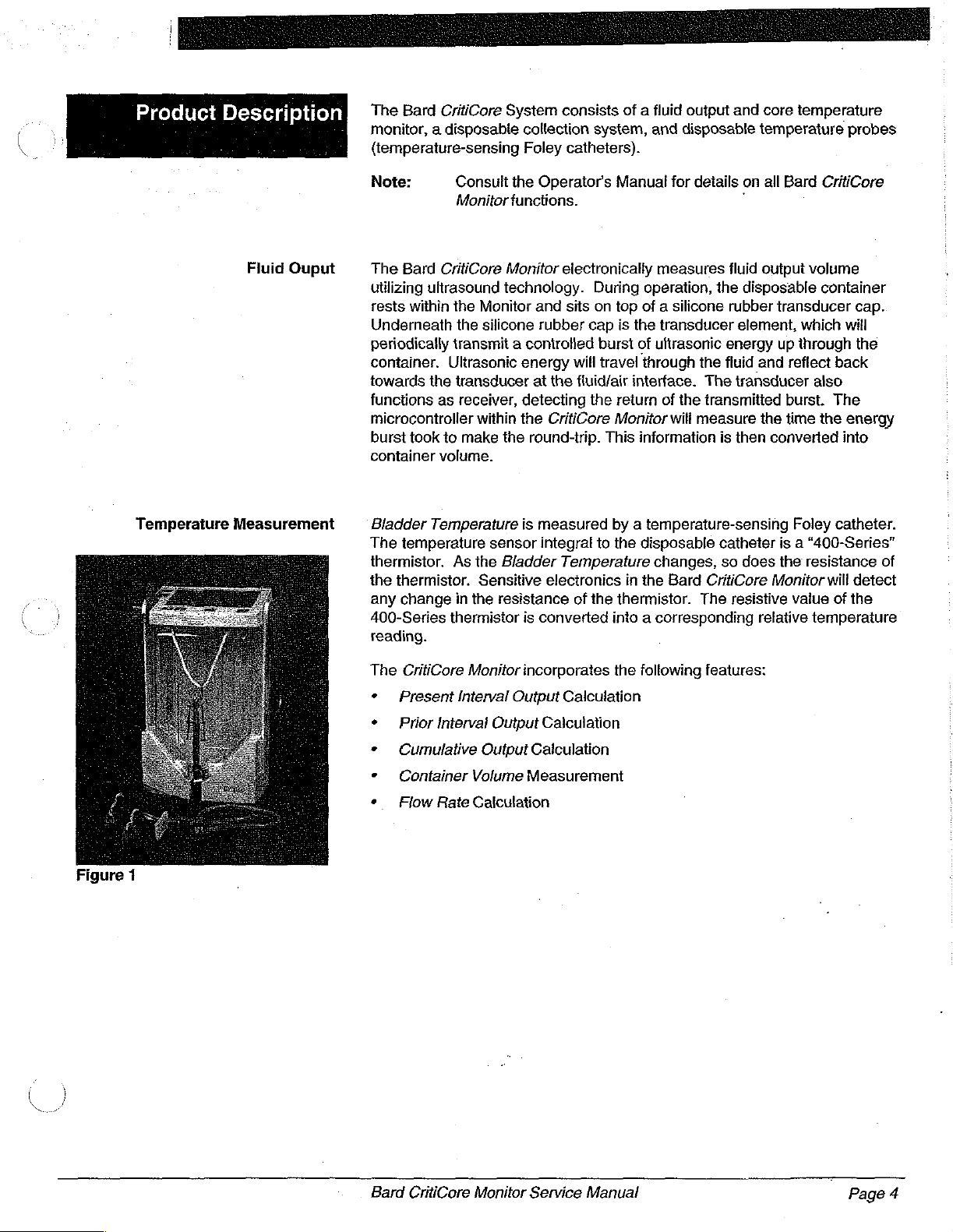

Communications

The

Bard

CritiCore

CritiCore

function

communications

and

Note:

With

in

one

*

+

Figure

2

*

Communications

of

the

the

CritiCore

Consult

functions.

the

CCM,

of

four

modes

210

Emulation

Urotrack®

container

220

Model

Bladder

mode.

Standard

-available

temperature

volume

Emulation

220

temperature

mode—This

from

CritiCore

the

Model

and

Module

Monitor

between a computer

Monitor.

the

user

mode—Emulates

mode—Emulates

Urotrack

the

and

was

designed

Module

Communications

CCM

Operator's

may

configure

(see

Figure

210

Monitor

are

transmitted

Model

and container

mode

Bard

CritiCore

container

volume

3):

communicates

is

to

accommodate

(highlighted

or

the

the

in

this

the

224

Monitors

volume

designed

Monitor.

data

area

Module

patient

Manual

CritiCore

manner

mode.

manner

data

to

Flow

are

transmitted

data

in

Figure

(CCM)

for

in

its

in

communicate

access

is

management

details

Monitor

which

the

data.

Flow

which

the

are

transmitted

all

of

rate,

bladder

the

Bard

2).

to

permit

on

all

to

transmit

Bard

Bard

their

the

in

this

The

system

CCM

data

rate

and

Urotrack

data.

in

this

information

mode.

+

FlexPort”

Bard

Management

mode—Allows

CritiCore

System

Monitor

the

user

to

and a SpaceLabs

(PCMS°)

Monitor.

set

up

communication

Medical

Patient

between

Care

the

у

Page

5

Bard

CritiCore

Monitor

Service

Manual

Page 9

Figure

3—CritiCore

Monitor

with

CCM

Installed

Bard

CritiCore

Monitor

Service

Manual

Page

6

Page 10

Page 11

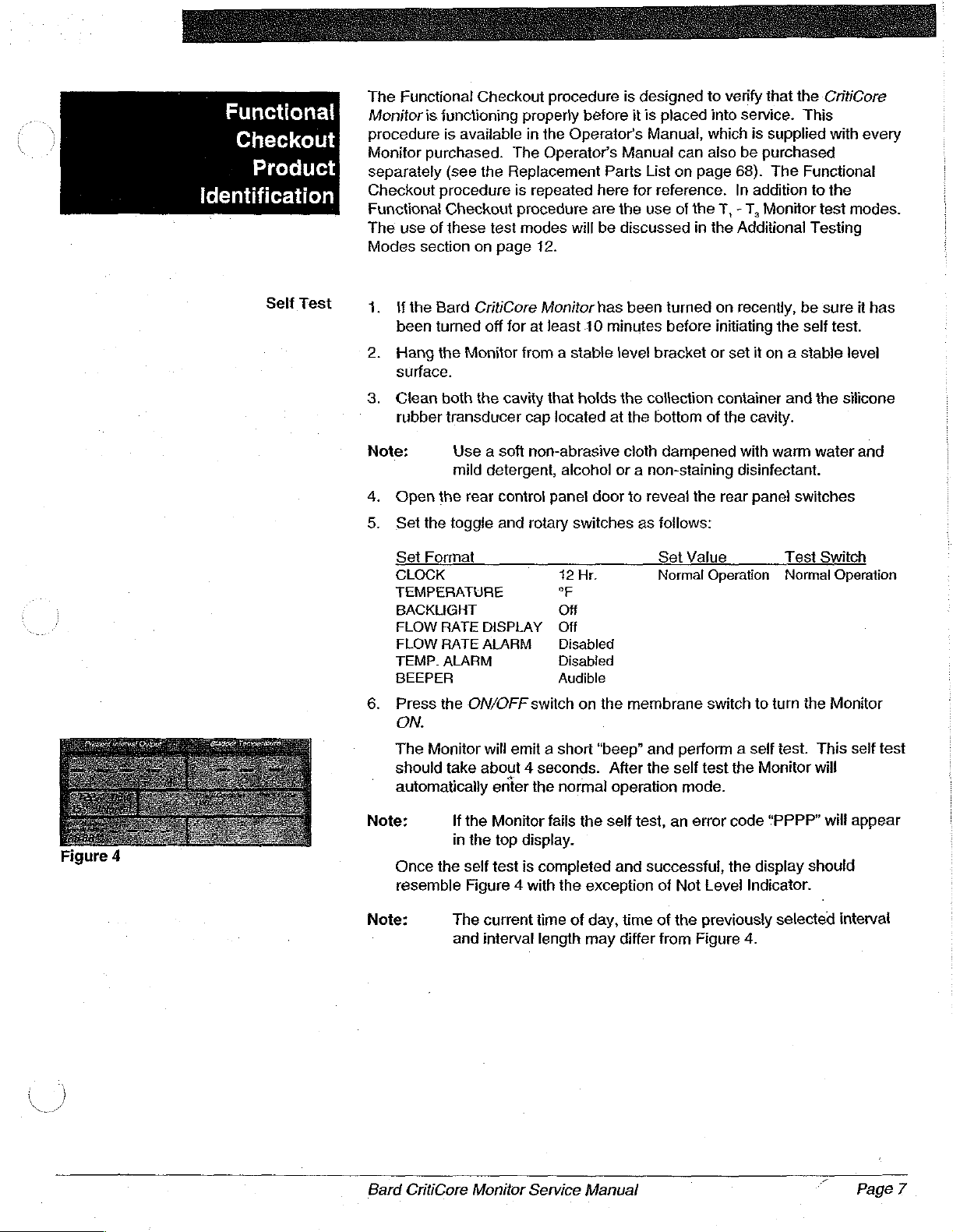

Functional

Chec

Product

t

Identification

Self

Test

The

Functional

Monitor

is

procedure

Monitor

purchased.

separately

Checkout

Functional

The

use

of

Modes

1.

2.

section

the

been

Hang

Bard

turned

the

surface.

3.

Clean

rubber

Checkout

functioning

is

available

The

(see

the

Replacement

procedure

Checkout

these

on

test

page

is

procedure

CritiCore

off

for

Monitor

both

the

cavity

transducer

procedure

properly

in

before

the

Operator's

Operator's

Parts

repeated

here

are the

modes

12.

Monitor

at

least

will

has

10

be

minutes

from a stable

that

holds

cap

located

at

is

designed

it

is

placed

Manual,

Manual

can

List

on

for

reference.

use

of

discussed

been

turned

before

levet

bracket

the

collection

the

bottom

to

verify

into

which

also

page

68).

In

the

T, - T,

in

the

Additional

on

recently,

initiating

or

set

container

of

the

that

the

service.

is

supplied

be

purchased

The

addition

Monitor

the

it

on a stable

and

cavity.

CritiCore

This

with

every

Functional

to

the

test

modes.

Testing

be

sure

it

self

test.

level

the

silicone

has

Note:

4.

Open

5.

Setthe

Set

Format

CLOCK

TEMPERATURE

BACKLIGHT

FLOW

FLOW

TEMP.

BEEPER

6.

Press

ON.

The

Monitor

should

automatically

Note:

Once

resemble

Use a soft

mild

detergent,

the

rear

control

toggle

RATE

RATE

ALARM

the

and

DISPLAY

ALARM

ON/OFF

will

take

about 4 seconds.

enter

If

the

Monitor

in

the top

the

self

test

Figure 4 with

non-abrasive

alcohol

panel

rotary

switches

42

Hr.

°F

Of

Off

Disabled

Disabled

Audible

switch

on

emit a short

the

normal

fails

the

display.

is

completed

the

exception

cloth

dampened

or a non-staining

door

to

reveal

as

follows:

Set

Value

Normal

the

membrane

“beep”

and

perform a self

After

the

self

operation

self

and successful,

test,

of

mode.

an error

Not

with

disinfectant.

the

rear

Operation

switch

test

the

code

the

Level

warm

water

panel

switches

Test

Switch

Normal

to

turn

the

test.

This

Monitor

“PPPP”

display

will

should

Indicator.

and

Operation

Monitor

self

will

appear

test

Note:

Bard

The

current

and

interval

CritiCore

Monitor

time

of

day,

length

may

Service

Manual

time

of

differ

from

the

previously

Figure

4.

selected

”

interval

Раде?

Page 12

Check

Container

Status

1.

2.

3.

Lift

the

the

Monitors

Lower

within

Verify

and

“O

display

front

the

iid

ensuring

the

Monitor.

that

the

ML"

appears

assembly

cavity.

that

Check

Container

in

the

and

install

it

completely

status

Present

an

empty

`

closes

indicator

Interval

Output

disposable

and

on

display.

traps

the

display

container

the

into

container

is

not

lit,

Temperature

System

Clock

1.

Install a temperature-sensing

plug

into

the

temperature

Note:

2.

Verify

temperature

employing a temperature

02Ε.

3.

Remove

catheter

and

1.

Tur

HOUR

status

2.

Use

the

3.

Turn

MINUTE

indicator

A

precision

connected

instead

plug

that

the

the

and

that

the

the

SET

position.

indicators

the

Tl

correct

the

SET

position.

are

hour..

of a calibration

resistances.

Check

reading

temperature

verify

Check

VALUE

Verify

are

switches

VALUE

Verify

flashing.

jack

(0.1%

or

to a 3.6mm

Probe

appears

calibration

calibration

that

the

Bladder

Probe

status

rotary

that

the

flashing.

on

the

membrane

rotary

that

Foley

on

the

better)

mono

plug.

status

switch

switch

indicator

in

the

indicator

on

hour

on

the

minute

catheter

left

decade

mini-phone

See

Bladder

plug

plug

Temperature

segment,

or a temperature

side

of

box

page

disappears

Temperature

the

value

or

temperature-sensing

is

lit.

the

rear

control

PM/AM

switch

the

to

rear

control

segment

the

display

set

to

plug

59

for

should

window

set

the

and

assembly.

1954.70

may

be

table

of

and

that

display.

be

displays

panel

to

and

Set

system

panel

to

Set

Value

calibration

and

used

calibration

a

If

98.6°F

+

Foley

“--.-”

the

Value

clock

to

the

status

Page

8

Intervals

4.

Use

the T switches

clock

to

5.

Return

position

that

the

1.

Turn

the

that

the

flashing.

2.

Use

the

intervals: 5 MIN;

3.

Set

the

VALUE

Bard

CritiCore

the

correct

the

SET

VALUE

and

verify

Set

Value

SET

VALUE

interval

Tl

interval

rotary

segment,

switches

length

switch

Monitor

on

time

that

status

rotary

onthe

10

MIN,

to

to

Service

the

membrane

of

day.

rotary

the

correct

indicator

switch

HA/MIN

membrane

15

MIN,

the

preferred

the

NORMAL

Manual

switch

time

is

to

and

20

switch

to

to

the

NORMAL

appears

not

lit.

the

INTERVAL

Set

Value

switch

MIN;

30

to

MIN;

interval

OPERATION

set

the

on

the

status

display

1HR;

and

return

position.

minutes

OPERATION

display.

position.

indicators

the

2HR.

the

of

Verify

Verify

following

SET

the

are

Page 13

Patient

Interval

Figure

5

Data

Heset/Present

Output/Container

Volume

1.

Filla

so

Note:

tf

step

2.

Cut

urine

jnstall

tnser

tube

container

5.

Press

6.

Using

allow

Monitor.

7.

Wait

Monitor

approximately

8.

Press

approximately

seconds

9.

Press

heard.

10.

Press

Volume

the

disposable

that

it

is

higher

A

60cc

container

this

use

an

irrigation

2.

the

inlet

sample

ihe

modified

the plastic

on

the

filled

extending

the

ON/OFF

either

approximately

approximately

and

the

Container

after

and

hold

the

Container

display

Present

Interval

container

than

irrigation

or

two CritiCore

procedure.

only.

syringe

tubing

port

the

the

“100

“100

the

is

of a second

connector.

second

molded

container

from

switch

irrigation

100ML

10

surface

ML"

Volume

ml"

container

the

Patient

Volume

should

Output

with

water

the

Monitor.

syringe

These

used,

seconds

of

in

Verify

read

containers

proceed

disposable

empty

Control

into

the

the

Monitor

to

tum

syringe

of

water

after

the

water

the

Present

switch.

that

volume

Data

switch a second

within

display

(approximately

can

be

used

disposable

to

container

Fit

connector

soft

plastic

(see

the

Monitor

or a second

to

drain

the

water

is

steady.

Interval

The

display

the

container

switch

Reset

switch

3mi

of

the

should

to

fill

containers

should

step

Figure

is

read

be

5,

otherwise

container

into

the

at

the

tubing

5).

ON.

disposable

into

the

has

The

Output

should

volume

pressed.

until a short

time.

value

between

2100mi)

the

collection

can

dedicated

one

inch

Monitor.

end

of

on

the

container,

container

drained

Monitor

display.

read

disappears

“beep”

The

Container

noted

in

“0”

and

hang

be

used

for

test

continue

below

」

the

drain

second

in

the

into

the

should

Step 8 and

and

is

“3

read

30

ML”.

it

for

with

the

Flow

Rate

1.

Set

the

2.

Set

the

Note:

3.

Press

heard.

and

that

4.

Allow a small

The

seconds

steady.

Bard

CritiCore

FLOW

Interval

If

at

step

until

and

hold

Verify

dashes

Present

after

Monitor

RATE

length

least

15

3.

If

less

the

beginning

the

Patient

that

“0

“----”

amount

Interval

the

water

Service

toggle

to “1

minutes

than

ML”

appears

appear

of

water

Output

flow

switch

HR.”

remain

15

minutes

of

the

hour

Data

Reset

in

in

the

to

drain

should

has

stopped

Manual

to

the

ON

position.

in

the

current

remain

before

switch

the

Present

Flow

into

display a new

in

proceeding

until a short

Rate

display.

the

container

and

the

hour,

proceed

the

current

Interval

Output

reading

water

surface

hour,

with

“beep”

in

the

within

with

wait

step

3.

is

display

Monitor.

15

is

Page

9

Page 14

Not

Level

Full

Container

Indicator

Alarm

5.

Repeat

adding

After

from

Interval

With

~

Verify

3.

Return

indicator

1.

Open

to

2.

Verify

alarm

AUDIBLE

3.

Press

displayed

4.

Drain

Container

5.

Press

displayed

step 4 after

only a small

exactly

dashes

Output

the

that

the

the

fill

the

that

is

heard.

the

about

the.

each

amount

10

minutes

*---”

to a value

display.

Monitor

disappears.

drain

container

position.

Container

is

status

Container

is

ON,

the

Not

Monitor

clamp

the

Full

Note

greater

200ml

indicator

less

than

Level

to a level

in

Container

than

from

minute

the

tilt

the

status

on

the

the

Monitor

that

the

Volume

2000mi

the

is

Volume

2000ml

increment

of

water

current

that

is 6 times

Monitor.

indicator

position

upper

container

to

status

BEEPER

switch

and

Monitor

not

lit

and

switch

and

is

for

each

time.

Flow

Rate

the

becomes

and

verify

2050

mi

of

indicator

and

is

container

and

not

flashes

toggle switch

verify

flashing.

the

audible

verify

flashing.

10

consecutive

display

value

in

lit.

that

the

or

use

an

water.

that

the

and

verify

alarm

that

the

minutes,

should

the

Present

Not

change

Level

irrigation

and

an

audible

should

be

Container

that

the

stops

beeping.

Container

syringe

in

the

Volume

Full

Volume

High

Temperature

Alarm

Before

calibration

1.

2.

3.

Note:

4.

5.

performing

plugs

Set

the

BEEPER

Verify

that

Temperature

Turn

the

Verify

that

display.

be

lit.

Use

the

98.4°F.

Turn

the

position.

status

indicator

98.6+

0.2

this

procedure,

and

reset

TEMP

The 101.0°F

ALARM

toggle

SET

The

limit

removed

Tl

SET

Insert a 98.6°F

switch

the

bell

display.

VALUE

the

Set

High

has

not

switches

VALUE

is

°F,:and

icon

Value

Alarm

for

lit,

is

the

Monitor.

toggle switch

to

the

AUDIBLE

appears

rotary

switch

status

and

Check

will

appear

been

reset

an

extended

on

the

membrane

rotary

switch

calibration

the

value

flashing

and

remove

to

in

the

to

indicator

Probe

only

or

if

both

period

to

plug.

in

the

Bladder

the

audible

any

temperature

the

ENABLED

position.

upper

the

HIGH

and

status

if

the

temperature

battery

of

time.

switch

the

NORMAL

Verify

position

right

corer

TEMP.

101.0°F

to

Temperature

alarm

flashes

indicators

packs

set

the

OPERATION

that

the

is

beeping.

probes

'

of

the

ALARM

should

alarm

have

been

alarm

High

display

or

and

the

Bladder

position.

on

the

also

default

limit

to

Alarm

is

Page

10

Bard

CritiCore

Monitor

Service

Manual

Page 15

Low

Temperature

Alarm

6.

Press

value

Alarm

7.

Reset

temperature

Remove

~

2.

Turn

and

on

should

the

in

Silenced

the

the

verify

the

display.

also

Alarm

the

Bladder

High

Temperature

alarm

the

calibration

SET

VALUE

that

the

be

lit.

silence

Temperature

status

value.

Set

The

Low

switch

indicator

Alarm

plug

and

rotary

switch

Value

status

Alarm

to

verify

display

is

lit.

limit

reset

to

indicator

and

Check

that

continues

to

the

the

LOW

the

audible

the

preferred

Monitor.

TEMP.

and

50.0°F

Probe

status

alarm

to

flash

high

ALARM

(10.0°C)

indicators

stops,

and

the

position

the

flashes

Backlighting

Note:

3.

Use

99.0°F.

4.

Tum

position.

5.

insert a 98.6°F

indicator

6.

Reset

alarm

Place

Press

3.

Do

not

that

it

Note:

4.

If

the

toggle

The

50°F

has

not

for

an

extended

the

TL

switches

the

SET

VALUE

-

is

lit

and

the

Low

value.

the

BACKLIGHT

any

switch

touch

any

will

automatically

It

may

backlight

Monitor

switch

will

to

will

appear

been

reset

period

on

ihe

rotary

calibration

the

audible

Temperature

toggle

on

the

membrane

other

key.

shut

be

necessary

is

visible.

be

used

the

OFF

position

only

or

if

both

of

time.

membrane

switch

plug.

Verify

alarm

Alarm

switch

Verify

off

after

to

dim

in

well-lit

to

if

the

temperature

battery

switch

to

the

NORMAL

that

the

is

beeping.

limit

to

the

in

the

ON

switch.

that

the

display

30

seconds.

the

room

conditions

maximize

packs

have

to

set

Low

Alarm

preferred

position.

backlight

lighting

retum

battery

alarm

default

been

the

alarm

OPERATION

status

low

temperature

is

before

the

the

BACKLIGHT

life.

limit

removed

limit

to

on

and

Monitor

At

this

point

the

Completion

containers

required.

Bard

CritiCore

Functional

used

to

Monitor

hold

Checkout

fluid

so

Service

they

can

Manual

Procedure

be

used

is

complete.

to

check

Store

the

the

Monitor

Page

two

as

11

Page 16

Additional

Testing

Modes

There

are

two

CritiCore

additional

mode

is

discussed

page

When

enter

cycling

Once

switch

Liquid

LCD

When

enter

Interval

Bladder

Monitor.

information

T,

is

60)

and

the

rotary

into a display

through a sequence

in

T,

settings.

Crystal

Display

the

rotary

into a software

Output

Temperature

necessary,

Customer

Service

manufacturing

Located

used

only

in

the

Installing

should

TEST

testing

mode,

the

This

allows

Display

procedure

TEST

checksum

window,

have

the

Monitors

Representative

on

on

the

for

calibration

only

be

SWITCH

mode.

of

cycle

will

the

(LCD)

(on

page

SWITCH

the

software

window,

test

modes

the

rear

status

of

of

and

Calibrating

performed

is

rotated

This

decimal

continue

technician

are

functioning

30)

for

is

rotated

and

revision

checksum

the

software

serial

number

for

the

available

control

certain

the

functions.

temperature

the

by

qualified

to

the

mode

will

and

hexadecimal

regardless

to

verify

properly.

details

to

the

display

revision

available

correct

for

panel,

Main

T,

position,

cause

of

that

on

this

T,

position,

will

be

values.

further

T,

PCB

checkout

and

T,

can

Please

circuitry.

procedure

note

Calibration

personnel.

the

Monitor

the

display

numbers/letters.

any

toggle

all

segments

See

the

Testing

test

mode.

the

Monitor

mode.

In

the

displayed.

number

and

is

displayed.

contact

of

provide

that

(on

to

begin

or

rotary

of

the

the

Present

In

the

your

the

.

te.

will

will

If

Bard

Page

12

Bard

CritiCore

Monitor

Service

Manual

Page 17

Troubleshooting

Information

The

following

problems

troubleshooting

with

your

Bard

flowcharts

CritiCore

are

Monitor.

provided

to

help

diagnose

Short

Monitor

the

batteries

Test

Battery

is

draining

prematurely

Y

current

consumption

(page

47)

Life

Troubleshooting

Current

consumption

OK?

Flow

Chart

No

Replace

Main

Circuit

Board

Yes

+

unit

Does

problem

persist?

Yes

to

Bard

Monitor

for

Service

Service

No

Manual

Problem

Send

Bard

CritiCore

Solved

Page

13

Page 18

"Not

"Not

not

Level"

lit

when

Level"

lit

monitor

level.

when

not

level.

indicator

indicator

monitor

is

is

is

is

Tilt

Sensor

„|

Test

the

SENSPWR

(page

Troubleshooting

signal

47).

Flow

Chart

Verify

is

Test

that

within

the

(page

Does

check

the

monitor

6°

of

level.

Display

29)

LCD

out

OK?

LCD

Does

out

Yes

signal

OK?

SENSPWR

check

у

Test

the

Tilt

Sensor

(page

55).

Does

Tilt

Sensor

check

Yes

out

OK?

No:

Replace

Main

Circuit

Board.

Lightly

№-—+

tap

housing

sensor

on

to

3

Tilt

Sensor

loosen

ball.

Page

14

No

Replace

LCD.

ㆍ

Problem

solved.

Re-test

the

(page

Replace

Main

Circuit

Board.

No

Does

check

Problem

Bard

CritiCore

Monitor

Service

Manual

Tilt

Tilt

out

Yes

Sensor

5).

55)

Sensor

OK?

solved.

Page 19

Container

Sensor

Troubleshooting

Flow

Chart

"Check

when

"Check

when

The

container

Transducer

Phototransistor

Test

the

Container"

container

Container"

container

y

Verify

the

following:

surface

is

of

not

cap

Display

indicator

is

not

present.

indicator

is

present.

fluid

in

the

vibrating.

is

clean.

is

clean.

LCD

(page

is

is

29).

not

lit

lit

Test

the

SENSPWR

(page

signal

47).

Does

SENSPWR

Test

the

signal

check

out

OK?

Yes

Phototransistor

(page

53).

No-

Replace

Main

Circuit

Board.

Does

LCD

check

No

Replace

out

LCD.

OK?

Does

Send

unit

Phototransistor

check

out

OK?

Yes

Does

problem

persist?

Yes

to

Bard

for

service.

No

No

Replace

Problem

Display

solved.

assembly.

Bard

CritiCore

Monitor

Service

Manual

Page

15

Page 20

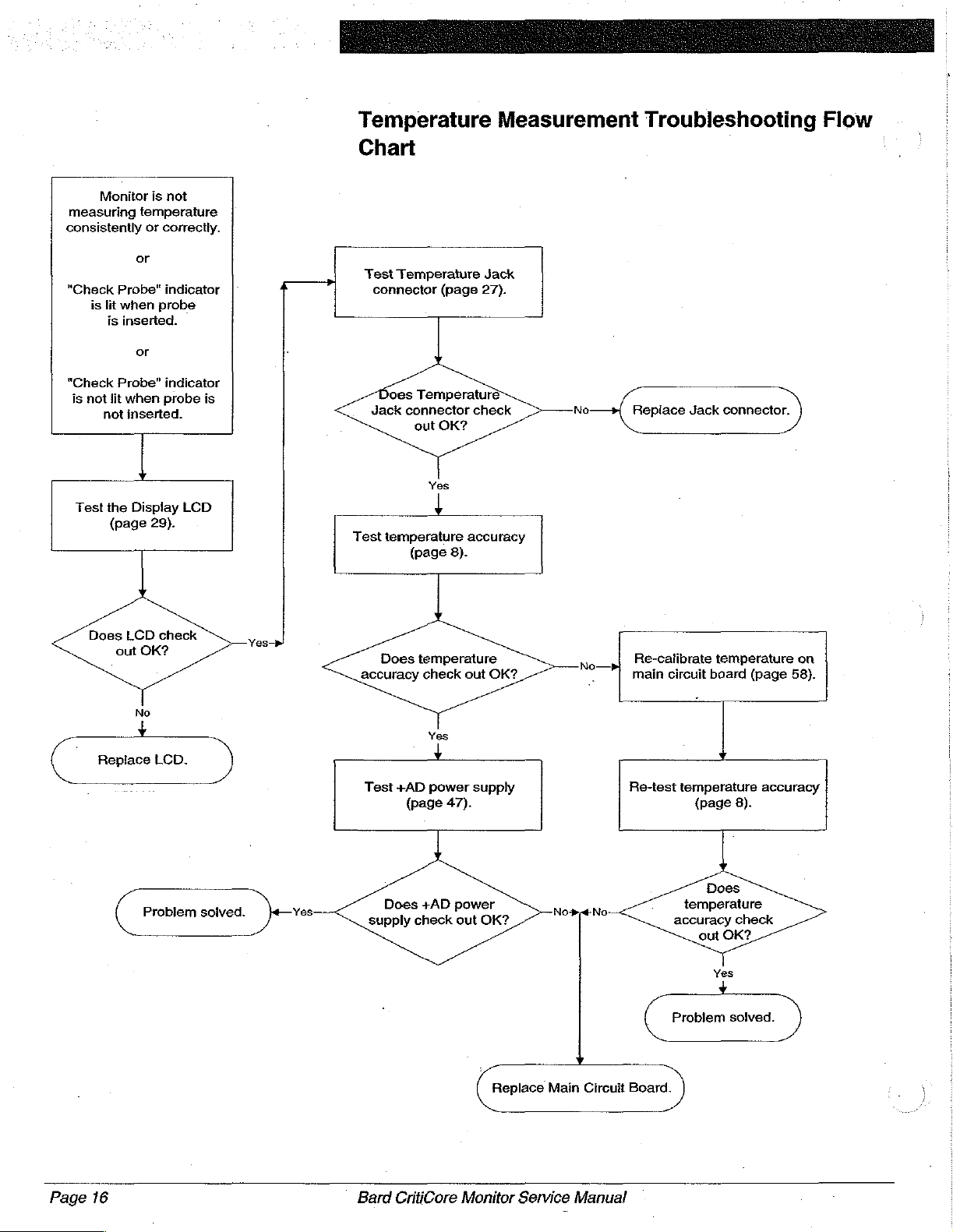

Monitor

measuring

consistently

"Check

is

or

Probe"

lit

when

is

inserted.

or

is

not

temperature

or

correctly.

indicator

probe

Temperature

Measurement

Troubleshooting

Flow

Chart

Test

|*

4

Temperature

connector

(page

Jack

27).

"Check

is

not

Test

Probe"

lit

when

not

inserted.

the

(page

indicator

probe

개

Display

29).

LCD

Does

LCD

|

Replace

out

check

OK?

No

LCD.

is

Does

Jack

Temperature

connector

out

OK?

Yes

check

No

Repiace

Jack

connector.

Test

temperature

(page

Does

accuracy

Test

temperature

+AD

(page

8).

check

Yes

+

power

47).

accuracy

out

OK?

supply

№—

Re-calibrate

main

circuit

Re-test

temperature

board (page

temperature

(page

8).

on

58).

accuracy

Page

16

Problem

solved.

Yes

Does

supply

Bard

+AD

power

check

out

CritiCore

OK?

Replace

Monitor

Main

Service

Circuit

Manual

Board.

Does

temperature

accuracy

out

Yes

Problem

check

OK?

solved.

Page 21

Volume

Measurement

Troubleshooting

Flow

Chart

Monitor

consistently

The

"Not

"Check

Transducer

_

Test

the

is

not

measuring

4

Verify

the

container

2000mi

Level"

Container"

holds

indicator

cap

Display

volume

or

correctly.

following:

less

than

of

fluid.

is

not

indicator

LCD

is

clean.

(page

is

lit.

not

29).

lit.

4

Test

the

STRTXM

signal

(page

Does

Test

STRTXM

check

Yes

the

Transducer

(page

out

y

charge

51).

signa

OK?

signal

50).

N

o:

Replace

Board.

Main

Circuit

Does

LCD

check

out

No

Replace

LCD.

OK?

?

signal

Does

Send

unit

Does

check

problem

to

Transducer

out

OK?

Yes

persist?

Yes

Bard

for

service.

No

z

ο

Replace

Problem

Transducer.

solved.

Bard

CritiCore

Monitor

Service

Manual

Page

17

Page 22

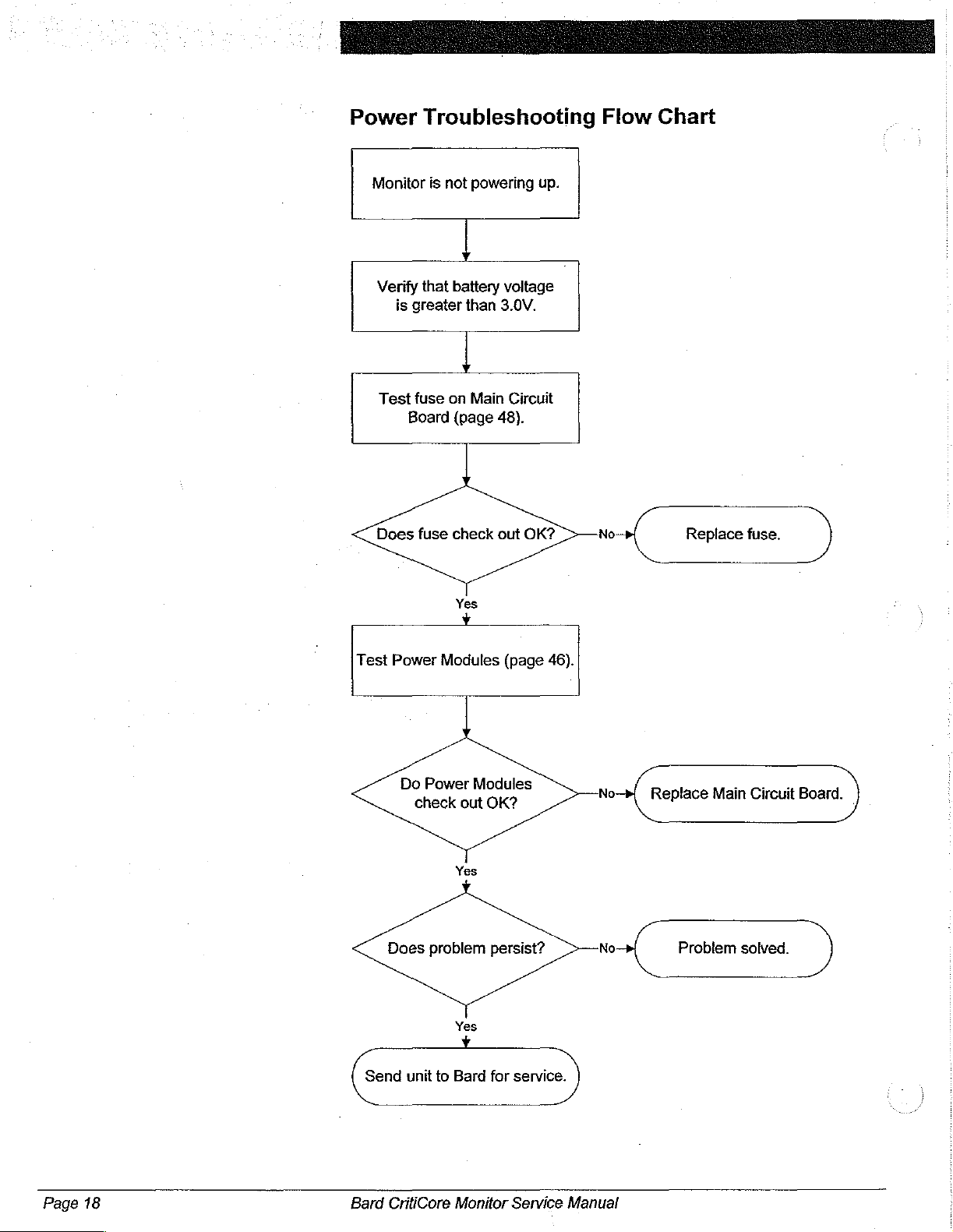

Power

==

Troubleshooting

Flow

Chart

Monitor

Verify

is

greater

Test

Board

Does

is

that

fuse

fuse

not

powering

г

battery

than

r

on

Main

(page

check

Yes

y

up.

voltage

3.0V.

Circuit

48).

out

OK?

No:

Replace

fuse.

Test

Power

Does

Send

Do

check

unit

Modules

Power

out

Yes

problem

Yes

to

Bard

(page

Modules

OK?

persist?

for

service.

46).

No

No

Replace

Problem

Main

Circuit

solved.

Board.

Page

18

Bard

CritiCore

Monitor

Service

Manual

Page 23

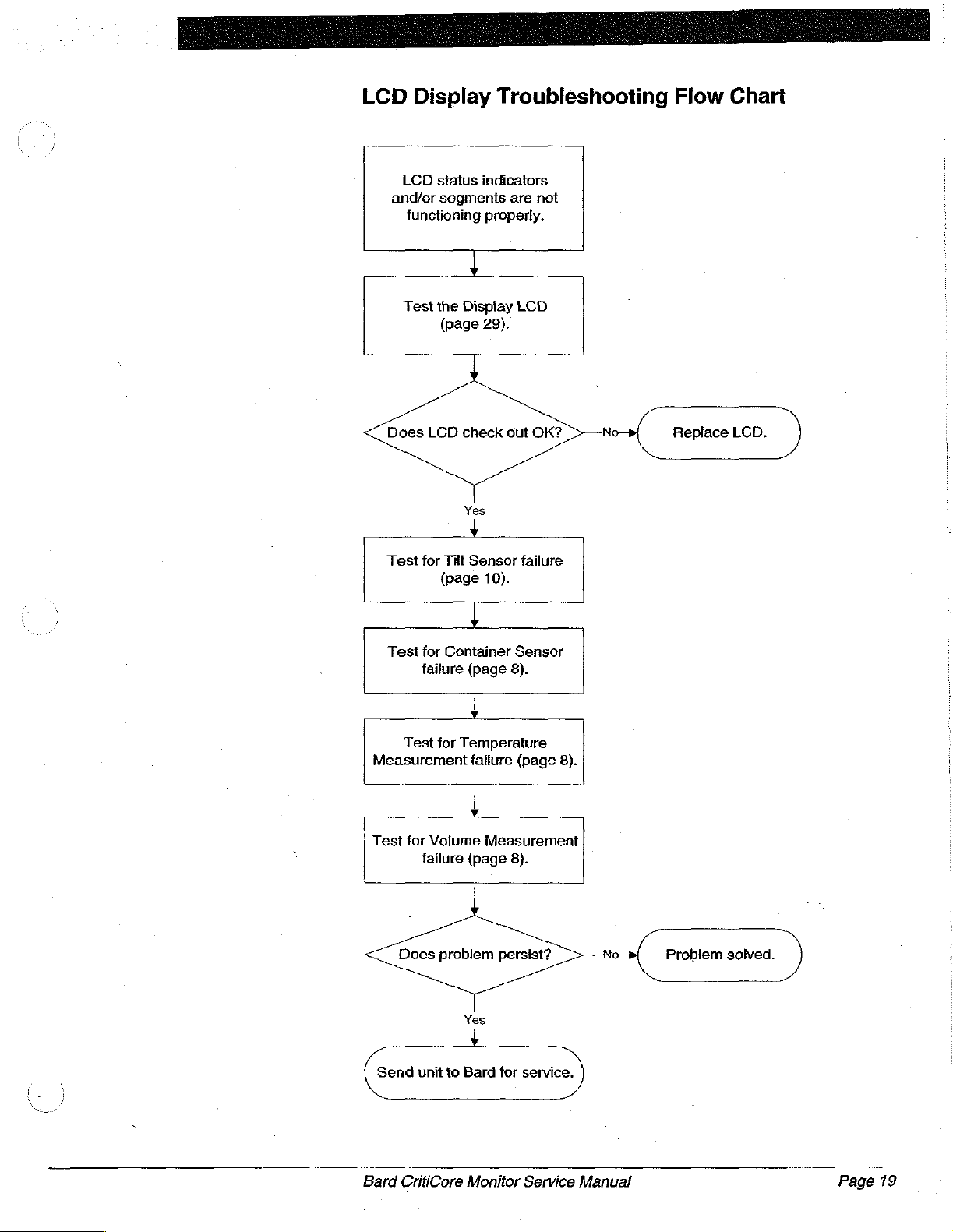

LCD

Display

LCD

status

and/or

segments

functioning

Test

the

(page

Troubleshooting

indicators

are

not

properly.

4

Display

LCD

29).

Flow

Chart

Does

LCD

Test

for

Tilt

(page

Test

for

Container

failure

o

Test

for

Measurement

Test

for

Volume

failure

check

out

Yes

Sensor

failure

10).

!

Sensor

(page

8).

Temperature

failure

(page

4

Measurement

(page

8).

OK?

No

8).

“|

Replace

LCD.

Does

problem

Send

unit

to

Bard

CritiCore

persist?

Yes

Bard

for

Monitor

service.

Service

No

Manual

Problem

solved.

Page

19

Page 24

Page 25

Mechanical

-and

A

Testing

Repair

The

following

assembly

CritiCore

sections

procedures

Monitor.

outline

for

the

the

appropriate

individual

testing,

mechanical

disassembly

components

of

and

the

re-

Bard

Figure

6

Testing

the

Bezel

Enclosure

Bezel

The

from

attached

pins.

the

attraction

container.

seated

signal

Visually

broken

be

must

40)

1.

2.

3.

Enclosure

bezel

enclosure

impact

attraction

replaced.

be

for

Place a disposable

_Lift

onto

and

ff

material

assembly

insert,

to

The

magnets

is

The

on

the

loss

when

inspect

or

cracked,

replaced.

magnet

the

the

rest

the

bezel

remove

and

the

bezel

plates

necessary

force

transducer

If

one

replacement

display

container

on

enclosure

inside

may

Enclosure procedure

must

be

replaced.

insert

and

hinge

isopropyl

alcohol.

(Figure

6)

contamination

top

and

inserted

which

on

to

the

are

apply

and

container

cap.

the

container

the

bezel

enclosure

it

may

allow

or

both

of

See

the

Attraction

procedure.

container

assembly

cap.

The

the

container

hinge

the

hinge

be

hindered.

the

hinge

pins

(below).

lf

foreign

pin

by

using a non

protects.

by

foreign matter.

is

hinged

to

affixed

attached

pressure

cap

This

in

turn

holds

little

for

damage.

fluid

to

enter

the

magnets

Plates

into

the

up

approximately

dispiay

cap.

pin

insert

pin/insert

junction,

To inspect

as

described

If

cracks

matter

abrasive

the

underside

the

front

to

the

bezel

to

the

front

to

ihe

top

ensures

allows

or

no

fluid.

into

are

missing

and

Monitor.

1/2

assembly

is

cracked,

for

cracks

in

are

found,

is

the

cause,

of

The

enclosure

enclosure

enclosure.

of

the

that

for

minimal

if

the

the

display

Magnets

inch

should

or

the

movement

the

Removing

the

clean

cloth

dampened

the

display

bezel

is

by

disposable

the

container

bezel

enclosure

PCB

or

damaged,

section

and

allow

drop

if

there

inside

the

bezel

out

PCB

directly

the

hinge

are

drawn

The

force

is

firmly

transducer

is

and

should

they

(on

page

it

to

drop

unhindered

is

foreign

of

the

display

hinge

pin

the

Bezel

enclosure

the

plastic

with

70%

to

of

Removing

the

Bezel

Enclosure

个

Equipment

*

No. 2 Phillips

e | Needle

Caution:

Required

screwdriver

nose

pliers

The

Bard

static

sensitive

internal

Discharge)

your

components

body

CritiCore

electronic

handling

and

your

Monitor

devices.

without

equipment.

work

station

main

proper

could

and

display

Do

not

ESD

Failure

result

PCB’s

contain

attempt

to

repair

(Electro-Static

to

properly

in

ground

damage

to

any

both

the

Monitor.

Bard

CritiCore

Monitor

Service

Manual

Page

20

Page 26

Page 27

Figure

‘Figure

8

9

Note:

Procedure

1.

Ensure

battery

2.

Place

3.

Remove

Monitor

it.

snap

remove

position

Using a needle-nose

After

Figure

6.

Open

the

puit

7.

Remove

Figures 9 and

door.

8.

Pull

the

the

set

9.

Pull

12),

display

Review

(see

you

that

packs.

the

the

enclosure.

The

snap

ring

it.

by

removing

8.

the

TEST

gently

the

straight

front

of

blank

aside

the

out

on

Disconnect

assembly

the

contents

Replacement

may

need

the

Monitor

Monitor

must

İf

rear

SWITCH

to

the

insert

the

face

hinge

pins

Each

ring

must

be

oriented

the

snap

using a small

both

snap

control

rotary

remove

four

(4)

10

(arrows

up

on

the

Monitor.

in

place

blank

plastic

ejector

the

is

totally

of

Parts

to

keep/discard

is

turned

down

on a soft

which

hinge

be

removed

properly,

ring

is

not

flathead

pliers,

the

6-32x3/8”

display

remove

rings,

pane!

door.

knobs

rotary

indicate

rear

enclosure

The

while

insert.

latches

cable

detached

arrow

the

bezel

List

on

during

off.

Remove

surface.

connect

knobs.

Phillips

removing

on

the

pin

has

in

order

as

properly

screwdriver.

both

pull

out

Ensure

are

set

pan-head

screw

(see

in

Figure

the

display

from

from

enclosure

page

66),

to

disassembly.

the

battery

display

an

e-style

illustrated

oriented,

snap

both

that

to

NORMAL

locations).

Figure

the

the

the

assembly

snap

to

pull

out

in

rings.

hinge

both

screws

11)

11.

illustrates

rear

enclosure.

cable

main

PCB.

Monitor.

replacement

confirm

Figure 7 in

rotate

pins

the

OPERATION,

Close

to

connector

which

doors

to

ring

mounted

the

hinge

it

into

as

illustrated

SET

VALUE

as

illustrated

the

separate

how

Remove

(see

At

this

parts

parts

and

the

pin.

order

correct

then

rear

panel

it

from

to

hold

Figure

point

kit

on

The

to

in

>

and

in

and

°

the

Fi

본

0

igure

Installing

the

Bezel

Enclosure

7

10.

Place

switch

11.

Separate

the

four

Equipment

e

No. 2 Phillips

+

Needle

Caution:

Bard

CritiCore

the

display

is

face

down.

the

bezel

(4)

6-32x1/4”

Required

screwdriver

nose

pliers

The

Bard

static

sensitive

internal

Discharge)

your

body

Monitor.

Monitor

assembly

enclosure

Phillips

CritiCore

electronic

components

handling

and

your

Service

on a soft

from

the

pan-head

Monitor

equipment.

work

Manual

main

devices.

without

station

surface.so

bezel

top

screws.

and

display

Do

not

proper

ESD

Failure

could

result

that

the

membrane

assembly

attempt

(Electro-Static

to

properly

PCB's

in

damage

by

contain

to

repair

ground

removing

any

both

to

the

Page

21

Page 28

Procedure

1.

2.

Figure

11

3.

4.

5.

6.

7.

8.

Install

the

four

(4)

6-32x1/4”

Reconnect

Ensure

are

Place

plastic

the

screws

Ensure

for

Insert

Insert

Stand

SET

on

when

Perform

alt

that

firmly

the

blank

rear

enclosure

(see

that

the

hinge

the

and

the

VALUE

the

two

they

the

display

bezel

enclosure

Phillips

the

display

the

cable has

closed.

rear

enclosure

insert

is

by

Figures 9 and

the

display

pins

are

two

hinge

connect

Monitor

knobs

were

and

the

up,

and

TEST

are

removed.

Functional

general

to

pan-head

cable

been

onto

held

into

installing

10).

assembly

clear.

pins

(see

battery

open

the

SWITCH

oriented

Checkout

Monitor

the

bezel

screws.

connector

fully

inserted

the

front

position

the

four

is

correctly

Figure

8),

packs

and

rear

control

rotary

in

the

same

procedure

functions

top

assembly

to

the

main

and

enclosure,

as

illustrated

(4)

6-32x3/8”

oriented

and replace

install

the

panel

knobs,

ensuring

direction

(see

are

working

by

installing

PCB

that

the

ensuring

in

Figure

Phillips

so

the

battery

door

and

that

that

they

page

7)

properly.

(see

Figure

ejector

that

11.

pan-head

that

the

snap

doors.

reattach

the

were

to

ensure

the

12).

latches

the

Instait

holes

rings.

the

arrows

in

that

Bezel

The

The

directly

enclosure

shows a bezel

Figure

13

Testing

Removing

the

the

Bezel

Bezel

т

Top

Top

Visually

cracked,

replaced.

Equipment

・

+

*

Caution:

Top

bezel

membrane

attached

No. 1 Phillips

No. 2 Phillips

Needle

top

is

which

top

inspect

it

may

Required

nose

The

static

internal

Discharge)

your

Monitor.

the

outermost

switch,

the

allow

Bard

bezel

to

the

bezel

is

hinged

with

the

bezel

fluids

screwdriver

screwdriver

pliers

CritiCore

sensitive

components

handling

body

and

plastic

enclosure

top.

The

by

the

hinge

membrane

top

for

damage.

to

enter

Monitor

electronic

without

equipment.

your

work

enclosure

and

bezel

pins

switch

into

the

main

devices.

proper

station

of

display

top

is

to

the

installed.

If

the

bezel

display

and

display

Do

ESD

Failure

could

the

display

PCB/LCD

assembled

front

enclosure.

top

PCB

not

attempt

(Electro-Static

to

properly

result

is

broken

and

PCB’s

in

damage

assembly.

assembly

to

should

to

the

bezel

Figure

or

be

contain

repair

ground

to

the

aré

13

any

both

Page

22

Bard

CritiCore

Monitor

Service

ポン

Manual

Page 29

Note:

Procedure

1.

Remove

procedure

2.

Disconnect

PCB

3.

Remove

display

PCB/LCD

display

two

Figure

15

15).

Review

replacement

to

confirm

disassembly.

the

on

the

(see

Figure

the

PCB/LCD

assembly

PCB

o-rings

on

the

which

bezet

enclosure

page

20.

membrane

14).

four

(4)

assembly

corners

the

temperature

contents

parts

kit

parts

switch

4-40x1/4”

to

from

the

as

illustrated

of

the

Bezel

(see

Replacement

you

may

per the

mylar

Phillips

the

bezel

bezel

top

in

jack

Top/Membrane

need

Removing

ribbon

pan-head

top.

by

gently

Figure

of

the

display

Parts

to

keep/discard

the

Bezel

cable

screws

Separate

pulling

15.

Take

PCB

List

from

which

the

up on

care

(arrow

Switch

on

page

during

Enclosure

the

display

attach

display

the

to

retain

in

Figure

66),

the

the

Installing

the

A

Bezel

Top

Caution:

Equipment

*

No. 1 Phillips

*

No. 2 Phillips

+ © Needle

Caution:

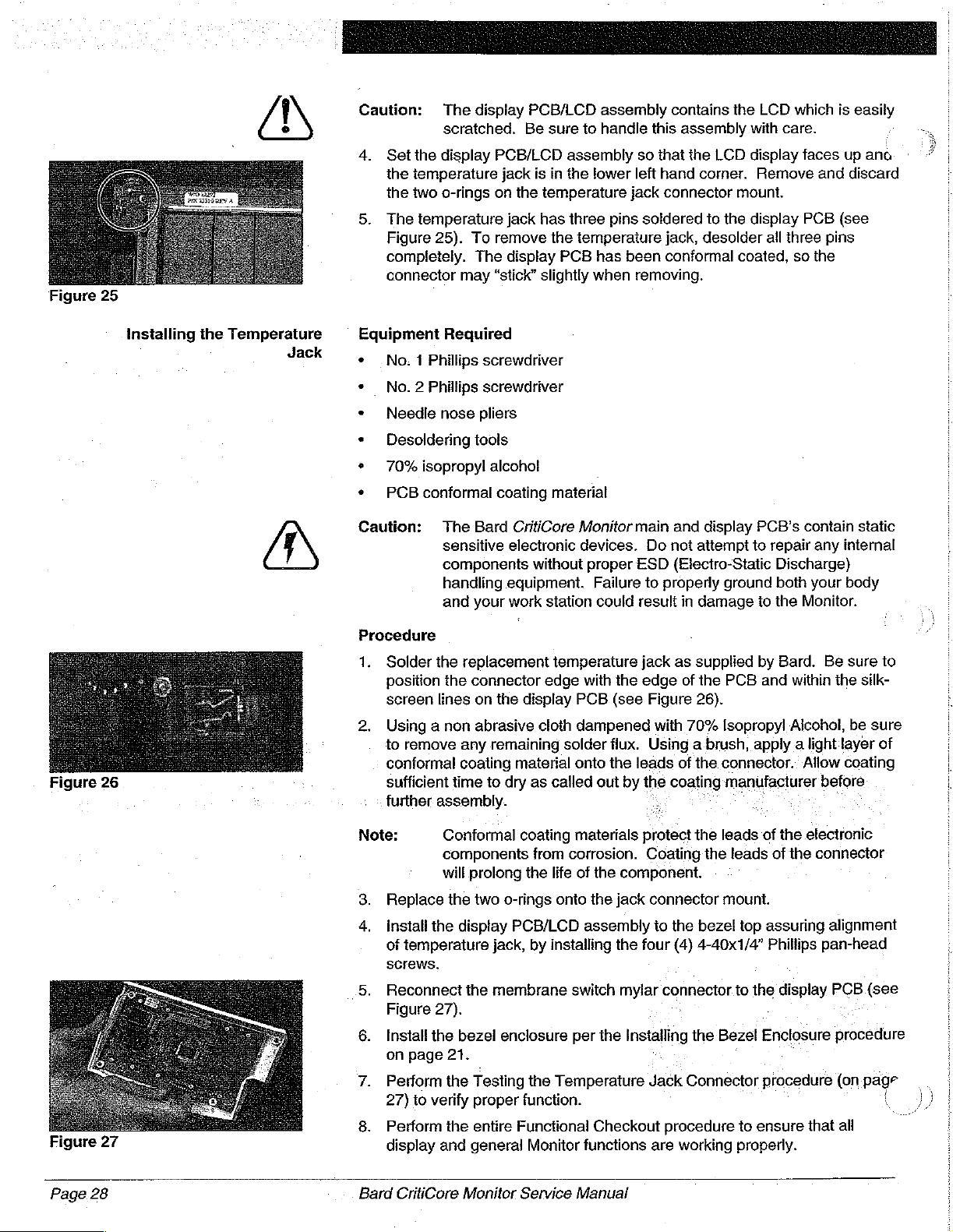

Procedure

1.

The

bezel

and

panel

procedure

2.

Perform

all

display

The

display

easily

scratched.

Required

screwdriver

screwdriver

nose

pliers

The

Bard

static

sensitive

internal

Discharge)

your

body

Monitor.

top/membrane

seal.

on

page

the

Functional

and

general

PCB/LCD

Be

CritiCore

electronic

components

handling

and

your

switch

To

install,

25.

Checkout

Monitor

assembly

sure

to

Monitor

devices...

without

equipment..

work

station

kit

follow

the

procedure

functions

contains

handle

main

and

Do

proper

comes

installing

ESD

Failure

could

with a new

(see

are

the

LCD

this

assembly

display

the

working

PCB's

not

attempt

(Electro-Static

to

propefly

result

in

damage

membrane

Membrane

page

7)

properly.

which

with

care.

contain

to:repair

ground

.

Switch

to

ensure

is

any.

both

to.tre

switch

that

-

Membrane

The

membrane

contact

adhesive

connects

is

transparent

(LCD).

and

impact.

Bard

CritiCore

Switch

switch

switches.

backing. A mylar

the

The

The

membrane

and

provides

membrane

Monitor

(Figure

membrane

switch

Service

16)

ribbon

switch

the

aiso

is a multi-layered

switch

cable

to

the

user

Manual

is

attached

with a connector

display

visibility

protects

of

the

PCB.

the

LCD

label

to

the

The

center

Liquid

from

containing

bezel

top

is

attached

viewing

Crystal

fluids,

Display

scratches,

6

via

and

area

Page

an

23

Page 30

Note:

There

are

membrane

viewing

gridlines.

The

area,

current

screened

designed

the

viewing

two

versions

switch

and

membrane

onto

the

for

use

area.

design

is

used

viewing

with

an

of

the

has

with

switch

area.

LCD

membrane

gridlines

an

design

which

LCD

This

has

screened

that

does

membrane

switch.

The

onto

does

not

not

have

switch

gridlines

screened

original

the

have

gridlines

is

onto

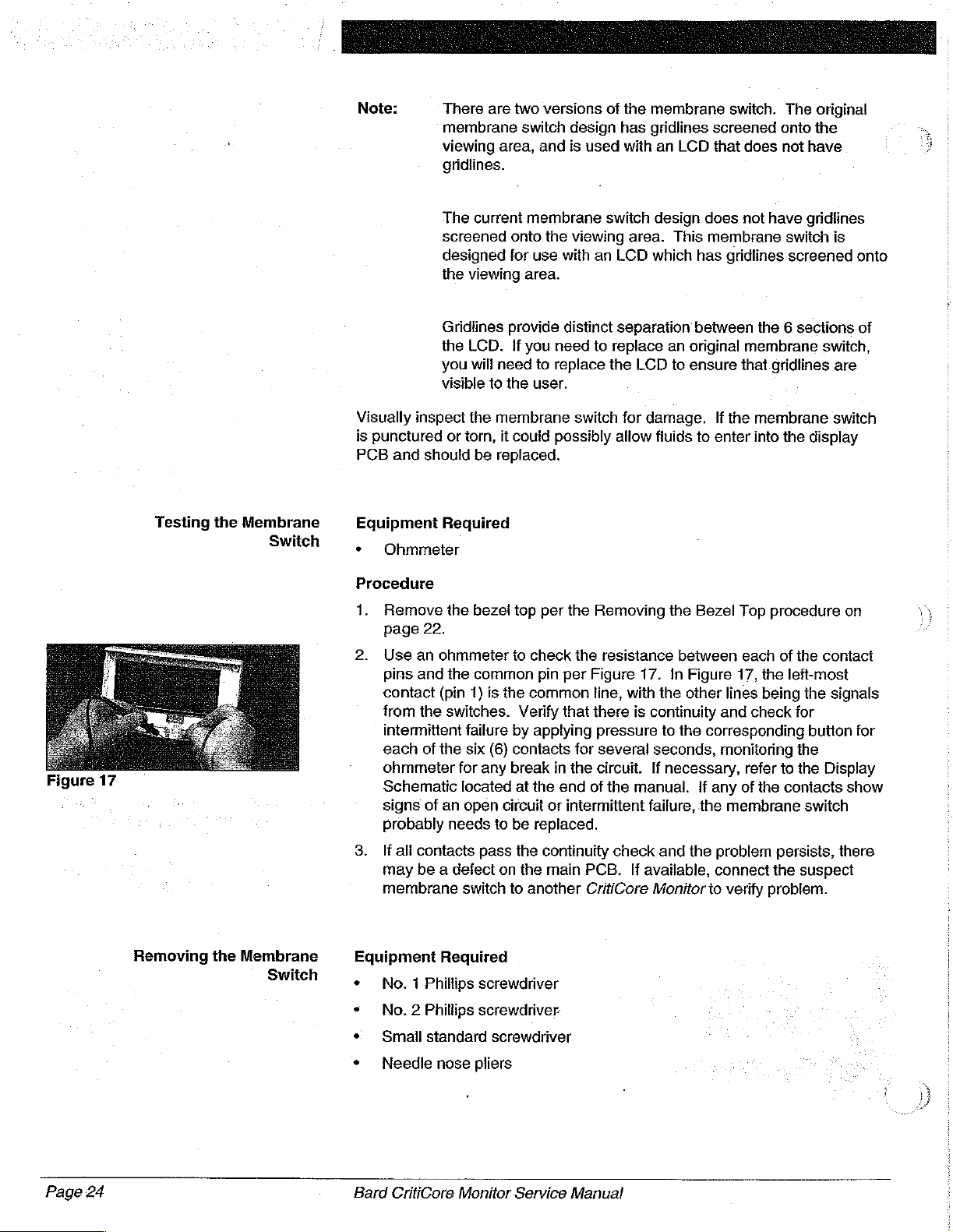

Figure

17

Testing

the

Membrane

Switch,

Visually

is

PCB

inspect

punctured

and

Equipment

Ohmmeter

Procedure

1.

Remove

page

2.

Use

an

pins

and

contact

from

intermittent

each

ohmmeter

Schematic

signs

probably

Gridlines

the

you

visible

or

should

Required

the

22.

ohmmeter

the

(pin

the

switches.

of

the

for

located

of

an

needs

provide

LCD.

will

need

to

the

the

membrane

torn,

it

be

replaced.

bezei

common

1)

is

the

failure

six

(6)

any

open

circuit

to

distinct

if

you

need

to

replace

user.

could

possibly

top

per

to

check

pin

per

common

Verify

that

by

applying

contacts

break

in

at

the

end

or

intermittent

be

replaced.

to

switch

the

Removing

the

resistance

Figure

line,

there

pressure

for

several

the

circuit.

of

the

separation

replace

the

altow

LCD

for

damage.

fluids

17.

with

the

is

continuity

an

to

the

In

to

seconds,

If

necessary,

manual.

failure,

between

original

ensure

to

Bezel

between

Figure

other

that

If

the

enter

Top

each

17,

lines

membrane

and

the

corresponding

monitoring

refer

If

any

of

the

membrane

the 6 sections

switch,

gridlines

membrane

into

the

procedure

of

the

being

check

are

switch

display

the

contact

left-most

the

signals

for

button

the

to

the

Display

the

contacts

switch

of

on

for

show

Page

24

Removing

the

Membrane

Switch

3.

If

all

contacts

may

be a defect

membrane

Equipment

*

No. 1 Phillips

«