Page 1

®

WARNING . . .

Spare actuators must

NEVER be used to bypass or

otherwise defeat the protective function

of a safety switch. To do so may create

an unsafe situation which could lead to

serious injury or death.

Machine Safety Switches

SI-LS42 Series Locking Style Switch

Features

• Positive opening safety contacts (IEC 60947-5-1) (not dependent upon springs)

•

Insulated device (IEC 60947-5-1)

• Choice of two locking mechanism types:

- Spring lock with energized solenoid release

- Energized solenoid lock with spring unlock

• Two solenoid voltages available:

- 24V ac/dc

- 24 to 48V dc or 24 to 230V ac

• Choose either of two stainless steel actuator types:

- Rigid in-line

- Flexible in-line

• Actuator head rotatable in 90° increments and can be positioned for either horizontal

or vertical actuation

• Choice of four switching contact configurations (with actuator engaged):

- 1 normally-open plus 1 normally-closed

- 2 normally-closed

- 2 normally-closed plus 1 normally-open

- 3 normally-closed

NOTE:

This symbol is used in the switching diagrams to identify the point in

actuator travel where the normally closed safety contact is fully open.

Printed in USA 07/06 P/N 60099 rev. D

Page 2

Machine Safety Switches –

SI-LS42 Series Locking Style Switch

Important Information Regarding the Use of Safety Switches

In the United States, the functions that Banner safety switches are intended to perform are regulated by the Occupational Safety

and Health Administration (OSHA). Whether or not any particular safety switch installation meets all applicable OSHA requirements

depends upon factors that are beyond the control of Banner Engineering Corp. These factors include the details of how the safety

switches are applied, installed, wired, operated, and maintained.

Banner Engineering Corp. has attempted to provide complete application, installation, operation, and maintenance instructions. This

information is found in the instruction manual packaged with each safety switch. In addition, we suggest that any questions regarding

the use or installation of safety switches be directed to the factory applications department at the telephone numbers or address

shown below.

Banner Engineering Corp. recommends that safety switches be applied according to the guidelines set forth in international

(ISO/IEC) standards listed below. Specifically, Banner Engineering Corp. recommends application of these safety switches in a

configuration which meets safety category 4, per ISO 13849 (EN954-1).

In addition, the user of Banner safety switches has the responsibility to ensure that all local, state, and national laws, rules, codes,

and regulations relating to the use of Banner safety switches in any particular application are satisfied. Extreme care is urged that all

legal requirements have been met and that all installations and maintenance instructions are followed.

Application Assistance

Toll Free: 1-888-3-SENSOR (1-888-373-6767)

Email: sensors@bannerengineering.com

Address: 9714 Tenth Avenue North

Minneapolis, MN 55441

U.S. Regulations Applicable to Use of Banner Safety Switches

OSHA Code of Federal Regulations: Title 29, Parts 1900 to 1910

Available from: Superintendent of Documents

Government Printing Office

P.O. Box 371954

Pittsburgh, PA 15250-7954

Tel: 202-512-1800

U.S. Standards Applicable to Use of Banner Safety Switches

ANSI B11 Standards for Construction, Care, and Use of Machine Tools”

Available from: Safety Director

AMT—The Association for Manufacturing Technology

7901 Westpark Drive

McLean, VA 22102

Tel: 703-893-2900

Applicable European and International Standards

ISO/TR 12100-1/-2 “Safety of Machinery

(EN292-1/-2)

ISO 13852 (EN 294) “Safety of Machinery

ISO 13853 (EN 811) “Safety of Machinery

ISO 13849-1 (EN 954-1) “Safety of Machinery

ISO 13855 (EN 999) “Safety of Machinery

ISO 14119 (EN 1088) “Safety of Machinery

IEC/EN 60204-1 “Safety of Machinery

IEC/EN 60947-5-1 “Low Voltage Switchgear

Available from:

15 Inverness Way East

Englewood, CO 80112-5704

Phone: 1-800-854-7179

Fax: 303-397-274

Global Engineering Documents

—Basic Concepts, General Principles for Design”

—Safety Distances to Prevent Danger Zones Being Reached by the Upper Limbs”

—Safety Distances to Prevent Danger Zones Being Reached by the Lower Limbs”

—Safety Related Parts of Control Systems”

—The Positioning of Protective Equipment in Respect to Approach Speeds of Parts of the Human Body”

—Interlocking Devices Associated with Guards—Principles for Design and Selection”

—Electrical Equipment of Machines”

—Electromechanical Control Circuit Devices”

0

2 P/N 60099 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

Machine Safety Switches –

0 (0)

7.0 (0.28)

8.0 (0.31)

9.0 (0.35)

41 (1.61)

mm (in)

Engaged

Disengaged

21-22

13-14

Safety

Monitor

0 (0)

41 (1.61)

mm (in)

Engaged

Disengaged

11-12

21-22

Safety

Safety

7.0 (0.28)

9.0 (0.35)

0 (0)

41 (1.61)

mm (in)

Engaged

Disengaged

31-32

13-14

Safety

Monitor

21-22

Safety

7.0 (0.28)

8.0 (0.31)

9.0 (0.35)

0 (0)

41 (1.61)

mm (in)

Engaged

Disengaged

11-12

31-32

Safety

Safety

21-22

Safety

7.0 (0.28)

9.0 (0.35)

13 14

21 22

13 14

21 22

21 22

11 12

43 44

31 32

E1

+

E2

-

43 44

31 32

E1

+

E2

-

21 22

31 32

13 14

41 42

E1

+

E2

-

41 42

E1

+

E2

-

21 22

31 32

11 12

21

22

11 12

31 32

21 22

11 12

21

22

31 32

13 14

43 44

31 32

E1

+

E2

-

43 44

31 32

E1

+

E2

-

41 42

E1

+

E2

-

41 42

E1

+

E2

-

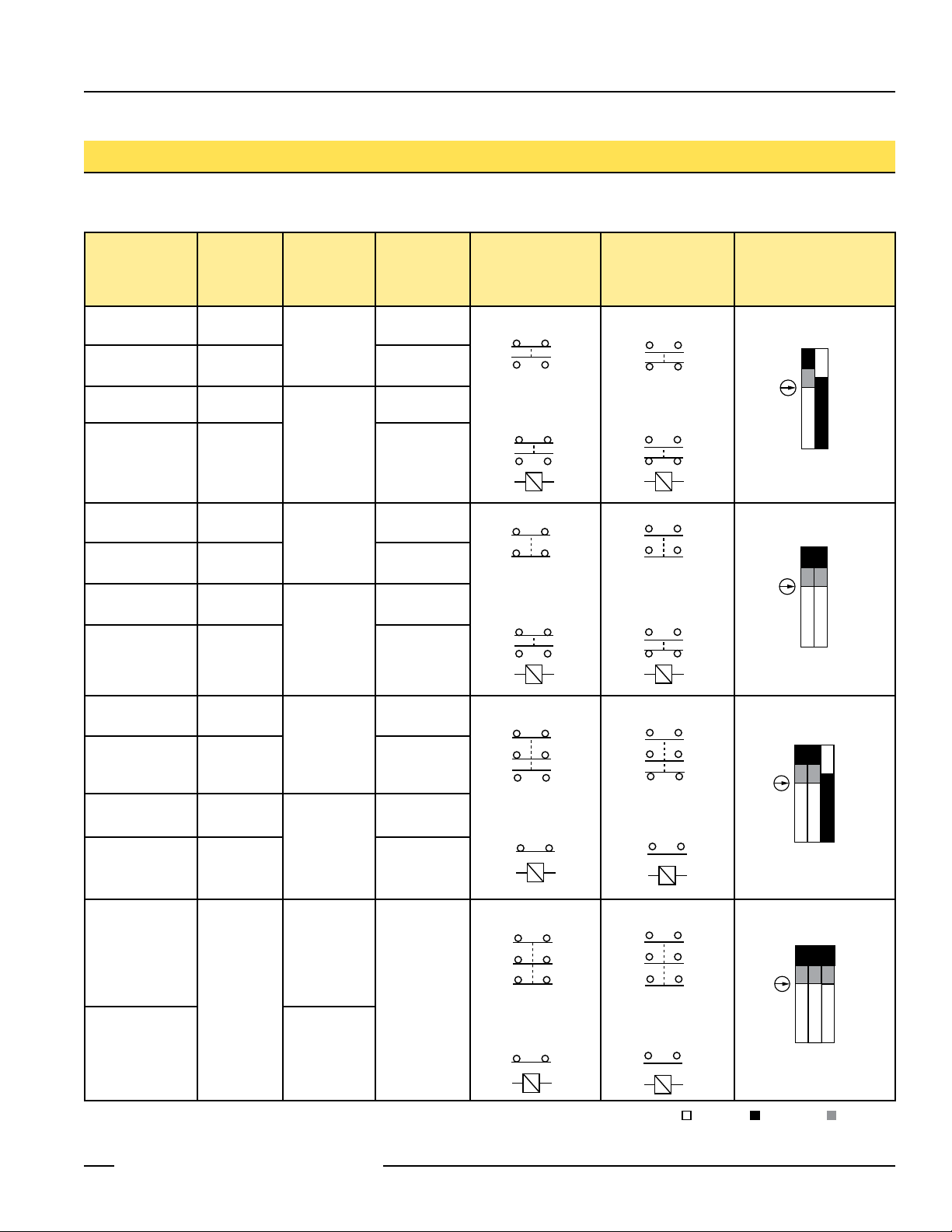

SI-LS42 Series Locking Style Switch

Models

For the following models, the actuator is mechanically locked when it is fully inserted into the actuator head. The actuator is unlocked by

applying voltage to the solenoid.

Kit

Model

†

Solenoid

Voltage

SI-LS42DMSG 24V ac/dc

SI-LS42UMSG

24-48V dc

24-230V ac

SI-LS42DMSGF 24V ac/dc

SI-LS42UMSGF

24-48V dc

24-230V ac

SI-LS42DMSH 24V ac/dc

SI-LS42UMSH

24-48V dc

24-230V ac

SI-LS42DMSHF 24V ac/dc

SI-LS42UMSHF

24-48V dc

24-230V ac

Actuator

†

Type

SI-QM-SSA

Rigid

In-Line

SI-QM-SMFA

Flexible

In-Line

SI-QM-SSA

Rigid

In-Line

SI-QM-SMFA

Flexible

In-Line

Interlock

†

Body

SI-LS42DSG

SI-LS42USG

SI-LS42DSG

SI-LS42USG

SI-LS42DSH

SI-LS42USH

SI-LS42DSH

SI-LS42USH

Contact

Configuration

(Actuator Engaged

and Locked)

Contact

Configuration

(Actuator Unlocked

and Removed)

Actuator Contacts Actuator Contacts

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

Actuator Contacts Actuator Contacts

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

Switching

Diagram*

SI-LS42DMSI 24V ac/dc

SI-LS42UMSI

24-48V dc

24-230V ac

SI-LS42DMSIF 24V ac/dc

SI-LS42UMSIF

24-48V dc

24-230V ac

SI-QM-SSA

Rigid

In-Line

SI-QM-SMFA

Flexible

In-Line

SI-LS42DSI

SI-LS42USI

SI-LS42DSI

SI-LS42USI

Actuator Contacts Actuator Contacts

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

Actuator Contacts Actuator Contacts

SI-QM-SSA

SI-LS42DMSJ

Rigid

In-Line

24V ac/dc

SI-QM-SMFA

SI-LS42DMSJF

†

A kit contains an interlock and actuator. Individual interlock bodies and actuators

are for replacement purposes only. See Warning on page 12.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 60099 rev. D 3

www.bannerengineering.com • Tel: 763.544.3164

Flexible

In-Line

SI-LS42DSJ

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

*Contacts: Open Closed Transition

Page 4

Machine Safety Switches –

0 (0)

7.0 (0.28)

8.0 (0.31)

9.0 (0.35)

41 (1.61)

mm (in)

Engaged

Disengaged

21-22

13-14

Safety

Monitor

0 (0)

41 (1.61)

mm (in)

Engaged

Disengaged

11-12

21-22

Safety

Safety

7.0 (0.28)

9.0 (0.35)

0 (0)

41 (1.61)

mm (in)

Engaged

Disengaged

31-32

13-14

Safety

Monitor

21-22

Safety

7.0 (0.28)

8.0 (0.31)

9.0 (0.35)

0 (0)

41 (1.61)

mm (in)

Engaged

Disengaged

11-12

31-32

Safety

Safety

21-22

Safety

7.0 (0.28)

9.0 (0.35)

13 14

21 22

13 14

21 22

21 22

11 12

43 44

31 32

E1

+

E2

-

43 44

31 32

E1

+

E2

-

21 22

31 32

13 14

41 42

E1

+

E2

-

41 42

E1

+

E2

-

21 22

31 32

11 12

21

22

11 12

31 32

21 22

11 12

21

22

31 32

13 14

43 44

31 32

E1

+

E2

-

43 44

31 32

E1

+

E2

-

41 42

E1

+

E2

-

41 42

E1

+

E2

-

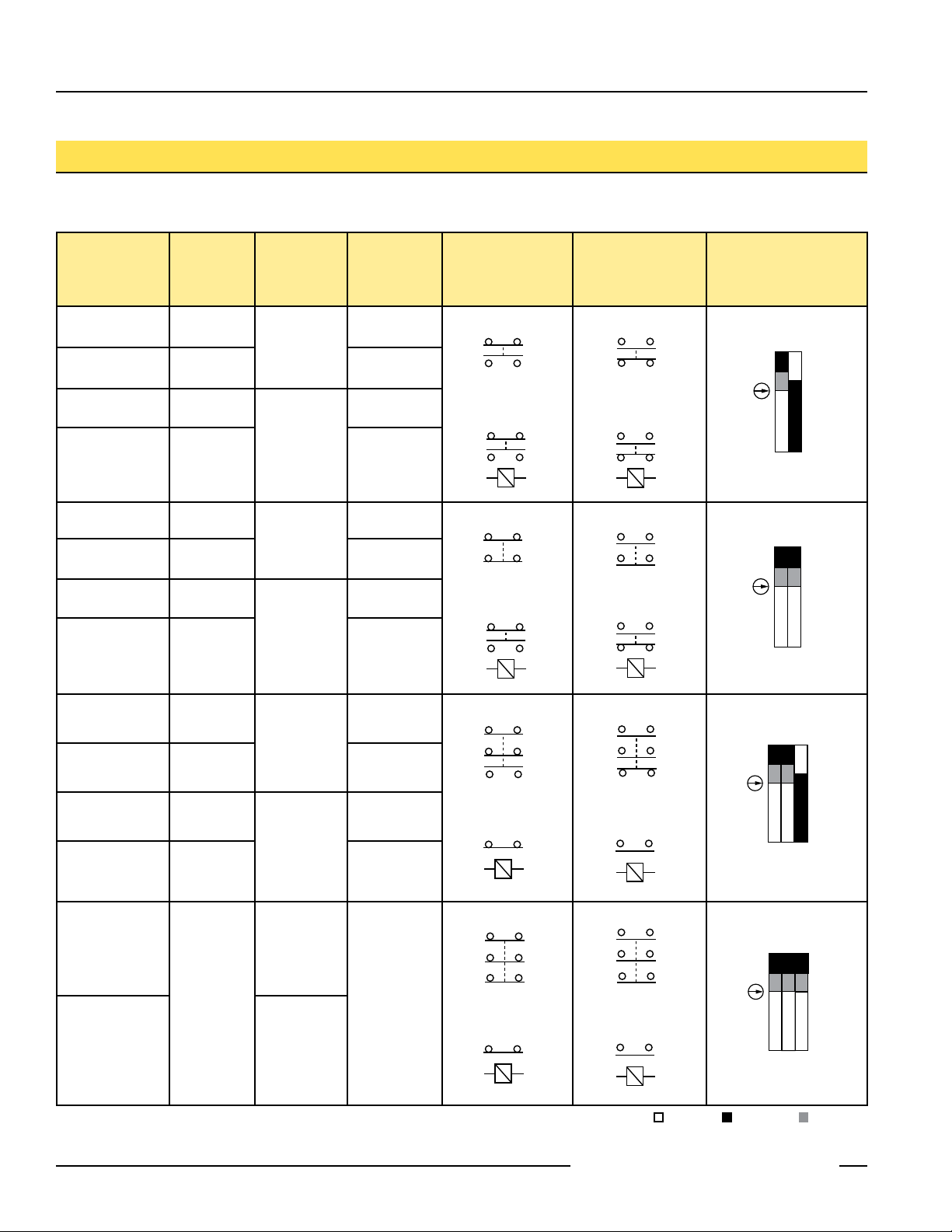

SI-LS42 Series Locking Style Switch

Models

For the following models, the fully inserted actuator is locked when voltage is applied to the solenoid. The actuator is unlocked when

voltage is removed from the solenoid.

Kit

Model

†

Solenoid

Voltage

SI-LS42DMMG 24V ac/dc

SI-LS42UMMG

24-48V dc

24-230V ac

SI-LS42DMMGF 24V ac/dc

SI-LS42UMMGF

24-48V dc

24-230V ac

SI-LS42DMMH 24V ac/dc

SI-LS42UMMH

24-48V dc

24-230V ac

SI-LS42DMMHF 24V ac/dc

SI-LS42UMMHF

24-48V dc

24-230V ac

Actuator

†

Type

SI-QM-SSA

Rigid

In-Line

SI-QM-SMFA

Flexible

In-Line

SI-QM-SSA

Rigid

In-Line

SI-QM-SMFA

Flexible

In-Line

Interlock

†

Body

SI-LS42DMG

SI-LS42UMG

SI-LS42DMG

SI-LS42UMG

SI-LS42DMH

SI-LS42UMH

SI-LS42DMH

SI-LS42UMH

Contact

Configuration

(Actuator Engaged

and Locked)

Contact

Configuration

(Actuator Unlocked

and Removed)

Actuator Contacts Actuator Contacts

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

Actuator Contacts Actuator Contacts

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

Switching

Diagram*

SI-LS42DMMI 24V ac/dc

SI-QM-SSA

SI-LS42DMI

Rigid

Actuator Contacts Actuator Contacts

SI-LS42UMMI

24-48V dc

24-230V ac

SI-LS42DMMIF 24V ac/dc

In-Line

SI-QM-SMFA

SI-LS42UMI

Solenoid Monitor

SI-LS42DMI

Flexible

SI-LS42UMMIF

24-48V dc

24-230V ac

In-Line

SI-LS42UMI

Actuator Contacts Actuator Contacts

SI-QM-SSA

SI-LS42DMMJ

Rigid

In-Line

24V ac/dc

SI-LS42DMJ

Solenoid Monitor

SI-QM-SMFA

SI-LS42DMMJF

Flexible

In-Line

†

A kit contains an interlock and actuator. Individual interlock bodies and actuators

are for replacement purposes only. See Warning on page 12.

4 P/N 60099 rev. D

Contacts

Contacts

Solenoid Monitor

Contacts

Solenoid Monitor

Contacts

*Contacts: Open Closed Transition

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

Machine Safety Switches –

Install

Tamper-Proof

Screw

Install

Tamper-Proof

Screw

0°

1.

2.

270°

90°

Holding

Clamp

180°

Pull Out

2

1

3

4

Figure 1. Horizontal actuator head position

(as received from the factory):

Install tamper-proof screw.

Figure 2. To change actuator head

orientation

SI-LS42 Series Locking Style Switch

Mechanical Installation

Horizontal or Vertical Actuation

Before installation, orient the switch actuator head for either horizontal (at a right angle

to the switch length) or vertical (in-line with the switch length) actuation. The switch is

shipped with the actuator head in the horizontal position (Figure 1). If this is the desired

orientation, install the M3 x 15 mm tamper-proof (one-way) screw, which is found in a

plastic bag, stored in the wiring chamber (see page 6 for information on opening the

wiring chamber access door).

If vertical actuation is required, remove the head by pulling straight up and off (Figure 2).

Re-orient the actuator head, and slide it back on in the new position until it snaps into

place. Install the tamper-proof screw, as shown in Figure 3.

Rotating Actuator Head to Desired Position

The actuator head may be rotated in increments of 90° to create eight possible actuator

engagement positions (i.e., four horizontal plus four vertical positions). To rotate the

head, pull the holding clamp forward, rotate the head (in either direction) to the desired

position, and push the holding clamp back in to lock. The head may be rotated with the

actuator either engaged or removed (Figure 4).

Installing the Switch and Actuator

NOTE: All mounting hardware is supplied by the switch user. The fasteners must be of

sufficient strength to avoid incidental breakage. Use of permanent fasteners or

locking hardware is recommended to prevent loosening or displacement of the

actuator and switch body.

The mounting holes in the switch body accept M5 (#10) screws. There are four holes

on a mounting pattern of 30 x 124 mm (see dimension drawing of switch, page 10). See

page 11 for dimensions of the actuator mounting holes.

Position the switch, with its actuator fully engaged, at the mounting location and mark

the mounting holes. Fasten the switch body and the actuator in place. The rigid in-line

actuator includes floating sleeves in the mounting holes to allow some forgiveness for

switch-to-actuator alignment. If the rigid in-line actuator is used, take care to not overtighten the actuator fasteners so as to allow this movement. After the mounting hardware

is secure, check the actuator/switch engagement for misalignment and binding.

Figure 3. Vertical actuator head position:

Install tamper-proof screw.

IMPORTANT: A safety switch must be installed in a manner which discourages

tampering or defeat. Mount each switch to prevent bypassing of the switching

function at the wiring chamber. A switch and its actuator must never be used as a

mechanical stop.

Manual Release for Spring Lock Models

Models with spring lock/solenoid unlock may be unlocked manually by rotating the unlock

mechanism, using an M3 Allen wrench (not supplied). First loosen the security screw

(see dimension drawing of switch, page 10), then turn the unlock mechanism in either

direction to the position.

IMPORTANT: After the switch is installed, check to be certain that the unlock

mechanism is in the position, and that the security screw is tight and covered with

Figure 4. Actuator head rotation

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 60099 rev. D 5

www.bannerengineering.com • Tel: 763.544.3164

tamper-resistant lacquer (user-supplied).

Page 6

Machine Safety Switches –

Safety Switch #1

Safety Switch #2

Input

Channel

#1

Input

Channel

#2

2-channel Safety Module

(2-channel E-stop Module

2-channel Gate Monitor Module, etc.)

Single gate

or guard

Solenoid

Monitor

Contact

Solenoid

Monitor

Contact

Actuator

Safety

Contact

Actuator

Safety

Contact

SI-LS42 Series Locking Style Switch

Electrical Installation

Access to Wiring Chamber

The wiring chamber is accessed via the hinged door. Simply insert a flat-blade

screwdriver, as shown in Figure 5, and pry gently down to open. Select the best wiring

entrance and thread in the ½" x 14 NPSM conduit adapter (supplied), or the optional M20

x 1.5 cable gland (page 12). The switch knockout will break loose with the final turn of

the conduit adapter or cable gland.

To open wiring chamber:

1. Insert the screwdriver

blade into slot in cover to

pry cover open.

To connect wires to terminals:

1. Insert the screwdriver blade into the slot below the

desired wiring terminal.

2. Twist the screwdriver blade in the slot to open the

terminal jaws; insert wire.

3. Hold wire in place and remove screwdriver.

CAUTION . . .

Electrical Installation

Two safety switches

must be used for each interlock guard

to achieve control reliability or Safety

Category 4 (per ISO 13849-1, EN 954-1) of

a machine stop circuit. Use of only one

safety switch per interlock guard is not

recommended.

In addition, normally-closed safety contacts

from each of the two safety switches should

be connected to the two separate inputs of a

2-channel safety module or safety interface,

as illustrated in Figure 6. This is required to

provide monitoring for safety switch contact

failure, and to provide the necessary reset

routine, as required by IEC 60204-1 and

NFPA 79 machine safety standards.

Figure 5. Access to wiring chamber – use a small flat-blade screwdriver

NOTE: Refer to the installation instructions provided with the safety module for information

Figure 6. Connect two redundant safety switches per interlock guard to an appropriate

6 P/N 60099 rev. D

regarding the interface of the safety module to the machine stop control elements.

2-channel input safety module.

WARNING . . .

Series

Connection of Safety

Interlock Switches

Monitoring multiple guards with a series

connection of multiple safety interlock

switches is not a Safety Category 4

Application (per ISO 13849-1, EN 954-1).

A single failure may be masked or

not detected at all. When such a

configuration is used, procedures must

be performed regularly to verify proper

operation of each switch.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

Machine Safety Switches –

SI-LS42 Series Locking Style Switch

WARNING . . .

It must not be possible for

personnel to reach any

hazard point through an opened guard

(or any opening) before hazardous

machine motion has completely stopped.

Please reference OSHA CFR 1910.217

and ANSI B11 standards (see page 2) for

information on determining safety distances

and safe opening sizes for your guarding

devices.

Connection to a Machine

Four contacts are offered. Two are safety contacts which must be wired in series, and

the other two are considered monitoring contacts which may be used, if desired.

The contact between terminals 11 and 12 or 21 and 22 is a safety contact which is

closed (i.e., it conducts) when the actuator is engaged. The contact between terminals 13

and 14 is the associated actuator monitoring contact.

The contact between terminals 31 and 32 is a safety contact which is closed when

the solenoid is in its locking state. The contact between terminals 43 and 44 is the

associated solenoid monitoring contact.

See the switching diagrams on pages 3 and 4 for contact state information.

Solenoid voltage connects to terminals E1 (+) and E2 (-).

As illustrated in Figure 6, the normally-closed safety contacts (i.e., safety contacts that

are closed when the actuator is engaged and the solenoid is in its locking state) from

each of two safety switches per interlock guard must connect to a 2-channel safety

module or safety interface in order to achieve a control reliable interface to the master

stop control elements of a machine.

Examples of appropriate safety modules include 2-channel emergency stop (E-stop)

safety modules and gate monitor safety modules.

Two functions of the safety module or safety interface are:

1. To provide a means of monitoring the contacts of both safety switches for contact

failure, and to prevent the machine from restarting if either switch fails; and

2. To provide a reset routine after closing the guard and returning the safety contacts to

their closed position. This prevents the controlled machinery from restarting by simply

reinserting the safety switch actuators. This necessary reset function is required by

ANSI B11 and NFPA 79 machine safety standards.

Use only positively-driven, normally-closed safety contacts from each switch for

connection to the safety module. The normally-open contacts may be used for control

functions that are not safety-related. A typical use is to communicate with a process

controller. Refer to the installation instructions provided with the safety modules for more

information regarding the interface of the safety module to the machine stop control

elements.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 60099 rev. D 7

www.bannerengineering.com • Tel: 763.544.3164

Page 8

Machine Safety Switches –

SI-LS42 Series Locking Style Switch

Periodic Checks

Periodic checks should be performed only by Designated Persons or Qualified Persons,

as specified below. Safety switches should be checked at each shift change or machine

setup by a Designated Person (see below) for:

1. Breakage of the switch body or actuator,

2. Good alignment and full engagement of the actuator with the receptor,

3. Confirmation that the safety switch is not being used as an end stop,

4. Loosening of the switch or actuator mounting hardware, and

5. Verification that it is not possible to reach any hazard point through an opened guard

(or any opening) before hazardous machine motion has completely stopped.

In addition, a Qualified Person should check for the following on a periodic schedule,

determined by the user, based upon the severity of the operating environment and the

frequency of switch actuations:

1. Check the wiring chamber for signs of contamination.

2. Check the contacts for signs of deterioration or damage.

3. Inspect the electrical wiring for continuity and damage.

4. Verify that wiring conforms to the instructions on pages 8 to 10 of this data sheet.

A Designated Person is identified in writing by the employer as being appropriately

trained to perform a specified checkout procedure. A Qualified Person possesses a

recognized degree or certificate or has extensive knowledge, training, and experience to

be able to solve problems relating to the safety switch installation (ANSI B30.2).

Repairs

NOTE: Do not attempt any repairs to the switch. It contains no field-replaceable

components. Return the switch to the factory for warranty repair or replacement.

If it ever becomes necessary to return a switch to the factory, please do the following:

1. Contact the Banner applications engineering department at the number or address

listed on the front cover. They will attempt to troubleshoot the system from your

description of the problem. If they conclude that a component is defective, they will

issue an RMA (Return Merchandise Authorization) number for your paperwork, and

give you the proper shipping address.

2. Pack the switch carefully. Damage which occurs in shipping is not covered by warranty.

8 P/N 60099 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 9

Machine Safety Switches –

SI-LS42 Series Locking Style Switch

Specifications

Contact Rating 4A @ 250V ac max.

2.5 kV max. transient tolerance

NEMA A300 P300

European Rating Utilization categories: AC15 and DC13 (IEC 60947-5-1)

Switches with 1 and 2 contact pairs:

= 250V ac

U

i

I

= 2.5A

th

Contact Material Silver-nickel alloy

Solenoid Power

Consumption

Maximum Actuator Speed 1.5 m/second (5'/second)

Minimum Actuator

Engagement Radius

Actuator Extraction Force 2000 Newtons (440 lbf) when locked

Short Circuit Protection 6 amp Slow Blow, 10 amp Fast Blow. Recommended external fusing or overload protection.

Mechanical Life 1 million operations

Wire Connections 10 cage clamp elements

Cable Entry M20 x 1.5 threaded entrance. Adapter supplied to convert M20 x 1.5 to ½" - 14 NPT threaded entrance.

Construction Glass fiber-reinforced polymide thermoplastic housing; UL 94-V0 rating

Environmental Rating IEC IP67

Operating Conditions Temperature:

Weight 0.3 kg

Certifications

1.1 VA / Inrush 56 VA (0.2 sec)

In-line actuators: 400 mm (16")

Flexible actuators: 150 mm (6")

1.5 mm stranded max. / 16 AWG

-30° to +70° C (-22° to +158° F)

Ue

24 4 3

110 4 0.77

230 4 0.3

40-60 Hz

Ie/AC-15 AIe/DC-13

V

A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 60099 rev. D 9

www.bannerengineering.com • Tel: 763.544.3164

Page 10

Machine Safety Switches –

40-46 mm

(1.6-1.8")

M20 x 1.5

45.0 mm

(1.77")

37.5 mm

(1.48")

15.0 mm (0.59")

*Found only on spring lock/solenoid unlock models.

19.5 mm

(0.76")

29.0 mm

(1.14")

29.0 mm

(1.14")

30-40 mm

(1.18"-1.58")

51.0 mm

(2.00")

21.0 mm

(0.83")

5.0 mm

(0.20")

135.0 mm

(5.32")

170.0 mm

(6.70")

66.0 mm ± 10

(2.60" ± 0.4")

Ø 5.3 mm

(0.21")

2.0 mm

(0.08")

32.0 mm

(1.26")

124.0 mm

(4.89")

184 mm

(7.25")

Unlocking

Mechanism*

Security

Screw*

5.0 mm

(0.20")

30.0 mm

(1.18")

42.5 mm

(1.67")

See page 11 for actuator dimensions

Model SI-LS42.. Interlock Body

SI-LS42 Series Locking Style Switch

Dimensions

10 P/N 60099 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 11

Machine Safety Switches –

20.0 mm

(0.79")

7.5 mm

(0.30")

15 mm

(0.59")

80.0 mm

(3.13")

ø 4.8 mm

(2 Holes)

40 mm

(1.6")

29 mm

(1.1")

C

L

50 mm

(2.0")

81 mm

(3.2")

41 mm

(1.6")

ø 5.5 mm

(0.22")

Actuator Dimensions

SI-LS42 Series Locking Style Switch

SI-QM-SSA Rigid In-Line Actuator

400 mm (16") minimum actuator engagement radius

SI-QM-SMFA Flexible In-line Actuator

150 mm (6") minimum actuator engagement radius

The flexible actuator mounting flange may be rotated

90° with respect to the actuator position. To rotate, push the flange in the

direction of actuation, turn the flange either direction, and release to lock

the flange in the new position; see the diagram above.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 60099 rev. D 11

www.bannerengineering.com • Tel: 763.544.3164

Page 12

Machine Safety Switches –

®

25.0 mm

(0.98")

M20 x 1.5

24.0 mm

(0.94")

1/2"-14 NPT

Internal Thread

M20 x 1.5

25.0 mm

(0.98")

37.0 mm

(1.46")

Size Model

Used with

Switch Models

SI-LS42 Series Locking Style Switch

Accessories

Cable Glands

For Cable

Diameters

Dimensions

M20 x 1.5

Plastic

SI-QS-CGM20 All

Description Model

½"-14 NPT

Plastic

Conduit Adaptor

Replacement

Terminal Cover

SI-QS-M20 All

SI-LS42-COVER All N/A

Description Model

5.0 to 12.0 mm

(0.20" to 0.47")

Replacement Parts

Used with

Switch Models

Accessory Actuators

Dimensions

Used with

Switch Models

Rigid In-line metal actuator used for doors or

covers. Slide-bolt design for use in heavy-duty

applications where alignment is difficult to maintain.

SI-QM-SB All

WARNING . . .

Spare actuators must NEVER be used to bypass or otherwise defeat the protective function of a safety switch. To do so may create an

unsafe situation which could lead to serious injury or death.

WARRANTY:

free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty

does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or

implied.

P/N 60099 rev. D

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or replace,

Loading...

Loading...