Page 1

U-GAGE T30 Series Proximity Mode Models

U-GAGE™T30 Series with Analog and Discrete Outputs

Ultrasonic Sensors with TEACH-Mode Programming

Printed in USA 01/03 P/N 57438 Rev. C

U-GAGE T30 Series Features

• Fast, easy-to-use TEACH-mode programming; no potentiometer adjustments

• Program both outputs together or independently, with either an upward or a

downward analog output slope

• Remote TEACH input for security and convenience

• Choose models with 150 mm to 1 m range (7.9" to 39.4") or 300 mm to 2 m

range (11.8" to 78.7")

•Wide operating temperature range of -20° to +70°C (-13° to +158°F)

•Choose models with NPN or PNP discrete output, plus 0 to 10V dc or 4 to 20 mA

sourcing analog output

• LED indicators for Power ON/OFF; Signal Strength; and Analog/Discrete Outputs

Conducting

• Choose 2 m (6.5') or 9 m (30') integral unterminated cable or 5-pin Euro-style QD

connector

• Compact, self-contained sensor package

•Rugged design for use in demanding sensing environments; rated IEC IP67,

NEMA 6P

*NOTES:

• 9 m (30') cables are available by adding suffix “W/30” to the model number of any cabled sensor (e.g., T30UINA/30).

• A model with a QD connector requires an optional mating cable, see page 9.

Ultrasonic, 228 or 128 kHz

Models

Range and

Frequency Cable*

Supply

Voltage Discrete Output Analog Output Response Time

T30UINA

T30UINAQ

150 mm to 1 m

(5.9" to 39")

228 kHz

2 m (6.5')

5-pin Euro QD

12 to 24V dc

NPN (sinking)

4 to 20 mA

Sourcing

48 milliseconds

T30UIPA

T30UIPAQ

2 m (6.5')

5-pin Euro QD

PNP (sourcing)

T30UUNA

T30UUNAQ

2 m (6.5')

5-pin Euro QD

NPN (sinking)

0 to 10V dc

Sourcing

T30UUPA

T30UUPAQ

2 m (6.5')

5-pin Euro QD

PNP (sourcing)

T30UINB

T30UINBQ

300 mm to 2 m

(11.8" to 79")

128 kHz

2 m (6.5')

5-pin Euro QD

NPN (sinking)

4 to 20 mA

Sourcing

96 milliseconds

T30UIPB

T30UIPBQ

2 m (6.5')

5-pin Euro QD

PNP (sourcing)

T30UUNB

T30UUNBQ

2 m (6.5')

5-pin Euro QD

NPN (sinking)

0 to 10V dc

Sourcing

T30UUPB

T30UUPBQ

2 m (6.5')

5-pin Euro QD

PNP (sourcing)

15 to 24V dc

12 to 24V dc

15 to 24V dc

Page 2

U-GAGE™T30 Series with Analog and Discrete Outputs

2 P/N 57438 Rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

U-GAGE T30 Series Overview

The U-GAGE is an easy-to-use ultrasonic sensor, ideal for demanding environments.

Simple push-button programming provides flexibility for a variety of applications.

Excellent for measurement applications such as sensing of liquid levels in a tank or, for

example, determining box heights for sorting purposes.

Each sensor includes both an analog and a discrete output, which may be programmed

independently with different window limits or together with identical limits. Each output

has the option of being set with a sensing distance set point centered within a 10-mm

window.

U-GAGE T30 Series Programming

Window Limits

Window limits may be taught to the sensor in several ways. The following methods

describe the programming procedures using the push buttons on the back of the

sensor; remote programming (remote TEACH) procedures are described on page 4.

NOTE: When the sensor changes state between PROGRAM and RUN modes, all of the

LED indicators turn OFF momentarily, before the appropriate LEDs come ON as

described below. The sensing window limits expand temporarily to full scale

(max range) during PROGRAM mode.

Teaching Limits for Either Analog or Discrete Output

1. Choose the output for the first set of window limits (analog or discrete) and push

and hold the corresponding button until the green Power LED goes OFF and the

appropriate yellow Output LED turns ON (solid). This indicates the sensor is waiting

for the first limit.

2. Position the target for the first limit and briefly “click” the same button. This will

teach the sensor the first limit. The yellow Output LED will flash to acknowledge

receiving the first window limit; it is now waiting for the second limit.

3. Position the target for the second limit and “click” the button again. This will teach

the sensor the second limit. The yellow Output LED turns OFF and the green Power

LED comes ON; the sensor is now in normal RUN mode.

4. Repeat for the other output (analog or discrete) if a second output is desired.

NOTE: Press and hold the same button > 2 seconds (before teaching the second limit)

to exit PROGRAM mode without saving any changes. The sensor will revert to

the last saved program.

Teaching Analog or Discrete Limits Using the Auto-Zero Feature

For some applications, a sensing distance set point centered within a minimum sensing

window may be required. The TEACH procedure for this application is simple: teaching

the same limit twice causes the sensor to program a 10-mm window centered on the

position taught (position ±5 mm).

NOTE: The sensor allows for some forgiveness in this procedure. If the two limits are

not exactly the same (but closer than the minimum 10-mm window required),

the sensor will put the set point at the “average” of the two limits.

Page 3

U-GAGE™T30 Series with Analog and Discrete Outputs

P/N 57438 Rev. C 3

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Teaching Identical Limits for Both Analog and Discrete Outputs Simultaneously

To set both the analog and the discrete outputs at exactly the same limits, both may be

set simultaneously.

1. Push and hold either the Analog or the Discrete programming push button until the

yellow Output LED turns ON. Push and hold the other push button until its yellow

Output LED turns ON. The sensor is waiting for the first limit.

2. Position the target for the first limit and “click” either programming push button.

Both yellow LEDs will flash to acknowledge receiving the first window limit; the

sensor is now waiting for the second limit.

3. Position the target for the second limit and “click” either button again to teach the

sensor the second limit.

4. The green Power LED will come ON to indicate that the sensor will now function in

normal RUN mode; both yellow Output LEDs will remain ON if the outputs are

conducting within the window limits.

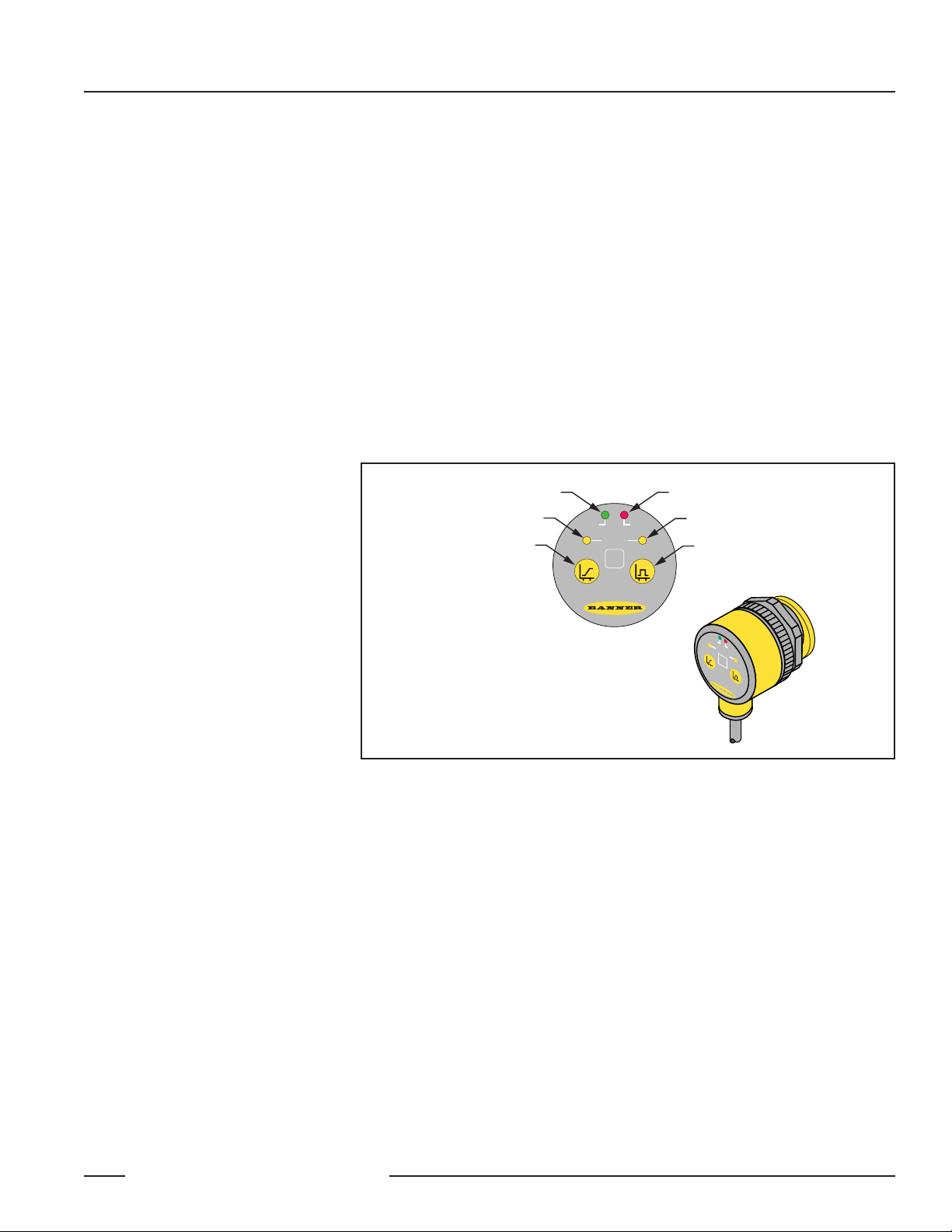

Figure 1. U-GAGE T30 Series sensor programming push buttons and indicators

General Notes on Programming:

1. The sensor will return to RUN mode if the first TEACH condition is not registered

within 120 seconds.

2. After the first limit is taught, the sensor will remain in PROGRAM mode until the

TEACH sequence is finished.

3. Press and hold the programming push button > 2 seconds (before teaching the

second limit) to exit PROGRAM mode without saving any changes. The sensor will

revert to the last saved program.

Green Power ON/OFF LED

Yellow Analog Output LED

Analog Output

Programming Push Button

POWER SIGNAL

OUTPUT

ANALOG

U-GAGE

Red Signal Strength LED

Yellow Discrete Output LED

DISCRETE

™

Discrete (Switched) Output

Programming Push Button

P

O

W

E

R

S

A

I

O

G

N

U

N

A

T

A

L

P

O

L

U

G

T

D

I

S

C

R

E

T

E

U

-

G

A

G

E

™

Page 4

U-GAGE™T30 Series with Analog and Discrete Outputs

4 P/N 57438 Rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

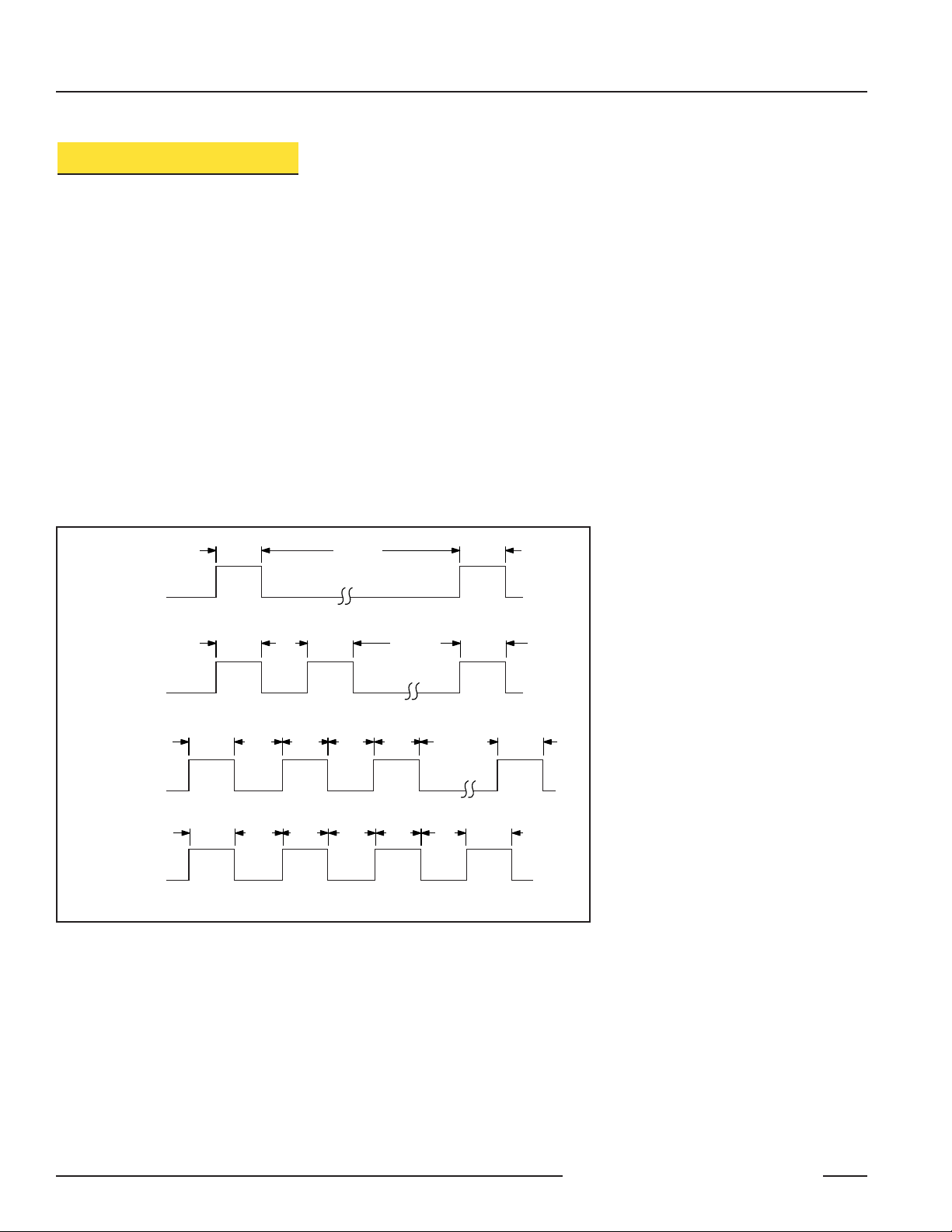

Figure 2. Timing programs for remote TEACH programming

Remote Programming

To program the sensor remotely or to disable the keypad, the Remote Programming

function may be used. Disabling the keypad prevents anyone on the production floor

from adjusting any of the programming settings. Connect the gray wire of the

sensor to +12 to 24V dc, with a remote programming switch connected between

them. NOTE: The impedance of the remote teach input is 55 kΩ.

Programming is accomplished by following the sequence of input pulses. The

duration of each pulse (corresponding to a push button “click”), and the period

between multiple pulses, are defined as: 0.04 seconds < T < 0.8 seconds.

•1 pulse: Programs first discrete limit. Wait > 0.8 sec. Next pulse programs

second discrete limit.

•2 pulses: Programs first analog limit. Wait > 0.8 sec. Next pulse programs

second analog limit.

•3 pulses: Programs first analog and discrete limit. Wait > 0.8 sec. Next pulse

programs second analog and discrete limit.

•4 pulses: Disables (locks out) or enables the keypad for security.

NOTE: Hold the Remote line high > 2 seconds (before teaching the second limit) to exit

PROGRAM mode without saving any changes. The sensor will revert to the last

saved program.

> 0.8 sec

T T

Teach First

Analog Limit

> 0.8 sec

T

Teach First Limits Teach Second Limits

T

Teach Second

Discrete Limit

Teach Second

Analog Limit

> 0.8 sec

TTT

Push Button Lockout

T

Discrete

Limits Only

Analog

Limits Only

Analog & Discrete

Together

Push Button

Lockout

T

Teach First

Discrete Limit

TT

TTTT

T TTT

0.04 sec < T < 0.8 sec

Page 5

U-GAGE™T30 Series with Analog and Discrete Outputs

P/N 57438 Rev. C 5

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

RUN Mode

NOTE: All LED indicators momentarily go OFF when sensor changes state between

PROGRAM and RUN modes.

Signal LED

The red Signal LED indicates the strength and condition of the sensor’s incoming

signal.

Signal LED Status Indicates

OFF

No signal is received, or the target is beyond the range limitations

of the sensor (with some tolerance beyond the recommended

minimum and maximum sensing distance)

Flashing Relative received signal strength

Power ON/OFF LED Indicates

OFF Power is OFF (or in PROGRAM mode, if other LEDs are ON)

ON Solid Sensor is operating normally (power is ON, RUN mode)

Output LEDs

Each yellow Output LED lights when a target is sensed within the programmed window

limits.

Power ON/OFF LED

The green Power ON/OFF LED indicates the operating status of the sensor.

Analog Output

The U-GAGE T30 Series sensor may be programmed for either a positive or a negative

output slope, based on which condition is taught first (see Figure 3). If the near limit is

taught first, the slope will be positive; if the far limit is taught first, the slope will be

negative. Banner’s scalable analog output automatically distributes the output signal over

the width of the programmed sensing window.

The U-GAGE T30 also features a 2-second hold upon loss of the analog signal, which is

useful for harsh and unstable applications. In the event of analog signal loss for longer

than 2 seconds, the analog output goes to 3.6 mA or 0V dc, which may be used to trigger

an alarm.

Self-Diagnostic Error Mode

In the unlikely event of a microprocessor memory error, all of the LEDs will flash in

sequence. If this occurs, the setup parameters have been lost and the sensor may be

corrupt. Contact your Banner representative for further information.

Figure 3. Output current as a function of

target position

NOTE: The analog current output tracks

slightly past each window limit

(from 3.8 to 20.5 mA).

4

Near

Window

Far

Window

20

Target Position

Analog Output (mA)

Positive

Slope

Current-Sourcing Models

Flashing Discrete output is overloaded (RUN mode)

Voltage-Sourcing Models

10

Positive

Slope

Analog Output (V dc)

0

Near

Window

Target Position

Far

Window

Page 6

U-GAGE™T30 Series with Analog and Discrete Outputs

6 P/N 57438 Rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

U-GAGE T30 Series Specifications

Proximity Mode Range

Supply Voltage Current-sourcing analog output models: 12 to 24V dc (10% max. ripple) at 90 mA, exclusive of load

Voltage-sourcing analog output models: 15 to 24V dc (10% max. ripple) at 90 mA, exclusive of load

Supply Protection Circuitry Protected against reverse polarity and transient voltages

Output Configurations Discrete (switched) output: SPST solid-state switch conducts when target is sensed within sensing

window; choose NPN (current sinking) or PNP (current sourcing) models

Analog output: Choose 0 to 10V dc sourcing or 4 to 20 mA sourcing output models; output slope may be

selected via TEACH sequence (see Window Limit Programming on pages 2-4)

Output Ratings Discrete (switched) output: 100 mA maximum

Off-state leakage current: less than 5 microamps

On-state saturation voltage: less than 1V at 10 mA and less than 1.5V at 100 mA

Analog output:

Voltage sourcing: 0 to 10V dc (at 1K ohm minimum resistance)

Current sourcing: 4 to 20 mA, 1 ohm to Rmax

Rmax = V

supply

- 7V

20 mA

Output Response Time Discrete output:

“A” suffix models: 48 milliseconds

“B” suffix models: 96 milliseconds

Analog output:

“A” suffix models: 48 milliseconds average, 16-millisecond update

“B” suffix models: 96 milliseconds average, 32-millisecond update

Sensing Performance

(Specified using a 10 cm x 10 cm

aluminum target at 25ºC under

fixed sensing conditions.)

Analog sensing resolution: ±0.25% of measured distance

Analog linearity: ±0.5% of full-scale sensing range

Sensing repeatability: ±0.25% of distance

Minimum window size: 10 mm (0.4")

Hysteresis of discrete output: 2.5 mm (0.10")

Adjustments Sensing window limits (analog or discrete): TEACH-mode programming of near and far window limits

may be set using membrane push buttons on sensor or remotely via TEACH input (see pages 2-4).

Discrete and analog window limits may be programmed separately, or together.

Analog output slope: the first limit taught is assigned to the minimum output value (4 mA or 0V)

“A” suffix models: 150 mm (5.9") min. near limit; 1 m (39") max. far limit

“B” suffix models: 300 mm (11.8") min. near limit; 2 m (79") max. far limit

Output Protection Protected against continuous overload and short-circuit; transient over-voltage; no false pulse on power-up

Indicators Four status LEDs:

In RUN mode:

Green

ON = Power ON, RUN mode

Flashing = Discrete output is overloaded

Red Flashing = Relative received signal strength

Yellow analog ON = Target is inside window limits

Yellow discrete ON = Output conducting

In Program mode:

Green OFF = PROGRAM mode

Red Flashing = Relative received signal strength

ON = Ready for first window limit

Yellow analog Flashing = Ready for second limit

OFF = Not teaching analog limits

ON = Ready for first window limit

Yellow discrete Flashing = Ready for second limit

OFF = Not teaching discrete limits

{

{

{

Page 7

U-GAGE™T30 Series with Analog and Discrete Outputs

P/N 57438 Rev. C 7

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

U-GAGE T30 Series Specifications (continued)

Construction

Environmental Rating Leakproof design is rated IEC IP67; NEMA 6P

Molded reinforced thermoplastic polyester housing

Vibration and

Mechanical Shock

All models meet Mil. Std. 202F requirements. Method 201A (Vibration: 10 to 60Hz max., double amplitude

0.06", maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G, 11 ms duration, half sine wave.

Operating Conditions Temperature: -20° to +70° C (-4° to 158° F)

Maximum relative humidity: 100%

Application Notes Objects passing inside the specified near limit will produce a false response.

NOTE: For more information about out-of-range and signal loss response of the analog output, see page 5.

Connections 2 m (6.5') or 9 m (30') 5-conductor PVC-covered attached cable, or 5-pin Euro-style quick-disconnect

fitting (see page 9 for optional quick-disconnect cables)

U-GAGE T30 Series Performance Curves

U-GAGE T30 Effective Beam with Plate Target (Typical)

1-Meter Models

2-Meter Models

U-GAGE T30 Effective Beam with Rod Target (Typical)

1-Meter Models

2-Meter Models

0

0 200 mm

(8.0 in)

400 mm

(16.0 in)

600 mm

(24.0 in)

800 mm

(32.0 in)

1000 mm

(40.0 in)

50 mm

50 mm

100 mm

100 mm

150 mm

150 mm

200 mm

200 mm

0

2.0 in

2.0 in

4.0 in

4.0 in

6.0 in

6.0 in

8.0 in

8.0 in

100 x 100 mm

10 x 10 mm

Width

Distance

0

0 400 mm

(16.0 in)

800 mm

(32.0 in)

1200 mm

(48.0 in)

1600 mm

(64.0 in)

2000 mm

(80.0 in)

100 mm

100 mm

200 mm

200 mm

300 mm

300 mm

400 mm

400 mm

0

4.0 in

4.0 in

8.0 in

8.0 in

12.0 in

12.0 in

16.0 in

16.0 in

100 x 100 mm

Width

Distance

0

0 200 mm

(8.0 in)

400 mm

(16.0 in)

600 mm

(24.0 in)

800 mm

(32.0 in)

1000 mm

(40.0 in)

50 mm

50 mm

100 mm

100 mm

150 mm

150 mm

200 mm

200 mm

0

2.0 in

2.0 in

4.0 in

4.0 in

6.0 in

6.0 in

8.0 in

8.0 in

25 mm Rod

10 mm Rod

Width

Distance

0

0 400 mm

(16.0 in)

800 mm

(32.0 in)

1200 mm

(48.0 in)

1600 mm

(64.0 in)

2000 mm

(80.0 in)

100 mm

100 mm

200 mm

200 mm

300 mm

300 mm

400 mm

400 mm

0

4.0 in

4.0 in

8.0 in

8.0 in

12.0 in

12.0 in

16.0 in

16.0 in

25 mm Rod

Width

Distance

Certifications

Page 8

U-GAGE™T30 Series with Analog and Discrete Outputs

8 P/N 57438 Rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

U-GAGE T30 Series Dimensions

Cabled Models Quick-Disconnect Models

U-GAGE T30 Series Hookups

Cabled NPN

Cabled PNP

Quick-Disconnect NPN Quick-Disconnect PNP

†

4-20 mA or 0-10V dc

††

100 mA maximum

*It is recommended that the shield wire be connected to earth ground

or dc common.

ø 40.0 mm

Jam Nut

(Supplied)

M30 x 1.5

Thread

(1.57")

ø 15 mm

(0.59")

bu

bn

wh

Analog

bk

Discrete

Remote Teach

gy

shield*

45.0 mm

(1.77")

12-24V dc

†

††

51.5 mm

(2.03")

11.5 mm

(0.45")

–

+

bu

bn

wh

Analog

bk

Discrete

Remote Teach

gy

shield*

66.5 mm

(2.62 in)

–

12-24V dc

+

†

††

bu

bn

wh

bk

gy

shield*

†

Analog

††

Discrete

Remote Teach

–

12-24V dc

+

bu

bn

wh

bk

gy

shield*

†

Analog

††

Discrete

Remote Teach

–

12-24V dc

+

Page 9

U-GAGE™T30 Series with Analog and Discrete Outputs

P/N 57438 Rev. C 9

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Quick-Disconnect (QD) Cables

Accessories

5-Pin

Euro-style

Right-angle

with shield

5-Pin

Euro-style

Straight

with shield

MQDEC2-506

MQDEC2-515

MQDEC2-530

2 m (6.5')

5 m (15')

9 m (30')

Style Model Length Connector

MQDEC2-506RA

MQDEC2-515RA

MQDEC2-530RA

2 m (6.5')

5 m (15')

9 m (30')

Style Model

Length Connector

Mounting Brackets

SMB30A

• Angled-mount bracket

• Stainless steel

SMB1815SF

• Compact 30 mm split clamp with swivel, black

reinforced thermoplastic polyester

• Stainless steel hardware included

44 mm max.

(1.7")

ø 15 mm

(0.6")

M12 x 1

38 mm max.

(1.5")

M12 x 1

ø 15 mm

(0.6")

38 mm max.

(1.5")

45 mm

(1.8")

30°

69 mm

6.3 mm

(0.25")*

7.6 mm

(0.30")

(2.70")

R 40 mm

(1.58")

ø 6.3 mm

(0.25")*

38.5 mm

(1.52")

61 mm

(2.40")

* Use 5 mm (#10) screws to mount bracket.

Drill screw holes 40.0 mm (1.58") apart.

ø 30.5 mm

(1.20")

42.0 mm

(1.65")

36.0 mm

(1.42")

50.8 mm

(2.00")

ø15.0 mm

(0.59")

10.6 mm

(0.42")

22.9 mm

(0.9")

25.4 mm

(1.00")

Page 10

U-GAGE™T30 Series with Analog and Discrete Outputs

10 P/N 57438 Rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SMB30C SMB30SC

• 30 mm split clamp with swivel, black reinforced

thermoplastic polyester

• Stainless steel hardware included

• 30 mm split clamp, black reinforced thermoplastic

polyester

• Stainless steel hardware included

Mounting Brackets

56.0 mm

13.5 mm

(0.53")

63.0 mm

(2.48")

(2.20")

45.0 mm

(1.77")

31.5 mm

2.5 mm

(0.10")

(1.24")

13 mm

(0.5")

Nut Plate

M5 x 0.8

x 80 mm

Screw (2)

50.8 mm

58.7 mm

(2.31")

(2.00")

66.5 mm

(2.62")

30 x 1.5 mm

internal thread

30.0 mm

(1.18")

29.0 mm

(1.14")

12.7 mm

(0.50")

Page 11

U-GAGE™T30 Series with Analog and Discrete Outputs

P/N 57438 Rev. C 11

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 12

U-GAGE™T30 Series with Analog and Discrete Outputs

Banner Engineering Corp., 9714 Tenth Ave. No., Mpls, MN 55441 • Ph: 763.544.3164 • www.bannerengineering.com • sensors@bannerengineering.com

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period.

This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty

either expressed or implied.

WARNING . . .

Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications.

A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety

Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

P/N 57438 Rev. C

!

Loading...

Loading...