Page 1

SC22-3/-3E Safety Controller Instruction Manual

P/N 133487 rev. C -- 10/7/2010

Original Instructions

Page 2

Contents

Contents

1 About This Document ..........................................................................................................6

1.1 Important . . . Read This Before Proceeding! ...........................................................................................6

1.1.1 Use of Warnings ..........................................................................................................................6

1.2 EC Declaration of Conformity (DOC) .......................................................................................................6

1.3 Standards and Regulations ......................................................................................................................7

1.3.1 U.S. Application Standards ..........................................................................................................7

1.3.2 OSHA Regulations ........................................................................................................................7

1.3.3 International/European Standards ................................................................................................7

1.3.4 Sources of Standards and Regulations ........................................................................................8

1.4 Contact Us ...............................................................................................................................................8

2 Overview ................................................................................................................................9

2.1 Ethernet-Compatible Model ......................................................................................................................9

2.2 Applications ............................................................................................................................................10

2.3 Design and Testing ................................................................................................................................10

2.4 Components ...........................................................................................................................................10

2.4.1 PC System Requirements ..........................................................................................................10

2.4.2 USB Connections .......................................................................................................................11

2.4.3 Ethernet Connections .................................................................................................................11

2.4.4 SC-XMP Programming Tool .......................................................................................................11

2.4.5 SC-XM1 External Memory (XM) Card ........................................................................................11

2.5 Configuring the Safety Controller ...........................................................................................................12

2.5.1 Onboard Interface (OBI) .............................................................................................................12

2.5.2 Personal Computer Interface (PCI) ............................................................................................14

2.6 Input and Output Connections ................................................................................................................15

2.6.1 Safety and Non-Safety Input Devices .........................................................................................15

2.6.2 Safety Outputs ...........................................................................................................................16

2.6.3 Status Outputs ............................................................................................................................17

2.6.4 Virtual Status Outputs .................................................................................................................17

2.6.5 I/O Mapping: the I/O Control Relationship ..................................................................................18

2.7 System Settings ......................................................................................................................................18

2.8 Internal Logic .........................................................................................................................................19

2.8.1 Additional Logic Functions ..........................................................................................................20

2.9 Password Overview ...............................................................................................................................20

2.10 Confirming a Configuration ..................................................................................................................20

3 Components and Specifications .......................................................................................21

3.1 Safety Controller Starter Kit Models .......................................................................................................21

3.2 Replacement Parts/Accessories .............................................................................................................21

3.3 Ethernet Cordsets ...................................................................................................................................22

3.4 Interface Modules ...................................................................................................................................22

3.4.1 Mechanically Linked Contactors .................................................................................................22

3.5 Specifications .........................................................................................................................................23

3.5.1 Dimensions ................................................................................................................................25

4 System Installation .............................................................................................................26

4.1 Appropriate Application ..........................................................................................................................26

4.2 Installing the Safety Controller ...............................................................................................................27

4.3 Safety Input Devices ...............................................................................................................................27

4.3.1 Signals: Run and Stop States .....................................................................................................28

4.3.2 Safety Input Device Properties ...................................................................................................28

4.4 Non-Safety Input Devices .......................................................................................................................31

4.5 Input Device Resets ...............................................................................................................................33

2 P/N 133487 rev. C

Page 3

Contents

4.5.1 Reset Signal Requirements ........................................................................................................34

4.5.2 Automatic and Manual Reset Inputs Mapped to the Same Safety Output .................................34

4.5.3 Perimeter Guarding and Pass-Through Hazards .......................................................................35

4.6 Safety Input Function ..............................................................................................................................35

4.6.1 Internal Logic .............................................................................................................................35

4.6.2 Two-Hand Control (THC) ............................................................................................................36

4.6.3 Enabling Devices ........................................................................................................................36

4.6.4 Mute Function ............................................................................................................................37

4.6.5 Bypass Function .........................................................................................................................38

4.6.6 Adjustable Valve Monitoring (AVM) Function .............................................................................39

4.7 EDM, OSSD (Safety Output), and FSD Hookup ....................................................................................40

4.7.1 External Device Monitoring (EDM) ............................................................................................40

4.7.2 Safety Outputs ...........................................................................................................................41

4.7.3 FSD Interfacing Connections .....................................................................................................43

4.7.4 Common Wire Installation ..........................................................................................................49

4.8 Status Outputs ........................................................................................................................................50

4.8.1 Status Output Signal Conventions .............................................................................................50

4.8.2 Status Output Functionality ........................................................................................................51

4.9 Virtual Status Outputs .............................................................................................................................52

4.10 Commissioning Checkout ....................................................................................................................52

5 PC Interface Configuration (PCI) .......................................................................................53

5.1 PC Interface (PCI) Overview ..................................................................................................................53

5.1.1 Configuration Tools .....................................................................................................................53

5.1.2 Build a Configuration ..................................................................................................................54

5.1.3 Revise an Existing Configuration ...............................................................................................59

5.1.4 Other Functions ..........................................................................................................................60

6 Onboard Interface Configuration (OBI) ............................................................................62

6.1 Onboard Interface (OBI) Overview .........................................................................................................62

6.2 Run Mode ...............................................................................................................................................64

6.3 Configuration Mode ................................................................................................................................64

6.3.1 Enter Controller Password ..........................................................................................................64

6.3.2 Configuration File ........................................................................................................................64

6.3.3 Confirm Configuration ................................................................................................................65

6.3.4 System Options .........................................................................................................................66

6.3.5 Exit Configuration ......................................................................................................................66

6.4 Edit Configuration ...................................................................................................................................66

6.4.1 Name Configuration ....................................................................................................................66

6.4.2 Inputs ..........................................................................................................................................66

6.4.3 Outputs/System Settings ...........................................................................................................67

6.4.4 Configuration Summary .............................................................................................................68

6.5 Add an Input ...........................................................................................................................................68

6.5.1 Add a Safety Input .....................................................................................................................68

6.5.2 Add a Non-Safety Input .............................................................................................................68

6.5.3 Configure Input Device Properties ..............................................................................................69

7 Operating Instructions .......................................................................................................71

7.1 Monitoring Controller Operation .............................................................................................................71

7.2 Display Controller Information — PC Interface (PCI) .............................................................................71

7.3 Display Controller Information — Onboard Interface (OBI) ....................................................................71

7.3.1 Run Mode Screen—OBI .............................................................................................................72

7.4 Manual Reset ........................................................................................................................................73

7.5 System Resets and Lockout Conditions .................................................................................................74

7.6 Reset Signal Requirements ....................................................................................................................74

8 System Checkout ...............................................................................................................75

8.1 Schedule of Required Checkouts ...........................................................................................................75

8.2 Commissioning Checkout Procedure .....................................................................................................75

3

Page 4

Contents

8.2.1 Verifying System Operation ........................................................................................................76

8.3 Initial Setup, Commissioning and Periodic Checkout ............................................................................76

9 Troubleshooting .................................................................................................................82

9.1 Cleaning .................................................................................................................................................82

9.2 Repairs and Warranty Service ................................................................................................................82

9.3 Troubleshooting—Finding and Fixing Faults .........................................................................................82

9.3.1 Troubleshooting Fault CodeTable ..............................................................................................83

9.4 Recovering from a Lockout .....................................................................................................................86

9.5 Fault Diagnostics—PCI ..........................................................................................................................87

9.5.1 Fault Log—PCI .........................................................................................................................87

9.5.2 Fault Log Recording—PCI ..........................................................................................................87

9.6 Fault Diagnostics—OBI ..........................................................................................................................88

9.6.1 View Current Faults—OBI ..........................................................................................................88

9.6.2 View Fault Log—OBI ..................................................................................................................89

9.6.3 Clear Fault Log—OBI .................................................................................................................89

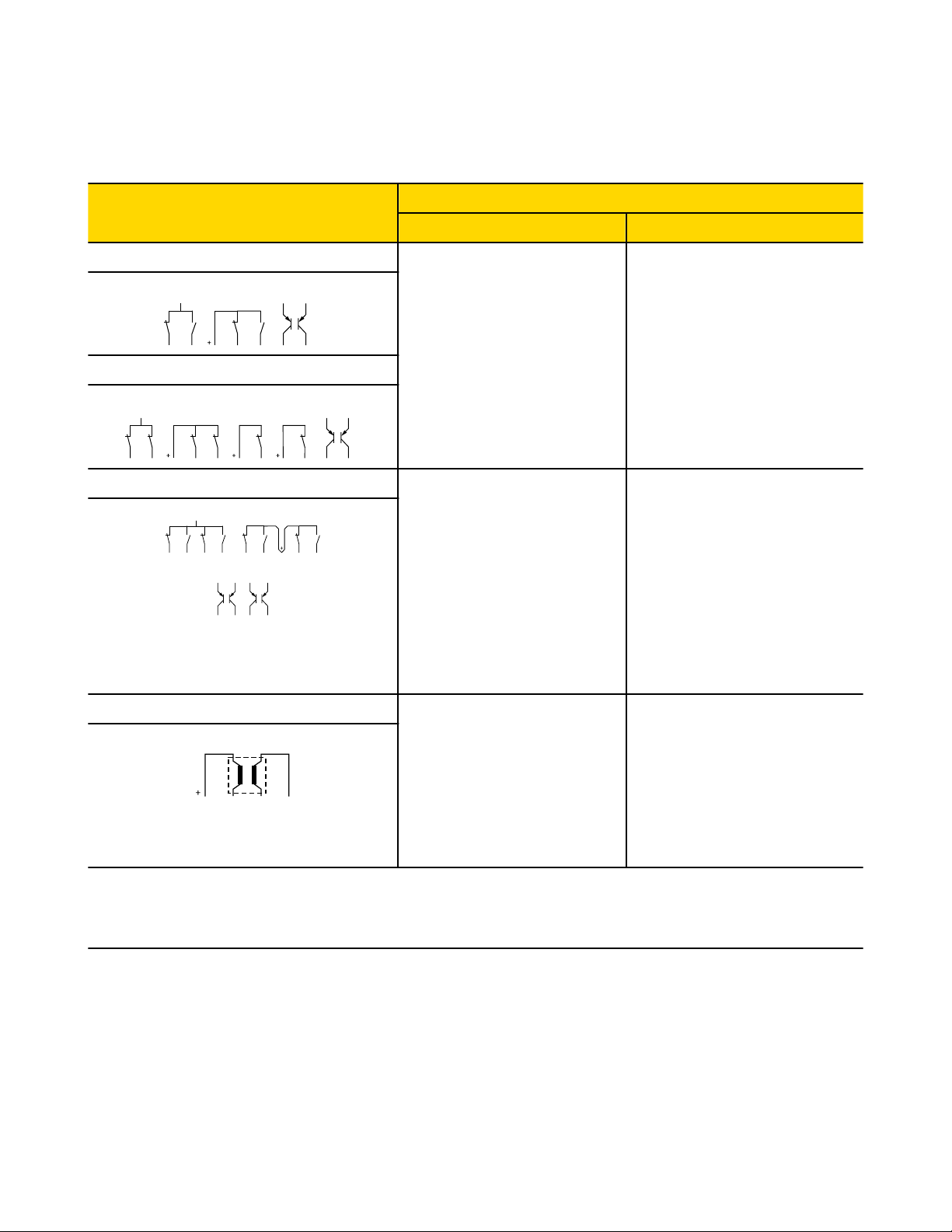

10 Input Device and Safety Category Reference ................................................................90

10.1 Safety Circuit Integrity and ISO 13849-1 (EN954-1) Safety Circuit Principles .....................................90

10.1.1 Safety Circuit Integrity Levels ...................................................................................................90

10.1.2 Fault Exclusion .........................................................................................................................92

10.2 Protective (Safety) Stop ........................................................................................................................92

10.2.1 Protective (Safety) Stop Requirements ....................................................................................92

10.2.2 Protective (Safety) Stop Hookup Options .................................................................................92

10.3 Interlocked Guard or Gate ....................................................................................................................93

10.3.1 Safety Circuit Integrity Levels ...................................................................................................93

10.3.2 Safety Interlock Switch Requirements ......................................................................................94

10.4 Optical Sensor ......................................................................................................................................98

10.4.1 Safety Circuit Integrity Levels ...................................................................................................98

10.4.2 Optical Sensor Requirements ...................................................................................................98

10.4.3 Optical Sensor Generic Hookup ...............................................................................................99

10.5 Two-Hand Control ..............................................................................................................................100

10.5.1 Two-Hand Control Separation (Safety) Distance ....................................................................101

10.5.2 Two-Hand Control Hookup Options ........................................................................................102

10.6 Safety Mats .........................................................................................................................................103

10.6.1 Safety Mat Requirements .......................................................................................................104

10.6.2 Safety Mat Hookup Options ....................................................................................................104

10.6.3 Safety Mat Installation ............................................................................................................105

10.7 Emergency Stop Push Buttons ...........................................................................................................106

10.7.1 Safety Circuit Integrity Levels .................................................................................................106

10.7.2 Emergency Stop Push Button Requirements .........................................................................107

10.8 Rope/Cable Pull ..................................................................................................................................109

10.8.1 Rope/Cable Pull Installation Guidelines ..................................................................................109

10.8.2 Rope Pull Hookup Options .....................................................................................................111

10.9 Enabling Device ..................................................................................................................................112

10.9.1 Enabling Device Guidelines ....................................................................................................112

10.9.2 Enabling Device Hookup Options ...........................................................................................112

10.10 Bypass Switches (Bypassing Safeguards) .......................................................................................114

10.10.1 Requirements of Bypassing Safeguards ..............................................................................114

10.10.2 Bypass Switch Hookup Options ............................................................................................115

10.11 Mute Sensor Pair ..............................................................................................................................116

10.11.1 The Muting Function .............................................................................................................116

10.11.2 Muting Function Requirements .............................................................................................117

10.11.3 Muting Device Hookup Options ............................................................................................118

10.11.4 Mute Enable (ME) .................................................................................................................119

10.11.5 Mute Lamp Output (ML) ........................................................................................................119

10.11.6 Muting Time Limit (Backdoor Timer) .....................................................................................120

10.11.7 Mute on Power-Up ................................................................................................................120

4 P/N 133487 rev. C

Page 5

Contents

10.11.8 Corner Mirrors, Optical Safety Systems, and Muting ............................................................120

10.11.9 Multiple Presence-Sensing Safety Devices ..........................................................................120

10.11.10 Mute Timing Sequences .....................................................................................................122

11 Ethernet Reference .........................................................................................................124

11.1 Ethernet Setting Access .....................................................................................................................124

11.2 EtherNet/IP Assembly Objects ...........................................................................................................124

11.3 Support Files ......................................................................................................................................125

11.3.1 Retrieving Current Fault Information .......................................................................................125

11.3.2 Retrieving Fault Log Information .............................................................................................125

11.4 Table Row and Column Descriptions .................................................................................................126

12 Glossary ..........................................................................................................................128

5

Page 6

SC22-3/-3E Safety Controller Instruction Manual

1 About This Document

1.1 Important . . . Read This Before Proceeding!

It is the responsibility of the machine designer, controls engineer, machine builder and/or maintenance electrician to apply and maintain

this product in full compliance with all applicable regulations and standards. The product can provide the required safeguarding function

only if it is properly installed, properly operated, and properly maintained. This manual attempts to provide complete installation, operational, and maintenance instruction. Reading the manual completely is highly recommended. Please direct any questions regarding the

application or use of the product to the Banner Engineering Applications at the locations listed here.

For more information regarding U.S. and international institutions that provide safeguarding application and safeguarding product performance standards, see the following sections.

WARNING: . . . User Responsibility

The user is responsible to:

• Carefully read, understand and follow the information in all documentation for this product.

• Perform a risk assessment of the specific machine guarding application.

• Determine what safeguarding devices and methods are appropriate per the requirements defined in ISO 13849-1 and

other appropriate standards.

• Create and confirm each configuration and then verify that the entire safeguarding system (including input devices and

output devices) is operational and working as intended.

• Periodically re-verify as needed, that the entire safeguarding system is working as intended.

Failure to follow any of these recommendations can potentially create a dangerous condition that may lead to serious injury or death.

1.1.1 Use of Warnings

Warnings are intended to remind the machine designer, control engineer, machine builder, maintenance electrician, or end user how to

avoid misapplication of this product and effectively apply the Safety Controller to meet the various safeguarding application requirements.

Reading and abiding by the warnings is highly recommended.

1.2 EC Declaration of Conformity (DOC)

Banner Engineering Corp. herewith declares that the SC22-3 Series Safety Controller is in conformity with the provisons of the Machinery Directive (Directive 98/37/EEC) and all essential health and safety requirements have been met. For more information, visit

www.bannerengineering.com/SC22.

6 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 7

SC22-3/-3E Safety Controller Instruction Manual

1.3 Standards and Regulations

The list of standards below is included as a convenience for users of this Banner product. Inclusion of the standards below does not imply

that the product complies specifically with any standard, other than those specified in the Specifications section of this manual.

1.3.1 U.S. Application Standards

ANSI B11.0 Safety of Machinery, General Requirements, and Risk

Assessment

ANSI B11.1 Mechanical Power Presses

ANSI B11.2 Hydraulic Power Presses

ANSI B11.3 Power Press Brakes

ANSI B11.4 Shears

ANSI B11.5 Iron Workers

ANSI B11.6 Lathes

ANSI B11.7 Cold Headers and Cold Formers

ANSI B11.8 Drilling, Milling, and Boring

ANSI B11.9 Grinding Machines

ANSI B11.10 Metal Sawing Machines

ANSI B11.11 Gear Cutting Machines

ANSI B11.12 Roll Forming and Roll Bending Machines

ANSI B11.13 Single- and Multiple-Spindle Automatic Bar and

Chucking Machines

ANSI B11.15 Pipe, Tube, and Shape Bending Machines

ANSI B11.16 Metal Powder Compacting Presses

ANSI B11.17 Horizontal Extrusion Presses

ANSI B11.18 Machinery and Machine Systems for the Processing

of Coiled Strip, Sheet, and Plate

ANSI B11.19 Performance Criteria for Safeguarding

ANSI B11.20 Manufacturing Systems

ANSI B11.21 Machine Tools Using Lasers

ANSI B11.22 Numerically Controlled Turning Machines

ANSI B11.23 Machining Centers

ANSI B11.24 Transfer Machines

ANSI/RIA R15.06 Safety Requirements for Industrial Robots and

Robot Systems

ANSI NFPA 79 Electrical Standard for Industrial Machinery

ANSI/PMMI B155.1 Package Machinery and Packaging-Related

Converting Machinery — Safety Requirements

ANSI B11.14 Coil Slitting Machines

1.3.2 OSHA Regulations

OSHA Documents listed are part of: Code of Federal Regulations

Title 29, Parts 1900 to 1910

OSHA 29 CFR 1910.212 General Requirements for (Guarding of)

All Machines

OSHA 29 CFR 1910.147 The Control of Hazardous Energy (lockout/tagout)

OSHA 29 CFR 1910.217 (Guarding of) Mechanical Power Presses

1.3.3 International/European Standards

ISO 12100-1 & -2 (EN 292-1 & -2) Safety of Machinery – Basic

Concepts, General Principles for Design

ISO 13857 Safety Distances . . . Upper and Lower Limbs

ISO 13850 (EN 418) Emergency Stop Devices, Functional Aspects

– Principles for Design

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 7

ISO 14121 (EN 1050) Principles of Risk Assessment

ISO 14119 (EN 1088) Interlocking Devices Associated with Guards

– Principles for Design and Selection

IEC 60204-1 Electrical Equipment of Machines Part 1: General Requirements

Page 8

SC22-3/-3E Safety Controller Instruction Manual

ISO 13851 (EN 574) Two-Hand Control Devices – Functional Aspects – Principles for Design

ISO 62061 Functional Safety of Safety-Related Electrical, Electronic and Programmable Control Systems

ISO 13849-1 (EN 954-1) Safety-Related Parts of Control Systems

ISO 13855 (EN 999) The Positioning of Protective Equipment in

Respect to Approach Speeds of Parts of the Human Body

IEC 61496 Electro-sensitive Protection Equipment

IEC 60529 Degrees of Protection Provided by Enclosures

IEC 60947-1 Low Voltage Switchgear – General Rules

IEC 60947-5-1 Low Voltage Switchgear – Electromechanical Control Circuit Devices

IEC 60947-5-5 Low Voltage Switchgear – Electrical Emergency

Stop Device with Mechanical Latching Function

1.3.4 Sources of Standards and Regulations

These and other standards are available from:

OSHA Documents: http://www.osha.gov (Tel: 202.512.1800)

American National Standards Institute (ANSI): http://www.ansi.org (Tel: 212.642.4900)

Robotics Industries Association (RIA): http://www.robotics.org (Tel: 734.994.6088)

National Fire Protection Association (NFPA): http://www.nfpa.org (Tel: 800.344.3555)

NSSN National Resource for Global Standards : http://www.nssn.org/ (Tel: 212.642.4980)

IHS Standards Store: http://www.global.ihs.com/ (Tel: 303.397.7956, 800.854.7179)

Document Center: http://www.document-center.com/home.cfm (Tel: 650.591.7600)

1.4 Contact Us

For more information: Contact your local Banner representative or Banner Corporate Offices around the world.

Corporate Headquarters: Banner Engineering Corp. 9714 Tenth Ave. North, Mpls., MN 55441, Tel: 763-544-3164, www.bannerengin-

eering.com, sensors@bannerengineering.com

Europe: Banner Engineering Europe Park Lane, Culliganlaan 2F, Diegem B-1831 BELGIUM,Tel: 32-2 456 07 80, Fax: 32-2 456 07 89,

www.bannereurope.com, mail@bannereurope.com

Latin America: Contact Banner Engineering Corp. (US) or e-mail Mexico: mexico@bannerengineering.com; or Brazil: brasil@banner-

engineering.com

Asia:

Banner Engineering China Shanghai Rep Office Rm. G/H/I, 28th Flr. Cross Region Plaza No. 899, Lingling Road, Shanghai 200030

CHINA, Tel: 86-21-54894500, Fax: 86-21-54894511, www.bannerengineering.com.cn, sensors@bannerengineering.com.cn

Banner Engineering Japan Cent-Urban Building 305 3-23-15, Nishi-Nakajima Yodogawa-Ku, Osaka 532-0011 JAPAN, Tel:

81-6-6309-0411, Fax: 81-6-6309-0416, www.bannerengineering.co.jp, mail@bannerengineering.co.jp

Banner Engineering Asia ─ Taiwan Neihu Technology Park 5F-1, No. 51, Lane 35, Jihu Rd., Taipei 114 TAIWAN, Tel:

886-2-8751-9966, Fax: 886-2-8751-2966, www.bannerengineering.com.tw, info@bannerengineering.com.tw

Banner Engineering India Pune Head Quarters Office, No. 1001 Sai Capital, Opp. ICC Senapati Bapat Road, Pune 411016 INDIA, Tel:

91-20-66405624, Fax: 91-20-66405623, www.bannerengineering.co.in, india@bannerengineering.com

8 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 9

2 Overview

NOTE: This section of this document provides a high-level discussion of the Banner models SC22-3 / SC22-3E Safety Controller, to

acquaint the user with the Controller's capabilities and features. For in-depth information about installation, wiring, and use of the

product, refer to later sections.

The Banner models SC22-3 / SC22-3E Safety Controller (the Safety Controller or the Controller) are easy-to-use, configurable, 24V dc

safety modules designed to monitor multiple safety and non-safety input devices and control up to three independent machine primary

control elements (MPCEs). They provide safety stop and start functions for machines with hazardous motion. The Safety Controller can

replace multiple safety relay modules in applications that include such safety input devices as E-stop buttons, gate interlocking switches,

safety light curtains, and other safeguarding devices. It also can be used in place of safety PLCs and other safety logic devices when

they are excessive for the application.

Configurations are created using an Onboard LCD and push-button interface, or using a PC connected to the Safety Controller via a USB

port.

2.1 Ethernet-Compatible Model

The model SC22-3E provides the same features of the SC22-3, and in addition provides the ability to interface to Ethernet (for example

to a PLC or HMI human interface touch panel), using Modbus/TCP or EtherNet/IP™ protocols.

Modbus/TCP is an open standard protocol developed by the Modbus IDA. It is similar to Modbus RTU, except that it uses standard

Internet communication protocols, just like Web communications or email. The master is referred to as the “client,” and the slave is the

“server.” (The SC22-3E is a “server.”) Modbus/TCP follows the same structure as Modbus RTU: clients initiate all communication, servers

can only respond.

EtherNet/IP (EtherNet Industrial Protocol) is an open standard protocol developed by Allen-Bradley, but managed by the ODVA. EtherNet/IP is an adaptation of the DeviceNet serial fieldbus protocol, using Internet communications protocols. EtherNet/IP is DeviceNet over

Ethernet. Compatible devices supported are:

• EtherNet/IP connection (using the CIP protocol) to the Allen-Bradley ControlLogix family of PLCs. Both implicit and explicit messaging

is supported.

• EtherNet/IP connection (using the PCCC protocol) to the Allen-Bradley SLC and PLC5 families of PLCs.

• Modbus/TCP connection to any compatible PLCs, HMIs, or devices.

P/N 133487 rev. C

www.bannerengineering.com - tel: 763-544-3164 9

Page 10

SC22-3/-3E Safety Controller Instruction Manual

2.2 Applications

The Safety Controller can be used wherever safety modules are

used. The Safety Controller is well suited to address many types of

applications, including, but not limited to:

• Two-hand control with mute function

• Robot weld/processing cells with dual-zone muting

• Material-handling operations that require multiple inputs and bypass functions

• Manually loaded rotary loading stations

• Multiple two-hand-control station applications

• Lean manufacturing stations

• Dynamic monitoring of single- or dual-solenoid valves or press

safety valves

Figure 1. A palletizing application with multiple safeguarding controlled by the Safety Controller

2.3 Design and Testing

The Safety Controller was designed for up to Category 4 PL e (ISO 13849-1) and Safety Integrity Level 3 (IEC 61508 and IEC 62061)

safeguarding applications. It has been extensively tested to ensure that it meets the UL, IEC, and ISO product performance requirements

for both safety functionality and operational reliability. This self-checking Controller incorporates:

• Redundant microcontrollers,

• Redundant input signal detection circuitry, and

• Redundant Safety Output control circuitry.

The safety circuit performance (e.g., categories) of a specific safety or safeguarding device(s) will be determined primarily by the devices

used and their interconnection to the Safety Controller.

See section 10 Input Device and Safety Category Reference on page 90 for specific information about integrating devices with the

Controller.

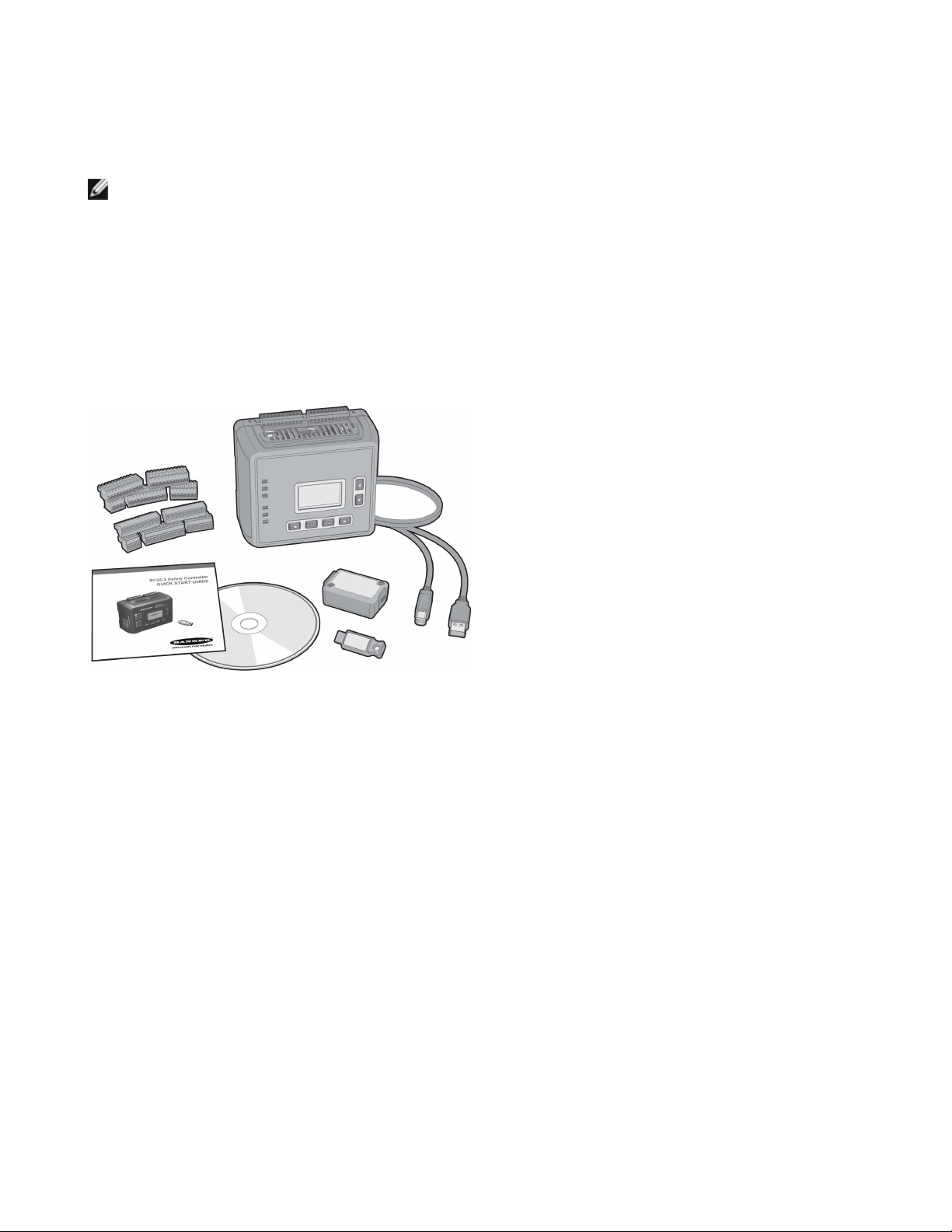

2.4 Components

The Safety Controller Starter Kit includes:

• 1 Safety Controller (model SC22-3 or SC22-3E)

• 1 set of removable terminals (choose screw or clamp type)

• 1 SC-XM1 external memory (XM) card

• 1 USB A/B cable (Ethernet models)

• 1 SC-XMP XM card programming tool (some models)

• 1 CD containing PCI software, instruction manual, and configuration tutorials (p/n 134534)

• 1 Quick Start Guide

Ethernet connection cables (for model SC22-3E) are user-supplied.

2.4.1 PC System Requirements

Operating system: Microsoft Windows® XP, Windows 2000, Vista®, Windows 7

10 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 11

SC22-3/-3E Safety Controller Instruction Manual

Hard drive space: 100 MB (plus up to 280 MB for Microsoft .NET 2.0, if not already installed)

Third-party software: Microsoft .NET 2.0, included and installed with PCI, if not already on computer Adobe® Reader® for Windows

version 7.0 or newer

USB port: USB 1.1 or 2.0 type A port

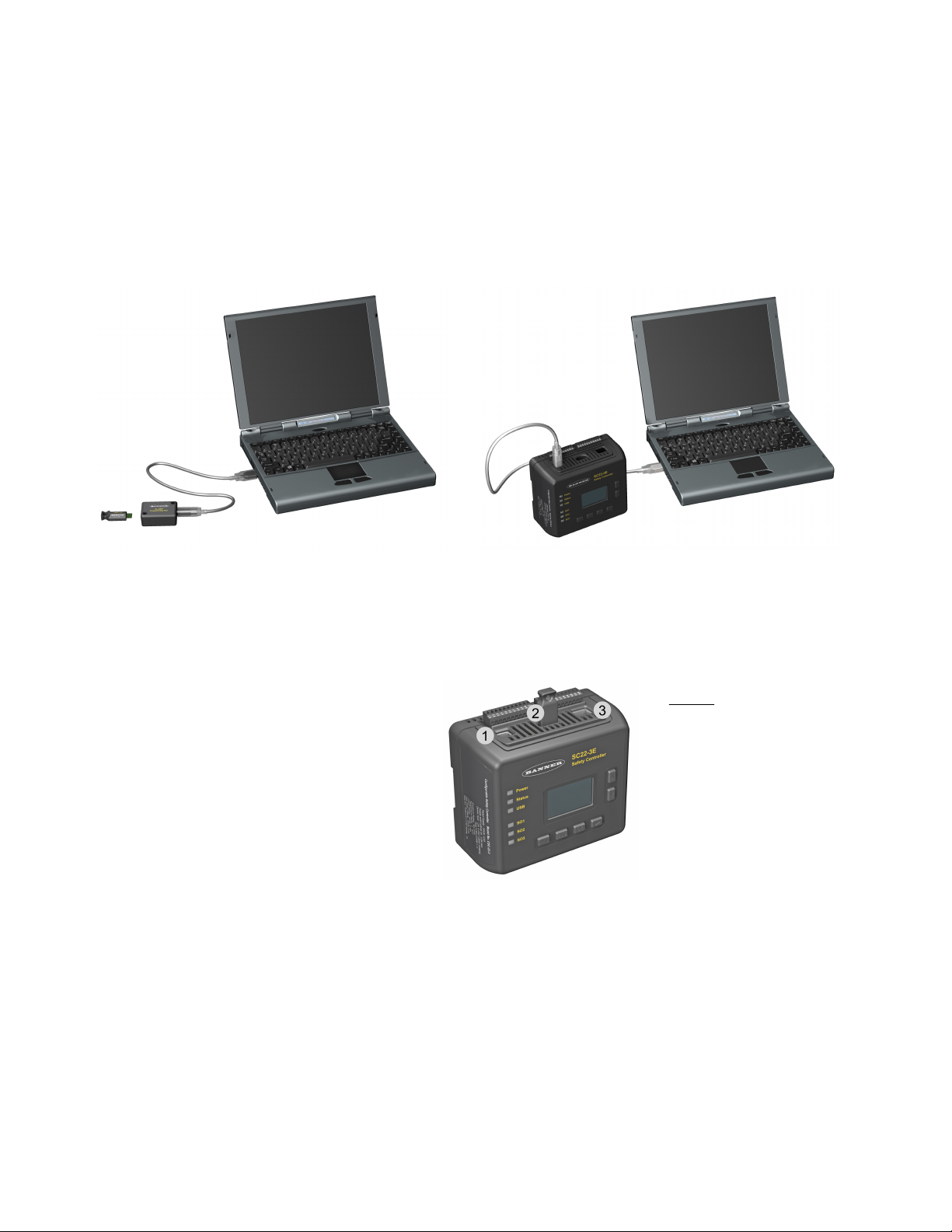

2.4.2 USB Connections

The Safety Controller is connected to a PC by way of a USB A/B cable. The cable is also used to connect the PC to the SC-XMP

programming tool, in order to download a configuration to the XM card.

Figure 2. USB connections: PC to SC-XMP programming tool

connection

Figure 3. USB connections: PC to Safety Controller USB port

connection

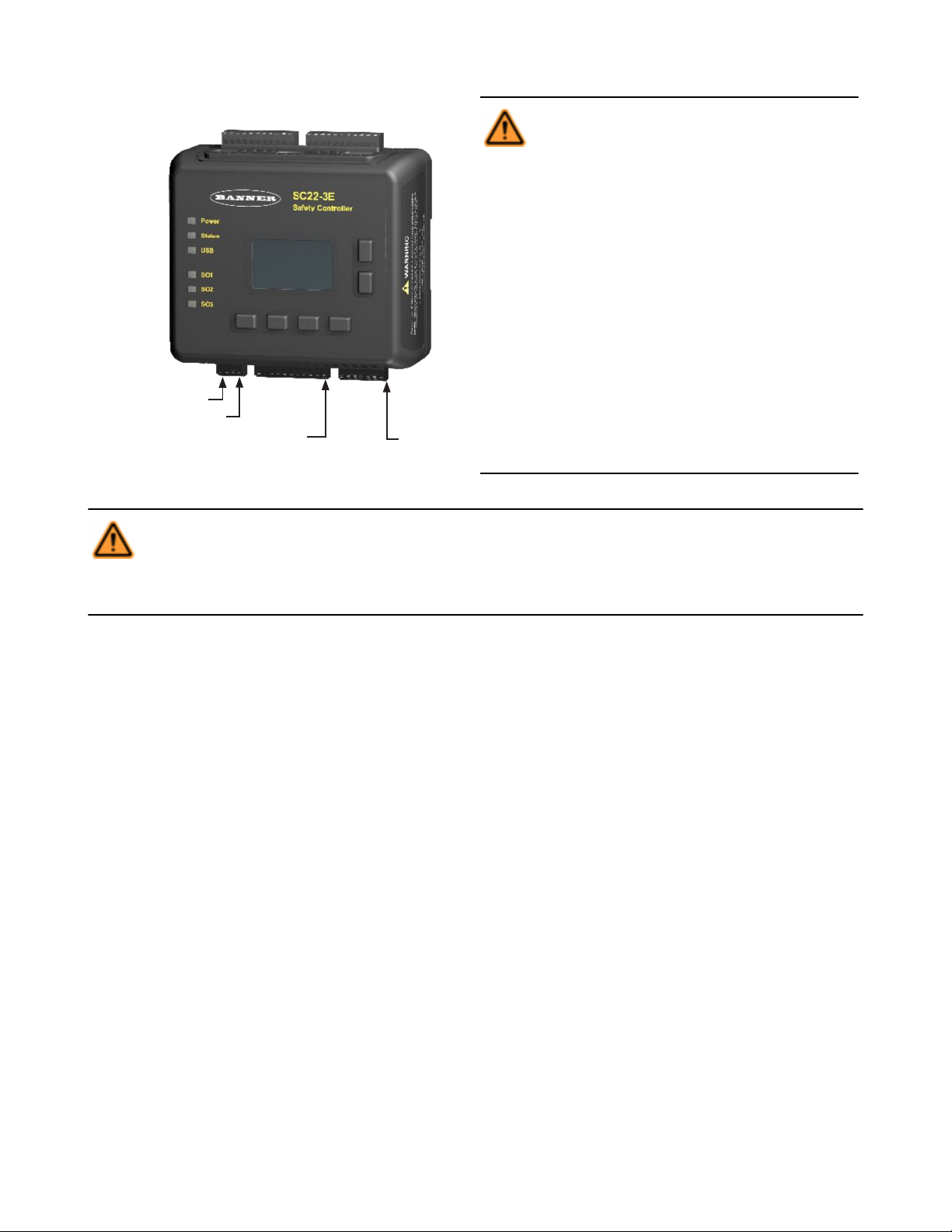

2.4.3 Ethernet Connections

Ethernet connections are made using an ethernet cable

from the SC22-3E Ethernet port to a network switch or the

user’s control device. The SC22-3E supports use of either

standard or crossover-style cables. Shielded cable may be

needed in high-noise environments.

Figure 4. Safety Controller external memory card (XM card) and

Ethernet (some models) connections

Legend

1 USB port

2 XM card port

3 Ethernet port

2.4.4 SC-XMP Programming Tool

The programming tool is a handy device that can be used to transfer a configuration from a PC (running the PCI software) to an XM card

or from an XM card to the PC, without requiring a Safety Controller. It connects to the PC via the USB A/B cable and the PC’s USB port.

2.4.5 SC-XM1 External Memory (XM) Card

The model SC-XM1 external memory (XM) card is a removable memory module that can store or be used to transfer a single configuration. The XM card has a write-on label on its reverse side where a configuration name or a machine identification can be noted.

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 11

Page 12

The XM card can be used to:

• Keep a backup copy of the Safety Controller’s configuration (to minimize downtime in the case of a hardware failure that may require

a Controller replacement).

• Transfer configurations from one Safety Controller to another Safety Controller.

• Send (download) identical configurations into multiple Safety Controllers.

• Transfer configurations between the Safety Controller and a personal computer.

Store a configuration on the XM card in one of two ways:

• Send a copy to the XM card using the PC Interface (PCI) and the SC-XMP programming tool.

• Send a copy from the Controller to the XM card, using the Onboard Interface (OBI).

NOTES:

1. A configuration can be stored permanently in an XM card, if the “lock” function is performed. However, once the card is locked, it

cannot be unlocked (it becomes "read-only").

2. Configurations on an XM card do NOT contain any network settings. The PCI software must be used to change network settings.

SC22-3/-3E Safety Controller Instruction Manual

2.5 Configuring the Safety Controller

Building a configuration for the Safety Controller is a simple process, using one of two interfaces: the push buttons and display on the

Controller itself (the Onboard Interface, or OBI) or the PCI software program included on the enclosed CD (p/n 134534). The process

comprises three main steps:

1. Define the safeguarding application (risk assessment).

• Determine the required devices.

• Determine the required level of safety.

2. Build the configuration.

• Select safety input device types and circuit connections.

• Map each input to one or more Safety Outputs, or to other input devices.

• Set optional Safety Output ON- or OFF-time delays.

• Select non-safety input device types and circuit connections, if needed.

• Assign Status Output signals, if needed.

• Create configuration name, file name, date, and author name.

3. Confirm the configuration.

• Controller verifies that the desired configuration is valid.

• User confirms that the configuration is what is expected.

2.5.1 Onboard Interface (OBI)

The Safety Controller can be configured using its built-in push buttons and LCD screen, the Onboard Interface (OBI). The LCD display

provides I/O device and system status information for any event that causes one or more of the Safety Outputs to turn OFF. The display

is used in conjunction with the six push buttons to:

• Create or modify password-protected configurations,

• Retrieve fault log information,

• Review device wiring detail and I/O logic relationships,

• Display I/O device fault details and likely remedial steps, and

• Display configuration checksum.

NOTES:

1. Onboard Interface functions are covered in more detail in Section 5 and the OBI tutorial, located separately on the disk.

2. The OBI cannot be used to change network settings; the PCI must be used for that function.

12 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 13

SC22-3/-3E Safety Controller Instruction Manual

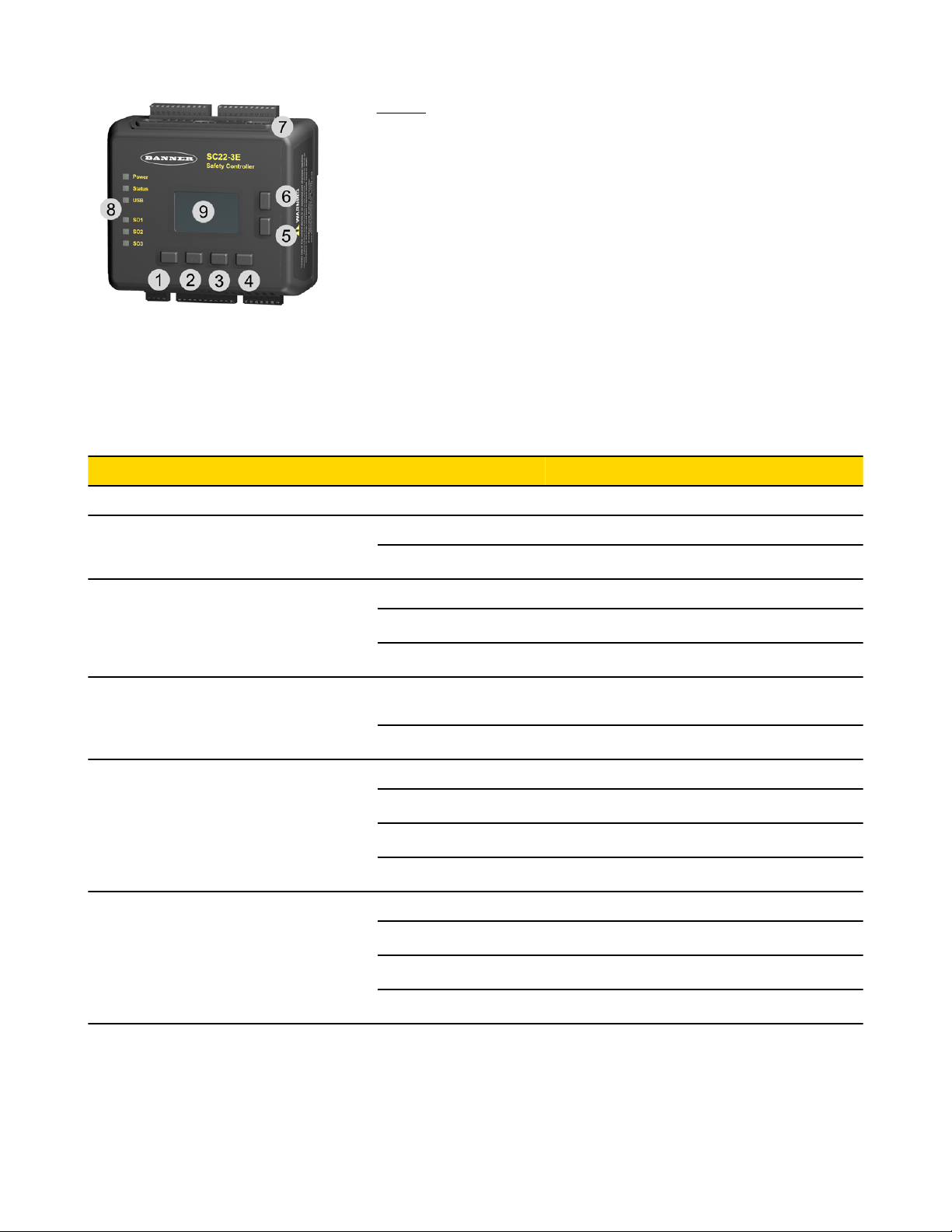

Legend:

1. Moves cursor to the left or selects settings.

2. Moves cursor to the pre-established point in the program to re-establish

a menu reference point.

3. Enters/stores the item highlighted in the display as the intended selection

or toggles a setting.

4. Moves cursor to the right or selects settings.

5. Moves cursor down or moves through a list to display individual list

items. Also used to select settings.

6. Moves cursor up or moves through a list to display individual list items.

Also used to select settings.

7. Ethernet connector indicators (Yellow and Green; Ethernet models only)

8. Status indicators

9. LCD display

Figure 5. Onboard Interface, including push buttons, LCD display and status indicators (model SC22-3E shown)

Status Indicator Condition Indicates Controller Status

All Indicators OFF — Initiation Mode

Power

Status (Controller Mode)

USB or Tx/Rx (depending on model)

Safety Output SO1, SO2, SO3

Ethernet Connector (model SC22-3E

only)

ON Green Power ON

OFF Power OFF

ON Red Configuration mode

Flashing Red Lockout mode

OFF Run mode

Flashing Green

Transmitting or receiving data (a link is established with the PC)

OFF Not transmitting or receiving data

ON Green Safety Output ON

ON Red Safety Output OFF

Flashing Red Safety Output fault detected

Flashing Green Safety Output waiting for reset

Yellow OFF No link

Yellow ON Link OK

Green OFF No activity

Green ON or flashing Activity detected

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 13

Page 14

SC22-3/-3E Safety Controller Instruction Manual

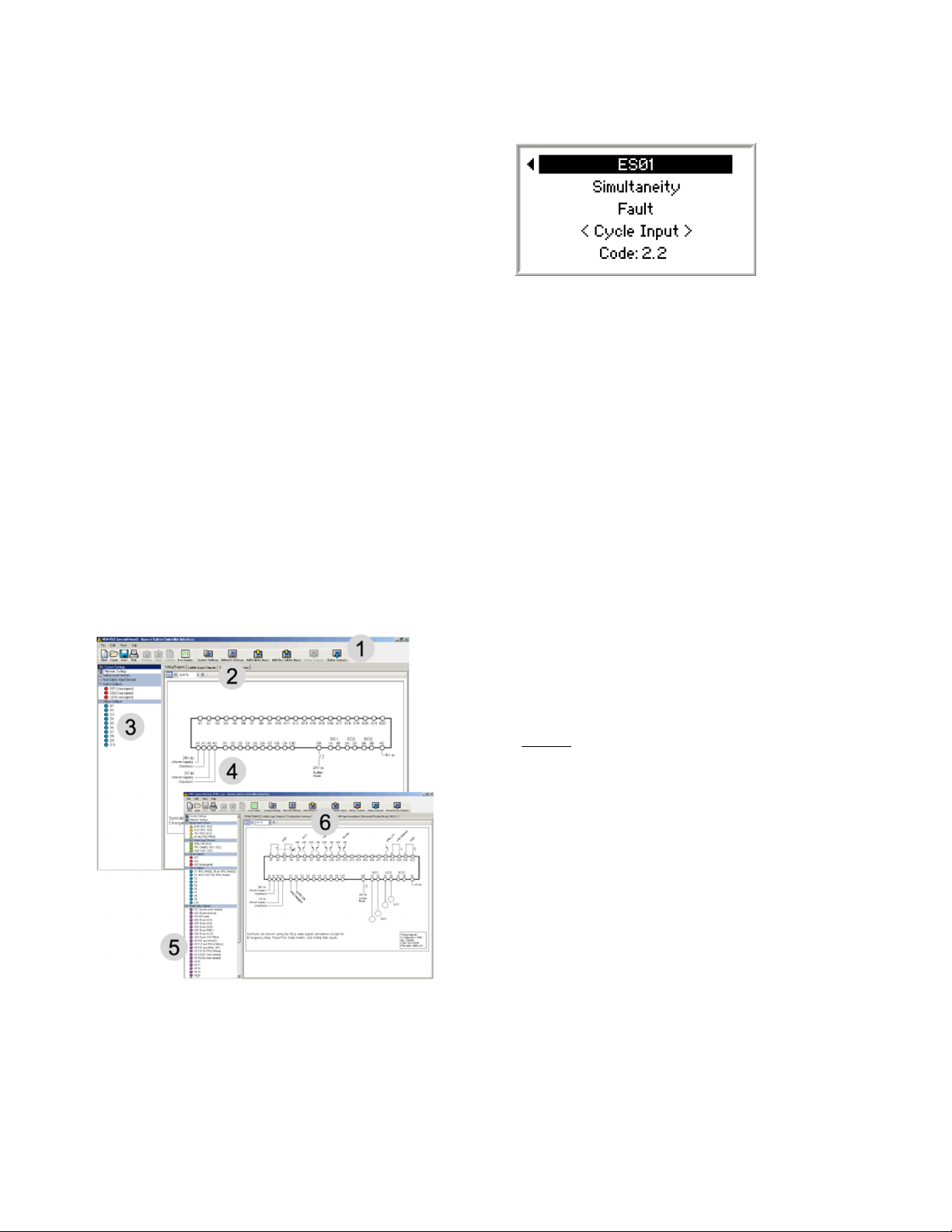

Accessing Fault Codes

Fault codes are displayed in the last line of the OBI fault diagnostics

menu (see example at right). Refer to OBI Configuration and Troubleshooting sections for more information.

2.5.2 Personal Computer Interface (PCI)

The Safety Controller can also be configured using a Windows®-based computer and the Safety Controller PC Interface (PCI) program.

This user-friendly interface makes use of icons and circuit symbols to simplify the selection of device properties during configuration. The

configuration wiring and ladder logic diagrams develop automatically as the configuration progresses.

Creating a configuration is simple. Once a configuration is created, it::

• Can be stored to a computer file for archiving and future use, or

• Can be emailed to a remote location as an attachment, or

• Can be sent directly to another Safety Controller or to the plug-in external memory card.

The PCI can be used to create a configuration, save it and send it as described above, and also monitor the function of a Controller using

the live display, as well as monitor the fault log for troubleshooting purposes.

To access the Ethernet functionality of the model SC22-3E, click on the Network Settings icon and check the Enable Network Interface

box. The Virtual Status Outputs will appear on the I/O Properties menu, as will additional tabs above the document section of the screen,

as shown in the following figure.

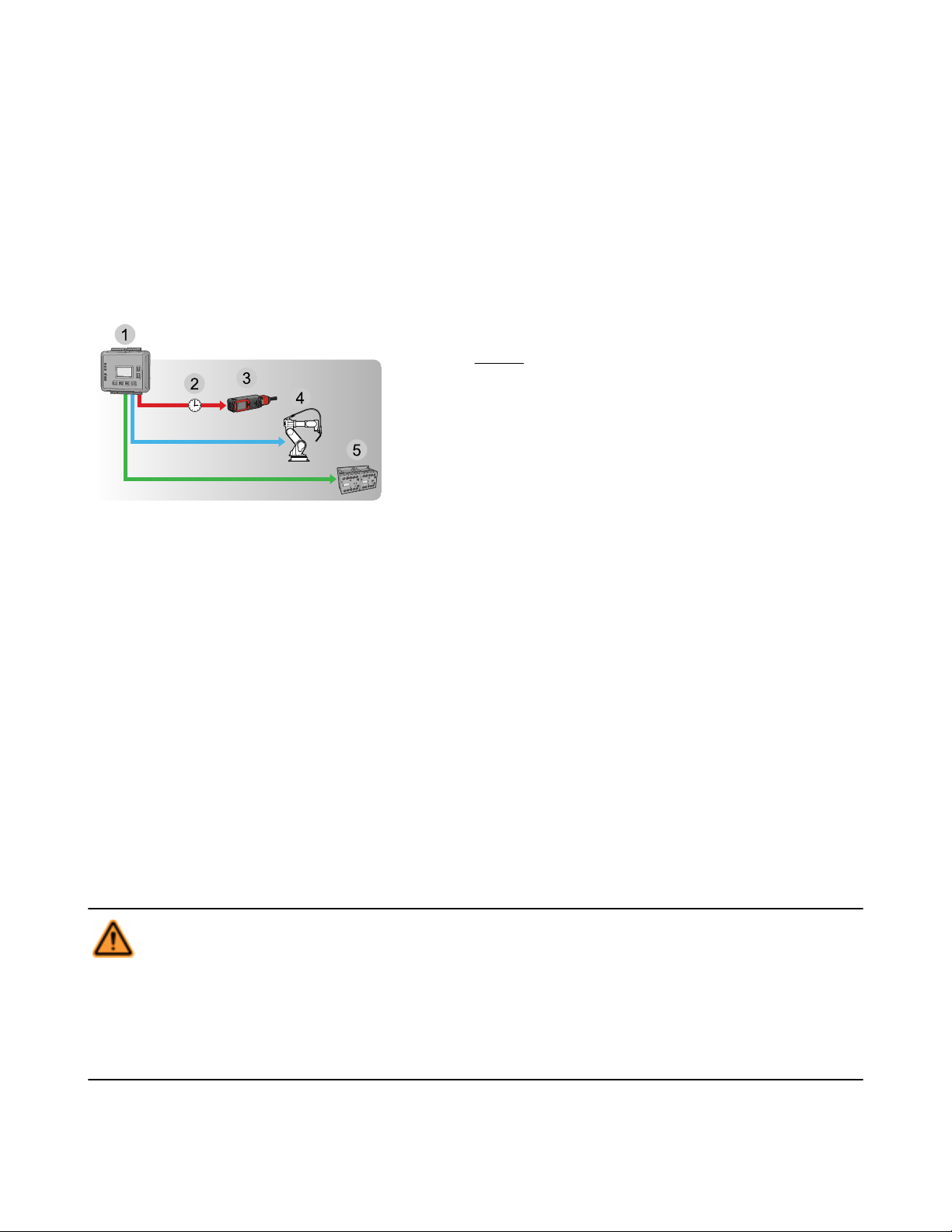

Legend:

1. Toolbar

2. Network settings

3. I/O properties

4. Document (in this case, Wiring Diagram)

5. Virtual Status Outputs (These outputs become

visible after the Enable Network Interface box is

checked under the Network Settings tab.)

6. New tab selections also become visible.

Figure 6. PC User Interface (PCI) main screens

• PC Interface functions are covered in more detail in section 5.1 PC Interface (PCI) Overview on page 53 and in the PCI tutorial.

• PC Interface network functions are covered in more detail in sections 4.9 Virtual Status Outputs on page 52 and 11 Ethernet Refer-

ence on page 124.

14 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 15

SC22-3/-3E Safety Controller Instruction Manual

PCI Software Compatibility

To identify the version of your PCI software (i.e., PC Interface), click on the "Help" tab located on the top tool bar and then click on

"Compatibility Information." The information contained in the pop-up window identifies what PCI software version is running and lists

when a feature was added or changed.

Newer PCI versions are backwards compatible with earlier SC22 firmware versions, although features must be supported by the SC22

firmware version or the feature will be unavailable. If an unsupported feature is attempted to be downloaded, an error message will be

displayed. The SC22 firmware version can be identified via the Onboard Interface (OBI) "Model #" menu item; see section 7.3 Display

Controller Information — Onboard Interface (OBI) on page 71. This screen identifies the Safety Controller model, the firmware versions

of microprocessors A and B, and the hardware version. Contact a Banner Applications Engineer with any questions.

2.6 Input and Output Connections

2.6.1 Safety and Non-Safety Input Devices

The Safety Controller has 22 input terminals that can be used to monitor either safety or non-safety devices; these devices may incorporate either solid-state or contact-based outputs. Each of these 22 input terminals can either monitor an input signal or provide 24V dc.

The function of each input circuit depends on the type of device connected to it; this function is established when the Controller is configured.

For general and specific information about input devices, their requirements, hookup options and appropriate warnings and cautions,

additional installation information (e.g., Safety Distance), refer to the sections 4 System Installation on page 26 and 10 Input Device and

Safety Category Reference on page 90, which contains hookup information and other useful information about integrating the following

devices:

• Safety Circuit Integrity

• Protective (Safety) Stop

• Optical Sensors

• Safety Gate (Interlock Guard)

• Two-Hand Control

• Safety Mat (Edges)

• Emergency Stop Push Buttons

• Rope (Cable) Pull

• Enabling Devices (Pendants)

• Bypass

• Muting

For further information about connecting any devices to the Safety Controller, contact Banner Engineering.

Safety Device Hookup Considerations

The Safety Controller inputs can be configured to interface with many types of safety devices, including safeguarding devices (e.g., safety

light curtains), complementary protective equipment (e.g., emergency stop push buttons), and other devices that impact the safe use of a

machine (e.g., equipment protection).

The way these devices interconnect impacts their ability to exclude or detect faults that could result in the loss of the safety function.

There are many standards, regulations and specifications that require certain capabilities of a safety circuit.

WARNING: . . . User Responsibility

The user is responsible for ensuring that all local, state, and national laws, rules, codes, and regulations relating to

the use of this product in any particular application are satisfied. Extreme care is urged that all legal requirements have

been met and that all installation, operation, and maintenance instructions contained in the product documentation are followed.

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 15

Page 16

SC22-3/-3E Safety Controller Instruction Manual

2.6.2 Safety Outputs

The Safety Outputs are designed to control final switching devices (FSDs) and machine primary control elements (MPCEs) that are the

last in the control chain to control the dangerous motion. These control elements include relays, contactors, solenoid valves, motor controls and other devices that incorporate force-guided (mechanically-linked) monitoring contacts, or control-reliable signals needed for external device monitoring.

The Safety Controller has three independently controlled and redundant solid-state Safety Outputs. The Controller’s self-checking algorithm ensures that the outputs turn ON and OFF at the appropriate times, in response to the assigned input signals and the system’s selfchecking test signals.

The Safety Outputs, SO1, SO2 and SO3, can be controlled by input devices with both automatic and manual reset operation.

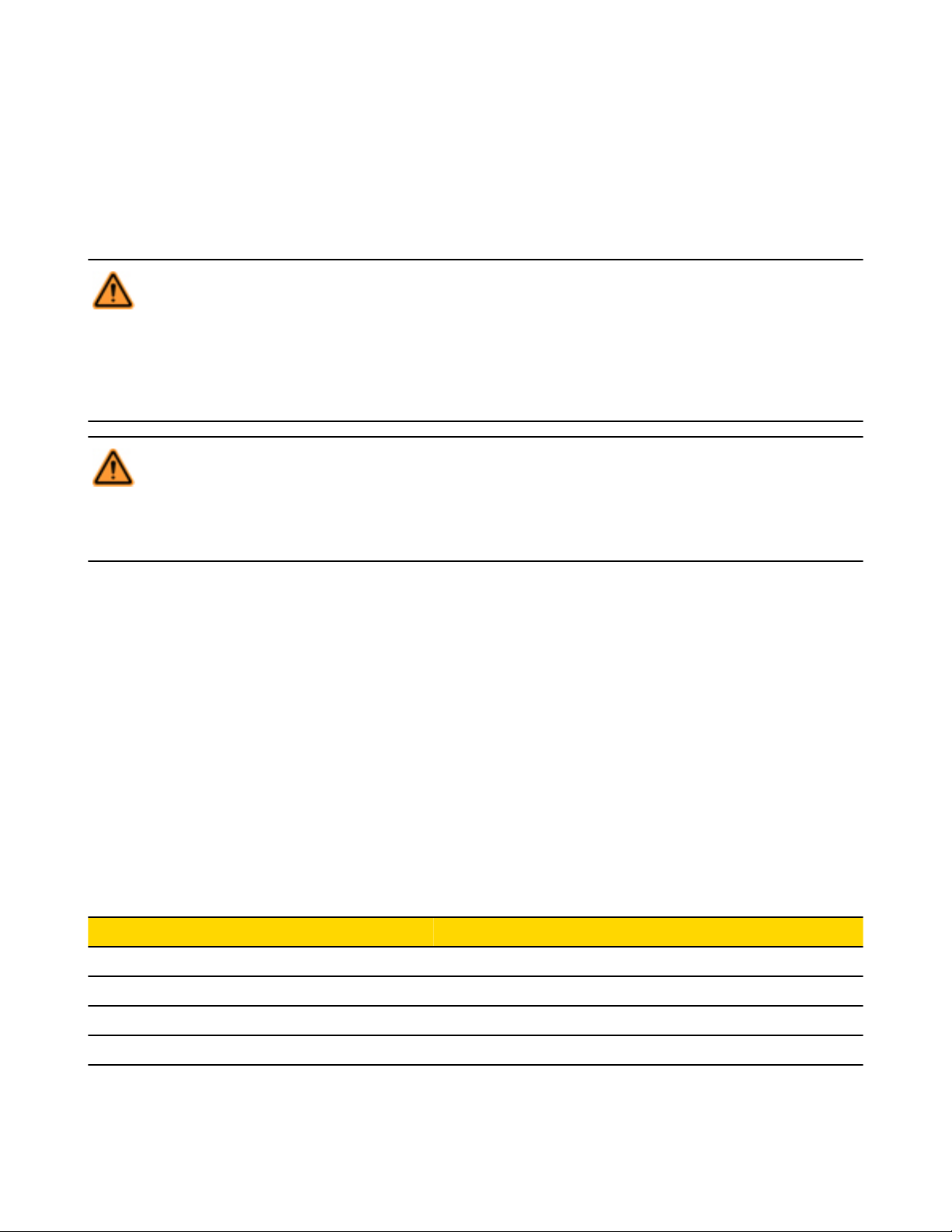

Legend:

1. Safety Controller

2. OFF-Delay

3. Solenoid locking switch

4. Robot

5. Contactors

Figure 7. Safety Outputs

See section 4.7.2 Safety Outputs on page 41 for more information about configuring Safety Outputs.

Functional Stops per IEC 60204-1 and ANSI NFPA79

The Controller is capable of performing the two functional stop types:

• Category 0: an uncontrolled stop with the immediate removal of power from the guarded machine

• Category 1: a controlled stop with a delay before power is removed from the guarded machine

Delayed stops can be used in applications where, for example, machines need power for a braking mechanism to stop the hazardous

motion.

ON-Delays and OFF-Delays

Each Safety Output can be configured to function with a time delay. There are two types of time delays: ON-delay and OFF-delay, where

the outputs turn ON or OFF only after the time limit has elapsed. The ON and OFF time delay limit options are from 100 milliseconds to 5

minutes, in 100 millisecond increments.

Safety Output ON-delays are sometimes used when a machine operation must be delayed before a safe machine startup is permitted. An

example application would be a robot weld cell.

WARNING: . . . Turning a Delayed Output ON/OFF

If an input that is mapped to both an immediate Safety Output and a delayed Safety Output opens and then closes

before the delay time of the delayed output has expired, the immediate Safety Output will turn OFF and remain OFF

while the delay time is running.

At the end of the delay time, the delayed output will also turn OFF. Both outputs will then remain OFF for about 500 ms,

before they will turn back ON. This will happen either automatically, if configured for auto reset, or after a valid manual reset

signal, if configured for manual reset.

16 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 17

SC22-3/-3E Safety Controller Instruction Manual

2.6.3 Status Outputs

The Safety Controller has 10 configurable Status Outputs, used to send non-safety status signals to programmable logic controllers

(PLCs) or to human machine interfaces (HMIs), or they may be used to power indicator lights. These outputs can be configured to report

on the status of input devices, Safety Outputs, or the Controller itself. See section 4.8.1 Status Output Signal Conventions on page 50

for more information.

Signal Convention

The Status Output signal convention can be configured to be 24V dc or 0V dc to indicate:

• When an input is in the Run state,

• When a Safety Output is in the ON state (see Note 1),

• When a Safety Output is in a logical ON state (ON or in an ON-delay; see Note 1),

• When the system is in a Lockout condition,

• When an I/O fault is present (see Note 2),

• When a system reset is needed,

• When a Safety Output needs a reset (see Note 3),

• When a Safety Input is muted,

• Which Safety Input, of a defined group of Safety Inputs, turned OFF first,

• When a Safety Input is bypassed,

• When a Safety Input has a Fault condition, or

• When a Safety Output's OFF-delay can be cancelled.

NOTES:

1. Only Safety Outputs that have inputs mapped to them can be mapped to a Status Output.

2. An I/O fault is a failure of one or more Safety Inputs, Safety Outputs, or Status Outputs.

3. Only Safety Outputs mapped to inputs configured with manual reset logic can have a Status Output configured to indicate a reset is

needed.

WARNING: . . . Status Outputs

The Status Outputs are not Safety Outputs and can fail in either the ON or OFF state. They must never be used to control

any safety-critical applications. If a Status Output is used to control a safety-critical application, a failure to danger

is possible and could lead to serious injury or death.

Monitored Mute Lamp Outputs

Status Outputs O9 and O10 can be configured to create a monitored mute lamp function for a mute operation. When the mute lamp is

ON, the Controller monitors for a short circuit in the load. When the lamp is OFF, it monitors for an open circuit in the load. If an open

circuit occurs before the start of a mute cycle, the next mute cycle will be prevented. If an open circuit occurs during a mute cycle, that

mute cycle will finish, but the next mute cycle will be prevented. If a short occurs before or during a mute, that mute cycle will start and

finish, but the next mute cycle will be prevented. If not used to monitor a mute lamp, these outputs may be used in the same ways as

outputs O1–O8.

IMPORTANT: Only terminals O9 and O10 have the extra monitoring circuitry needed for a monitored mute lamp. If monitoring of

the mute lamp is not required (depending on applicable standards), any of the Status Outputs (O1–O10) may be used to indicate a mute

condition. Because of this feature, these Status Outputs will always appear ON with no load (see Specifications on page 23).

2.6.4 Virtual Status Outputs

Using the PCI, the model SC22-3E (only) can configure up to 32 Virtual Status Outputs. These outputs can communicate the same

information as the Status Outputs, but over a network.

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 17

Page 18

SC22-3/-3E Safety Controller Instruction Manual

WARNING: . . . Virtual Status Outputs

The Virtual Status Outputs are not Safety Outputs and can fail in either the ON or the OFF state. They must never be used

to control any safety-critical applications. If a Virtual Status Output is used to control a safety-critical application, a

failure to danger is possible and could lead to serious injury or death.

2.6.5 I/O Mapping: the I/O Control Relationship

The term “map” implies a control logic relationship between an input and an output or between an input and another input, where the

state of the first input determines the state of the output or of the second input.

Inputs Mapped to Outputs. The following devices can be mapped directly

to the Safety Outputs:

• Emergency stop buttons

• Safety gate switches

• Optical sensors

• Two-hand control devices

• Safety mats

• Protective stop switches

• Rope pulls

Inputs Mapped to Inputs. Muting sensors and bypass switches work in conjunction with certain safety input devices to temporarily suspend the Stop signal of a safety input device. These sensors and switches are mapped directly to the safety inputs; they are then indirectly mapped to the Safety Output(s) that the muted safety inputs control (see section 4.6.4 Mute Function on page 37).

• Enabling devices

• External device monitoring

• ON/OFF devices

• Manual reset devices

• Solenoid or press safety valves

• Cancel OFF-delay devices

Figure 8. Input and Output mapping

2.7 System Settings

The Controller’s system settings define parameters for both the configuration file and the Controller. These settings include:

• Configuration name

• Author’s name

• Power-up mode

• Mute on power-up enable

• Monitored system reset

Configuration Name

The configuration name identifies the configuration that will be used in a Safety Controller application. The configuration name can be

displayed on the Controller and will be useful to be sure that the configuration in a Controller is the correct one.

Author’s Name

The author’s name may also be helpful when questions arise about configuration settings.

Power-Up Mode (Operational Characteristics When Power Is Applied)

The Controller provides three power-up mode types to choose from, to determine how the Controller will behave just after power is supplied. These modes are: Normal, Automatic, and Manual.

• Normal Power-Up Mode (default). In normal power-up mode, after power is applied:

• Only those Safety Outputs that have automatic reset inputs will turn ON.

• Safety Outputs that have one or more manual reset inputs will turn ON only after a manual (latch) reset operation is performed.

• Exception: Two-hand control inputs, bypass inputs, and enabling device inputs must be seen to be in the Stop state at power-up,

regardless of the power-up mode selection. If these are seen to be in the Run state at power-up, the outputs will remain OFF.

• Automatic Power-Up Mode. In automatic power-up mode, after power is applied:

18 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 19

SC22-3/-3E Safety Controller Instruction Manual

• All Safety Outputs will turn ON immediately if the inputs that are mapped to these outputs are all in the Run state.

• Exception: Two-hand control inputs, bypass inputs, and enabling device inputs must be seen to be in the Stop state at power-up,

regardless of the power-up mode selection. If these are seen to be in the Run state at power-up, the outputs will remain OFF.

• Manual Power-up Mode. In Manual Power-up Mode, after power is applied:

• Safety Outputs will turn ON only after all inputs mapped to this output are in the Run state and a System Reset has been performed. (A manual latch reset is not required.)

• Exception: Two-hand control inputs, bypass inputs, and enabling device inputs must be seen to be in the Stop state at power-up,

regardless of the power-up mode selection. If these are seen to be in the Run state at power up, the outputs will remain OFF.

WARNING: . . . Automatic Power-Up

When the Controller is configured for automatic system reset power-up mode, the Controller acts as if all input devices are

configured for auto (trip) reset. Each Safety Output will immediately turn on at power-up if the assigned input devices

are all in the Run state, even if one or more of the input devices is configured for manual (latch) reset. If the application requires that a manual (latch) reset operation be performed before the Safety Output turns ON, then either manual or

normal power-up mode configuration must be used. Failure to do so could cause a machine to operate in an unexpected

way at power-up or after temporary power interruptions.

WARNING: . . . Controller Operation on Power-Up

It is the responsibility of the user of the Controller to assess what safeguarding devices and methods are appropriate for

any given machine or application. The Qualified Person who configures, installs, and/or maintains it must be aware of

the power-up behavior of the Controller and instruct the machine operator on the operation of the Controller and its

associated devices.

Mute On Power-Up Enable

If configured, the Mute on Power-Up function will initiate a mute cycle after power is applied to the Safety Controller if the muted safety

inputs are active (Run state or closed), and either M1-M2 or M3-M4 (but not all four) are signaling a muted condition (e.g., active or

closed).

• For more information on the Mute On Power-Up function, see section 4.6.4 Mute Function on page 37.

Monitored System Reset

Monitored System Reset is enabled by default and requires an OFF-ON-OFF signal at the reset input, where the ON-duration must be

between 0.3 and 2 seconds (trailing edge reset), in order to reset the system.

If unchecked (Monitored System Reset disabled), the reset input requires only a signal from OFF to ON (leading edge reset), in order to

reset the system.

2.8 Internal Logic

The Controller’s internal logic is designed so that a Safety Output can turn ON only if all the controlling input device signals are in the Run

state and the Controller’s self-check signals are in the No-Fault state.

Safety Input 1 Safety Input 2 Safety Controller Safety Output 1

Stop Stop Run (No Fault) OFF

Stop Run Run (No Fault) OFF

Run Stop Run (No Fault) OFF

Run Run Run (No Fault) ON

The table above illustrates the logic for two safety input devices mapped to control Safety Output 1. If any of the safety input devices are

in the Stop state, then Safety Output 1 is OFF. When both safety inputs are in the Run state, then Safety Output 1 will turn ON.

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 19

Page 20

SC22-3/-3E Safety Controller Instruction Manual

2.8.1 Additional Logic Functions

Other logic functions are slight variations of the general AND logic rule set.

• Two-Hand Control: The machine initiation signal incorporating a 0.5 second actuator simultaneity limit and anti-tie-down logic, designed to prevent single-actuator machine cycle operation.

• Safety Device Muting: The automatic suspension of one or more safety input Stop signals during a portion of a machine operation

when no hazard is present or when access to the hazard is otherwise safeguarded.

• Safety Device Bypass: The manually activated, temporary suspension of one or more safety input Stop signals when the hazard is

otherwise safeguarded.

• Enabling Device Control: The actively controlled manual suspension of a Stop signal during a portion of a machine operation when

a hazard could occur.

• Cancel OFF-Delay: The option to cancel a configured OFF-delay time by either keeping the Safety Output ON, or turning it OFF

immediately.

The rules that apply to these special cases are explained in section 10 Input Device and Safety Category Reference on page 90.

2.9 Password Overview

To provide security, the Safety Controller requires use of a password in some cases. For information about changing a Controller’s password, refer to sections 5.1.4.6 Changing the Password Using the Personal Computer Interface (PCI) on page 61 and 6.3.4 System

Options on page 66. If the password becomes lost, contact the Factory for assistance.

Creating a Configuration

• Via computer using the Safety Controller PC Interface (PCI) program (no password needed)

• Via the Controller Onboard Interface (OBI) (password needed)

Confirming a Configuration

• Via the PCI, using the PC connected to a powered Controller (password needed)

• Via the OBI, on a powered Controller (password needed)

Sending a Confirmed Configuration to the Controller

• Via a direct connection between the PC and the Controller, using the SC-USB1 cable and the PC Interface program (password needed)

• Via the PC, the XM card programming tool, and the XM card (password needed)

2.10 Confirming a Configuration

Although a Controller will accept an unconfirmed configuration, it will only activate it (adopt the configuration and function according to its

parameters) after the configuration is confirmed, using the OBI or PCI.

IMPORTANT: If any modification is made to a confirmed configuration, or if a configuration is edited during the confirmation

process, the PCI and the Controller will recognize this modified configuration as being new and will require it to be confirmed

before it can be activated and used.

Once confirmed, a configuration can be stored and reused without reconfirmation. The configuration code will be validated automatically

each time it is downloaded to a Controller and whenever the Controller powers up. Configurations, confirmed or not, can be sent via

email. Sending (downloading) a new confirmed configuration to a Controller requires entry of the Controller password.

20 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 21

3 Components and Specifications

To order the Safety Controller ready for use, order it as part of a kit

(see following table). It also can be ordered alone, without terminals,

as a replacement part.

Kits include the Safety Controller, model SC22-3 or SC22-3E, a set of

plug-on terminal blocks (screw or cage-clamp type, depending on

model), a USB A/B cable (for direct connection between a PC and the

Safety Controller, included with some kits), external non-volatile memory card (XM card, with write-on label on reverse side), XM card programming tool (included with some models), a user CD (includes software interface, online manual, ethernet references and configuration

tutorials), and quick start guide.

3.1 Safety Controller Starter Kit Models

Kit Model

SC22-3-S Screw

SC22-3-C Clamp

SC22-3-SU1 Screw

SC22-3-CU1 Clamp

SC22-3E-S Screw

SC22-3E-C Clamp

SC22-3E-SU1 Screw

SC22-3E-CU1 Clamp

Terminal

Type

Safety

Outputs

6 PNP

Terminals

(3 pairs)

Status

Outputs

10 Status

10 Status

plus

32 Virtual

Status

Safety Out-

put Rating

0.75 amps

each output

0.5 amps

each output

3.2 Replacement Parts/Accessories

Model Description

SC22-3 Replacement Controller (no terminals)

SC22-3E Replacement Controller (no terminals), Ethernet compatible

SC-XM1 External memory card (XM card)

USB A/B

Cable

─

1.8 m Yes

─ ─

1.8 m Yes

XM

Card

Yes

XM Card Pro-

gramming Tool

Communication

Protocol

─

─

EtherNet/IP &

Modbus/TCP

SC-XM1-5 Bulk pack of 5 XM cards

SC-XMP USB programming tool for XM card

SC-TS1 Screw terminal replacement set

SC-TC1 Cage clamp terminal replacement set

SC-USB1 USB A/B cable, 1.8 m

134534 CD including PCI program and instruction manual

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 21

Page 22

SC22-3/-3E Safety Controller Instruction Manual

3.3 Ethernet Cordsets

Shielded Models Cat5e Crossover Models Length

STP07 STPX07 2.1 m

STP25 STPX25 7.6 m

STP50 STPX50 15.5 m

STP75 STPX75 23 m

3.4 Interface Modules

SC-IM9 series interface modules are for use only with the Safety Controller; dry contacts for use with higher ac/dc voltage and current.

With 10A output, DIN-mount housing, removable (plug-in) terminal blocks for OSSD outputs (screw terminal block supplied). Measures

approx. 72 mm H, 170 mm D, and 45 mm , 90 mm, or 140 mm W, (2.8" H, 6.7" D, and 1.8", 3.5", or 5.5" W) depending on model. See

datasheet p/n 131845 for more information.

NOTE: External device monitoring (EDM) is required to be wired separately to the N.C. contacts to comply with ISO 13849-1

categories and ANSI/OSHA control reliability; see section 4.7.1 External Device Monitoring (EDM) on page 40.

Model Description

SC-IM9A

SC-IM9B

SC-IM9C

IM-T-9 series interface modules have 6A output, 22.5 mm DIN-mount housing, removable (plug-in) terminal blocks. Low current rating of

1V ac/dc @ 5 mA, high current rating of 250V ac/dc @ 6A. See datasheet p/n 62822 for more information.

NOTE: External device monitoring (EDM) is required to be wired separately to the N.C. contacts to comply with ISO 13849-1

categories and ANSI/OSHA control reliability; see section 4.7.1 External Device Monitoring (EDM) on page 40.

Model Supply Voltage Inputs Safety Outputs Output Rating EDM Contacts Aux. Outputs

IM-T-9A

IM-T-11A 2 N.O. 1 N.C.

For use with 1 Safety

Controller Safety Output

For use with 2 Safety

Controller Safety Outputs

For use with 3 Safety

Controller Safety Outputs

24V dc

Supply

Voltage

24V dc

(Controller

supplied)

2 (dual-channel

hookup)

Inputs (Safety

Controller Outputs)

2

(SO1)

4

(SO1 and SO2)

6

(SO1, SO2, and SO3)

3 N.O.

Safety Outputs

3 N.O.

Total of 6

(3 N.O. per output)

Total of 9

(3 N.O. per output)

6 amps 2 N.C.

Output

Rating

10 amps

EDM Con-

tacts

1 N.C. pair per

output

—

3.4.1 Mechanically Linked Contactors

Provides an additional 10 or 16 amp carrying capability to any safety system. If used, two contactors per Safety Output pair (e.g., 2 x

SO1), are required. The N.C. contacts are to be used in an external device monitoring (EDM) circuit.

NOTE: External device monitoring (EDM) is required to be wired separately to the N.C. contacts to comply with ISO 13849-1

categories and ANSI/OSHA control reliability; see section 4.7.1 External Device Monitoring (EDM) on page 40.

22 www.bannerengineering.com - tel: 763-544-3164 P/N 133487 rev. C

Page 23

SC22-3/-3E Safety Controller Instruction Manual

Model Supply Voltage Inputs Outputs Output Rating

11-BG00-31-D024

24V dc 2 (dual-channel hookup) 3 N.O. and 1 N.C.

11-BF18C01-024 18 amps

10 amps

3.5 Specifications

Power

24V dc, ± 20%

Model SC22-3: 0.4 A (Controller only), 5.9 A (all outputs ON @ full rated load)

Model SC22-3E: 0.4 A (Controller only), 4.9 A (all outputs ON @ full rated load)

The Controller should be connected only to a SELV (safety extra-low voltage, for circuits without earth ground) or a

PELV (protected extra-low voltage, for circuits with earth ground) power supply.

Safety and Non-Safety Inputs (22 terminals)

Input ON threshold: > 15V dc (guaranteed on), 30V dc max.

Input OFF threshold: < 5V dc (guaranteed off with any 1 fault), –3V dc min.

Input ON current: 8 mA typical @ 24Vdc, > 2 mA (guaranteed with 1 fault)

50 mA peak contact cleaning current @ 24V dc

Sourcing current: 30 mA minimum continuous (3V dc max. drop)

Input lead resistance: 300 Ω max. (150 Ω per lead)

Input requirements for a 4-wire safety mat:

• Max. capacity between plates: 0.5 µF

• Max. capacity between bottom plate and ground: 0.5 µF

• Max. resistance between the 2 input terminals of one plate: 20 Ω

Safety Outputs (6 terminals, 3 redundant outputs)

Rated output current:

Model SC22-3: 0.75 A max. @ 24V dc (1.0V dc max. drop)

Model SC22-3E: 0.5 A max. @ 24V dc (1.0V dc max. drop)

Output OFF threshold: 0.6V dc typical (1.2V dc max. guaranteed with 1 fault)

Output leakage current: 50 µA max. with open 0V

Load: 0.1 µF max., 1 H max., 10 Ω max. per lead

Status Outputs (10 terminals)

Rated output current: 0.5A @ 24V dc (individual), 1.0 A @ 24V dc (total of all outputs)

O1 to O8 (General Purpose)—Output OFF voltage: < 0.5V dc (no load), 22 KΩ pull down to 0V

O9 and O10 (General Purpose or Monitored Mute Lamp)—

Output OFF voltage: Internal 94 KΩ pull up to 24V dc supply

Output ON/OFF threshold: 15V dc +/−4V dc @ 24V dc supply

NOTE: For O9 and O10 (when configured as a monitored mute lamp output), if a short circuit or other fault condition causes the output to drop below this threshold while the output is ON, a lockout will occur. If an open circuit or

other fault condition causes the output to rise above this threshold while the output is OFF, a lockout will occur.

Response and Recovery Times

Response Time (ON to OFF): 10 ms max. (with standard 6 ms debounce; this can increase if debounce time increases.

Refer to the configuration summary for actual response time.)

P/N 133487 rev. C www.bannerengineering.com - tel: 763-544-3164 23

Page 24

SC22-3/-3E Safety Controller Instruction Manual

Recovery Time (OFF to ON): 400 ms max. (with manual reset option)

Recovery Time (OFF to ON): 400 ms max. plus input debounce time (auto reset)

Onboard LCD Information Display—Password Requirements

Password is not required:

Run mode (I/O status)

Fault (I/O fault detection and remedial steps)

Review configuration parameters (I/O properties and terminals)

Password is required:

Configuration mode (create/modify/confirm/download configurations)

Environmental Rating

NEMA 1 (IEC IP20), for use inside NEMA 3 (IEC IP54) or better enclosure

Operating Conditions

Temperature range: 0° to +55° C (+32° to 131° F)

Mechanical Stress

Shock: 15g for 11 milliseconds, half sine, 18 shocks total (per IEC 61131-2)

Bump: 10g for 16 milliseconds, 6000 cycles total (per IEC 61496-1)

Vibration: 3.5 mm occasional / 1.75 mm continuous @ 5Hz to 9Hz, 1.0g occasional and 0.5g continuous @ 9Hz to 150Hz:

(per IEC 61131-2) and 0.35 mm single amplitude / 0.70 mm peak-to-peak @ 10 to 55Hz (per IEC 61496-1), all @ 10 sweep

cycles per axis

EMC

Meets or exceeds all EMC requirements in IEC 61131-2, IEC 61496-1 (Type 4), and IEC 62061 Annex E, Table E.1 (increased immunity levels)

Removable Terminals

Screw terminals

Wire sizes: 16, 18, 20, 22 or 24 AWG (0.20 – 1.31 mm²)

Wire strip length: 5.00 mm (0.197")

Tightening torque: 0.23 Nm (2 in. lbs.) nominal; 0.34 Nm (3.0 in. lbs.) maximum

Clamp terminals

Important: Clamp terminals are designed for 1 wire only. If more than 1 wire is connected to a terminal, a wire could

loosen or become completely disconnected from the terminal, causing a short.

Wire size: 16, 18, 20, 22, or 24 AWG (0.20 – 1.31 mm²)

Wire strip length: 9.00 mm (0.35")

Network Interface (Model SC22-3E only)

Ethernet 10/100 Base-T/TX, RJ45 modular connector

Selectable auto negotiate or manual rate and duplex

Auto MDI/MDIX (auto cross)

Protocols: EtherNet/IP (with PCCC), Modbus/TCP

Data: 32 configurable virtual Status Outputs; fault diagnostic codes and messages; access to fault log

Product Performance Standards

IEC 62061 Safety of Machinery – Functional Safety of Safety-Related Electrical, Electronic and Programmable Electronic

Control Systems: SIL CL 3