Page 1

F90 Series.

601–0400/02

10/05/2017

User Manual

Page 2

Barco Fredrikstad AS

Habornveien 53, N-1630 Gamle Fredrikstad, Norway

Phone: +47 6930 4550

Fax: +47 6930 4580

Support: Support.fre@barco.com

Visit us at the web: www.barco.com

Printed in N0

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fi tness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time w ithout notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically m ade to the information in this

publication; these changes are incorporated in new editions of this publication.

The latest edition of Barco manuals can be downloaded from the Barco web site w

h

ttps://www.barco.com/en/signin.

ww.barco.com or from the secured Barco web site

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable p rotection aga inst harmful interference when the equipm ent is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may c ause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in which case the user will be responsible for correcting any interference at his own expense

Changes or modifications not expressly approved by the party responsible for compliance could void the user ’s authority to operate the

equipment

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their respective holders.

All brand and product names me ntioned in this manual serve as comments or examples and are not to be understood as advertising for

the products or their manufacturers.

Turkey RoHS compliance

Türkiye Cumhu riyeti: AEEE Y önetmeli ğine Uygundur.

[Republic of Turkey: In conformity with the WEEE Regulation]

Disposal Information

Waste Electrical and E lectronic Equipment

This symbol on the product indicates that, under the European Directive 2012/19/EU governing waste from electrical and electronic

equipment, this product must not be disposed of with other municipal waste. Please dispose of your waste equipment by handing it over to

a designated co llection point for t he recycling of waste electrical and electronic equipm ent. To prevent possible harm to the environment

or human health from uncontrolled waste disposal, please separate these items from other types of waste and recycle them responsibly

to promote the sustainable reuse of material resources.

For more information about r ecycling of this product, please contact your local city office or your municipal waste disposal service.

For details, please visit the Barco website at: h

ttp://www.barco.com/en/AboutBarco/weee

Disposal of batteries in the product

This product contains batteries covered by the Directive 2006/66/EC which must be collected and disposed of separately from

municipal waste.

If the battery contains more than the s pecified values of lead (Pb), mercury (Hg) or cadmium (Cd), these chemical symbols will appear

below the crossed-out wheeled bin symbol.

By participating in separate collection of batteries, you will help to ensure proper disposal and to prevent potential negative effects on the

environment and human health.

Page 4

Guarantee and Compensation

Barco provides a guara ntee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. O n receipt, the purchaser

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the fault o r p rovide a replacement

at its own discretion w ithin an appropriate period. If this measure proves to be impossible or unsuccessful, the purchaser ca n demand a

reduction in the purchase pr ice or cancellation of the contract. All other claims, in particular tho se relating to com pensa tion for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided by Barco, being a component

of the system or independent service, will be deemed invalid provided the damage is n ot proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out m odifications or repairs on goods delivered by B arco, or if the goods ar e handled incorrectly,

in particular if the systems are o perated incorrectly or if, after the transfer of risk s, the

the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are sy stem failures

which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as well as normal

maintenance are not subjec t to the guarantee provided by Barco either.

The environmental conditions as well as t he servicing and maintenance regulations specified in this manual must be com plied with by the

customer.

goods are subject to influences not agreed upon in

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be r ecorded, transmitted or

stored in a retrieval system without the prior written consent of Barco.

Software License Agreement

You should carefully read the following terms and conditions before using this software. Your use of this software indicates your acceptance

of this license agreement and warranty.

Terms and Conditions:

1. No redistribution of the software is allowed.

2. Reverse-Engineering. You may not reverse engineer, decompile, disassemble or alter this s oftware product.

Disclaimer of Warranty:

This software and the accompanying files are sold “as is” and without warranties as to performance or merchantability or any other war ranties whether expressed or implied. In no event shall B arco be

interruption or other pecuniary loss arising directly or indirectly. Any liability of the s eller will be exclusively limited to replacement of the

product or refund of purchase price.

liable for damage of any kind, loss of data, loss of profits, business

Page 5

Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................ 3

1.1 General considerations .............................................................................................................. 3

1.2 Important safety instructions ........................................................................................................ 5

1.3 Projector Hazard Distances ......................................................................................................... 7

1.4 High Brightness Precautions........................................................................................................ 7

1.5 Hazard Distance for fully closed projection system ................................................................................ 9

1.6 HD in function of the lens Throw Ratio (TR)........................................................................................10

1.7 Safety symbols ......................................................................................................................11

1.8 RoHS compliance ...................................................................................................................13

1.9 Contact adresses....................................................................................................................16

1.10 Product Info . . ........................................................................................................................ 16

1.11 Statement ............................................................................................................................ 16

2. Getting to know the projector .......... ................ ................ ................ ................ .........17

2.1 Main components . . ..................................................................................................................17

2.2 Service and maintenance . ..........................................................................................................18

2.3 LED status light ...................................................................................................................... 18

2.4 Power on / Standby button backlight indications ...................................................................................18

2.5 LCD panel . .. ........................................................................................................................ 19

2.6 Local keypad......................................................................................................................... 19

2.7 Remote control, Battery installation.................................................................................................20

2.8 Remote control, protocol setup .....................................................................................................21

2.9 Functionality overview ............................................................................................................... 22

2.10 Projector Address....................................................................................................................22

2.10.1 Controlling the projector ......................................................................................................22

2.10.2 Displaying and Programming addresses into the RCU . . ....................................................................23

2.11 Connector panel ..................................................................................................................... 23

2.12 Color Wheels ........................................................................................................................24

2.12.1 Color Wheel range . . . .........................................................................................................24

2.12.2 Change the color wheel ...................................................................................................... 24

2.13 Optional accessories ................................................................................................................25

3. Lenses.................... ................ ................ ................ ................ ................ ...........27

3.1 Approved Lenses . .. .................................................................................................................27

3.2 Lens range . . . ........................................................................................................................ 27

3.3 Replace a lens.......................................................................................................................29

3.4 Lens shift............................................................................................................................. 31

3.5 Adjust zoom,focus andiris..........................................................................................................31

4. Physical installation ..............................................................................................33

4.1 Installation process ..................................................................................................................33

4.2 Installation conditions ............................................................................................................... 33

4.3 Initial inspection......................................................................................................................35

4.4 Positioning the projector............................................................................................................. 36

4.5 Mounting the projector, general considerations . ...................................................................................36

4.6 Projector safe attachmentpoints....................................................................................................38

4.7 Throw distance ......................................................................................................................38

4.8 Scheimpflug (Boresight) adjustment ................................................................................................41

4.9 Scheimpflug adjustment procedure .................................................................................................42

5. Getting started .......... ................ ................ ................ ................ .................. .........45

5.1 Projector source and control connections . . ........................................................................................45

5.1.1 Making connections . . ......................................................................................................... 45

5.1.2 Connector specifications...................................................................................................... 45

5.1.2.1 DVI-I ....................................................................................................................45

5.1.2.2 Display Port 1.2 ........................................................................................................46

5.1.2.3 HDMI 2.0................................................................................................................46

5.1.2.4 3G-SDI..................................................................................................................47

5.1.2.5 HDBase T...............................................................................................................47

5.1.3 Control interfaces.............................................................................................................47

5.1.3.1 RS-232..................................................................................................................48

5.1.3.2 LAN/Ethernet...........................................................................................................48

5.1.3.3 USB-A port .............................................................................................................48

5.2 Power upthe projector ..............................................................................................................48

5.3 Power down the projector ........................................................................................................... 48

5.4 Power modes ........................................................................................................................49

5.5 Customize projector settings ........................................................................................................49

5.6 User interface........................................................................................................................49

5.6.1 On Screen Display (OSD) ....................................................................................................49

6. Source menu ...... ................ ................ ................ ................ ................ ................ .51

6.1 Connector selection .................................................................................................................51

6.2 Connector Settings ..................................................................................................................51

601–0400 F90 SERIES. 10/05/2017

1

Page 6

Table of contents

6.3 Using Dual DVI or Dual Display Port................................................................................................51

7. Image menu ................... ................ ................ ................ ................ ................ .....53

7.1 Output Resolution ...................................................................................................................53

7.2 Contrast..............................................................................................................................53

7.3 Brightness ........................................................................................................................... 53

7.4 Saturation ............................................................................................................................ 53

7.5 Advanced image adjustments ....................................................................................................... 53

8. Installation menu ..................................................................................................55

8.1 Lens . . ................................................................................................................................55

8.2 Orientation...........................................................................................................................55

8.3 Warp ................................................................................................................................. 56

8.4 Basic Blend ..........................................................................................................................57

8.5 Illumination...........................................................................................................................59

9. Settings menu......... ................ ................ ................ ................ ................ .............61

9.1 Communication ...................................................................................................................... 61

9.2 Apply a menu theme ................................................................................................................61

9.3 Service ...............................................................................................................................61

10. Status menu ............. ................ ................ ................ ................ ................ ...........63

10.1 Source status........................................................................................................................63

10.2 Product...............................................................................................................................63

10.3 Illumination........................................................................................................................... 63

10.4 Communication ......................................................................................................................63

11. Reset Menu.........................................................................................................65

11.1 Factory Reset........................................................................................................................65

11.2 Selectable Reset .................................................................................................................... 65

12. User Maintenance .................................................................................................67

12.1 Update Projector Firmware. .........................................................................................................67

13. Cleaning the projector............... ................ ................ ................ ................ .............69

13.1 Projector lenses .....................................................................................................................69

13.2 Projector cabinet.....................................................................................................................69

13.3 Filters ................................................................................................................................69

2

601–0400 F90 SERIES. 10/05/2017

Page 7

1. SAFETY

About this chapter

Read this c hapter thoroughly before attempting to install or operate the projector.

To prevent personal injury to users or physical damage to the projector while installing and using your projector, ensure that you

understand and follow all safety guidelines, instructions and warnings included in this chapter and this manual.

Clarification of the term F70 / F90 series used in this document

Use in this document of the term, F70 / F90 series, means that the content is applicable for the followi

• F90–W13WUXGA

• F90–4K13 4KUHD/WQXGA

•F70—4K6

•F70—W6

Defining the GP6 platform

The F90 series products in general, are all p roducts within the Barco GP6 Platform.

Defining the GP7 platform

The F70 series products in general, ar e all products within the Barco GP7 Platform

Overview

ng products:

1. Safety

• General considerations

• Important safety instructions

• Projector Hazard Distances

• High B rightness Precautions

• Hazard Distance for fully closed projection system

• HD in function of the lens Throw Ratio (TR)

• Safety sym bols

• RoHS compliance

• Contact adresses

• Product Info

• Statement

1.1 General considerations

Notice on optical radiation F90 Series

• The projector is Class 1 laser product that conforms with IEC EN 60825-1:2014. For Northern America, the projector is class

3R laser product up to throw ratio 2.33. The projector conforms with IEC 60825–1:2007, and with performance standards for

laser products under 21 CFR 1040, except with respect to those characteristics authorized by Variance Number 2016–V-0144

effective March 6, 2017

Do no t stare into Beam.

• This projector is Risk Group 2 (RG2) according to IEC EN 62471-5.

This projector may become Risk Group 3 (RG3) when an interchangeable lens with throw ratio greater than 3.15 is installed.

For Northern America, installation requirements according to Risk group 3 (RG3) must be followed when interchangeable lens

with throw ratio greater than 2.33 is installed.

Refer to the manual for the lens list and throw ratio before operation.

Such combination of projec tor and lens are intended for professional use only, and are not intended for consumer use.

• For RG3, no direct exposure to the beam shall be permitted.

For RG3, operators s hall control access to the beam within the hazard distance or install the product at a height that will p revent

eye exposure within the hazard distance.

• This projector has two (2) built-in Class 4 laser clusters. Disassembly or modification is very dangerous and should never be

attempted.

• Any operation or adjustment not specifically instructed by the user’s guide creates the risk of hazardous laser radiation exposure.

• Do not open or disassemble the projector as this may cause damage by the exposure of laser radiation.

601–0400 F90 SERIES. 10/05/2017

3

Page 8

1. Safety

Notice on optical radiation F70 Series

• The projector is Class 1 laser product that conforms with IEC EN 60825-1:2014. For Northern America, the projector is class

3R las er product up to throw ratio 2.5. The projector conforms with IEC 60825–1:2007, and with performance standards for

laser products under 21 CFR 1040, except with respect to those characteristics authorized by Variance Number 2016–V-0144

effective March 6, 2017

Do no t stare into Beam.

• This projector is Risk Group 2 (RG2) according to IEC EN 62471-5.

This projector may become Risk Group 3 (RG3) when an interchangeable lens with throw ratio greater than 4.

Northern America, installation requirements according to Risk group 3 (RG3) must be followed w hen interchangeable lens with

throw ratio greater than 2.5 is installed.

Refer to the manual for the lens list and throw ratio before operation.

Such combination of projec tor and lens are intended for professional use only, and are not intended for consumer use.

• For RG3, no direct exposure to the beam shall be permitted.

For RG3, operators s hall control access to the beam within the hazard distance or install the product at a height that will p revent

eye exposure within the hazard distance.

• This projector has one (1) built-in Class 4 laser clusters. Disassembly or modification is very dangerous and should never be

attempted.

• Any operation or adjustment not specifically instructed by the user’s guide creates the risk of hazardous laser radiation exposure.

• Do not open or disassemble the projector as this may cause damage by the exposure of laser radiation.

7 is installed. For

General safety instructions

• This product contains no user serviceable parts except the Color Wheel. Attempts to modify/replace mechanics or electronics

inside the housing or compartm ents will violate any warranties and may be hazardous.

Do not remove/replace any other parts than the Color Wheel. Other parts, service personnel only – Warranty void if Removed.

Follow the instructions in the User Guide to replace the Color Wheel.

• Do not stare into beam when the projector is on. The bright light may result in permanent eye damage.

• Not following the prescribed control, adjustment or operation procedure may cause damage by the exposure of laser radiation.

• Before operating this equipment please read this manual thoroughly and retain it for future reference.

• Installation and preliminary adjustments should be performed by properly trained and qualified personnel.

• All warnings on the projector and in the documenta tion manuals m ust be adhered to.

• All instructions for operating and use of this equipment must be followed precisely.

• All local installation codes should be adhered to.

Notice on safety

This equipment is built in accorda nce with the requirements of the international safety standards IEC 60950-1, as basis for National

safety regulation world wide. The safety standard covers information technology equipment including electrical business equipment

intended to operate in “normal” environments (offices and homes). This safety standard imposes important requirements o n the

use of safety critical components, materials and insulation, in order to protect the user or operator against risk of electric shock and

energy hazard and having access to live parts. Safety standards also impose limits to the internal and external temperature rises,

radiation levels, mechanical stability and strength, enclosure construction and protection against the risk of fire. Simulated single

fault condition testing reduce the risk of hazards and contribute to ensure the safety of the equipm ent to the user even when the

equipment’s normal operation fails.

Users definition

Throughout this manual, the term SERVICE PERSONNE L refers to Barco authorized persons having appropriate technical training

and experience necessary to be knowledgeable of potential hazards to which they are exposed (including, but not limited to HIGH

VOLTAGE ELEC TRIC and ELEC TRONIC CIRCUITRY and HIGH BRIGHTNESS PROJ ECTORS) in performing a task, and of measures to minimize the potential risk to themselves or other persons. Only Barco authorized SERVICE PERSONNEL, knowledgeable

of such risks, are allowed to perform service functions inside the product enclosure. The term USER and OPERATOR refers to any

person other than SERVICE PERSONNEL. When an interchangeable lens with throw ratio 3.15 or more is installed, the F70 / F90

series projector becomes RG3. Refer to the manual for the lens list and hazard distance before operation. Such combination of

projector and lens are intended for professional use only, and are not intended for consumer use.

FOR PRO FESS IONAL USE ONLY means installation can only be carried out by Barco AUTHORIZED PERSONNEL familiar with

potential hazards associated with high i

ntensity light beam s.

4

601–0400 F90 SERIES. 10/05/2017

Page 9

1.2 Important safety instructions

To prevent the risk of electrical shock

• This product should be operated from a mono phase AC power source.

• This apparatus must be grounded (earthed) via the supplied 3 conductor AC power cable. If none of the supplied power cables

are the correct one, consult your dealer.

If you are unable to insert the plug into the outlet, co ntact your electrician to replace your obsolete outlet. Do not defeat the

purpose of the grounding-type plug.

Never use 2-prong power cords, as this is dangerous and could lead to electrical shock.

• Do not allow anything to rest on the power c ord. Do not locate this product where persons will walk on the cord. To disconnect

the cord, pull it out by the plug. Never pull the cord itself.

• Use only the power cord supplied w ith your device or original replacement cords. While appearing to be similar, other power

cords have not been safety tested at the factory and may not be used to power the device. F or a replacement power cord,

contact your dealer.

• Do not operate the projector with a damaged cord. Replace the cord.

Do not operate the projector if the projector has been dropped or dam aged - until it has been examined and approved for

operation by a qualified service technician.

• Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

• If an extension cord is necessary, a cord with a current rating at least equal to that of the projector should be used. A cord rated

for less amperage than the projector may overheat.

• Never push objects of any kind into this product through cabinet slots as they may touch dangerous voltage points or sho rt out

parts that could result in a risk of fi re or electrical shock.

• Make sure that no objects enter into the vents and openings of the set.

• Do not expose this projector to rain or moisture.

• The projector is designed for indoor use only. Never operate the unit outdoors.

• Do not immerse or expose this projector in water or other liquids.

• Do not spill liquid of any kind on this projector.

• Should any liquid or solid object fall into the c abinet, unplug the set and have it checke

resuming op erations.

• Do not d isassemble this projector, always take it to an authorized trained service person when service or repair work is required.

• Do not use an accessory attachment whic h is not recommended by the manufacturer.

• Lightning - For added protection for this video product during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet. This will prevent damage to the device due to lightning and AC power-line surges.

d by qualified service personnel befo re

1. Safety

To prevent personal injury

• To prevent injury and physical damage, always read this m anual and all labels on the system before connecting to the w all

outlet or adjusting the projector.

• To prevent injury, take note of the weight of the projector.

• To prevent injury, ensure that the lens and all covers are correctly installed. See installation procedures.

• Warning: high intensity light beam. NEVER look into the lens! High luminanc e could result in damage to the eye.

• Warning: extremely high brightness laser: This projector uses extremely high brightness laser. Never attempt to look directly

into the lens or at the laser.

• Always switch off the projector and disconnect from the mains power supply before attempting to remove any of the p rojector

covers or access parts inside the projector.

• This product contains no user serviceable parts except the Color Wheel. Attempts to modify/replace mechanics or electronics

inside the housing or compartm ents will violate any warranties and may be hazardous.

• Do not remove/replace any other parts than the Color Wheel. Other parts, s

• Do not place this equipment on an unstable cart, stand, or table. The product may fall, causing serious damage to it and

possible injury to the user.

• Only place the projector on a stable surface, or mount it securely using an approved ceiling-mount.

• It is hazardous to operate without lens or lens cap. Lenses or shields shall be changed if they have bec ome visibly damaged,

for example with cracks or deep scratches, to such an extent that the ir effectiveness is impaired.

ervice personnel only Warranty void if removed

601–0400 F90 SERIES. 10/05/2017

5

Page 10

1. Safety

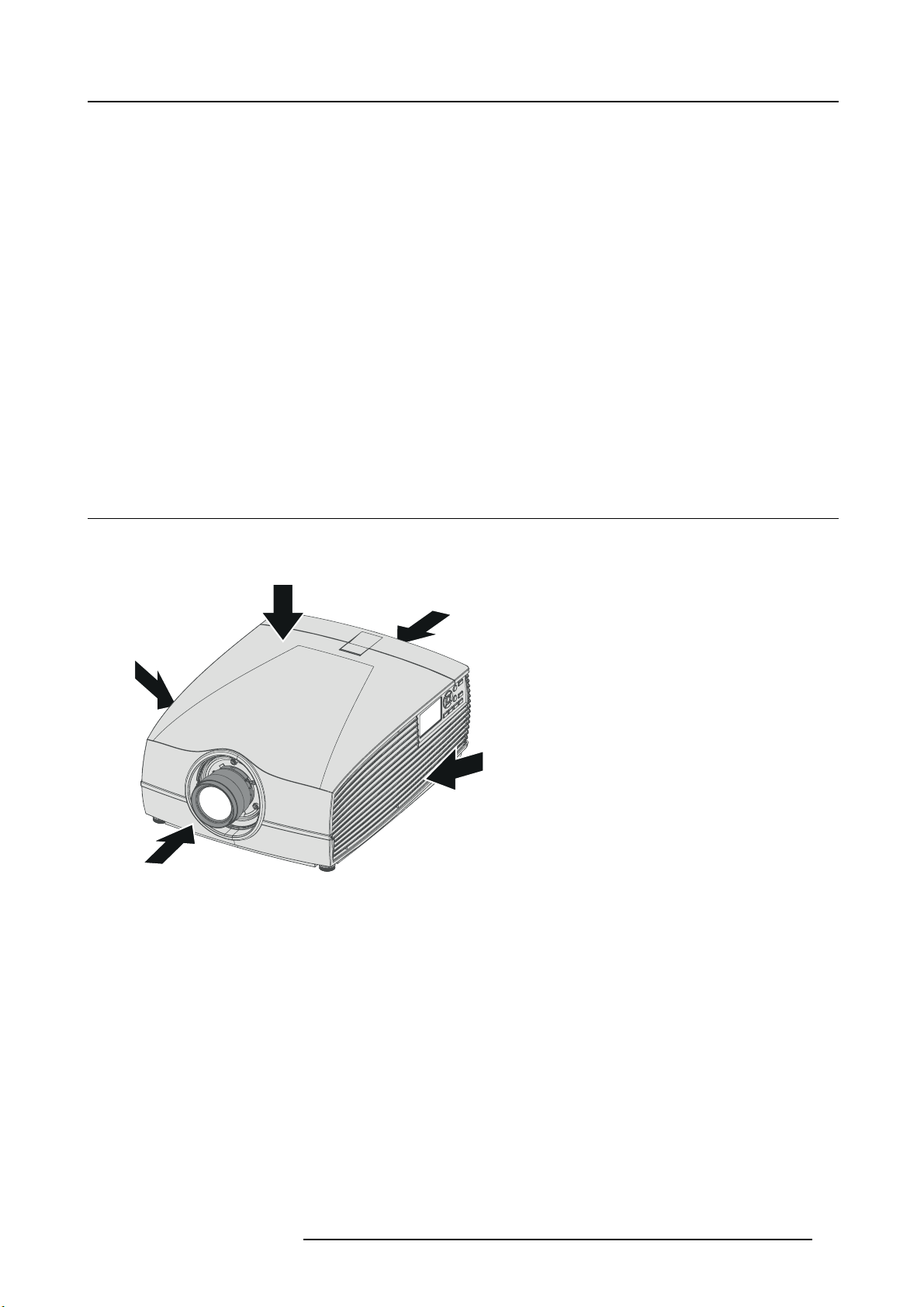

To prevent fire hazard

• Barco projection products are designed and manufactured to meet the most s tringent safety regulations. This projector radiates

heat on its external surfaces and from ventilation ducts during normal operation, which is both normal and safe. Exposing

flammable or combustible m aterials into close proximity of this projector could result in the spontaneous ignition of that material,

resultinginafire. For this reason, it is absolutely necessary to leave an “exclusion zone” around all external s urfaces of the

projector whereby no flammable or combustible materials are present. The exclusion zone in the exhaust area must be not

less than 100 cm (40”). The exclusion zone on the intake area must not be less than 50 cm (20”).

• Do not place flammable or combustible materials near the projector!

• For the F90 projector, the exclusion zone on the lens side within the light beam must be at least 1,5m.

• For the F70 projector the exclusion zone on the lens side within the light bea m must be at least 1,0m.

• Caution! Hot air is exhausted from the rear vent. Do not place objects that are sensitive to heat nearer than 100 cm ( 40”) to

the ex haust vent.

• Slots and openings in this equipment are provided for ventilation. To ensure reliable operation of the projector and to protect it

from overheating, these openings must not be blocked or covered.

• The openings should never be blocked by placing the projector too close to walls, or other similar surface. A llow for sufficient

distance to walls and ceilings to avoid overheating. Minimum s afety distance to the exhaust area of the unit must not be less

than 100 cm (40”) and to the intake area, not less than 50 cm (20”).

• This projector should never be placed near or over a radiator or heat register.

• This projector should not be placed in a built-in installation o r enclosure unless proper ventilation is provided.

• Do not cover the projector or the lens with any material while the projector is in operation. Keep flammable

materials away from the projector at all times.

• Mount the p rojector in a well-ventilated area away from sources of ignition and out of direct sun light. A lways allow ample airflow

through the projector.

• Never expose the projec tor to rain or moisture. In the event of fire, use sand, CO2 or d ry powder fire extinguishers.

• Never use water on an electrical fire.

• Always have service performed on this projector by authorized B arco service perso

placement parts. Nev er use non-Barco replacem ent parts as they may degrade the safety of this projector.

• Projection rooms must be well ventilated or cooled in order to avoid heat buildup.

• Let the projector cool down completely before storing. Remove cord from the projector when storing.

nnel. Always insist on genuine Barco re-

and combustible

To prevent projector damage

• To ensure correct airflow is maintained the projector should only be operated when all of its covers in place.

• Always remove lens cap before switching on th e projector. If the lens cap is not rem oved, it m ay melt due to the high energy

light emitted through the lens. Melting the lens cap may permanently damage the surface of the projection lens

• Only connect the projector to signal sources and voltages as described in the technica l specification. Connecting to unspecified

signal sources or voltages may lead to malfunction and permanent damage of the unit.

• To ensure correct airflow is maintained, it should only be operated when all of its covers are in place.

• The projector must always be installed in a manner which ensures free flow of air into its air inlets and unim peded evacuation

of the hot air from its cooling system.

• Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to protect it from

overheating, these openings must not be blocked or covered. The openings should never be blocked by placing the p roduct

on a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or heat register. The

device should not be placed in a built-in installation or enclosure unless proper ventilation is provided. Ensure that nothing c an

be spilled on, or dropped inside the projector. If this does happen, switch off and unplug the mains supply immediately. Do not

operate the projector again until it has been checked by Barco authorized service personnel.

• Do not block the projector cooling fans or free air m ovem ent around the projector. Minimum safety distance to the exhaust area

of the unit must not be less than 100 cm (40”) and to the intake area, not less than 50 c m (20”).

• Do not use this equipment near water.

• Do not operate the projector outside its temperature and humidity specifications as this may result in overheating and malfunction.

• Never place the projector in direct sun light. Sun light on the lens can severely damage the Digital Mirror Devices™ in which

case there is a loss of warranty.

• Save the original shipping carton and packing material. T hey will come in handy if y ou ever have to ship your equipment. For

maximum protection, repack your set as it was originally packed at the factory.

• Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp cloth for

cleaning. Never use strong solvents, such as thinner or benzine, or abrasive cleaners, since these will damage the cabinet.

Stubborn stains m ay be removed with a cloth lightly dampen ed with mild detergent solution.

• To ensure the highest optical performance and resolution, the projection lenses are specially treated with an anti-reflective

coating, therefore, avoid touching the lens. To remove dust on the lens, use a soft dry cloth. Do not use a damp cloth, detergent

solution, or thinner.

6

601–0400 F90 SERIES. 10/05/2017

Page 11

1. Safety

On servicing

• Do not attempt to service this product y ourself, as opening or removing covers may expose you to dangerous voltage p otentials

and risk of electric shock.

• Refer all servicing to Barco authorized repair centers.

• Attempts to alter the factory-set internal controls or to change other control settings not specially discussed in this manual can

lead to permanent damage to the projector and cancellation of the warranty.

• Unplug this product from the wall outlet and refer servicing to Barco authorized service pers onnel or technicians under the

following conditions:

- If liquid has been spilled into the equipment.

- If the product has been expo sed to rain or water.

- If the p roduct does not o perate normally when the operating instructions ar e followed. Adjust only those controls that are

covered by the operating instructions since improper adjustment of the other controls may r esult in damage and will often

require extensive work by a qualified technician to restore the product to normal operation.

- If the product has been dropped or the cabinet has been dam aged.

- If the product exhibits a distinct change in per formance, indicating a need for service.

- When the power cord or plug is damaged or frayed.

• Replacement parts: When replacement parts are re quired, be sure the service technician has used original Barco replacement parts. U nauthorized substitutions may result in degraded performance and reliability, fire, electric shock or other hazards.

Unauthorized substitutions may v oid warranty.

• Safety check: Upon completion of any service or repairs to this projector, ask the service technician to perform safety checks

to determine that the product is in proper operating condition.

1.3 Projector Hazard Distances

For F90 series: WARNING. This may be a RG3 laser Product, dependent on whi ch lens u

This projector may become Risk Group 3 (RG3) whe n an interchangeable lens with throw ratio greater than 3.15 is installed. For

Northern America, installation requirements according to Risk group 3 (RG3) must be followed when interchangeable lens with throw

ratio greater than 2.33 is installed

Refer to t he product ma nual for the lens list and throw ratio before operation.

Do not look directly in to the beam from the projector lens.

No direct eye exposure to the beam is permitted.

Operators shall c ontrol access to the beam within the hazard distance or install the product at a height that will prevent eye exposure

within the hazard distance.

See table below for a definition of hazardous dis tances versus the throw ratio of the lens.

For F70 Series: WARNING. This may be a R G3 laser Product, dependent on which lens used.

This projector may becom e Risk Group 3 (RG 3) when an interchangeable lens with throw ratio greater than 4.7 is installed. For

Northern America, installation requirements according to Risk group 3 (RG3) must be followed when interchangeable lens with throw

ratio greater than 2.5 is installed

Refer to t he product ma nual for the lens list and throw ratio be

Do not look directly in to the beam from the projector lens.

No direct eye exposure to the beam is permitted.

Operators shall c ontrol access to the beam within the hazard distance or install the product at a height that will prevent eye exposure

within the hazard distance.

See table below for a definition of hazardous dis tance

s versus the throw ratio of the lens.

fore operation.

sed.

1.4 High Brightness Precautions

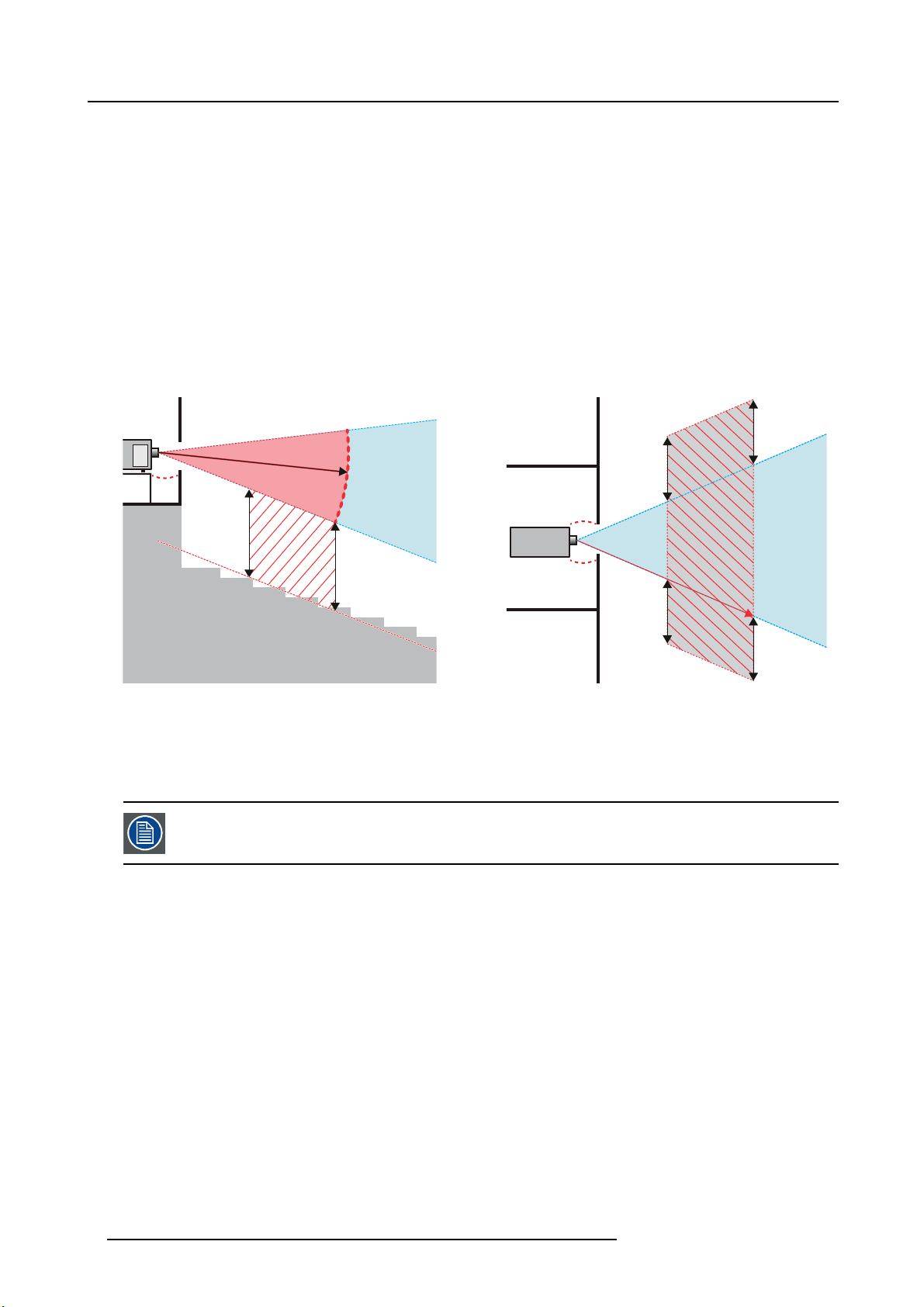

Restriction Zone (RZ) based on the HD (Hazard Distance).

The HD depends on the amount of lumens produced by the projector and the type of lens installed. S ee next chapter"HD in function

of the lens Throw Ratio (TR)", page 8 .

To protect untrained end users (as cinema visitors) the installation shall comply with the following installation requirements: Operators shall control access to the beam within the hazard distance or install the product at the height that will prevent spectators’ eyes

from being in the hazard distance. Radiation le

above any surface upon which persons other than operators, performers, or employees are permitted to stand or less than 1.0 meter

(SH) lateral separation from any place where such persons are permitted to be. In non-cinema environments where unrestrained

601–0400 F90 SERIES. 10/05/2017

vels in excess of the limits will not be permitted at any point less than 2.0 meter (SH)

7

Page 12

1. Safety

behavior is reasonably foreseeable, the minimum separation height should be greater than or equal to 3.0 meter to prevent potential

exposure, for example by an individual sitting on another individual’s sho ulders, within the HD.

These values are minimum values and are based on the guidance provided in IEC 62471-5:2015 section 6.6.5.

The end user m ust understand the risk and apply protective measures based upon the hazard distance as indicated on the label and

in the user information. Installation method, barriers, detection system or other applicable control measure shall prevent hazardous

eye access to the radiation within the hazard distance.

For example, projectors that have a HD greater than 1 m and emit light into an un controlled area where pe rsons may be present

should be positioned in accordance with “the fixed projector installation” parameters, resulting in a HD that does not extend into

the audience area unless the beam is at least 2.0 meter above the floor level. In non-c inema environmen

behavior is reasonably foreseeable, the minimum separation height should be greater than or equal to 3.0 meter to prevent potential

exposure, for example by an individual sitting on another individual’s shoulders, within the HD. For example, a sufficiently large

separation height may be achieved by mo unting the image projector on the ceiling or through th

For applications installed in the USA market the abov e limits for cinema like environments do not apply. The relevant minimum

separation height is 2.5m (8,2 ft) by the FDA CDRH. Non cinema like environments require 2.5 meter (8.2 ft) separation height

and 1.0 me ter (3.3 ft) separation width for areas where restrained behavior is to be expected. All other areas require 3.0 (9.9 ft)

separation height.

e use of physical bar riers.

ts where unrestrained

RA TH

SH

Image 1-1

A Side View

BTopView

RA Restricted Area

PR Projector

TH Theater

RZ Restriction Zone in the theater

SH Separation Height

SW Separation Width

Regarding the SH Distance: For Cinema applications, the distance must be >2m. For Concert applications,

thedistancemustbe>3m.

HD

RZ

SH

TH

SW

RZ

SW

RA

PR

HD

SW

1m

SW

(B) TOP VIEW(A) SIDE VIEW

Based on national requirements, no person is allowed to enter the projected beam within the zone between the projection lens and

the related hazard dis tance (HD). This shall b e physically impossible by creating sufficient separation height or by placing bar riers.

The minimum separation height takes into account the surface upon which persons other than operator, performers or employees

are permitted to stand.

On image 1-2 a typical setup is displayed. It must be verified if these minimum requirements are met. If required a restricted zone

(RZ) in the theater must be established. This c an be done by using physical barrier, like a red rope as illustrated in image 1-2.

The restricted a rea sticker can be replaced by a sticker with only the sy mbol.

8

601–0400 F90 SERIES. 10/05/2017

Page 13

Image 1-2

RESTRICTED

AREA

AREA

1. Safety

PR

RESTRICTED

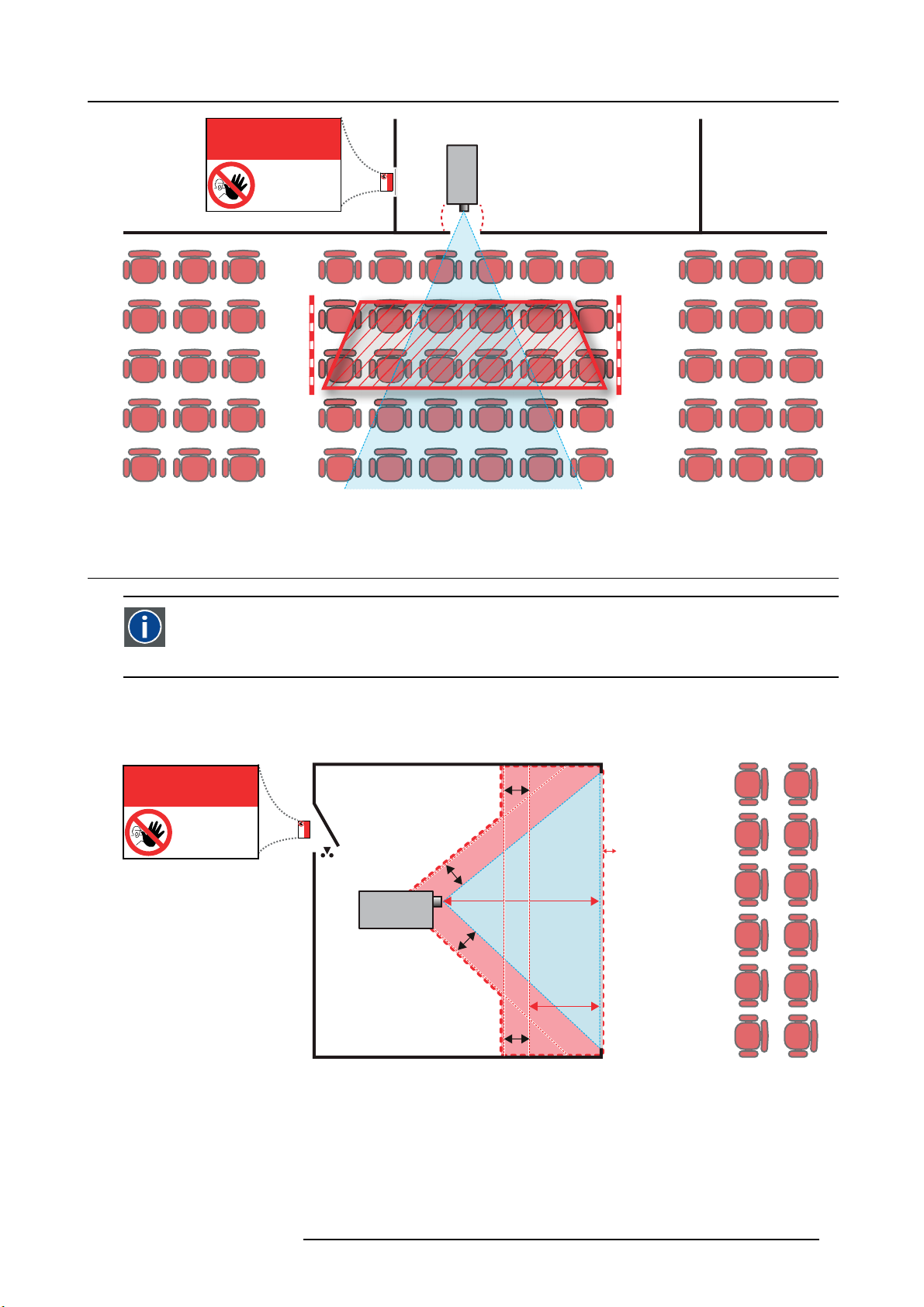

1.5 Hazard Distance for fully closed projection system

HD

Hazard Distance (HD) is the distance measured from the projection lens at which the intensity or the energy per surface

unit becomes lower than the ap plicable exposure limit on the cornea or on the skin. The light beam is considered (to

be) unsafe for exposure if the distance from a person to t

he light source is less than the HD .

Restriction Zone RZ Based on the HD

The projector is also suitable for rear proje

in image 1-3 two areas should be considered: the restricted enclosed pr ojection a rea (RA) and the observation area (TH).

RESTRICTED

ction applications; projecting a beam onto a defuse coated projection screen. As displayed

RA TH

sw

AREA

RESTRICTED

AREA

HDDIFFUSE

RZ

sw

PR

sw

PD

HD

REFLECTION

Image 1-3

RA Restricted Access location (Enclosed projection area)

PR Projector.

TH Theater (observation area).

RZ Restriction Zone

PD Projection Distan

SW Separation Widt

Restriction zo

h. Must be minimum 1 meter.

ne (RZ) based on the HD continued.

For this type of setup 3 different HD sh all be considered:

601–0400 F90 SERIES. 10/05/2017

sw

9

Page 14

1. Safety

• HD as discussed in "High Brightness precautions: Hazard Distance (HD)", page 6 , relevant for intrabeam exposure.

• HDreflection : the distance that has to be kept restrictive related to the reflected light from the rear projection screen.

• HDdiffuse : the relevant distance to be considered while observing the defuse surface of the rear projec tion sc reen.

As desc ribed in "High Brightness precautions: Hazard Distance ( HD)", page 6 , it is mandatory to create a restricted zone within

the beam areas closer than any NOHD. In the enclosed projection area the combination of two restricted zones are relevant: The

restricted zone of the projected beam toward the screen; taking into account 1 meter Separation Width (SW) from the beam onward.

Combined with the restricted zone related to the rear reflection from the screen (HDreflection); also taking into ac count a 1 m eter

lateral separation.

The HDreflection distance equals 25 % of the difference between the determined HD distance and the projection distance to the rear

projection screen. To determine the HD distance for the used lens a nd projector model see graphs in chapter "HD in f unction of the

lens Throw Ratio (TR)", page 8 .

HDreflection = 25% (HD – PD)

The light emitted from the s creen within the observation shall never exceed the RG 2 exposure limit, determined at 10 cm. The

HDdiffuse can be neglected if the m easured light at the screen surface is below 5000 c d/m² or 15000 LUX.

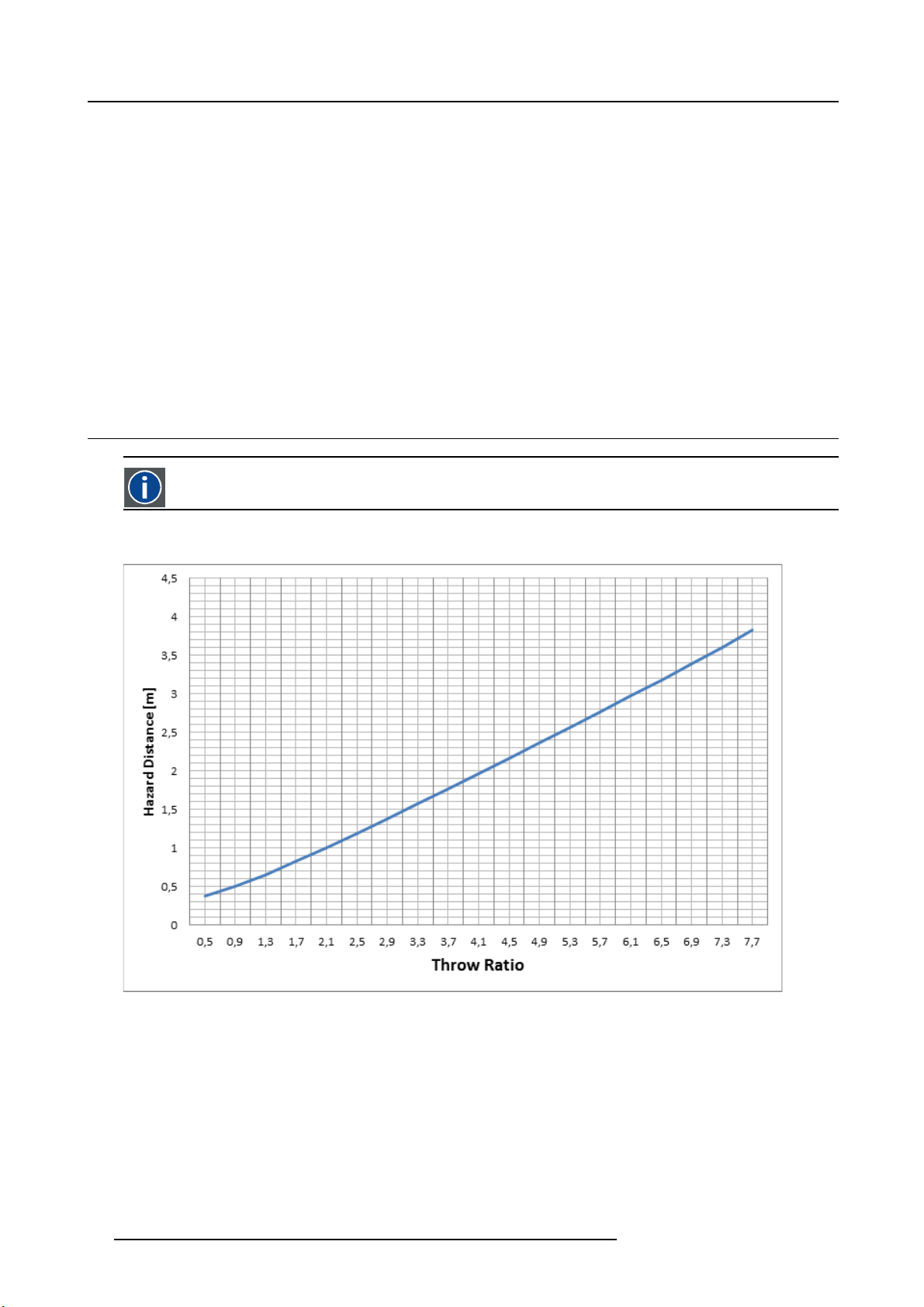

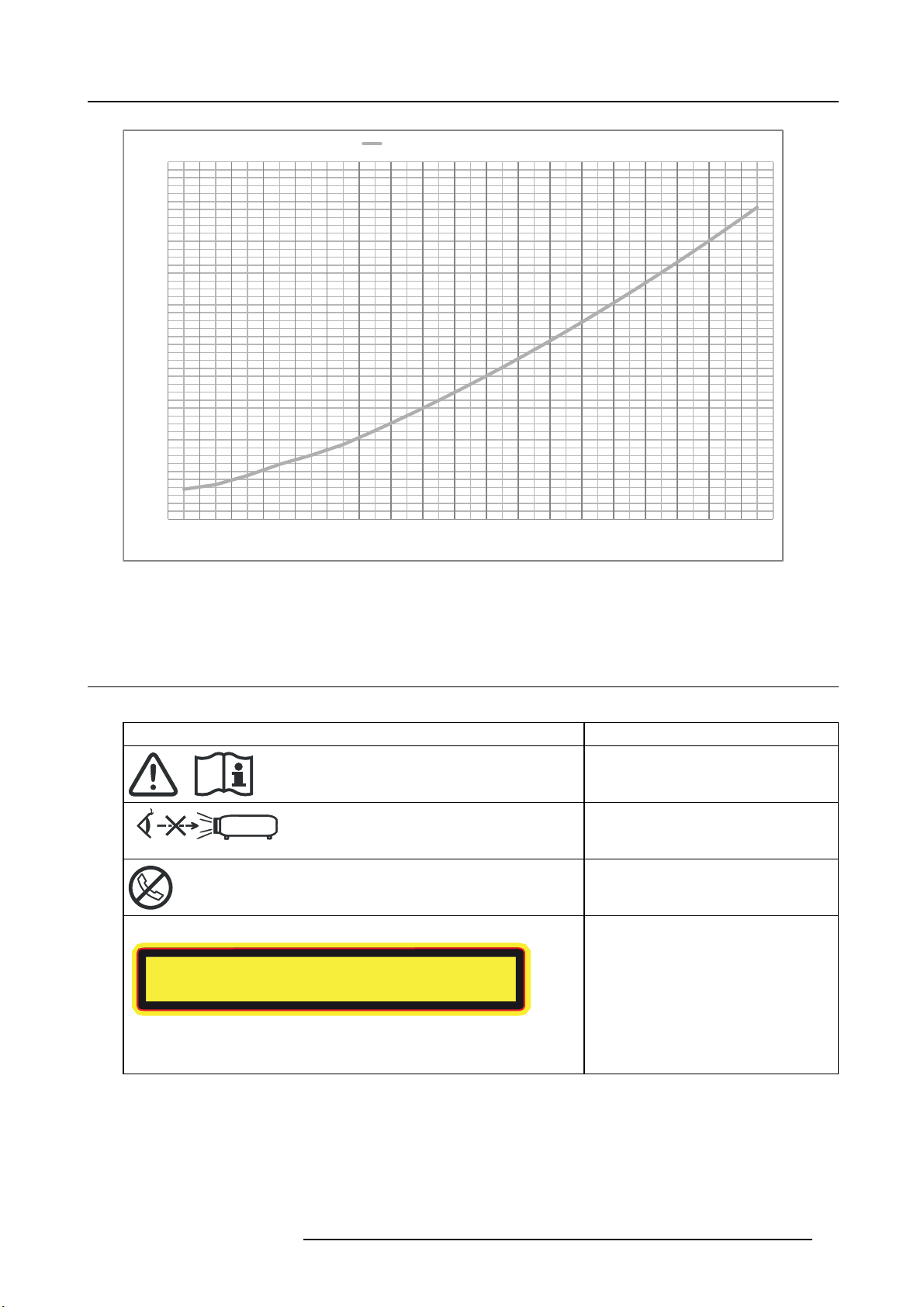

1.6 HD in function of the lens Throw Ratio (TR)

TR (Throw Ra ti o)

The ratio of the distance to the screen (throw) to the screen width.

HD versus Throw Ratio

Image 1-4

Hazard Distance in meters versus Throw ratio of the lens for the F90 projectors

10 601–0400 F90 SERIES. 10/05/2017

Page 15

Hazard Distance Thermal Acidental Exposure

䲙

1,8

1,6

1,4

1,2

1

0,8

Hazard Distance [m]

0,6

0,4

0,2

0

0,5 0,9 1,3 1,7 2,0 2,3 2,7 3,1 3,5 3,9 4,3 4,7 5,1 5,5 5,9 6,3 6,7 7,1 7,5

Image 1-5

Hazard Distance in meters versus Throw ratio of the lens for the F70 projectors

Throw Rao

Graphs shows Hazard D istance in m eters versus Throw ratio o f the lens

1. Safety

1.7 Safety symbols

Description of safety symbols used in product documentation or on product.

Image Description

Refer to user manual for further information!

Caution! Do not stare into beam, RG2

product.

No telephone! Do not connect to telephone

lines.

For F90 series: Warning Label

For North America, this projector may become RG3 when an interchangeable lens with throw ratio greater than

2.33 is installed. Refer to the manual for the lens list and hazard distance before operation. Such combinations of

projector and lens are intended for professional use only, and are not intended for consumer use.

Ce projecteur peut devenir un projecteur RG3 en cas d'installation d'un objectif interchangeable

dont le rapport de projection est supérieur à 3,15. Veuillez vous reporter au manuel pour en savoir

plus sur la liste des objectifs et la distance de sécurité avant toute utilisation. De telles combinaisons

entre projecteur et objectif sont conçues pour des applications professionnelles uniquement et pas

pour des applications grand public.

This projector may become RG3 when an interchangeable lens with throw ratio greater than 3.15 is

installed. Refer to the manual for the lens list and hazard distance before operation. Such combinations

of projector and lens are intended for professional use only, and are not intended for consumer use.

ᵜᣅᖡᵪᆹ㻵ᣅሴ∄བྷҾ3.15Ⲵᦒ䮌ཤˈᡀѪRG3DŽࡽˈ䈧৲㘳 ѝ䮌ཤঅ઼ড

䐍DŽ

ᵜᣅᖡᵪо䮌ཤ㓴ӵуъ֯⭘ˈ䶎Პ䙊⎸䍩㘵֯⭘DŽ

Caution! For North America: With

interchangeable lens with throw ratio greater

than 2.33, consider hazard distance and

installation requirements for RG3 product.

Refer User Manual.

Caution! With Interchangeable lens

with throw ratio greater then 3.15,

consider hazard distance and installation

requirements for RG3 product. Refer User

manual.

601–0400 F90 SERIES. 10/05/2017 11

Page 16

1. Safety

䲙

Image Description

For F90 series: FDA Label

THIS PRODUCT IS IN CONFORMITY

WITH PERFORMANCE STANDARDS

FOR LASER PRODUCTS UNDER 21

CFR 1040, EXCEPT WITH RESPECT TO

THOSE CHARACTERISTICS

AUTHORIZED BY VARIANCE NUMBER

2016-V-0144 EFFECTIVE

MARCH 6, 2017.

For F70 Series: Warning label

For North America, this projector may become RG3 when an interchangeable lens with throw ratio

greater than 2.5 is installed. Refer to the manual for the lens list and hazard distance before operation.

Such combinations of projector and lens are intended for professional use only, and are not intended

for consumer use.

Ce projecteur peut devenir un projecteur RG3 en cas d'installation d'un objectif interchangeable

dont le rapport de projection est supérieur à 4.7. Veuillez vous reporter au manuel pour en savoir

plus sur la liste des objectifs et la distance de sécurité avant toute utilisation. De telles combinaisons

entre projecteur et objectif sont conçues pour des applications professionnelles uniquement et pas

pour des applications grand public.

For F70 Series: FDA Label

THIS PRODUCT IS IN CONFORMITY WITH

PERFORMANCE STANDARDS FOR LASER

PRODUCTS UNDER 21 CFR 1040, EXCEPT

WITH RESPECT TO THOSE CHARACTERISTICS

AUTHORIZED BY VARIANCE NUMBER

2016-V-0144 EFFECTIVE MARCH 6, 2017.

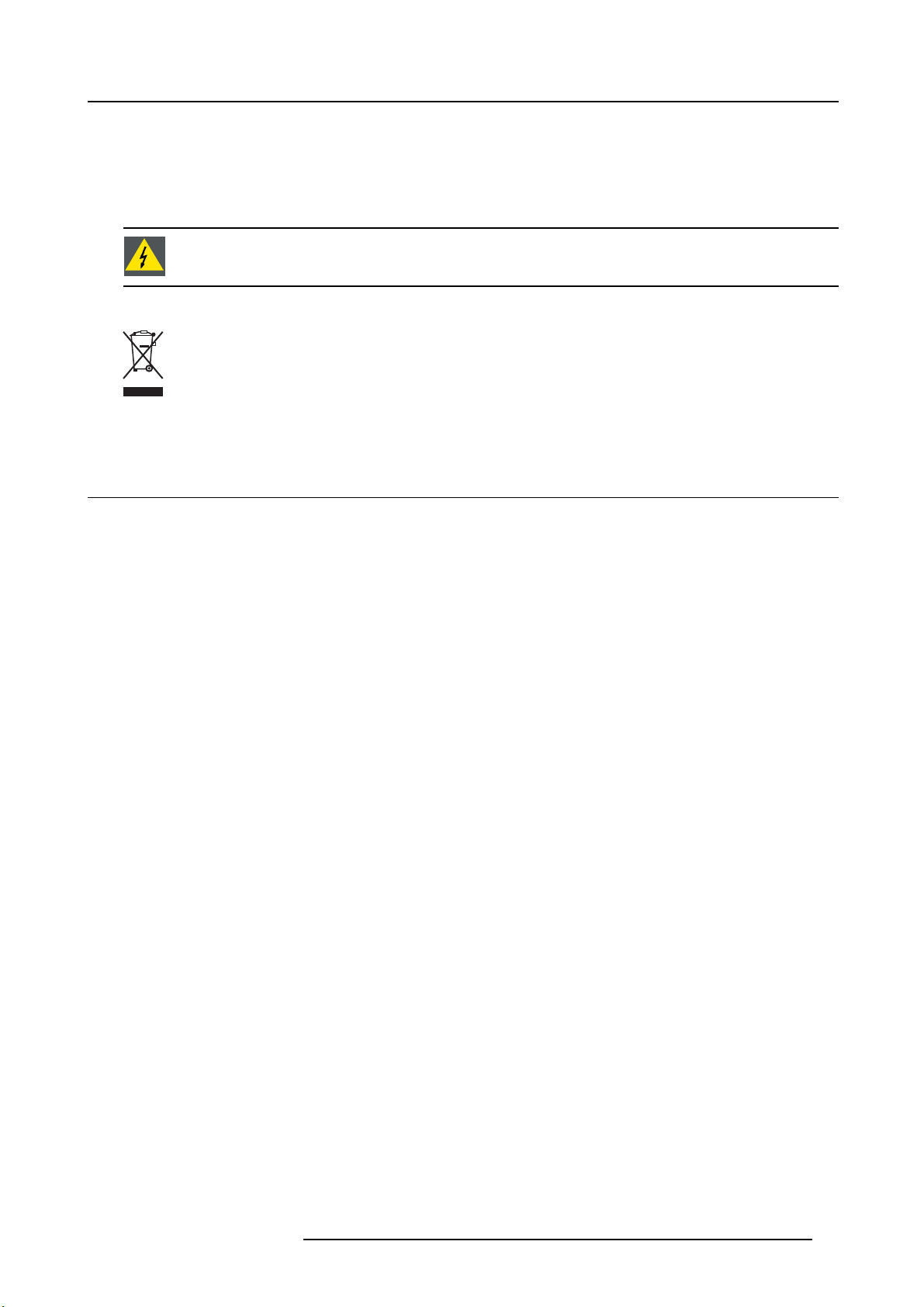

Location of Safety Label

This projector may become RG3 when an interchangeable lens with throw ratio greater than 4.7 is

installed. Refer to the manual for the lens list and hazard distance before operation. Such

combinations of projector and lens are intended for professional use only, and are not intended

for consumer use.

ᵜᣅᖡᵪᆹ㻵ᣅሴ∄བྷҾ4.7 Ⲵᦒ䮌ཤˈᡀѪRG3DŽࡽˈ䈧৲㘳ѝ䮌ཤঅ઼ড

䐍DŽ

ᵜᣅᖡᵪо䮌ཤ㓴ӵуъ֯⭘ˈ䶎Პ䙊⎸䍩㘵֯⭘DŽ

Caution! For North America: With

interchangeable lens with throw ratio greater

than 2.5, consider hazard distance and

installation requirements for RG3 product.

Refer User Manual

Caution! With Interchangeable lens with

throw ratio greater then 4.7, consider hazard

distance and installation requirements for

RG3 product. Refer User manual.

9

Image 1-7

F70 Projector

Image 1-6

F90 Projector

8

Disposal Information

Waste Electrical and Electronic Equipment

This symbol on the product indicates that, under the E uropean Directive 2012/19/EU governing waste from electrical and

electronic equipment, this product must not be disposed of with other municipal waste. Please dispose of your waste equipm ent by

handing it over to a designated collection point for the recycling of waste electrical and electronic equipment. To prevent possible

harm to the environment or human health from uncontrolled waste disposal, please separate these items from other types of waste

and recycle them responsibly to promote the sustainable reuse of material resources.

For more information about recycling of this product, please contact your local city office or your municipal waste disposal service.

For details, pleas e visit the Barco website at: h

12 601–0400 F90 SERIES. 10/05/2017

ttp://www.barco.com/en/AboutBarco/weee

Page 17

WEEE Information

This product conforms to all requirements of the EU Directive on waste electrical and electronic equipment (WEEE). This product

shall be recycled properly. It can be disassembled to facilitate proper recycling of it’s individual parts.

Consult your dealer or relevant public authority regarding drop-off points for collection of WEEE. For details, please visit the Barco

website at: http://www.barco.com/en/ AboutBarco/weee.

WARNING: This product contains chemicals, including lead, known to the S tate of California to cause birth

defects or other reproductive harm. Recycle properly, do not dispose of in ordinary waste!

Turkey RoHS compliance

Türkiye Cumhuriyeti: AEEE Yönetmeliğine Uygundur.

[Republic of Turkey: In conformity w ith the WEEE R egulation]

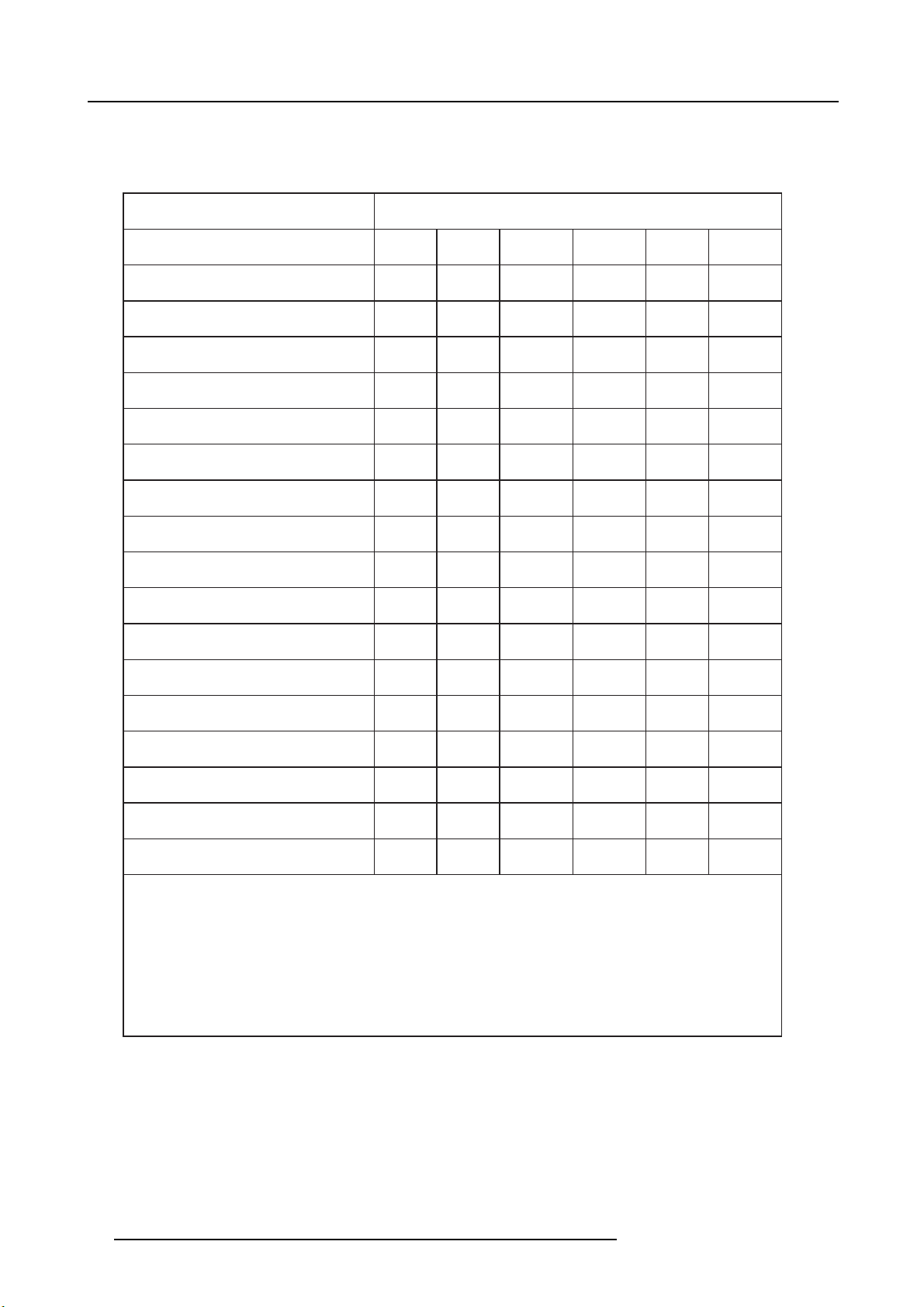

1.8 RoHS compliance

中国大陆 RoHS (Chinese Mainland RoHS)

根据中国大陆《电器电子产品有害物质限制使用管理办法》(也称为中国大陆RoHS ), 以下部分列出了Barco产品中可能包含的有毒

和/或有害物质的名称和含量。中国大陆RoHS 指令包含在中国信息产业部MCV标准:“电子信息产 品中有毒物质的限量要求”中。

According to the “Management Methods for the Restriction o f the Use of Hazardous Substances in Electrical and Electronic Products” (Also called RoHS of Chinese Mainland), the table below lists the names and contents of toxic and/or hazardous substances

that Barco’s product may c ontain. T he RoHS of Chinese Mainland is in

Industry of China, in the section “Limit Requirements of t oxic substances in Electronic Information Products”.

cluded in the MCV standard of the Ministry of Information

1. Safety

601–0400 F90 SERIES. 10/05/2017

13

Page 18

1. Safety

夃

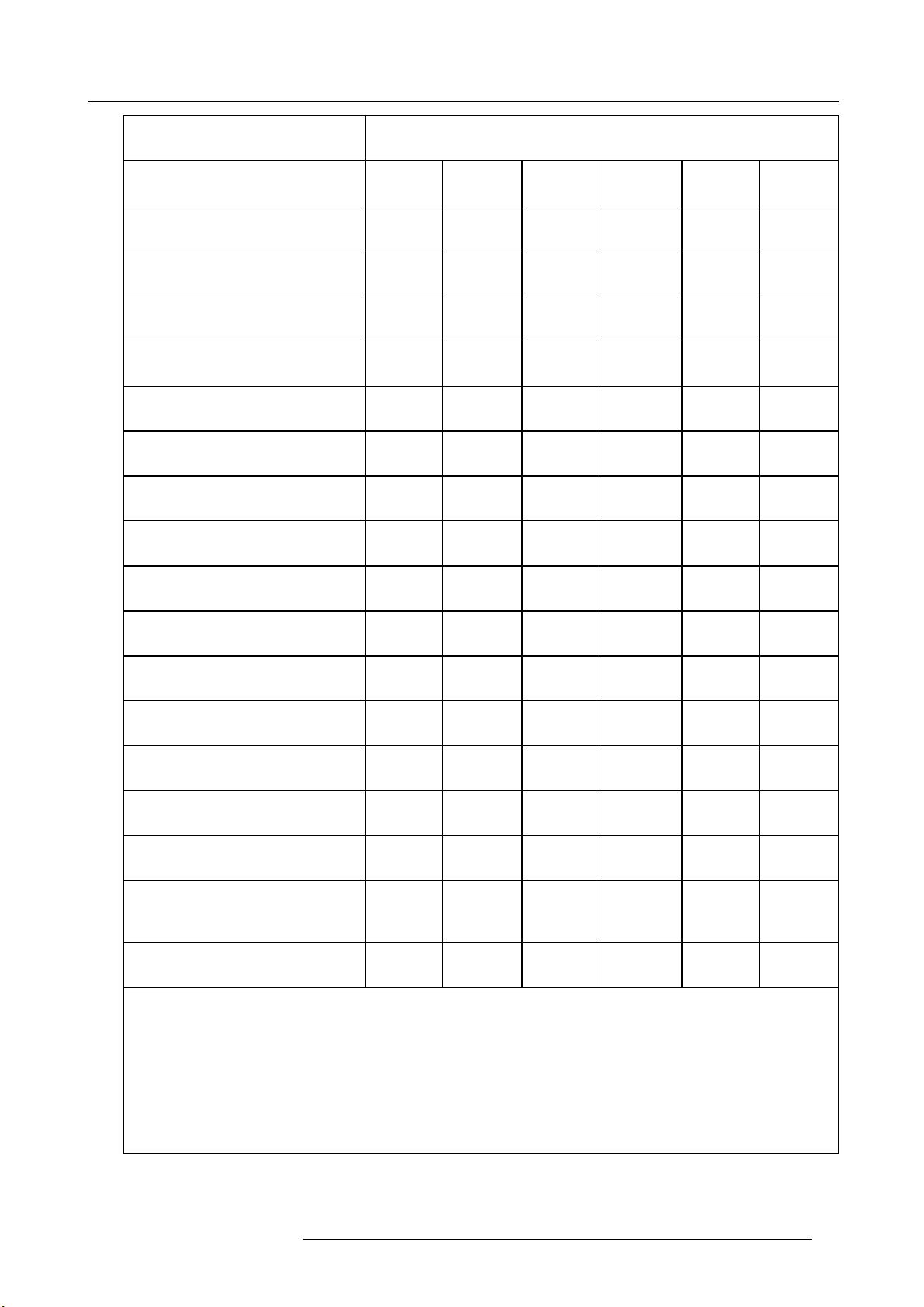

零件項目(名稱) 有毒有害物質或元素

Component Name Hazardous Substances or Elements

(Pb) (Hg) (Cd) (Cr6+) (PBB) (PBDE)

印製電路配件

Printed Circuit Assemblies

外接電(線)纜

External Cables

緉部線路

Internal wiring

鏡頭支架

Lensholder

激光發生器

Laser

底架

Chassis

外殼

Enclosure

螺帽,螺釘(栓),螺旋(釘),䐭圈緊固件

Nuts, bolts, screws, washers. Fasteners

電源供應商

Power Supply Unit

散熱片(器)

Heatsinks

風扇

Fan

塑膠外殼

Plastic Enclosure

外殼

Enclosure

電池(組)

Batteries

文件茢明書

Paper Manuals

裝置配件

Installation kit

附電池遙控器

Remote control

本表格依據 SJ/T 11364 的規定編制。

This table is prepared in accordance with the provisions of SJ/T 11364.

O: 表示該有毒有害物質在該部件所有均質材料中的含量均在 GB/T 26572 標準規定的限量要求以下。

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is below the

limit requirement in GB/T 26572

X: 表示該有毒有害物質至少在該部件的某一均質材料中的含量超出 GB/T 26572 標準規定的限量要求。

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used forth is part

is above the limit requirement in GB/T 26572.

鉛 汞

X O X O O O

X O O O O O

X O O O O O

X O O O O O

X O O O O O

O O O O O O

O O O O O O

X O O O O O

X O O O O O

O O O O O O

X O O O O O

O O O O O O

O O O O O O

O O O O O O

O O O O O O

O O O O O O

X O O O O O

六價壗 多䘳聯䴙 多䘳二䴙慂

Image 1-8

14 601–0400 F90 SERIES. 10/05/2017

Page 19

1. Safety

零件项目 (名称)

Component Nam e

印制电路配件

Printed Circuit Assemblies

外接电( 线)缆

External Cables

內部 线路

Internal wiring

镜头支架

Lensholder

激光发生器

Laser

底架

Chassis

外壳

Enclosure

螺帽,螺钉(栓 ),螺旋( 钉 ),垫圈, 紧固件

Nuts, bolts, screws, washers, Fasteners

电源供应器

Power Supply Unit

散热 片 (器 )

Heatsinks

风扇

Fan

塑胶外壳

Plastic Enclosure

外壳

Enclosure

电池 ( 组)

Batteries

文件说明书

Paper M anuals

装置配件

Installation kit

有毒有害物质或元素

Hazardous Substances or Elements

铅

(Pb)

X

X

XOOOOO

XOOOOO

X

OOO OOO

OOO OOO

X

X

OOO OOO

X

OOO OOO

OOO OOO

OOO OOO

OOO OOO

OOO OOO

汞

(Hg)

O

OOOOO

OOOOO

OOOOO

OOOOO

OOOOO

镉

(Cd)

X

六价 铬

(Cr6+)

OOO

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

附電池遙控器

Remote control

本表格依据SJ/T 11364的规 定编制

This table is prepared in accordance with the provisions of SJ/T 11364.

O: 表示该有毒有害物质在 该部件所有均质材料中的含量均在 G B/T 26572 标准规定的限量要求以下.

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement in GB/T 26572.

X: 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 标准 规定的限量要求.

X: Indicates that this toxic or hazardous substance c ontained in at least one of the homogeneous materials used for this part

is above the limit requirement in GB/T 26572.

在中国大陆销售的相应电子信息产品(EIP )都必须遵照中国大陆 《电 子电 气产 品有害物质限制使用标识要求》标准贴 上环保使用期

限(EFUP)标签。Barco产品所采用的EFUP标签(请参阅实例,徽标内部的编号使用于指定产 品)基于中国大陆的《电子信息产品 环

保使用期限通则》 标准。

601–0400 F90 SERIES. 10/05/2017

XOOOOO

15

Page 20

1. Safety

All Electronic Information P roducts (EIP) that are sold within Chines e Mainland must comply with the “Marking for the restriction of

the use of hazardous substances in electrical and electronic product” of Chinese Mainland, marked with the Environmental Friendly

Use Period (EFUP) logo. The number inside the EFUP logo that Barco uses (please r efer to the photo) is based on the “ General

guidelines of environment-friendly use period of electronic information products” of Chinese Mainland.

10

1.9 Contact adresses

For Taiwan:

AWIND Inc., 33F., No. 16. Xinzhan Rd., Banqiao Dist.,, New Taipei City 220, Taiwan

Tel: +886-2-7715-0099, Fax: +886-2-7715-0097

E-mail: sales@awindinc.com

1.10 Product Info

Product info

Image 1-9

product name 產 品名稱:

projector 投影機

model 型號:GP6/GP7

1.11 Statement

EN55032/CISPR32 Class A MME (MultiMedia Equipm

Warning : Th is equipment is compliant with Class A of CISPR 32. In a residential environment this equipment m ay cause radio

interference.

Class A ITE (Information Technology Equipment)

Warning : This is a clas s A product. In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

ent)

16

601–0400 F90 SERIES. 10/05/2017

Page 21

2. Getting to know the projector

B

R

F

L

T

2. GETTING TO KNOW THE PROJECTOR

Overview

• Main com ponents

• Service and maintenance

• LED status light

• Power on / Standby button backlight indications

• LCD panel

• Local keypad

• Remote c ontrol, Battery installation

• Remote c ontrol, protocol setup

• Functionality overview

• Projector Address

• Connector panel

• Color Wheels

• Optional acces sories

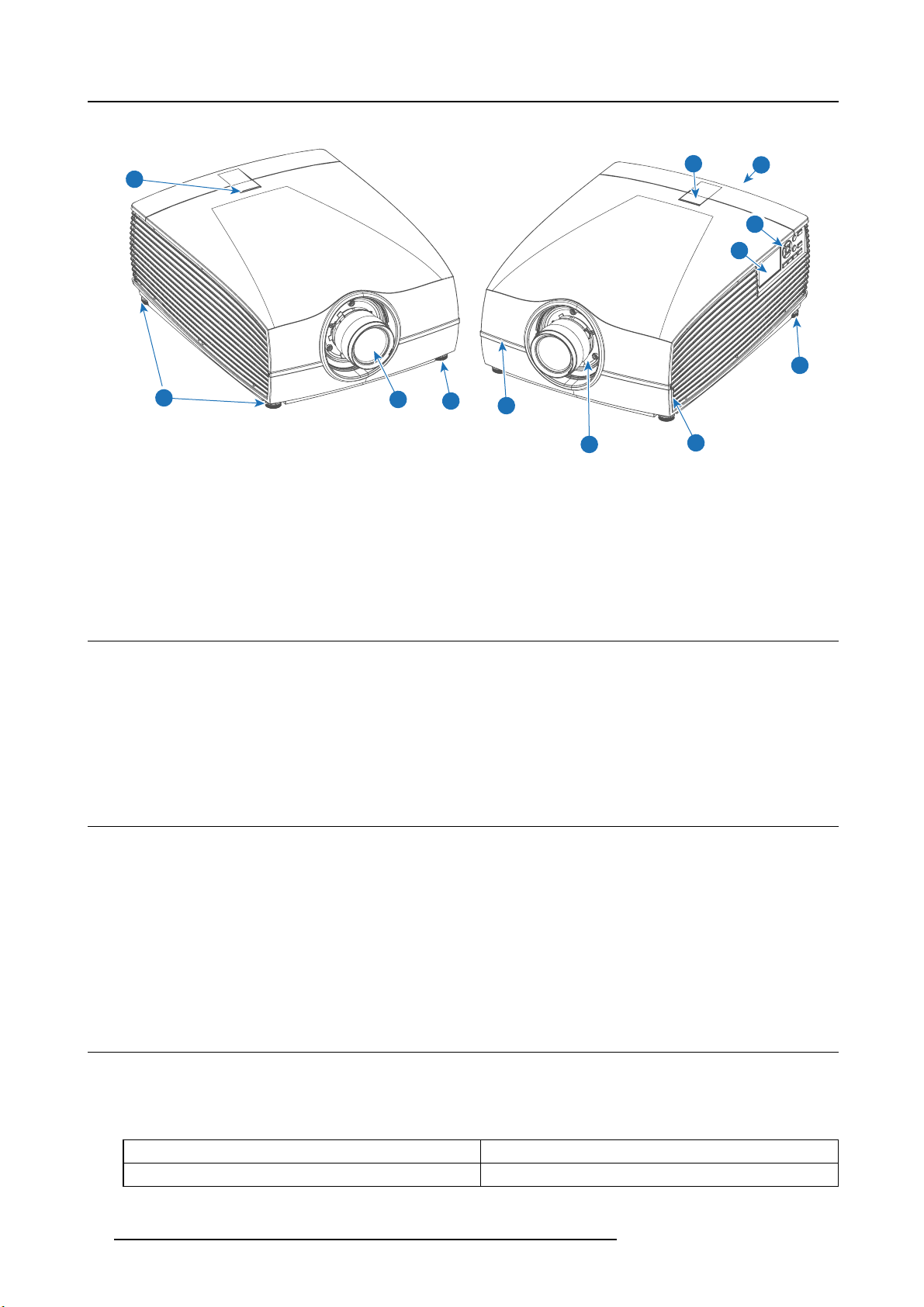

2.1 Main components

Naming conventions

Image 2-1

L Left

TTop

BBack

R Right

F Front

601–0400 F90 SERIES. 10/05/2017 17

Page 22

2. Getting to know the projector

Projector Front

1

2

1

Image 2-2

1 LED status light

2 Adjustable feet

3 Projector lens

4 Lens holder

5 IR Receiver: for remote control communication

6 LCD panel

7 Keypad

8 Connector panel

9 Front USB and triggerboard

5

8

7

6

2

1

3

2

1

5

9

4

1

2.2 Service and maintenance

General

The F90 does not have any user-serviceable parts.

All service tasks must only be carried out by the manufacturer, or a Barco authorized service personnel or Barco technicians.

The projector color wheel is a designed consuma ble that can be replaced by users in the field. See "C hange the color wheel ", page

24 for more information.

2.3 LED status light

About

The F90 status indicator is located on the top side of the projector, near the IR receiver (ref. 1, image 2-2).

During normal operation the LED is unlit. In the event of a c ritical error or high temperature, the LED will display red.

In event of a c ritical error, the projector c annot be restarted until the projector is disc onnected from the power supp ly and then

reconnected again. If the reason for the error persists, the projector will again go to critical error status.

If the root cause of the error is h

the normal operating limitations.

igh temperature, the projector will restart when it has cooled down, and temperatures are back within

2.4 P ower on / Standby button backlight indications

Indicator

In addition to the LE D indicator, the projector also displays status indications in the backlight of the Power / Standby button.

The table below shows the details r egarding this indications.

Operating Status Indication Color / Behavior

On (active) Blue

18 601–0400 F90 SERIES. 10/05/2017

Page 23

2. Getting to know the projector

Operating Status Indication Color / Behavior

Wait on

Standby (off)

Wait

Overheating Red flashing

Configure/upgrade White fast flashing

Standby ECO

Blue flas hing

White

White short flashing

White heartbeat

2.5 LCD panel

About

The LCD panel (reference 1, image 2-3) is located on the right side of the projector, and has two ma

1. Showing the menus and adjustment information. and also a mirror of the OSD, (On Screen Display) described in User Interface

when this is enabled.

2. Information regarding the status of the projector showing this data:

- Projector status

- Network address

- Active source

- Current firmware version

- Operation Data

- Active functions (Enabled Functions).

Toggle between the two indications by using the Menu button on the keypad, or on the remote control

The LCD Display will fade out 30 seconds after the last key operation.

in functions:

2.6 Local keypad

About

The Keypad gives direct access to s everal functions, in addition to access to the menu system. The keypad and remote control

functions are equal.

The keypad has a back light that can be switched o n and off manually. The light turns off automatically after a preset time.

The keys are equipped with white and blue backlit LEDs. Power button is equipped with white, blue and red backlit. The LEDs are

controlled according to the features available.

1

2

3 4

5

6

10

Image 2-3

601–0400 F90 SERIES. 10/05/2017 19

9 8

7

Page 24

2. Getting to know the projector

Item

Name Description

No.

1

LCD Display Shows Projector status and navigation menu.

2 Navigation keys

3

OSD Display Enables the Home Menu on the LCD screen and the OSD.

4

Standby Power on / standby

5Back

6

OSD ON/OFF Deactivate the On Screen Display (OSD). Only critical w arnings will be displayed.

7 Input

8

Shutter Enable and disable the lens shutter function. This is not a mec hanical shutter, but it toggles

9 Test Patterns

10 Lens

Navigation arrows (up, down, left, right), confirm selection (

Undo action / back to previous screen.

Shortcut to input source m enu on LCD. Use navigation keys to select and enable input.

the laser source on and off. Backlight is red when the shutter are enabled.

Shortcut to test pattern menu on LCD. Use navigation keys to select the desired pattern.

Shortcut to lens function. A test pattern displays on the OSD. LCD screen displays the

navigation keys to manage and confirm actions.

)

2.7 Remote control, Battery installation

Where to find the batteries for the remote control ?

The b atteries are not placed in the remote control unit to avoid control operation in its package, resulting in a s horter battery life

time. At delivery the batteries can be found in a separated b

install the batteries first.

ag attached to the remote control unit. Before using your remote control,

How t o install

1. P ush the battery cover tab with the fingernail a little backwards (1) and pull, at the s ame time, the cover upwards (2).

1

Image 2-4

2. Insert the two AA size batteries, making sure the polarities match the + and - m arks inside the battery compartment.

+

-

-

+

2

Image 2-5

3. Insert (1) both lower tabs of the battery cover in the gaps at the bottom of the remote control, and press (2) the cover until it clicks

in place.

20

601–0400 F90 SERIES. 10/05/2017

Page 25

2. Getting to know the projector

2

Image 2-6

+

-

When replacing batteries, t he broadcast address o f the RCU will be reset to its default value ’0’.

1

-

+

CAUTION: Replace with the correct battery type. Use two AA size batteries. There is a risk of explosion if the

battery is replaced with an incorrect type.

CAUTION: Replace the battery as explained above. There is a risk of explosion if the battery is incorrectly

installed.

2.8 Remote control, protocol setup

About the used protocol

The protocol is the code send out by th e remote control when a button is pressed. Depending on this code, the projector can decode

the signals. The remote control can be used with two different protocols, RC5 and NEC. Depending on the projector to control the

remote control can be switched between these protocols.

Which protocol to use

•TheNEC protocol have to be used for Barco projectors based on the Pulse platform: F 70, F80, F90, HDX 4K , UDX, ...

•TheRC5 protocol have to be use all other Barco projectors: HDX W, HDF W, HDQ 2 K, ...

How to set

1. R emov e the cover. For more info on how to remo ve, see "Remote c ontrol, B attery installation", page 20.

2. P lace the switch in the N EC position.

Image 2-7

601–0400 F90 SERIES. 10/05/2017 21

Page 26

2. Getting to know the projector

2.9 Functionality overview

Remote Control Unit buttons

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

24

23

22

21

20

19

18

17

16

1

Button pressed indicator.

2

Shutter Open.

3

Shutter Close.

Touch Panel O n/Off. (Not in

4

use).

5

OSD On/Off.

6

Lens Zoom.

7

Lens Shift.

8

Menu Activation.

9

Menu Selection, OK button.

10

Menu Navigation.

11

Input Selection.

12

Address button.

Numeric buttons.

13

Backspace (while entering

14

values)

XLR connector.

15

Decimal mark (while entering

16

values)

Macro button. (Not in use)

17

Menu Bac k.

18

Default button. (Not in use).

19

Lens Focus.

20

Real Color menu..

21

Test Patterns.

22

Power On.

23

Power Off.

24

Stereo Jack.

25

RCU On/Off.

26

2625

The projector re mote control is a full feature wireless rem ote control, powered by two (2) standard AA batteries. The battery compartment is on the back side of the remote control.

The remote control is backlit for use in dark environments. It also has an Jack connector for wired connec tion to the projector. When

the wire is connected, the IR beam is s witched off.

2.10 Projector Address

Projector address

Address installed in the projector to be individually controlled.

Broadcast ad dress

Projector will always execute the command coming from a RCU programmed with that broadcast address.

2.10.1 Controlling the projector

Why a projector address?

As more than one projector can be installed in a room, each pr ojector should be separately addressable with an RCU or com puter.

Therefore each projector ha

s its own address.

Set up an individual Project

The set up of a projector address can be done via the software.

22

or Address

601–0400 F90 SERIES. 10/05/2017

Page 27

2. Getting to know the projector

Projector controlling

Every projector requires an individual address between 0 and 255.

When the address is set, the projector can be controlled now:

• with the RCU: only for addresses between 0 and 31.

• with a computer: for any address between 0 and 255.

Broadcast Address

Every projector h as a broadcast (common) address ’0’ or ’1’. The default address is ’0’.

The choice between ’0’ and ’1’ c an be selected in the GUI: “Sy stem Settings” → “Communication” →“IR Control “.

Placing new batteries in the remote control o r p lugging t he remote to a projector via XLR cable will automatically reset the address back to its default value ’0’.

2.10.2 Displaying and Programming addresses into the RCU

Displaying the P roje ctor Address on the Screen.

1. P ress the Address button to s ee the projector address (proximately 2 seconds).

The projector ’s address is displayed on the LCD status screen.

How to Program an Address into the RCU?

1. P ress the Address button until the Button pressed indicator lights up continuously (

2. E nter the address w ith the digit buttons within the time the indicator lights u p (also proximately 5 seconds).

Note: That address can be any value between 0 and 31.

Tip: A few examples:

To enter address 3, press "3" digit button on the RCU to set the RCU’s address to 3 and wait until the button pressed

indicator is out. Alternatively, you c an also press “0” and “3”. This way, he button pressed indicator goes out immed iately.

To enter address 31, then press “3” and “1” on the digit button on the RCU and the button pressed indicator goes out

immediately.

proximately 5 seconds).

2.11 Connector panel

General

The source input panel is located at the back of the projector. For source specifications, see "Connector specifications", page 45.

Image 2-8

Name Pcs Description Purpose

DMX IN 1 DMX 512 input

DMX OUT

RS-232

Sync

Trigger 3 (one in

1 DMX 512 output

1 9–pin DB9 c onnector

3

front, two

on rear

panel)

BNC Sync Port IN/OUT; B idirectional

mini-DIN (1x 3D sync Out, and 2x

Sync In/Out)

12VDC - 0,5A (6W) For Controlling Peripherals, like motorized screens, curtains

For Projector Control

For Projector Control

For Projector Control. A llows for wired remote control and

monitoring of m any projector functions used in installation

environments

For Projector ControlThis is mainly used in multiple projector

installations with requirement of synchronization between

the units

etc. Give 12V output when projector are switched onSee

also the note below.

601–0400 F90 SERIES. 10/05/2017 23

Page 28

2. Getting to know the projector

Name Pcs Description Purpose

RC

USB

LAN 1

DP 2

DL-DVI-D 2

HDMI 1

HDBaseT 1

SDI

1

3

2

Regarding the Trigger Outpu t: If these outputs are loaded too heavy, there is a risk that the p rojector will go

in reset mode, and restart. This causes no dam age to the projector, but is an undesirable resp onse. This

will also happen if the startup current for the external equipment is too h igh, even though the nom inal p ow er

consumption is less than 0,5A.

Jack connector for wired remote For Projector Control

USB 2.0 type A, 4 pin( 2x Rear and

1x Front)

Standard RJ45 connector For Projector Control

Standard display port

Dual DVI-I 1.0 (DVI_D Functionallity).

Standard HDMI 2.0

Standard RJ45 8P8C Connector For Projector Control

SDI1 is Input, SDI 2 is pass through.

(out)

Connectors

For Software upgrade

For Projector Input

For Projector Input. These connectors can also be used to

form one uniform image by feeding half of the image into

each connector. HDCP compliant for sources up 165 Mhz

For Projector Input

For Projector Input

2.12 Color Wheels

Overview

• Color Wheel range

• Change the color wheel