Page 1

Refrigeration, Heating & Air Conditioning

Common Furnace Components and

Blower Maintenance Procedures

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914..Moving ahead, just as

planned.

Manual No.: 2100-066 Rev, A

Date: 10/18/95

©Copyright 1995

Page 2

Contents

Cabinet

Temperature Treatment Section

Heat Sections.......................................................................1

Cooling Section....................................................................3

Biower...................................................................................3

Beit Drive Biower

Direct Drive Blower..............................................................3

Filter.......................................................................................3

Thermostat............................................................................3

Electrical System Components

Furnace Circuits...................................................................4

Blower Motors......................................................................4

Fan Control Switch

Downflow and Horizontal Units

Limit Control.........................................................................6

Upper Limit Control

Additive Cooling Relay........................................................7

24 Volt or Low Voltage Control Circuit

Transformer..........................................................................7

Thermostat............................................................................7

Basic Maintenance Procedures..........................................7

Thermostat............................................................................9

.................................................................................

........................................

.................................................................

...........................................

..............................................................

..........................................

.............................................................

..............................

Maintenance Check Sheet

Maintenance Checksheet

Pre-Service Check

Blower Compartment Check.............................................10

Nondisposable Slab (Polyurethane)

Disposable Slab (Fiberglass/Cardboard)

Direct Drive Blower............................................................10

Post-Service Checks

Heat Section Checks

...............................................................

..................................................

....................................................

................................

........................

.........................................................

.........................................................

1

1

3

4

4

5

6

7

7

8

9

10

10

12

12

Page 3

Cabinet

Generally speaking, all heating and cooling components (except

the thennostat) are housed in sheet steel cabinets. The cabinet

helps protect the components and adds to the attractiveness of

the units.

The heating unit or furnace cabinet is normally located indoors. It

has connection provisions for attaching the cooling coil, supply air

plenum and return air plenum. The cabinet also contains openings

or knockouts for electrical service and required plumbing.

Designed into the cabinet are removable access doors to allow for

servicing the unit. The front door to oil and gas furnaces is slotted

to allow combustion air to enter (this is not necessary on electric

furnaces, since no fuel is burned).

Since the cooling system’s outdoor unit is exposed to the weather

elements and in the public eye, it is especially important the

cabinet is durable, weather resistant and attractive in appearance.

Like the furnace cabinet, the outdoor cooling unit cabinet has

service access doors and provisions for electrical and mechanical

(i.e. refrigerant line) connections.

Gas is fed into the burners and ignited by a pilot flame on a call for

heat from the thermostat. The burning gas warms the heat

exchanger and the blower distributes the heat throughout the house.

The oil heat section is made up of a firebrick pot and steel heat

exchanger. When the thermostat calls for heat, oil is pumped

through a nozzle and ignited by a spark from a set of high voltage

electrodes. A ball of fire is produced in the firebrick pot, which

heats the steel heat exchanger. The blower then moves this heated

air to the various distribution points.

Temperature Treatment Section

The temperature treatment section of a heating or cooling unit is

that portion of the unit which produces the heating or cooling. (All

types of heating units and cooling systems are discussed in greater

detail in the sections that follow.)

Heat Sections

Most residential furnaces use either natural or liquefied propane

(LP) gas, oil or electricity as their source of heat.

The heat section of an electric furnace consists of one or more

electric heating elements. The element is much like that in an

electric toaster, only bigger. When the thermostat demands heat, an

electrical resistance to the flow of electricity in the element

produces heat. The heated air is moved by the furnace blower

through the ducts and distributed to points all over the home.

The heat section of a gas (either natural or propane) furnace

consists of a steel heat exchanger and gas burners. The

burners fit in a cavity at the bottom of the heat exchanger.

Bard Total Electric Features

Built-In Cooling Coil Compartment—Slidein type for easier conversion to summer cooling,

Accomodates 1-1/2, 2, 2-1/2, and 3 ion

cooling coils.

Controls—On demand from the wall

thermostat, the heating elements are energized

by electrical contactors. The 15 thru 30K.W

versions have the blower motor interlocked with

each stage for safety. Easily two staged.

Limit Switch—Thermal snap disc in each

heating element shuts oif power automatically

if system air temperature becomes excessive

Built-In Transformer—Provides power

supply for heating and optional cooling controls

Blower Relay—Provides automatic blower

speed change-over to meet heating and cooling

air delivery requirements.

Branch Circuit Fusing—Factory installed in

models rated over 48 amps.

Heating Elements—Nickel-chrome wire with

individual fusible links for long life. Entire

assembly slides out for easy maintenance.

Motor—Multi-speed for both heating and

cooling.

Blower—Heated air is quietly circulated by

large volume centrifugal blower that is matched

to the electrical heating system for efficiency.

Slides out for easy maintenance.

Fillers—Twin permanent type slide out from

front for easy cleaning on all models except

Models EFC5 andEFClO.

Page 4

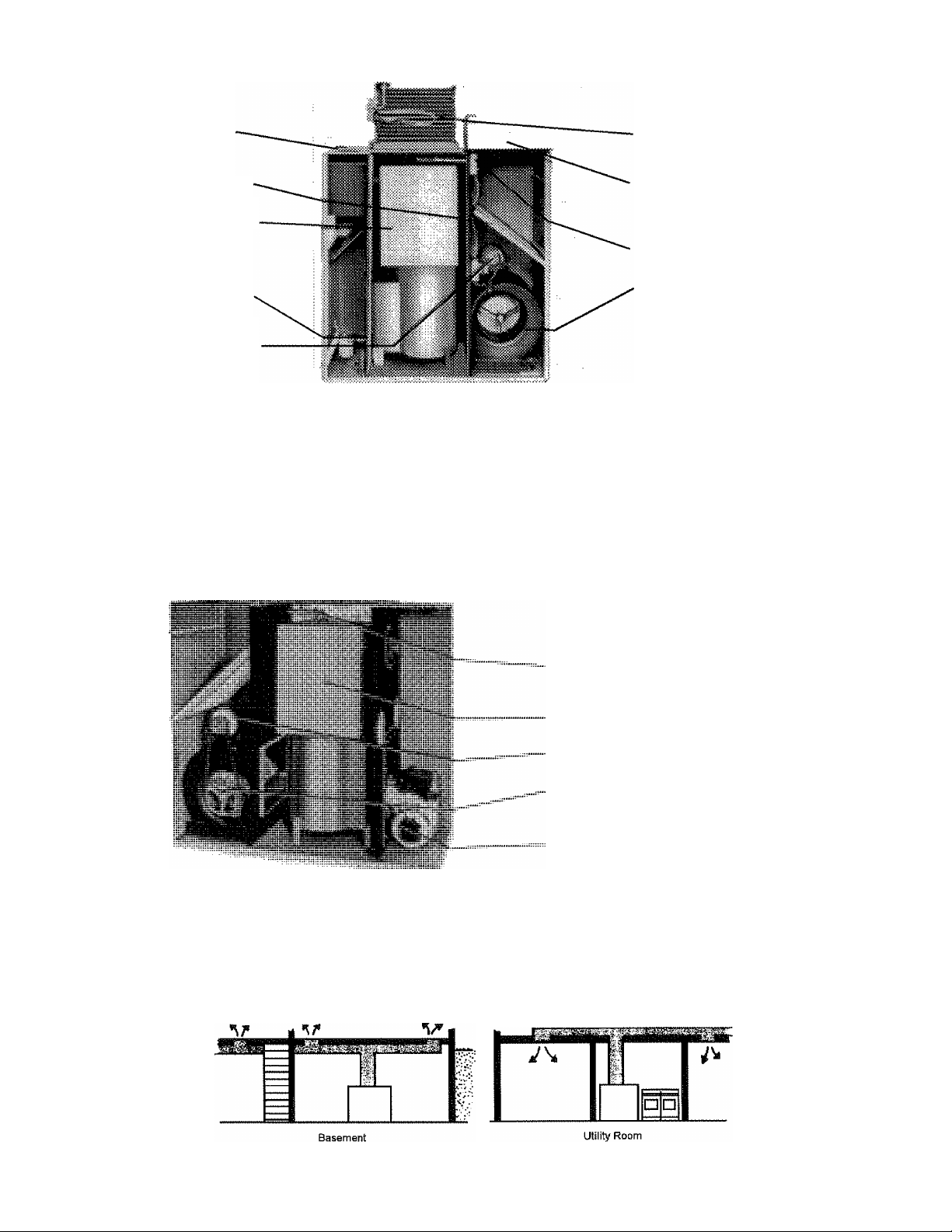

Typical Gas Furnace

Sled Cabinet is accoustically and ihennaUy

insulated for quieter operation and minimum

heat loss.

Filter is extra large for better system air cleaning

efficiency.

Heat Exchanger efficiently extracts all usable —

heat for greater fuel economy.

Safety Pilot provides 100% automatic shut-o£f

for safely.

Mono“.Jet® Burner provides ease in adjustment

and has uniform flame distribution for maximum

efficiency.

Powerful Blower Motor is resilient mounted for

quieter operation.

Model G152

All components are easily accessible for service and inspection.

Typical Oil Furnace

Bard Cooling Coils with plenum and system matched

components are optional for converting to summer

air conditionirrg.

Electrostatic Air Cleaner traps up to 95% of air-bome

dust, bacteria-size particles, smoke, odors and 99%

pollen. This optional accessory may be installed with

furnace or added later.

Fan and Limit Control with helcx element

automatically controls blower and burner operation.

Blower is capaci^ matched to heating components and

quietly circulates air throughout system.

Typical Installations

steel Cabinet is accoustically and ihermaOy

insulated for quieter operation and minimum heat

loss.

Fan and Limit Control with helex element

automatically controls blower and burner

operation.

Heat Exchanger provides more heating surface

for efficiency.

Motor has resilient base mounting for both

heating or cooling applications.

Blower is centrifugal type, dynamically balanced

and mounted on rubber grommets for quieter

operation.

Burner is designed for super-quiet efficiency.

Page 5

Cooling Section

This cooling section in a typical split-system application is the

indoor evaporator coil. This coil is located in the supply plenum of

the furnace. Stated simply, cool refrigerant is pumped through the

evaporator coil by the cooling unit. The refrigerant in the

evaporator coil removes heat from the air, and the furnace blower

distributes this cool air to the conditioned spaces.

Blower

The device which moves the treated air to points throughout the

home is called the blower, The blower consists of a wheel with air

scoops sometimes called a scroll and a motor to drive the wheel.

There are two types of blowers; a belt drive and a direct drive.

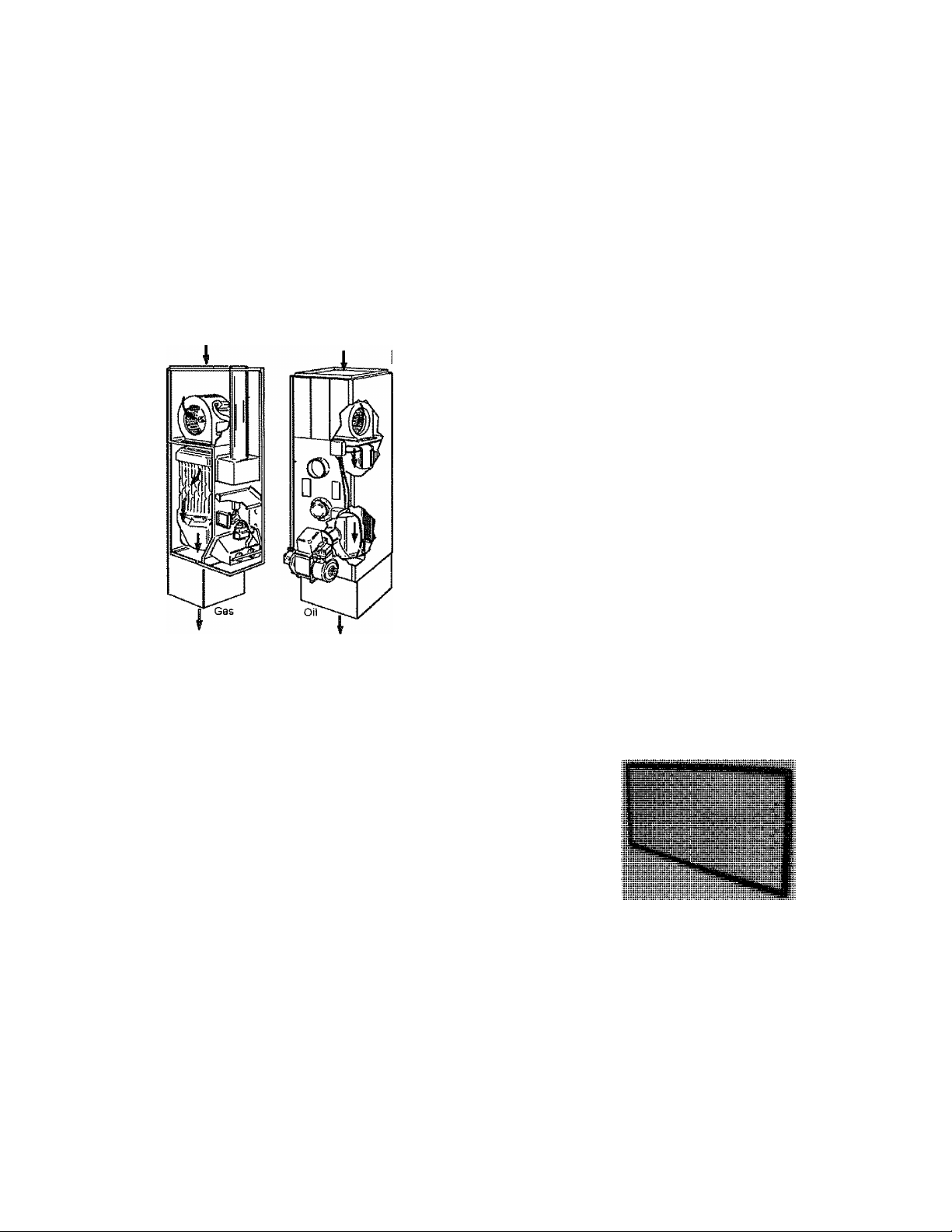

Illustrated here are typical gas-fired and oil-burning

counterllow furnaces.

Belt Drive Blower

A belt runs from a pulley mounted on the motor to a pulley

mounted on the blower wheel, All moving parts are anchored on a

rigid U-ffame, which in turn is fastened on resilient mountings to

the furnace. The design of this frame insures easy adjustment and

alignment of pulleys and belts for optimum performance. Varying

amounts of air can be moved by a belt drive blower, depending

upon the motor pulley size adjustment (see diagram). The pulley

can be made larger by screwing one side of the pulley inward

toward the other side; this causes the blower wheel to rotate faster.

Screwing one side outward from the other side reduces the pulley's

effective circumference, which in turn reduces the speed of the

blower wheel. If volumes of air are desired, which caimot be

obtained by motor pulley adjustment, the motor or blower pulleys

themselves can be changed,

NOTE: A larger pulley might also necessitate a larger motor.

Direct Drive Blower

The direct drive blower motor is mounted inside the blower and is

directly linked to the blower wheel. Air volume changes are made

by electrically varying the speed of the motor. The speed in direct

drive blowers is changed depending upon which of several wire

leads (speed taps) coming from the motor are used. Usually two to

five speeds can be obtained by wiring the hot wire to the desired

speed tap lead and the neutral wire to the common motor lead. The

unused hot wire leads must be taped separately to prevent coming

in contact with an electrical ground. The rotating motor produces a

back voltage (emO of approximately 200 vac through

electromagnetic induction.

WARNING

A

Use caution when handling these leads with 200 vac

electrical potential. If not taped, they could cause arcing

to ground, shorts or serious electrical shocks.

Filter

A filter is the device in a forced air heating or cooling unit which

mechanically screens out dust, dirt, lint and other impurities from

the Systran's airstream.

The filter is usually located just upstream from the blower, in the

return air side of the system. A fiberglass media commonly acts as

the screen, cleaning the air before it is recirculated throughout the

system by the blower.

A dirty filter greatly reduces the system's airflow, which greatly

reduces the operating efficiency of the heating or cooling unit. For

this reason, The homeowner should be instructed to check the filter

monthly and clean or replace it if necessary. (Never reuse a dirty

filter by turning it bottomside up; this will result in the collected

dirt being dumped back into the airstream.)

Two types of filters are the disposable and the permanent. Most

slab filters are disposable, consisting of rectangular fiberglass

screen in a cardboard frame. These come in a variety of sizes to fit

completely across the airstream. Arrows marked on the frame

indicate correct placement with respect to system airflow. When

the filter becomes dirty, it should simply be removed and a new one

put in its place. A nondisposable slab filter uses a polyurethane

media encased in a metal frame. When this filter becomes dirty, the

media may be cleaned (washed or vacuumed) and reused.

Thermostat

The thermostat is a heat sensitive switch that serves as the

automatic control center for heating and cooling system operation.

Since the thermostat was discussed in detail in a previous manual,

its story will not be repeated here. The student should review the

manual on thermostats if necessary.

Page 6

Electrical System Components

Furnace Circuits

All circuits within the oil firmaces are designed and wired in

accordance with Underwriters Laboratories’ requirements. They

have been inspected and tested at the factory to qualify for the UL

label which is attached to the furnace.

All circuits within the gas firmace are designed and wired in

accordance with American Gas Association requirements. They

have been inspected and tested at the factory to qualify for the

AGA Label which is attached to the furnace.

Black

White

Fused switch box

All switching within the furnace line voltage circuits is done in the

hot 120V leg. The reason is that switching, if done in the ground

leg, could result in an unsafe grounding fault. See diagram.

Switch open, furnace

does not run, fuse blows_

when switch closes

Short to

ground

X

To

Gi|(-

Switch in hot leg

Right

Wrong

Switch in ground leg

furnace.

connected electrically. These variations and the reasons for each are

discussed in Manual 2100-058, “Basic Electricity.”

The type and size of blower motor installed in a fiimace depends

upon flie blower load required to deliver the correct amount of air to

the heating system. Because the heating system varies from one

installation to another, the blower speed needs to be adjustable to

match the needs of the air distribution system. This speed

adjustment may be done either mechanically or electrically.

The motor may be connected to the blower by a belt and pulley. In

this case, the speed adjustment is accomplished mechanically by a

change in the pulleys. This is referred to as a “belt-drive blower.”

Or the blower wheel may be mounted directly on the motor shaft.

In this case, the motor speed must be changed electrically. This is

referred to as a “direct-drive blower,”

To

G.||-

Switch open

furnace runs

fuse does not blow

furnace

ground

The first load in all forced warm air systems is the blower motor

which is always line voltage. Therefore, the fiimace blower motor

is the first electrical component wired into the system.

Now when the disconnect switch lever is closed to the “on”

position, this will make a complete circuit and energize the

blower motor. This motor, in turn, drives the blower which

delivers the air through the furnace and duct system. When

the lever is placed in the “off” position, the circuit is not complete

and the blower motor will not run. Airflow in the system will stop.

The fuse in the switch is placed there to monitor the amount of

current flow in the circuit. If there should be excessive current

flowing in the circuit, the fuse will bum out and open the circuit.

Blower Motors

At this point, the blower motor has been wired into the circuit. This

is the basic circuit shown in the wiring diagrams. However, there

are variations in the blower motors used and the way they are

Fan Control Switch

One of the major controls in the line voltage circuit will be the fan

control. The fan control switch is a heat-actuated switch which is

equipped with normally open contacts. It contains a bi-metal type

of heat sensing probe which senses the temperature of the air

passing from the furnace into the system.

The furnace illustration shows the location of the fan control in an

upflow type fiimace. The probe is usually a “spiral” type and is

installed into the heating unit on the front side of the cabinet with

the bimetal probe inserted through the cabinet into the heat

exchanger portion of the furnace. Its position must be such that the

bimetal probe can sense the temperature of the air passing from the

Page 7

heat exchanger. When this temperature reaches a predetermined

point, the bi-metal closes the normally open contacts thus making a

complete circuit, starting the blower motor.

Internal view of L4064, showing use of screwdriver to connect

to disconnect wires at push-in terminals, NOTE: Because the

dial turns when the eiement temperature changes, the lettering

on the dial may not be horizontal

There are basically two types of fan controls. One is called a

combination control. See illustration. The fan control portion is

provided with two adjustable levers—one to set the blower

“on” temperature and the other to set the blower “off” temperature.

The “break” or “off” point on the switch can be field set and

should usually be set about 25“ below the make point. If the switch

is set well below return air or room temperature during the normal

heating season, continuous blower operation would be

accomplished.

The difference between the fan "on” and “off” points is called the

fan control differential. The temperature difference between these

two points may be set from 15 to 25“. If the differential is set too

low, the control will cycle because of slight temperature

fluctuations. This causes undesirable fan cycling. If set at more

than 25“, the blower would have to wait too long before coming

“on” increasing the heat loss fi'om the furnace and reducing the

furnace efficiency.

The other type is the single fan control. It has just one adjustable

lever by which the desired blower “off” temperature is set. This is

a fixed differential control with a built-in differential of 25“ F,

Therefore, the blower “on” temperature will always be 25“ F higher

than the blower “off” dial setting.

Note that if the homeowner desires to have continuous air

circulation (CAC), it will be necessary to set the open or

break point below the normal return air temperature. In this

way, the air passing over the heat exchanger will remain above the

setting even though the burners are off and the blower will continue

to run.

Fan contro! switch*

upfiow, highboy furnaces.

The settings of the fan control are normally field adjusted according

to the desires of the homeowner and the “on” or “make” point is

usually somewhere around 100“. This means that when the air

passing over the heat exchanger reaches approximately 100“, the

switch will “make” and the fan will come on, delivering air to

the space.

Combination fan and limit control

Fan (on)

25^ Differential setting

Downflow and Horizontal Units

Downflow and horizontal units present a little different problem

than the upflow units. The fan control probe location in a downflow

imit will work fine on the “make” or “on” cycle, because the fan

would not be running and the heat exchanger would rise through

the heat exchanger actuating the probe. However, once the fan is

Page 8

running, the air is flowing in the opposite direction from the probe

and when the burners would go off, the probe would sense the cool

return air rather than the heat in the heat exchanger. This would

fool the probe into thinking that the heat exchanger had cooled

down and could actuate the contacts to their normal position,

cycling the fan off too soon. Once off, it would sense the residual

heat in tlie heat exchanger being transferred to the air around it and

again, actuate the contacts energizing the blower and cycling it

until the heat exchanger has been cooled sufficiently,

The same type of problem would be true for a horizontal type

furnace, since it would not be possible to locate the blower

control in an ideal position for both the “make” and “break”

actions.

Limit Control

A safety device is connected into the line voltage circuit next. It is

called a limit control. The purpose for this “limit” is to turn off the

burner and control circuits if the air temperature becomes too high.

Some limit controls are combined with the fan control. See

photograph. In this case, one bimetal actuates both the fan

control switch and the limit control switch. As the temperature

rises, the bimetal will first turn on the fan switch and start the

blower. If a condition exists which causes overheating, the bimetal

will continue to warp or turn until the limit cutout temperature is

reached and it trips the limit switch.

The limit switch in the combination control is provided with an

adjustable lever. A step is installed which will not allow the lever

to be set above the safe cutout temperature—usually 200° F. The

lever should not be adjusted below this high limit temperature

since it will cause false or nuisance burner cycling.

The limit control prevents overheating of the furnace which could

cause a fire or damage to the fiimace components. It shuts off the

burner if conditions or failure should occur such as blower failure,

dirty air filter, blockage of the duct system or any condition which

abnormally restricts air flow through the fiimace.

The limit control is actuated by a bimetal element in the discharge

air stream. Therefore, it monitors the air temperature leaving the

heat exchanger. The bimetal is linked to a normally closed switch

which has an SPST action. If the air temperature rises to the limit

cutout temperature, the bimetal opens the switch and breaks the

line voltage circuit to the burner and controls.

Limit Control

Pictorial symbol

On most furnaces, the limit control is calibrated to shut off the

burner if the discharge air temperature reaches or exceeds 200° F.

The limit control will automatically recycle (reclose its contacts)

when the temperature drops 25° below the cutout point. Therefore,

the limit control will recycle the burner if the thermostat is calling

for heat, but will not allow the temperature to exceed 200° F.

The limit cutout temperature is factory set and the differential is

built into the switch. Neither should be readjusted or changed in

the field. Otherwise the equipment warranty will be voided and a

hazardous condition will be created.

Another common limit control is illustrated. This limit has its own

bimetal element and is located at a different point on the furnace

than the fan control. It acts the same as the combination limit but

does not have a dial setting. It is a fixed setting and fixed

differential control. Again the setting is usually 200° F and the

differential is 25° F. These are set and sealed by the control

manufacturer.

Upper Limit Control

As was outlined imder the discussion of the fan control, for

downflow and horizontal heating imits, an additional limit

control is used. This upper limit is installed in the blower

outlet or between the blower outlet and the heating section,

or very near the blower section of the imit.

The reason is that the high temperature limit is at the discharge end

of the heat exchanger. Before the blower comes on, the warm air

rises away from this high limit preventing it from sensing the

temperature and providing the protection needed, During this

period, the upper limit provides backup protection by sensing the

heated air that rises upward in the unit by gravity.

This upper limit control provides protection in case of blower

failure or excessive restriction in the system which prevents the

movement of air. Usually the limit cutout temperature is 140° F

with a differential of 25° F.

The switch in the upper limit control is an SPDT action. The

normally closed contacts are located in series ahead of the

high limit contacts in the electrical circuit. Therefore, if either

limit is “open” the burner and control circuits become deenergized.

The upper limit does one other thing. When the limit contacts are

open, the other normally open contacts then close. This completes a

circuit directly to the blower motor starting the blower.

There are several reasons for this feature. One is to put the upper

limit back in step if it should trip open from residual heat after the

fan control has turned the blower off. It simply overrides the fan

control to provide cool air on its own elements. When the limit

contacts reclose the blower contacts open, shutting off the blower.

A second reason is to back up the fan control timer if it should fail

to operate as it should.

Page 9

A third reason is that the upper limit control de-energizes the

control circuit. Under some circumstances, this secondary limit

could be open up to one hour preventing the control circuit from

operating the fan timer or burner circuits. For the thermostat to do

its job and get the furnace back in operation, power must be

provided to the control circuit.

Additive Cooling Relay

NOTE: When cooling is added to a standard furnace, an

additive cooling relay is required.

The line voltage side of this relay has a set of contacts which

bypass the fan control, delivering power directly to the blower

motor. The contacts are pulled in by a low voltage coil which

is energized on a call for cooling from the thermostat or if the

thermostat fan switch is set for constant blower operation. Note

that electrically both the 24 V and 120 V circuits are completely

independent, but one controls the other by pulling in its contacts.

The blower relay is necessary because on cooling, the temperature

of the air being circulated through the system would be below the

set point of the fan control and this would shut off and not allow

the blower to run. Under cooling without the blower running, the

evaporator coil would ice up and the condensing unit would go off

on its limit control.

The transformer must be sized to handle the current (amperage)

requirement of the load or loads connected to the secondary side of

the transformer. The transformer select may be

requirement, but the transformer can never be smaller than the load

requirement (amp-draw). Short circuit protection for the 24V side

of the transformer is provided in some cases by a replaceable fuse

and in others as fusible link. The fusible link is built in and

requires replacement of the entire transformer if it bums out.

larger than the load

Additive

coDling relay

24 Volt or Low Voltage Control Circuit

In almost all residential forced warm air heating systems, the

control circuits are powered with low voltage (24 volts). There

are several reasons for using low voltage: ease of installation, lower

installation cost, closer (better) temperature control and less

possibility of electrical shocks.

Transformer

In order to supply 24 volt power in control circuits, a “step-down”

transformer is used. Tlie line side is wired directly into the 115V

power supply.

Basically a transformer consists of two coils of insulated wire

wound on a common iron core. The coil connected to the line

voltage or input side is the primary coil and the output or load side

is always the secondary. If the voltage on the line side is greater

than that on the load side, it is a “stepdown” transformer. If the

voltage on the load side is greater than the line side, it is a “setup”

transformer. Therefore, to supply 24V on the load side from 115V

line, a stepdown transformer is used.

Transformers are always rated in volt amperes (VA), which is the

amount of electrical power (volts x amps) it can supply.

Thermostat

The first load that will be attached to the low voltage circuit is the

thermostat. Basic operation of the thermostat and its internal

wiring has been discussed in a previous manual, and here the

common leg will be connected to one side of the transformer and

the fan and heating circuits will be connected to the other side of

the transformer. The thermostat can now control the fan circuit

independently from the heating and cooling circuits.

Basic Maintenance Procedures

Regularly scheduled basic maintenance calls are mutually

beneficial to both the service firm and the homeowner/customer.

Normally, this involves two maintenance calls per year—one in the

fall prior to the heating season and one in the spring prior to the

cooling season.

Maintenance Check Sheet

A maintenance check sheet has been developed which has

checklists for residential gas, oil and electric heating units and

cooling systems and accessories. The check sheet had checklists

Page 10

Maintenance Checksheet

Dealer

___

_________________________________________

Customer

Date

Equipment Make & Models

Notes

________

Pre-Service Check

n Customer satisfied with system performance

□ Customer dissatisfied with system performance.

Thermostat Checks

□ Record thermostat settings: Temp.;

Mode: HEAT OFF COOL FAN ON AUTO

□ Check terminal connections for tightness

n Clean bimetal. Inspect mercury switch

n Check thermostat for level

□ Check control circuit amperage;________________

D If customer dissatisfied with temperature control in heating season, adjust

anticipator to match control circuit amp draw

□ Initiate appropriate seasonal demand from thermostat

Blower Compartment Checks

n Check supply voltage at junction box; _

□ Check blower motor amperage;

□ Turn power at unit main disconnect to OFF

n Check alt wiring for loose connections and bad insulation

______

D Clean or change filter

Direct Drive Blower

n Check blower bearings

□ Lubricate blower bearings

□ Clean blower and compartment

□ Check blower wheel for free and balanced rotation

D Check all blower housing mounts and setscrews for tightness

□ Unused motor leads taped and out of way

Beit Drive Blower

n Remove biower belt and check for wear

□ Check motor bearings for wear

□ Lubricate motor bearings

□ Check blower wheel bearings for wear

n Lubricate biower wheel bearings

n Clean blower and compartment

D Check blower wheel for free and balanced rotation

□ Check pulley alignment

□ Check motor and blower pulley setscrews for tightness

D Put belt back on blower and motor pulley and check belt tension

□ Check all biower housing and motor mounts for tightness

Person

_____________

_________

nameplate rating

______

time

Address

Address

____

Time Out

dcmv closed circuit _

_______________

“F

Time In

Standing Pilot

□ Check pilot flame

□ Check thermocouple open circuit

□ Check pilot valve safety drop>aut time _

□ Check automatic vent damper system

□ Check iimit safety

□ Check temperature rise

□ Gas manifold hand valve is open before leaving

_________________

Oil

□ Check electrical wiring — connections and insulation

n Inspect combustion chamber

D inspect for soot in heat exchanger

□ Change fuel oil tank for sludge/watar

□ Change oil line filter

□ Check oil lines

D Service oil burner

□ Conduct combustion efficiency test:

__________

□ Check iimit safety

□ Check temperature rise

D Check primary control

□ Check furnace vent for rust

in.w,c, smoke

_______________

% C02.

Cooling

□ Check electrical wiring — connections and insulation (indoor)

G Check/clean evaporator coil

D Check/clean condensation drain

□ Check static pressure drop

□ Check wiring — connections and insulation (outdoor)

□ Check/clean condenser coil

□ Lubricate condenser fan motor

D Check line set and connections for evidence of leaks

□ Check and record supply voltage

□ Check refrigerant charge

□ Check amperage draw on condenser fan motor

□ Check amperage draw on compressor

___________

in. w.c.

_________

Humidifier

□ Check electrical wiring — connections and insulation

□ Check transformer voltage

□ Check damper position

_____________________

dcmv

min.

°F net

_cfm (dry coil)

Heating Section Checks

Electric

□ Check electrical wiring — connections and insulation

□ Check amperage draw of each element

□ Check total amperage draw of elements

□ Check temperature rise

n Return outdoor thermostats to original settings if present

________________________

___________

Gas

□ Check ail electrical wiring for loose connections and damaged insulation

D Check burners for lint, dust and scale

□ Check for cracks in heat exchanger

G Check furnace vent for size and deterioration

□ Check for quiet, even burner ignition

□ Check supply line gas pressure NAT

D Check manifold gas pressure NAT

Electronic Ignition Control

□ Check electronic ignition control sequence of operation

D Check safety lockout

n Check pressure switch

____________________

_____________________

________

________

in. w.c, LP____________in. w.c.

in. w.c. LP

min.

____________

amps

F

in. w.c.

Spray Type

□ Check solenoid valve

□ Check nozzle spray pattern

Drum Type

□ Check for free rotation and scale

□ Check wafer level adjustment

□ Check overflow/drain line

Electronic Air Cleaner

□ Check electrical wiring — connections and insulation

G Check sail switch or electrical biower interlock

□ Cheekiest button operation

□ Check supply voltage

□ Check voltage to collecting ptates

□ Check voltage to ionization wires_

GTURN power OFF

D Wash cells

□ Wash prefilter screens

_________________________

_ vac (120 vac)

vdc (3500 vdc)

^ vdc (8000 vdc)

Post-Service Checks

G Return thermostat to original settings recorded at beginning of service call

G Leave copy of completed checksheef wHh customer

□ Power ON before leaving

FI 385-895

Page 11

which itemize the basic maintenance steps and assist in organizing

the service tasks to be performed.

It is suggested the service person attach the check sheet to a

clipboard and cany it to the service call. Filing in the checklists

while proceeding with the call will ensure that all the necessary

checks are performed efficiently. The check sheet should be

completed in duplicate. One copy is for the customer. The check

sheet folder copy is for the firm’s reference file.

The check sheet also has other potential uses. For example, listing

the make and model of the equipment gives the firm quick

reference for service and parts information. And by analyzing “time

in and out”, the firm can accumulate labor cost data on its planned

service operation. It is a valuable sales tool for add-on and

replacement and accessory business. Service personnel should

always keep this important aspect in mind. Tips that generate sales

will help you and your company grow. The maintenance sheet is a

convenient means to document this information.

The checks corrunon to all heating and cooling units, namely those

at the thermostat, blower and filter, will now be covered.

□ Check terminal connections for tightness.

1, Remove thermostat cover,

2, Tighten terminal connections if necessary.

□ Clean bimetal.

1. Carefully remove dust and dirt from bimetal with soft brush

or by blowing on it.

2. Inspect the mercury switch for cracks in the glass bulb and

brush away any accumulated dust. If mercury switch is

damaged, discuss problem with homeowner and notify

sales manager.

□ Check thermostat for level.

1. Place level on thermostat and adjust thermostat position if

not perfectly level. A level thermostat is a necessity for

precise temperature control.

□ Check control circuit amperage_

1. Single-stage heating or cooling thermostat. Connect one clip

of 10 loop amperage multiplier to “power from transformer”

thermostat terminal; coimect other multiplier clip to

“heating” thermostat terminal if checking heating system or

“cooling” terminal if checking cooling system; snap amprobe

just around multiplier coil and record actual amperage draw

(move decimal point of amprobe reading one place to the left

to obtain actual amp draw, i.e. 4.5 reading ~ .45 actual amp

draw).

_amps.

Pre-Service Check

□ Customer satisfied with system performance.

□ Customer dissatisfied with system performance.

1. The planned service appointment should be scheduled in

advance so that arrangements can be made to gain access to

the comfort equipment.

2. Prior to beginning the maintenance checks, the service person

should ask the customer how the system is performing. This

will help get a reading on current system operation and

pinpoint possible problems to investigate and correct.

3. If the customer indicates satisfaction with the system

operation, the service person can concentrate on the routine

maintenance checks.

Thermostat

Record thermostat settings:

Temp

__________

□ Cool Fan switch:

1. Recording these settings will enable service personnel to

reset thermostat to customer’s desires at end of service call.

2, Some electric units may also employ an outdoor thermostat

for multiple staging of heat elements (see Electric Heat

Section). Record outdoor thermostat setting.

°F Mode:

□ Heat □ Off

□ On □ Auto

2. With two-stage heating thermostat. Check first stage circuit

amperage using method outlined above for single thermostat.

To check second stage circuit amperage, attach one jumper

wire clip to power terminal and other clip to “first stage heat”

terminals; attach one amperage multiplier clip to “power”

terminal; connect other multiplier clip to the “second stage

heating” thermostat terminal; record actual amperage draw

(by adjusting reading one decimal to tlie left).

□ If customer is dissatisfied with temperature control in heating

season, adjust heat anticipator setting to match control circuit

amp draw reading.

1. If customer is satisfied with temperature control, do not

adjust anticipator and proceed with next service check.

2, If during the heating season the customer complains of being

too hot even after the furnace has cycled off, the heat

anticipator setting should be adjusted to shorten the fiomace’s

“on” cycle; if the customer is too cool, the anticipator should

be adjusted to lengthen the “on” cycle. The cooling

anticipator is usually nonadjuslable. Review the thermostat

manual details on anticipator adjustment.

Page 12

□ initiate appropriate seasonal demand from the thermostat

with fan switch on auto; □ Heat □ Cool

1. if making heating unit checks, demand is created by turning

thermostat to highest setting with mode switch on heat.

2. if making cooling system checks, demand is created by

turning thermostat to lowest setting with mode switch on

coo!.

3. if the electric frimace employs an outdoor thermostat for

staging of heat elements, set the dial at its highest setting to

initiate a multiple stage demand. Return dial to original set

points before leaving the site.

Blower Compartment Check

□ Check supply voltage at unit junction box.

__________

1, Remove access doors on front of unit,

2, Set volt-ohm meter above 120 vac,

3, Attach volt-ohm meter probes to incoming line voltage and

neutral wires in junction box.

□ Check blower motor amperate^

1. Snap amprobe around neutral or common wire leading to the

blower motor.

vac

_______________

_^Nameplate A rating

time

A.

3. Compare amp reading with amp rating on motor nameplate.

An excessive amp draw reading is a clue the motor is

working too hard. Possible causes:

Extremely dirty motor prevents air from dissipating heat

and motor runs hot. Seized or worn bearings cause excess

pull or drag; motor (and/or pulley on belt drive blowers)

improperly sized in relation to blower wheel. Poorly

designed system application.

if following service checks do not alleviate high

motor amperage, refer problem to residential equipment

troubleshooter or service manager.

4, Remove blower compartment door.

□ Turn power at unit main disconnect to off.

□ Check all wiring for loose connections and bad insulation.

I, Tighten loose connections. Wrap electrical tape around wires

with cracked or worn insulation.

□ Clean or change filter.

NOTE: See unit installation instructions for removing filters from

downflow furnaces.

Nondisposable Slab (Polyurethane)

1. Remove filter from unit.

2. Remove media from frame.

3. Wash or vacuum media.

4. If media is washed, use hot water and detergent,

5. Squeeze water from media, put in frame and coat side of

media opposite the blower with a filter spray (the oil spray

enhances collection of dirt particles).

6. Place filter back into unit.

Disposable Slab (Fiberglass/Cardboard)

1. Remove filter from unit.

2. Wrap in newspaper and discard.

3. Place new filter of same size in unit. Make sure filter is

placed so that arrows on filter frame agree with system

airflow, if applicable.

Direct Drive Blower

WARNING

A

Be sure power to furnace is off.

2, In order to stimulate the tme operating condition, put blower

compartment door in place. Leave a small opening to allow

for reading the amprobe.

10

Page 13

Cutoff plate

1. Spin wheel. If wheel is badly out of balance or hits against

housing, blower should be replaced. Notify service manager.

2. If dislodged balance weights are found, place them in exact

location they formerly occupied. Look for scratches on blades

to show where weight clip was attached.

When wheel is spun, the heavier side will fall to bottom. This

means the side minus the weight is probably on top. If the

old location cannot be found, leave weights off rather than

risk further imbalance by inconect placement,

Direct drive biovrer showing cutoff piate

□ Check blower motor bearings.

1. Grasp blower wheel and move in back and forth and up and

down directions.

2. There should be no more than 1/8 inch back and forth

movement. There should not be any up and down movement,

3. if there is movement, bearings are wearing. Service person

should inform customer of bearing condition. If problem is

severe, blower motor should be replaced. Notify service

manager.

□ Lubricate blower motor bearings.

1. Check motor for service instructions and lubrication instructions

in xmit installation instruction manual,

2. Prelubricated motor bearings with oil ports require a few drops

of SAE No. 10 nondetergent oil every two years.

A

□ Clean blower compartment.

A

NOTE: It is necessary to remove cutoff plate when removing

□ Check blower wheel for free and balanced rotation.

CAUTION

Do not over lubricate motor bearings. Excessive oil

attracts dust and dirt.

CAUTION

Do not dislodge balanee weights attached to blower

wheel blades.

Balance weight clip

1. Remove dust and dirt for air scoops or vanes of blower

wheel. This may be done with moist rag or vacuum.

2. if blower is exeessively dirty, it should be removed from unit

and thoroughly washed/eleaned using high pressure hose.

Remove motor from blower assembly when washing blower.

Make sure motor is completely dry before it is put back

into operation.

motor. Be sure to replaee plate before replacing

motor to ensure proper airflow.

3. If blower was removed for cleaning, reinstall at this time.

□ Check all blower housing mounts and setscrews for tightness.

□ Check that unused motor leads are taped and out of the way.

Belt Drive Motor

WARNING

A

Be sure power to hamace is off.

□ Remove belt and check for wear.

1. Loosen motor mount and push motor toward blower wheel.

2. Remove belt by sliding it off the pulleys,

3. Check for wear by turning belt inside out and looking for

splits and cracks in the rubber.

4. Replace belt if there are signs of wear. (Leave belt off to

perform the following checks. You will be instructed when to

put it back on.)

□ Check motor bearings for wear.

1. Grasp motor pulley,

2. Push pulley in inward and outward directions. Assuming the

pulley is mounted tightly to the motor shaft or drive, there

should be no more than 1/8 inch movement or play in

either direction.

3. Move pulley in up and down directions. There should be no

movement in either direction.

4. If there is movement in motor shaft, bearings are wearing.

Service person should inform eustomer of bearing condition.

If problem is severe, motor should be replaced. Notify

serviee manager.

□ Lubricate motor bearings.

1. Check motor for service instructions and lubrication

instruction in unit installation manual.

2. Prelubricated bearings require a few drops of SAE No. 10

nondetergent oil every two years.

CAUTION

A

Do not over lubricate motor bearings. Excessive

lubrieation attracts dirt and dust. Oil splash on the belt

eauses shortened belt life.

11

Page 14

3. Motor bearings with oil cups or holes. Add a few drops of

automotive 10 nondetergent oil.

□ Check blower wheel bearings for wear.

1. Grasp blower pulley and move in up and down directions.

Also push in and out. There should be no movement in any

direction if the pulley is mounted tightly to the blower shaft.

2. Grasp shaft and test bearings on opposite side of blower

wheel. There should be no movement.

3. If there is in and out movement on either side, move locking

collars on the affected side closer to bearing as follows:

On the pulley side, loosen set screw on shaft and

remove pulley.

Loosen collar set screw and move collar snugly against

bearing housing. Tighten collar setscrew.

2. If grooves of pulleys do not line up, loosen shaft setscrew and

move motor pulley until it is aligned with blower pulley,

3. Tighten motor pulley setscrew and recheck alignment.

□ Check motor and blower pulley setscrews for tightness.

An adjustable motor pulley has two setscrews, one to tighten

the adjustable pulley sheave and one to tighten the pulley to

the motor shaft.

Set screw to tighten

pulley on motor shaft

Set screw to tighten

adjustable sheave

4. If there is still movement, bearings are worn. Inform

customer of bearing condition. If problem is severe, blower

bearings should be replaced. Notify service manager.

□ Lubricate blower wheel bearings.

1. Bearings with no lubricant fittings. These are permanently

sealed and lubricated and require no service.

2. Bearings with grease cups, Turn grease cup down

approximately one turn yearly. When cups are turned to the

bottom, refill with lubricant.

Bearings with grease plugs. These are normally prelubricated

and require lubrication about every two years. If lubricant is

required, use No. 2 neutral mineral grease. Check lubrication

instruction.

□ Clean blower and compartment.

1. Remove dirt from air scoops or vanes of blower wheel. This

may be done with moist rag or vacuum.

2. If blower is excessively dirty, it should be removed and

thoroughly washed/cleaned using high pressure hose.

Remove motor from blower assembly before washing blower.

Make sure motor is completely dry before it is put back into

operation.

□ Check blower wheel for free and balanced rotation.

1. Spin wheel. If wheel is badly out of balance or hits against

housing, blower should be replaced.

2. If dislodged balance weights are found, place them in exact

location they formerly occupied. Look for scratches on blades

to show where weight clip was attached.

□ Put belt back on blower and motor pulleys and check

belt tension.

1. Place belt around pulleys.

2. Adjust motor mount to tighten belt.

3. Check tension by pushing down on belt halfway between

pulleys. Belt should move or deflect from 3/4" to 1".

4. When proper tension is obtained, tighten adjustable motor

mount.

□ Check all blower housing and motor mounts for tightness.

Post-Service Checks

□ Return theimostat(s) to original setting(s) recorded at beginning

of service call,

□ Leave copy of completed check sheet with customer.

□ Power on before leaving.

1. Be sure unit disconnect has been turned on before leaving to

avoid a needless, time consuming callback.

□ Leave all service areas neat and clean.

When wheel is spun, the heavier side will fall to bottom, This

means the side minus the weight is probably on top. If old

location cannot be found, leave weights off rather than risk

further imbalance by incorrect placement,

3. If blower was removed from unit for cleaning, reinstall at

this time.

□ Check pulley alignment,

1, Cheek alignment by placing a straight rod across grooves of

the motor and blower pulleys.

12

Heat Section Checks

These are discussed individually, according to type of fuel used, in

the next sections.

Page 15

1. CoH

2. Flue connection

3. Cabinet

4. Heat exchanger

5. Gas valves & controls

6. Gas burner & manifold

7. Blower

8. Electronic air cleaner

With properly designed systems, add-on equipment and

components will increase the degree of comfort produced

for the homeowner.

Coil

Illustrated here are typical gas-fired and oil-burning horizontal furnaces.

13

Loading...

Loading...