Page 1

FLM series

Service manual

R59770072/00

19/03/2007

Page 2

Barco nv Events

aan 5, B-8520 Kuurne

Noordl

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

sales.events@barco.com

E-mail:

Visit us at the web: www.barco.com

PrintedinBelgium

Page 3

Table of contents

TABLE OF CONTENTS

1. Safety ................................................................................................................ 5

1.1 Safety Instructions.................................................................................................................... 6

2. General info ......................................................................................................... 9

2.1 Locationof modules.................................................................................................................10

2.2 Spare part kits....................................................................................................................... 13

3. Troubleshooting...................................................................................................15

3.1 1000 → 1017 : Lamp parameters related errors . . .................................................................................16

3.2 1692 → 1699 : Formatter related errors ............................................................................................17

3.3 2000 → 2808 : Lamp Power Supply (LPS) related errors . . . ...................................................................... 21

3.4 4000 : Incompatible hardware error ................................................................................................26

3.5 4198 : Pixel map related error . . ....................................................................................................27

3.6 5095 → 5098 : Flash memory related errors . . .....................................................................................28

3.7 7658 → 7999 : Temperature, fan & motor related errors ... ....................................................................... 29

3.8 8000 → 8001: Shutter related errors . ..............................................................................................55

3.9 8002 : Lamp EEPROM error .. . . .................................................................................................... 56

3.10 9198 → 9398: CPU related errors ..................................................................................................57

3.11 10498 : Input module related error . ................................................................................................58

4. About lenses .......................................................................................................59

4.1 Available lenses .....................................................................................................................60

4.2 Lens selection . . . ....................................................................................................................61

4.3 Lens formulas for FLM R20+ ........................................................................................................ 62

4.4 Lens formulas for FLM HD projectors. . . ............................................................................................63

4.5 Lens installation . . ...................................................................................................................64

4.6 Lens removal . .......................................................................................................................66

5. Carrying handle....................................................................................................67

5.1 Replacementof the bottom carrying handle........................................................................................ 68

5.2 Installing the carrying handle on top of the projector . . .............................................................................69

6. Removal and installation of projector covers................................................................71

6.1 Removalofthe front cover.......................................................................................................... 72

6.2 Removalofthe side cover...........................................................................................................73

6.3 Removalofthe lamp cover.......................................................................................................... 74

6.4 Removalofthe input cover..........................................................................................................75

6.5 Removalofthe back cover.......................................................................................................... 76

6.6 Removalofthe top cover............................................................................................................ 77

6.7 Installationof thetop cover..........................................................................................................78

6.8 Installationof thebackcover........................................................................................................79

6.9 Installationof thefrontcover........................................................................................................80

6.10 Installation of the sidecover ........................................................................................................81

6.11 Installation ofthe lamp cover........................................................................................................ 82

6.12 Installation of the input cover. . . .....................................................................................................83

7. Dust filters..........................................................................................................85

7.1 Replacementof the dust filter on the frontside .................................................................................... 86

7.2 Replacementof the dust filter on the bottom side..................................................................................87

7.3 Replacementof the dust filter on the top side......................................................................................88

8. Lamp and lamp house............................................................................................89

8.1 Removal of the lamp house ..... .................................................................................................... 90

8.2 Installationof thelamphouse .......................................................................................................91

8.3 Realignmentofthe lamp inits reflector.............................................................................................93

9. Input & communication unit.....................................................................................95

9.1 Removalofthe input & communication unit........................................................................................ 96

9.2 Installation of the input & communication unit ...................................................................................... 97

9.3 Removal of an input module . . . .....................................................................................................98

9.4 Installation of an input module . . ....................................................................................................99

10. Light processor + light pipe assembly ...................................................................... 101

10.1 Diagnostics .........................................................................................................................102

10.2 Removalof thelightprocessor.....................................................................................................103

10.3 Installing the light processor .......................................................................................................106

11. Integration rod................................................................................................... 109

11.1 Rod diagnostic ......................................................................................................................111

11.2 Removal of the integrationrod assembly..........................................................................................112

11.3 Installinganew integration rod assembly .........................................................................................113

11.4 Adjusting theintegration rod .......................................................................................................115

R59770072 FLM SERIES 19/03/2007

1

Page 4

Table of contents

12. UV filter............................................................................................................ 117

12.1 UV filter replacement...............................................................................................................118

13. Cold mirror assembly........................................................................................... 119

13.1 Diagnostic. . .........................................................................................................................120

13.2 Removalof thecold mirror assembly..............................................................................................121

13.3 Mounting thenew cold mirror + fan assembly.....................................................................................124

13.4 Adjusting thecoldmirror ...........................................................................................................127

14. Lens holder....................................................................................................... 129

14.1 Removing thelens holder..........................................................................................................130

14.2 Installing the lens holder ...........................................................................................................132

14.3 Adjusting thelensholder...........................................................................................................135

15. Vertical and Horizontal shift motors......................................................................... 139

15.1 Removing thevertical shift motor..................................................................................................140

15.2 Mounting a newverticalshift motor................................................................................................143

15.3 Removalof thehorizontal lens motor..............................................................................................146

15.4 Mounting thenew horizontal lens motor...........................................................................................149

16. FLM liquid cooling circuit...................................................................................... 153

16.1 Safety ...............................................................................................................................155

16.2 Introduction .........................................................................................................................156

16.3 Diagnostics .........................................................................................................................157

16.4 Pressure verificationof theliquid coolingcircuit...................................................................................159

16.5 Draining theliquidcooling circuit...................................................................................................160

16.6 Fillingthe liquidcooling circuit .....................................................................................................163

16.7 Refreshing the liquidcooling circuit................................................................................................167

16.8 Expelling airfromthe liquidcooling circuit.........................................................................................170

16.9 Pressurizing theliquidcooling circuit ..............................................................................................172

16.10 Calibratingthe liquidcooling circuit................................................................................................175

17. Heat exchanger .................................................................................................. 179

17.1 Removing the defective heat exchanger . . . . . .....................................................................................180

17.2 Disassembling the heat exchanger assembly . ....................................................................................182

17.3 Assembling the new heat exchanger ..............................................................................................184

17.4 Mounting the heat exchanger assembly into the projector... .....................................................................186

18. Cooling pump .................................................................................................... 189

18.1 Maintainingthe cooling pump......................................................................................................190

18.1.1 Opening thecooling pump androtormovement............................................................................191

18.1.2 Cleaning pump ...............................................................................................................192

18.1.3 Closing thepump ............................................................................................................193

18.2 Cooling pump body replacement...................................................................................................194

18.2.1 Removing the pump body ...................................................................................................195

18.2.2 Mounting the new pump body ...............................................................................................196

18.3 Coolingpumpreplacement.........................................................................................................197

18.3.1 Removing the pump .........................................................................................................198

18.3.2 Mounting the new pump . . ...................................................................................................200

19. Shutter replacement ............................................................................................ 203

19.1 Shutterreplacement................................................................................................................204

20. Formatter Interface Board ..................................................................................... 207

20.1 Removing theFIB ..................................................................................................................208

20.2 Mounting a newFIB ................................................................................................................209

21. Pixel map processor board.................................................................................... 211

21.1 Diagnostics .........................................................................................................................212

21.2 Building outthe PMP...............................................................................................................213

21.3 Mounting a newPMP board........................................................................................................216

22. LCD panelreplacement ........................................................................................ 219

22.1 Removing the LCD panel. ..........................................................................................................220

22.2 Mounting a new LCD panel . . . . . ...................................................................................................223

23. Keypad board replacement.................................................................................... 227

23.1 Removing thekeypad unit..........................................................................................................228

23.2 Mounting thenew keypad unit .....................................................................................................230

24. Fan replacements ............................................................................................... 233

24.1 Heat exchanger fan.................................................................................................................234

24.1.1 Building out the heat exchanger assembly. .................................................................................235

24.1.2 Replacing the old fanwith a new fan........................................................................................237

24.1.3 Mounting the heat exchange assembly into the projector ..................................................................238

24.2 Cold mirror fan......................................................................................................................239

24.2.1 Removal of the coldmirror fan ..............................................................................................240

24.2.2 Mounting a new cold mirror fan. . . ...........................................................................................242

2

R59770072 FLM SERIES 19/03/2007

Page 5

Table of contents

24.3 Light processorcompartment fan..................................................................................................244

24.3.1 Removeof thetop plate .....................................................................................................245

24.3.2 Removal of the axial fan.....................................................................................................246

24.3.3 Mounting a new axial fan . ...................................................................................................247

24.3.4 Mounting the top plate . ......................................................................................................248

24.4 Cathode fan replacement ..........................................................................................................249

24.4.1 Removal of the fanassembly................................................................................................250

24.4.2 Fan replacement.............................................................................................................253

24.4.3 Mounting the fan assembly ..................................................................................................254

24.5 Anode fan replacement. . ...........................................................................................................257

24.5.1 Accessto theanodefan .....................................................................................................258

24.5.2 Removing the anode fan.....................................................................................................260

24.5.3 Fan replacement.............................................................................................................262

24.5.4 Mounting the fan assembly ..................................................................................................264

24.5.5 Finalizingthe replacement...................................................................................................266

24.6 Mains input fan .....................................................................................................................267

24.6.1 Replacing the mainsinput fan...............................................................................................268

24.7 SMPS fans..........................................................................................................................270

24.7.1 Replacing the right fan.......................................................................................................271

24.7.2 Replacing the left fan ........................................................................................................273

25. Peltier replacement ............................................................................................. 275

25.1 Remove a Peltier element from the DMD..........................................................................................276

25.2 Mounting a Peltierelement onthe DMD...........................................................................................279

25.3 Remove a Peltier element on the heat pipe cooling block ........................................................................282

25.4 Mounting a Peltier element on the heat pipe cooling block . . .....................................................................284

26. Power input....................................................................................................... 287

26.1 Gettingaccess to the power elements.............................................................................................288

26.2 Mains filter replacement............................................................................................................290

26.2.1 Removing the mains filter....................................................................................................291

26.2.2 Mounting a new mains filter . . ...............................................................................................292

26.3 Mains switchreplacement..........................................................................................................293

26.3.1 Removing the mains switch .................................................................................................294

26.3.2 Mounting the new mains switch . . ...........................................................................................295

26.4 Closing the power input compartment . ...........................................................................................296

27. Lamp power supply............................................................................................. 297

27.1 LPS diagnostic LED’s ..............................................................................................................299

27.2 Removing the LPS module... . . . ...................................................................................................301

27.3 Installing the LPS module ..........................................................................................................303

28. Start pulse generator ........................................................................................... 305

28.1 Troubleshooting.....................................................................................................................306

28.2 Removal of the start pulse generator ..............................................................................................307

28.3 Installation of the start pulse generator............................................................................................309

29. Convergence adjustment ...................................................................................... 313

29.1 Action of theconvergence controls ................................................................................................314

29.2 Re-converging Green onBlue .....................................................................................................315

29.3 Readjustment of the plungers ......................................................................................................318

29.4 Re-converging Red on Blue........................................................................................................319

Glossary ............................................................................................................... 323

Index.................................................................................................................... 325

R59770072 FLM SERIES 19/03/2007 3

Page 6

Table of contents

4 R59770072 FLM SERIES 19/03/2007

Page 7

1. SAFETY

About this chapter

Read this chapter attentively. It contains important information to prevent personal injury while servicing the FLM projector. Furthermore, it includes several cautions to prevent damage to the FLM projector. Ensure that you understand and follow all safety

guidelines, safety instructions and warnings mentioned in this chapter before servicing the FLM projector. After this chapter, additional “warnings” and “cautions” are given depending on the service procedure. Read and follow these “warnings” and “cautions” as

well.

Overview

• Safety Instructions

1. Safety

R59770072 FLM SERIES 19/03/2007

5

Page 8

1. Safety

1.1 Safety Instructions

WARNING: Before Removing/Replacing any projector components, turn off the Main Power Switch and un-

plug the Main AC power cable.

Safety Instructions

1. Before returning an instrument to the customer, always make a safety check of the entire instrument, including, but not limited

to, the following items:

a) Be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1) Protective shield

are provided on this chassis to protect both the technician and the customer. Correctly replace all missing protective shields,

including any removed for servicing convenience. (2) When reinstalling the chassis and/or other assembly in the cabinet,

be sure to put back in place all protective devices, including, but not limited to, insulating materials, barriers, co

and isolation resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective

devices correctly installed and functioning. Servicers who defeat safety features or fail to perform safety checks may be

liable for any resulting damage.

b) Be sure that there are no cabinet openings through which an adult or child might be able to insert their fingers and contact a

hazardous voltage. Such openings include, but are not limited to, (1) excessively wide cabinet ventilation slots, and (2) an

improperly fitted and/or incorrectly secured cover panels.

c) Leakage Current Hot Check. With the instrument completely reassembled, plug the AC line cord directly into a 220 V AC

outlet (Do not use an isolation transformer during this test). Use a leakage current tester or a metering system that complies

with American National Standards Institute (ANSI) C101.0 Leakage Current for Applianc

(UL) 1410, (50.7). With the instrument AC switch first in the on position and then in the off position, measure from a known

earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the instrument (antennas, handle bracket, metal

cabinet, screwheads, metallic overlays, control shafts, etc.). espe

return path to the chassis. Any current measured must not exceed 1.5 mA. Reverse the instrument power cord plug in the

outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE INSTRUM

BEFORE CONNECTING ACCESSORIES.

cially any exposed metal parts that offer an electrical

es and Underwriters Laboratories

ENT TO THE CUSTOMER OR

s

vers/shields,

AC Leakage Test

Leakage Current Tester

Reading should

not be above

Device Under Test

1.5 mA

+-

Test all exposed metal surfaces

2-Wired cord

Also test with plug reversed

(Using AC Adapter plug as required)

Earth

Ground

Image 1-1

AC Leakage Test

d) Ultraviolet Radiation exposure - Warning: This lamp can cause serious skin burn and eye inflammation from shortwave

ultraviolet radiation if not operated in enclosed fixtures. DO NOT operate this lamp in a fixture with a missing or broken lens

cover.

e) Ozone: Operating lamp generates ozone gas which is harmful to the respiratory system. Therefore the lamp should be

operated in adequately ventilated equipment.

2. Read and comply with all caution and safety-related notes on or inside the projector cabinet or on the projector chassis, or on

the picture tube.

3. Design Alteration Warning - Do not alter or add to the mechanical or electrical design of this apparatus. Design alterations and

additions, includin

connections, might alter the safety characteristics of this apparatus and create a hazard to the user. Any design alterations

or additions may void the manufacturer’s warranty and may make you, the servicer responsible for personal injury or property

damage resulting t

g, but not limited to, circuit modifications and the addition of items such as auxiliary audio and/or video output

herefrom.

6

R59770072 FLM SERIES 19/03/2007

Page 9

1. Safety

4. Lamp explosion Protection Warning – The lamp in this projector operates with a high internal pressure and there is a slight risk

that the lamp may explode, particularly if it is used beyond its rated life. Do not remove, install, or otherwise handle the lamp

in any manner without first putting on shatterproof goggles equipped with side shields. People not so equipped must be kept

safely away while lamps are handled. Keep the lamp away from your body. For continued explosion protection, replace the

lamp only with one of the same type number. Always replace the lamp before the rated life time.

5. Hot Chassis Warning - This projector chassis has two ground systems: the primary ground system is formed by the negative

voltage of the rectified mains (power) and is only used as a reference in primary circuits; the secondary ground system is

connected to earth ground via the earth conductor in the mains (power) lead. Separation between primary and secondary

circuits is performed by the safety isolation transformers. Components bridging this transformers are also safety components

and must never be defeated or altercated. All user-accessible conductive parts must be connected to earth ground, or are kept

at SELV (Safety Extra Low Voltage).

6. Observe original lead dress. Always inspect in all areas for pinched, out-of-face, or frayed wiring. Do not chan

between components, and between components and the printed-circuit board. Check AC power cord for damage. Take extra

care to assure correct lead dress in the following areas:

a) near sharp edges

b) near thermally hot parts - be sure that leads and components do not touch thermally hot parts

c) the AC supply

d) high voltage

7. Components, parts, and/or wiring that appear to have overheated or are otherwise damaged should be replaced with components, parts, or wiring that meet original specifications. Additionally, determine the cause of overheating and/or damage and, if

necessary, take corrective action to remove any potential safety hazard.

8. PRODUCT SAFETY NOTICE - Many electrical and mechanical parts have special safety-related characteristics some of which

are often not evident from visual inspection, nor can the protection they give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc. Use of a substitute replaceme

teristics as the recommended replacement part in BARCO service data parts list might create shock, fire, and/or other hazards.

Product Safety is under review continuously and new instructions are issued whenever appropriate. For the latest information,

always consult the appropriate current BARCO service literature.

9. Do not spray chemical on or near this instrument or any of its assemblies.

10. Electrostatically Sensitive (ES) Devices Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Device

circuits and some field-effect transistors and semiconductor "chip" components. The following techniques should be used to

help reduce the incidence of component damage caused by static electricity:

a) Immediately before handling any semiconductor-equipped assembly, drain off any electrostatic charge on your body by

touching a known earth ground. Wear a commercially available high impedance discharging wrist strap device.

b) After removing an electrical assembly equipped with ES devices, place the assembly on a static dissipative surface such as

a 3M No 8210 table mat, to prevent electrostatic charge buildup or e

c) Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

d) Do not remove a replacement ES device from its protective package until immediately before you are ready to install it

(Most replacement ES devices are packaged with leads electri

comparable conductive material).

e) Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis orcircuit assembly into which the device will be installed. CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

f) Minimize bodily motions when handling unpacked replacement ES devices (Otherwise harmless motion such as the brush-

ing together of your clothes fabric or the lifting of your fo

damage an ES device).

cally shorted together by conductive foam, aluminium foil or

ot from a carpeted floor can generate static electricity sufficient to

nt that does not have the same safety charac-

s. Examples of typical ES devices are integrated

xposure of the assembly.

ge spacing

R59770072 FLM SERIES 19/03/2007

7

Page 10

1. Safety

8 R59770072 FLM SERIES 19/03/2007

Page 11

2. GENERAL INFO

Overview

• Location of modules

• Spare part kits

2. General info

R59770072 FLM SERIES 19/03/2007

9

Page 12

2. General info

2.1 Location of modules

Convention - Projector orientation

L

a

s

p

m

d

o

e

i

r

n

p

I

u

t

s

i

d

e

Front

Image 2-1

Projector orientation

Rear side and Lamp side

Rear

Light processor side

A

B

Image 2-2

Reference

A IR receiver

B

C

D

E

F Backlight unit

Description

Lamp power supply unit (LPS) unit

Lamp unit

Cathode fan assembly

Input & communication unit

F

C ED

10 R59770072 FLM SERIES 19/03/2007

Page 13

Lamp side

2. General info

G

H

I

J

Image 2-3

Reference

G

H

I Motor control board

J

K

Description

Backplane

Signal distribution board

Switched mode power supply (SMPS) unit

Formatter interface board

K

R59770072 FLM SERIES 19/03/2007 11

Page 14

2. General info

Light processor side - Front side

L

S

R

Q

Image 2-4

Reference

L IR receiver

M

N

O Anode fan

P

Q Cold mirror assembly

R

S

M N O P

Description

Heat exchanger + fan

Light processor assembly (light processor + light pipe)

Start pulse generator

Cold mirror fan

Manometer + pressure vessel

12 R59770072 FLM SERIES 19/03/2007

Page 15

2.2 Spare part kits

Overview

2. General info

Order number kit

B3245964DK

B3245651DK

R848645K

B4009521DK

R9854470

R9854480

B4009232K Heat exchanger

R851014K Housing: back cover

R851012K

R851013K

R851015K Housing: lamp cover

R851011K Housing: side cover light processor side

R851030K Housing: top cover

R848591K

R9854540

R9854541

R9854420

R9854520

R848500K Lens holder assembly

R854296K Integration rod assembly

R855831K Integration rod assembly

R847532K Light pipe assembly

R853768K Light pipe assembly

R849622K

R853761K

R849250K

R8492501K

R849151K

R764773K

R764775K

R764760K

R765132K

R764833K

Description FLM R20+ FLM HD18 FLM HD14

Fan axial 59LS 50$MDL

Fan radial 24V 143D175CP

Cold mirror + fan assembly

Cooling pump

Front and bottom filters (6 pieces each)

Front and bottom filters (24 pieces each)

Housing: front cover

Housing: input & communication cover

Input & communication unit

(DVI, HDSDI-SDI, 5-cable input included)

Lamp house (3.5 kW lamp included

Lamp house refurbished (3.5 kW lamp

included)

Lamp house (3 kW lamp included)

Lamp house refurbished (3 kW lamp

included)

Light processor & light pipe (shutter included)

Light processor & light pipe (shutter included)

IR UV filter

IR UV filter

Shutter blizzard assembly

Communication interface

Fan & motor control unit

Formatter interface board

Formatter interface board

Lamp power supply (LPS)

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x - -

- x -

- x -

x - x

x - x

x x x

x - -

- x x

x - -

- x x

x - -

- x x

x - -

- x x

x x x

x x x

x x x

x - -

- x x

x x x

R59770072 FLM SERIES 19/03/2007 13

Page 16

2. General info

Order number kit

R764818K

R764822K

R764774K

R764869K Keypad unit

V322203K

B3722365K

B3580251K

B3580252K

R764240K Projector tilt switch

R848914K

Description FLM R20+ FLM HD18 FLM HD14

Signal distribution board

Start pulse generator

Switched mode power supply

LCD panel 160x80 6H$LED BL

Mains switch 35A UL/CSA

Motor DC 12V D17 + 134:1

Motor DC 12V D17 + 134:1

Carry handle (without parts for top mounting)

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

14 R59770072 FLM SERIES 19/03/2007

Page 17

3. Troubleshooting

3. TROUBLESHOOTING

About this chapter

This chapter enumerates all possible error codes which can appear on the local LCD display of the FLM projector. The code displayed is preceded by a “-”signincaseofawarning or a “+”signincaseofarealerror. Note that not all codes have a warning

and an error state. Some only have an error state, others have only a warning state. In case of a “warning” the projector remains

to operate. Nevertheless, it is recommended to solve the problem which causing the “warning” as soon as possible otherwise, the

“warning” state may turn into an “error” state which will switch off the projector consequently.

The codes are placed in ascending order to make it easier to look up the code and find an appropriate solution.

Overview

• 1000 → 1017 : Lamp parameters related errors

• 1692 → 1699 : Formatter related errors

• 2000 → 2808 : Lamp Power Supply (LPS) related errors

• 4000 : Incompatible hardware error

• 4198 : Pixel map related error

• 5095 → 5098 : Flash memory related errors

• 7658 → 7999 : Temperature, fan & motor related errors

• 8000 → 8001: Shutter related errors

• 8002 : Lamp EEPROM error

• 9198 → 9398: CPU related errors

• 10498 : Input module related error

R59770072 FLM SERIES 19/03/2007

15

Page 18

3. Troubleshooting

3.1 1000 → 1017 : Lamp parameters related errors

Error 1000 → 1017 : “Wrong lamp parameters”

These error codes may appear during the start up of the projector.

Situation Solution

Wrong lamp house detected in lamp

compartment of the projector.

No communication with the lamp

house.

A

Replace the lamp house with a compatible lamp house for this projector. Note that a 3,5

kW lamp is not suitable for the FLM R20+ or FLM HD14.

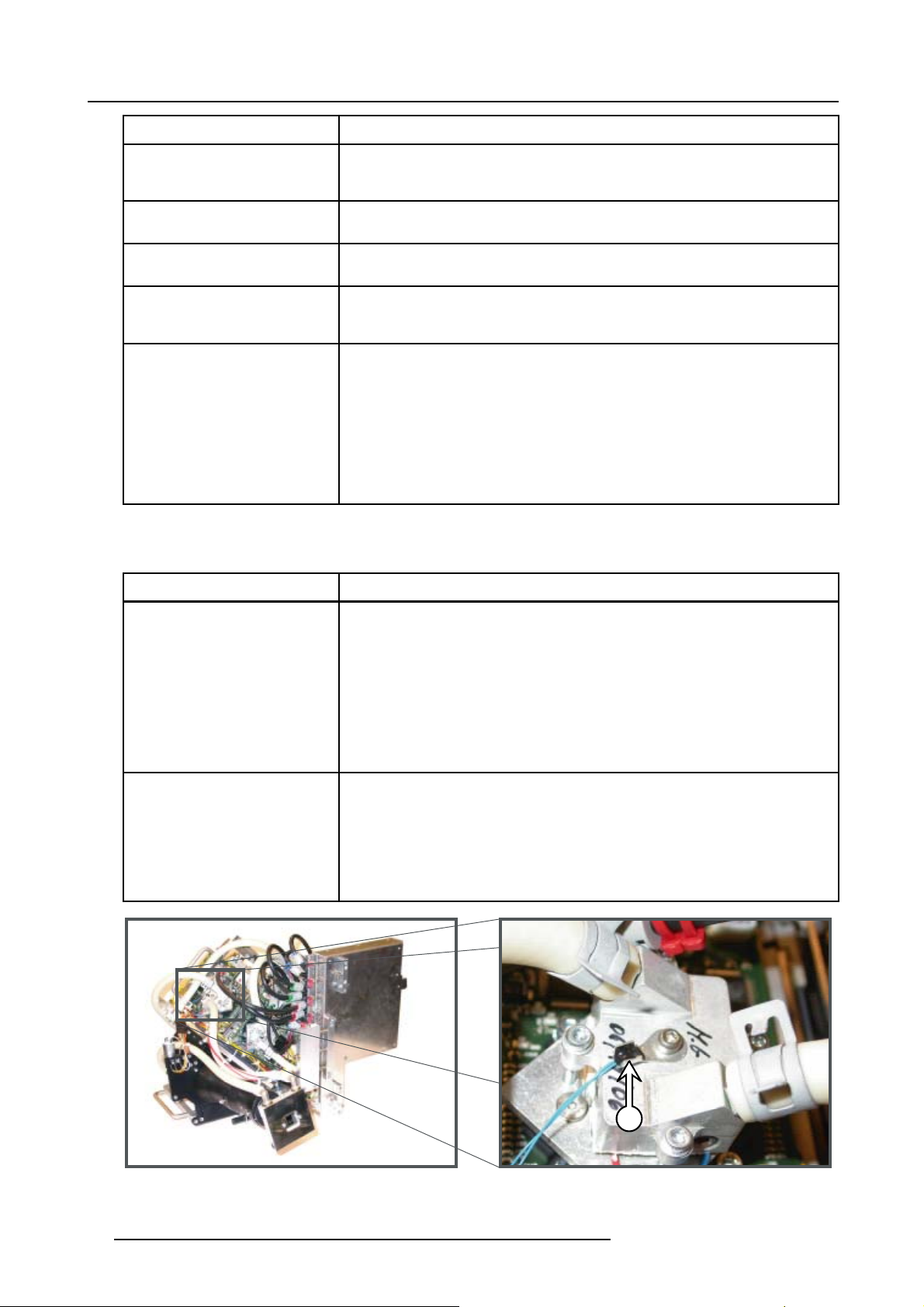

• Check if the blue socket (ref A image 3-1) of the lamp house is not damaged.

Warning: Never attempt to repair the lamp house. Reinstall a new lamp house and

send the damaged lamp house back to factory for repair.

• Check if the blue socket (ref B image 3-1) in the upper left corner of the lamp

compartment is not damaged.

• Check the wiring at the rear side of the blue socket (ref C image 3-2) inside the

projector. The rear side of the blue socket in the projector is visible after removal of

the left side cover (light processor side).

• Check if the wire unit coming from the blue socket in the lamp compartment

is plugged into its socket (ref D image 3-2) on the backplane behind the input

& communication unit.

B

Image 3-1

Image 3-2

D

C

16 R59770072 FLM SERIES 19/03/2007

Page 19

3.2 1692 → 1699 : Formatter related errors

Error 1692 : “Form. PWRGood”

Situation Solution

3. Troubleshooting

Formatter “Power Good" signal not

OK. The local power supplies on

the Formatter Interface Board fails.

The orange LED “PWRGood” (ref

Aimage3-3&image3-4)onthe

Formatter Interface Board remains

off.

The status LED’s of the Formatter

Interface Board (FIB) are visible

through the filter grid behind the

front filter. So, you have to remove

the projector front cover and the

front filter first to see the LED’s on

the FIB.

B

C

FLM

• Check if all wire units between the Formatter Interface Board and the three

formatter boards are not damaged. A damaged wire unit can cause a short circuit

in the local power supply of the Formatter Interface Board.

• Check if none of the pins of the connectors on the FIB or formatter boards are

bend over.

• Replace the Formatter Interface Board.

• If the problem remains contact Barco for further instructions. The formatter boards

are malfunctioning and have to be replaced at the factory.

A

A

B1 B2 B3 B4

Image 3-3

Status LED’s of the Formatter Interface Board (non HD version). Visible trough the grid behind the front filter.

A Orange LED “PWRGood” OK.

B1 Green LED “+5V”.

B2 Green LED “+3.3V”.

B3 Green LED “+2.5V”.

B4 Green LED “+2.1V”.

C Green LED “FPGA DONE”.

R59770072 FLM SERIES 19/03/2007

17

Page 20

3. Troubleshooting

C

B

A

FLM HD

Image 3-4

Status LED’s of the Formatter Interface Board (HD version). Visible trough the grid behind

the front filter.

A Orange LED “PWRGood” OK.

B PowerGood status: LED color = Green “High”; Yellow “Low”;

Red “Fail”.

C FPGA status: LED color = Green “Normal”; Yellow “Boot”; Red

“Fail”.

Error 1693 : “Blue form. start failed”

Situation Solution

No communication with the

tter board of the blue channel.

forma

The projector fails to start.

• Check if the data cables between the Formatter Interface Board (FIB) and the

formatter board of the blue channel are plugged in properly.

• Check if none of the wires came loose from the plugs on the wire unit.

• Reboot the projector. If the problem remains contact Barco for further instructions.

The formatter board of the blue channel is malfunctioning and has to be replaced

he factory.

at t

FLM FLM HD

Image 3-5

Formatter board with data cables plugged in. Two data cables for FLM and three data cables for FLM HD per formatter board.

18 R59770072 FLM SERIES 19/03/2007

Page 21

Error 1694 : “Green form. start failed”

Situation Solution

3. Troubleshooting

No communication with the

formatter board of the green

channel. The projector fails to start.

• Check if both wire units between the Formatter Interface Board (FIB) and the

formatter board of the green channel are plugged in properly.

• Check if none of the wires came loose from the plugs on the wire unit.

• Reboot the projector. If the problem remains contact Barco for further instructions.

The formatter board of the green channel is malfunctioning and has to be replaced

at the factory.

Error 1695 : “Red form. start failed”

Situation Solution

No communication with the

formatter board of the red channel.

The projector fails to start.

• Check if both wire units between the Formatter Interface Board (FIB) and the

formatter board of the red channel are plugged in properly.

• Check if none of the wires came loose from the plugs on the wire unit.

• Reboot the projector. If the problem remains contact Barco for further instructions.

The formatter board of the red channel is malfunctioning and has to be replaced

at the factory.

Error 1696 : “Formatter ctrl init failed”

Situation Solution

The Formatter Interface Board

failed to initialize. The orange LED

“PWRGood” lights up. The green

status LED “FPGA DONE” on the

Formatter Interface Board remains

off (image 3-3 & image 3-4).

The local power supplies on the

Formatter Interface Board fails. The

orange LED “PWRGood” remains

off (image 3-3 & image 3-4).

The Formatter Interface Board has

no power. All status LED’s on the

Formatter Interface Board remains

off while the status LED “+5V FIB”

(image 3-6) on the Fan & Motor

Control Board lights up.

To see the status LED’s of the Fan

& Motor Control Board you have to

remove the projector input cover.

The Formatter Interface Board has

no power. All status LED’s on the

Formatter Interface Board remains

off and the status LED “+5V FIB”

(image 3-6)on the Fan & Motor

Control Board remains off as well.

To see the status LED’s of the Fan

& Motor Control Board you have to

remove the projector input cover.

• Try to reload the flash software of the Formatter Interface Board.

• Check if the Formatter Interface Board is inserted well.

• If the problem remains replace the Formatter Interface Board.

Replace the Formatter Interface Board.

Replace the Formatter Interface Board.

• Check if the Formatter Interface Board is well inserted.

• Replace the Fan & Motor Control Board.

R59770072 FLM SERIES 19/03/2007 19

Page 22

3. Troubleshooting

L2 L4 L6

L1 L3 L5 L7

Image 3-6

Status LED’s of the Fan & Motor Control Board. Located behind the input cover.

L1 Green LED “+30V”.

L2 Green LED “+VMTR”.

L3 Green LED “+VTEC”.

L4 Green LED “++5V”.

L5 Green LED “+5V FIB”.

L6 Green LED “+5V PMP”.

L7 Red LED “ ERROR”.

Error 1697 : “Formatter init failed”

Situation Solution

The projected image is missing

one of the three base colors (red,

green or blue). which indicates that

there is no communication with

the formatter board of the missing

color. You can verify this situation

by activating the internal service

patterns of the formatter boards.

The internal pattern of the involved

channel fails while the others works

fine.

No image can be projected. None

of he internal service patterns of the

formatter board of the red, green

or blue channel can be projected.

The green LED “FPGA DONE” (ref.

C image 3-3 & image 3-4) on the

Formatter Interface Board rema

off while the other status LED’s of

the Formatter Interface Board light

up.

• Check if both wire units between the Formatter Interface Board (FIB) and the

involved formatter board are plugged in properly.

• Reboot the projector. If the problem remains contact Barco for further instructions.

The formatter board of the involved channel is malfunctioning and has to be

replaced at the factory.

• Check if all wire units between the Formatter Interface Board and the three

formatter boards are plugged in prope

• Check the “Error logging”. In case the logging indicates an error with one of the

formatter boards, send the light processor back to factory to replace the involved

ins

formatter board.

• Try to reload the flash software of the Formatter Interface Board.

• If the problem remains, replace the Formatter Interface Board.

rly.

20 R59770072 FLM SERIES 19/03/2007

Page 23

3.3 2000 → 2808 : Lamp Power Supply (LPS) related errors

See also chapter "LPS diagnostic LED’s", page 299, for more diagnostic information about the LPS unit.

Error 2000 : “No LPS detected”

Situation Solution

3. Troubleshooting

No communication with the Lamp

Power Supply.

A C

Image 3-7

A LPS address wire unit.

C LPS control wire unit.

G LPS grey wire unit.

• Check if the grey wire unit (ref G image 3-7) at the rear side of the projector is

connected properly with the “CTRL IN” socket of the LPS module.

• Check if the address wire unit (ref A image 3-7) is plugged in between the LPS units.

• Check if the wire unit (ref H image 3-8) is plugged into its socket on the backplane

behind the “Input and communication unit”

• Check if the pins of the sockets of the SMPS and/or Fan & Motor control board

are not damaged or bend over.

A

C

G

H

Image 3-8

H LPS grey wire unit.

R59770072 FLM SERIES 19/03/2007

21

Page 24

3. Troubleshooting

Error 2001 : “Mains voltage to low”

Situation Solution

The mains voltage applied to the

“MAINS INPUT” sockets of the LPS

module is to low.

Image 3-9

• Check if the main power cables (image 3-9) are connected with the “MAINS

INPUT” sockets of the LPS module.

• Check if the mains voltage applied to the projector power socket is between 200

and 240 VAC.

• Make sure that the electrical dimensions of the extension leads to the projector

meet the power requirements of the projector.

Error 2002 : “Lamp start failed”

The Lamp Power Supply succeeded in igniting the lamp but shortly after ignition the lamp goes out.

Situation Solution

Hot restrike of the lamp. The lamp

fails to illuminate when switched on

shortly after the lamp was switched

off.

Lamp with many strikes, maximum

run time exceeded. The Lamp

Power Supply and the Start Pulse

Generator are working normally.

Nevertheless, the lamp fails to

illuminate.

Malfunction SPG unit. You can not

hear the SPG module three times

clicking in an attempt to ignite the

lamp. The voltage on the “LAMP

OUT” pins of the LPS module is first

140 volt during the attempt to ignite

and then drops to 0 volt after a few

minutes.

Note: The ambient noise must be

low to hear the SPG clicking in an

attempt to ignite the lamp.

Let cool down the lamp for at least 3 minutes before switching the projector from

standby to operating mode.

Replace the exhausted lamp with a new one.

• Check the cabling of the SPG module.

• Replace the SPG module.

Error 2004 : “Lamp goes out”

Situation Solution

Exhausted lamp. Lamp with

many strikes, maximum run time

exceeded.

Replace the exhausted lamp with a new one.

22 R59770072 FLM SERIES 19/03/2007

Page 25

Error 2005 : “Lamp stop failed”

Situation Solution

3. Troubleshooting

No communication with the Lamp

Power Supply.

• Switch off the projector.

• Reboot the projector. If problem remains, replace the Lamp Power Supply.

Error 2006 : “One LPS down, reduced power”

This is not a real error but a warning. The projector will continue to operate.

Situation Solution

Main power cable disconnected

from one of the LPS units

Disconnected wire unit between

the “CTRL IN” and “CTRL OUT”

sockets of the LPS units.

Malfunctioning of one of the LPS

units. The red LED “ERR” of the

malfunctioning LPS unit flashes

fast.

Check if the main power cable is connected with the “MAINS INPUT” socket of the

LPS unit (image 3-9).

Reconnect the wire unit between the “CTRL IN” and “CTRL OUT” sockets of the LPS

units (image 3-7).

Replace the LPS module.

Error 2201 : “PFC start failed”

This error is generated by the LPS unit with address 0x20.

Situation Solution

The power factor corrector of one of

the LPS units fails to start.

Replace the LPS module.

Error 2202 : “LPS start failed”

This error is generated by the LPS unit with address 0x20.

Situation Solution

One of the LPS units fails to start. Replace the LPS module.

Error 2203 : “BOOST start failed”

This error is generated by the LPS unit with address 0x20.

Situation Solution

One of the LPS units fails to place

the start up voltage of 140 volt,

which is required to trigger the SPG,

on the “LAMP OUT” pins of the LPS

unit.

Replace the LPS module.

Error 2206 : “Lamp ignition failed”

This error is generated by the LPS unit with address 0x20.

R59770072 FLM SERIES 19/03/2007

23

Page 26

3. Troubleshooting

Situation Solution

You can hear the SPG module three

times clicking in an attempt to ignite

the lamp. The voltage on the “LAMP

OUT” pins of the LPS module is first

140 volt during the attempt to ignite

and then drops to 0 volt after a few

minutes.

Note: The ambient noise must be

low to hear the SPG clicking in an

attempt to ignite the lamp.

You can not hear the SPG module

three times clicking in an attempt

to ignite the lamp. The voltage on

the “LAMP OUT” pins of the LPS

module is first 140 volt during the

attempt to ignite and then drops to

0 volt after a few minutes.

Note: The ambient noise must be

low to hear the SPG clicking in an

attempt to ignite the lamp.

You can not hear the SPG module

three times clicking in an attempt

to ignite the lamp. The voltage on

the “LAMP OUT” pins of the LPS

module is below 140 volt during the

attempt to ignite. The diagnostic

LED’s of the LPS module indicates

a problem with the LPS module.

Note: The ambient noise must be

low to hear the SPG clicking in an

attempt to ignite the lamp.

• The LPS and SPG seem the work normally but the lamp is exhausted. Install

a new lamp.

• If the problem remains, replace the SPG module.

• Check the cabling of the SPG module.

• Replace the SPG module.

• Check the cabling of the LPS module.

• Replace the LPS module.

Error 2207 : “Lamp voltage range”

s error is generated by the LPS unit with address 0x20.

Thi

Situation Solution

AMP OUT” voltage of the

The “L

lamp power supply is out of range.

•Reb

• If problem remains, replace the LPS module.

oot the projector.

Error 2208 : “Lamp power range”

This error is generated by the LPS unit with address 0x20.

Situation Solution

The power delivered by the lamp

power supply is out of range.

• Reboot the projector.

• If problem remains, replace the LPS module.

Error 2501 : “PFC start failed”

The same troubleshooting checklist can be applied to as for Error 2201. The only difference is that this error is generated by the

LPS unit with address 0x22.

Error 2502 : “LPS start failed”

The same troubleshooting checklist can be applied to as for Error 2202. The only difference is that this error is generated by the

LPS unit with address 0x22.

Error 2503 : “BOOST start failed”

The same troubleshooting checklist can be applied to as for Error 2203. The only difference is that this error is generated by the

LPS unit with address 0x22.

24

R59770072 FLM SERIES 19/03/2007

Page 27

3. Troubleshooting

Error 2506 : “Lamp ignition failed”

The same troubleshooting checklist can be applied to as for Error 2206. The only difference is that this error is generated by the

LPS unit with address 0x22.

Error 2507 : “Lamp voltage range”

The same troubleshooting checklist can be applied to as for Error 2207. The only difference is that this error is generated by the

LPS unit with address 0x22.

Error 2508 : “Lamp power range”

The same troubleshooting checklist can be applied to as for Error 2208. The only difference is that this error is generated by the

LPS unit with address 0x22.

Error 2801 : “PFC start failed”

The same troubleshooting checklist can be applied to as for Error 2201. The only difference is that this error is generated b

LPS unit with address 0x28.

ythe

Error 2802 : “LPS start failed”

The same troubleshooting checklist can be applied to as for Error 2202. The only difference is that this error is generated by the

LPS unit with address 0x28.

Error 2803 : “BOOST start failed”

The same troubleshooting checklist can be applied to as for Error 2203. The only diffe

LPS unit with address 0x28.

rence is that this error is generated by the

Error 2806 : “Lamp ignition failed”

The same troubleshooting checklist can be applied to as for Error 2206. The only difference is that this error is generated by the

LPS unit with address 0x28.

Error 2807 : “Lamp voltage range”

The same troubleshooting checklist can be applied to as for Error 2207.

LPS unit with address 0x28

The only difference is that this error is generated by the

Error 2808 : “Lamp power range”

The same troubleshooting checklist can be applied to as for Error 2208. The only difference is that this error is generated by the

LPS unit with address 0x28.

R59770072 FLM SERIES 19/03/2007

25

Page 28

3. Troubleshooting

3.4 4000 : Incompatible hardware error

Error 4000 : “Incompatible hardware”

Situation Solution

One or more parts of the projector

are replaced with incompatible

parts.

I2C related error. One of the boards

with an I

hardware error.

2

C address causes a

• Reinstall the original parts of the projector. Use only original Barco spare parts

for servicing.

• If the problem persists, contact Barco for further instructions.

• Check the I2C status of the boards via the user interface: Service >

Diagnoses > I

• If the problem persists, contact Barco for further instructions.

2

C and replace the malfunction board.

26 R59770072 FLM SERIES 19/03/2007

Page 29

3.5 4198 : Pixel map related error

Error 4198 : “FPGA-PMP init failed”

Situation Solution

3. Troubleshooting

The controller was unable to

initialize the FPGA of the Pixel Map

Processor (PMP).

• Reboot the projector.

• If the problem persists, reinstall the PMP firmware using the Projector Toolset.

• If the problem persists, replace the PMP.

R59770072 FLM SERIES 19/03/2007 27

Page 30

3. Troubleshooting

3.6 5095 → 5098 : Flash memory related errors

Error 5095 : “Restoring unsuccessful”

Situation Solution

Restoring the custom settings from

the internal backup device has

failed.

• Check if the latest projector software is installed.

• Reinstall the latest projector software.

• If the problem persists, contact Barco for further instructions.

Error 5096 : “Storing unsuccessful”

Situation Solution

Storing the custom settings from the

internal backup device has failed.

• Check if the latest projector software i

• Reinstall the latest projector software.

• If the problem persists, contact Barco for further instructions.

Error 5097 : “Flash management full”

Situation Solution

The reserved memory for flash

management has reached its limits.

• Check if the latest projector software is installed.

• Delete some unnecessary custom made image files.

• Delete some unnecessary custom made layout files.

• If the problem persists, contact Barco for further instructions.

Error 5098 : “Flash full”

Situation Solution

s installed.

Internal backup device has reached

its maximum capacity.

• Check if the latest projector software is installed.

• Delete some unnecessary custom made image files.

• Delete some unnecessary custom made layout files.

• If the problem persists, contact Barco for further instructions.

28 R59770072 FLM SERIES 19/03/2007

Page 31

3.7 7658 → 7999 : Temperature, fan & motor related errors

Error 7658 : “Engine air temp short”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

3. Troubleshooting

Damaged insulation of the wire unit

of the temperature sensor (ref E

image 3-10), which measures the

temperature inside the compartment

of the light processor. When

disconnecting the wire unit (ref E

image 3-11) of the temperature

sensor from the Formatter Interface

Board the error code is changed to

7659 : “Engine air temp open”.

Defect temperature sensor (ref E

image 3-10) of the light processor.

When disconnecting the wire

unit (ref E image 3-11) of the

temperature sensor from the

Formatter Interface Board (FIB) the

error code is changed to 7659 :

“Engine air temp open”.

Damaged socket (ref E image 3-10)

on the FIB.

• Repair the insulation of the wire unit using shrink sleeve.

• If not repairable, replace the whole wire unit and temperature sensor.

Replace the temperature sensor.

Check if no pins are bent over of the socket for the wire unit of the temperature sensor

(E).

Image 3-10

E Engine air temperature sense.

E

R59770072 FLM SERIES 19/03/2007

29

Page 32

3. Troubleshooting

R G B

BL

FR

TB

TG

TR

Image 3-11

Sockets on the Formatter Interface Board (FIB) of the FLM HD series

R Temperature sense Red channel.

G Temperature sense Green channel.

B Temperature sense Blue channel.

BL Temperature sense DMD water cooling blocks.

FR Temperature sense DMD front.

E Temperature sense light processor air (Engine).

H Temperature sense Heat pipes cooling block.

TB Power supply for TEC front blue.

TG Power supply for TEC front green.

TR Power supply for TEC front red.

Error 7659 : “Engine air temp open”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

E

H

Wire unit of the temperature sensor

(ref E image 3-10) is disconnected

from the Formatter Interface Board.

Damaged wire unit of the

temperature sensor (ref E

image 3-10) causing an open

circuit.

Defect temperature sensor (ref E

image 3-10) of the light processor.

Plug the wire unit of the temperature sensor (E) into its socket on the Formatter

Interface Board. See image 3-11.

• Repair the wire unit.

• If not repairable, replace the hole wire unit and temperature sensor.

Replace the temperature sensor.

Error 7660 : “Engine air temp high”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

Air temperature inside the

compartment of the light processor

is to high.

• Check if the air inlet at the front and at the bottom of the projector are free.

• Check if the bottom filter of the projector is not filthy. Replace with new filter

if necessary.

• Check if the front filter of the projector is not filthy. Replace with new filter if

necessary.

• Check if the air outlet at the rear of the projector is not covered. There should be at

least one meter of free area at the rear of the projector.

• Make sure that the plate, on which the projector is mounted for transport, is

removed.

Error 7662 : “Blue block temp short”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

30

R59770072 FLM SERIES 19/03/2007

Page 33

Situation Solution

3. Troubleshooting

Damaged insulation of the wire unit

of the temperature sensor (ref B

image 3-12), which measures the

temperature of the water cooling

block of the blue channel. When

disconnecting the wire unit (ref B/BL

image 3-11) of the temperature

sensor from the Formatter Interface

Board (FIB) the error code is

changed to 7663 : “Blue block temp

open”.

Defect temperature sensor on the

water cooling block of the blue

channel. When disconnecting the

wire unit of the temperature sensor

from the Formatter Interface Board

(FIB) the error code is changed to

7663 : “Blue block temp open”.

• Repair the insulation of the wire unit using shrink sleeve.

• If not repairable, replace the whole wire unit and temperature sensor.

Replace the temperature sensor.

B

Image 3-12

B Temperature sensor DMD cooling block blue channel.

Error 7663 : “Blue block temp open”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

Wire unit (ref B/BL image 3-11)

of the temperature sensor is

disconnected from the Formatter

Interface Board (FIB)

Damaged wire unit of the

temperature sensor (ref B

image 3-12) which measures

the temperature of the water cooling

block of the blue channel.

Defect temperature sensor (ref B

image 3-12) on the water cooling

block of the blue channel.

Error 7664 : “Blue block temp high”

This error may be preceded by a warning. This error can only appear on the FLM HD series. Temperature of the water cooling block

of the blue channel is to high. If this problem persist the projector will shut down the lamp.

Plug in the wire unit of the temperature sensor into its socket on the Formatter Interface

Board.

• Repair the wire unit.

• If not repairable, replace the hole wi

Replace the temperature sensor.

re unit and temperature sensor.

R59770072 FLM SERIES 19/03/2007

31

Page 34

3. Troubleshooting

Situation Solution

Interruption of the liquid cooling

circuit.

The liquid cooling circuit of the light

processor is mistakenly excluded

from the main liquid cooling circuit.

Water cooling pump electrical

disconnected.

Blocked high density filter of the

heat exchanger.

No or insufficient liquid inside the

cooling circuit. The pump is sucking

air and sounds noisier then normal.

Malfunction pump of the water

cooling circuit. You don’t feel any

vibrations when touching the pump

after activating the “Refill mode” via

the user interface:

Service > Refill mode >

Yes

Note: to exit the “Refill mode” you

have to switch off the projector.

Check if the loop of the liquid cooling circuit is closed.

Reconnect the cooling circuit of the light processor with the pump and heat exchanger.

Check if the wire unit (ref C image 3-13) of the pump is properly connected.

Replace the blocked high density filter with a new one.

Fill the cooling circuit with liquid and expel all air. Pressurize the circuit. See "FLM

liquid cooling circuit", page 153.

• Check the electrical resistance of the pump’s winding. Replace the pump if infinite.

See "Cooling pump replacement", page 197.

• Drain the liquid cooling circuit, open the pump and check if the pump is not blocked.

If so, remove the rotor (ref R image 3-13) and clean the bearings of the pump. See

"Maintaining the cooling pump", page 190.

P

C

Image 3-13

P Pump liquid cooling circuit.

C Electrical connection pump.

R Rotor of pump.

Error 7666 : “Green block temp short”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

R

32

R59770072 FLM SERIES 19/03/2007

Page 35

Situation Solution

3. Troubleshooting

Damaged insulation of the wire unit

of the temperature sensor (ref G

image 3-14), which measures the

temperature of the water cooling

block of the green channel. When

disconnecting the wire unit (ref G/BL

image 3-11) of the temperature

sensor from the Formatter Interface

Board (FIB) the error code is

changed to 7667 : “Green block

temp open”.

Defect temperature sensor on the

water cooling block of the green

channel. When disconnecting the

wire unit of the temperature sensor

from the Formatter Interface Board

(FIB) the error code is changed to

7667 : “Green block temp open”.

• Repair the insulation of the wire unit using shrink sleeve.

• If not repairable, replace the whole wire unit and temperature sensor.

Replace the temperature sensor.

G

Image 3-14

Error 7667 : “Green block temp open”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

Wire unit (ref G/BL image 3-11)

of the temperature sensor is

disconnected from the Formatter

Interface Board (FIB)

Damaged wire unit of the

temperature sensor (ref B

image 3-14) which measures

the temperature of the water cooling

block of the green channel.

Defect temperature sensor (ref B

image 3-14) on the water cooling

block of the green channel.

Plug in the wire unit of the temperature sensor into its socket on the Formatter Interface

Board.

• Repair the wire unit.

• If not repairable, replace the hole wire unit and temperature sensor.

Replace the temperature sensor.

Error 7668 : “Green block temp high”

This error may be preceded by a warning. This error can only appear on the FLM HD series. Temperature of the water cooling block

of the green channel is to high. If this problem persist the projector will shut down the lamp.

Situation Solution

Interruption of the liquid cooling

circuit.

Check if the loop of the liquid cooling circuit is closed.

R59770072 FLM SERIES 19/03/2007 33

Page 36

3. Troubleshooting

Situation Solution

The liquid cooling circuit of the light

processor is mistakenly excluded

from the main liquid cooling circuit.

Water cooling pump electrical

disconnected.

Blocked high density filter of the

heat exchanger.

No or insufficient liquid inside the

cooling circuit. The pump is sucking

air and sounds noisier then normal.

Malfunction pump of the water

cooling circuit. You don’t feel any

vibrations when touching the pump

after activating the “Refill mode” via

the user interface:

Service > Refill mode >

Yes

Note: to exit the “Refill mode” you

have to switch off the projector.

Reconnect the cooling circuit of the light processor with the pump and heat exchanger.

Check if the wire unit (ref C image 3-13) of the pump is properly connected.

Replace the blocked high density filter with a new one.

Fill the cooling circuit with liquid and expel all air. Pressurize the circuit. See "FLM

liquid cooling circuit", page 153.

• Check the electrical resistance of the pump’s winding. Replace the pump if infinite.

See "Cooling pump replacement", page 197.

• Drain the liquid cooling circuit, open the pump and check if the pump is not blocked.

If so, remove the rotor (ref R image 3-13) and clean the bearings of the pump. See

"Maintaining the cooling pump", page 190.

Error 7670 : “Red block temp short”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

Damaged insulation of the wire unit

of the temperature sensor (ref R

image 3-15), which measures the

temperature of the water cooling

block of the red channel. When

disconnecting the wire unit (ref R/BL

image 3-11) of the temperature

sensor from the Formatter Interface

Board (FIB) the error code is

changed to 7671 : “Red block temp

open”.

Defect temperature sensor (ref R

image 3-15) on the water cooling

block of the red channel. When

disconnecting the wire unit of

the temperature sensor from the

Formatter Interface Board (FIB) the

error code is changed to 7671 :

“Red block temp open”.

• Repair the insulation of the wire unit using shrink sleeve.

• If not repairable, replac

Replace the temperature sensor.

e the whole wire unit and temperature sensor.

R

Image 3-15

34 R59770072 FLM SERIES 19/03/2007

Page 37

Error 7671 : “Red block temp open”

This error may be preceded by a warning. This error can only appear on the FLM HD series.

Situation Solution

3. Troubleshooting

Wire unit (ref R/BL image 3-11)

of the temperature sensor is

disconnected from the Formatter

Interface Board (FIB)

Damaged wire unit of the

temperature sensor (ref R

image 3-15) which measures

the temperature of the water cooling

block of the red channel.

Defect temperature sensor (ref R

image 3-15) on the water cooling

block of the red channel.

Plug in the wire unit of the temperature sensor into its socket on the Formatter Interface

Board.

• Repair the wire unit.

• If not repairable, replace the hole wire unit and temperature sensor.

Replace the temperature sensor.

Error 7672 : “Red block temp high”

This error may be preceded by a w

of the red channel is to high. If this problem persist the projector will shut down the lamp.

Situation Solution

Interruption of the liquid cooling

circuit.

The liquid cooling circuit

processor is mistakenly excluded

from the main liquid cooling circuit.

Water cooling pump electrical

disconnected.

arning. This error can only appear on the FLM HD series. Temperature of the water cooling block

Check if the loop of the liquid cooling circuit is closed.

of the light

Reconnect the cooling circ

Check if the wire unit (

uit of the light processor with the pump and heat exchanger.

ref C image 3-13) of the pump is properly connected.

Blocked high density filter of the

heat exchanger.

No or insufficient l

cooling circuit. The pump is sucking

air and sounds noisier then normal.

Malfunction pump o

cooling circuit. You don’t feel any

vibrations when touching the pump

after activat

the user interface:

Service > Refill mode >

Yes

Note: to exi

have to switch off the projector.

iquid inside the

fthewater

ing the “Refill mode” via

t the “Refill mode” you

Replace the blocked high density filter with a new one.

Fill the cooling cir

liquid cooling circuit", page 153.

• Check the electrical resistance of the pump’s winding. Replace the pump if infinite.

See "Cooling pump replacement", page 197.

• Drain the liquid cooling circuit, open the pump and check if the pump is not blocked.

If so, remove the rotor (ref R image 3-13) and clean the bearings of the pump. See

"Maintaining the cooling pump", page 190.

cuit with liquid and expel all air. Pressurize the circuit. See "FLM

Error 7674 : “Front block temp short”