Page 1

THE WALL-MOUNT™ AIR CONDITIONERS - WL (60HZ)

with LEFT SIDE CONTROL PANEL

WL - SERIES Refrigerant 22 60Hz

1.5 to 6 Ton (18,300 to 67,000 Btuh)

Left Side Control Panel

The Bard Wall-Mount Air Conditioner with Left Side Control Panel is

designed to provide complete service access (i.e. compressor, electric heat

strip and electrical controls) when two units are mounted side by side with

minimal space between. The left side unit is the ideal product for

telecommunication and over-the-road medical and communication vans

requiring two wall-mount air conditioners be mounted side by side by using

a WL (left side access) unit and a WA (right side access) unit on the same

building. Factory or field installed accessories are also available to meet

specific job requirements.

Engineered Features

Aluminum Finned Copper Coils:

Grooved tubing and enhanced

louvered fin for maximum heat transfer

and energy efficiency.

Twin Blowers:

Move air quietly. Most models feature

multispeed blower motors providing

airflow adjustment for high and low

static operation. Motor overload

protection is standard on all models.

Air Conditioner Compressor:

Reciprocating compressors with

crankcase heater and dual discharge

muffler are standard on 1.5 and 2 ton

models.

Scroll Compressors eliminate need for

crankcase heater. Standard on 2.5 to

5 ton, and available on 2 ton models.

Phase Rotation Monitor:

Standard on all 3 phase scroll

compressors. Protects against reverse

rotation if power supply is not properly

connected. Not required on

reciprocating compressors.

Galvanized 20 Gauge Zinc Coated

Steel Cabinet:

Cleaned, rinsed, sealed and dried

before the polyurethane primer is

applied. The cabinet is handsomely

finished with a baked on textured

enamel, which allows it to withstand

1000 hours of salt spray tests per

ASTM B117-03.

Electrical Components:

Are easily accessible for routine

inspection and maintenance through a

left side, service panel opening.

Features a lockable, hinged access

cover to the circuit breaker or pull

disconnect switch.

Electric Heat Strips:

Features an automatic limit and

thermal cut-off safety control. Heater

packages can be factory installed for

all 1.5 through 6 ton models.

One Inch, Disposable Air Filters:

Are standard equipment. Optional one

inch washable filters available and filter

racks permit the addition of 2" pleated

filter. Factory or field installed.

Built-in Circuit Breakers:

Standard on all single (230/208 volt) and

three phase (230/208 volt) equipment.

Toggle disconnects are standard on all

three phase (460 volt) equipment.

Slope Top:

Standard feature for water run-off.

Top Rain Flashing:

Standard feature on all models.

Full Length Mounting Brackets:

Built into cabinet for improved

appearance and easy installation.

NOTE: Bottom mounting bracket

included to assist in installation.

Auto-Reset High Pressure Switch:

Built-in lock-out circuit resets from the

room thermostat. Provides commercial

quality protection to the compressor.

Auto-Reset Low Pressure Switch:

Built-in lock-out circuit and low pressure

timed bypass circuit. Resets from room

thermostat.

Compressor Control Module:

Built-in off-delay timer adjustable from 30

second to 5-minutes. 2-minute on-delay

if power interrupt. 120-second bypass for

low pressure control, and both soft and

manual lockouts for high and low

pressure controls. Alarm output for alarm

relay.

Low Ambient Control:

Permits cooling operation down to 0°F

outdoor ambient.

Alarm Relay:

Dry contacts for remote alarm capability

on manual high or low pressure controls.

MEA# 357-93-E

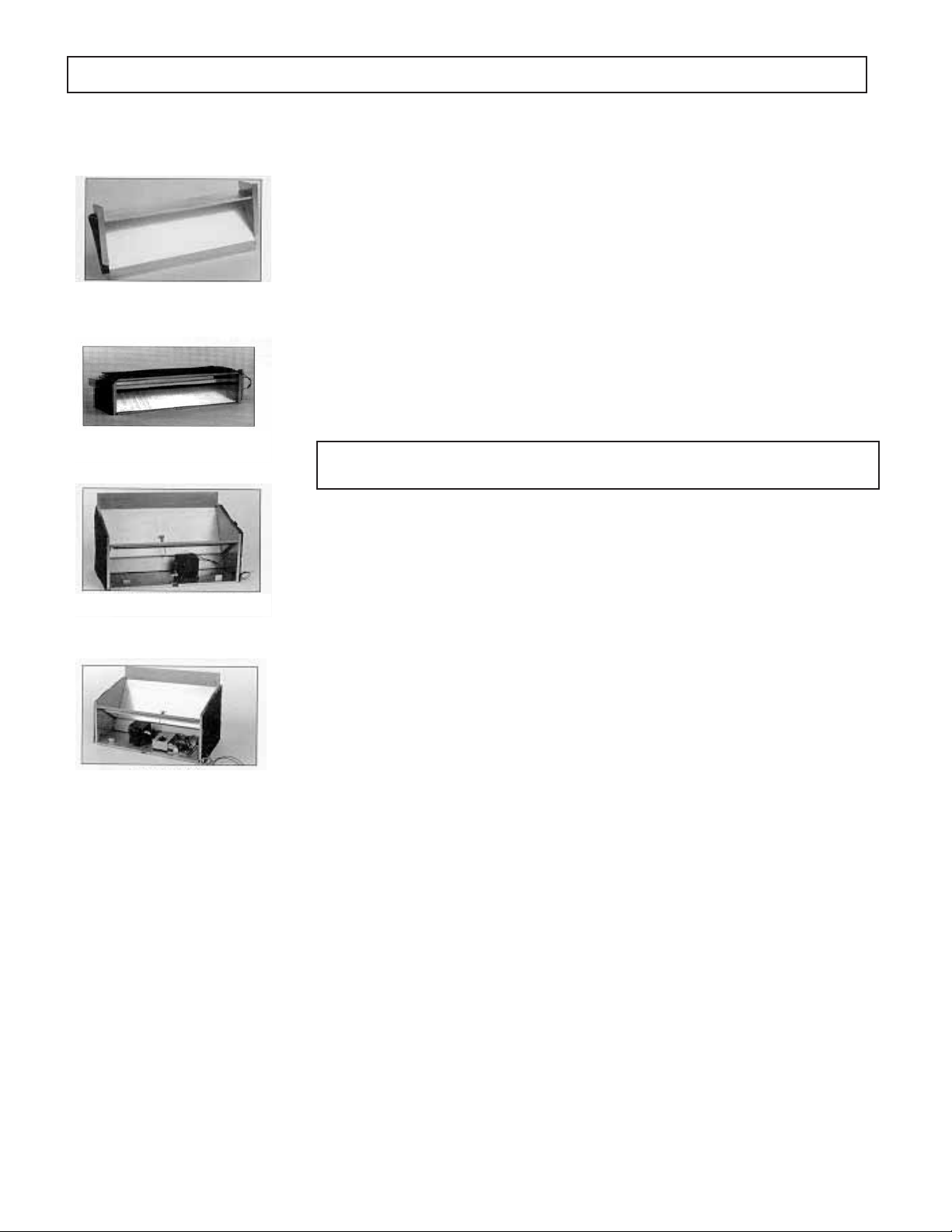

Ventilation System Packages

All packages are designed

to meet your specific

ventilation requirements

utilizing one of five

ventilation options for the

product. The ventilation

package is mounted within

the unit eliminating the need

for an exterior mounted

hood or damper assembly

on the unit. All assemblies

can be factory installed,

installed in the field at time

of installation or as a retrofit

system after installation.

Standard - Barometric

Fresh Air Damper

Optional - Motorized

Fresh Air Damper

Optional - Blank off Plate

Optional - Commercial

Room Ventilator with Exhaust

• CRV - Spring Return

• CRVP - Power Return

Optional - Economizer w/Exhaust

• Complies with efficiency requirements of ASHRAE/IESNA 90.1-2004.

• Certified to ARI Standard 390-2003 for SPVU (Single Package Vertical Units).

• Commercial Product - Not intended for Residential application.

Form No. S3279-206

Supersedes S3279-106

Page 1 of 12

Page 2

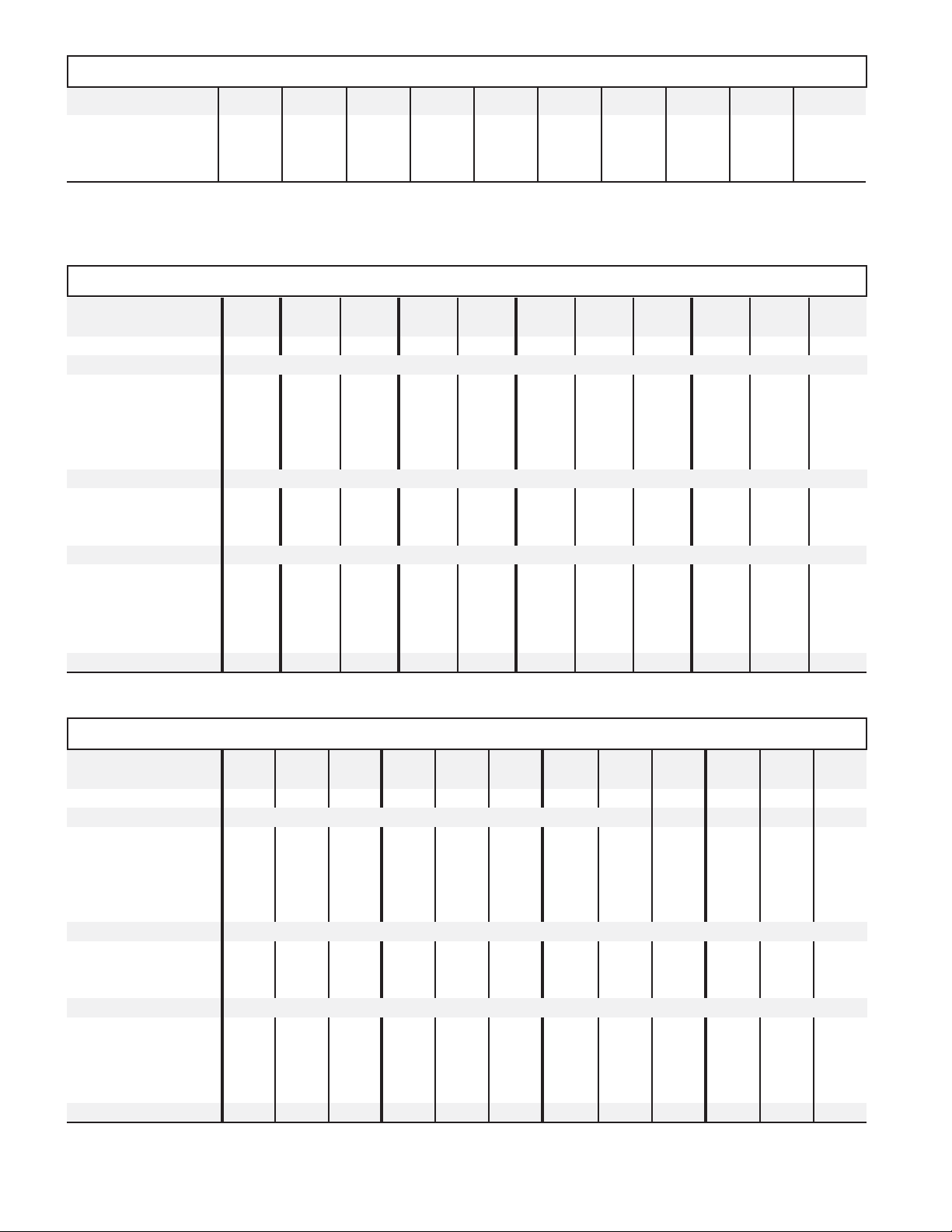

Capacity and Efficiency Ratings

SLEDOM 281LW 242LW 352LW 203LW 273LW 324LW 484LW 206LW A-207LW C,B-107LW

HUTByticapaCgnilooC 1 003,81000,42000,32000,03000,63000,24005,74005,75000,46000,76

REE 2 02.902.908.903.902.902

REES 3 02.0105.0100.1106.0100.0106.0100.1102.0100.01-

1

.906.907.800.900.9

1 Capacity is certified in accordance with ARI Standard 390-2003 and tested in accordance with ARI Standard 210/240-2003.

2 EER = Energy Efficiency Ratio and is certified in accordance with ARI Standard 390-2003.

3 SEER = Seasonal Energy Efficiency Ratio and is tested in accordance with ARI Standard 210/240-2003.

All ratings based on fresh air intake being 100% closed (no outside air introduction).

Specifications 1-1/2 through 3 Ton

SLEDOM A-281LW A-242LW B-242LW A-352LW B-352LW A-203LW B-203LW C-203LW A-273LW B-273LW C-273LW

zH06--gnitaRlacirtcelE

egnaRegatloVgnitarepO

AtiucriC--rosserpmoC

egatloV

spmAdaoLdetaR

tnerruCnoitceleStiucriChcnarB

spmArotoRkcoL

epyTrosserpmoC

resnednoC&rotoMnaF

MPR--PH--rotoMnaF

spmA--rotoMnaF

MFC/AID--naF

.pavE&rotoMrewolB

DPS-MPR-PH--rotoMrewolB

spmA--rotoMrewolB

.P.S.E&gnilooCMFC

)lioCteW-detaR(retliF/w

.DTS)sehcni(seziSretliF

.SBL--thgieWgnippihS

1-802/032 1-802/032 3-802/032 1-802/032 3-802/032 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064

352-791352-791352-791352-791352-791352-791352-791605-414352-791352-791605-414

802/032 802/032 802/032 802/032 802/032 802/032 802/032 064 802/032 802/032 064

0.8/0.7 0.01/5.9 9.6/6.6 5.9/6.8 0.7/5.6 9.21/2.21 4.8/4.8 2.4 3.71/5.61 0.11/5.01 2.5

0.9 0.01 0.7 3.01 1.7 1.41 0.9 5.4 3.71 0.11 5.5

94/9465/6515/1545/4554/5437/3736/3623001/00177/7773

.piceR.piceR.piceRllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcS

5701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/15701-5/1

2.12.12.12.12.15.15.14.15.15.14.1

0061-"810061-"810061-"810061-"810061-"810012-"020012-"020012-"020091-"020091-"020091-"02

1-0011-6/11-0011-6/11-0011-6/11-0011-6/11-0011-6/12-0011-3/12-0011-3/12-0011-3/12-0011-3/12-0011-3/12-0011-3/1

0.10.10.10.10.12.22.21.12.22.21.1

04.-05602.-00802.-00802.-00802.-00804.-000104.-000104.-000103.-001103.-001103.-0011

1x52x611x52x611x52x611x52x611x52x611x03x611x03x611x03x611x03x611x03x611x03x61

003 003 003 003 003 553 553 553 553 553 553

Specifications 3-1/2 Ton through 6 Ton

SLEDOM A-324LW B-324LW C-324LW A-484LW B-484LW C-484LW A-206LW B-206LW C-206LW A-207LW B-107LW C-107LW

egatloV

spmAdaoLdetaR

spmArotoRkcoL

epyTrosserpmoC

spmA--rotoMnaF

MFC/AID--naF

Form No. S3279-206

Supersedes S3279-106

Page 2 of 12

zH06--gnitaRlacirtcelE

egnaRegatloVgnitarepO

AtiucriC--rosserpmoC

tnerruCnoitceleStiucriChcnarB

resnednoC&rotoMnaF

DPS-MPR-PH--rotoMnaF

.pavE&rotoMrewolB

DPS-MPR-PH--rotoMrewolB

spmA--rotoMrewolB

.P.S.E&gnilooCMFC

)lioCteW-detaR(retliF/w

.DTS)sehcni(seziSretliF

.SBL--thgieWgnippihS

1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064

352-791352-791605-414352-791352-791605-414352-791352-791605-414352-791352-791605-414

802/032 802/032 064 802/032 802/032 064 802/032 802/032 064 802/032 802/032 064

0.12/3.91 8.11/8.11 1.6 9.02/2.02 3.31/9.11 2.6 5.82/0.62 4.81/1.81 8.6 0.13/1.92 5.12/5.02 2.01

0.12 5.21 5.6 8.12 9.21 5.6 0.92 0.91 0.9 0.23 0.22 2.01

721/72188/8824131/13119/1964841/841731/73126671/671651/05157

llorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcS

2-058-3/12-058-3/11-058-3/12-058-3/12-058-3/11-058-3/12-058-3/12-058-3/11-058-3/12-058-3/12-058-3/11-058-3/1

5.25.23.15.25.23.15.25.23.15.25.23.1

0062-"420062-"420062-"420062-"420062-"420062-"420062-"420062-"420062-"420062-"420062-"420062-"42

2-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/12-0701-2/1

3.33.39.13.33.39.13.33.39.13.33.39.1

03.-004103.-004103.-004102.-055102.-055102.-055103.-007103.-007103.-007102.-008102.-008102.-0081

1x03x021x03x021x03x021x03x021x03x021x03x021x03x021x03x021x03x021x03x021x03x021x03x02

005 005 005 005 005 005 005 005 005 025 025 025

Page 3

Ventilation System Packages

Bard Wall-Mounts are designed to provide optional ventilation packages to meet all of your ventilation and indoor air quality requirements.

All units are equipped with a barometric fresh air damper as the standard ventilation package. All ventilation packages can be built-in at the

factory, or field-installed at a later date.

BAROMETRIC FRESH AIR DAMPER - BFAD STANDARD

The barometric fresh air damper is a standard feature on all models. It is installed on the inside of the service

door and allows outside ventilation air, up to 25% of the total airflow rating of the unit, to be introduced through the

air inlet openings and to be mixed with the conditioned air. The damper opens during blower operation and

closes when the blower is off. Adjustable blade stops allow different amounts of outside air to be introduced into

the building and can be easily locked closed if required.

Barometric Fresh Air Damper

Motorized Fresh Air Damper

Commercial Room Ventilator

BLANK OFF PLATE - BOP OPTIONAL

A blank off plate is installed on the inside of the service door. It covers the air inlet openings which restricts any

outside air from entering the unit. The blank off plate should be utilized in applications where outside air is not

required to be mixed with the conditioned air.

MOTORIZED FRESH AIR DAMPER - MFAD OPTIONAL

The motorized fresh air damper is internally mounted behind the service door and allows outside ventilation air,

up to 25% of the total airflow rating of the unit, to be introduced through the air inlet openings and to be mixed

with the conditioned air. The two position damper can be fully open or closed. The damper blade is powered

open by a 24VAC motor with spring return on power loss. The damper can be controlled by indoor blower

operation or can be field connected to be managed based on building occupancy.

NOTE: The above vent systems are intake only without built-in exhaust capability. Building will likely require

separate field installed barometric relief or mechanical exhaust elsewhere within the conditioned space. Balancing

dampers in the return air grille may be required to achieve specified amount of outdoor air intake.

COMMERCIAL ROOM VENTILATOR - CRV OPTIONAL

The built-in commercial room ventilator is internally mounted behind the service door and allows outside

ventilation air, up to 50% of the total airflow rating of the unit, to be introduced through the air inlet openings.

It includes a built-in exhaust air damper.

The commercial room ventilator (CRV) is a simple and innovative approach to improving the indoor air quality by

providing fresh air intake and exhaust capability through the CRV. The damper can be easily adjusted to control

the amount of fresh air supplied into the building. The CRV can be controlled by indoor blower operation or field

controlled based on room occupancy. Two versions available (except on 1.5 and 2-ton models). The CRV and

CRVS are power open - spring return on power loss, and CRVP is power open and power return. Complies with

ANSI/ASHRAE Standard 62.1 “Ventilation for Acceptable Indoor Air Quality”.

ECONOMIZER - EIFM OPTIONAL

The built-in economizer system is internally mounted behind the service door and allows outdoor air to be

introduced through the air inlet openings. The amount of outdoor air varies in response to the system controls and

settings defined by the end user. It includes a built-in exhaust air damper. The economizer is designed to provide

“free cooling” when outside air conditions are cool and dry enough to satisfy cooling requirements without running

the compressor. This in turn provides lower operating costs, while extending the life of the compressor.

Economizer

Standard Features:

• One Piece Construction - Easy to install with no mechanical linkage adjustment required.

• Exhaust Air Damper - Built in with positive closed position. Provides exhaust air capability to prevent

pressurization of tight buildings.

• Actuator Motor - 24 volt, power open, spring return with built in torque limiting switch.

• Proportioning Type Control - for maximum “free cooling” economy and comfort.

• Moisture Eliminator & Prefilter - permanent, washable aluminum construction

• Enthalpy Control - adjustable to monitor outdoor temperature and humidity.

• Minimum Position Potentiometer - adjustable to control minimum damper blade position for ventilation

purposes.

• Mixed Air Sensor - to monitor outside and return air to automatically modulate damper position.

Manufactured under U.S. Patent Nos. 5,485,878; 5,301,744; 5,002,116; 4,924,934; 4,875,520; 4,825,936

Form No. S3279-206

Supersedes S3279-106

Page 3 of 12

Page 4

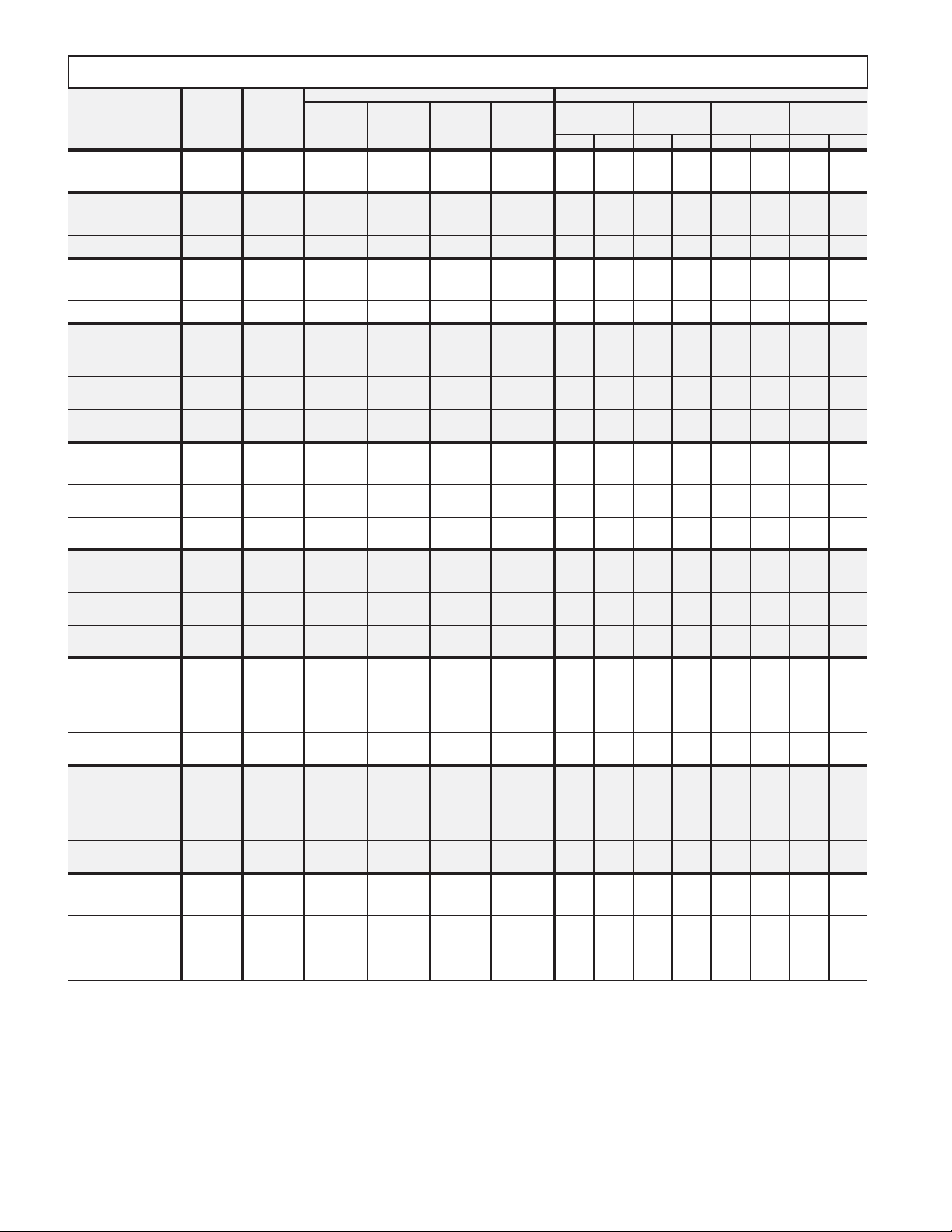

Electrical Specifications

tiucriCelgniS tiucriClauD

detaR

ledoM

Z0A-281LW

50A

80A

01A

Z0A-242LW

50A

80A

01A

Z0B-242LW

60B

Z0A-352LW

50A

80A

01A

Z0B-352LW

60B

Z0A-203LW

50A

80A

01A

51A

Z0B-203LW

90B

51B

Z0C-203LW

90C

51C

Z0A-273LW

50A

01A

51A

Z0B-273LW

90B

51B

Z0C-273LW

90C

51C

Z0A-324LW

50A

01A

51A

Z0B-324LW

90B

51B

Z0C-324LW

90C

51C

Z0A-484LW

50A

01A

51A

Z0B-484LW

90B

51B

Z0C-484LW

90C

51C

Z0A-206LW

50A

01A

51A

Z0B-206LW

90B

51B

Z0C-206LW

90C

51C

Z0A-207LW

50A

01A

51A

Z0B-107LW

90B

51B

Z0C-107LW

90C

51C

stloV

esahPdna

1-802/032

1-802/032

3-802/032

1-802/032

3-802/032

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

3 muminiM

dleiF.oN

rewoP

stiucriC

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1 mumixaM

tiucriC

yticapmA

61

03

54

65

71

03

54

65

31

22

81

03

54

65

41

22

42

13

74

75

38

71

23

05

01

71

62

82

23

85

48

02

33

15

11

71

62

63

63

95

58

52

43

25

31

71

62

83

83

95

58

42

43

25

21

71

62

44

44

95

58

23

43

25

61

71

62

84

84

95

58

63

63

25

71

71

62

02

03

54

06

02

03

54

06

51

52

52

03

54

06

02

52

53

53

05

06

09

02

53

05

51

02

03

53

53

06

09

52

5

3

06

51

02

03

05

05

06

09

53

53

06

51

02

03

05

05

06

09

53

3

5

06

51

02

03

06

06

06

09

54

54

06

02

02

03

06

06

06

09

05

05

06

52

52

03

2 dleiF

esuFlanretxE

.rkrB.tkCro

8

6

8

6

8

6

8

8

8

6

4

8

8

8

8

6

4

8

6

8

8

6

4

8

8

6

8

8

6

4

8

8

6

8

8

6

4

8

8

6

8

8

6

4

8

8

6

2 dnuorG

rewoP

eziSeriW

21

01

21

01

41

01

01

01

21

01

21

41

21

01

01

41

01

01

41

21

01

41

21

01

21

21

01

21

21

01

eriW

21

01

01

01

21

01

01

01

21

01

01

01

01

01

21

01

01

01

01

01

8

21

01

01

41

21

01

01

01

01

8756206036010101

01

01

01

41

01

01

01

01

01

8

01

01

01

41

21

01

01

01

01

8956206036010101

01

01

01

41

21

01

01

01

01

8

01

01

01

21

21

01

01

01

01

8

01

01

01

21

21

01

1 Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

2 Based on 75C copper wire. All wiring must conform to the National Electrical Code and all local codes.

3 These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electrical Code (lastest version), Article 310

for power conductor sizing.

Caution: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention to note 8 of Table 310

regarding Ampacity Adjustment Factors when more than three (3) current carrying conductors are in a raceway.

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses and conductor wires in accordance with

the National Electrical Code and all local codes.

3 muminiM

tiucriC

A.tkC B.tkC A.tkC B.tkC A.tkC B.tkC A.tkC B.tkC

75 62 06 03 6 01 01 01

95 62 06 03 6 01 01 01

95 62 06 03 6 01 01 01

956206036010101

1 mumixaM

yticapmA

2 dleiF

esuFlanretxE

.rkrB.tkCro

rewoP

eziSeriW

2 dnuorG

eziSeriW

Form No. S3279-206

Supersedes S3279-106

Page 4 of 12

Page 5

Commercial Room Ventilator Performance Data - CRV-2

WL18, WL24 & WL25 TOTAL AND VENTILATION AIRFLOW

1100

1000

900

800

700

600

500

Airflow (cfm)

400

300

200

100

0

Total Air 0 ESP

Total Air .15 ESP

Total Air .3 ESP

Vent Air 0 ESP

Vent Air .15 ESP

Vent Air .3 ESP

ABCDE F

Vent Position

Form No. S3279-206

Supersedes S3279-106

Page 5 of 12

Page 6

Commercial Room Ventilator Performance Data - CRVS-3 and CRVP-3

WL30 & WL37 HIGH SPEED TOTAL AND VENTILATION AIRFLOW

1200

1100

1000

900

800

700

600

Airflow (cfm)

500

400

300

200

100

Total Air 0 E SP

Total Air .15 ESP

Total Air .3 ESP

Vent Air 0 ESP

Vent Air .15 ESP

Vent Air .3 ESP

0

1000

900

800

700

600

500

Airflow (cfm)

400

300

ABCDEF

Vent Positio n

WL30 & WL37 LOW SPEED TOTAL AND VENTILATION AIRFLOW

Total Air 0 ESP

Total Air .15 ESP

Total Air .3 ESP

Vent Air 0 ESP

Vent Air .15 ESP

Vent Air .3 ESP

200

100

0

Form No. S3279-206

Supersedes S3279-106

Page 6 of 12

ABCDEF

Vent Position

Page 7

Commercial Room Ventilator Performance Data - CRVS-5 and CRVP-5

WL42 & WL48 HIGH SPEED TOTAL AND VENTILATION AIRFLOW

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

Airflow (cfm)

800

700

600

500

400

300

200

100

0

ABCDEF

Vent Position

Total Air 0 ESP

Total Air .2 ESP

Total Air .4 ESP

Vent Air 0 ESP

Vent Air .2 ESP

Vent Air .4 ESP

1700

1600

1500

1400

1300

1200

1100

1000

900

800

Airflow (cfm)

700

600

500

400

300

200

100

0

WL42 & WL48 LOW SPEED TOTAL AND VENTILATION AIRFLOW

Total Air 0 ESP

Total Air .2 ESP

Total Air .4 ESP

Vent Air 0 ESP

Vent Air .2 ESP

Vent Air .4 ESP

ABCDEF

Vent Position

Form No. S3279-206

Supersedes S3279-106

Page 7 of 12

Page 8

Commercial Room Ventilator Performance Data - CRVS-5 and CRVP-5

WL60 & WL70 HIGH SPEED TOTAL AND VENTILATION AIRFLOW

2200

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

Airflow (cfm)

900

800

700

600

500

400

300

200

100

0

ABCDEF

Vent Position

Total Air 0 ESP

Total Air .2 ESP

Total Air .4 ESP

Vent Air 0 ESP

Vent Ai r .2 ESP

Vent Ai r .4 ESP

1600

1500

1400

1300

1200

1100

1000

900

800

700

Airflow (cfm)

600

500

400

300

200

100

0

WL60 & WL70 LOW SPEED TOTAL AND VENTILATION AIRFLOW

Total Air 0 ESP

Total Air .2 ESP

Total Air .4 ESP

Vent Air 0 ESP

Vent Air .2 ESP

Vent Air .4 ESP

ABCDEF

Vent Position

Form No. S3279-206

Supersedes S3279-106

Page 8 of 12

Page 9

Indoor Blower Performance - CFM at 230 or 460 Volts

81LW

PSE

ni

O

H

2

0579/02015131/5931539/0590081/58810061/05610002/00220541/0061

1.509/0690721/0431519/0395661/07

2.008/5680911/5821588/0190551/53610041/05410081/0002-/-

3.537/0280011/5021038/5580041/0

4.056/5370001/0111557/0085821/07315711/00310061/5771-/-

5.535/516078/5001-/-0511/0521-/-5741/0

Above data is with 1" standard disposable filter and 1" washable filter.

For optional 2" pleated filter - reduce ESP by .15 in.

See installation instructions for maximum ESP information on various KW application.

42LW

52LW

lioCteW/yrD

03LW

73LW

deepShgiH

lioCteW/yrD

deepSwoL

lioCteW/yrD

710051/05510091/00125731/5251

0510031/05310071/5781-/-

24LW

84LW

deepShgiH

lioCteW/yrD

deepSwoL

lioCteW/yrD

deepShgiH

lioCteW/yrD

561-/-

07LW,06LW

Electric Heat Table - Refer to Electrical Specifications for Availability by Unit Model

lanimoN

WK

wK spmAhP-1 spmAhP-3 hutB wK spmAhP-1 spmAhP-3 hutB wK spmAhP-3 hutB wK spmAhP-3 hutB

0.50.58.02560,7157.30.81997,21

0.60.64.41874,0205.45.21953,510.62.7874,0225.59.6048,81

0.80.83.33403,7200.68.82874,02

0.90.97.

0.010.017.14031,4305.71.63895,52

0.510.515.261.63591,1552.111.452.13693,830.510

rasretaehcirtceleesehT)2(

)1(V042tA )1(V802tA )2(V084tA )2(V064tA

12717,0357.67.81830,320.98.01717,0382.84.01062,82

.81591,1508.313.71990,74

.ylnostinuV802/032nielbaliavaerasretaehcirtceleesehT)1(

.ylnostinuV084nielbaliavae

deepSwoL

lioCteW/yrD

Unit Service Access Overview

15"

ELECTRIC HEAT

ACCESS PANEL

ELECTRICAL

CONTROL

ACCESS PANEL

COMPRESSOR

ACCESS

NOTE: A 15-inch clearance between units is required when model WL and model WA are mounted side by side. This provides for proper

service access to condenser fan and motor shroud assembly and adequate condenser air flow.

Model WL with Left Side

Control Panel

Model WA with Right Side

Control Panel

ELECTRIC HEAT

ACCESS PANEL

ELECTRICAL

CONTROL

ACCESS PANEL

COMPRESSOR

ACCESS

Form No. S3279-206

Supersedes S3279-106

Page 9 of 12

Page 10

Cooling Application Data - Outdoor Temperature 1

ledoM

2

/57

26

281LW

242LW

352LW

203LW

273LW

324LW

484LW

206LW

A-207LW

C,B-107LW

1 Below 65

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

/57

26

/08

76

/58

27

o

F (18.3C), unit requires a factory or field installed low ambient control.

2 Return air temperature.

.B.W/.B.D

gnilooC

yticapaC

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

ooCelbisneS

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

ooCelbisneS

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

ooCelbisneS

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

57oF 08oF 58oF 09oF 59oF 001oF 501oF 011oF 511oF 021oF 521oF

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnil

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnil

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnil

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

gnilooCelbisneS

006,91

528,41

79,02

5

526,41

059,42

057,41

009,42

009,91

006,62

003,91

003,13

577,91

004,32

001,91

009,42

005,81

007,92

000,91

009,03

007,52

000,33

009,42

003,93

005,52

003,73

001,82

008,93

002,72

004,74

009,72

002,34

000,53

001,64

009,33

009,45

007,43

002,84

021,93

044,15

059,73

009,95

057,83

053,06

071,54

006,46

059,34

008,67

009,44

002,66

006,05

007,0

7

001,94

002,48

003,05

007,96

005,94

055,47

050,84

007,88

051,94

576,81

007,41

063,02

564,41

087,32

026,41

088,32

035,91

040,62

061,91

053,03

034,91

006,22

007,81

006,42

003,81

008,82

006,81

007,92

003,52

003,23

008,42

008,73

002,52

007,53

007,72

009,83

001,72

005,54

005,72

007,14

003,43

004,54

006,33

001,35

001,43

003,64

025,83

044,05

008,73

056,85

052,83

005,75

007,34

057,26

069,24

003,37

074,34

006,36

009,74

003,96

009,64

000,18

006,74

008,66

000,84

058,27

001,74

001,58

057,74

527,71

574,41

017,91

003,41

026,22

004,41

078,22

041,91

024,52

079,81

062,92

040,91

008,12

004,81

002,42

002,81

008

,72

003,81

005,82

009,42

006,13

006,42

003,63

007,42

002,43

003,72

000,83

000,72

007

,34

002,72

001,04

005,33

005,44

002,33

001,15

004,33

056,44

086,73

046,94

006,73

,75

042

054,73

036,45

081,24

096,06

038,14

016,96

079,14

000,16

004,54

007,76

000,54

007,77

002,54

009,36

006,64

050,17

002,64

055,18

053,64

528,61

091,41

020,91

531,41

,12

064

090,41

076,12

027,81

047,42

047,81

020,82

095,81

02

000,12

009,71

007,32

009,71

008,62

008,71

004,72

004,42

009,03

004,42

009,43

003,42

008,23

13

008,62

000,73

008,62

008,14

006,62

004,83

008,23

004,34

008,23

000,94

006,23

070,34

14

015,73

057,84

004,73

053,55

032,73

023,25

011,14

091,95

051,14

047,66

048,04

004,85

005,34

000,66

005,34

005,47

002,34

001,16

003,54

001,96

003,54

059,77

059,44

529,51

038,31

003,81

079,31

513,02

096,31

088,02

572,81

000,42

064,81

046,62

090,81

001,

006,71

000,32

007,71

006,52

004,71

001,62

009,32

000,03

001,42

004,33

007,32

004,

004,62

000,63

006,62

000,04

001,62

006,63

000,23

000,24

003,23

007,64

007,13

003,

000,73

005,74

003,73

007,25

006,63

000,05

000,04

005,75

004,04

008,36

006,93

007,55

00

0,24

000,46

004,24

001,17

06,14

0

003,85

000,44

000,76

054,44

004,47

055,34

050,

51

093,31

045,71

046,31

081,91

091,31

009,91

008,71

012,32

041,81

011,52

035,71

002,91

001,71

003,22

004,71

004,42

009,61

001,52

003,32

002,92

007,32

000,23

000,32

001,03

008,52

001,53

002,62

004,83

004,52

008,43

002,13

005,04

007,13

003,44

007,03

043,93

031,63

098,54

047,63

007,94

075,53

066,74

048,83

016,55

075,93

087,06

062,83

002,35

008,04

000,26

005,14

008,76

002,04

055,55

008,24

008,46

006,34

008,07

431,24

571,41

088,21

057,61

032,31

050,81

016,21

029,81

003,71

053,22

077,71

044,32

029,61

003,81

006,61

005,12

000,71

002,32

002,61

000,42

007,22

003,82

003,32

005,03

002,22

009,82

002,52

001,43

008,52

008,63

006,42

000,33

002,03

009,83

000,13

000,24

006,92

091,73

019,43

029,34

008,53

007,64

051,43

092,54

046,73

045,35

066,83

007,75

018,63

007,05

001,04

008,95

001,14

005,46

002,93

008,25

006,14

004,26

057,24

052,76

007,04

523,31

003,21

029,51

027,21

039,61

039,11

069,71

077,61

054,12

053,71

026,12

062,61

004,71

002,61

007,02

007,61

001,22

007,51

009,22

002,22

003,72

009,22

001,92

005,12

008,72

005,42

001,33

003,52

002,53

007,32

000,13

003,92

000,73

003,03

004,93

004,82

048,43

033,33

095,14

094,43

008,34

023,23

019,24

093,63

062,15

076,73

035,45

062,53

001,84

006,93

004,75

009,04

001,16

004,83

051,05

055,04

009,95

059,14

056,36

003,93

005,21

046,11

060,51

521,21

518,51

551,11

000,71

512,61

084,02

098,61

006,02

045,51

004,61

006,51

007,91

002,61

007,02

000,51

009,12

005,12

003,62

003,22

007,72

006,02

007,62

008,32

001,23

007,42

008,33

008,22

000,92

003,82

009,43

004,92

007,63

001,72

003,23

004,13

009,83

008,23

058,04

001,03

005,04

001,53

008,84

006,63

003,15

006,33

005,54

005,93

008,45

001,

14

006,75

009,73

005,74

005,93

052,75

051,14

001,06

058,73

007,11

007,01

004,41

006,11

007,41

004,01

050,61

003,51

000,91

007,51

574,91

007,41

004,51

001,51

006,81

008,51

004,91

003,41

008,02

008,02

002,52

007,12

002,62

006,91

007,52

009,22

001,13

000,42

003,23

007,12

009,62

002,72

006,23

005,82

009,33

008,52

009,03

000,03

001,83

050,23

001,93

007,82

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

001,11

051,01

008,31

000,11

006,31

056,9

050,51

003,41

055,71

004,41

004,81

009,31

003,41

006,41

004,71

003,51

009,71

00

6,31

007,91

001,02

000,42

001,12

007,42

007,81

006,42

001,22

000,03

002,32

009,03

6,02

00

007,42

001,62

001,03

005,72

000,13

004,42

005,92

007,82

052,73

053,13

054,73

00

5,72

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

A/N

srotcaFreilpitluMyticapaC

wolfriAdetaRfo%01-detaR01+

HUTBlatoT579.00.120.1

HUTBelbisneS059.00.150.1

Form No. S3279-206

Supersedes S3279-106

Page 10 of 12

Page 11

sseccAecivreSrofderiuqeRsecnaraelC

otderiuqeRsecnaraelCmuminiM

slairetaMelbitsubmoC

SLEDOM 1

TCUDRIAYLPPUS

TEEFEERHTTSRIF

TENIBAC

52LW,42LW,81LW"0"0

73LW,03LW"4/1"0

07LW,06LW,84LW,24LW"4/1"0

wolFriAresnednoCetauqedAdna

SLEDOM EDISTFEL EDISTHGIR

73LW,52LW,42LW,81LW"02"51

07LW,06LW,84LW,24LW"02"02

NOTE: For side by side installation of two (2) WL models there

must be 20" between units. This can be reduced to 15" by using a

WL model (left side compressor and controls) for the left unit and

WA (right side compressor and controls) for right unit.

HTDIW

LEDOM

)W(

81LW

42LW

52LW

03LW

73LW

24LW

84LW

06LW

07LW570.24234.2

003.33521.71365.0788.788.9188.1188.9100.5305.8157.5265.0257.6260.8252.9200.7236.231.4360.2255.0191.400.2100.5

002.83521.71365.0788.788.7288.3188.7200.0405.8157.5239.7157.6257.8252.9200.7257.291.9357.2241.991.400.2100.5

570.24234.22578.4888.988.9288.5188.9288.3401.9166.1300.0386.2349.6296.4334.2373.388.2488.3200.0100.200.6188.1

2578.4988.988.9288.5188.9288.3401.9166.1400.0386.2449.6396.4434.2473.388.2488.3300.0100.200.6188.1

HTPED

)D(

THGIEH

)H(

YLPPUS NRUTER

A B C B E F G I J K L M N O P Q R S T

1 Refer to the Installation Manual for more detailed information.

)lanimoN(stnemeriuqeRnoitallatsnIdnalarutcetihcrAroftinUcisaBfosnoisnemiD

.elacsottonerasgniwardlanoisnemiD.sehcninierasnoisnemidllA

1

1

1 21.00 inches on model WL701

FRONT VIEWSIDE VIEWBACK VIEW

Form No. S3279-206

Supersedes S3279-106

Page 11 of 12

Page 12

Air Conditioning Wall-Mount Model Nomenclature

MODEL NUMBER |

WL 37 2 A 10 X X X X X J

REVISION

KW

CONTROL MODULES

J - Standard on all models

CAPACITY |

18 - 1½ Ton

24 - 2 Ton

25 - 2 Ton

30 - 2½ Ton

37 - 3 Ton

42 - 3½ Ton

48 - 4 Ton

60 - 5 Ton

70 - 6 Ton

VOLTS & PHASE |

A - 230/208/60/1

B - 230/208/60/3

C - 460/60/3

VENTILATION OPTIONS

See Table Below

FILTER OPTIONS

X - 1 inch Disposable (Standard)

W - 1 inch Washable

P - 2 inch Pleated

COLOR OPTIONS

X - Beige (Standard)

1 - White

2 - Mesa Tan

- Buckeye Gray

4

5 - Desert Brown

8 - Dark Bronze

| COIL OPTIONS

X - Standard

1 - Phenolic Coated Evaporator

2 - Phenolic Coated Condenser

3 - Phenolic Coated Evaporator

and Condenser

| OUTLET OPTIONS

X - Front (Standard)

NOTE: For 0 KW and circuit breakers (230/208 Volt) or toggle disconnects (460 Volt) applications, insert 0Z in the KW field of the model number.

snoitpOnoitalitneV

sledoM 52LW,42LW,81LW 73LW,03LW 07LW,06LW,84LW,24LW

noitpircseD

dradnatS-repmaDriAhserFcirtemoraBX2-DAFBX 3-DAFBX 5-DAFB

etalPffO-knalBB2-POBB3-POBB 5-POB

repmaDriAhserFdezirotoMM2-DAF

tsuahxE/wnruteRgnirpS-rotalitneVlaicremmoCV2-VRCV 3-SVRCV 5-SVRC

icremmoC

gnitaludoMylluF-rezimonocE 1 EB2-MFIEEC3-MFIEEC5-MFIE

tsuahxE/wnruteRrewoP-rotalitneVla

dellatsnIyrotcaF

.oNedoC

MM3-DAFMM

------

dellatsnIdleiF

.oNtraP

dellatsnIyrotcaF

.oNedoC

P3-PVRCP 5-PVRC

dellatsnIdleiF

.oNtraP

dellatsnIyrotcaF

.oNedoC

dellatsnIdleiF

.oNtraP

5-DAFM

gnitaludoMylluF-rezimonocE 21 DA/NDA/NDA/N

1 Low ambient control is required with economizer for low temperature compressor operation.

2 For use only with “V” Control Module and TCS22 Controller.

seludoMlortnoCgninoitidnoCriA

SNOITPOLORTNOCELBALIAVA

CPH 1 CPL 2 MCC 3 CAL 4 RLA 5 KS 6 CDD 7

dradnatSdradnatSdradnatSdradnatSdradnatSJylnOyrotcaF

dradnatSdradnatSdradnatSdradnatSdradnatS

dradnatSdradnatSdradnatSdradnatSdradnatS

M

6

V8 ylnOyrotcaF

llA

sledoM

edoCdellatsnIyrotcaF traPdellatsnIdleiF

ylnOyrotcaF

1 HPC: High pressure control is auto reset. Always used with compressor control module (CCM) which is included. See note 3.

2 LPC: Low pressure control is auto reset. Always used with compressor control module (CCM) which is included. See note 3.

3 CCM: Compressor control module has adjustable 30-second to 5-minute delay-on-break timer (which also provides a delay-on-make equal to 10% of delay-

on-break setting). The module also provides the lockout feature (with 1 retry) for high and/or low pressure controls, and a 2-minute timed bypass for low

pressure control.

4 LAC: Low ambient control permits cooling operation down to 0°F.

5 ALR: The alarm relay has a set of normally open and normally closed dry contacts to provide the ability to signal a condition of shutdown on either high or

low pressure controls.

6 SK: Start kit can be used with all -A single phase models only. Is not used or available for -B or -C three phase models.

7 DDC: Incorporates 4 additional sensors: discharge air temperature, indoor blower airflow, compressor current, and dirty filter. These sensing devices

function to input analog data such as temperature, as well as digital data such as air flow, compressor status or filter status.

8 "V" control module should be ordered in conjunction with direct digital controller (DDC) model TCS22. Refer to DDC specification sheet S3280 for more

information.

BARD MANUFACTURING CO.

BRYAN, OHIO 43506

www.bardhvac.com

Due to our continuous product improvement

policy, all specifications subject to change

without notice.

Form No.

S3279

February, 2006

Form No. S3279-206

Supersedes S3279-106

Page 12 of 12

Before purchasing this appliance, read important energy

cost and efficiency information available from your retailer.

Supersedes S3279-106

Loading...

Loading...