Page 1

SLE10 Expert™Series Teach-Mode Slot Sensor

Self-contained opposed-mode sensor pair with Teach Mode

Printed in USA P/N 60378

SLE10 Expert Series Slot Sensor Features

• An easy-to-use, self-contained opposed-mode sensor pair in a rugged U-shaped

housing

• Easy push-button programming automatically adjusts sensitivity to optimal setting

• Dynamic TEACH programming option provides on-the-fly convenience and

minimizes the effects of web flutter

• Separate TEACH input allows remote programming by an external device, such as

a switch or a process controller

• Easy output programming eliminates the need for Light or Dark Operate selection

• Choose fast 500 microsecond or 150 microsecond output response

• 1 mm effective beam

• Visible red beam

• Molded-in beam guides simplify mounting and beam placement

• 10 mm slot width for a wide variety of sensing applications

• Applications include label detection, hole detection, edge guiding and counting,

small parts detection

• 10 to 30V dc operation

• Bipolar PNP/NPN outputs

• Choose integral, unterminated cable or QD models

Models

Slot

Width Cable*

Supply

Voltage

Output

Type Response Repeatability

SLE10B6V

SLE10 Expert Series Slot Sensor Models

Visible red, 680 nm

500 microseconds 100 microseconds

10.0 mm

(0.39")

2 m (6.5')

5-wire cable

10-30V dc

Bipolar

NPN (sinking)

and

PNP (sourcing)

5-Pin

Euro-style QD

SLE10B6VQ

2 m (6.5')

5-wire cable

5-Pin

Euro-style QD

SLE10B6VYQ

SLE10B6VY

150 microseconds 75 microseconds

*NOTES: 1) 9 m (30') cables are available by adding suffix “W/30” to the model number of the cabled version (e.g., SLE10B6V W/30).

2) A model with a QD connector requires an accessory mating cable. See page 5.

Page 2

SLE10 Expert™Series Slot Sensor

2

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

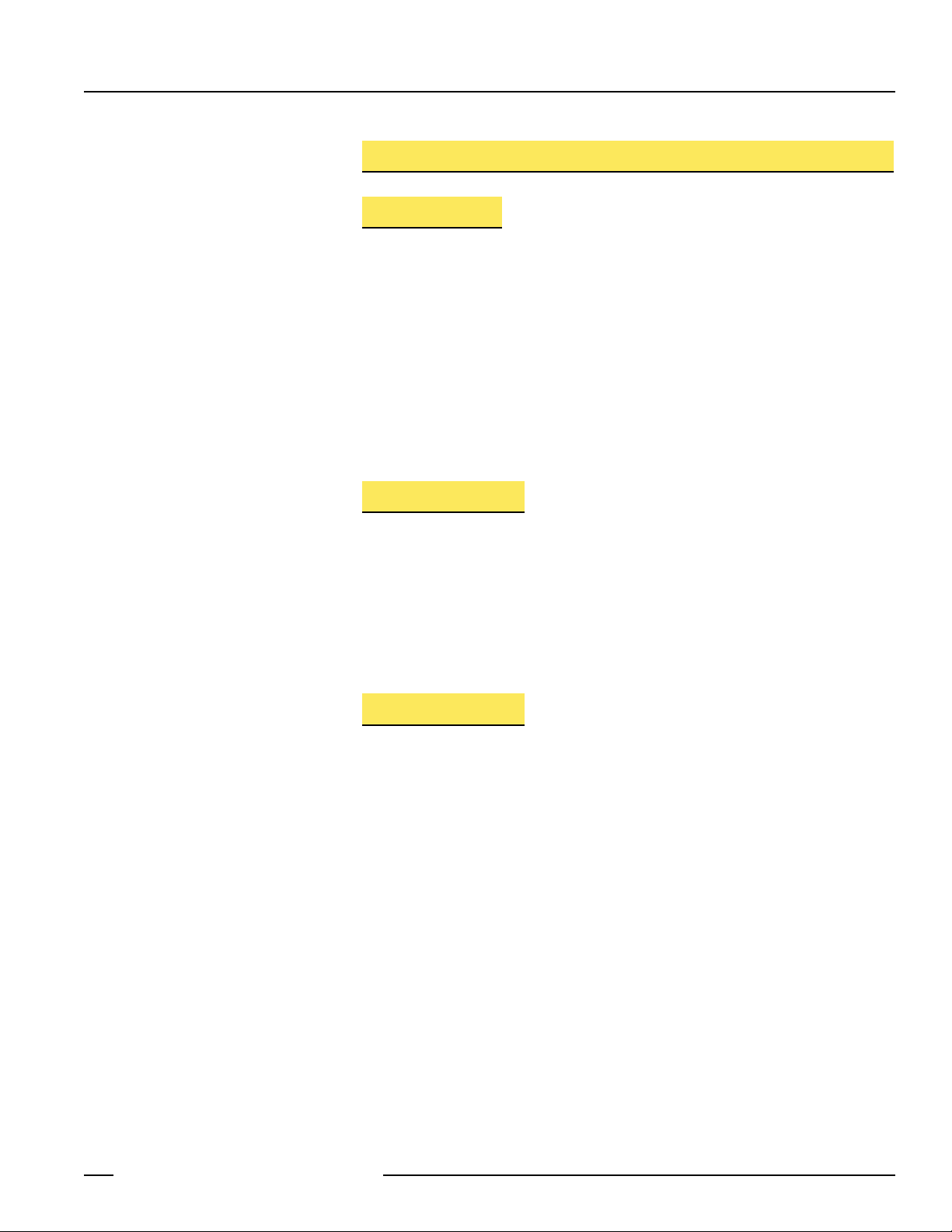

Figure 2. SLE10 Expert Series typical applications

Figure 1. SLE10 Expert Series features

SLE10 Expert Series Slot Sensor Overview

The SLE10 Series Slot Sensor (sometimes called a “Fork Sensor”)

comprises an opposed-mode emitter and its receiver inside a single

convenient housing. Opposed-mode sensing is very reliable, and the

single self-contained housing provides easy installation, with no

sensor alignment required. In addition, the molded-in arrow on the

emitter portion of the housing and the slotted design on the receiver

portion of the housing show at a glance the position of the beam,

simplifying installation placement.

Expert series sensors feature easy-to-use push-button programming,

performed in TEACH mode. TEACH-mode programming may be

performed using either the push button, or remotely, using a remote

switch or process controller. The programming determines whether

the sensor outputs will conduct in light or dark conditions, and defines

the light and dark conditions for the sensor in each application. The

remote switch also may be used to disable the programming push

button for security.

The Dynamic TEACH option provides a means for teaching a series of

conditions; the SLE10 monitors the sensing events and automatically

sets the threshold between light and dark conditions.

Register Mark Detection

on Clear Film

Label Detection

Emitter

Signal LED

Power ON LED

Receiver (Beam Aligns at Groove)

TEACH

Pushbutton

Packaging Film

Register Marks

Page 3

SLE10 Expert™Series Slot Sensor

3

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Using the SLE10 Expert Series Slot Sensor

RUN Mode

Normal operation of the SLE10 Expert is called RUN mode. The two LED indicators

(bi-color Green/Red and Yellow) operate as follows in RUN Mode:

Green (RUN Mode): ON steady whenever power is applied

Flashes as received light level approaches the switching threshold

(stability indicator. The stability indicator signals when

maintenance or reprogramming is needed during RUN mode.)

Yellow (Output): ON when the outputs are energized (conducting)

OFF when the outputs are de-energized (not conducting)

If contrast is marginal, the bi-color indicator will flash green (to indicate instability).

Reprogramming the sensor, or cleaning the sensor lenses may solve a problem with

stability.

TEACH Mode

Programming of the SLE10 Expert – setting the sensitivity and selecting output ON and

OFF conditions – is performed in TEACH Mode. The SLE10 provides two methods for

programming: Static TEACH and Dynamic TEACH. Static TEACH is used in all

programming situations to set up the sensor’s output ON and output OFF conditions.

Sensitivity is then set using either the Static method described below or the Dynamic

method on page 4.

Both Static TEACH and Dynamic TEACH may be performed using either the sensor’s

TEACH push button or the Remote TEACH line (see page 6).

Static TEACH

Determining the Output ON and OFF Conditions

The two sensing conditions may be presented in either order. The condition presented

first is the condition for which the outputs will energize (the “Output ON” target).

Setting Sensitivity

Sensitivity is automatically set (and optimized) when teaching the sensor the ON and

OFF conditions. When the push button is clicked, the sensor samples each sensing

condition and registers it into memory. After the second sensing condition is

registered, the SLE10 Expert automatically sets the sensitivity to the optimum value

for the application, and then returns to RUN mode.

The two LED indicators (bi-color Green/Red and Yellow) operate as follows in

TEACH Mode:

Red (TEACH Mode): Lights when the sensor “sees” its modulated light source;

pulse rate is proportional to the received light signal strength

during TEACH programming

Yellow (Output): ON to indicate TEACH output ON condition

OFF to indicate TEACH output OFF condition

The Signal Strength indicator is Banner’s exclusive AID™(Alignment Indicating

Device). Its pulse rate increases as the received light signal strength increases (during

programming). This feature simplifies accurate alignment during TEACH mode, and

gives a relative indication of sensing contrast between the light and dark conditions.

Page 4

SLE10 Expert™Series Slot Sensor

4

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

A Note About the “Clicks”: Clicks are meant to be pressed firmly, then quickly

released. Indicators go ON or OFF after a brief delay; do not wait until LEDs change

status before releasing push button. (If push button is pressed for 2 seconds or

longer, sensor will automatically return to RUN mode.)

Dynamic TEACH

Dynamic TEACH is a method of setting the sensor’s sensitivity while the object to be

sensed is in motion. Typical applications are label sensing and small parts detection. In

a label application, web flutter may change the amount of light passing through the

label and its backing material. Dynamic TEACH will sense this variation and adjust the

sensitivity to account for it.

In a small parts detection application, alignment of the object to the sensor’s effective

beam may make Static TEACH difficult. In this case, Dynamic TEACH will allow you to

pass individual or multiple parts through the beam; the sensor then will detect them and

set the sensitivity automatically.

Determining the Output ON and OFF Conditions

Dynamic TEACH is used for optimizing the sensor’s sensitivity and will not configure the

output ON and OFF conditions. A Static TEACH must be used first to change the output

ON and OFF conditions, if needed. If the outputs are configured properly for your

installation, Dynamic TEACH may be performed as needed without reverting back to

Static TEACH.

Setting Sensitivity

Sensitivity is automatically set and optimized when the sensor is taught dynamically.

When the push button is depressed and held, the sensor continues to sample events

and registers them into memory. Upon release of the button, the sensor chooses the

optimum setting for the application and then returns to RUN mode.

Push Button Resulting Indicator Status

TEACH Condition #1

(Output ON state)

Present the first

sensing condition to

the sensor and singleclick.

†

Press and hold until

the bi-color (green/red)

indicator begins to

flash red, or turns OFF.

Yellow: ON

Red: Pulses to indicate relative received signal

strength.

Yellow: OFF

Red: Pulses to indicate relative received signal

strength.

TEACH Condition #2

(Output OFF state)

Present the second

sensing condition to

the sensor and singleclick.

If contrast is acceptable, the sensor returns to

RUN mode; other wise it will return to TEACH

Condition #1.

Green: ON (or flashes if signal is close to the

switching threshold).

Yellow: OFF, until the sensing condition changes.

†

NOTE: The sensor will return to RUN mode if the first TEACH condition is not registered within 90 seconds. TEACH mode may be cancelled

before either condition #1 or #2 by holding the push button depressed for ≥ 2 seconds.

Static TEACH Sequence

Push and Hold

≥ 2 Seconds

Single-Click

Single-Click

Sensing

Condition #1

(Output ON State)

Sensing

Condition #2

(Output OFF State)

Page 5

SLE10 Expert™Series Slot Sensor

5

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Dynamic Sampling Rate

When using Dynamic TEACH to sample an application for programming, it is important

to consider the speed of the object being sensed. The sensor’s sampling rate during this

set-up process is much slower than its response time in RUN mode. Once sampling is

complete and the sensor returns to RUN mode, sensor response time returns to its

original value.

Use the following formula to calculate the target object speed for Dynamic TEACH

sampling:

Max. speed of object =

as it passes the sensor

For example, for an object 0.125" wide: Or for an object 2 mm wide:

(0.125" - 0.04") (2 - 1 mm)

Max. object speed = = 9.4" /second Max. object speed = = 111 mm/second

0.009 seconds 0.009 seconds

*NOTE: The Dynamic Sampling Rate for high-speed models (“Y” model suffix) is

8 milliseconds (0.008 seconds)

†

NOTE: The sensor will return to RUN mode if the first TEACH condition is not registered within 90 seconds. Dynamic TEACH mode may be

cancelled by waiting 90 seconds or by cycling sensor power.

Dynamic TEACH Sequence

Push Button Resulting Indicator Status

Initiates Dynamic

TEACH Mode

Press and hold until

the bi-color (green/red)

indicator begins to

flash red, or turns OFF.

Yellow: ON

Red: Pulses to indicate relative received signal

strength.

Yellow: Pulses at 0.5 Hz.

Red: ON

Ends TEACH Process

If contrast is acceptable, the sensor returns to RUN

mode. Otherwise, it will return to Static TEACH

mode; double-click to initiate Dynamic TEACH.

Green: ON (or flashes if signal is close to the

switching threshold).

Yellow: ON or OFF, depending on condition

Starts TEACH Process

Present the sensing

condition while holding

the button

Yellow: ON Solid

Red: ON Solid

Width of object (in inches) — effective beam (0.04")

Dynamic Sampling Rate (0.009 seconds)*

Sensing

Condition

Push and Hold

≥ 2 Seconds

Double-Click

Push and Hold

≥ 2 Seconds

Release

Page 6

SLE10 Expert™Series Slot Sensor

6

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Remote Programming

The gray wire of the SLE10 Expert may be connected to a remote

switch or process controller to disable or enable the push button

(four-pulse) or to program the sensor (single-pulse) through

TEACH mode. Remote programming may be done for both the

Static and Dynamic TEACH procedures.

A remote programming switch is connected between the gray wire

and dc common (see hookup diagrams on page 9). The switch may

be either a normally-open contact, or an open-collector NPN

transistor with its emitter connected to dc common.

Programming is accomplished using a specified sequence of

input pulses. The duration of each pulse is defined as:

0.04 seconds<T<0.8 seconds.

The required spacing between adjacent pulses in a sequence

(a “four-pulse”) is also: 0.04<T<0.8 seconds. The timing diagrams

(Figure 3, right) illustrate the input requirements.

Locking Out (Disabling) the Push Button

When remote programming is used exclusively, it may be beneficial to disable the

push button on the SLE10 Expert to increase the security of the settings. The push

button can be enabled and/or disabled via the remote line only. If the push button is

disabled, TEACH mode cannot be accessed from the push button.

Pulse the Remote TEACH line 4 times (four-pulse) to enable or disable the push

button (see timing diagram, Figure 3).

Static TEACH Programming Using the Remote TEACH Line

To pulse the TEACH line, momentarily connect the remote wire to dc common (no

press-and-hold procedure is required to enter TEACH mode). This is the equivalent of

a “click” when using the sensor TEACH push button.

1. Position the “Output ON” condition and pulse the Remote TEACH line once. The

bi-color (green/red) indicator begins to flash red or turn OFF (the AID

™

function is

indicating signal strength) and the yellow Output indicator will flash briefly and then

go OFF.

2. Position the “Output OFF” condition and pulse the Remote TEACH line again. The

green indicator will turn ON and the sensor will return to RUN mode with the new

settings, if the contrast is adequate. If the contrast is not adequate, the yellow

indicator will turn ON and the red AID indicator will remain active, indicating that

the sensor is waiting for the first TEACH condition to be retaught. (RUN mode

begins a few seconds after the end of TEACH mode.)

NOTE: To exit Static TEACH without updating, hold the Remote TEACH line low

(longer than 2 seconds) until the green indicator goes ON, before teaching the

second target.

Figure 3. Timing programs for remote programming

Single-

Pulse

Input

FourPulse

Input

T

T

0.04 sec

Wait > 0.8 seconds

before next input

T T T

T T T

< T < 0.8 sec

> 0.8 seconds

Wait

before next input

Page 7

SLE10 Expert™Series Slot Sensor

7

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Dynamic TEACH Programming Using the Remote TEACH Line

To pulse the TEACH line, momentarily connect the Remote (gray) wire to dc common; no

press-and-hold procedure is required to enter TEACH mode. (This is the equivalent of a

“click” when using the sensor TEACH push button.)

1. Using the Static TEACH procedure, set up the application’s Output ON and OFF

conditions. (This step is not necessary if the Output ON and OFF conditions already

are configured properly for your application.)

2. Double-pulse the Remote TEACH line (see Figure 3). The sensor is now ready for

Dynamic TEACH. The bi-color (green/red) indicator will be ON solid red and the

yellow indicator will flash.

3. Hold the Remote line low. Sample sensing events while continuing to hold the

Remote line low.

4. Release the Remote line when event sampling is complete. The green indicator will

turn ON and the sensor will return to RUN mode with the new settings, if the

contrast is adequate.

If the contrast is not adequate, the red indicator will flash at a rate proportional to the

received light signal strength and the yellow indicator will be ON solid, indicating that the

sensor needs to be retaught. In this case, return to step 2.

NOTE: To exit Dynamic TEACH without updating, wait 90 seconds or cycle sensor power.

Troubleshooting

The SLE10 Expert’s Power LED may begin to alternate flashing red/green; this

indicates a microprocessor memory error. If it occurs, try reteaching the sensor, or

try cycling power ON and OFF, then reteaching the sensor. If this does not solve the

problem, or if it occurs frequently, replace the sensor.

Page 8

SLE10 Expert™Series Slot Sensor

8

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

SLE10 Expert Series Slot Sensor Specifications

Supply Voltage and Current 10 to 30V dc (10% maximum ripple) at less than 45 mA, exclusive of load

Supply Protection Circuitry Protected against reverse polarity and transient voltages

Output Configuration Bipolar: One current sourcing (PNP) and one current sinking (NPN) open-collector transistor

Output Rating 150mA maximum each output at 25°C, derated to 100 mA at 70°C (derate ≈1 mA per °C)

OFF-state leakage current: less than 5µA @ 30V dc

ON-state saturation current: less than 1V @ 10 mA; less than 1.5V @ 150 mA

Output Protection Circuitry Protected against false pulse on power-up and continuous overload or short-circuit of outputs

Output Response Time Sensors will respond to either a “light” or a “dark” signal of 500 microseconds (or 150 microseconds,

depending on model) or longer duration, 1 kHz max.

NOTE: 1 second delay on power-up; outputs are non-conducting during this time.

Repeatability 100 microseconds or 75 microseconds, depending on model

Adjustments Push-button TEACH mode sensitivity setting (see TEACH mode, page 3); remote TEACH mode input is

provided (gray wire)

Indicators Two LEDs:Yellow and Bi-color Green/Red

Green (RUN Mode): ON when power is applied

Flashes when received light level approaches the switching threshold

Red (TEACH Mode): OFF when no signal is received.

Pulses to indicate signal strength (received light level). Rate is proportional to

signal strength (the stronger the signal, the faster the pulse rate). This is a

function of Banner’s patented Alignment Indicating Device (AID™, USpatent

4356393).

Alternating Red/Green: Microprocessor memory error (see Troubleshooting, page 7)

Flashing

Yellow (Static TEACH): ON to indicate sensor is ready to learn output ON condition

OFF to indicate sensor is ready to learn output OFF condition

Yellow (Dynamic TEACH): Pulses at 0.5 Hz when ready to sample

ON to indicate Dynamic TEACH sampling

OFF to indicate sampling was accepted

Yellow (RUN Mode): ON when outputs are conducting

Construction ABS/polycarbonate housing, acr ylic lenses

Environmental Rating Meets NEMA 6; IEC IP67

Connections PVC-jacketed 5-conductor 2 m (6.5') or 9 m (30') unterminated cable, or 5-pin Euro-style

quick-disconnect (QD) fitting are available. QD cables are ordered separately; see page 10.

Operating Conditions Temperature: -20° to +70°C (-4° to +158°F)

Maximum relative humidity: 90% at 50°C (non-condensing)

Application Notes The first condition presented during TEACH mode becomes the output ON condition.

Effective Beam 1.0 mm (0.04")

Page 9

SLE10 Expert™Series Slot Sensor

9

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

SLE10 Expert Series Slot Sensor Hookups

SLE10 Expert Series Slot Sensor Dimensions

Cabled Models

Quick-Disconnect Models

10.0 mm

(0.39)

Power LED

(Green)

Signal LED

(Yellow)

10.0 mm

(0.39)

45.0 mm

(1.77")

72.0 mm

(2.84")

6.0 mm

(0.24")

bn

bu

wh

bk

gy

52.0 mm

(2.05")

Load

Load

6.0 mm

(0.24")

40.0 mm

(1.58")

17.5 mm

(0.69")

11.5 mm

(0.45")

2x ø5.6 mm

(0.22")

18.8 mm

(0.74")

+

10 - 30V dc

–

Remote

Teach

M12 x 1

bn

bu

wh

bk

gy

Load

Load

+

10 - 30V dc

–

Remote

Teach

20.2 mm (0.80")

Page 10

SLE10 Expert™Series Slot Sensor

10

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Accessories

Quick-Disconnect Cables

The following cables are available for SLE10 Expert Series Slot Sensor QD models

Style Model Length Dimensions

5-pin

Euro-style

straight

MQDC1-506

MQDC1-515

MQDC1-530

2 m (6.5')

5 m (15')

9 m (30')

Pin-out

5-pin

Euro-style

right-angle

MQDC1-506RA

MQDC1-515RA

MQDC1-530RA

2 m (6.5')

5 m (15')

9 m (30')

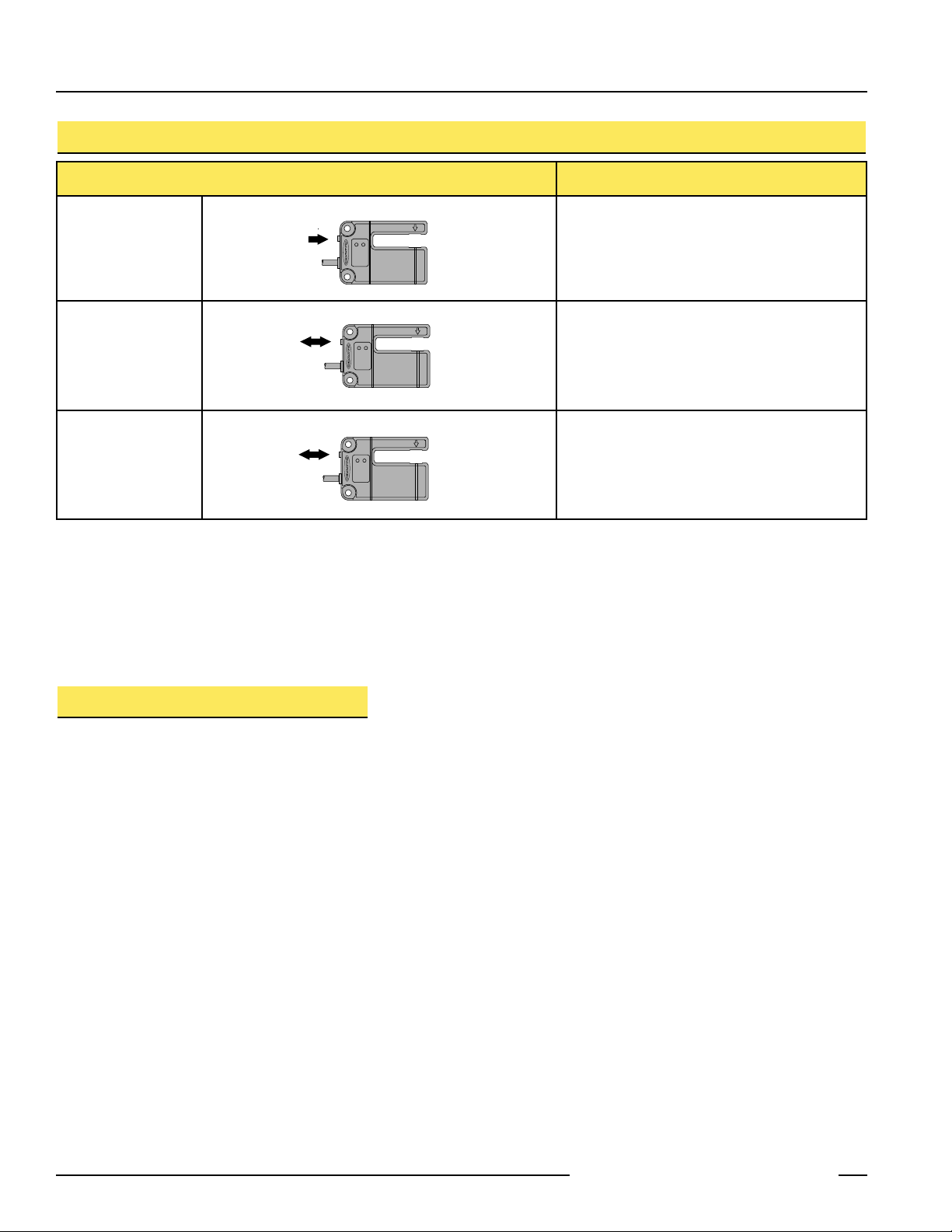

Mounting Brackets

SMBSL

• Angled bracket

• 304 stainless steel; hardware included

44 mm max.

(1.7")

38 mm max.

M12 x 1

ø 15 mm

(0.6")

12x R2.5mm

(0.10")

8.9 mm

(0.35")

6x ø5.5mm

(0.22")

(1.5")

ø 15 mm

(0.6")

M12 x 1

38 mm max.

(1.5")

Brown Wire

Black Wire

White Wire

Blue Wire

Gray Wire

30.4 mm

(1.20")

10.9 mm

(0.43")

7.6 mm

(0.30")

21.6 mm

(0.85")

41.3 mm

(1.62")

39.9 mm

(1.58")

19.1 mm

(0.75")

51.9 mm

(2.05")

6.0 mm

(0.24")

30.1 mm

(1.19")

10.9 mm

(0.43")

6.4 mm

(0.25")

40.0 mm

(1.58")

10.2 mm

(0.40")

6.0 mm

(0.24")

Page 11

SLE10 Expert™Series Slot Sensor

11

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Page 12

SLE10 Expert™Series Slot Sensor

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 888.373.6767 • www.baneng.com • E-mail: sensors@baneng.com

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 888.

Loading...

Loading...