Page 1

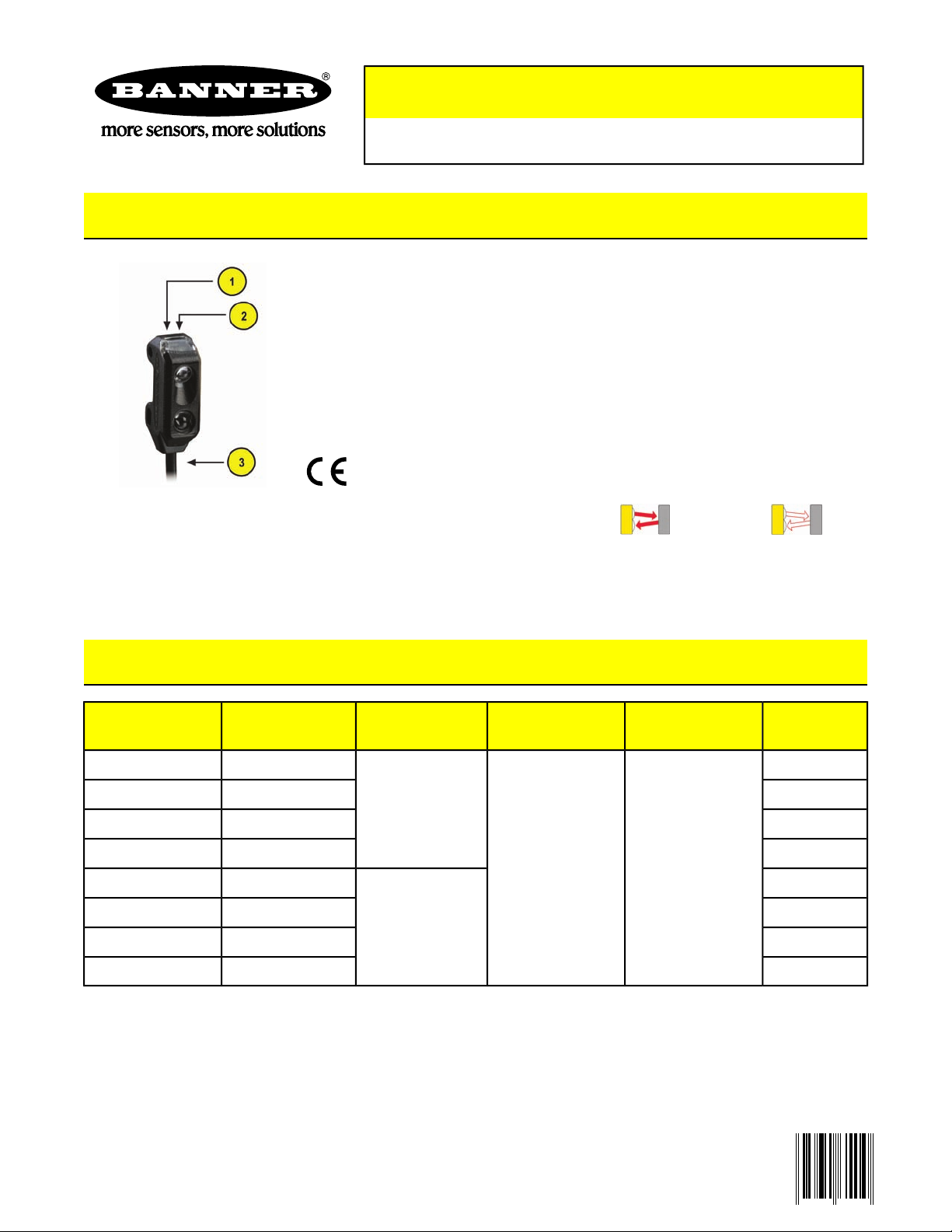

1. Power ON Indicator

_564 65_N

2. Received Signal Indicator

3. 2 m Cable or Pigtail Quick-Disconnect

VS1 Series

Miniature, Self-Contained Convergent-Mode Sensors

Features

• Totally self-contained miniature sensors

• 10 to 30V dc operation

• Visible red or infrared sensing beam, depending on model

• 10 mm (0.4") or 15 mm (0.6") convergent point, depending on model

• NPN (sinking) or PNP (sourcing) output, and dark or light operate,

depending on model

• 3-wire hookup; output load capacity to 50 mA

• Choice of integral cable or pigtail quick-disconnect connector

ConvergentConvergent

Infrared, 865 nmVisible Red, 630 nm

Models

Visible Red Beam

Models

* Only standard 2 m (6.5') cable models are listed above. For other cable/connector options:

• 9 m cables: add suffix “W/30” to the model number (e.g., VS1AN5CV10 W/30).

• 150 mm (6") pigtail with threaded 3-pin Pico-style QD: add suffix “Q” to the model number (e.g., VS1AN5CV10Q).

A model with a QD connector requires a mating cable; see Quick-Disconnect (QD) Cordsets on page 5.

Infrared Beam

Models

VS1AN5C10VS1AN5CV10

VS1AN5C20VS1AN5CV20

10 mm (0.4")

15 mm (0.6")

2 m (6.5') 3-wire

integral cable

Output TypeSupply VoltageCable*Focus

NPN/LO

NPN/DOVS1RN5C10VS1RN5CV10

PNP/LOVS1AP5C10VS1AP5CV10

PNP/DOVS1RP5C10VS1RP5CV10

10 to 30V dc

NPN/LO

NPN/DOVS1RN5C20VS1RN5CV20

PNP/LOVS1AP5C20VS1AP5CV20

PNP/DOVS1RP5C20VS1RP5CV20

11/2009P/N _56465_ rev. D

Page 2

VS1 Series

Overview

VS1 Series miniature self-contained sensors are designed for precision sensing in small areas previously accessible

only to remote or fiber optic models.Typical applications include mounting inside vibrating feeders and electronic

component handling equipment, where larger sensors will not fit.

The sensing energy of a convergent-mode sensor is concentrated at the specified f ocus point (see Models on page

1). Convergent-mode sensors are less sensitive to background reflections, compared with diffuse-mode sensors.

Contact the factory if background reflections are a problem.

Installation Notes

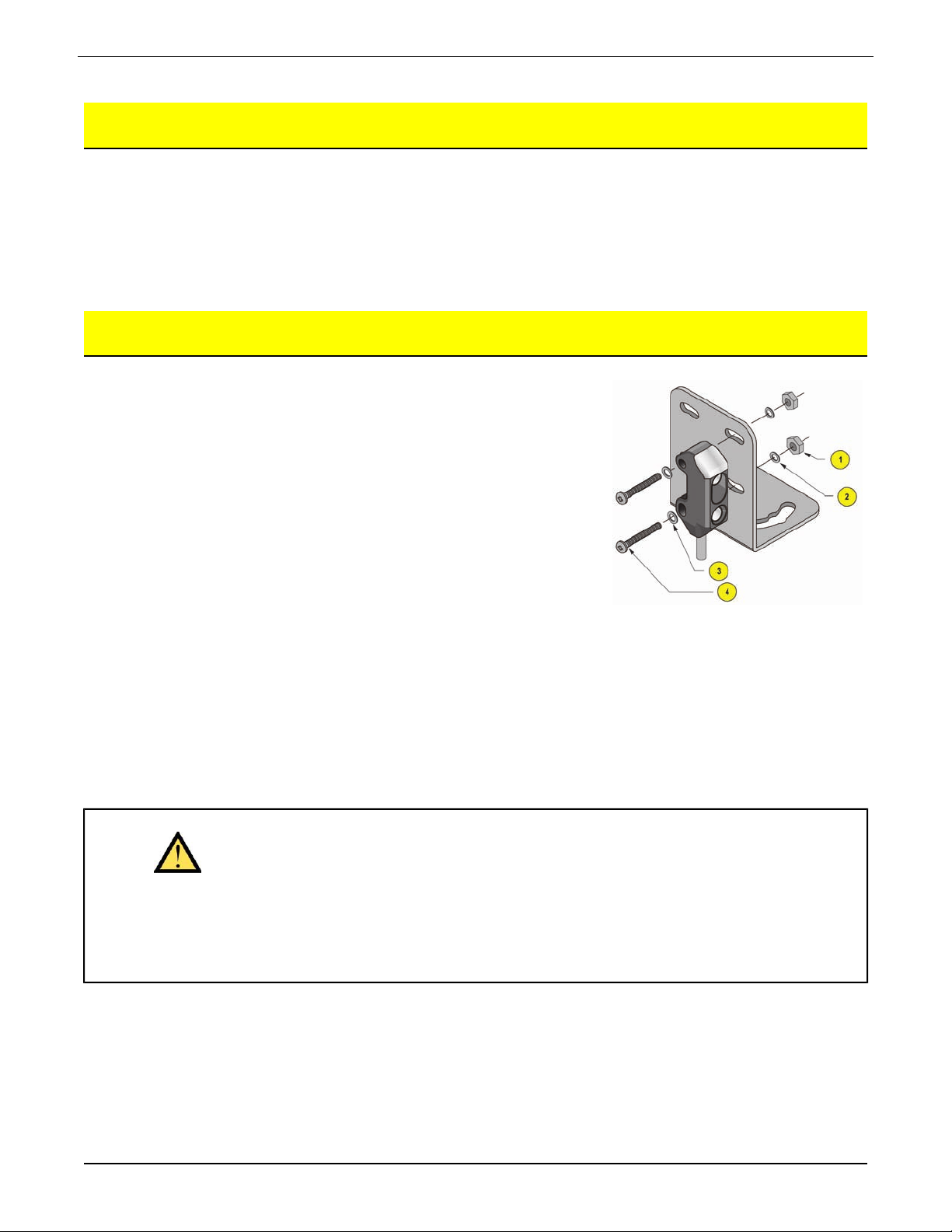

Included with each sensor is a hardware packet containing two stainless

steel M2 x 0.4 x 16 mm Phillips pan-head machine screws, flat washers, loc k

washers, and hex nuts.To mount the sensor, use the supplied flat washer

against the front surface of the sensor housing, between it and the screw

head. If mounting to one of the optional brackets, place the lock washer

against the back of the bracket, followed by the nut. If mounting directly to

a threaded hole, place the lock washer between the scre w head and the flat

washer (see Figure 1).

For best results, mount the VS1 where it is protected from moisture, high

humidity and dirt.

Figure 1. Sensor Mounting

1. Hex Nut (2)

2. Lock Washer (2)

3. Washer (2)

4. M2 x 0.4 x 16 mm Phillips

Pan-head Machine Screw (2)

WARNING . . . Not To Be Used for Personnel Protection

Never use this product as a sensing device for personnel protection. Doing so

could lead to serious injury or death

This product does NOT include the self-checking redundant circuitry necessary to allow its use in personnel safety

applications. A sensor f ailure or malfunction can cause either an energiz ed or denergized sensor output condition.

Consult your Banner Safety Products catalog for safety products that meet OSHA, ANSI and IEC standards for

personnel protection.

2

Tel: 763.544.3164

P/N _56465_ rev. DBanner Engineering Corp. - Minneapolis, MN USA - www.bannerengineering.com

Page 3

VS1 Series

Current

Circuitry

Specifications

DescriptionFeature

10 to 30V dc (10% maximum ripple) at less than 25 mA (exclusive of load)Supply Voltage and

Protected against reverse polarity and transient voltagesSupply Protection

Output Configuration

Output Rating

Output Protection

Circuitry

Indicators

SPST solid-state switch

NPN (current sinking) or PNP (current sourcing), depending on model

Light operate (N.O.) or dark operate (N.C.), depending on model

50 mA maximum

OFF-state leakage current: < 1 microamp at 24V dc

ON-state saturation voltage: < 0.25V at 10 mA dc; < 0.5V at 50 mA dc

Protected against false pulse on power-up and continuous overload or short circuit of

outputs. Overload trip point 100 mA.

1 millisecond ON and OFFOutput Response Time

250 microsecondsRepeatability

Two LEDs: Green and Yellow

Green ON steady: sensor power ON

Green flashing: output overload

Yellow ON steady: light is sensed

Yellow flashing: marginal excess gain (1-1.5x) in light condition

Black ABS/polycarbonate housing with clear acrylic lensConstruction

Connections

Operating Conditions

Application Notes

Certifications

P/N _56465_ rev. D

IP54; NEMA 3Environmental Rating

2 m (6.5') attached cable: three #28 ga stranded conductors with PE insulation; PVC

outer cable jacket; or pigtail with 3-pin Pico-style quick-disconnect fitting. QD cab les are

ordered separately.

Temperature: –20° to +55° C (–4° to +131° F)

Maximum Relative Humidity: 80% at 50° C (non-condensing)

M2 stainless steel mounting hardware included (see “Installation Notes”). Optional

mounting brackets are available (see Accessory Mounting Brackets on page 6).

3Banner Engineering Corp. - Minneapolis, MN USA - www.bannerengineering.com

Tel: 763.544.3164

Page 4

VS1...CV10

VS1...CV20

VS1 Series

Performance Curves

Visible Red Beam Models

Beam PatternExcess Gain

Performance based on 90% reflectance white card test

VS1...C10

VS1...C20

Y: Excess GainX: Distance

Infrared Beam Models

Beam PatternExcess Gain

Performance based on 90% reflectance white card test

Y: Beam PatternX: Distance

Y: Excess GainX: Distance

4

Tel: 763.544.3164

Y: Beam PatternX: Distance

P/N _56465_ rev. DBanner Engineering Corp. - Minneapolis, MN USA - www.bannerengineering.com

Page 5

34.7 mm

(1.37")

9.6 mm

(0.38")

M8 x 1

4

3

1

VS1 Series

Dimensions

1. 150 mm (6") Pigtail

3-pin Pico-style

straight with M8

threads

Hookups

QD hookups are shown. Cabled hookups are functionally identical.

Quick-Disconnect (QD) Cordsets

PKG3M-2

PKG3M-9

2 m (6.5')

9 m (30')

Key:PNP OutputsNPN Outputs

1 = Brown

3 = Blue

4 = Black

X = Load

PinoutDimensionsLengthModelStyle

Female

Wiring Key:

1 = Brown

3 = Blue

4 = Black

P/N _56465_ rev. D

Tel: 763.544.3164

5Banner Engineering Corp. - Minneapolis, MN USA - www.bannerengineering.com

Page 6

Accessory Mounting Brackets

SMBVS1TCSMBVS1T

•• Tall compact bracketTall bracket

• •300 series stainless steel 300 series stainless steel

VS1 Series

SMBVS1SCSMBVS1S

•• Tall compact bracketTall compact bracket

• •300 series stainless steel 300 series stainless steel

Warranty: Banner Engineering Corp. will repair or replace, free of charge, any product

of its manufacture found to be def ective at the time it is returned to the f actory during

the warranty period.This warranty does not cover damage or liability f or the improper

application of Banner products.This warranty is in lieu of any other warranty either

expressed or implied.

Loading...

Loading...