Page 1

F90-series Colorwheel Change

Replacement Procedure

The F90-series has two (2) colorwheel variants: COLOR (shipped with the projector) and BRIGHTNESS (installed).

COLOR delivers great depth of color and a broad gamut. BRIGHTNESS provides an extra boost to white segments and very good primary and

secondary colors. Choice of colorwheel depends on the application and the user’s perception of the image.

The F90 design enables users quickly and easily to change the colorwheel on site. You do not need any special tool for this operation. The

projector detects which colorwheel installed, and will automatically compensate the colorwheel index in the software to a standard value.

For optimal rendering, perform an index adjustment after every colorwheel change. See procedure at the end of this guide.

If necessary to order a colorwheel, the article numbers are:

COLOR: R9801432

BRIGHTNESS: R9801431

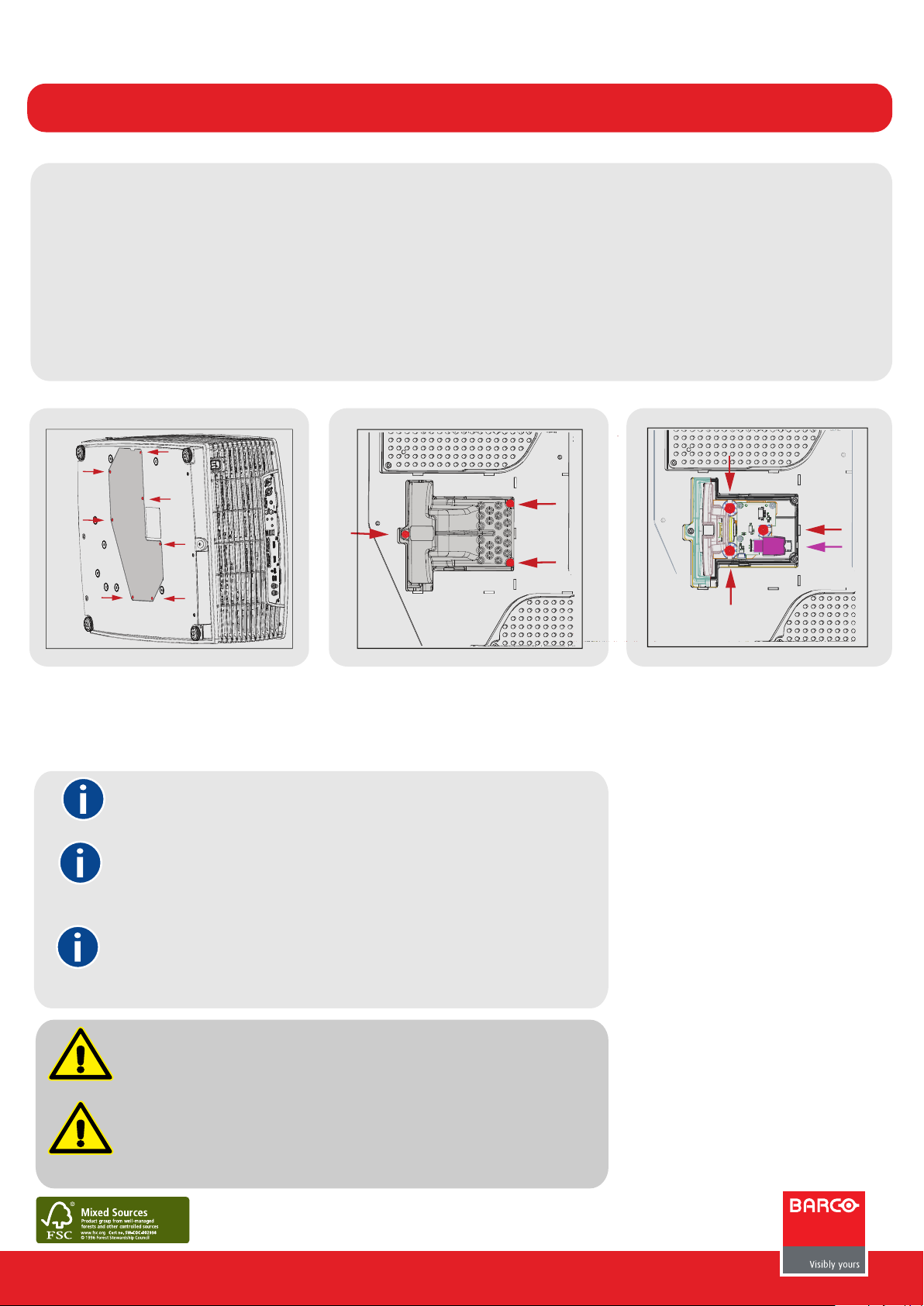

1: Place the projector on it’s right side on a

flat surface. Release the seven captive

screws securing the projector bottom cover,

indicated by the arrows. Carefully remove

the cover.

The CW assembly contains no serviceable parts, and further de-assembly should

not be attempted.

The bottom of the projector shipping box may be used for docking the projector

during the colorwheel replacement process.

Remove the middle longitude spacer in the container bottom in order to release

this cutout.

A video illustration of the complete colorwheel change process is available on

“MyBarco” support web. (F90)

CAUTION: Projector weight is 44,5kg. Two person lift is always required.

CAUTION: This procedure shall be carried out on a flat, clear surface. Always

secure the projector properly before starting the replacement procedure.

Failure to do this may result in damage to personnel and equipment.

2: When the bottom cover is removed, the

color wheel module is visible. Release the

tree captive screws (indicated by the red

circles), and carefully remove the

colorwheel cover.

3: Release the three captive screws

(indicated by the red circles) which hold

the color wheel module. Carefully lift out

the module, and simultaneously disconnect the connector, indicated by the

purple color.

4: Replace with the new color wheel, and

reassemble the projector in reverse order.

5: If necessary, adjust the colorwheel

index as described on the next page.

Printed on FSC certied paper (www.fsc.org)

601-0432-00

Page 2

Colorwheel index adjustment procedure

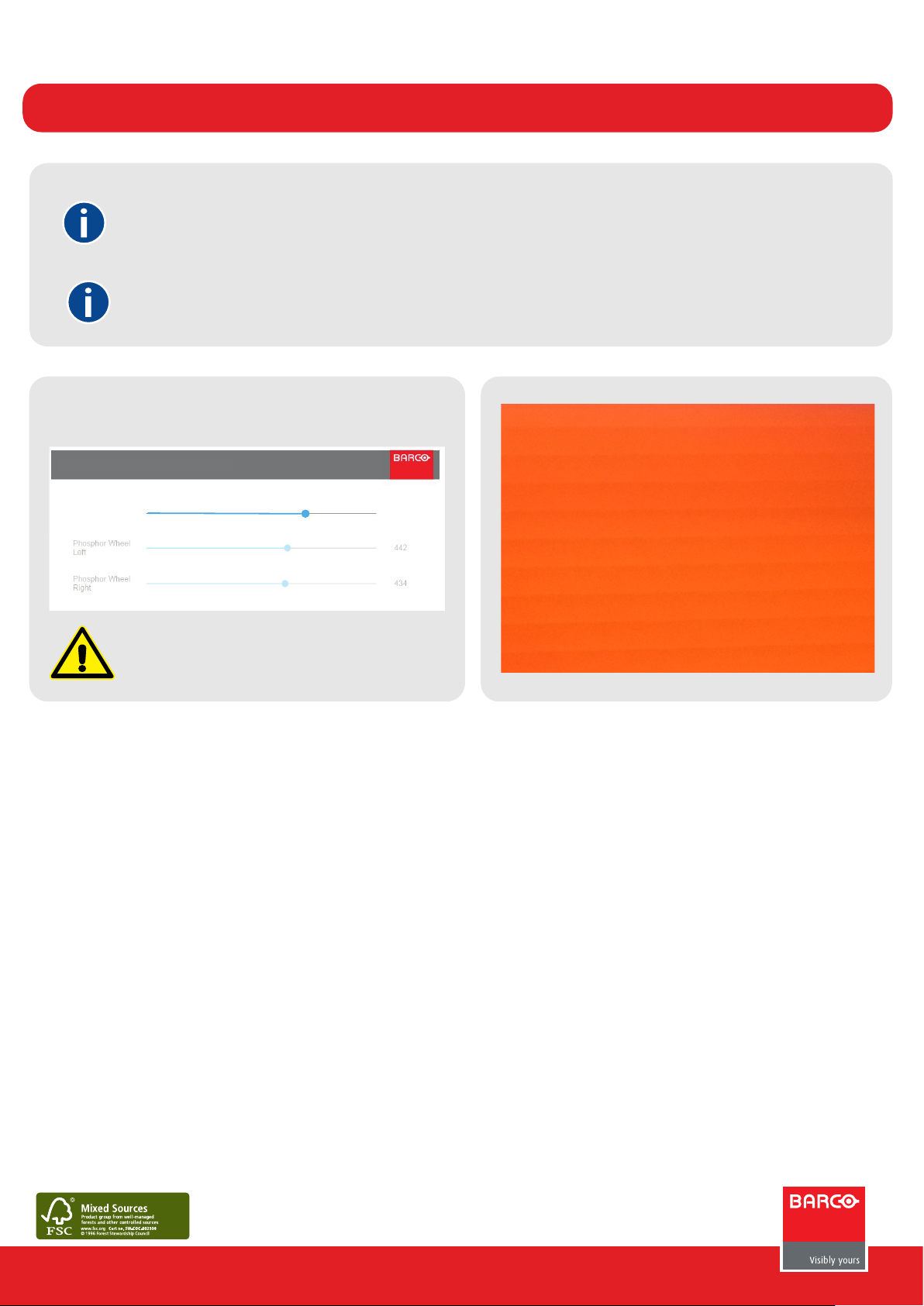

Perform the calibration of the colorwheel via the implemented service menu in the projector.

Enter the menu by this path: Home/System Settings/Service/Color wheel.

Enter the Service Menu code when prompted. Use the code 292920.

To avoid visual disturbances, disable the OSD during the process, and use only the LCD panel on the projector.

Home / System Settings / Service / Color Wheel

Clean Up Wheel

500

NOTE: Ensure NOT, by mistake, to enable and adjust

the Phosphor Wheel sliders.

Index adjustment menu. Use the Clean Up Wheel slider during the

Illustration of the picture disturbance

calibrating process.

In order to calibrate the projector you will need a pure red test image (255,0,0,) from an external source that can be displayed at high resoluton

at full screen.

1: In the menu enable the Clean up Wheel slider, and use the arrow keys on the projector keypad to move the slider to the left step by step,

until a slight disturbance occurs on the screen. Horizontal orange /yellow lines on the screen identify this disturbance.

2: To find the exact point where the distortion starts to be visible, move the slider back and forth around the observed distortion start point.

Find the exact point where the disturbance is visible, and note the value that appears to the right of the Clean up Wheel slider.

3: Move the slider to the right, until the distortion in the picture occurs again, typically approximately 15 steps. This is the same type of distortion as described above, but the orange/yellow lines appear to be wider. Repeat the same process for this point, and note also this value.

4: Find the average value by adding the two values, and divide by two (A+B)/2. Move the slider until the value on the right side of the slider

indicates the calculated value.

Exit the menu.

The calibration of the colorwheel index is now completed.

Printed on FSC certied paper (www.fsc.org)

601-0432-00

Loading...

Loading...