IMPORTANT

Installers' Information Manual, Users' Information Manual, Wiring Diagram, Parts List and

Warranty are inside or attached and should be read before the Installation is started or before

service is attempted.

After factory final assembly, this furnace has been dielectrically tested. Operation tests have

been performed on the burners, fan control and blower motor.

- TO THE INSTALLER -

AFFIX THIS PACKET ADJACENT TO

THE FURNACE.

- TO THE OWNER -

RETAIN THIS PACKET AND ITS CONTENTS FOR

FURTHER REFERENCE.

in

TABLE OF CONTENTS:

INSTALLERS' MANUAL

INSTALLERS' INFORMATION MANUAL

GAMA VENTING TABLES ADDENDUM

SIDEWALL VENTING ADDENDUM

USER'S MANUAL

(PRINTED IN RED AND BLACK AND INSERTED IN THE CENTER OF THIS PACKET.)

F\ (0 hi

408320 A

f

f'

r’i r\

>, C ;

t f

/■ /

i

ï: 7/- -i-

RAGE

1-35

36-62

63-66

MANUAL PACKET 403293 A

INSTRUCTION ASSEMBLY 408310 B

COVER ASSEMBLY 406303 A

PARTS

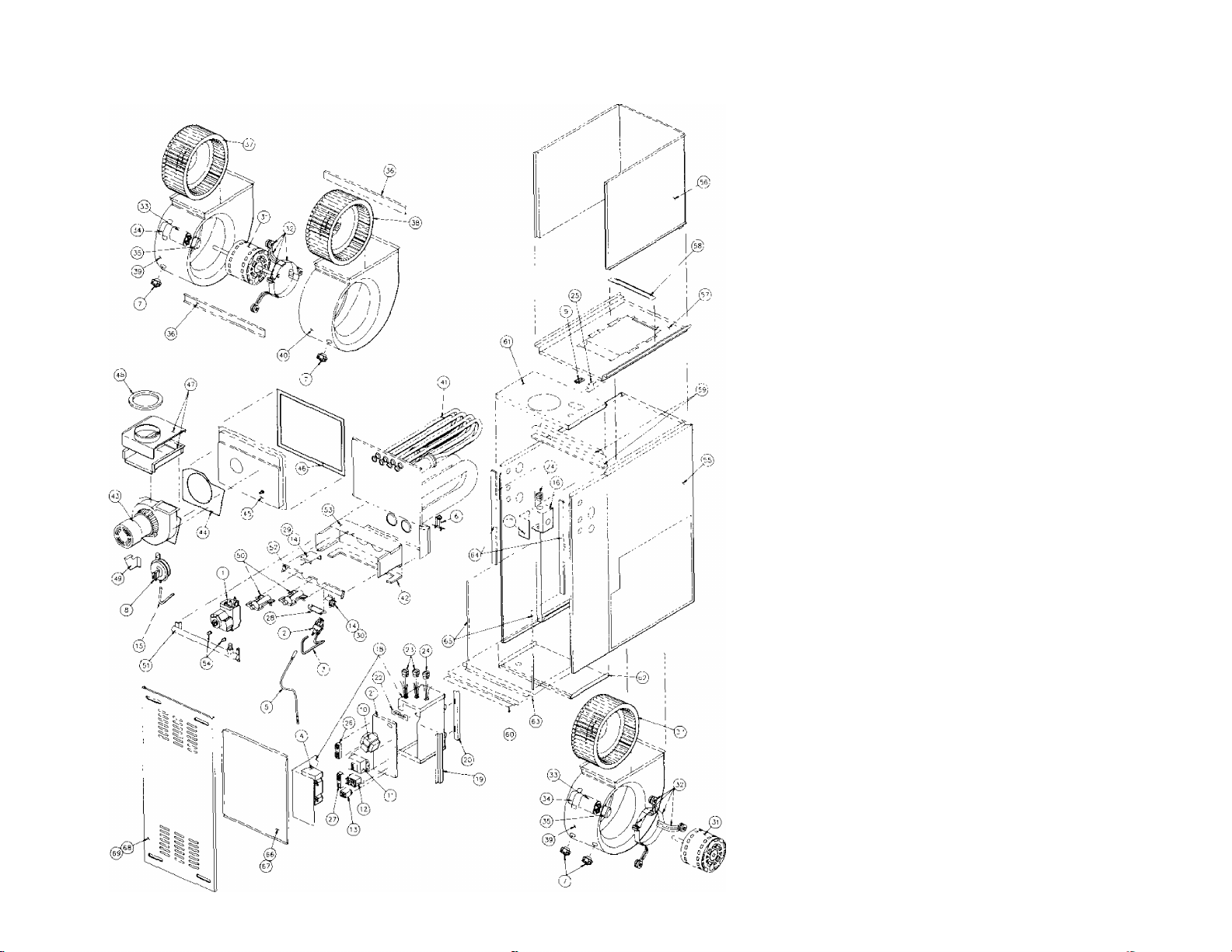

FUNCTIONAL PARTS LIST

The format of this parts list allows you to get the part

number quickly. It allows you to easily identify the part and

the part number. Propane Conversion Kit and Filter Frames

are also listed in the parts list.

If you do not know the part number, find the part illustra

tion to the left and note the illustration number. Locate the

illustration number in the Parts List on the back foldout of

this packet Read across the list to locate the part number

for the appropriate size furnace.

EXAMPLE: You need an inducer motor relay for a

60,000 BTUH input 1/3 H.P. furnace:

1. Find the inducer motor relay in the

illustration and get the illustration

number (In this case 13).

2. Go to the table and read down to

illustration number 13.

3. Read across the row to find the part

number for the 60,000 BTUH input

1/3 H.P.furnace.

A.

Read part number 9043-316.

408360 A

INSTALLERS' MANUAL

To assure both sate and proper operation, please caretully toliow the instructions in this manual to

correctly install this new turnace.

ATTENTION, INSTALLER! After installing turnace, give the user:

—Users’ Information Manual —Parts List

—Installers’ Information Manual —Warranty Information

ATTENTION, USER! Your furnace installer should give you the above four important documents relating

to your furnace. Keep these as long as you keep your furnace. Pass these documents on to later furnace

purchasers or Users'. If any of the four documents is missing or damaged, contact your installer or furnace

manufacturer for replacement. For efficient service, please give your furnace model and serial number,

listed in Section 1 of your Users’ Information Manual or from your furnace rating plate. Throughout this

Installers' Information Manual, we frequently use the word "you" when referring to the person responsible

for application, installation and service of your furnace. Please remember to have only qualified service

technicians perform these services.

WARNING', Individuals who install this furnace, must have the training and experience necessary

to Install gas furnaces. They must also have training and experience necessary to Install related

comfort air conditioning appliances. Improper installation could create a hazard, resulting In damage,

injury or death.

While we have written these instructions as accurately and thoroughly as possible, they may not

cover every system variation or contingency. Also, questions of interpretation may arise. For more

information, solutions to particular problems or clarification, contact your focal distributor or the

manufacturer. See the furnace rating plate for who to contact.

Furnace installation must follow all applicable NATIONAL, STATE and LOCAL CODES.

UPFLOW

ELECTRONIC IGNITION INDUCED DRAFT FURNACE

WARNING: FOR YOUR SAFETY, WHAT TO DO IF YOU SMELL GAS:

— DO NOT TRY TO LIGHT ANY APPLIANCE;

— DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONE IN THE BUILDING;

— IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR'S PHONE; FOLLOW GAS

SUPPLIER'S INSTRUCTIONS;

— IF YOU CANNOT REACH GAS SUPPLIER, CALL FIRE DEPARTMENT.

HORIZONTAL

DOWNFLOW

IMPORTANT SAFETY NOTE: After installing the furnace, show the user how to turn off gas and

electricity to furnace. Point out control and switch locations for turning off gas and electricity. Go over

Sections 4 and 6 of Users' Information Manual and Section 29 in this manual with user. Make sure user

understands the importance of following all safety precautions.

920101

404200 A

SECTION

_________________________

TABiE Of CONTENTS

____________________________________

PAPE

SECTION 1

SECTION

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION

SECTION 8

SECTION 9

SECTION

10

SECTION 11

SECTION 12

SECTION

SECTION

13

14

SECTION 15

SECTION

SECTION

SECTION

16

17

18

SECTION 19

SECTION 20

SECTION 21

SECTION 22

SECTION

23

SECTION 24

SECTION 25

SECTION 26

SECTION 27

SECTION

28

SECTION 29

SECTION 30

PREPARING TO INSTALL FURNACE..............................................................................................................................2

IMPORTANT SAFETY RULES..........................................................................................................................................3

2

MEETING CODES.............................................................................................................................................................3

DETERMINING BEST FURNACE LOCATION..................................................................................................................3

IDENTIFYING FURNACE DIMENSIONS. SPECIFICATIONS, AND POSITION..............................................................4

ALLOWING FOR CLEARANCES.......................................................................................................................................7

SUSPENDING FURNACE.................................................................................................................................................8

7

PROVIDING FOR COMBUSTION AND VENTILATION AIR........................................................................................... 9

PROVIDING FOR PROPER VENTING

......

...........................................................................

-........................................13

TOOLS NEEDED FOR INSTALLATION..........................................................................................................................17

INSTALLING GAS PIPING.............................................................................................................................................. 18

INSTALLING ELECTRICAL WIRING.............................................................................................................................. 19

FOLLOWING FIELD WIRING DIAGRAMS......................................................................................................................19

ADJUSTING ROOM THERMOSTAT HEAT ANTICIPATOR...........................................................................................19

SEQUENCE OF OPERATION.........................................................................................................................................20

INSTALLING DUCTWORK..............................................................................................................................................20

SELECTING AND INSTALLING FILTER FRAMES.........................................................................................................23

CHECKING BEFORE STARTING FURNACE.................................................................................................................25

ADJUSTING PILOT..........................................................................................................................................................25

ADJUSTING MANIFOLD PRESSURE.............................................................................................................................26

CHECKING GAS INPUT..................................................................................................................................................27

ORIFICE SIZE..................................................................................................................................................................29

DERATING FOR HIGH ALTITUDES...............................................................................................................................29

ADJUSTING BLOWER SPEED.......................................................................................................................................30

MEASURING DUCT WORK STATIC PRESSURE.........................................................................................................31

MEASURING AIR TEMPERATURE RISE.......................................................................................................................32

CHECKING CONTROLS.................................................................................................................................................33

BLOWER TIMINGS..........................................................................................................................................................33

MAINTAINING FURNACE IN GOOD WORKING ORDER............................................................................................. 34

GETTING OTHER INFORMATION AND PUBLICATIONS.............................................................................................34

SICTION 1 -

PREPARING TO INSTALL TURNACB.

A. Literature.

Review this manual. Users’ Information Manual and Parts

List. In particular, see User's Information Manual and

Parts List for location and identification of furnace com

ponents.

After installing furnace, give this Installers' Information

Manual, Users' Information Manual, Warranty and Parts

List to user. You may have questions as you install the

furnace. If you need help on any of the installation in

structions or other matters relating to the furnace, contact

the office where you bought the furnace. You may also

refer to the furnace rating plate for a contact name.

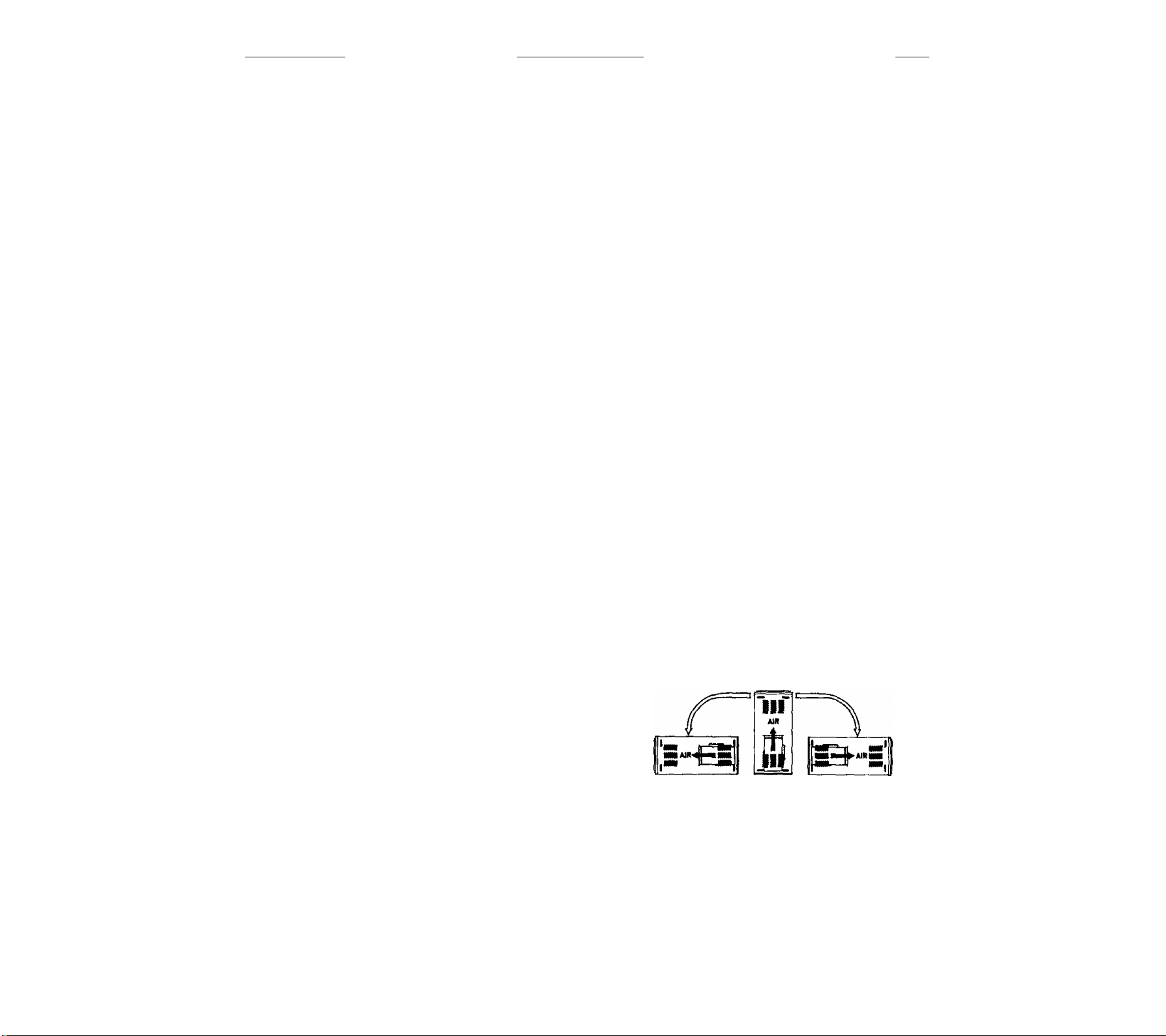

B, Installation Positions.

1. You may install furnace as-shipped in an upflow or

horizontal configuration in one of three positions

shown in Figure 1.

VENT

OUTLET

VENT

OUTLET

HORiZONTAL

LEFT SIDE DOWN

TVPE 1

UPftOW

TVPE 2

HORIZONTAL

RIGHT SIDE OOWN

TVPE 3

FIGURE 1

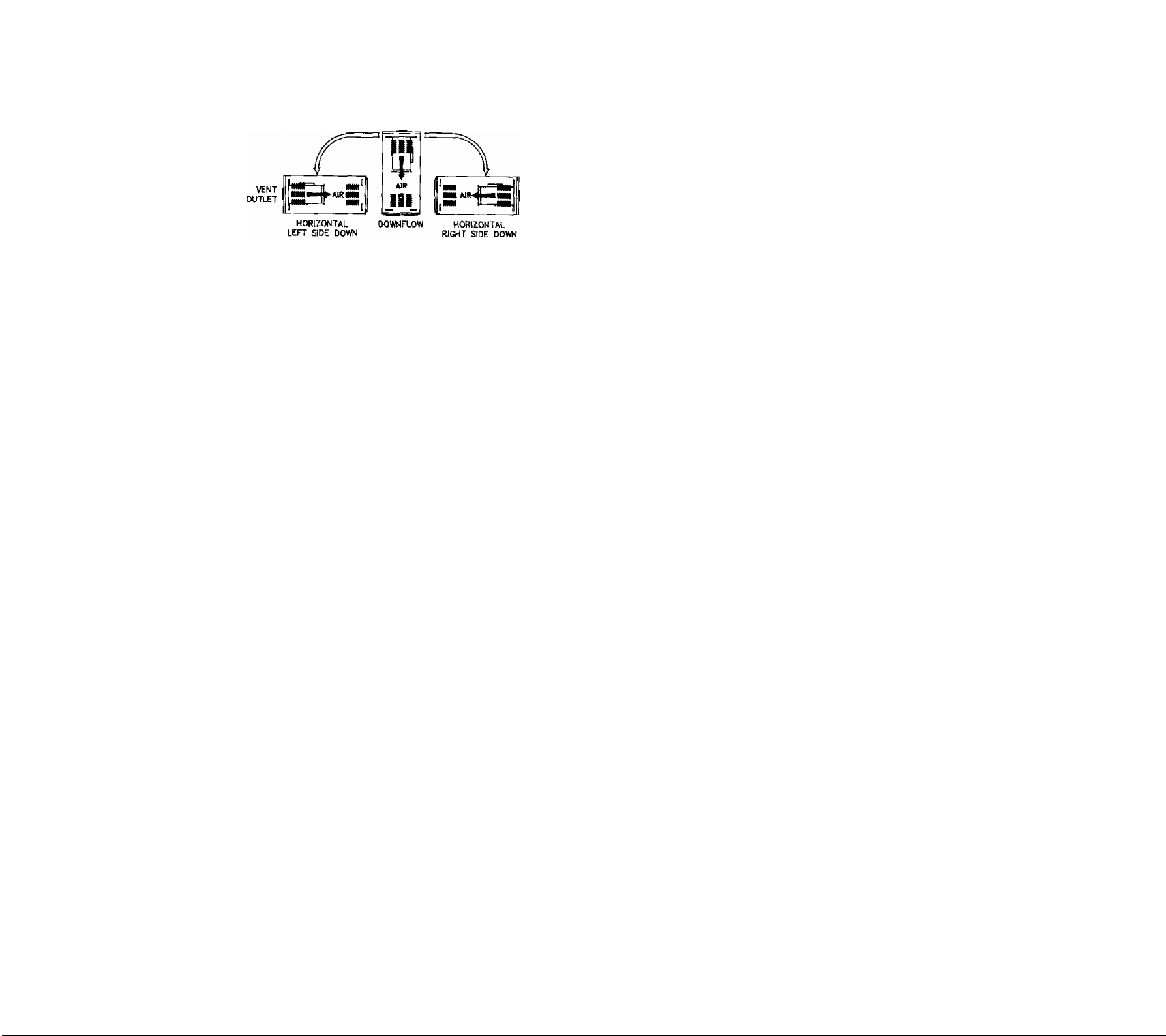

2. You may convert furnace quickly and easily from its

as-shipped configuration. After conversion, you can

install it as a downflow or horizontal furnace In one

of three positions shown in Figure 2.

VENT

OUTLET

VENT

OUTLET

G. Provide adequate combustion and ventilation air to space

where furnace is being installed. See Section 8 for more

information. Connect this furnace to an approved vent

system, venting combustion products outdoors. See Sec

tion 9 for more information.

H. Never test for gas leaks with an open flame. Use a com

mercial soap made specifically for leak detection to check

all connections. See Section 11 for more information.

VENT

OUTLET

TYPE 4

TYPE 5

TYPE 6

FIGURE 2

SECTION 2 — IMPORTANT SAFETY RULES*

WARNING: Read and exactly follow these rules. Fail

ure to do so could cause Improper furnace operation,

resulting In damage, injury or death.

A. Signal words.

To alert you to potential hazards, we use the signal words

"WARNING" and "CAUTION" throughout this

manual. "WARNING" alerts you to situations that could

cause serious injury or death. "CAUTION” alerts you to

situations that could cause minor or moderate injury or

property damage. To help you, we use the words "must"

and "should" in this manual. "Must" is mandatory, "Should"

is advisory.

6. Use only the type of gas approved for this furnace; refer

to furnace rating plate.

WARNING: Only use natural gas In furnaces de

signed for natural gas. Only use Propane (LP) gas

for furnaces designed for Propane (L.P) gas. Make

sure furnace will operate properly on gas type avail

able to user. Do not use this furnace with butane.

Using wrong gas could create a hazard, resulting In

damage, injury, or death.

C. DO NOT install this furnace outdoors or in a mobile home,

trailer or recreational vehicle. It is not A.G.A. designcertified for these installations. This furnace is suitable

for a home built on site or manufactured home completed

at final site.

D. Carefully choose furnace installation site. DO NOT di

rectly expose furnace to drafts, wind or other outdoor

conditions. See Section 8 for more information.

E. DO NOT install furnace in a corrosive or contaminated

atmosphere. Make sure all combustion and ventilation

air requirements are adhered to in addition to local codes

and ordinances. See Section 8 for more information.

F. DO NOT use this furnace during construction when ad

hesives, sealers, and/or new carpets are being installed.

If the furnace must be used during construction, provide

clean outdoor air for combustion and ventilation to ^rnace

space. See Section 8 for more information.

I. Always install duct system with furnace. Be sure duct

system has external static pressure within allowable fur

nace range. See Sections 16 and 25 for more information.

J. Completely seal supply and return air ducts to furnace

casing. Duct work must run to an area outside furnace

air space. Seal duct work wherever it runs through walls,

ceilings or floors. See Section 16 for more information.

SECTION 3 — MEETING CODES.

Before installing furnace, make sure you know all applicable

codes, National, state and local codes may take precedence

over any instructions in this manual. Be sure to consult:

— Authorities having jurisdiction over furnaces;

— Local code authorities for information on electrical

wiring, gas piping and vent pipe;

— Current National Fuel Gas Code ANSI Z223.1/NFPA

54:

— Current National Electrical Code ANSI/NFPA 70.

See Section 30 for information on getting copies of these

codes.

SECTION 4 — DETERMINING BEST

FURNACE LOCATION.

You may install this furnace as an upflow or downflow fur

nace in an alcove, attic, basement, closet, garage, or utility

room. Install furnace so all electrical components are pro

tected from water.

You may install it as a horizontal furnace in an alcove, garage,

attic, basement or crawl space.

Select furnace location to meet all requirements in this manual,

making sure to refer to;

— Section 2 for safety rules;

— Section 6 for minimum clearances;

— Section 7 for furnace suspension;

— Section 8 for combustion and ventilation air;

— Section 9 for venting:

— Section 11 for gas piping;

— Section 12 for electrical wiring;

— Section 16 and 25 for duct work;

— Section 17 for filters.

Consult local code authorities for additional location require

ments.

Locate the furnace close to the chimney/vent and as near the

center of the air distribution system as possible. Install furnace

as level as possible.

Provide ample space for servicing and cleaning. Location

must allow 30 inches minimum front clearance for service.

Always comply with minimum clearances shown on inside of

front door. Do not install furnace directly on carpeting, tile or

any combustible material other than wood flooring.

NOTE: A combustible floor base, available from manu

facturer, is required for downflow furnace installation on

wood flooring.

HAZARDOUS LOCATIONS.

When furnace is in a residential garage, it must be installed

so that burners and ignition source are located no less than

fS'inches above the floor. Also, furnace should be protected

from physical damage by vehicles.

When furnace is in public garages, airplane hangers, or other

buildings having hazardous atmospheres, install unit in ac

cordance with recommended good practice requirements of

the National Fire Protection Association, Inc. See Section 30.

SECTION 5 — IDENTIFYING FURNACE DI

MENSIONS, SPECIFICATIONS, AND POSITION.

2, Furnace as-shipped position may be converted to a

downflow furnace by following instructions in B. be

low. Once conversion is complete, furnace may be

installed as a downflow furnace. Furnace may also

then be installed as a horizontal on its right or left

side. See Figure 2.

WARNING: Do not install furnace on its back. Doing so

could cause a fire, resulting In damage, injury or death.

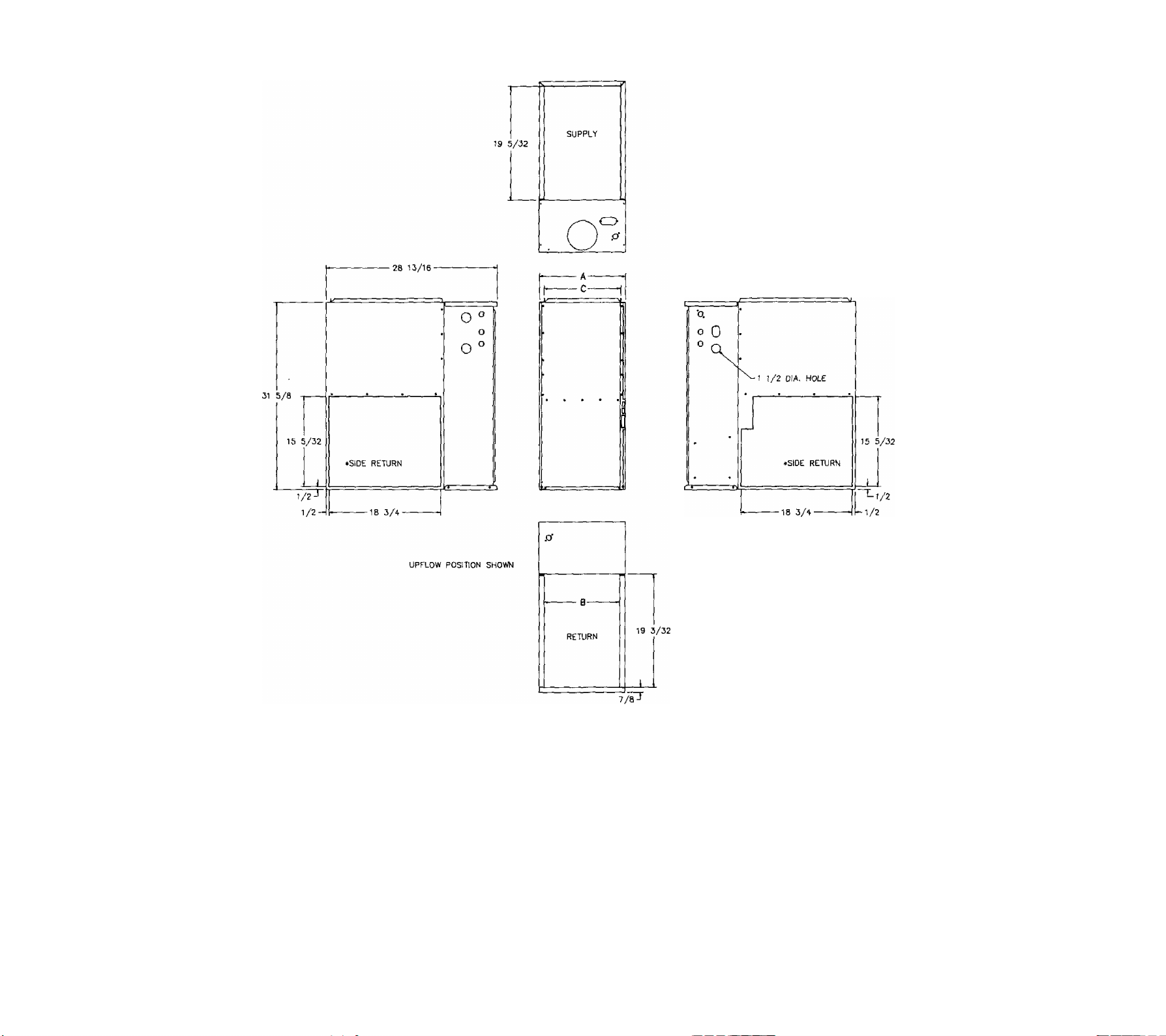

See Figure 3 for dimensional drawings and specification table.

B. Converting furnace from as-shipped configuration.

READ ALL INSTRUCTIONS THOROUGHLY BEFORE

STARTING CONVERSION.

NOTE: Start conversion with furnace on its back.

A. A unique feature of this furnace is that it may be installed

as an upflow furnace, horizontal furnace, or downflow

furnace (minor conversion required).

1. Furnace as-shipped is an upflow furnace. Furnace

may be installed in this position or may be installed

as a horizontal on its right or left side without any

conversion. See Figure 1.

BTUH*

INPUT

40,000

40,000 1/3 3"

60,000 1/4 4"

60.000 1/3 4"

60,000

80,000

80,000

60,000

80,000 3/4 4"

100,000 1/3 4"

100,000

100,000 3/4 4"

120,000 1/2 5"

120,000

140,000 3/4 5"

140,000 3/4

'See Furnace rating plate located on blower door.

MOTOR*

H.P.

1/4

1/2 4“

1/4

1/3

1/2

1/2

3/4

VENT

DIAMETER

3"

4"

4"

4"

4"

5'

5'

FURNACE

WIDTH

A

14-1/2

14-1/2

14-1/2

14-1/2 12-7/8"

17-1/2

14-1/2

14-1/2

17-1/2

20-1/2 13-7/8" 18-15/16" (2) 10-4

17-1/2 15-7/8" 15-15/16"

17-1/2

20-1/2

20-1/2 18-7/8" 18-15/16"

20-1/2

23-1/2 21-7/8" 21-15/16"

23-1/2

RETURN

AIR SIZE

13- 23 /3 2" X B

WARNING: When servicing controls, all wires must

be labeled prior to disconnection. Mlswlring can cause

improper operation resulting In damage, Injury, or

death.

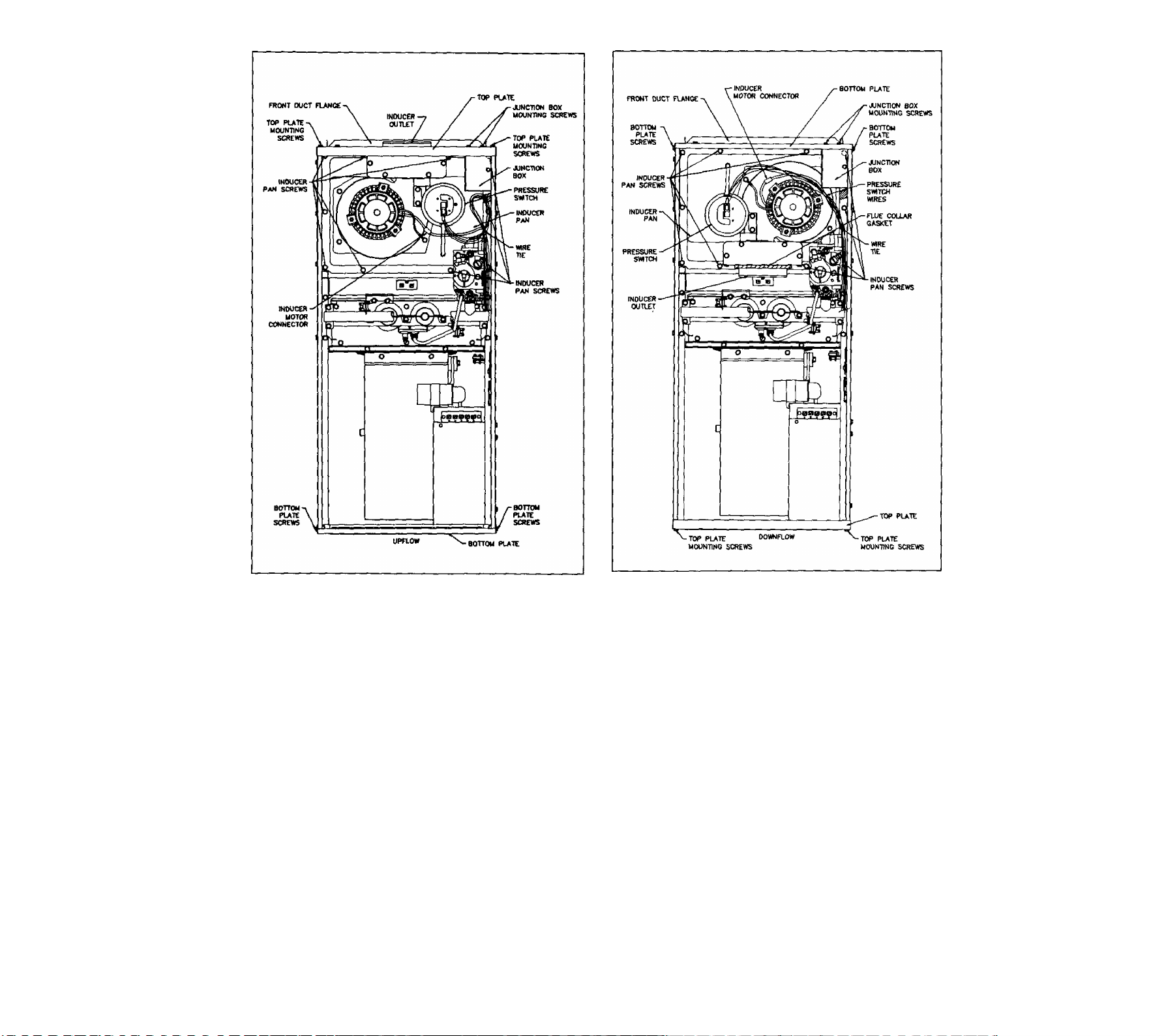

1. Remove front door. Study components described in

conversion. See Figure 4.

SUPPLY

AIR SIZE

78-1S/16'* X C

12-7/8" 12-15/16" 10-4 50-80

12-7/8* 12-15/16" 10-6

12-7/8" 12-15/16"

15-7/8" 15-15/16" 10-8

12-7/8" 12-15/16*

12-7/8" 12-15/16" 10-6

15-7/8" 15-15/16*

15-7/8" 15-15/16* 10-8

18-7/8"

18-7/8" 18-15/16" (2) 10-4

21-7/8"

12-15/16" 10-6 45-75

18-15/16"

21-15/16*

BLOWER

WHEEL

SIZE

10-4 45-75

10-4

10-8 50-80

10-6 55-85 1245

(2) 10-4

10-8

(2} 10-4

(2) 10-6

TEMP

RISE “F

30-60 1265

35-65 1635

50-80 915

40-70 1235

40-70 1930

50-80 1585

40-70

45-75 1660

45-75

45-75 I860

50-80 2235

CFM

at 0.50“ W.C.

805

850

1260

1645

1950

1965

FURNACE AND DIMENSIONS SPECIRCATIONS

FIGURE 3

AS-SHIPPED CONFIGURATION

FIGURE 4

CONVERTED CONFIGURATION

FIGURE 5

2. Remove two junction box mounting screws from top

plate. Remove four top plate mounting screws. Save

all screws. Remove top plate and front duct flange.

3. Disconnect pressure switch wires and inducer motor

connector wires.

4. Remove ten screws from the inducer pan; save

screws. DO NOT drop screws into heat exchanger

openings.

5. Lift inducer pan (with inducer motor and pressure

switch stilt in place) about 1/4 inch and tilt left side

up to clear casing flanges. Use care not to damage

inducer gasket.

NOTE: If possible, decide on direction of gas entry

now. Screws to inlet gas valve fitting are accessible.

See Section 11.

6. Rotate inducer pan 180 degrees, line up mounting

holes and place inducer pan in furnace. Use care

not to damage gasket. Replace ten screws in in

ducer pan. See Figure 5.

7. Pressure switch wires will no longer reach pressure

switch. Remove cable tie around excess length of

red/yellow piggyback, blue and purple pressure switch

wires.

8. Connect pressure switch wires as follows. Wires are

numbered on insulation near terminals.

a. #1 Purple wire to pressure switch, terminal 'C

(Common).

b. #2 Blue wire to pressure switch, terminal 'NC

(Normally Closed).

c. #7 and #8 Red/Yellow piggyback wire to pres

sure switch, terminal 'NO' (Normally Open).

d. Route all pressure switch wires over inducer

motor.

e. Reconnect inducer motor connector.

f. Replace wire tie in area that prevents wires from

touching hot surfaces.

9. Rgmove four screws that secure bottom plate to cas

ing sides. Remove bottom plate; save screws,

10. Install top plate, removed in step 2, where bottom

plate was. Secure with four screws. Inducer outlet is

now lined up with vent outlet in top plate.

11. Stand up furnace with top plate down. Line front duct

flange up with holes. Place bottom plate on top of

duct flange and secure both to casing with four

screws.

12. Install junction box on bottom plate using two #6B

screws removed in Step 2. Junction box cover and

screw of junction box must face front of furnace.

13. Gasket around flue collar must be in place. If gasket

is loose, glue It. If gasket is damaged, replace it.

14. Install a single wall vent pipe section (minimum length

30 inches) (Field-Supplied) to inducer outlet with three

equally spaced screws. This pipe serves as an in

ducer outlet extension to which an appropriate vent

can be attached. Due to minor variations in vent pipe,

available from different manufacturers in the field,

and to assure the tightest seal possible, inducer out

let extension is not supplied with furnace. Additional

vent pipe sections or Type B1 adapter may then be

added when installing the furnace.

WARNINGS If Inducer outlet extension Is shorter than

30 Inches and chimney or vent becomes blocked, com

bustion products may be drawn Into furnace. This could

cause nausea or asphyxiation, resulting In Injury or death.

15. Conversion from as-shipped configuration is now

complete.

SECTION 6 — ALLOWING FOR CLEARANCES.

WARNING: Do not Install furnace on Its back, doing so

could cause a fire, resulting In damage. Injury or death.

Establishing clearances from combustible material.

Locate clearance label on inside of front door. See Figure 6.

WARNINGS Furnace Installation must meet all minimum

clearances from combustible material specified In this

manual and all applicable codes. Failure to provide re

quired clearance between furnace and combustible mate

rials could cause a fire, resulting In damage, injury, or

death.

WARNINGS This furnace Is A.G.A. design certified for

direct Installation on wood flooring for upflow and hori

zontal positions.

• Do not install furnace on carpeting, tile or other

combustible material.

• Do not Install furnace In a closet In horizontal

position.

• Do not Install furnace on wood flooring without

special base In downflow position.

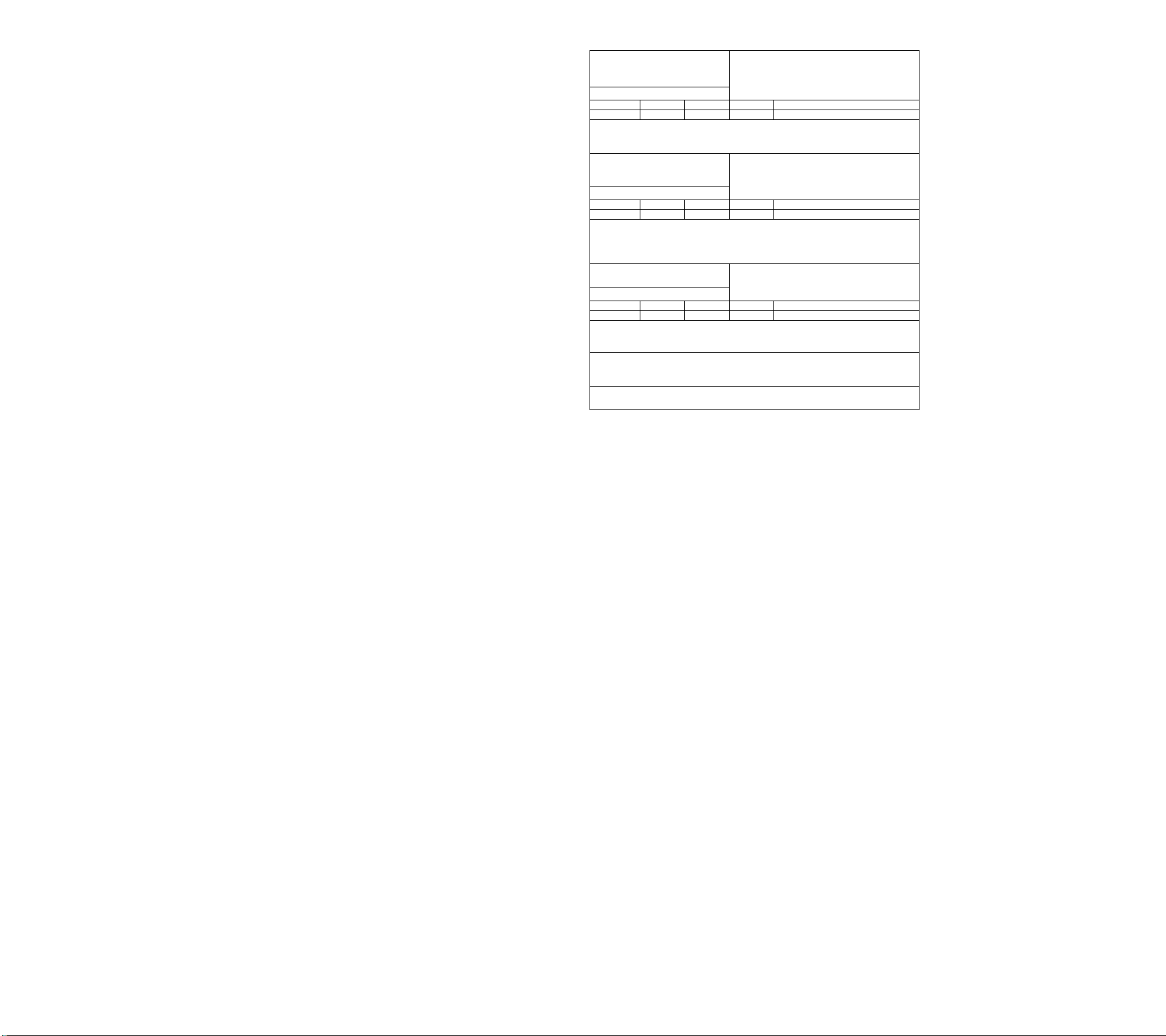

MINIMUM INCHES CLEARANCE

CLOSET.

UPFLOW POSITION

• FOR CASING WIDTHS 17 INCHES OR LARGER 0 CLEARANCE MAY

BE USED. 18 INCH FRONT CLEARANCE REQUIRED FOR ALCOVE. FOR

INSTALLATION ON COMBUSTIBLE FLOORING.

MINIMUM INCHES CLEARANCE

CLOSET.

DOWNFLOW POSITJON

• FOR CASING WIDTHS 17 INCHES OR LARGER 0 CLEARANCE MAY

BE USED. 18 INCH FRONT CLEARANCE REOUIRED FOR ALCOVE. FOR

INSTALLATION ON COMBUSTIBLE FLOORING ONLY WHEN INSTALLED ON

SPECIAL BASE PART N0. 4-024400.

MINIMUM INCHES CLEARANCE

• CLEARANCE SHOWN IS FOR AIR INLET AND AIR OUTLET ENDS.

VENT MUST MAINTAIN CLEARANCE LISTED ABOVE.

FOR INSTALLATION ON COMBUSTIBLE FLOORING.

FOR HORIZONTAL POSITION LINE CONTACT IS ONLY PERMISSIBLE

BETWEEN LINES FORMED BY INTERSECTIONS OF TOP AND TWO SIDES OF

FURNACE JACKET AND BUILDING JOISTS. STUDS OR FRAMING.

ALL POSITIONS RLOUIRE 30 INCHES FRONT CLEARANCE FOR SERVICE*

TOP SIDES BACK

1 1* 0

1 0 0 2

TOP SIDES BACK

1 1* 0 6

1 0

HORiZONTAL POSmON

TOP SIDES* BACK

1 2*

1

2*

0 COMBUSTIBLE MATERIAL IN ALCOVE OR

FRONT VENT

0 COMBUSTIBLE MATERIAL IN ALCOVE OR

FRONT VENT

0 2

rO COMBUSTIBLE MATERIAL IN ALCOVE.

FRONT VENT

0 18

0 18

6 WHEN USING SINGLE WALL

6

1 WHEN USING B1

6 WHEN USING SINGLE WALL

1 WHEN USING B1

6 WHEN USING SINGLE WALL

1 WHEN USING B1

40ZB№

MINIMUM CLEARANCES

FROM COMBUSTIBLE MATERIALS

FIGURE 6

1. Upflow Installation.

Upflow position is approved for installation on

wood flooring. Typical upflow furnace installa

tions are an alcove, attic, basement, closet, ga

rage, or utility room. See Figure 6 or furnace

clearance plate for minimum clearances to com

bustible materials.

2. Horizontal Installation

a. Horizontal position is approved for installa

tion on wood flooring. Typical horizontal fur

nace installations are an alcove, garage, at

tic, or crawl space. See Figure 6 or furnace

clearance plate for minimum clearances to

combustible materials.

b. Attic Installation.

Line contact is permissible for furnaces

installed in horizontal positions. The in

tersection of furnace top and sides forms

a line. This line may be in contact with

combustible material. However, maintain

a 6" clearance to vent connection unless

Type B1 vent is used. See Figure 7.

Doing any of the above could cause a fire resulting in

damage, injury, or death.

TYPICAL ATTIC INSTALLATION

FIGURE 7

When using single wall vent pipe in horizon

tal installations, horizontal furnaces with

14.50" high casings must be raised 1" to

have 6” clearance to combustible material.

See Figure 7.

Furnace installation on combustible flooring is

permitted with combustible floor base available

from manufacturer. Read installation instructions

packaged with combustible floor base to correctly

install. See Figure 8.

c. Install a platform under furnace that extends

a minimum 30" in front of furnace. This pro

vides a work area and keeps insulating ma

terials away from combustion air openings.

Secure platform to ioists.

WARNINOs When a furnace Is installed

In an attic or other Insulated space, keep

all insulating materials at least 12" away

from furnace and all burner combustion

air openings. Failure to do so could cause

nausea, asphyxiation or fire, resulting In

damage. Injury, or death.

d. Crawl Space Installation.

Furnace can be hung from floor joists or in

stalled on suitable blocks or pad. Pad or

blocks should provide enough height to re

duce potential for water damage. See Sec

tion 7.

3. Downflow Installation.

You must convert furnace from as-shipped con

figuration for downflow furnace installation. See

Section 5.

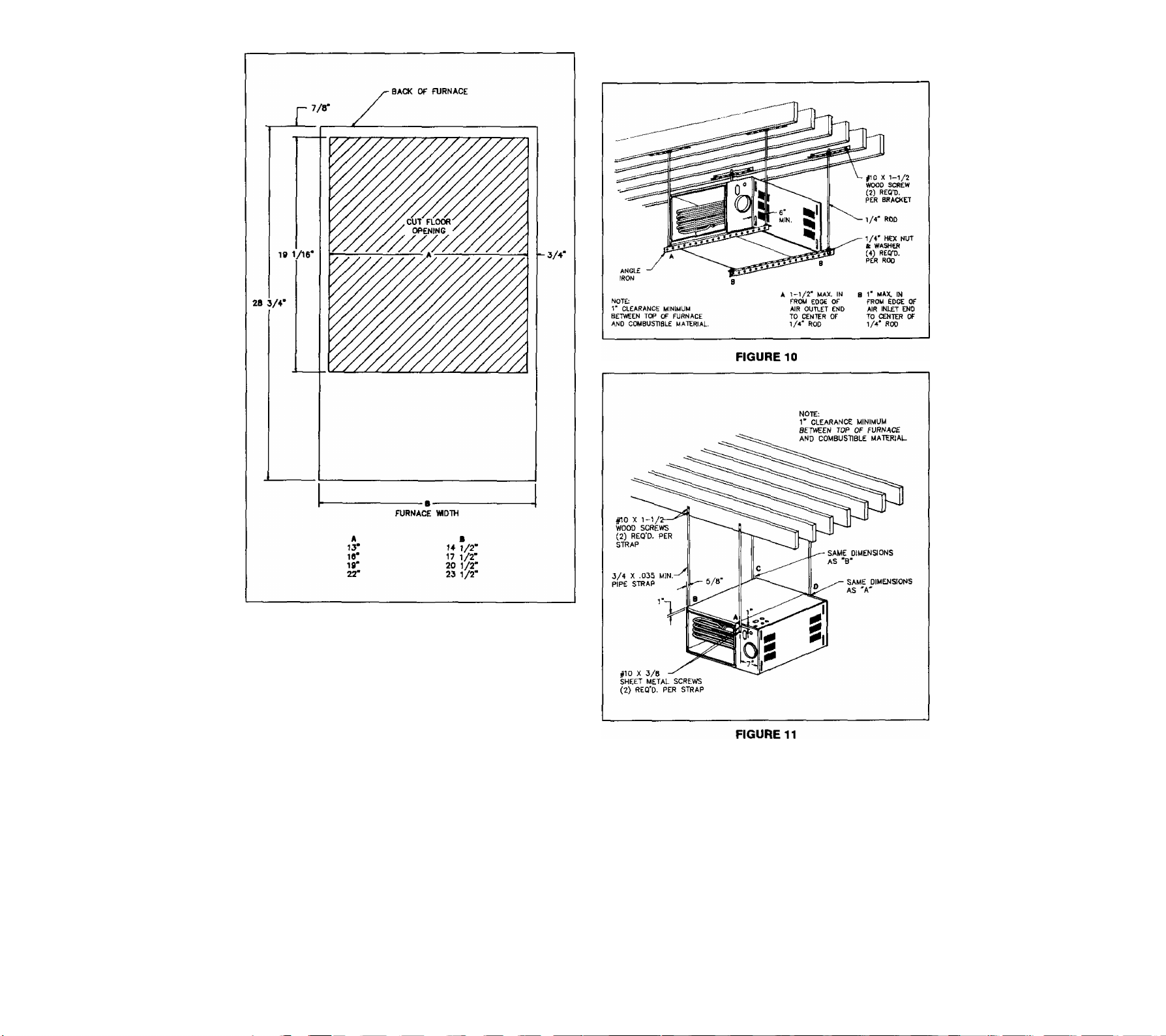

DOWNFLOW FLOOR OPENING

FIGURE 8

See Figure 9 for installation diagram on com

bustible floor.

4. Service Clearance.

Allow minimum front clearance of 30 inches for service.

See Figure 6 or inside of front door for minimum service

clearance.

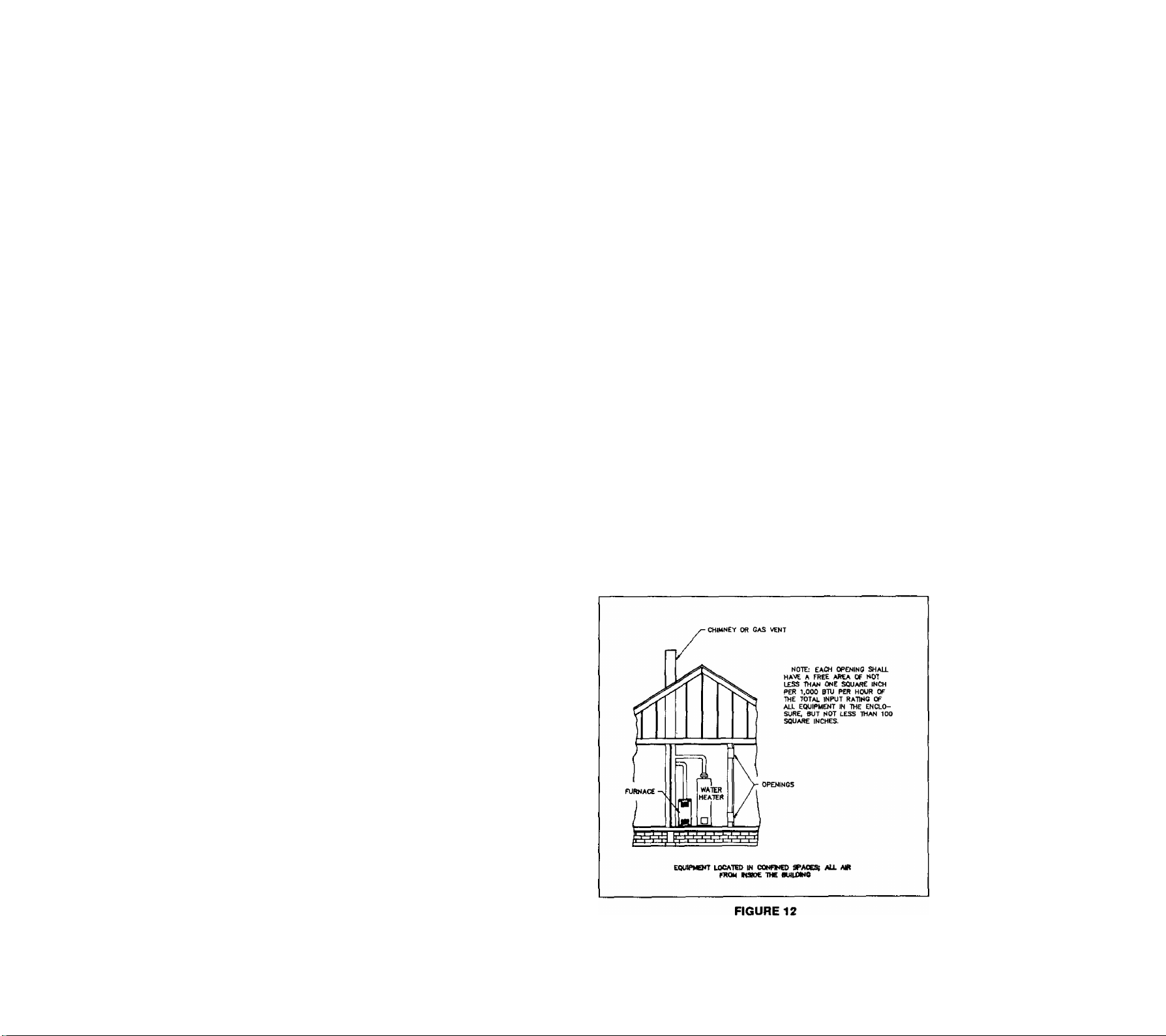

SECTION 7 — SUSPENDING FURNACE.

Some installations will require that furnace be suspended

from rafters or floor joists.

A common way to do this using threaded rods is shown in

Figure 10. Consider this means when people may walk un

derneath furnace. Figure 11 shows another common suspen

sion means using pipe strap. Other means that provide ad

equate support may be used.

When furnace is not suspended in a crawl space, elevate

furnace off ground to avoid water damage and allow for air

conditioning coil drain.

Downflow position is approved for installation on

non-combustible flooring. Typical downflow fur

nace installations are an alcove, attic, closet,

basement, garage, or utility room. See Figure 6

or furnace clearance plate for minimum clear

ances to combustible materials.

NOTE: Level furnace from front to back and from left to right

within 1M" per four feet.

FURNACE, PLENUM, AND BASE INSTALLED ON A

COMBUSTIBLE FLOOR

FIGURE 9

SICTION S PROVIDING FOR COMBUSTION

AND ViNTILATION AIR.

Before you begin installing furnace, pian to provide enough

combustion and ventiiation air following:

— Current National Fuel Gas Code ANSI Z223.1/NFPA

54, Section 5;

— Local Code authorities. Refer to Section 31 of this

manual for these codes.

Ventilation is the process of replacing air which is required

for furnace operation. The total amount of ventilation air pro

vided within structure must equal all requirements of gas ap

pliances in the building, plus any air quantities removed by

range hoods, exhaust fans, etc.

Another reason to supply fresh outdoor air for combustion

and ventilation is that it dilutes contaminants found in indoor

air. These contaminants include bleaches, adhesives, clean

ing solutions, detergents, solvents, cat litter, spray can pro

pellants and most refrigerants.

WARNINDi Furnace and any other fuel-burning appli

ances must have enough fresh air for propsr combus

tion and ventilation. Lack of adequate combustion and

ventilation air could cause nausea or asphyxiation, re

sulting in injury or death.

WARNINOi During construction, do not use air from

inside structure for combustion and ventilation. Vapors

from soma construction adhesives and materials can be

come corrosive in the presence of a flame. This could

cause failure of heat exchanger or vent system, result

ing in damage. Injury or death.

WARNINO: Combustion and vsntllatlon air that contains

chlorine, fluorine, bromine and Iodine could cause heat

exchanger or vent system failure, resulting In damage,

Injury or death,

WARNINO: When installing a furnace In an attic or other

insulated space, keep furnace free and clear of all lnsu>

lating materials. Make surs all Insulation Is at least 12"

away from burner combustion air openings and well away

from openings into furnace space that supply air for

combustion and ventilation. Failure to do this could causa

nausea, asphyxiation or fire, resulting In damage, injury

or death.

WARNINGS When Installing furnace in an alcove, attic,

basement, closet, garage, or utility room do not store

items in front of furnace or In front of closet or utility

door which would block combustion air openings to fur*

nace. Failure to do this could cause nausea, asphyxia

tion or fire, resulting In damags, Injury or death.

DO NOT install furnace where any combustion or ventilation

air openings will allow outside air to blow directly against

furnace.

WARNINGS Drafts blowing directly against furnace could

cause improper combustion which could cause heat ex

changer failure or fire, resulting In damage, Injury or

death.

Sufficient air MUST be provided to insure there wilt not be a

negative pressure in furnace room or space. In addition, there

MUST be a positive seal between furnace and return air duct

to avoid pulling air from burner area.

Provide adequate combustion and ventilation air by consider'

ing volume of furnace installation space. Use these instruc

tions and current National Fuel Gas Code ANSI Z223.1/NFPA

54 to determine whether furnace is in an unoonfined or con

fined space.

If ratio is less than 50, installation space is a con

fined space. If ratio is 50 or greater, installation space

is an unconfined space.

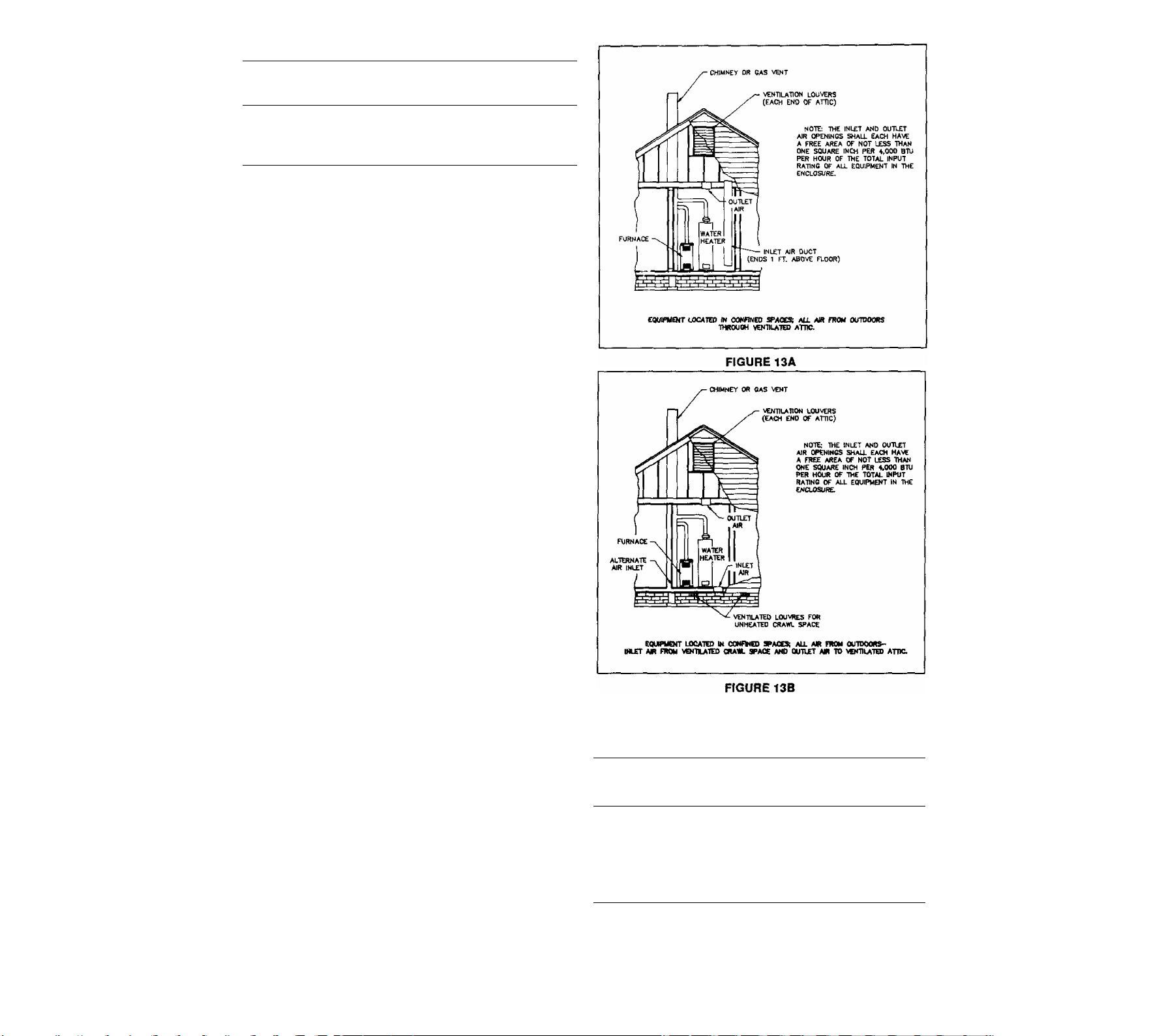

B. Installing furnace In confined space.

WARNING: You must provide permanent air open

ings to a conflned furnace installation space from

another area as described below. Failure to do ao

could result In Inadéquat# combustion and vsntllatlon

air. Thsae could cause nausea, asphyxiation or fire,

resulting In damage, injury or death.

1. Combustion and ventilation air openings.

a. All combustion and ventilation air from inside the

structure.

1. The furnace space must be provided with

two permanent openings to an additional

room(s) of sufficient volume so that the

combined volume of all spaces meet the cri

teria above for an unconfined space.

The total input of all gas appliances within

the combined space must be considered in

making this determination. See Figure 12.

2. a. Each opening must have minimum free

area of one square Inch per 1,000 Btuh

per hour of the total combined input rat

ing of all gas appliances within the con

fined furnace space, but not less than

100 square inches. One opening must

be within 12 inches of the top and an

other opening within 12 inches of the

bottom of the furnace space. See Fig

ure 12.

A. Determining If your space Is confined or unconflned.

Two factors determine whether a furnace installation

space is confined or unconfined:

— Volume of installation space;

— Total gas input of appliances to be installed in that

space.

To determine which your space is:

1. First calculate furnace installation space volume in

cubic feet.

2. Determine combined input rating (BTUH) of all gas

appliances in furnace installation space, including

furnace input. This is the total combined input rating.

3. Divide total combined input rating by 1,000. Then

divide this number into installation space volume.

Here's the formula:

Space Volume

Ratio

Total lnput/1,000

10

For example:

Total Input

Btuh (square Inches)

40,000-100,000 100

120,000 120

140,000

b. If building is of unusually tight construc

tion, provide a permanent opening di

rectly communicating with the outdoors.

Opening shall have a minimum free area

of one square inch per 4000 Btuh of

total input rating for all equipment in the

enclosure.

If return air is taken directly from hall

way or space next to furnace that com

municates with furnace spaces, all air

for combustion must come from out

doors.

b. All combustion and ventilation air from outdoors.

1. The furnace space must be provided with

two permanent air openings directly to the

outdoors, or by ducts to the outdoors or

spaces (attic or crawl spaces) that freely ac

cess the outdoors. These combustion and

ventilation openings will give fresh air free

access to furnace space for combustion and

ventilation. You must also provide air suffi

cient for all other gas appliances within fur

nace space.

Free Area Per Opening

140

Ducts must freely access outdoors or spaces

(attic or crawl spaces) which freely access

the outdoors. Well ventilated attics or crawl

spaces usually satisfy this requirement.

2. Locate one combustion and ventilation air

operîing within 12" of top of furnace space.

Locate another within 12" of bottom of fur

nace space.

3. When directly accessing the outdoors, each

opening must have a minimum free area of

one square inch per 4,000 Btuh of total

combined input rating of all gas appliances

within furnace space. See Figure 13A.

4. If combustion air ducts will run vertically,

ducts and each opening must have a mini

mum free area of one square inch per 4,000

Btuh total combined input rating. You must

allow for all gas appliances within the fur

nace space. See Figure 13B.

For example:

Required

Total Input

Btuh

40,000 10.0 4

60,000 15.0 5

80,000

100,000

120,000 30.0 7

140,000 35.0

Free Area per Opening

(square inches)

20.0 6

25.0 6

Suggested

Round Pipe

(inches dia.)

7

11

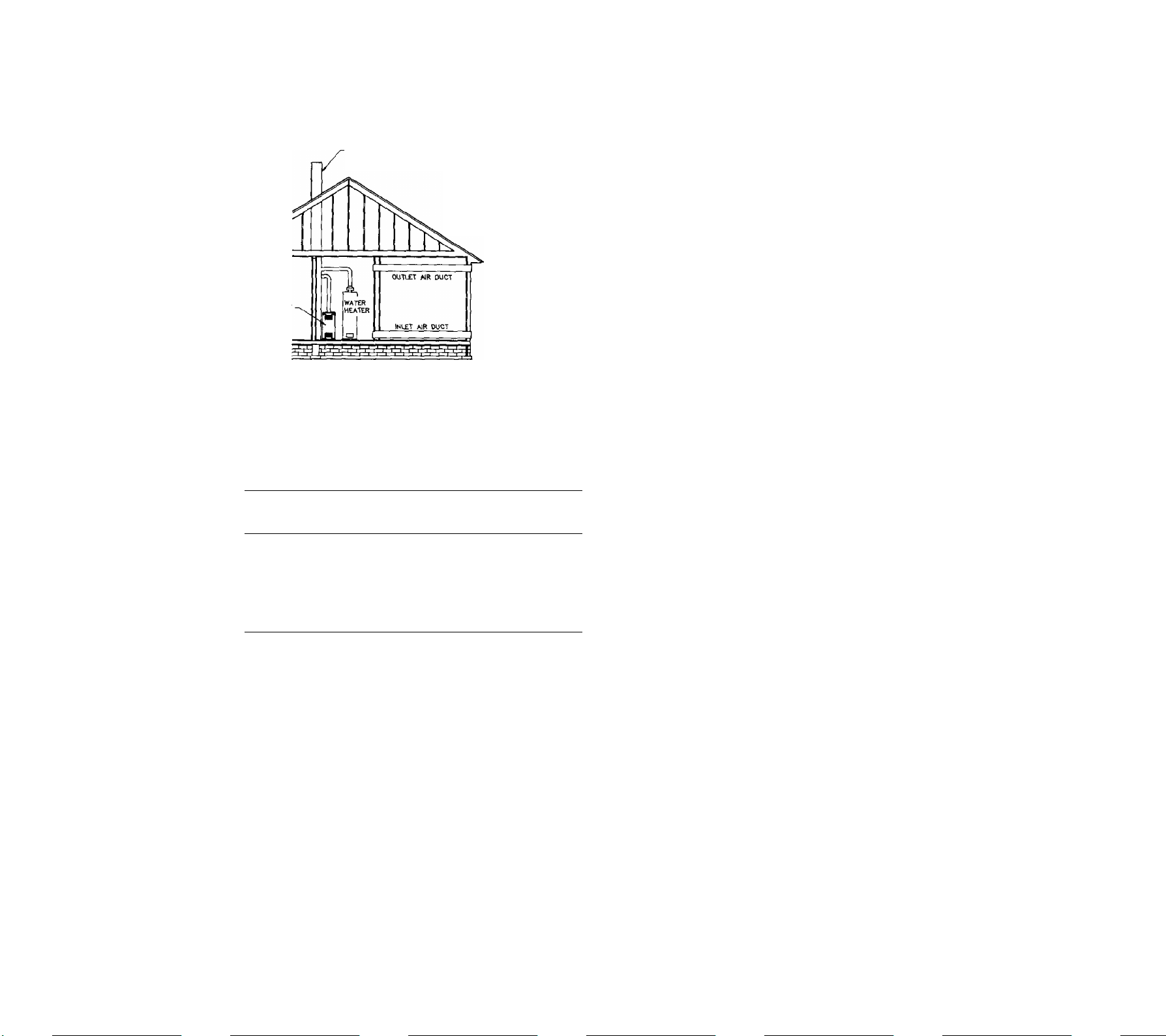

5. if combustion air ducts will run horizontally, ducts

and each opening must have a minimum free

area of one square inch per 2,000 Btuh total

combined input rating. You must allow for all

gas appliances within the furnace space. See

Figure 14.

CHIMNEY OR CAS vent

NOTE: EACH AIR DUCT

OPENINO SHALL HAVE A

FREE AREA OF NOT LESS

THAN ONE SQUARE INCH

PER 2.000 BTU PER HOUR

OF THE TOTAL INPUT RATInC

OF ALL EQUIPMENT IN THE

ENCLOSURE

to 25% free area. Assume metal louvers and grilles

have 60 to 75% free area. Refer to current National

Fuel Gas Code ANSI Z223.1/NFPA 54.

Example: Furnace is 100,000 Btuh input and is to be

installed in a confined space that contains no other

gas appliances. Rectangular combustion and ventilation air ducts will run horizontally from outdoors to

furnace space.

a. Calculate free area required.

Because combustion and ventilation air ducts run

horizontally, allow 2,000 Btuh. See 2b. above.

Furnace Input

Btuh

Free Area Required

2,Q0Q Btuh

per square inch

IF THE EQUIPMENT ROOM IS LOCATED AGAINST AND OUTSIDE WALL ANO THE AIR OPENINGS

COMMUNICATE OIRECTLY WITH THE OUTDOORS. EACH OPENING SHALL HAVE A FREE AfffiA

OF NOT less than one SQUARE INCH PER 4,000 BTU PER HOUR OF THE TOTAL INPUT

RATING OF ALL EQUIPMENT IN THE ENCLOSURE.

EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM OUTDOORS.

FIGURE 14

For example:

Total input

Btuh

Free Area per Opening

(square Inches)

Round Pipe

(Inches dia.)

40,000 20 6

60,000 30

80,000 40

100,000

50 8

120,000 60 9

140,000 70

6. Ducts which introduce combustion and ventila

tion air from outside structure into furnace space,

must have the same cross sectional area as the

free area of openings to which they connect.

The minimum dimension of rectangular air ducts

shall not be less than 3 inches.

2. Louvers, grilles, and screens.

Sometimes, louvers, grilles, or screens cover com

bustion and ventilation air openings. If so, you must

provide larger openings than those calculated above.

This is necessary because louvers, grilles and

screens block and reduce an opening's free area.

Louver, grille and screen manufacturers supply tech

nical data on their products, which usually includes

the Tree area." Sizing the openings with louvers,

grille or screen in place will provide minimum free

area to furnace space as calculated above. Do not

use screen smaller than 1/4" mesh. If you do not

know free area, assume that wood louvers have 20

7

8

10

100,000

50 square inches

2,000

Each opening must have a free area of 50 square

inches.

Calculate overall area of openings to give needed

b.

free area once you cover them to keep out rain

and other outside elements.

Example: If you will use wood louvers to cover

combustion and ventilation air openings and you

do not know free area of wood louvers, use 20%,

as suggested in ANSI Z223.1/NFPA 54.

100 x Free area

from a) above)

Louver free area

openings expressed

overall area of

openings with wood

louvers installed

as a percentage

100 x 50

250 square inches

20

Each of the two combustion and ventilation air

openings must have a total area of 250 square

inches. This is when wood louvers cover openings

for a 100,000 Btuh input furnace and combustion

and ventilation air ducts run horizontally.

c. Calculate minimum rectangular duct size needed.

If you choose a rectangular duct with the mini

mum allowed dimension of 3", the other duct

dimension must be at least 16-2/3". This is cal

culated by dividing the 50 square inches of free

area from a) by 3", with equals 16-2/3".

WARNINGi You must fix combustion and ventila

tion air louvers and grilles In open position or Inter

lock them with furnace operation. Furnace operation

12

with louvvrs or grilles closed could cause Inadequate

combustion or ventilation air, resulting In Injury or

death.

C. Installing furnace in unconfIned space.

Refer to current National Fuel Gas Code ANSI 2223.1/

NFPA 54 for more information. This code does not re

quire that you make special provisions for combustion

and ventilation when furnace is in an unconfined space.

However, it is always prudent to arrange for combustion

and ventilation air as if installation space is confined

space.

In the past, infiltration through loose construction pro

vided enough air for combustion and ventilation when

furnace was in an unconfined space. Current construction

methods may now prevent infiltration of air into unconfined

space. These current methods include increased insula

tion, vapor barriers, tight fitting doors and windows, and

weather-stripping.

D. Allowing for exhauet fan operation.

1, When furnace is in a ventilated attic, crawl space,

residertce garage, or outside the heated space, ex

haust fan drafts can adversely affect its operation.

These drafts can come from kitchens, bathrooms,

clothes dryers or anywhere within the heated space.

WARNING: Exhaust fans that blow against fur

nace could cause heat exchanger failure or fire,

resulting In damage, Injury, or death.

2. When furnace is in a repair garage or inside the

heated space, exhaust fans can adversely affect its

operation. Exhaust fans in kitchens, bathrooms,

clothes dryers or anywhere within heated space in

crease combustion and ventilation air requirements.

This is because exhaust fans reduce the amount of

combustion and ventilation air available to the fur

nace. A fireplace also reduces amount of combus

tion and ventilation air. You must allow for these

reductions.

WARNING: You must allow for reduction of air

available for combustion and ventilation by ex

haust fans and fireplaces. Failure to do so could

result In Inadequate combustion and ventilation

sir. This could cause nausea, asphyxiation, or

firs, resulting In damage, Injury, or death.

3. Exhaust fan air may contain compounds of chlorine,

fluorine, bromine, and iodine. If used for combus

tion, this contaminated air will adversely affect fur

nace operation.

WARNING: If used for combustion and ventila

tion, contaminated exhaust fan air could cause

heat exchanger or vent system failure resulting

In damage, Injury, or death.

SICTION 9 —

PROVIDING P

Vent furnace using these instructions and Venting Adden

dum. Also, meet requirements of local utilities and other local

code authorities. You must connect furnace to a vent or fac

tory-built chimney or a suitably sized, constructed and lined

masonry chimney. Vent or factory-built chimney must meet a

recognized standard. Chimney lining method and material

must comply with local requirements. Use corrosion-resistant

material meeting nationally recognized standards for vent

construction.

INTING.

WARNING: Inadequate vent or chimney could allow

combustion products to collect In structure, resulting In

Injury or death.

WARNING: Vent this furnace separately from any appli

ance designed to burn solid fuel, particularly wood-burn-

Ing or coal burning appliances. Improper venting could

allow combustion products to collect In structure, result

ing In injury or death.

A. Venting category.

The furnaces covered by this manual are design-certified

as CATEGORY 1 for venting, CATEGORY 1 furnaces

have non-positive vent static pressure and rely on the

beat content of combustion products to vent. You may

common vent CATEGORY 1 furnaces.

The furnaces covered in this manual are also designcertified as CATEGORY 3 for venting, only when they

are installed with manufacturer specified vent system

components and installation practices.

Category 3 gas appliances rely on the heat content of

combustion products and mechanical or other means to

vent. You may not common vent CATEGORY 3 gas ap

pliances.

B. Types of vent systems.

These definitions will help you understand the terms we

use.

1. "Vent" and "chimney" refer to open passageways.

These passageways convey vent gases from vent

connectors to the outside. Gases begin their final

ascent at the vent or chimney. Vents and chimneys

usually run vertically or nearly vertical. When they

serve only one gas appliance, they are called "dedi

cated" vents or chimneys. Whan they serve multiple

gas appliances, they are called "common" vents or

chimneys.

2. A "vent connector" connects a gas appliance to a

vent or chimney. Vent connectors usually run directly

from the furnace draft inducer collar to vent or chim

ney. Vent connectors may have vertical and horizon

tal runs.

3. A "venting system" is a continuous open passage

way from the draft inducer collar to the outside.

Venting systems usually have vent connector(s) and

a vent or chimney. Venting systems commonly serve

a single furnace or a single furnace and a water

heater. Other multiple-appliance venting systems are

13

less common.

C. Design considerations.

1. General considerations.

Avoid oversizing furnace for your application. Se

lect a furnace model with a rated heating output

close to the calculated heating toad. This extends

the firing period, decreasing the potential for con

densate formation in the vent.

a. Too small a vent cannot carry all combustion

products outdoors. Too large a vent will not vent

combustion products rapidly enough to avoid

potential for condensation. Refer to Venting Ad

dendum for correct size vent.

b. Vent height must be a minimum of five feet.

Minimize vent connector horizontal runs to the

extent possible for best performance.

c. The designer must consider the building's ori

entation, answering these questions. Will the

vent terminate outside the building where its op

eration could be adversely affected by winds?

Could any adjacent buildings adversely affect

vent operation? Allowing for these factors can

reduce the possibility of downdraft conditions.

b. Use Type B1 vent connectors in or through at

tics, crawl spaces, or other cold areas. Install

thimbles that meet local codes when vent con

nectors pass through walls or partitions of com

bustible material.

c. Keep vent connectors as short as possible by

locating furnace as dose as practical to vent or

chimney. Avoid unnecessary turns or bends

which create resistance to

Adding an elbow adds resistance. For example,

adding a 6" 90-degree elbow would be the

equivalent of adding 20 feet of horizontal 6" pipe.

45-degree elbows have lower resistance than 90degree elbows, and can work for most vent runs.

d. You may increase vent connector diameter to

overcome installation limitations and obtain con

nector capacity equal to furnace input. Make this

increase as close as possible to draft inducer

collar, allowing for necessary adapters and fit

tings.

e. If you join two or more vent connectors before

they enter the vertical vent or chimney, use cau

tion. See Venting Addendum.

flow of vent gases.

d. If your local experience indicates possible con

densation problems, provide for draining and

disposal of venting system condensate.

2. Vent sizing.

a. Sometimes the horizontal distance from the fur

nace to the vent or chimney is already given;

this is known as the horizontal vent connector

run. The vent or chimney height is also usually

given as is the Btuh input of the gas appliances

served by the vent.

Check these parameters to be sure the venting

system will work. Use approved engineering

practices, Venting Addendum, these instructions,

and Part 7 of current National Fuel Gas Code

ANSI Z223.1/NFPA 54. Use vent capacity tables

in Venting Addendum to check existing or new

vent sizes for CATEGORY 1 furnaces.

b. See Venting Addendum for single appliance

venting and multiple appliance (common) vent

ing. For multi-story installations, refer to current

National Fuel Gas Code ANSI Z223.1/NFPA 54.

c. Minimum vent connector diameter from furnace

to vent or chimney is same as draft inducer col

lar.

3. Vent connector.

a. Vent connectors must be made of noncombus

tible, corrosion resistant material capable of

withstanding vent gas temperatures. They must

be thick enough to withstand physical damage

and be accessible for inspection, cleaning and

replacement.

f. Do not connect this furnace to any portion of a

vent system which operates under positive pres

sure. Positive pressure would result with CAT

EGORY 3 and 4 appliances connected to the

vent.

g. Do not connect vent connector to a chimney flue

serving a fireplace unless you permanently seal

fireplace flue opening.

4. Vertical vent or chimney.

a. Vents and chimneys usually extend vertically with

offsets not exceeding 45-degrees. Consider vent

pipe runs more than 45'degrees as horizontal

runs. Include their length in the total horizontal

run.

b. Designer and installer must provide an appropri

ately sized common vent for all appliances con

nected to it. See Venting Addendum.

c. Connect this CATEGORY 1 furnace only to vent

systems with other CATEGORY 1 appliances.

WARNING: Do not connect this Category 1

furnace to a vent system used by Category 3

and 4 appliances. Do not connect It to vents

with mechanical draft systems operating at

positive pressure. Improper venting could al

low combustion products to collect in struc

ture during use, resulting In damage, Injury

or death.

5. Chimney.

Furnace is suitable for venting into a properly sized

and lined masonry chimney. Consult National Fuel

Gas Code ANSI Z223.1/NFPA 54 for construction

details. If chimney is oversized, liner is inadequate

14

OT evidence of condensate exists, consider using

chimney as a pathway for suitably sized Type B1

vent liner. See Figure 15.

FIGURE 15

WARNIN9I Support Type B1 vent liner in ma

sonry chimney. Maintain at least a 1" clearance

on all sides to reduce possibility of condensate

in vent. Condensate may cause vent to deterio

rate allowing combustion products to collect In

structure, which could result In injury or death.

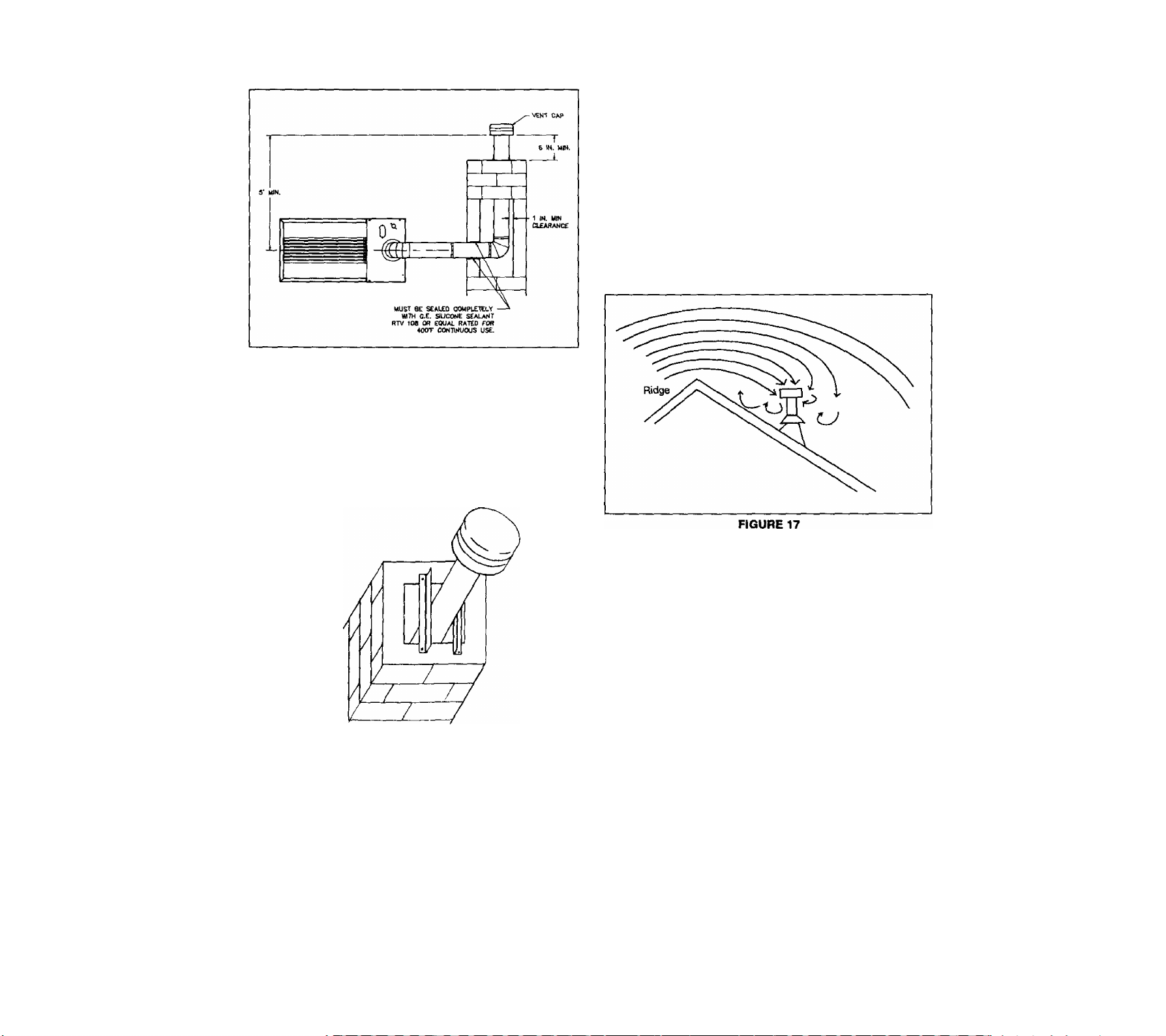

See Figure 16.

NOTE; For more information on proper chimney in

spection and relining procedures, Gas Research In

stitute (GRI) has a topical report entitled "Masonry

Chimney Inspection and Reiintng". Obtain copies

through American Gas Association (A.G.A.) at

1-800-841-8400.

6. Vent termination.

a. Terminate ail verticai vents with a iisted vent

cap or roof assembly unless local codes require

otherwise. See vent cap or roof assembly

manufacturer's instructions. Locate vent termi

nation (vent cap or roof assembly) in an area

without positive wind pressures or eddy currents.

Eddy currents occur when air swirls over roof

peaks. They can cause down-drafts and ad

versely affect vent operation. See Figure 17.

FIGURE 16

WAKNINOi Vent liner muet not block opening

where other epplicncee' vent connector* enter

chimney. Blocked opening* could cau»* com

bustion products to collact In atructur*, r*sutt-

Ing In damag*, Injury or dssth.

WARNINOt Do not uaa unllnad masonry chlm-

naya. Thasa Incraasa risk of condansats forma

tion, which may causa chlmnay to datariorata,

allowing combustion products to collact In

structura, raaulting In damaga. Injury or death.

Some vent terminations or caps protect against

eddy currents and down-drafts, Consult their

manufacturer's instructions. Vent terminations or

caps should usually be at least the same size as

the vent. They may be larger if the installation

warrants.

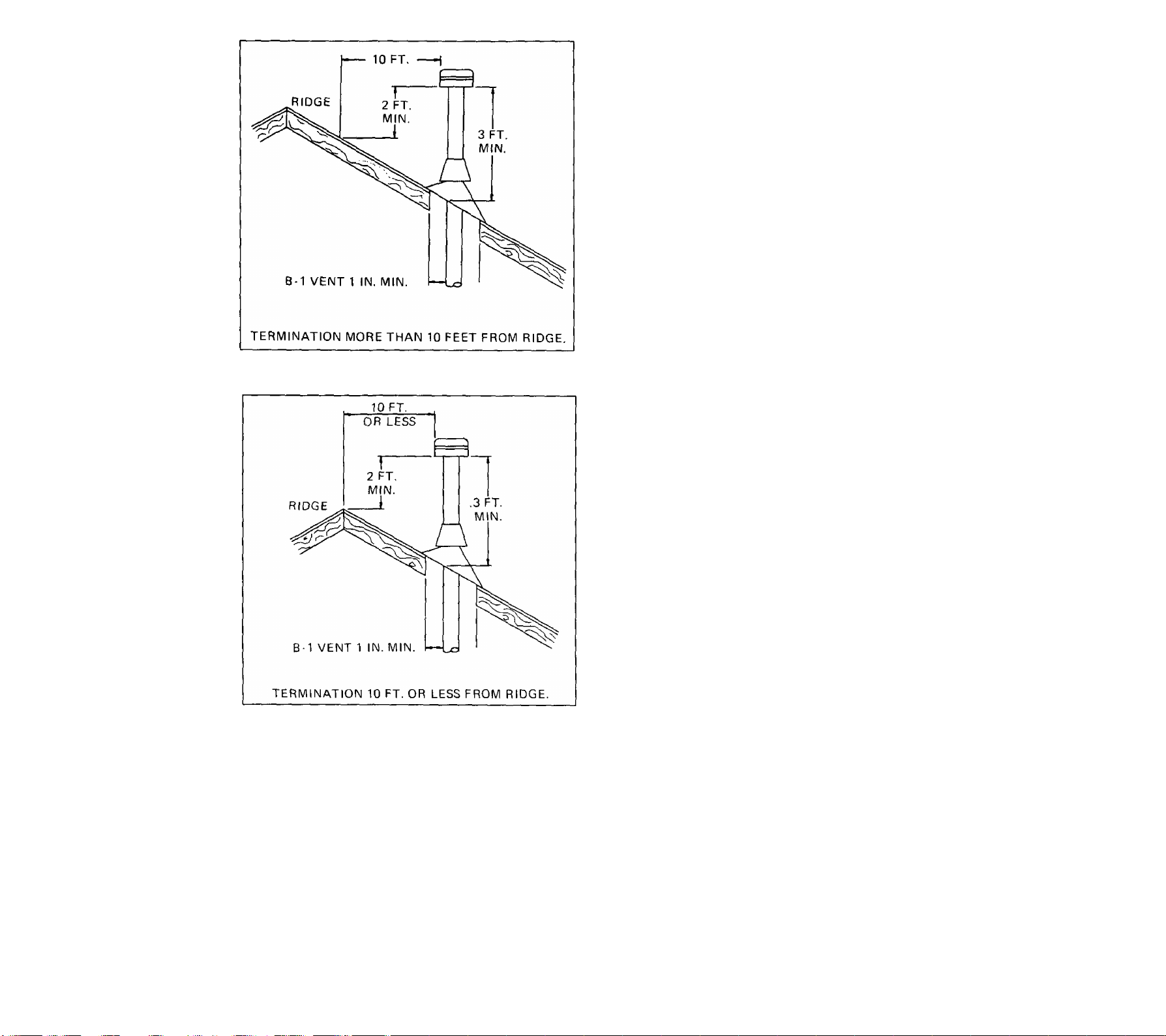

b. Vent systems must end at least five feet above

the highest gas appliance connection. Vent pipe

must extend at least three feet above the point

where it passes through the roof. Vent termina

tion must be at least two feet higher than any

portion of building within ten feet horizontal and

vent termination must be at least two feet higher

than roof peaks within ten feet horizontal. See

Figures 18 and 19. Some vent cap manufactur

ers offer vent caps that allow reduced clearances.

Consult their Instructions.

15

D. Installation.

1. Vent connectors.

Attach vent connector at draft inducer collar. Make

sure flue gasket is in place providing a seat. Use a

minimum of three equally spaced screws around

connection. Connect all other vent pipes using three

equally spaced screws at each joint. Exception is

only when you use Type B1 vent pipe with self

locking connections or high temperature plastic pipe.

WARNINGS Unsecured vent pips connections

may loosen. This can allow combustion products

to collact In structura, resulting In Injury or death.

Install vent connectors without any dips or sags.

Slope them upward from furnace at least f/4” per

foot. To prevent sagging, at each joint support vent

connectors and horizontal portions using hinges,

straps or equivalent. Seal all connections where vent

connectors enter chimney. See Figure 15.

TERMINATION MORE THAN 10 FEET FROM RIDGE

FIGURE 18

TERMINATION 10 FEET OR LESS FROM RIDGE

FIGURE 19

WAftNINGt Failure to properly terminate

vent chimney systems could allow combus

tion products to collect In structure, result

ing In Injury or death.

c. Terminate venting system at least three feet

above any forced-air building inlet within ten feet.

Consider doors, windows and gravity air building

inlets. Locate vent termination at least four feet

below, four horizontal feet from or one foot above

any of these openings.

To avoid blockage, attach vent connector to a ma

sonry chimney above the extreme bottom. For in

spection ease, use thimble or slip joint to make vent

connector removal easy. Firmly attach connector.

Insert all vent connectors into, but not beyond, inside

chimney wall.

2. Vertical vent or chimney systems.

Install vent materials following their listing terms,

manufacturer's instructions, these instructions and

local codes.

A gas vent passing through a roof must extend

through roof flashing, jack or thimble. It must termi

nate above roof surface.

E. Existing vent considerations.

Masonry chimneys previously used for venting solid fuel

or oil burning equipment should be lined with suitable

metal liner. Also provide an accessible clean out per cur

rent National Fuel Gas Code ANSI Z223.1/NFPA 54.1.

1. Inspection of vents (chimneys).

a. Make sure existing vent or chimney is proper

size and construction for appliances that will use

it. The best way to do this is to size as if it were

a new installation. Compare the existing vent to

your calculations and make necessary correc

tions.

b. Examine vent or chimney cleanouts to make sure

they remain tightly closed when not in use. Make

sure vent or chimney passageway is clear and

free of obstructions. Look for evidence of con

densate or deterioration in vent or chimney. Ei

ther of these means an inadequate vent.

c. If you find an inadequate vent or chimney, do

not leave it as is. Repair or replace it. A new

vent must meet these instructions and current

16

National Fuel Gas Code ANSI Z223.1/NFPA 54.

Rabuild a chimney to meet national standards.

MCriON 10 —

TOOLS NIIDID rOR INSTALLATION.

WARNINOi An Inadequate vent or chimney

could allow combuatlon products to collect

In structure, resulting In Injury or death.

d. Sometimes you wiii repiace a common vented

appliance. Make sure common vent size is cor

rect for aJl appliances connected to it. If you re

move a furnace from a common vent without

replacing it, the vent will likely be too large for

remaining appliances. See Venting Addendum.

e. The following steps shall be followed with each

appliance remaining connected to common vent

ing system placed in operation, while other ap

pliances remaining connected to common venting

system are not in operation.

1. Seal any unused openings in common vent

ing system.

2. Visually inspect venting system for proper

size and horizontal pitch and determine there

is no blockage or restriction, leakage, corro

sion and other deficiencies which could

cause an unsafe condition.

3. Insofar as is practical, close all building doors

and windows and all doors between space

in which appliances remaining connected to

common venting systems are located and

other spaces of building. Turn on clothes

dryers and any appliances not connected to

common venting system. Turn on any ex

haust fans, such as range hoods and bath

room exhausts so they will operate at maxi

mum speed. Do not operate a summer ex

haust fan. Close fireplace dampers.

4. Follow Operating Instructions. Place appli

ance being inspected in operation. Adjust

thermostat so appliance will operate con

tinuously.

5. After it has been determined that each ap

pliance remaining connected to common

venting system properly vents when tested

as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any

other gas-burning appliance to their previous

conditions of use.

6. If improper venting is observed during any

of the above tests, common venting systems

must be corrected.

NOTE: Follow current National Fuel Gas

Code ANSI 2223.1/NFPA 54 to correct im

proper common vent operation. Any common

vent resizing must approach minimum size

determined by using Venting Addendum.

ITEM

TOOL DESCRIPTION

HAND TOOLS

A.

1. Carton KnHe

1/4" nut driver

2.

5/16" nut driver

3.

4. 3/8” nut driver

1/4" X 8" straight-

5.

blade screwdriver

#2 X 8" Phillips

6.

screwdriver

7/16" open end or

7.

tubing wrench

2-8" to 14" pipe

8.

wrenches

4" adjustable

9.

wrench

10. 8” Channel-lock

ptiei^

3/16" Allen

11.

wrench

12.

9/64" Allen

wrench

B.

SUPPLIES

13. Pipe thread sealant

suitable for use with

propane (LP) gas

14.

Bottle of soap

solutbn

15.

2-1/8” pipe, manual

shutoff valves

C.

TEST INSTRUMENTS

16.

Volt meter with 50

and 150 volt ranges

17. Clamp around

ammeter with 10 amp

and higher ranges

USED FOR

Furnace removal from

carton

Control box cover

Casing and blower

Blower and motor

mounts

Wire terminals and manifold

pressure adjustment

Components in control box

Main burner orifices

Gas pipe installatbn

Blower wheel set screw

tightening

Strain reliefs

Inlet and outlet pressure tap

plug removal from gas control

Honeywell gas inlet fitting

Gas pipe and controls

Gas leak checking

Gas control inlet and

pressure checking

Electrbal chedt of controls

and power supply

Amp draw of motors and

control check

17

18. 10-turn coil of wire

to fit on ammeter

19. "U" Tube Water

Manometer with O.V

resolution 0“to 15"

W.C. range

20. Slope gauge with

0.01” pressure

measurement taps

and tubing, Oto 1"

W.C. range

Room thermostat heat

anticipator setting

Gas pressure

measurement

Duct work static pressure

furnace. A convenient way to do this when you have

reduced bottom clearance, is to make drip leg by

using a 1/2" to Г NPT Tee, Then install a 1-1/2"

long.l” NPT nipple in Tee with a Г NPT pipe cap to

complete drip leg.

3. When using black iron gas pipe, install an A.G.A.

listed ground joint union between drip leg (sediment

trap) and furnace gas control. Locate ground joint

union to allow easy servicing of burner assembly

and gas control.

4. Install gas pipe to inlet side of furnace gas control.

21. 2 thermometers

with 1 -degree

Fahrenheit

resolution, 50

degrees F to 175

degrees F range

22. Stop watch

23. Torque wrench

(100 inch-pounds)

Temperature rise measured

through lurnace

Gas input meter timing

Proper screw installation

SICTION 11 — INSTALLING GAS PIPING.

Equipment needed: Save time by getting these tools before

you start: Item number(s) 8,12.13 and 14 listed in Section

10.

A. Preparation.

Gas piping must meet requirements of current National

Fuel Gas Code ANSI Z223.1/NFPA 54 and local codes.

Size of pipe running to furnace depends on:

• Length of pipe;

• Number of fittings;

• Specific gravity of gas;

• Input requirements fBtuh) of all gas-fired appli

ances attached to same main supply line.

Refer to current National Fuel Gas Code ANSI Z223.1/

NFPA 54 for correct gas pipe sizing information.

Plan furnace gas supply piping so it will not interfere with

removal of burner assembly, front door or blower door

for servicing.

Always use a pipe thread sealant which is resistant to

propane (LP) gas solvent action. Sparingly apply sealant

to all joints on male threads only, starting two threads

back from end.

B. Installation.

1. Install A.G.A. listed manual shut-off valve in gas

supply line immediately upstream of furnace. Install

1/8" NPT plugged tapping accessible for test gauge

connection. Omit separate, plugged tapping if local

area accepts plugged tapping in gas control inlet.

2. After in-line manual shut-off valve, install a drip leg

(sediment trap) at gas supply line inlet connection to

WARNINGS Do not thread gas pipe too far. Do

ing so may cause gas control to split or crack

which could cause a gas leak or distortion or

malfunction of gas control. Thasa could causa a

firs or explosion resulting in damage, Injury or

death.

5. Isolate gas control from gas supply line pressure

during leak check. Gas supply line test pressure de

termines how you isolate gas control.

WARNINGS At gas supply line, test pressure

equal to or less than 14 Inches W.C. (1/2 PSI).

Isolate gas control from gas supply line by turning

furnace gas control knob clockwise > to off posi

tion. Unexpected surges could damage gas con

trol causing gas to leak, resulting In firs or ex

plosion.

WARNINGS When test pressure la above 14

Inches W.C. (1/2 PSI), completely disconnect gas

control from gas supply line. Failure to Isolate

gas control from test pressure could damage H,

causing gas to leak, resulting in firs or explosion.

6. Use a commercial soap solution made to detect leaks

and check all gas piping connections. Bubbles indi

cate gas leakage. Seat all leaks before proceeding.

WARNINGi Never use an open flams to check

for gas leaks. If a leak doss exist, a firs or explo

sion could occur, resulting In damage. Injury or

death.

Furnace Gas Entry Piping.

1. See below for gas entry holes and knockouts.

a. A 1-1/4* X 2-3/4" knockout in top plate.

b. A 1-1/2" diameter hole and a 1-1/4" x 1-15/16"

knockout in right side of casing.

c. Two 1-5/8" diameter knockouts in left side of

casing.

2. Changing Gas Control Inlet.

You may want to change direction of gas inlet elbow

on gas control. Gas control is shipped for right side

gas entry. If you need top entry, remove the fitting. If

you need left side gas entry, rotate the fitting 180

degrees.

18

a. Use 9/64" Hex Allen wrench to remove tour

screws. Check that O-ring is in bottom of gas

inlet elbow. Rotate elbow to desired position.

WARNINGi Provide furnace with ita own separate elec

trical circuit, means of circuit protection and electrical

disconnect switch. Follow current National Electrical Code

ANSI/NFPA 70 and state and local codes. Failure to pro

vide these shut-off means could cause electrical shock

or fire, resulting In damage, Injury or death.

install proper electrical grounding by attaching grounding

source to green wire conductor in furnace junction box. Fol

low current National Electrical Code ANSI/NFPA 70 and local

codes.

WARNINGS Furnace must have proper electrical ground.

Failure to provide a proper electrical ground could cause

electrical shock or fire, resulting In damage. Injury or

death.

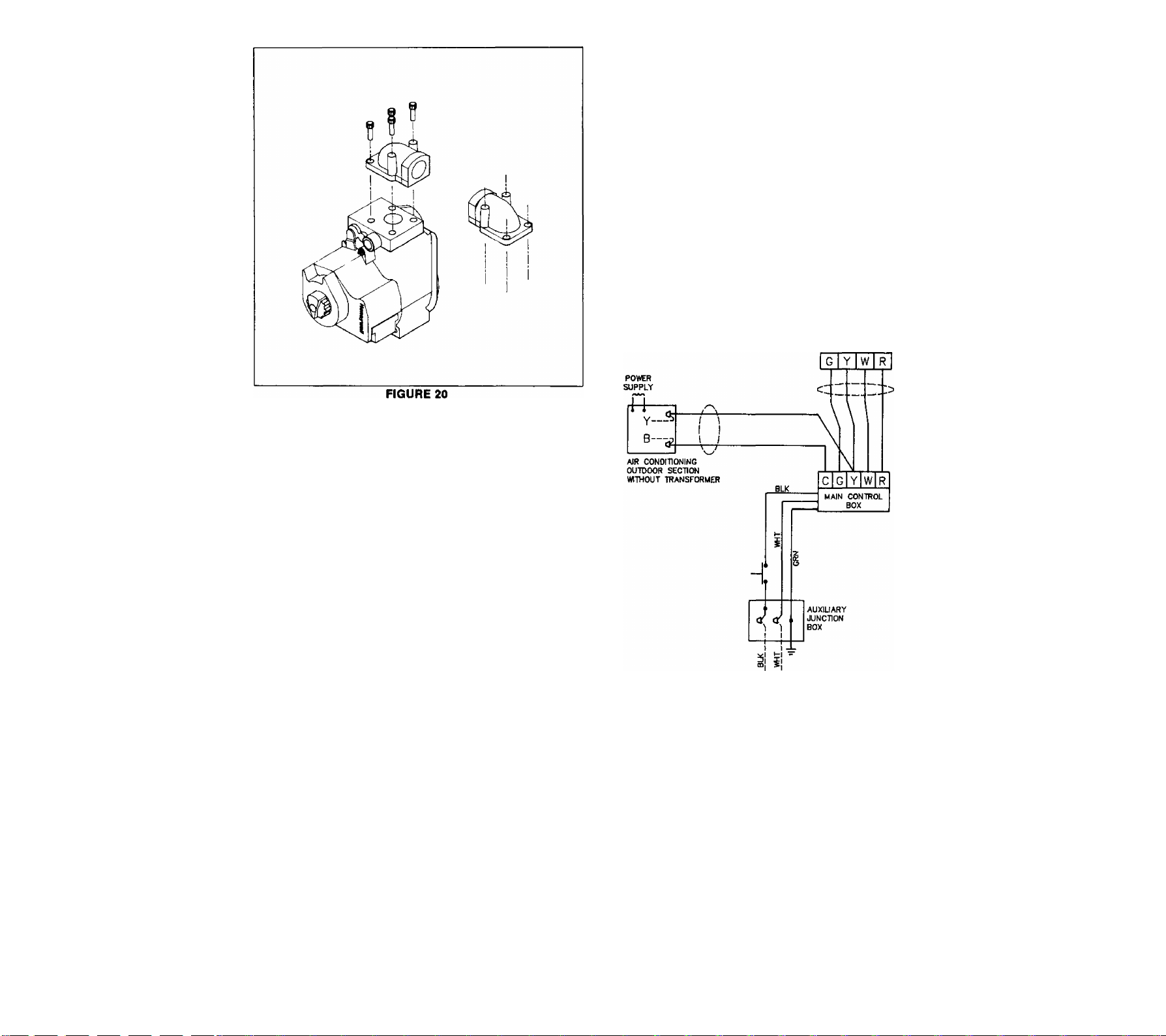

fICTION 13 —

FOLLOWING FIELD WIRING DIAGRAM

HEATING COOUNG

THERMOSTAT MODEL

b. Alternately tighten tour screws to 45 inch pounds

to form a gas tight seal.

c. Use a commercial soap solution made to detect

leaks and check all gas piping connections.

Bubbles indicate gas leakage. Seal all leaks be

fore proceeding.

WARNINOi Never use an open flame to

check for gas leaks. If a leak does exist, a

fire or explosion could occur, resulting In

damage, Injury or death.

3. Allowing tor Electronic Air Cleaners.

Some large electronic air cleaners will interfere with

incoming gas line. Install air cleaner on opposite fur

nace side from gas entry or route gas pipe over top

of air cleaner through one of alternate knockouts.

SICTION 12 —

INSTALLING ILICTRICAL WIRING.

Equipment Needed: Save time by getting these tools before

you start: Item number(s) 2 listed in Section 10.

Select a location for room thermostat that is away from sup

ply and return air registers, on draft-free interior wall, and not

near lights, television, direct sunlight, or other heat sources.

Install thermostat following field wiring diagram in Section

13. Use electrical wiring that meets current National Electrical

Code ANSI/NFPA 70 and local codes. Use Type T (63 de

grees C rise) wire or equivalent. See Section 30 for code

information.

TO 115V 1 PH 60 H2

POWR SUPPLY PER

LOCAL CODES

FIELD WIRING DIAGRAM

FIGURE 21

NOTE: When replacing original wire, use same type, color,

or equivalent wire. Remember to renumber wire ends.

SECTION 14 — ADJUSTING ROOM

THERMOSTAT HEAT ANTICIPATOR

Equipment Needed: Save time by getting these tools before

you start: Item number(s)5,17 and 18 listed in Section 10.

Wire system using field wiring diagram in Section 13.

19

A. Exact haat anticipator setting.

SECTION 1 5 — SEQUENCE OF OPERATION.

Exactly setting heat anticipator helps avoid potential call

backs. If you have any of the following factors, set heat

anticipator to match actual current draw in circuit.

• The system contains controls other than those

specified on wiring diagram;

• The system contains nonstandard (18 AWG) size

thermostat wire;

• The system has longer than a 30-foot distance

between thermostat and furnace.

Follow these steps to exactly set heat anticipator:

1. Use 2-foot piece of 24-guage thermostat wire,

stripped on both ends.

2. Use ammeter capable of reading exact amperage in

0-10 amp range. If it is adjustable, set on 0-10 scale.

3. Wind the 2-foot piece of 24-guage thermostat wire

ten times around one open arm of ammeter. Close

ammeter arms. This will act as a ten times multiplier.

4. Make sure 115-volt power to furnace is on. Connect

ends of wire on ammeter across terminals "R" and

"W" of thermostat sub-base. Follow Figure 22.

■Riermostat Sub-Base Terminals

Ten (10) Turns

>^24 Ga. Wire

See Figure 23 for furnace wiring diagram.

Thermostat calls for heat, energizing electronic ignition lock

out module. Electronic ignition lockout module provides power

to gas control and igniter to light pilot. After proving pilot

flame, inducer relay (IDR) closes, energizing inducer motor.

Inducer motor starts and pressure switch closes, energizing

gas control and time delay relay (TDR). Time delay relay

energizes main blower within 20 to 30 seconds.

NOTE: If system locks out, set room thermostat below room

temperature for at least 10 seconds, then return to desired

setting. To purge gas lines, it may be necessary to operate

furnace through more than one lockout cycle at start-up.

After room thermostat is satisfied, gas control and inducer

relay are de-energized simultaneously. Inducer motor de-en

ergizes and returns pressure switch to normally closed (N.C.)

position. Main blower remains energized through time delay

relay for up to 180 seconds.

SECTION 16 — INSTALLING DUCT WORK,

CAUTION: Install all duct work to meet current standards:

• ASHRAE/NFPA 90, Standard for Installation of

Warm Air Heating and Air Systems;

• State and local codes.

Failure to follow these standards could reduce air flow

or increase air leakage, resulting In reduced system per

formance or furnace damage.

Amprobe ^

FIGURE 22

5.

Read amp draw of furnace circuit on ammeter and

divide by 10. This gives you an exact heat anticipator

setting.

Example:

Meter reading - 9 amos

Divide by 10 turns - 10

Heat anticipator setting « .9 amps

6. Set room thermostat's heat anticipator to this amp

setting. Follow instructions provided with thermostat.

B. Approximate heat anticipator setting.

Find heat anticipator under room thermostat cover. Set

heat anticipator at 0.6 amps. Follow instructions provided

with thermostat.

Properly size duct work based on heat loss and heat gain

calculations. Doing so assures:

• Good heating and cooling installations;

• Potentially fewer callbacks;

• Delivery of required circulating air.

For all furnaces, design duct systems for minimum and maxi

mum external static pressures detailed in Figure 24. See

Section 25 on measuring duct work static pressure.

NOTE: When furnace is installed in an upflow position, air

delivery above 1800 CFM requires both sides of furnace be

used for return air, or a combination of one side and bottom

or bottom only.

Downflow installations use top return or top and side return.

Horizontal installations use end return or end and top return.

20

FIGURE 23

21

EXTERNAL STATIC PRESSURE

(Inches of Water Column)

"INPUT

MINIMUM

MAXIMUM

(BTU/HR)

40,000

60,000

80,000

100,000

120,000

140,000

0.10

0.12

0.12

0.15

0.50

0.50

0.50

0.50

0.20 0.50

0.20

0.50

‘Input is on furnace rating plate on blower door.

FIGURE 24

A. Supply air duct work.

NOTE: Supply air duct (plenum) connection must be the

same size as the furnace supply air opening. Attach to

furnace duct flanges.

If you install furnace in horizontal position with an air

conditioner, design a minimum 18" long transition that

allows free air flow through furnace and cooling coil. Make

sure furnace temperature rise is within range noted on

furnace rating plate. Also, consult air conditioner's duct

work installation Instructions.

Seal supply air duct work to furnace casing, walls, ceilings

or fioors it passes through. End duct work outside furnace

space.

B, Return air duct work.

1. In upflow position, return air duct must be a mini

mum depth of 23-31/32". See Figure 25.

2. In downflow position, return air duct must be a mini

mum 19-7/8" inside depth. See Figure 26.

CASING

WIDTH

14.50

20.50

23.50

BTU/HR"

INPUT

40,000

40,000

60,000

60,000

60,000

80,000

80,000

80,000

80,000

100,000

100,000

100,000

120,000

120,000

NOTE: In upflow position, if bottom return air is not

used, you must attach a solid bottom closure panel

to bottom return air opening. Bottom closure panel is

available from manufacturer as follows:

MOTOR*

H.P.

1/4

1/3

1/4

1/3

1/2

1/4

1/3

1/2

3/4

1/3

1/2

3/4

1/2

BOTTOM CLOSURE

PART NUMBER

4045900

4045901

4045900

4045901

4045902

4045901

4045902

3/4

FIGURE 25

140,000

140,000

3/4

3/4

"See furnace rating plate on blower door.

22

4045903

WARNINOt Failure to install bottom closure

panel could allow combustion products to enter

circulating air stream, resulting In injury or death.

When furnace is installed so that supply air ducts carry

air to areas outside the space containing the furnace,

return air must also be handled by a duct(s) sealed to

furnace casing and terminating outside the space con

taining furnace.

Avoid vent system reverse pressure by running return

air duct work outside furnace space. Seal return air duct

work to furnace casing, walls, ceilings or floors It passes

through. End duct work outside furnace space.

WARNINOt Failure to seal return air duct work could

allow combustion products to enter circulating air

stream through air stream leaks, resulting in Injury

or death.

C. Duct dampers.

You may balance air flow with dampers installed in each

branch run duct and adjust for even temperature

throughout the heated space. For proper furnace opera

tion, make sure:

• Supply air registers and return air grilles are

open;