Page 1

DUAL FUEL ADD-ON HEAT PUMP GUIDE

FOR OPERATIONAL COST SAVINGS

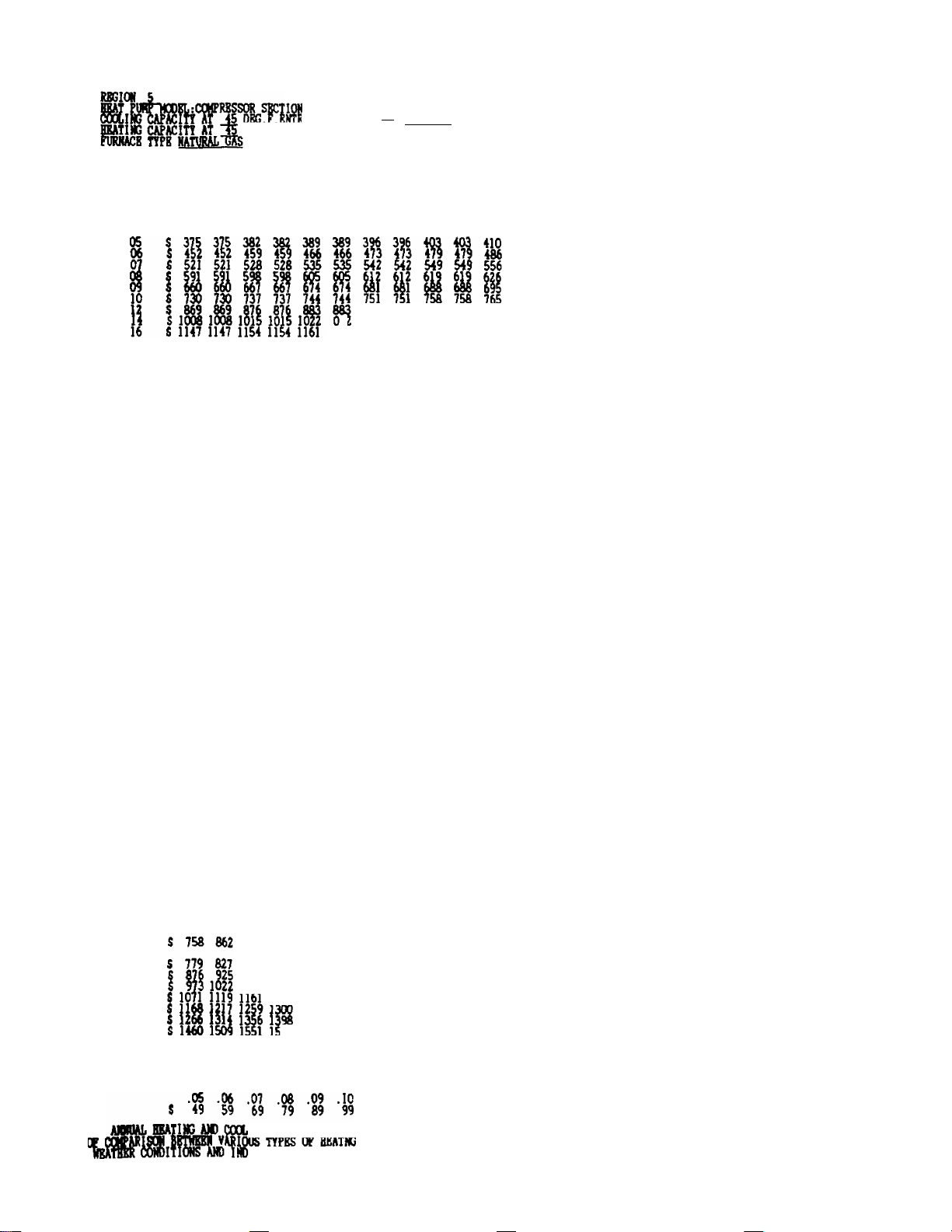

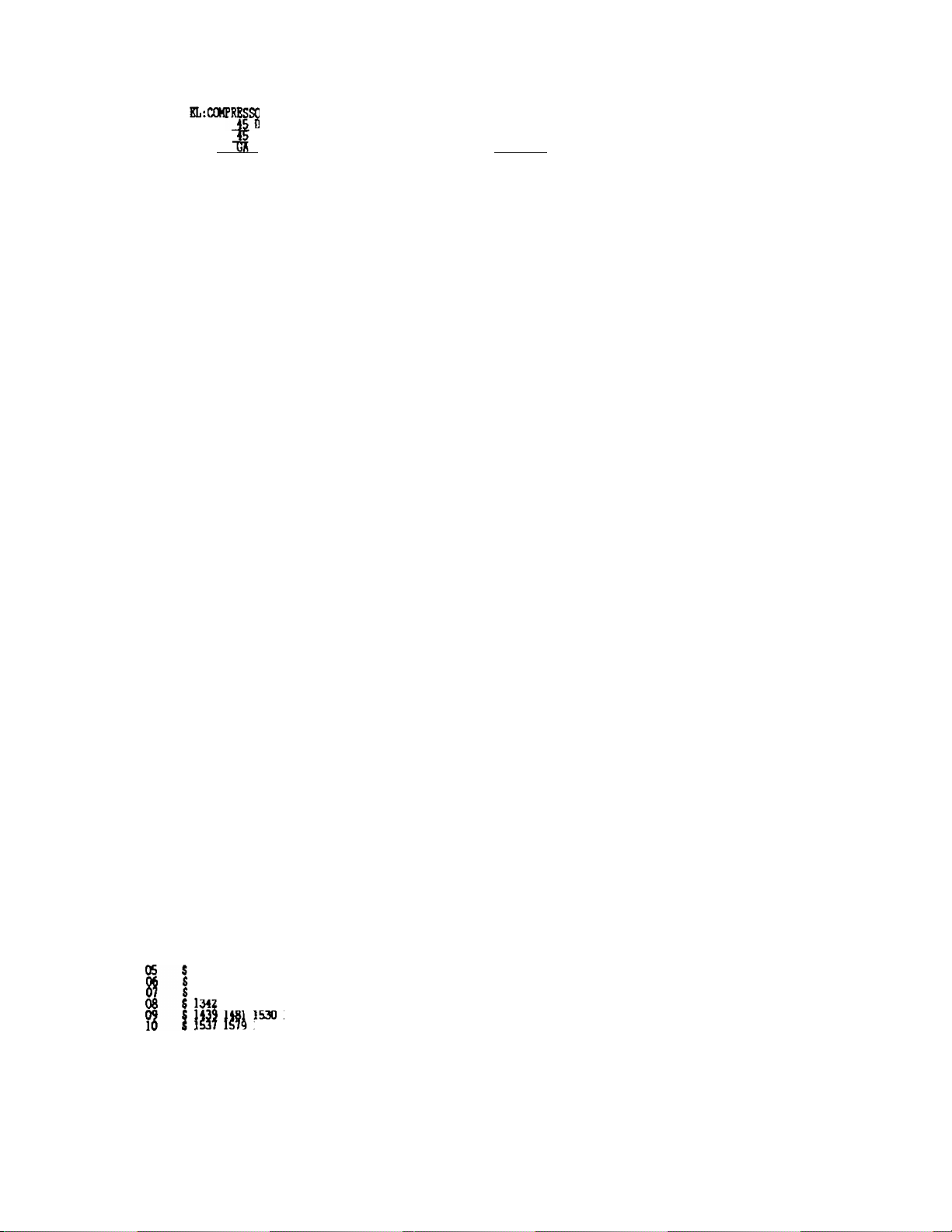

REGION 5

BARD MANUFACTURING COMPANY, BOX 607, BRYAN, OHIO 43506

(419) 636-1194

MANUAL 2100-073 REV. B

SUPERSEDES REV. A

Page 2

X

COPYRIGHT JULY, 1991

BARD MANUFACTURING COMPANY

BRYAN, OHIO

Page 3

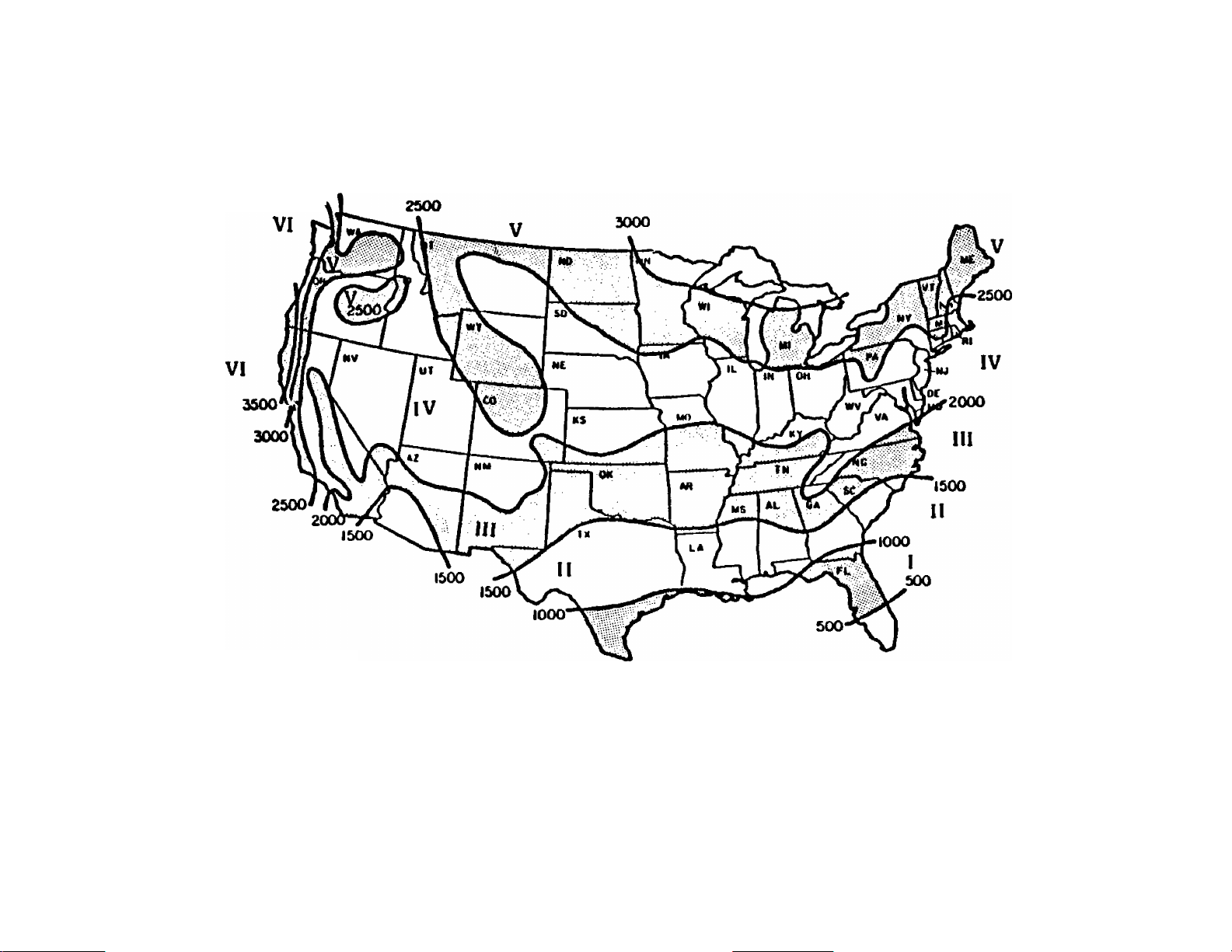

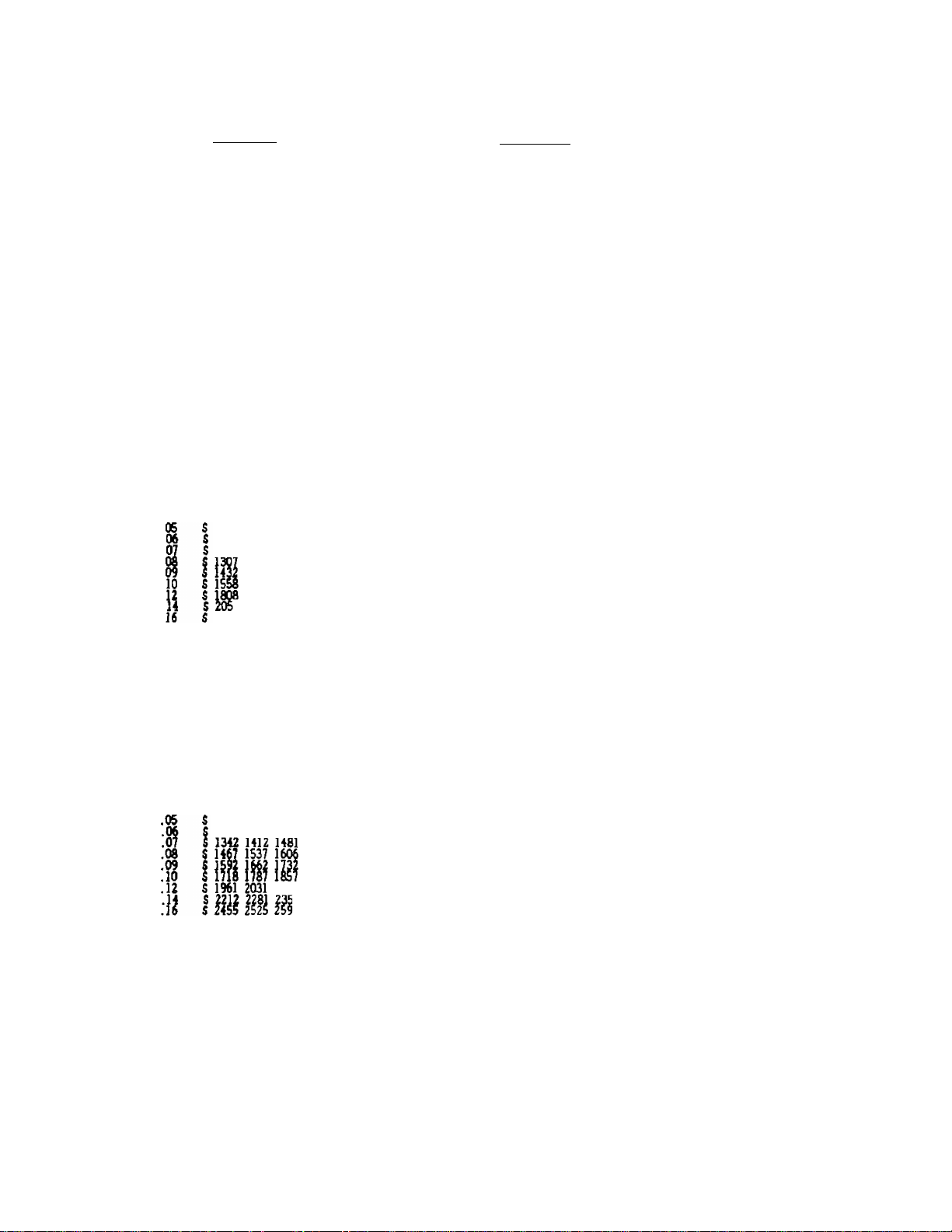

3000^

2500

REGION HEATING LOAD HOURS

Region HLHr

I

II

III

IV

V

VI

750

1250

1750

2250

2750

2750

This map is reasonably accurate for the most parts of the

United States but 1s necessarily highly generalized and

consequently not too accurate In mountainous regions,

particularly In the Rockies.

Page 4

TABLE OF CONTENTS

X

General Description

How To use ....

Heat Pump

Outdoor Model

WQS30A

WQS36A A36AQ-A Electric 100%

Heat Pump

Indoor Model

A36AQ-A

Furnace Fuel

Electric 100%

Natural Gas

Oil

Propane 78%

Natural Gas 78%

on

Propane

WQS42A

A42AQ-A Electric

Natural Gas

oil

Propane

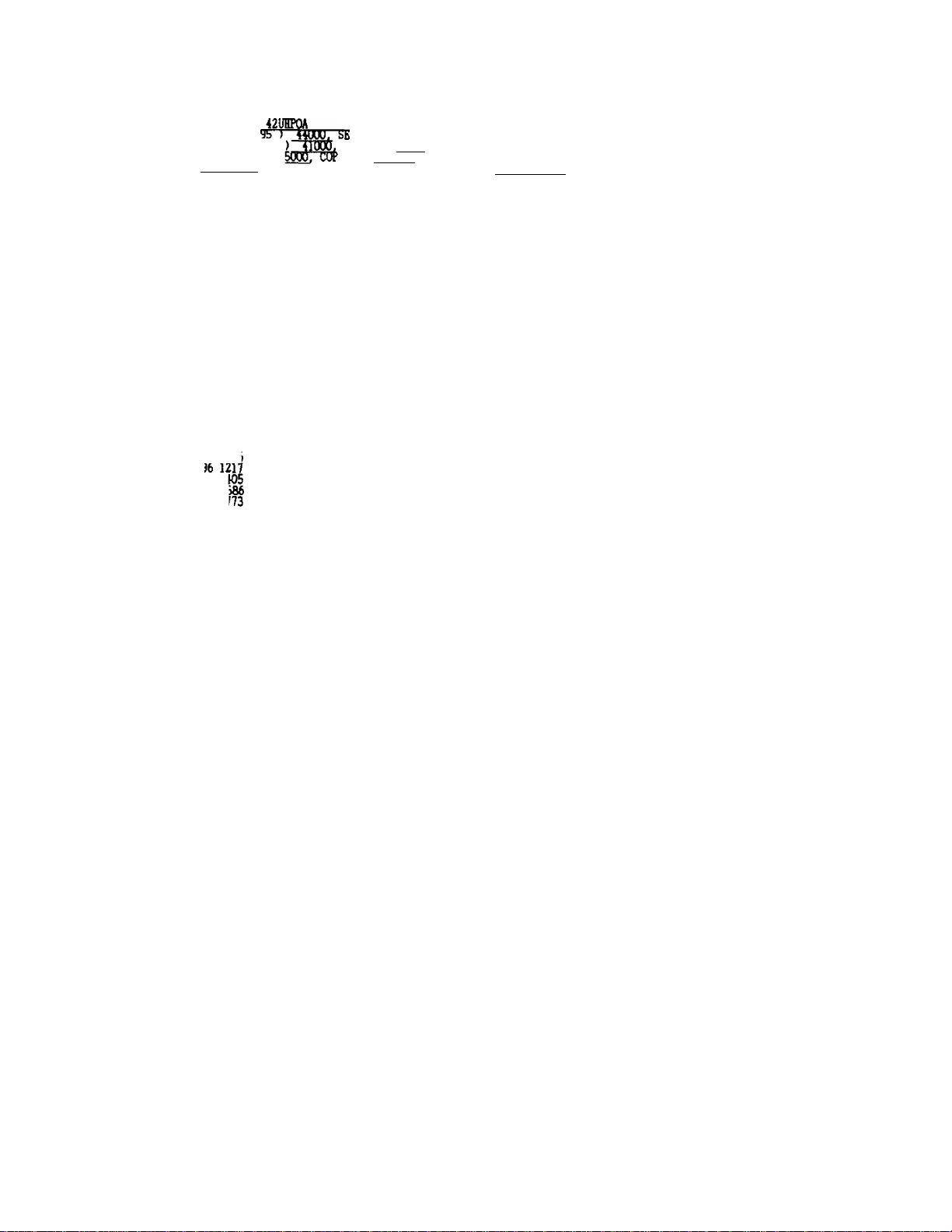

24UHPQA

A30AQ-A Electric

Natural Gas

Oil

Propane

Furnace AFUE

Efficiency Rating

78%

78%

78% 7

78%

100% 9

78% 10

78%

78%

100%

78% 14

78% 15

78%

1

i 1

Pag

1

2

3

4

5

6

8

11

12

13

16

24UHPQB

30UHPQA

30UHPQA

30UHPQA

36UHPQA

A36AQ-A

Electric

Natural Gas

on

Propane

A36AQ-A Electric

Natural Gas

on

Propane

A37AQ-A

Electric

Natural Gas

on

Propane

A42AS-A

A36AQ-A

Electric

Natural Gas

Oil

Propane

Electric

Natural Gas

Oil

Propane

100%

78% 18

78%

78%

100%

78%

78%

78%

100%

78%

78%

78%

100%

78%

78%

78%

100%

78%

78%

78%

17

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

11

Page 5

TABLE OF CONTENTS

Heat Pump

Outdoor Model

36UHPQA

36UHPQA

42UHPQA

48UHPQA

60UHPQA

Heat Pump

Indoor Model

A37AQ-A

A42AS-A

A61AQ-A

A61AQ-A

A61AQ-A

Furnace AFUE

Furnace Fuel

Electric

Natural Gas

Oil

Propane

Electric

Natural Gas 78%

Oil

Propane

Electric

Natural Gas

Oil

Propane

Electric

Natural Gas

Oil

Propane

Electric

Natural Gas

Oil

Propane

Efficiency Ratinq

100%

78%

78%

78%

100%

78%

78%

100%

78%

78%

78%

100%

78%

78%

78%

100%

78%

78%

78%

Pa^

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

m

Page 6

GENERAL DESCRIPTION

WHAT DOES THIS GUIDE SHOW?

This operational cost savings guide has been prepared to show theoretical

cost savings for Bard dual fuel “add-on” heat pumps when used with either

existing or new furnaces. It covers add-on applications for electric, oil,

propane gas and natural gas type forced air furnaces. It Includes both air

source heat pumps and ground water source heat pumps at many combinations of

gas, oil and electrical rates. It enables the user not only to make a

theoretical operating cost comparison at today's fuel costs but also at

future estimated higher energy costs.

It Is Important to understand that this Is a theoretical comparison between

fuels. Actual operation costs can vary depending on many difficult to

predict variables such as the actual design heating or cooling load, air

Infiltration, and wind effects, solar effect, efficiency of existing furnace,

severity of weather for a given heating or cooling season and also individual

usage pattern.

X

SPECIAL FEATURE—FUEL SAVER MODULE

These estimates utilize the Bard Fuel Saver Module which permit the heat pump

to operate below the balance point to maximize the energy savings. For each

application an analysis should be made to determine the economic balance

point which Is the outdoor temperature at which It becomes more cost

effective to shut the heat pump down with an outdoor thermostat. This

temperature varies with each combination of fuel cost and furnace and heat

pump efficiency level. Refer to tables included in the instructions with the

Fuel Saver Module.

FURNACE EFFICIENCY

For purposes of these cost estimates, furnace efficiency levels of 100% AFUE

for electric, 78% AFUE for natural and propane gas and 78% AFUE for oil was

chosen. We recognize that any variation in efficiency from these values will

change the operating cost somewhat. These values were chosen to best

represent typical efficiency levels of most equipment in the field today.

IV

Page 7

нон то USE DUAL FUEL ADD-ON

HEAT PUMP GUIDE TO ENERGY COST SAVINGS

Determine the heating Btuh loss and cooling Btuh gain for structure

1.

using a Bard "Whole-House Heat Loss and Gain Work Sheet," Form BOOS,

ACCA "Load Calculation," Manual 0.

a. Heating house Btuh loss is ________________________ .

b. Cooling house Btuh gain is ________________________ .

Determine the type of fuel available at structure (what type of [fuel}

2.

heating system is already there).

a. Electricity

b. Natural Gas

c. Propane Gas

Call local utilities and determine area energy costs.

3.

a. Electricity

b. Natural Gas

c. Propane Gas

d. Fuel Oil

Tentatively select an add-on heat pump system using Bard Manual

4.

2100-057, "Heat Pump Sizing" as a guide, and a Bard equipment catalog.

a- Air to air heat pump

b. Water to air

______________________________

__________________________

__________________________

Model

Btuh

__________

___________

D. Fuel Oil

E. Good water supply and disposal

$Kilowatt-hour

$/Therm

$/Gallon

_____

$/Gallon

Indoor Coil

Heat Btuh

Cool

Model _

Btuh

Determine heating region where the structure is located. To do this,

5.

find the geographic location of house on regional heating load hours

map, A map is located inside the front cover of this guide.

A. Region structure is located

_____________________

Indoor Coil

Heat Btuh

•

YOU ARE NOW READY TO USE THE "DUAL FUEL ADD-ON HEAT PUMP GUIDE"

6. Select the "Dual Fuel Add-On Heat Pump Guide" for the region the

structure is located. (See step 5 above.)

Cool

Page 8

Locate the add-on heat pump model or models you tentatively selected

(Step 4) in the "Guide." Refer to Table of Contents.

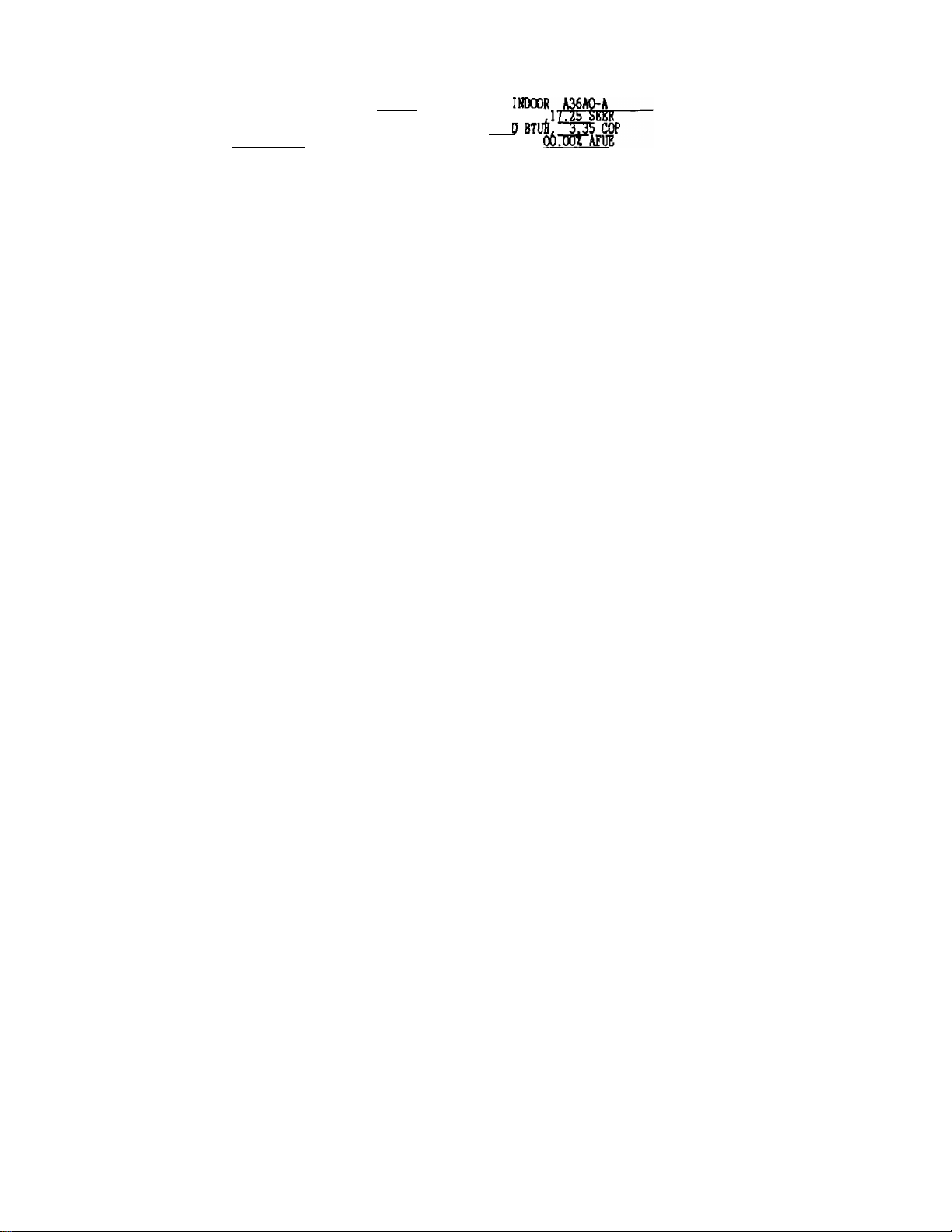

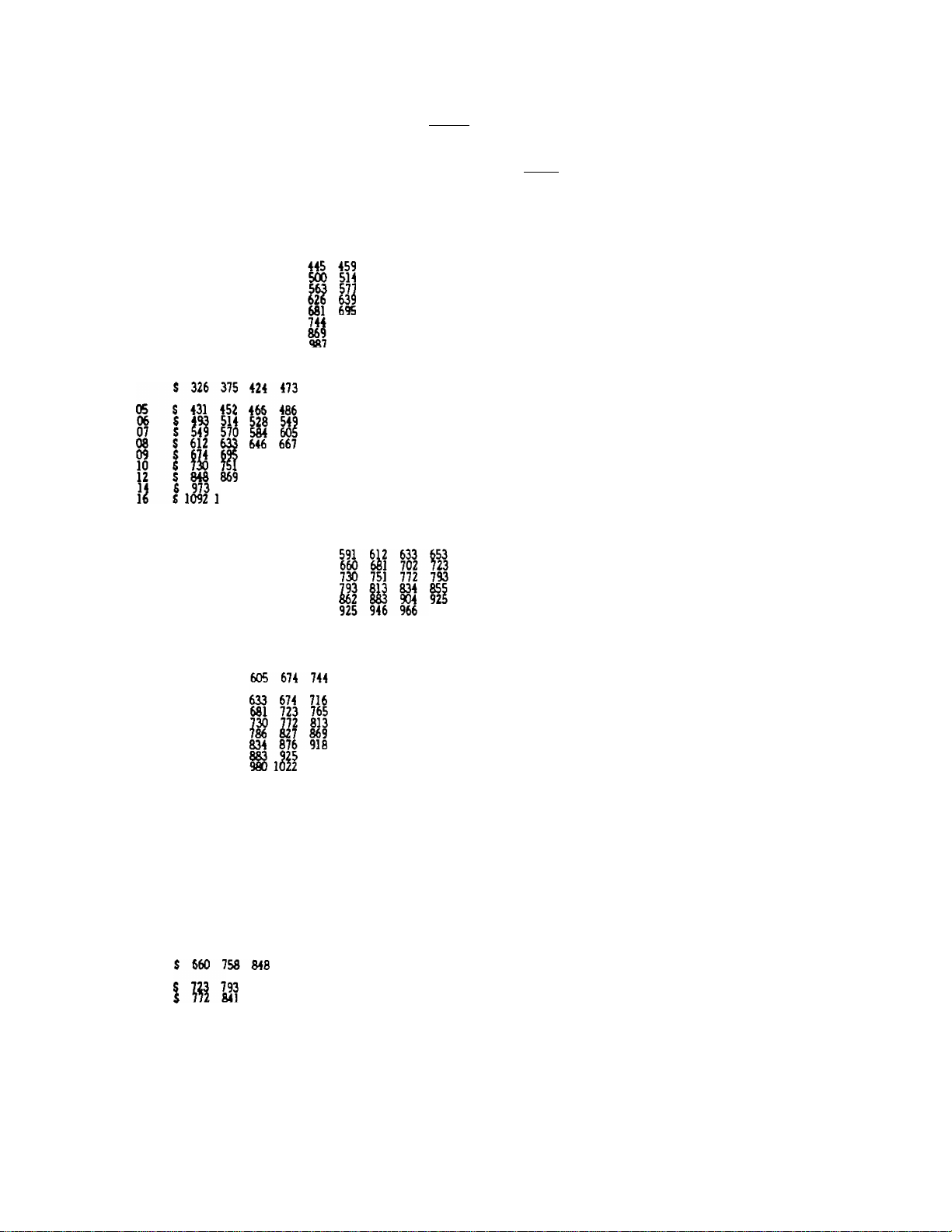

EXAMPLE: 36UHPQA w/A36AQ-A Indoor Coil

BARD HANUFACTURIMG COHPANY

DUAL FUEL ADD-OH HEAT PUMP GUIDE TO BKERGY COST SAVINGS

X

RBCIOK 5

Utl .

ARI RATED HEATING CAP.; STUB (47 )

8.

Now locate the furnace type by fuel used (Step 2).

BTUH (17 )_J

36UHPQA/A36AO-A .

INDOOR A36AO-A

C()P(I^_L90, BSPF

) 2.2(T

90 HIN.DHR REG IV

EXAMPLE: A fuel oil furnace with AFUE of 78%.

9.

FURNACE nPB FUEL OIL

You now have located the page or pages that will help you determine annual

FURiWCF EFFICIENCY 78.00 X AFUE

operating cost. See example—Figure 1.

A. Locate the closest structure loss in Btuh column on left side of

page (step 1).

EXAMPLE: 70,000 Btuh Heat Loss

B. Locate the heating cost per unit at top of page (step 3).

EXAMPLE: $1.40 per gallon fuel oil

C. Now read down the fuel cost column until directly across from the

structure heat loss in Btuh. This will be the theoretical annual

heating cost using only the furnace.

EXAMPLE: 70,000 Btuh heat loss 0 $1.40 per gallon fuel oil,

the annual cost will be $1,912.

D. Next locate the electric cost $/KW under Heat Loss Btuh for

structure (step 3).

EXAMPLE; $.06 KW rate

E. Now once again read down the fuel cost column until directly across

from electric cost $/KW. You now have located the annual heating

cost for the house using an add-on heat pump with the furnace.

EXAMPLE: 70,000 Btuh structure heat loss, with $.06 KW cost and

$1.40 per gallon fuel oil. The annual cost using a

36UHPQA Bard heat pump with the oil furnace would be

$1,613 for an annual savings of $299 ($1,912 minus $1,613),

Now repeat steps 8 through 9 for each type fuel and/or heat pump

selected. This will enable you to select the best combination of

furnace and heat pump to use for a structure.

VT

Page 9

10. The balance point (the outdoor temperature at which the heat pump Is

running 100% of the time and just meeting structure heat loss

requirements) is located on right side of page.

EXAMPLE: For a structure with a 70,000 Btuh with a 36UHPQA heat pump has

a balance point of 31®F. Below this theoretical balance

point, the heating load is automatically transferred between the

heat pump and the furnace by the wall thermostat to maintain the

desired temperature. This is accomplished with the Fuel Saver

Module.

70,000

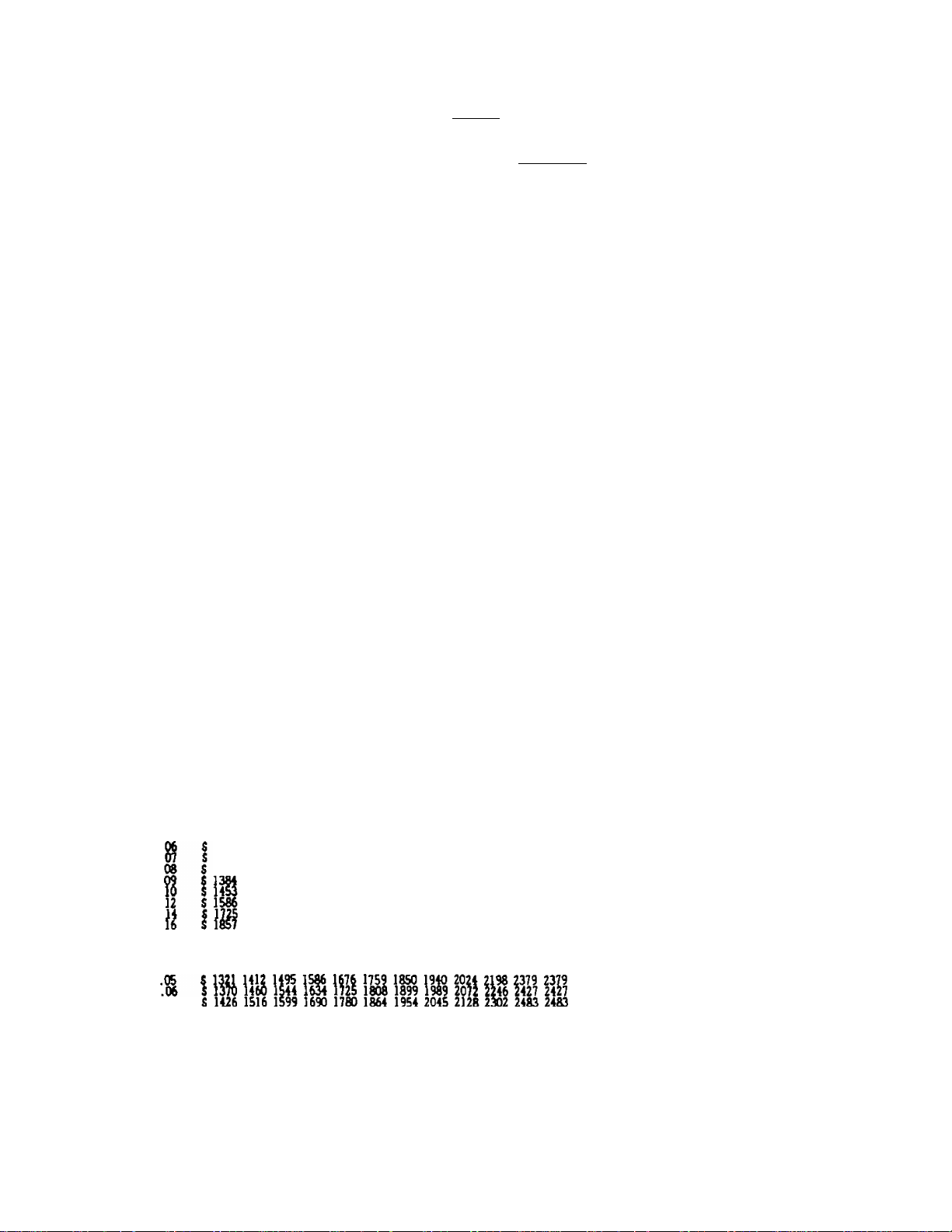

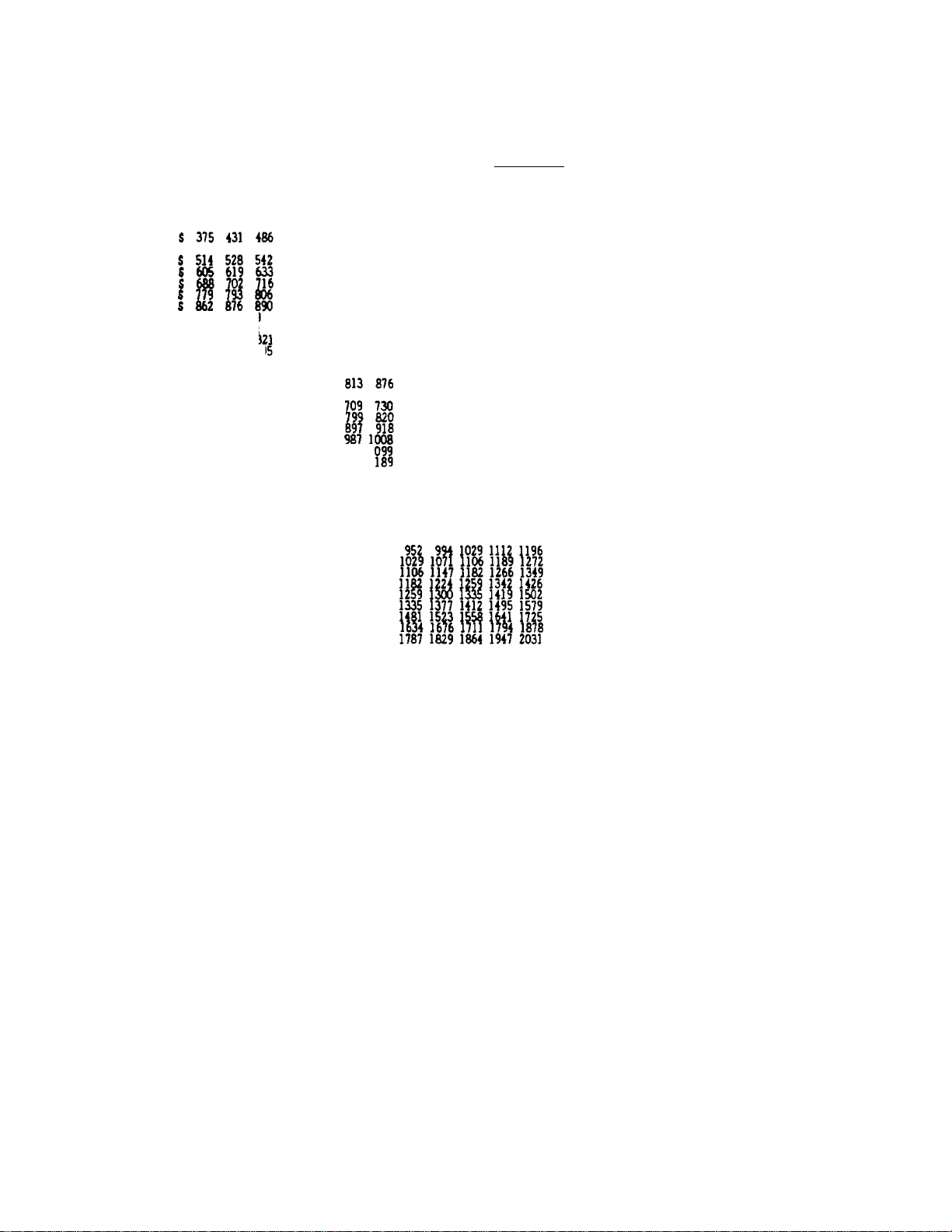

S 952 1092 1231 1363 1502 1641 1780 1912 2052 2191 2323 2462 <“THKIRmCAL HEATING COST • FURNACE ONLY

946 1029 1119 1203 1286 1377 1460 1544 1627 1718 1801 1885

238 1328 1412 1495 1586 1669 1752 1836 1926 2010 2093154

1224

130

1293

?? m i^ii Í634

1432

)16 1606 1690 1773 1864 1947¡2031

565 1655 173

1^25 I

1905 1996 2079

1975 2065 2149

2114 2205 2288 2372

53 2344 242

92 2483 2561

THEORETICAL HEATING

:163

'232

2511

2650

■ALANCE POINT 31 DEG

COST • FURN.+ HEAT PUMP

s year

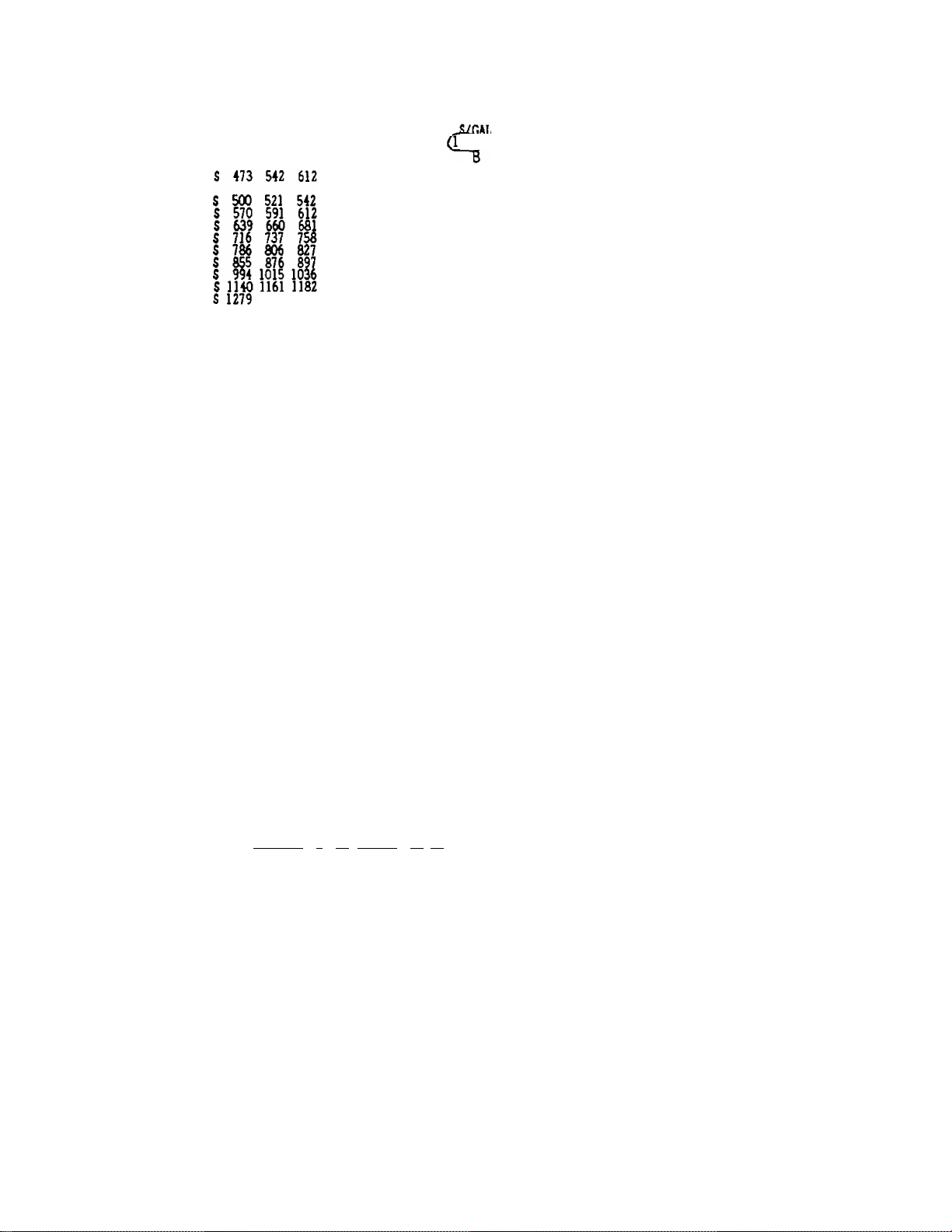

11. To find annual cooling cost of heat pump, look at the bottom of page under

annual air conditioning cost. Directly under the electric rate $/KW (step

3) line, is located the annual cooling cost.

EXAMPLE: At .06 $/KW rate for electricity, the cooling cost would be

$91.00 annually.

ANNUAL AIR CONDITIONING COST WHEN COOLING LOAD IS SIZED TO HATCH COaiNG CAPACIH OF HEAT PUMP

.05 /00 . 07 . 08 , 09 .10 .12 ,14 .16

S 75(Jyi06 121 136 151 182 212 243

ACTUAL HEATHER CONDITIONS AND INDIVIDUAL USAGE PAHERN,

IHATES ONLY AND ARE PROVIDL, .

ACTUAL VALUES HAY VARY DEPENDl

<--ELBCTRlC RATE S/XHH

<--THE0RETICAL AIR CONDITIONING COST

A COKHON

ON

¡0

___

NOTE: The accuracy of the "Dual Fuel-Add-On Heat Pump Guide to

Energy Cost Savings," is directly affected by how accurately you

estimate the structure's heat loss and heat gain in step 1.

Because of uncontrollable variables, Bard Manufacturing Company is

not responsible for any variation In actual operating costs from

these theoretical estimates.

VI 1

Page 10

FIGURE 1

ч

35,000

40,000

50,000

ш

5/Ш

.05

.06

.01

.09

: 1 S

;Ì6^

.05

.06

.07

.08

.09

.10

.12

:ìt

.05

.06

.07

.10

.12

.14

.16

.70 .80 .90 1.00 1.10 1.20 1.30

1300 1321

S 542 626 702 779 855 939 1015 1^92 1168 1252 1328 1405 <--THEORETICAL HEATING СОЕГ * FURNACE ONLY

563

591

646

674

723

751

799

827

§59 9в}

1119 1147

1279 1307

1439 1467

S 681 779 876 973 1071 1168 1266 1^ 1467 1565 1662 1759 <--THEORETICAL HEATING COST * FURNACE ONLY

695

744

765

813

834

883

952

1015

1036 1085 1133

1175 1224 1272

1314 1363 1412

1453 1502 1551

шине OIL COffT -

681 751 820 890 952 1022 1092 1161 1231 <-THE0RETlCAL HEATING COST * FURNACE ONLY

563 584

633 653

702 723

779 799

848 869

918 939

1057 1078

1203 1224

1342 1363

612 639

695 723

772 799

848 876

932 959

1008 1036

1168 1196

1328 1356

1488 1516

841 890

793

911 959

862

980 1029

932

1050 1099

1001

1064

1112 1161

1182 1231

1321 1370

1460 1509

1599 1648

605 626

674 695

744 765

820 841

890 911

959 980

1099 1119

1245 1266 1

1384 1405

660

688

744

820

897

1^ IO

I2Ì7 1245 1266 ì;86

un 1405 1426 1 46

1537 1565 1586 li 06

709

772

793

848

869

925

946

1029 .

1106 1

939 987 1C 36

1008 1057 1106

1078 1126 II75

1147 1196 1

1210 1259 1

1279 1328 Ш7

1419 1467 1П6

1558 1606 1(55

1697 1745 1I

LOjj

15)1.50 1.60 1.70 1.80

(46

667

737

'86

806

883

m

952

!32

, 1022 1043 1064 1092

n

40 1161 1182 1203 1231

-,86 1307 1328 1349 1377

1|26 1446 1467 1488 1516

30

758 779 806 827

841 862 890 911

918 939 966 987

3

994 1015 1043 1064

Í66

К

1078 1099 1126 1147

1154 1175 1203 1224

1314 1335 1363 1384

1474 1495 1523 1544

1634 1655 1683 1704

1085 1133 1189 1238

1154 1203 1259 1307

1224 1272 1328 1377

1293 1342 1398 1446

1356 1405 1460 1509

1426 1474 1530 1579

1565 1613 1669 1718

1704 1752 1808 1857

1843 1892 1947 1996

4

709

779

848

92f

737

806

876

952

688

758

827

54

90'

973 994 1022

THEORETICAL HEATING COST

THEORETICAL

THEORETICAL HEATING COST

S PER YEAR

BALANCE POINT 13 DEG.F.

S P

BALANCE POINT 16 DEG.F.

S PER YEAR

BALANCE POINT 22 DEG.F.

NG COST АНFURH.+ HEAT PUMP

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

60,000

#

ANNUAL AIR CONDITIONING COST WHEN COOLING LOAD IS SIZED TO HATCH COOLING CAPACITY OF HEAT PUMP

JIS Of CCMPARlStJ*ÌÌTHB8ÌPT?pÌs^oÌ%J?

ACTUAL HEATHER CONDITKNIS AND INDIVIDUAL USAGE FAHERN.

S 820 939 1050 1168 1286 1405 1523 1^41 1759 1878 1996 2107 <--THEORETICAL HEATING COST • FURNACE ONLY

.05

S 820

.06

S 883

S 946

.07

S 1001

S 1064

.09

.10

.12

ПШ

S 1370

.14

S 1495

.16

S 952 1092 1231 1363 1502 1641 1780¿@2052 2191 2323 2462 <"TREORETICAL HEATING COST * FURNACE ONLY

S 946

5 1085 1168 1259 1342

$ 1154 1238 1328 1412

$ 1224 1307 1398 1481

S 1293 1377 1467 1551

$ 1432 1516 1606 1690

890 966

952 1029

1015 1092

1071 1147

1133 1210

1196 1272

1321 \m

1439 1516

1565 1641

1029 1119 1203

_ 1099 1169"Шг

5 im

IШ m \iâ \ш

.05

.06

75

91

1036 1112

1099 1175

1161 1238

1217 1293

1279 1356

1342 1419

1467 1544

1586 1662

1711 1787

.07

106

1189 1259 1335 1405 1481 1551 1627

1252 1321 i;98 1467 1544 1613 1690

1314 1384 11370 1439 1Í

1432 1502 1!

1495 1565 К

1620 1690 1'

1739 1808 li

1864 1933 2C

1286 1377 1460

1350 144ú«WOO

1426 1516 1599

1495 1586 1669

1565 1655 1739

1634 1725 1808

1773 1864 1947

1912 2003 2086

2052 2142 2225

.09

.08

136

121

.. 1530 1606 1676 1752

16 1586 1662 1732 1808

‘ 1648 1725 1794 1871

1711 1787 1857 1933

1836 1912 1982 2059

1954 2031 2100 2177

2079 2156 2225 2302

1718 1801 1885

Лб27

1787 1871 1954

1857 1940 2024

Wd

1926 2010 2093

1836

1822 1905

1892 1975

2031 2114

2170 2253

2309 2392

.12

.10

151

.14

182

212

S ARE THEORETICAL ESTIMATES 01

AND COOMNG SYSTEMS.

1996 2079 2163

2065 2149 2232

2205 2288 2372

2344 2427 2511

2483 2566 2650

.16

243

..

ACTUAL

.....

THEORETICAL HEATING COST

BALANCE POINT 27 DEG.F.

THEORETICAL HEATING COST * FURN.-^ HEAT PUMP

BALANCE POINT 31 DEG.F.

<-ELBCTRIC RATE S/KMH

<”THEORETICAL AIR CONDITIONING COST

AND ARE FROV

ALUES MAY VARY

S PER YEAR

S PER YEAR

FURN.+ HEAT PUMP

FOR A COHHON

‘ING OH

___

viii

Page 11

BARD MANUFACTURING COMPANY

DUAL FUEL ADD-ON HEAT PUMP GUIDE TO ENERGY COST SAVINGS

REGION 5

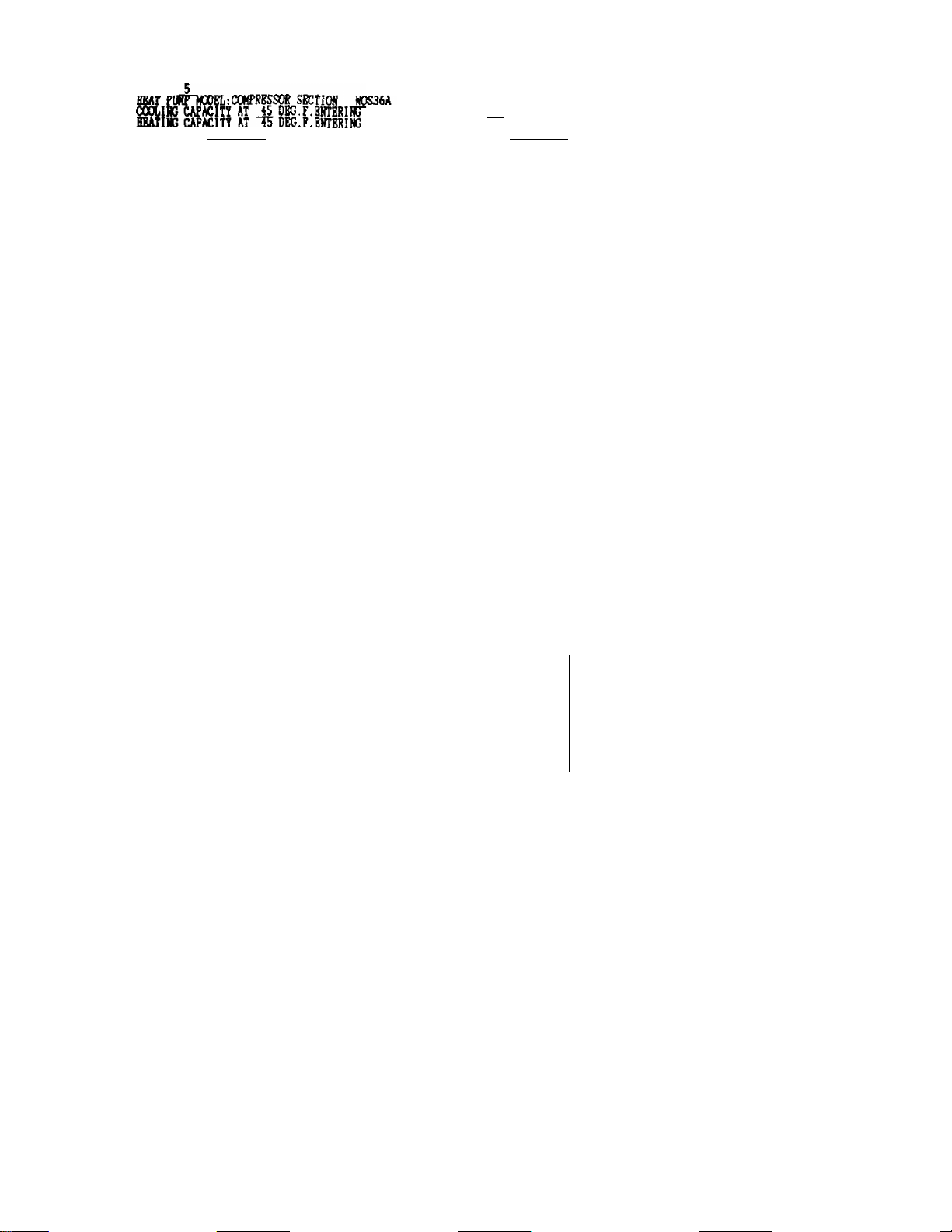

ffiAT PURPHOOBLiCOHPRBSSOR SECTION .NOS^A

COOLING CAPACITY AT 45 DEG.F.BKTERINUli^KK M.;J09g0 BTUH

HEATING CAPACITY AT 15 DEG.P.ENTERING HATER TE№. ;~7^_ :

FURNACE TYPE BLECTRICT“ FURNACE EFFTCIKNCY 1

ELEC.

COST

S/THH

_

___

_____

25,000

30,000

35,000

HEAT PUMP HITH ELECTRIC HEAT ELECTRIC HEAT ONLY

5 306

.05

.06

S

s

•01

$

M

s 556 1391

.09

s

.10

s

.12

s

.14

.16

s

HEAT

«

•95

s

.06

s

.07

s

.08

s

.09

,10

s 730

s

-12

s

.14

s

.16

HEAT PUMP HITH ELECTRIC HEAT ELECTRIC HEAT ONLY

S

.05

S

.06

S

.07

s

.08

s 758

.09

s

.10

s

.12

s

.14

s

.16

— THEORETICAL ANNUAL HEATING COST —

368 925

438 1085

433 1238

619

744

862 2170

994

PUKP'ii] m?'

361

438 1112

507

584 1488

653

876 2232

1022

1168 2977

— THEORETICAL ANNUAL HEATING COST —

417 1085

500

591

667 1732

841

1008 2601

1182

1349 3471

772

2476

925

1300

1669

1857

2601

1300

1516

1947

2170

3039

lAT ONLY

BALANCE POINT 15- DEG.F.

BALANCE POINT 3- DEG.F.

40,000

HEAT PUMP HITH ELECTRIC HEAT ELECTRIC HEAT ONLY

.05

.06

.07

.09

:iS

:]t

50,000

.05

.06

.07

.08

.09

.16

ANNUAL AIR COMDITIOHIHG COST HHEN COOLING LOAD IS SIZED TO MATCH COOLING CAPACin OF HEAT PUMP

HEAT PUMP HI

i

; 869

t 994

i 1119

i 1245

s m

! 1996

s •§! -55 'S f 1^ lit

THE ABOVE AIHUAL HEATING AND COOLING OPERATING COSTS ARB THEORETICAL ESTIMATES ONLY AND ARB PROVIDED FOR A COMMON

BASIS OP COMPARISON BBTMBBH VARIOUS HPES OF HEATNG AND COOLING SYSTEMS. ACTUAL VALUES MAY VARY DEPENDING ON

ACTUAL HEATHER CONDITIONS AND INDIVIDUAL USAGE PAHERN.

— THEORETICAL ANNUAL HEATING COST —

479

577

862

959

1147

1342

1530

1238

1488

1732

1982

2232

2476

2977

3471

3965

fP» Mr

1544

IBS!

2170

3095

3721

4340

4959

AT ONLY

BALANCE POINT 5 DEG.F.

BALANCE POINT 17 DEG.F.

<—

<—

C RATE S/KHH

"ICAL AIR “

CONDITIONING COST

Page 12

BARD KANUFACTURING COMPANY

DUAL FURL ADO-OH HEAT PUMP GUIDE TO ENERGY COST SAVINGS

REGIO» S

X

ffiAIlHG CAPACITY AT iS DEG.F.ENTERING HATER TEMP.:

FURNACE TYPE NATURAL~GAS FURNACE EFFTUTENCY

BEAT

ELEC.

25,000 S

.05

.06

.07

.08

,09

.10

.12

.14

.16

30,000 $

.05

.06

•22

.08

.09

.10

.12

.14

.16

35,000 s

.05

,06

.07

.08

.09

.10

.12

.14

.16

.35

236

S

271

$

319

S

375

473

5

521

S

626

S

723

$

827

278

s

313

$

375

s

431 438

$

493

$

549

$ 612

s

730

s

848

s

959

326

s

361

s

431

5

493

$

556

s

626

s

688

$

820

s

,946

s

1078

.40

271

271

319

375

473

521

626

723

827

319

319

382

500

556

619

737

855

966

375

361

431

493

556

626

688

820

946

1078

1085

NATURAL

.50 .55

333

278

326

382

479

528

633

730

834

403

326

389

№ 7

563

626

744

862

973

473

375

445

507

570

639

702

834

959

1099

GAS COST -

368 403

278 278

326

382

479

528

633

730 730

834 834

445 486

326

389 396

445

507

563

626

744 751

862

973 980

521 563

382 389

452

514 521

577

646

709 716

841 848

966 973

,45

299

271

319

375

424 431

473

521

626

723

827

361

319

382

438

500

556

619

737

855

966

424

368

438

500

563

633

695

827

952

1092

326

382

479

528

633

333

452

514

570

633

869

459

584

653

1106

.60 .65

438

285

333

389

438

486

535

639

737

841

528

333

396

452

514

570

633

751

869

980

612

396

466

528

591

660

723

855

980

1112

______

S/THERH

.70 .75

473

507

285

285

333

333

389

389

438

433

486

486

535

535

639

639

737

737

841

841

605

563

333

340

396

403

459

452

514

521

570

577

633

639

751

758

869

876

987

980

709

660

396

403

473

466

535

528

598

591

660

667

723

730

862

855

980

987

1119

1112

wm BTu6.^^ COP

Y TCTtME

.80 .90

542 605

292

340

396 403

445

493 500

542 549

646

744 751

848 855

646

340

403 410

459

521 528

577 584

639 646

758

876

987

758

410

479

542

605

674 688

737 751

869 883

9941008

1126

1.00

674

674 <”THEORETICAL HEATING COST * FURNACE ONLY

299

299

347

347

403

452

452

500

549

653

653

751

855

730

813

354

347

417

466

473

535

591

653

765

772

890

883

1001

994

946

848

431

424

500

493

563

556

626

619

695

758

890

1015

1140

1147

THEORETICAL HEATING COST • FURN.+ HEAT PUMP

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

S PER YEAR

S PER YEAR

BALANCE POINT 15- DEG.F.

S PER YEAR

BALANCE POINT 3- DEG.F.

40,000

50,000

ANNUAL AIR CONDITIONING COST WHEN COOLING LOAD IS SIZED TO MATCH COOLING CAPACITY OF HEAT PUMP

TBB ABOVE

s

.05

s

$

.06

$

.07

s

s

:§l

.10

s 758

$

.12

s

.14

5

.16

$

$

.05

$

.06

s

s

$

.09

1

:1S

$

.14

s

.16

HEATING AND COOLING OPERATING COSTS ARB THEORETICAL ESTIMATES ONLY AND ARE PROVIDED FOR A COMMON

"" BETHBEN VARIOUS HPES OF HEATNG AMD COOLING SYSTEMS. ACTUAL VALUES HAY VARY DEPENDING ON

ITI^ AND INDIVIDUAL USAGE PAHEi

375

403

473

549

6sl

,897

1036

1175

473

493

556

619

681

744

806

M2

1057

1175

.05

35

1043

1182

1085

1203

431

486

410 431

486

479

563

556

626

695

772

765

911

904

1050

1189

542

605

549

521

612

584

W

799

772

862

98?

M9

1112

1231

.06

.07

50

42

542

500

577

786

925

1064

1203

674

577

639

827

890

1015

1140

1259

.08

57

591

646

438 445

507 514

584 591

653

660

723

730

793 799

932

939

10711078

1210

1217

744

813

605 626

667 688

730

793

III

855

Bib

918

939

1043

1064

11681189

1286

1307

.09

.10

64

71

702

452

521

598

667

737

806

946

1085

1224

876

653

716

UÌ

904

966

1092

1217

1335

.12

85

758

459

528

605

674

744

813

952

1092

1231

946

681

744

806

869

932

1245

1363

.14

100

813

466

535

612

681

751

820

959

1099

1238

1015

709

772

834

897

959

1022

114?

1272

1391

,16

114

862

973

479 493

549 563

626 639

695

709

765

779

834 848

973 987

1112

1126

12521266

1217

1085

737 793

799

855

862

918

925

980

9871043

1050

1106

1175

1231

1300

1356

14191474

<-THEORETICAL HEATING COST * FURNACE ONLY

1085

507

THEORETICAL HEATING COST

577

653

723

793

862

1001

1140

1279

1356

841

904

966

1029

1092

1154

1279

1405

1523

BALANCE POINT 5 DEG.F.

<-THEORETICAL HEATING COST * FURNACE ONLY

THEORETICAL BEATING COST

BALANCE POINT 17 DEG.F.

<-ELECTRIC RATE S/KHH

<-THEORETlCAL AIR CONDITIONING COST

S PER YEAR

FURH.+ HEAT PUMP

FURN.+ HEAT PUMP

S PER YEAR

Page 13

BARD MAHUFACTURING COKPAHY

DUAL FUEL ADD-ON HEAT PUMP GUIDE TO ENERGY COST SAVINGS

RB6I0N 5

HBAT PWniOOBL:COMPRESSOR SECTION

^ifííÍG CAPACITY AT TS OEÓ.F.ENfÉRiNG HATER TE№. : ^47Ь0"ВТЦ&!COP

FURNACE TYPE FUEL OIC" FURNACE EFFTCTETCY ТкЩПШ

HEAT

BTUH

CAPACITY AT « DSG.F.EinBRIIlO

ELEC.

COST

S/KMH

.70

.80

.90

HEATING

1.00

1.10 1.20

'ГКНРЛ 30900^^Л

OIL COST - S/GALLON

1.30

1.50 1.60 1.70

1.40

EER—

1.80

25,000 S 340

.05

.06

.07

.08

.09

.10

.12

.14

.16

30,000 S 410

.05

.06

M

.09

.10

.12

.14

.16

35,000

.05

.07

.08

.09

.10

.12

.14

.16

278

5

326

5

S 382

s

431

$

479

S 528

5 633

730

5

S 834

5 326

S 389

5 445

5 507

S 563

S

626

5 744

S

862

S

973

S 473

S 375

s

445

$

507

570

5

S

^9

5 702

S

834

5 959

S 1092

389

278

326

382

431

528

633

730

834

466 521

326

389

445

507

563

626

744 751 758 758 765

862

973

542

382

452

514

577

646

709

841

966

1099

438

285 285

333

389 389

m

486

535 535

639 639

737

841

333

396

452

514 521

570 577

633

869

980

612 681

389

459

521

584

653

716

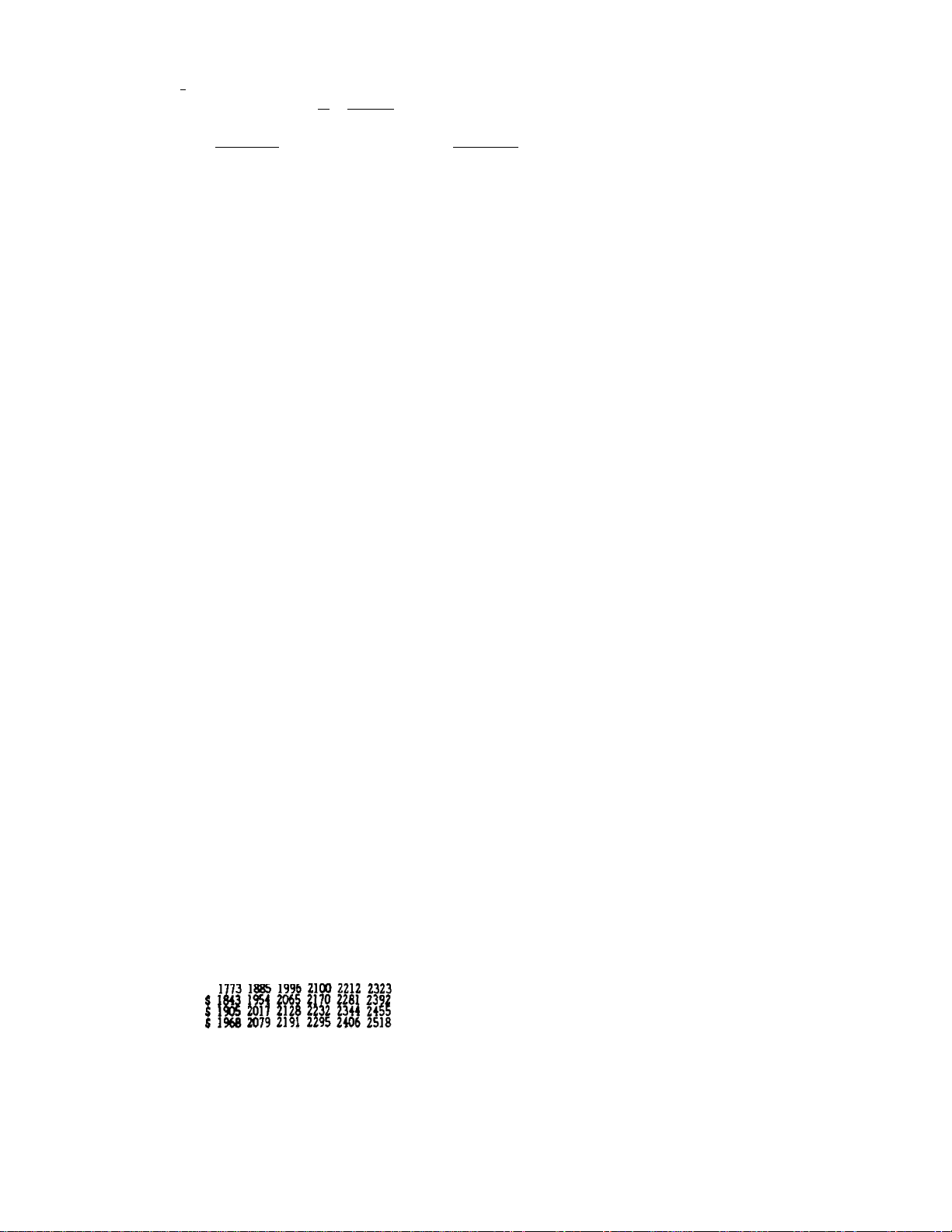

848

,973

1119

1106

486 535 584

292 292

340

333

396

438

45

486

493 493

542 542

646 646

737

744 744

841

848 848

639 702

584

340 340 347

403 403 410

459 459

521 528

577 584

639 639 646

876 876 883

987

987

751 820

410

403

479

^23

542

535

605 612

598

667

624

730 737 744

869

862

994 1001

987

1126 1133

340

396

445

466

994

417

486

549

681

876

633

299

347

403

452

500

549

653

751

855

758

354

417

473

535

591

653

772

890

1001

890

424

493

556

619

688

751

883

1008

1140

681

299

347

403

452

500

549

653

751

855

820

354

417

473

535

591

653

772

890

1001

952

431

500

563

626

695

758

890

1015

1147

730

306

354

410

«9

507

556

660

758

862

876

361

424

479

542

598

660

779

897

1008

1022

438

507

570

633

702

765

897

1022

1154

779 827

306

313

361 361

354

410 417

459 466

507

514

556

563

660 667

758 765

862 869

939

994

368

368

431

431

486 486

549

549

605

605

667 667

786 786

904

904

1015 :1015

1092

1161

452 459

521

528

584

591

646 653

723

116

779

786

911 918

1036 1043

1168:1175

876

313

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

417

466

514

563

667

765

869

1050

375

438

THEORETICAL HEATING COST • FURN.+ HEAT PUMP

493

556

612

674

793

911

1022

<-THEORETICAL HEATING COST * FURNACE ONLY

1231

466

535

THEORETICAL HEATING COST

598

660

730

793

925

1050

1182

S PER YEAR

S PER YEAR

BALANCE POINT 15- DEG.F.

S PER YEAR

BALANCE POINT 3- DEG.F.

FURNACE ONLY

FURN.+ HEAT PUMP

.06

.06

.08

S

S

5

5 577

5S646

5 786

5

S

S 1203

S 681

S 577

S 639

S

5 765

5 827

<

5

5

S

40,000

.05

.07

;8I

.10

.12

.14

.16

50,000

.05

•02

.09

•JO

.12

.14

.16

ANNUAL AIR CONDITIONING COST HHEN COOLING LOAD IS SIZED TO HATCH COOLING CAPACITY OF HEAT PUMP

THE ABOVE ANNUAL BEAT]№ AND COOLING OPERATING COSTS ARB THEORETICS ESTIMATES ONLY AND ARE PROVIDED FOR A COKHON

B^S Qg CQgARlSOM BBTipN VARipUS TYPES OF PATNG AND COOLING SYSTEMS. ACTUAL VALUES HAY VARY DEPENDING ON

ACTUS NEAITO CONDITIO^ USAGrpAnERN.

626

542

438

431

500

loi

584

653

723

716

793

925

932

1071

1064

1210

779

619

681

702

806

869

8%

932

1015

1057

1140

1182 1217 1259

1300

1259

.06

.05

35

42

779 855 939

702

452

535

521

612

598

667

737

806 820

959 966 980

946

1099

1085

1238

1224

973 1071 1168

876

695

653

758 793 834

716

820

lb

883

¿41

946

904

966

1008

1092

1133

1377 1412 1453

1335

.08

.07

57

50

473 486

542

619 633

827 841

1106 1119

1245 1259

730 772

855

918 959

980 1022

1043 1085

1168

1293

.09

64

556

702

m

897

1210

1335

.10

71

1015

500

570

646

855

994

1133

1272

1266

813

876

939

1001

1064

1126

1252

1377

1495

.12

85

1092

514

584

660

730

799

869

1008

1147

1286

1363

848

911

973

1036

1099

1161

1286

1412

1530

.14

100

1168

521

591

667

737

806

876

1015

1154

1293

1467

890

952

1015

1078

1140

1203

1328

1453

1572

.16

114

1252 1328

535

549

605 619

681 695

765

151

820

834

890

904

1029 :1043

1168 1182

1307 1321

1565 1662

925 966

987

1029

1050

1092

1112 1154

1175 :

1217

1238

1279

1363

1405

1488 1530

1606

1648

1405

<-THEORETICAL HEATING COST * FURNACE ONLY

556

THEORETICAL HEATING COST

626

702

772

841

911

1050

1189

1328

1759

1001

THEORETICAL HEATING COST

1064

1126

1189

1252

1314

1439

1565

1683

<-ELECTRIC RATE S/KMH

i-THBORETICAL AIR CONDITIONING COST

S PER YEAR

BALANCE POINT 5 DEG.F.

S PER YEAR

BALANCE POINT 17 DEG.F.

FURN.+ HEAT PUMP

FURNACE ONLY

FURN.+ HEAT PUMP

Page 14

BARD HAKUFACTURING COMPANY

DUAL FUEL ADD-ON HEAT PUMP GUIDE TO ENERGY COST SAVINGS

RBGICN

HEAT pi

штш саршт!_ат_15^6ёс:р:шк1'»)с щ1ш:1“тш"ии&;ЧЗ^сор

FURNACE ПРВ PROPANOAS

HEAT

т

_____

tins CAPAC

Е1ЛС.

COGI

5/ККН

:CO№RBSSOR SECTION H0S30A TUnoOR .

1 AT ^ РЕд.Р.ВШ1Ми%Ш 1Ж.: 30900 ВТ1ШЛ7ЛГ

FURNACE'ЁГГТШИСУ тбЛЮГАРЦЕ

.60 .65 .70 .75 .80 .85 .90

s/GALLON

.95

1.00 1.10 .20 1.20

...

АЗур-А

)ББГ

V

Ч.

25,000

30,000

35,000

702

744

.05

.06

.01

.10

.16

.05

.06

.01

.09

,10

.12

.14

.16

S 626 674 730 779 834 883 939 987 1043 1147 1252 1252 <-THEORETICAL HEATING COST * FURNACE ONLY

.05

.06

,07

.08

.12

.14

,16

S 1112 1119

285

292

292 292 299

340

333

438 445 445 44i

486 493 493 49535 535 542 542 ...

^9 639 646 646 646

737 737 744 744 744

333 340 340 347 347 354 354

396 403 403 410 410 417 417

(52 459 459 466 466 473

^14 521 521' 528 S2’8 535

570 577 577 584 584 591

\ 7

396 403

466 473

528 535

591 598

660 667

723 730

855 862

,980 987

639

765 765 772

758

410

403

479

542

Ш

605

598

674

667

730

737

869

862

994 1001 1008 1015 1022 1029 1043 1050 1050

987

_____

1119 1126 1133 1140 1147 1154 1161 1175 1182 1182

452 452

500 500

549 549

653 653

751 751

417

424

486

493

556

549

612

619

688

681

751

744

876

883

_ . _

306

306

354

354

410

410

459

459

507

507

556

556

660

758

758

862

862

890

848

361 361

424

424

535

591

431

500

563

626

695

758

890

479

542

542

598

598

660

660

779

779

897

897

1008

1008 1015 1022 1022

445

438

507

514

570

577

639

633

709

772

897

904

_____________________

890

813

319

313

368

361

424

417

466

473

521 sh

514

570

563

667

^11 ^11

772

765

876

869

980 1071

375

368

438

431

493

486

549

556

605

612

667

674

793

786

911

904

459

466

535

528

598

591

660

653

730

793

925

918

890 <-THEORETICAL HEATING COST * FURNACE ONLY

319

368

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

424 S PER YEAR

473

570

772

876

1071 (-THEORETICAL HEATING COST * FURNACE ONLY

375

438 THEORETICAL HEATING COST * fURN.^ HEAT PUMP

493

556

612

674

793

911

466

THEORETICAL HEA

535

598

660

730

793

925

S PER YEAR

BALANCE POm 15- DEG.F.

S PER YEAl

BALANCE POINT 3- DEG.F.

COST * FURN.+ HEAT PUMP

40,000

50,000

ANNUAL AIR CONDITIONING COCT HHEN COOLING LOAD IS SIZED TO MATCH COOLING CAPACITY OF BEAT PUMP

THE йоте ANNUAL BBATIHG AND COOLING OPERATING COSTS ARE THEORETICAL ESTIMATES ONLY AND Ш PROVIDED FOR A COMMON

S 709 772 834 890 952 1008 1071 1126 1189 1307 1426 1426 <-THEORETICAL HEATING COST • FURNACE ONLY

.05

S 452 466

.06

S 521 535

.07

S 598 612

S 667 681

.08

.09

S 737 751

.10

S 806 820

.12

S 946 959

.14

S 1085 1099

.16

S 1224 1238

S 890 966 1043 1112 1189 1266 1335 1412 1488 1634 1787 1787 <--THEORETlCAL HEATING COST * FURNACE ONLY

.05

.06

.07

.09

:1S

;}б^

660 688

723 751

S 911 939 973 1001 1029

i гШ i??i

S 1224 1252

S 1342 1370

.05 .06 .07 .08 .09 .10 .12 .14 .16

35 42 50 57 64 71 85 100 114

473 479

542 549

619 626

688 695

758 765

827 834

966 973

3106 1112

1245 1252

751

723

813

786

348

876

911

939

1036 1064 1092

1161 1189 1217

1286 1314 1342

1405 1432 1460

500

486

570

556

646

633

702

772

786

855

841

980

994

Ш9 1133

1259 1272

806

779

841

869

932

994

1057

1119

1245

1370

1488

507

514

577

653

723

793

862

1001

1140 1347

1279 1286

841

904

966

1029

1092

1154 1182

1279 Ш

1405 1432

1523 1551

528

584

598

660

674

730

744

813

799

869

883

1008 1022

“ ■ 1161

1300 1314

897 959 1015 1015

869

959 1022 1078 1078

932

994 1022 1085 1140 1140

1057 1085 1147 “ '

1147 1210 1266 1266

1119

1210 1272 1328 1326

1335 1398 1453 1453

1460 1523 1579 1579

1579 1641 1697 1697

COOLING SYSTEMS. ACTUAL VALUES HAY VARY DEPENDING ON

542

612

688

897

1036

1175

563

563

633

633

709

709

779

779

848

848

918

918

1057

1057

1196 1196

1335 1335

1203 1203

THEORETICAL HEATING COST

THEORETICAL HEATING COST

<-ELECTRIC RATE S/KHH

<-THBORETICAL AIR CONDITIONING COST

S PER YEAR

BALANCE POINT 5 DEG.F.

S PER YEAR

BALANCE POINT 17 DEG.F.

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

Page 15

BARD MANUFACTURING COMPANY

DUAi, FUEL ADD-ON HEAT PUMP GUIDE TO ENERGY COST SAVINGS

REGION 5

..^JBGÍAPACm AT 45 DEG. P. ENTER INU HATER TKHF7I

HEATING CAPACITY AT 15 DEG.P.ENTERING WATER TEMP.:

FURNACE nPB ELECTRIC"

BEAT

35,000

40,000

ELEC.

COST

S/KHH

.05

,06

.01

.09

.10

.12

.14

.16

•S

.06

.07

.09

.10

,12

.14

.16

;COKPRBSSai SECTIOj

“ AT 45 DEG.P.EKT

HEAT PUKP KITH ELECTRIC HEAT ELECTRIC HEAT ONLY

HEAT PUKP KITH ELECTRIC HEAT

S

$

s

s

s

s

s

s

s

— THBORFTICAL ANNUAL HEATING COST —

417

500

577

667

751

1168

1328

— THEORETICAL ANNUAL

466

563

660

751

841

939

1126

1307

1502

INDOOR

36950 BTUH.15«IT

_

____

FURNACE EFFICIENCY

32300 BTUé. ■‘1750 COP

1085

1300

m

1947

M

3039

3471

ING COST —

LECTRIC HEAT ONLY

1238

1488

1732

1982

2232

2476

2977

3471

3965

106

m~AFUE

BALANCE POINT 13- DEG.F.

50,000

,05

.06

.07

.08

,09

.10

.12

.16

60,000

.05

.06

•52

.00

-09

.10

.12

.14

.16

70,000

ANNUAL AIR COHDITIOHIHG COST KHKN COOUHG LOAD IS SIZED TO MATCH COOLING CAPACITY OF HEAT PUKP

HEAT PUKP KITH ELECTRIC HEAT ELECTRIC HEAT ONLY

s

s

s

s 925

s

s

$

s 1620

s

HEAT PUKP KITH ELECTRIC HEAT ELECTRIC HEAT ONLY

$ 709

s

s

s

s

$

s

s

$ 2260

HEAT PUKP KITH ELECTRIC HEA'

S

07

s

10

1

ii

s 2782

16

™ THEORETICAL ANNUAL HEATING COST —

577

695

806

1043

1154

1384

1850

— THEORETICAL ANNUAL HEATING COST —

848

987

1126 2977

1272

1412

1697

1982

AL

869

1036

1217

1739

.05

44

.06

53

• a

.0870.09

79

.10

88

1544

1857

2170

2476

278?

3095

3721

4340

4959

1857

2232

2601

3345

3721

4465

5210

5954

ING COST —

TRIG HEAT ONLY

3039

3471

3902

4340

U

6942

l06 Í23

.16

141

BALANCE POINT 2 DEG.F.

BALANCE POINT 12 DEG.F.

BALANCE POINT 20 DEG.F.

;TR1C RATE S/KNH

<-BLl

IRETICAL AIR CONDITIONING COST

<-t:

__

THE ABOVE ANNUAL HEATING AND COOLING OPERATING COSTS ARB THEORETICAL ESTIMATES ONLY AND ARE PROVIDED FOR^A COMMON

BASIS OP COMPARISON BBTKEBN VARIOUS TYPES OF HBATNG AND COOLING SYSTEMS. ACTUAL VALUES HAY VARY DEPENDING ON

ACTUAL KBATHKR CONDITIONS AND INDIVIDUAL USAGE PATTERN.

Page 16

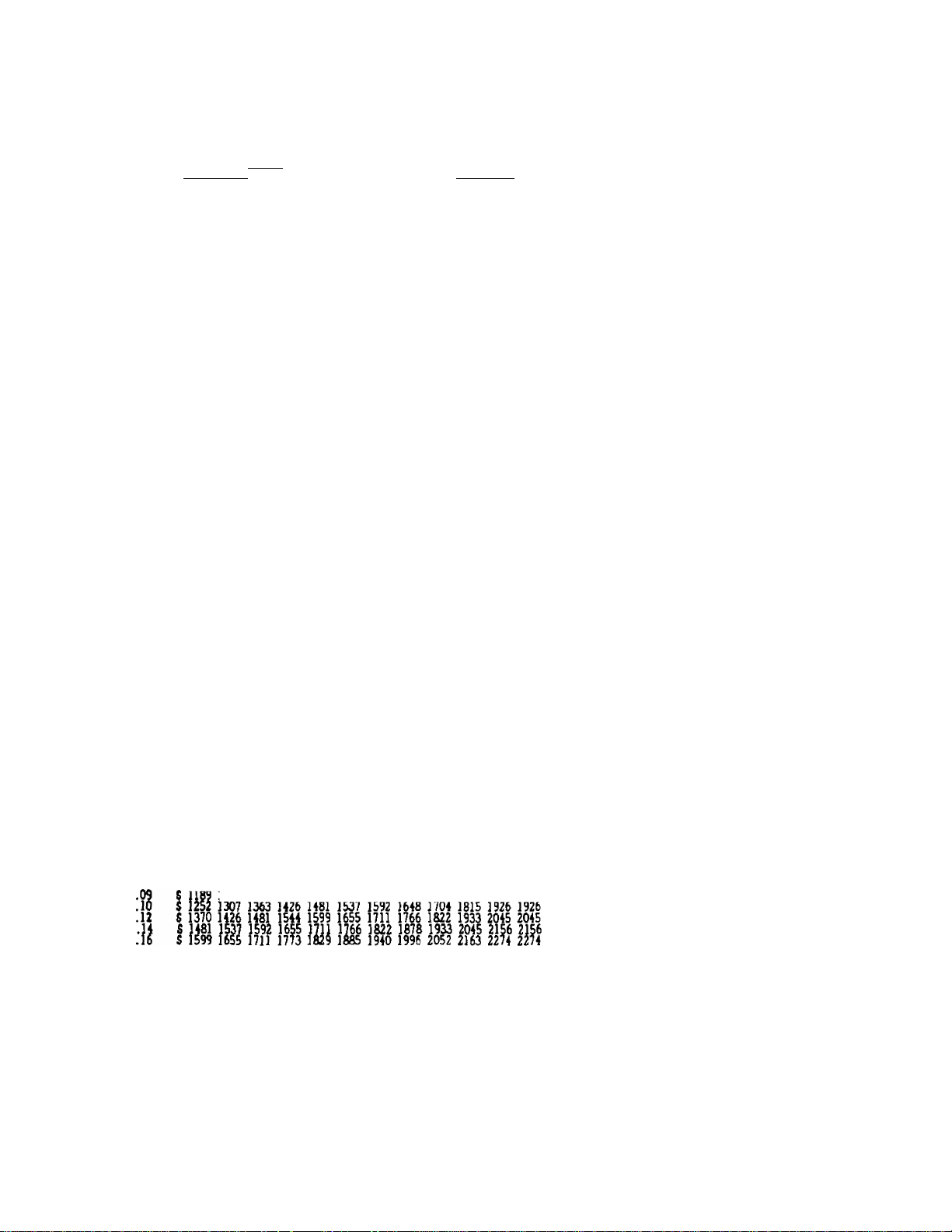

BARD KANUFACTURINC COHPANY

DUAL FUEL AOO-OK HEAT PUHP GUIDE TO ENERGY COST SAVINGS

FUWttCB TYPE NATURAL~CTS

HEAT

30,000

35,000

40,000

ELEC.

COST NATURAL GAS COST - S/THERK

S/WH .35 . 40 . 45 . 50 . 55 . 60 . 65 . 70 . 75 . 80 . 90 1.00

.05

.06

.■S

.09

.10

.12

.05

.08

:î?

.12

FURNACE EFFICIENCY ?éni6t~AFlJE

S 278 319 361 403 445 486 528 563 605 646 730 813 <--THEORETICAL HEATING COST * FURNACE ONLY

S 313 313 319 319 326 326 333 333 340 340 347 354

S 368 368 3^ 375 382 382 389 389 396 396 403 410

$ 431 431 438 438 445 445 452 452 459 459 466 473

THEORETICAL HEATING COST * FURN.^ HEAT PUMP

S PER YEAR

i |fl p Si IS I?? lU lU 111 in

I K3 723 730 llo 737 7« 7« 751 ^ ^ III

I 841 841 848 848 855 855 862 862 869 869 876 883

S 952 952 959 959 966 966 973 973 980 980 987 994

S 326 375 424 473 521 563 612 660 709 758 848 946 <--THEORETICAL HEATING COST * FURNACE ONLY

S 361 361 368 368 375 375 382 382 389 389 396 403

S 431 431 438 438 445 445 452 452

S 4M 493 500 500 507 507 514 514

S 563 563 570 570 577 577 584 584

5 633 633 639 639 646 646 653 653

6

695 695 702 702 m 709 716 716 723 723 730 737

S

M4 834 841 841 848 ¿48 855 855 862 ¿62 ¿69 ¿76

S

.............

966 966 973 973 980 980 987 987 994 994 1001 1008

S 1099 1099 1106 1106 1112 1112 1119 1119 1126 1126 1133 1140

S 375 431 486 542 591 646 702 758 813 862 973 1085 <-THEORETlCAL HEATING COST * FURNACE ONLY

410 410 417

III III

633 633

??l ??l

925 925

1078 1078 1085 1092 1092 1099 1106 1106 1112

1224 1224 1231 1238 1238 1245 1252 1252 1259

_________________________________

639

709

786

932

424

493

570

646

M

939

424

493

570

646

939

431

500

577

653

723

799

946

438

507

584

660

230

¿06

952

459 459 466 473

521 521 528 535

II ■■■

59Í 59Í 598'

660 660 667

438

445

507

514

584

591

660

667

730

606

952

959 966 973 980

■ 1119 1126 1133

605

674

_____

_____

459

452

i

528

605

681

466

535

612

688

8?? ¡20 l\] M

1266 1272 1279

THEORETICAL HEATING COST • FURN.^ HEAT PUHP

THEORETICAL^^

S PER YEAR

BALANCE POIKT 63 DEG.F.

COST » FURN.+ HEAT PUMP

BALANCE POINT 13- DEG.F.

50,000

60,000

70,000

ANNUAL AIR COWITIONING COST WHEN COOLING LOAD IS SIZED TO HATCH COOLING CAPACITY OF HEAT PUMP

TIE ABOVE ANNUAL HEATjJGAH) CaXING OPERATING COSTS ARE THEORETICAL ESTIMATES ONLY AND ARE PROVIDED FOR A C0№»N

S 473 542 605 674 744 813 876 946 1015 1085 1217 1356 <-THEORETICAL HEATING COST * FURNACE ONLY

05

06

07

.05

.06

:S¡

.09

06

s

r9Î \\\ m

660 674 681 695

¡1Í ¡4^ ¡4I UÍ

911 925 932 946

1085 1099 1106 1119 1

1252 1266 1272 1286 1

1419 1432 1439 1453 1460 1467 1481 1488 1502 1509 1530 1551

S 563 646 730 813 890 973 1057 1133 1217 1300 1460 1627 <-THEORETICAL HEATING COST * FURNACE ONLY

584

612

688

‘

...

...............

633

fi\

660

¡ÍÍ Ui i

911 939 959

1314 1342 1363 1391

1481 1509 1530 1558

5 660 758 848 946 1043 1133 1231 1328 1419 1516 1704 1899 <-THEORETICAL HEATING COST * FURNACE ONLY

674 709 751 786 827 862 897 939 973 1015 1092 1161

s

® ¡8

s

liSiSli .

S 1245 1279 1321

I ilil ill! iiiï

.05 .06 .07 .08 .09 ;iO ,12 ,14 .16. - . .37

S 44 53 61 70 79 88 106 123 141

535

619

626

709

702

793

786

869

¿76

952

_ .. 994 1001 1022 1043

959

??

® 5itl 1^^2t ®

660

688 709 737 758 786 813 862 911

737

765 786 813 834 862 890 939 987

820

848 869 897 918 946 973 1022 1071

904

987

1064

1231

m...

952 980 1001 1029 1057 1106 Í154

1015 1036 1064 1085 1112

1092 1112 1140 1161 1189

1259 1279 1307 1328 1356

1419 r439 1467 1488 I5l6 1544 1592 1641

1586 1606 1634 1655 1683 1711 1759 1808

III II) iS? 1811 i?!l i??l m li

ill

Ú

356 1398 1432 1467 1509 1544 1586 1662 1732

5« 1565

lin ill| illl É1111 ill? 1Í5!

15S5

563

556

639

723

806

890

973

980 1001 1029

.«4 JIJ6 j||,

577 584 605 626

646

660 6^ 688 709

730

744 751 772 793

813

¿27 834 855 876

897

911 918 939 959

980

1140 1189 1238

1217 1266 1314

1384 1432 1481

THEORETICAL HEATING COST

THEORETICAL HEATING COST

THEOREtICAI,j,|»J^ COST

<-ELBCTRIC RATE S/KHH

S PER YEAR

BALANCE POINT 2 DEG.F.

S PER YEAR

BALANCE POINT 12 DEG.F.

BALANCE POINT 20 DEG.F.

<-THBORETICAL AIR CONDITIONING COST

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

Page 17

DUAL fUKl ADD-ON BEAT PUMP GUIDE TO ENERGY COST SAVINGS

REGION

FURNACE nPB PURL OIIT"

HEAT

ELEC.

BARD HANUFACTURING COHPMfY

.70 .80

BEATING OIL COCT - S/GALLON

.90 1.00 1.10 1.20 1.30 1.40 1.50 1,60 1.70 1.80

HATER TEMP.I 36^BTUH,1 ^tSeIT

HATER TEMP. :32^BTUil.~I30 COP

FURNACE EFFTCTENCY 7813DrAFUR

30,000

35,000

40,000

50,000

S 410 466 521 584 639 702 758 820 876 939 994 1050 <-THEORBTICAL HEATING COCT • FURNACE ONLY

.05

,06

.07

.10

.12

.14

.16

.05

.06

:S

.09

:1? I ISi

.14

.16

.05

.06

:S

.09

.10

.12

.06

.07

.08

.09

.10

:i?

.16

E ^ 51?

438 445 452 452 459 466 466 473 473 479 486 486

tn IS Wo Wo Hi 111 111 l\f Ilf li IJI

612 619 626 626 633 639 639 646 646 653 660 660

730 737 744 744 751 758 758 765 76S 772 779 779

848 855 862 862 869 87 6 876 883 883 8» 897 897

959 966 973 973 980 987 987 994 994 1001 1008 1008

S 473 542 612 681 751 820 890 952 1022 1092 1161 1231 <-THEORETICAL HEATING COCT • FURNACE ONLY

375 382

368

445 452

438

5^? Hi

Wo

646 653

639

848

Ikl

987

980

973

S 1106 1112 1119 1119 1126 1133 1140 1140 1147 1154 1154 1161

S 542 626 702 779 855 939 1015 1092 1168 1252 1328 1405 <"THEORFTICAL HEATING COST * FURNACE ONLY

438

431

424

493

570

646

793

939

0

II

s

681

s 528

s 612

$ 695

s

779

s

¿62

s 946

s

5

s 1453

507

500

577

584

653

660

7^

723

799

№ 6

946

952

1106 1112 ni9 1126 1133 1133 1140 1147 1154 1161

1252 1259 1266 1272 1279 1279 1286 1293 1300 1307

779

876

542 556

626 639

709 723

793 806

890

¿76

959

973

1147

1314

1481

1467

389

382

452

514

584

653

987

445

514

591

667

959 966

973 1071 1168 1266

570

653

737

820

904

987

1161

1328

1495

396

459

521

591

598

660

723

862 869

5

994 1001

459

452

521

598

661

674

l\]

IIS

973

598

584

6^ 681 695

751 765 779

848 862 890

834

932

918

1001

1015

1189

1175

1356

1342

1509

1523 1537

466

528

667

730

528

605

403

403

473

535

605

674

737

176

1008 1008 1015 1022 1022 1029

466

535

612

688

758 758 765 772 779 786

¿34 ¿34 ¿41 ¿48 ¿55 ¿62

980 980 987 994 1001 1008

612

946

1029

1203

1370

410 417

473

479 486

542 549

535

612 619

605

681 688

674

737

876

sU llo

466

473

535

542

619

612

695

688

1363

1467

626

639

709

723

793

806

959

973

1057

1043

\m№

1551

1565

479

549

626

702

1565

660

744

827

911

994

1078

1586

417

486

549

619

688

751

890

486

556

633

709

1662

674

758 772

841

925

1008

1092

1266

1432

1599

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

424

493

THEORETICAL HEATING COST

556

626

695

¡1?

493

THEORETICAL HEATING COST

563

639

716

1759

688

THEORETICAL HEATING COST

855

939

1022

1106

1279

1446

1613

S PER YEAR

S PER YEAR

BALANCE POINT 63 DEG.F.

S PER YEAR

BALANCE POINT 13- DEG.F.

S PER YEAR

BALANCE POINT 2 DEG.F.

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

FURNACE ONLY

FURN.^ HEAT PUMP

60,000

70,000

ANNUAL AIR COWITIONING CO?T WHEN COOLING LOAD IS SIZED TO MATCH COOLING CAPACITY OF HEAT PUMP

ANNUAL BEATING AND COOLING OPERATING COSTS ARE THEORETICS ESTIMATES ONLY AND ARE PROVIDED FOR A COMMON

s 820 939

.05

.06

:U

.09

05

660 702 737 772 806 841 883 918 952 987 1022 1057

737 779 813 848 883 918 959 994 1029 1064 1099 1133

820 862 897 932 9W 1001 1043 1078 1112 1147 1182 1217

M 946 980 1 015 1 0» 1085 1126 1161 1196 1^1 1266 1300

987 1029 1064 1099 1133 1168 1210 1245 1279 1314 1349 1384

m wfi lii? \^¿ Hi? 1515 i?ii 115! m m \tfi

1391 1432 1467 1502 1537 1572 1613 1648 1683 1718 1752 1787

1558 1599 1634 1669 1704 1739 1700 1815 1850 1885 1919 1954

5 952 1092 1231 1363 1502 1641 1780 1912 2052 2191 2323 2462 <-THEORETICAL HEATING COST * FURNACE ONLY

$ 793 841 897 952 1008 1064 1119 1168 1224 1279 1335 1391

! II! igf iss? 1??! m m m \iu iia \m iiii m

$ 1036 1085 1140 1196 1252 1307 1363 1412 1467 1523 1579 1634

$ 1363 1412 1467 1523 1579 1634 1690 1739 1794 1850 1905 1961

S J5I3

S 1690 1739 1794 1850 1905 1961 2017 2065 2121 2177 2232 2288

.05

jlif|^^*IHDIVl5ff UsO^AT^ COOLING SYSTEMS. ACTUAL VALUES MAY VARY DEPENDING ON

1050

1168

1690 1745 1801 1857 1905 1961 2017 2072 2128

.07

.06

53

44

.08

61

70

1286

.09

79

1405 1523

.10

.12

88

106

1641

.14

123

1759

.16

i41

1878

1996

2107

THEORETICAL HEATING COST

balance point 12 DEG.F.

THEORETICALp^AJIg COST * FURN.+ HEAT PUMP

BALANCE POINT 20 DEG.F.

<-ELECTRIC RATE S/KNH

<-THKmiCAL AIR CONDITIONING COST

S PER YEAR

FURNACE ONLY

FURN.* HEAT PUMP

Page 18

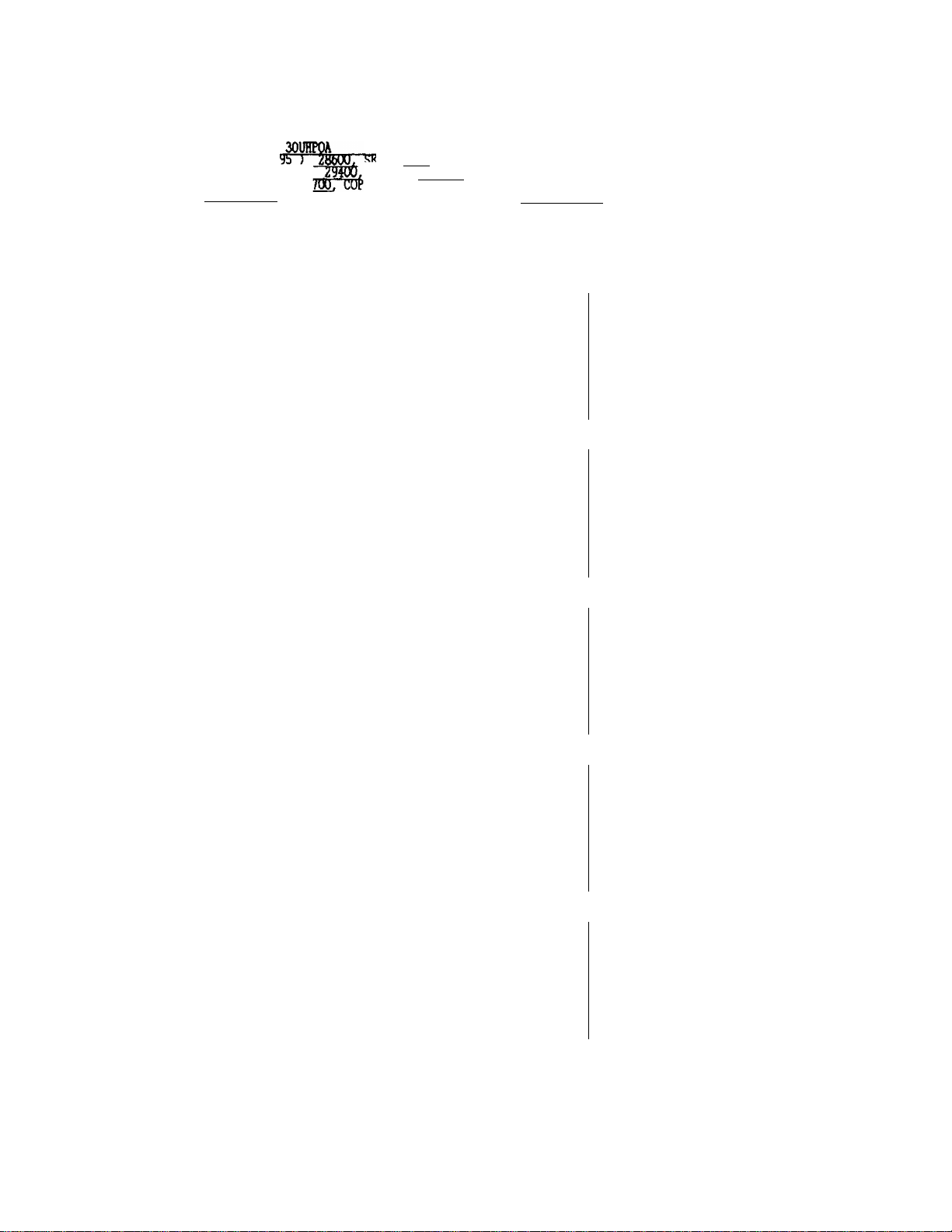

bm HAMUt'ACIUSit« CuHrAHl

DUAL FUEL ADO-OM BEAT PUMP GUIDE TO ENERGY COST SAVINGS

REGIOM

^ING CAPACiTf AT IS 6BG;F. ENTER IMG NATBR TEMP.:

FURNACE TYPE PROPAHETAS FURNACE E

BEAT ELBC.

.65 .70

Ш

.60

ÎSÏrI NG^TKK eV: 36950^

GAS Cl

75 Ю

.85

Ш, lb ли Jeer

BTUHXrSD COP

;y жжлш

.95 1.00 1.10 1.20 1.20

Ч

X

s.

30,000

35,000

40,000

50,000

•22

.10

:11

.16

.05

.06

:й

.09

:i§

.14

.16

.05 S

.09

.10

.12

.05

.06

.07

.10

.12

.14

.16

5 535

£ 333

M

5 389

$ 452

! Ш

S 626

$

s Ш Ш HI

$ 973

£ 626

£ 382

£

5

£ Ш

£ 653

1

S 987

S 1119

s

577 626

333 340

389 396

Щ

626

973 980

674 730

382 389

452

452

111

653 660

Ш Ш

987

1119

709

772 834

438 445 445

507 514 514

584 591 591

660 667 667

Ш Ш

952 959 959

m \ш Ш

S 890 966 1043 1112 1189 1266 1335 1412 1488 1634 1787 1787 <--THEORniCAL HEATING COST * FURNACE ONLY

570

556

639

653

737

723

820

904

987

973

S 1147 1161 1168 1182 1196 1203 1217 1224 1238 1259 1279 1279

I IM4 1328 Ш 1349 1363 1370 1384 1391 1405 1426 1446 1446

$ 1481 1495 1502 1516 1530 1537 1551 1558 1572 1592 1613 1613

667

709

758

347

354

354 36

340

41

403

396

459

459

Sll 111

633

633

980

779

389

459

459

521

521

591

591

660

723

723

862

862

994

994

1126

1126

890

452 459 459

598 605

674 681 681

Ш ё II

966 973 973

пи

577 591

660 674

744 758

Ш

994 1008 1022 1029 1043 1050 1064 1085 1106 1106

403

466

466

111

639

639

758

758

876

987

987

834

396

466

528

598

674

667

730

869

876

1001

1008

1133

1140

952

1008

528 528

■ ■ 605

ш?

605

688

772

J9

876

994 994 1001 1008 1015 1015

939 987 1043 1147 1252 1252 <-THEORETICAL HEATING COST * FURNACE ONLY

883

403

403

473

473

535

È

605

674

737

466 473

535 542

612 619

688 695

ш w

980 987

\ш

779 793

862 876

946 95S

361 368 375 375

410 '

41? 424 431 431

479 486 493 493

473

Ip IS Ш 61 !

653 660 667 667

646

765

2 779 786 786

Й

0 897 904 904

S83

417

410

410

479

Ш

542

612

681

1286

633

716

799

Ï66

619

612

681

688

479 486

549 556

626 633

702 709

ш ш

994 1001

1147 1154

1293 1

300

646

667

730

813

918

ir-

1001

486

549

751

834

424

493

556

626

695

500 500

570 570

646 646

723 723

793 793

869 869

1015 1015

\1П Р

688

772

855

939

1022 1022

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

424

THEORETICAL HEATING COST

493

556

626

695

1161

THEORETIC^p|EATJNG COST • FURN.+ HEAT PUMP

314

688

THEORETICAL BEATING COST

772

855

939

$ PER YEAR

S PER YEAR

BALANCE POINT 63 DEG.F.

BALANCE POINT 13- DEG.F.

S PER YEAR

BALANCE POINT 2 DEG.F.

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

50,000

70,000

AHNUAL AIR COWITIONING COST WHEN COOLING LOAD IS SIZED TO MATCH COOLING CAPACITY OF HEAT PUMP

--------- COOLING SYSTEMS. ACTUAL VALUES KAY VARY DEPENDING ON

S 1071 1161 1252 1335 1426 1516 1606 1697 1787 1968 2142 2142 <-THEORETlCAL HEATING COST • FURNACE ONLY

737 765 793 820 848 876 904 932 959 1015 1071 1071

813 841 869 897 925 952 980 1008 1036 10Э2 1147 1147

897 925 952 980 1008 1036 1064 1092 1119 1175 1231 1231

980 1008 1036 1064 1092 1119 1147 1175 1203 1259 1314 1314

1064 1092 1119 1147 1175 1203 1231 1259 1286 1342 1398 1398

11Й

1307 1335 1363 1391 Î4Ï9 1446 1474 1502 1530 1586 1641 1641

1467 1495 1523 1551 1579 1606 1634 1662 1690 1745 1801 1801

1634 1662

£ 1252 1356 1460 1565 1669 1773 1878 1982 2086 2295 2504 2504 <-THEORETICAL HEATING COST • FURNACE ONLY

S 904 946 987 1029 1071 1112 1154 1196 1238 1321 1405 1405

05

£ 987 1029 1071 1112 1154 1196 1238 1279 1321 1405 1488 1488

£ 1064 1106 1147 1189 1231 1212 1314 1356 1398 1481 1565 1565

£ 1147 1189 1231 1272 1314 1356 1398 1439 1481 1565 1648 1648

08

I ifîi Щ \ll\ i?lf \Ш \Ш ilîl m ü?? Ш1

12

s 1474 1516 1558 1599 1641 1683 1725 1766 1808 1892 1975 1975

n

.05

.06

44

53

1224 1252 1279 1307 1335 1363 1419 1474 1474

■■ 1690

1718 1745 1773 1801 1829 1857 1912 1968 1968

1975 2059 2142 2142

.10 .12 .14 .16 <"EUBCTR

.09

79

88 106 123

70

COOLING OPERATING COSTS ARE THEORETICAL ESTIMATES ONLY AND ARB PROVIDED FOR A COMMON

.16

141

2302 2302

THEORETICAL HEATING COST

THEORETICAL^

8

S PER YEAR

BALANCE POINT 12 DEG.F.

COST * FUFN.+ HEAT PUMP

BALANCE POINT 20 DEG.F.

RATE S/RNB

ICAL AIR CONDITIONING COST

FÜRN.+ HEAT PUMP

Page 19

HEAT

BARD MAHUFACTURING COKFANY

DUAL FUEL ADD-ON BEAT PUMP GUIDE TO ENERGY COST SAVINGS

8BGIM1 5

---

PUPOOOBL:COMPRESSOR

,IMG CAPACITY AT “

iTIHG CAPACin AT

■ ':b hpe electri

ELEC.

COST

S/KNE

------DEG.P.ENTERING HATER TEMP.;“

I’EHtTT 43

FURNACE El

40.000

50,000

60,000

HEAT PUMP HITH ELECTRIC HEAT ELECTRIC HEAT ONLY

.05 $ 486

.06 S

:S 1

.09 S 876

1

.14 S 1363

.16 S

HEAT PUMP'iilf'

.05

S 598

.06

I 716

.07

; 834

.08

i 952

.09

i 1071

! 1196

.10

.12

; 1432

S 1669

.14

.16

! 1905

BEAT PUMP HITH ELECTRIC HEAT ELECTRIC HEAT ONLY

.05 $ 709

.06 S

.07 s 994

.08 S

.09

s

.10

s

.12 5 1704 4465

5 1989 5210

.16 S 2274

— THEORETICAL ANNUAL HEATING COST —

584

1238

1488

7?9

2232

I?S

1565

iRETICAL ANNUAL

'.ECTRIC HEAT ;LECTRlC*^ArONLY

l\]l

3471

3965

2170

2476

2789

3095

3721

4340

4959

— THEORETICAL ANNUAL HEATING COST —

855

1140

1279

14l9

1857

2232

2601

2977

3345

3721

5954

BALANCE POINT 8- DEG.F.

BALANCE POINT 4 DEG.F.

70.000 — THEORETICAL ANNUAL HEATING COST —

HEAT PUMP HITH ELECTRIC HEAT ELECTRIC HEAT ONLY

.05

.06 S 1008

.09

.12 $ 2024 5210

.14 s

.16

80,000

07

ANNUAL AIR CONDITIONING COST WHEN COOLING LOAD IS SIZED TO HATCH COOLING CAPACITY OF HEAT PUMP

THE ABOVE ANNUAL HEATING AND COOLING OPERATING COSTS ARE THEORETICAL ESTIMATES ONLY AMD ARE PROVl^ FOR A COMMON

BASIS OF COMPARISON BETHESN VARIOUS nPES OF HEATN6 AND COOLING SYSTEMS. ACTUAL VALUES HAY VARY DEPENDING ON

ACTUAL HEATHER CONDITIONS AND INDIVIDUAL USAGE PATTERN.

841

S

s

1182 3039

5

1349

1516

S

1690

s

2358

2698

s

HEAT PUMP Hll

ilC

1405

2010

ANNUAL HEATING COST —

HEAT ELECTRIC HEAT ONLY

$ 3220

f, il •?! i? lil lii ii§

2170

2601

3471

3902

4340

6079

6942

2476

2977

3471

3965

4465

i

7936

BALANCE POINT 13 DEG.F.

BALANCE POINT 19 DEG.F,

<—

RATE S/KHH

ICAL AIR CONDITIONING COST

Page 20

BEAT

BARD HAKUFACTURING COHPANY

DUAL FURL ADO-OH HEAT PUMP GUIDE TO SHERGY COST SAVINGS

■iW." 43600^SuH^l

nfliiuv IDrU . ; Tik/WA/ Di Vll^J i arilSIl

DBG.P.ENTERING

EL8C.

.35 ,40 .45

HATER TEMP.: 375TO BTU6.“3T0 COP

FURNACE EFFTCMT

‘ÎJ-.T5 ,80 .50 1.C«

X

X

35.000

40.000

50.000

60.000

S 326 375 424 473 521 563 612 660 709 758 848 946 <“TBEORBTICAL HEATING COST * FURNACE ONLY

THEORETICAL HEATING COST

890 890 897 897 904 911

102;

1029 1029 10^ 1036 10» 1050

1161

1168 1168 1175 1175 1182 1189

S 375 431 486 542 591 646 702 758 813 862 973 1085 <-THEORETlCAL HEATING COST * FURNACE ONLY

.05

.06

.07

.09

.10

.12

.14

.16

,05

.06

.07

.08

;5?

.12

;i^

.07

:io

■,iî

.16

424

431

500

507 514 514 521

431 438 438 445

507

IS Ilf Ilf 111 I|1 ^

9?3 Mo kj 98? Hi 994

1133 1140 1140 1147 1147 1154 1161

1293 1300 1300 1307 1307 1314 1321

S 473 542 605 674 744 813 876 946 1015 1085 1217 1356 <-THEORETICAL HEATING COST * FURNACE ONLY

S 514 521 526

I fit

799 806 813

. ... ... 820 827 834 841 848 855 869 883

IS IIÎ iSÎ i§ji M i21! ili\ iHI iH2 ilil 1^? Æ

$ 1175 11^ 1189 1196 1196 1203 1210 1217 1224 1231 1245 1259

535 542 549 556 563 570 584 598

535

633

723

820

m HS W n? fâ ÏÏ2 fâ

m m m an m m ^ ^

S 563 646 730 813 890 973 1057 1133 1217 1300 1460 1627 <--THEORETICAL HEATING COST * FURNACE ONLY

$

S

^ ^ 115 HI ^ SÎ

s

806 820 834 841 855 869 883 890 904 918 939 966

$

S 1

iSii lUi ii^ 1^^ M lia is?f m \w El

S 1119 1133 1147 1154 1168 1182 1196 1203 1217 1231 1252 1279

‘

........ 1405 1412 1426 1439 1460 1488

452

452

528

528

... n fâ Î4l

605

^ iU III

688

765 772 772 779

765

848

848 855 855 862

1001

1001 1008 1008 1015 1029

1161 1168 1168 1175 1189

1321 1328 1328 1335 1349

1613 1620 1634 1646 1669 1697

1622 1629 1843 1857 1876 1905

479

556

633

716

793

876

1620 1634

THEORETICAL HEATING COST

THEORETICAL

THEORETICAL HEATING COST

S PER YEAR

S PER YEAR

BALANCE POINT 63 DEG.F.

HEATING

ER YEAR

S P

BALANCE POINT 8- DEG.F.

S PER YEAR

BALANCE POINT 4 DEG.F.

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

COST * FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

70.000

80,000

S 660 758 848 946 1043 1133 1231 1328 1419 1516 1704 1899 <-THEORETICAL HEATING COST • FURNACE ONLY

$

.05

.06

.07

:o9

:1?

:\i

OS

695 730

$

793 827

I 987 1022

S 1085 1119

115f? l4^^5 5 1572 1606 S 1773 1808

758

855

786

883

613

911

841

939

676 904

973 1X1

932 959 1022 1078

. . 1029 1057 1119 1175

THEORETICAL HEATING COST

Mim^mmmmmEuwo

1634 1662 1690 1718 1752 1780 1808 1836 1899 1954

1836 1864 1692 1919 1954 1982 2010 2038 21X 2156

973 1085 1189 13X 1405 1516 1627 1732 1947 2170 <-TREORETlCAL HEATING COST • FURNACE ONLY

869 911 952 994 1036 1085 1126 1168 1252 1342

lOM 1106 i?47 1189 ill? lilt Ills i?4? IH?

1203 1245 1286 1328

142 1384 1426

____

39 1481 1523

92 1634 1676 716

377

1419 1460 1544 1634

1555 JMl 1732

613 1655 1739 1829

766 1606 1850 1933 2024

THEORETICALpgAT|jg COST

i m m m isi ® iiiJ liY? m m w

AHRUU. AIR COBDITIOHING COST WHEN COaiNG LOAD IS ^.^ZED TO MATCH COaiNG CAPACITY Of HEAT PUMP

<—

<—

THE ABOVE

»■

.16

14

139

159

ING OPERATING COSTS ARE THEORETICAL ESTIMATES ONLY AND ARE PRIDED FOR AXmON

"iVlDOAL'uSAGrpATTEWp SYSTEMS. ACTUAL VALUES MAY VARY DEPENDING ON

10

S PER YEAR

BALANCE POINT 13 DEG.F.

BALANCE POINT 19 DEG.F.

1C RATE S/KNH

“ICAL AIR CONDITIONING COST

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

Page 21

BARD MAHUFACTURINC COKPAWY

DUAL FUEL ADD-ON HEAT PUMP GUIDE TO EliERGY COST SAVINGS

REGp

CAPACITY AT 45 DEG.F.EinBRI8G%rEinW7r 43600 BTUH.l/.46 ghHK

„IlfecAfiiCl„

HEATING CAPACITY _

FURNACE TYPE FUEL OIC^

HEAT ELEC.

№

BTUH

35,000

40,000

50,000

COST

S/KMH

05 $ 362

06 S 459

22

$

10 S 737

11 li!il iSS

16 S 1154

05 S 438

0621S 514

08

09

IS

14 S 1147

16 S 1307

.05 S 535

.06

.07

08 S 820

•0?

,10 S 1008

12 S 1196

.14

.16

556

793

695

786

IWnOR

Ì4 43

570 577

786

.925

486

563

63?

723

799

612

619

709

716

799

897

987

994 1001

1085

1092 1099 1112

:COKPRRSSOR SECTION HOS42A IK»OR A42AO-A

AT is DEG.F.ENTERING RATER TEHP.;"Í/bíSD BTUH.^TD COP

.70

S 473

8 528

1 II?

$ 542

S 591

S 674

Í 751

S 834

S 987

S 681

S 633

S 723

S 911

S 1384

S 1572

.80

542

389

466

535

744

1161

626

445

521

758

111

1154

1314

779

542

n

827

918

1015

1203

... 1398 1412 1419 1432 1439 1446 1460

ii?i

579 1586 1599 1606 1620 1627 1634 1648

HEATING OIL COST - S/GALLQN

.90 1.00 1.10 1.20 1.30 1.40 iTSO 1.60 1.70 1.80

612 681 751 820 890 952 1022 1092 1161 1231 <--THEORETICAL HEATING COST • FURNACE ONLY

396

396

473

473

542

542

751 751 758 765 772 772

1029 1029 1036 1043 1050 1050 1057 1064 1064 K ^

1168 1168 1175 1182 1189 1189 1196 1203 1203 1210

702 779 855 939 1015 1092 1168 1252 1328 1405 <--THBORETICAL HEATING COST • FURNACE ONLY

452

452

528

^ I III

765 765 772

848 855

1001 1008 1015 1022

1321 1328 1335 1342 1349 1356 1356 1363 1370

876 973 1071 1168 1266 1363 1467 1565 1662 1759 <”TEEOREriCAL HEATING COST * FURNACE ONLY

549

563

646

660

737

751

834

848

925

939

FURNACE BFFTÜTENCY T^IDOTAFUE

417

417

549

459

535

570

855

946

486

556

466

542

619

702

779

862

584

681

772

869

959

1057

493

493

563

563

479

473

549

626

716

709

786

)9

876 883 883

1029 1036 1036

598

591

688

779

883

876

973

966

1064 1071

438

431

514

507

584

577

653

723

793

786

932

925

1071

486 493 500

563 570 577

^ ^

799 806 813

■ : 890 897

6 1043 1050

639

626

723

813

904 911

II]

925

1015

1474 1488

1662 1676

THEORETICAL HEATING COST

THEORETICAL BEATING COST

THEORETICAL !

S PER YEAR

S PER YEAR

BALANCE POINT 63 DEG.F.

S Pi

BALANCE POIirr 8- DEG.F.

COET * FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

FURN.+ HEAT PUMP

S 820

60,000

70,000

80,000

.05

.06

.07

.08

.09

.10

S 1161 1175 1196 1230 1231 1245 1266 1279 1300 1314 1335 1349

S 1370 1384 1405 1419 1439 1453 1474 1488 1509 1523 1544 1558

■W

S 1579 15« 1613 1627 1648 1662 1683 1697 1718 1732 1752 1766

.16

S 1787 1801 1822 1836 1857 3871 1892 1905 1926 1940 3961 1975

S 952 1092 1231 1363 1502 1641 1780 1912 2052 2191 2323 2462 (-THEORETICAL HEATING COST * FURNACE ONLY

.05

.06

.09

.10

.12

.14

.16

S 1092 1252 1405 1565 1718 1878 2031 2191 2344 2504 2657 2817 (-THEORETICAL HEATING COST * FURNACE ONLY

S .911 973 1036 1099 1161 1224 1286 1349 1412 1474 1537 1599

I i?8? m M ill? iif? i??i m !?n ÌI8I Hi m m

5 1^ 1266 1328 1391 1453 1516 1579 1641 1704 1766 1829 1892

II m m iHi 111? Wii Ili? n p m m

S 1592 1655 1718 1780 1843 1905 1968 2031 2093 2156 2219 2281

939 1050 1168 1286 1405 1523 1641 1759 1878 1996 2107 (-THEORETICAL HEATING COST * FURNACE ONLY

939

646

660

681

751

765

848

862

952 966 987 1001 1022 1036 1057 .

1K7 1071 1092 1106 1126 1140 1161 11

786

827

883

925

980 3022 3071 1)12 1154 1196 1238 327? 3321 1363 3405 3446

1078 1119 1168 1210 1252 1293 1335 1377 1419 Í460 1502 1544

1175 1217 3266 1307 1349 1391 1432 3474 3516 1558 1599 3641

iüi m 11^ ìli? iig ini m ìiii ili?

3662 3704 1752 3794 3836 3878 1919 1963 2003 2045 2086 2128

1864 1905 1954 1996 2038 2079 2121 2163 2205 2246 2288 2330

695

786

799

883

897

876 918 959 1001 1043 1085 1126 1168 1210 1252

973 3015 1057 1099 1140 1382 3224 1266 1307 3349

716

820

918

730

834

932

m

952

765

869

966

786 799 820 834