Page 1

OPERATION INSTRUCTIONS

ENERGY RECOVERY VENTILATOR

WITH EXHAUST

Model:

For Use With Bard

2 Through 5 Ton

920-0074

QWSERV

QW*S Series

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

Manual: 2100-533A

Supersedes: 2100-533

File: Volume II, Tab 14

Date: 12-08-10

Manual 2100-533A

Page 1 of 12

Page 2

CONTENTS

Electrical Specifications .......................................... 3

General Description of ERV ................................... 3

Control Requirements ............................................ 3

Recommended Control Sequences ....................... 4

Control Wiring ........................................................ 4

Ventilation Airflow ................................................... 4

Performance & Application Data ............................ 5

Energy Recovery Ventilator Maintenance ........6 & 7

Maintenance Procedures ....................................... 7

Figures

Figure 1 Blower Speed Adjustment ....................... 4

Figure 2 Belt Replacement .................................... 8

Figure 3 Hub Assembly with Ball Bearings ............ 9

Figure 4 Disconnect & Tape Off Wiring ................ 11

Figure 5 Field Set CO

Wiring Diagram

.............................................................. 10

Tables

Table 1 Ventilation Air (CFM)................................ 4

Table 2 Summer Cooling Performance ................ 5

Table 3 Winter Heating Performance ................... 6

Sensor Jumpers .............. 12

2

Manual 2100-533A

Page 2 of 12

COPYRIGHT DECEMBER 2009

BARD MANUFACTURING COMPANY, INC.

BRYAN, OHIO USA 43506

Page 3

ELECTRICAL SPECIFICATIONS

ledoMegatloVspmA

4700-029802/0322.2V42

egatloV

GENERAL DESCRIPTION

The Energy Recovery Ventilator was designed to

provide energy efficient, cost effective ventilation to

meet I. A. Q. (Indoor Air Quality) requirements while

still maintaining good indoor comfort and humidity

control for a variety of applications such as schools,

classrooms, lounges, conference rooms, beauty salons

and others. It provides a constant supply of fresh air for

control of airborne pollutants including CO2, smoke,

radon, formaldehyde, excess moisture, virus and

bacteria.

The ventilator incorporates patented rotary heat

exchange state-of-the-art technology to remove both

heat & moisture and provides required ventilation to

meet the requirements of ASHRAE 62.1 standard.

It is designed as a single package which is factory

installed. The package consists of a unique rotary

Energy Recovery Cassette that can be easily removed

for cleaning or maintenance. It has two 15-inch

diameter heat transfer wheels for efficient heat transfer.

The heat transfer wheels use a permanently bonded dry

desiccant coating for total heat recovery.

Ventilation is accomplished with 2 blower/motor

assemblies each consisting of a drive motor and dual

blowers for maximum ventilation at low sound levels.

Motor speeds can be adjusted so that air is exhausted at

the same rate that fresh air is brought into the structure

thus not pressuring the building. The rotating energy

wheels provide the heat transfer effectively during both

summer and winter conditions.

lortnoC

ledoM

4700-029

ehthtiwesUroF

stinUgniwolloF

C-,B-,A-S2WQ

C-,B-,A-S3WQ

C-,B-,A-S4WQ

C-,B-,A-S5WQ

CONTROL REQUIREMENTS

1. Indoor blower motor must be run whenever the ERV

is run.

2. Select the correct motor speed on the ERV. Using

Table 1 of the ERV Installation Instructions

determine the motor speed needed to get the desired

amount of ventilation air needed. For instance, do

not use the high speed tap on a ERV if only 200

CFM of ventilation air is needed. Use the low speed

tap. Using the high speed tap would serve no useful

purpose and would effect the overall efficiency of the

air conditioning system. System operation costs

would also increase.

3. Run the ERV only during periods when the

conditioned space is occupied. Running the ERV

during unoccupied periods wastes energy, decreases

the expected life of the ERV, and can result in a large

moisture buildup in the structure. The ERV can

remove up to 60 to 70% of the moisture in the

incoming air, not 100% of it. Running the ERV

when the structure is unoccupied allows moisture to

build up in the structure because there is little or no

cooling load. Thus, the air conditioner is not running

enough to remove the excess moisture being brought

in. Use a control system that in some way can

control the system based on occupancy.

NOTE: The Energy Recovery Ventilator is NOT a

dehumidifier.

NOTE: Operation is not recommended below 5°F

outdoor temperature because freezing of

moisture in the heat transfer wheel can occur.

IMPORTANT

Operating the ERV during unoccupied periods

can result in a build up of moisture in the

classroom.

Manual 2100-533A

Page 3 of 12

Page 4

RECOMMENDED CONTROL

SEQUENCES

Several possible control scenarios are listed below:

1. Use a programmable electronic thermostat with

auxiliary terminal to control the ERV based on daily

programmed occupancy periods. Bard markets and

recommends Bard Part No. 8403-060 programmable

electronic thermostat for heat pump applications.

2. Use a motion sensor in conjunction with a

mechanical thermostat to determine occupancy in

the classroom. Bard markets the CS2000A for this

use.

3. Use a DDC control system to control the ERV based

on a room occupancy schedule.

4. Tie the operation of the ERV into the light switch.

The lights in a room are usually on only when

occupied.

5. Use a manual timer that the occupants turn to

energize the ERV for a specific number of hours.

VENTILATION AIRFLOW

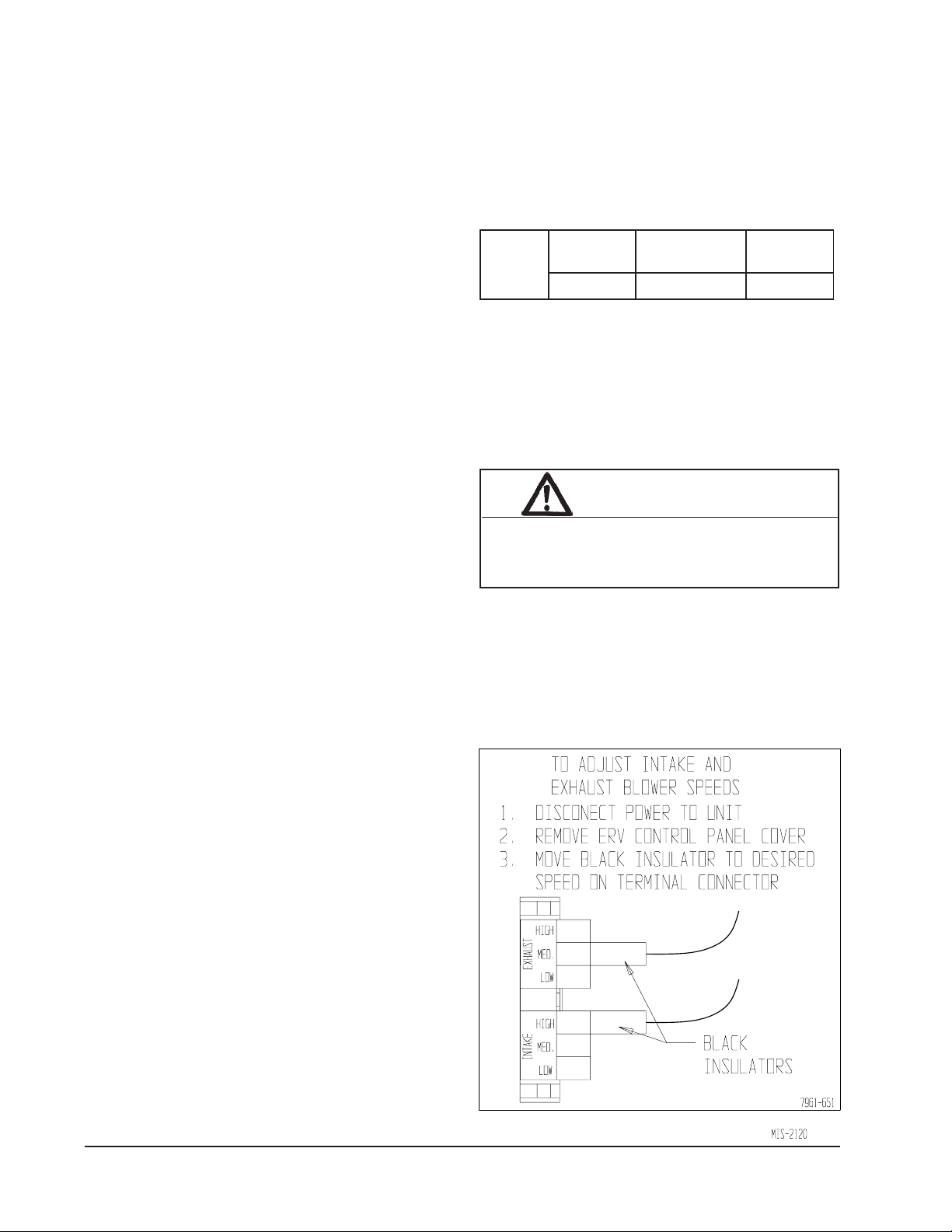

The ERV is equipped with a 3-speed motor to provide

the capability of adjusting the ventilation rates to the

requirements of the specific application by simply

changing motor speeds.

TABLE 1

VENTILATION AIR (CFM)

deepShgiH

)kcalB(

MFC

The ERV units are wired from the factory on medium

intake and low exhaust speeds. The ERV is equipped

with independently controlled 3-speed motor to provide

the capability of adjusting the ventilation rates to the

requirements of the specific application and to be able to

provide positive pressure in the structure. This is

accomplished by setting the intake blower on a higher

speed than the exhaust blower.

054573003

deepSmuideM

)eulB(

)deR(

deepSwoL

6. Use a programmable mechanical timer to energize

the ERV and indoor blower during occupied periods

of the day.

7. Use Bard Part No. 8403-056 CO2 controller for “ondemand” ventilation.

CONTROL WIRING

The QWSERV comes wired in the low voltage control

circuit from the factory.

With the “X” Remote Thermostat Option, it is default

wired into the “A” terminal, which drives the vent to

operate only during occupied periods when using a Bard

8403-060 thermostat or Bard CS2000 controller. If you

prefer for the QWSERV to operate anytime the blower

is operational, you will need to install a jumper wire

from “G” to “A”. If you prefer to use Bard 8403-056

CO2 controller to make the ventilation “on-demand”,

there is a connection adjacent to the thermostat

connections in the unit upper right-hand corner, and is

marked to match CO2 controller connections.

Furthermore, disconnect and tape off the wire as shown

in Figure 4 and you will need to field set the CO2 sensor

jumpers per Figure 5.

WARNING

Open disconnect to shut all power OFF before

doing this. Failure to do so could result in injury

or death due to electrical shock.

Moving the speed taps located in the control panel can

change the blower speed of the intake and exhaust. See

Figure 1.

FIGURE 1

BLOWER SPEED ADJUSTMENT

With the “D” Door Mounted Thermostat Option, the

thermostat is already connected and programmed to

operate the QWSERV only during occupied periods.

With the “H” Door Mounted Thermostat and CO

controller, the unit is ready to go with “on-demand”

ventilation as controlled by the CO2 controller.

Manual 2100-533A

Page 4 of 12

2

Page 5

PERFORMANCE AND APPLICATION DATA

1

1

TABLE 2

SUMMER COOLING PERFORMANCE

(INDOOR DESIGN CONDITIONS 75° DB / 62° WB)

tneibmA

.D.O

BW/BD

FseergeDTLVSLVLLVTRHSRHLRHTLVSLVLLVTRHSRHLRHTLVSLVLLVTRHSRHLRH

57

56412

08541

4886

501

07

08541

08541

0

56

08541

08541

0

08

09513

05121

04491

57

56412

05121

4139

001

07

25321

05121

202

56

05121

05121

0

06

05121

05121

0

08

09513

0279

07812

57

56412

0279

44711

59

07

25321

0279

2362

56

0279

0279

0

06

0279

0279

0

08

09513

0927

00342

57

56412

0927

57141

09

07

25321

0927

2605

56

0927

0927

0

06

0927

0927

0

08

09513

0684

03762

57

56412

0684

50661

58

07

25321

0684

2947

56

0684

0684

0

06

0684

0684

0

57

56412

0342

53091

07

25321

0342

08

570756

56

2524

06

0342

25321

2524

06

0

2299

0342

2281

0342

0

0

25321

0

2524

0

0

MFC054–ETARNOITALITNEV

ycneiciffE%56

25931

7749

5744

78871

05121

7375

7749

7749

0

05121

05121

0

7749

7749

0

05121

05121

0

33502

7987

53621

52362

52101

00261

25931

7987

4506

78871

52101

2677

9208

7987

131

39201

52101

861

7987

7987

0

52101

52101

0

7987

7987

0

52101

52101

0

33502

8136

51241

52362

0018

52281

25931

8136

4367

78871

0018

7879

9208

8136

1171

39201

0018

3912

8136

8136

0

0018

0018

0

8136

8136

0

0018

0018

0

33502

8374

49751

52362

5706

05202

25931

8374

3129

78871

5706

21811

9208

8374

0923

39201

5706

8124

8374

8374

0

5706

5706

0

8374

8374

0

5706

5706

0

33502

9513

47371

52362

0504

57222

25931

9513

39701

78871

0504

73831

9208

9513

0784

39201

0504

3426

9513

9513

0

0504

0504

0

9513

9513

0

0504

0504

0

25931

9751

27321

78871

5202

26851

9208

9751

9446

39201

5202

8628

4672

9751

4811

3453

5202

8151

9751

9751

0

5202

5202

0

9208

0

9208

39201

0

39201

4672

0

4672

3453

0

3453

0

0

0

0

0

0

MFC573–ETARNOITALITNEV

ycneiciffE%66

50811

8108

6873

01341

0279

0954

8108

8108

0

0279

0279

0

8108

8108

0

0279

0279

0

47371

2866

29601

06012

0018

06921

50811

2866

3215

01341

0018

0126

3976

2866

111

5328

0018

531

2866

2866

0

0018

0018

0

2866

2866

0

0018

0018

0

47371

5435

82021

06012

0846

08541

50811

5435

9546

01341

0846

0387

3976

5435

7441

5328

0846

5571

5435

5435

0

0846

0846

0

5435

5435

0

0846

0846

0

47371

9004

56331

06012

0684

00261

50811

9004

6977

01341

0684

0549

3976

9004

4872

5328

0684

5733

9004

9004

0

0684

0684

0

9004

9004

0

0684

0684

0

47371

2762

10741

06012

0423

02871

50811

2762

2319

01341

0423

07011

3976

2762

0214

5328

0423

5994

2762

2762

0

0423

0423

0

2762

2762

0

0423

0423

0

50811

6331

96401

01341

0261

09621

3976

6331

7545

5328

0261

5166

8332

6331

2001

5382

0261

5121

6331

6331

0

0261

0261

0

3976

0

3976

5328

0

5328

8332

0

8332

5382

0

5382

0

0

0

0

0

0

MFC003–ETARNOITALITNEV

ycneiciffE%76

7859

2156

5703

2156

2156

0

2156

2156

0

01141

7245

3868

7859

7245

0614

7155

7245

09

7245

7245

0

7245

7245

0

01141

1434

8679

7859

1434

6425

7155

1434

5711

1434

1434

0

1434

1434

0

01141

6523

45801

7859

7155

6523

6523

01141

7589

7155

0712

0712

7859

7155

9981

5801

7155

9981

0

336

6523

622

6523

0

6523

0

6523

0712

93911

0712

6147

0712

6433

0712

0

0712

0

5801

2058

5801

2344

5801

418

5801

0

0

7155

0

9981

0

0

LEGEND

VLT = Ventilation Load – Total HRT = Heat Recovery – Total

VLS = Ventilation Load – Sensible HRS = Heat Recovery – Sensible

VLL = Ventilation Load – Latent HRL = Heat Recovery – Latent

Manual 2100-533A

Page 5 of 12

Page 6

TABLE 3

WINTER HEATING PERFORMANCE — (INDOOR DESIGN CONDITIONS 70°F DB)

tneibmA

.D.OETARNOITALITNEV

BD

FseergeD

TLVSRHSLVTLVSRHSLVTLVSRHSLV

56034244916845202046158302618231292

06068488832790504082307704236562385

5509272385854157060294451106845893578

05027967774491001816569351084631356611

5405121027903425210110284291001824668541

04085414661161920512114899032027907970571

5301071806312043571411841139620431189291402

03044912555188830026122131870306921726013332

52078126947147345228126741364308541559114262

02003420449106840520220461848300261482316192

51037624831264355722224081232402871216418023

01061928233223850034238691716404491149519943

5095132725281365236232312200506012962711973

0020436127240860538246922783508622895812804

5-054630619209275730340642177500342629914734

01-088834011367770042344262651602952452126664

LEGEND

VLT = Ventilation Load – Total HRS = Heat Recovery – Sensible VLS = Ventilation Load – Sensible

.ffE%08MFC054.ffE%18MFC573.ffE%28MFC003

NOTE: Sensible

performance only

is shown for

winter application.

ENERGY RECOVERY VENTILATOR

MAINTENANCE

GENERAL INFORMATION

The ability to clean exposed surfaces within air moving

systems is an important design consideration for the

maintenance of system performance and air quality.

The need for periodic cleaning will be a function of

operating schedule, climate, and contaminants in the

indoor air being exhausted and in the outdoor air being

supplied to the building. All components exposed to the

airstream, including energy recovery wheels, may

require cleaning in most applications.

Rotary counterflow heat exchangers (heat wheels) with

laminar airflow are “self-cleaning” with respect to dry

particles. Smaller particles pass through; larger

particles land on the surface and are blow clear as the

flow direction is reversed. For this reason the primary

need for cleaning is to remove films of oil based

aerosols that have condensed on energy transfer

surfaces. Buildup of material over time may eventually

reduce airflow. Most importantly, in the case of

desiccant coated (enthalpy) wheels, such films can close

off micron sized pores at the surface of the desiccant

material, reducing the efficiency with which the

desiccant can adsorb and desorb moisture.

FREQUENCY

In a reasonably clean indoor environment such as a

school, office building, or home, experience shows that

reductions of airflow or loss of sensible (temperature)

effectiveness may not occur for ten or more years.

However, experience also shows that measurable

changes in latent energy (water vapor) transfer can occur

in shorter periods of time in commercial, institutional

and residential applications experiencing moderate

occupant smoking or with cooking facilities. In

applications experiencing unusually high levels of

occupant smoking, such as smoking lounges, nightclubs,

bars and restaurants, washing of energy transfer

surfaces, as frequently as every six months, may be

necessary to maintain latent transfer efficiency. Similar

washing cycles may also be appropriate for industrial

applications involving the ventilation of high levels of

smoke or oil based aerosols such as those found in

welding or machining operations, for example. In these

applications, latent efficiency losses of as much as 40%

or more may develop over a period of one to three years.

Manual 2100-533A

Page 6 of 12

Page 7

CLEANABILITY AND PERFORMANCE

In order to maintain energy recovery ventilation

systems, energy transfer surfaces must be accessible for

washing to remove oils, grease, tars and dirt that can

impede performance or generate odors. Washing of the

desiccant surfaces is required to remove contaminate

buildups that can reduce adsorption of water molecules.

The continued ability of an enthalpy wheel to transfer

latent energy depends upon the permanence of the bond

between the desiccant and the energy transfer surfaces.

Bard wheels feature silica gel desiccant permanently

bonded to the heat exchange surface without adhesives;

the desiccant will not be lost in the washing process.

Proper cleaning of the Bard energy recovery wheel will

restore latent effectiveness to near original performance.

MAINTENANCE PROCEDURES

NOTE: Local conditions can vary and affect the

required time between routine maintenance

procedures, therefore all sites (or specific units

at a site) may not have the same schedule to

maintain acceptable performance. The

following timetables are recommended and can

be altered based on local experience.

QUARTERLY MAINTENANCE

1. Inspect mist eliminator/prefilter and clean if

necessary. This filter is located in the wall sleeve

and can be accessed by either removing the exterior

louver grille, the vent package from inside the unit,

or by disconnecting the unit from the wall brackets,

and rolling the unit away from the sleeve on its

integral wheel system. The filter is an aluminum

mesh filter and can be cleaned with water and any

detergent not harmful to aluminum.

2. Inspect the comfort air filter and clean or replace as

necessary. This filter is located behind the fronthinged service door.

6. Use a shop vacuum with brush attachment to clean

both sides of the energy recovery wheels.

7. Reverse shop vacuum to use as a blower and blow

out any residual dry debris from the wheel.

NOTE: Discoloration and staining of the wheel

does not affect its performance. Only

excessive buildup of foreign material needs

to be removed.

8. If any belt chirping or squealing noise is present,

apply a small amount of LPS-1 or equivalent dry

film lubricant to the belt.

ANNUAL MAINTENANCE

1. Inspect and conduct the same procedures as outlined

under Quarterly Maintenance.

2. To maintain peak latent (moisture) removal

capacity, it is recommended that the energy

recovery wheels be sprayed with a diluted nonacid

based evaporator coil cleaner or alkaline detergent

solution such as 409.

NOTE: Do not use acid based cleaners, aromatic

solvents, temperatures in excess of 170°F or

steam. Damage to the wheel may result.

Do not disassemble and immerse the entire heat

wheel in a soaking solution, as bearing and

other damage may result.

3. Rinse wheel thoroughly after application of the

cleaning solution, and allow to drain before

reinstalling.

4. No re-lubrication is required to heat wheel bearings

of the drive motor, or to the intake and exhaust

blower motors.

5. If any belt chirping or squealing noise is present,

apply a small amount of LPS-1 or equivalent dry

film lubricant to the belt.

3. Inspect energy recovery ventilator for proper wheel

rotation and dirt buildup. This can be done in

conjunction with Item 2 above. Energize the energy

recovery ventilator after inspecting the filter and

observe for proper rotation and/or dirt buildup.

4. Recommended energy recovery wheel cleaning

procedures follow: Disconnect all power to the unit.

Open the front-hinged service door to the unit.

5. Remove the front cassette retaining panel from the

front of the ERV. Unplug the amp connectors to the

cassette drive motor. Slide energy recovery cassette

out of the ventilator.

Manual 2100-533A

Page 7 of 12

Page 8

If belts "squeak" or "chirp"

lubricate lightly with LPS-1

or equivalent "dry film"

lubricant.

FIGURE 2

BELT REPLACEMENT INSTRUCTIONS

Route (1) replacement belt

in top groove of pulley.

Route (1) replacement belt

in bottom groove of pulley.

Belt Replacement

Instructions

Manual 2100-533A

Page 8 of 12

MIS-2166

Page 9

FIGURE 3

HUB ASSEMBLY WITH BALL BEARINGS

Manual 2100-533A

Page 9 of 12

Page 10

Relay

Control

4

1

2

2

Motor Plug

Motor Plug

Exhaust

Motor

Blower

Capacitor

Exhaust

4

1

3

Exhaust

Motor Plug

Intake

Intake

1

Capacitor

Intake

Motor Plug

Ground

To Unit High Voltage 240/208-60-1

Power Plug

Speed Plug

Exhaust

32

1

2

3

Power Plug

Green

Black

Block

Term.

Black

23 23

23

2

2

4114-100

Motor

Blower

4

3

480V

208V

Transformer

120 V

Com

Speed Plug

Intake

Capacitor

Cassette

Motor Plug

4

3

1

Damper

Motor

Control Relay

Motor

Cassette

2

Motor Plug

Cassette

CO2 Disconnect

Red

Red

Relay

24

Control

29

Brown/White

Brown/White

Black/White

2134567891011

for Wiring Energy Recovery to Unit

12

Note: See Control Wiring Section of Installation Inst.

Black/White

Brown/White

CO2 SENSOR IS USED

DISCONNECT WHEN

2

27

Control Plug

21 3456789101112

Red/White

Brwn/White

Black/White

Orange

Black

1

Black/White

Blk/Red

Red

Transformer

480

240

208

COM

120 V

Exhaust

Speed

Plug

Black

Black

Black

Intake

Speed Plug

Yellow

White

Capacitor

WIRE FOR 208V OPERATION

TERMINAL BLOCK AND CONNECT RED

DISCONNECT ORANGE WIRE FROM

1

26

26

28

28

25

25

Note: See Control Wiring Section of Installation Inst. for Wiring Energy Recovery to Unit

25

25

28

28

26

Brown

Yellow

Green

Orange

26

26

2

3

Cassette

4

Motor Plug

Black

Capacitor

3

Motor

Red (Low Speed)

White

2

28

Motor Plug

Intake

Blue (Med. Speed)

1

Black (High Speed)

Intake

4

Blower

Red (Low Speed)

Blue (Med. Speed)

Black (High Speed)

White

25

2

431

Motor Plug

Exhaust

DANGER

!

*DISCONNECT POWER BEFORE

*ELECTRICAL SHOCK HAZARD

SERVICING.

WARNING

!

USE COPPER CONDUCTORS

75° C.

ONLY SUITABLE FOR AT LEAST

Motor

Blower

Capacitor

Exhaust

1

Black/White

White

Green

Brown

Motor

Cassette

Brown/White

Component Capacitor

Bl ower M otor 4/3 70

Cassette Motor 3/250

Motor

Intake

Damper

Manual 2100-533A

Page 10 of 12

Page 11

FIGURE 4

DISCONNECT & TAPE OFF WIRE

MIS-2759

DISCONNECT AND TAPE OFF FOR

CO2 CONTROLLED VENTILATION

Manual 2100-533A

Page 11 of 12

Page 12

FIGURE 5

FIELD SET CO

SENSOR JUMPERS

2

QWSERV VENT PACKAGE

2 CONTROLLER SETTING FOR 1000 PPM

CO

OFF

"SW1" SET TO ON

ON

OFF

OUTSW2SW1

ON

0-100%

AN

VOLTAGE

CURRENT

20-100%

"AN" SET TO VOLTAGE"SW2" SET TO ON

"OUT" SET TO 20-100%

MIS-2756

Manual 2100-533A

Page 12 of 12

Loading...

Loading...