Page 1

25 26

13 14

25 26

13 14

25 26

13 14

13-14

25-26

Break

Pull

50N

70N

0 (0)

1.6 (0.06)

3.6 (0.14)

4.4 (0.17)

5.0 (0.20)

mm (in)

13-14

25-26

Break

Pull

50N

70N

0 (0)

1.2 (0.05)

3.2 (0.13) Latch

4.8 (0.19)

mm (in)

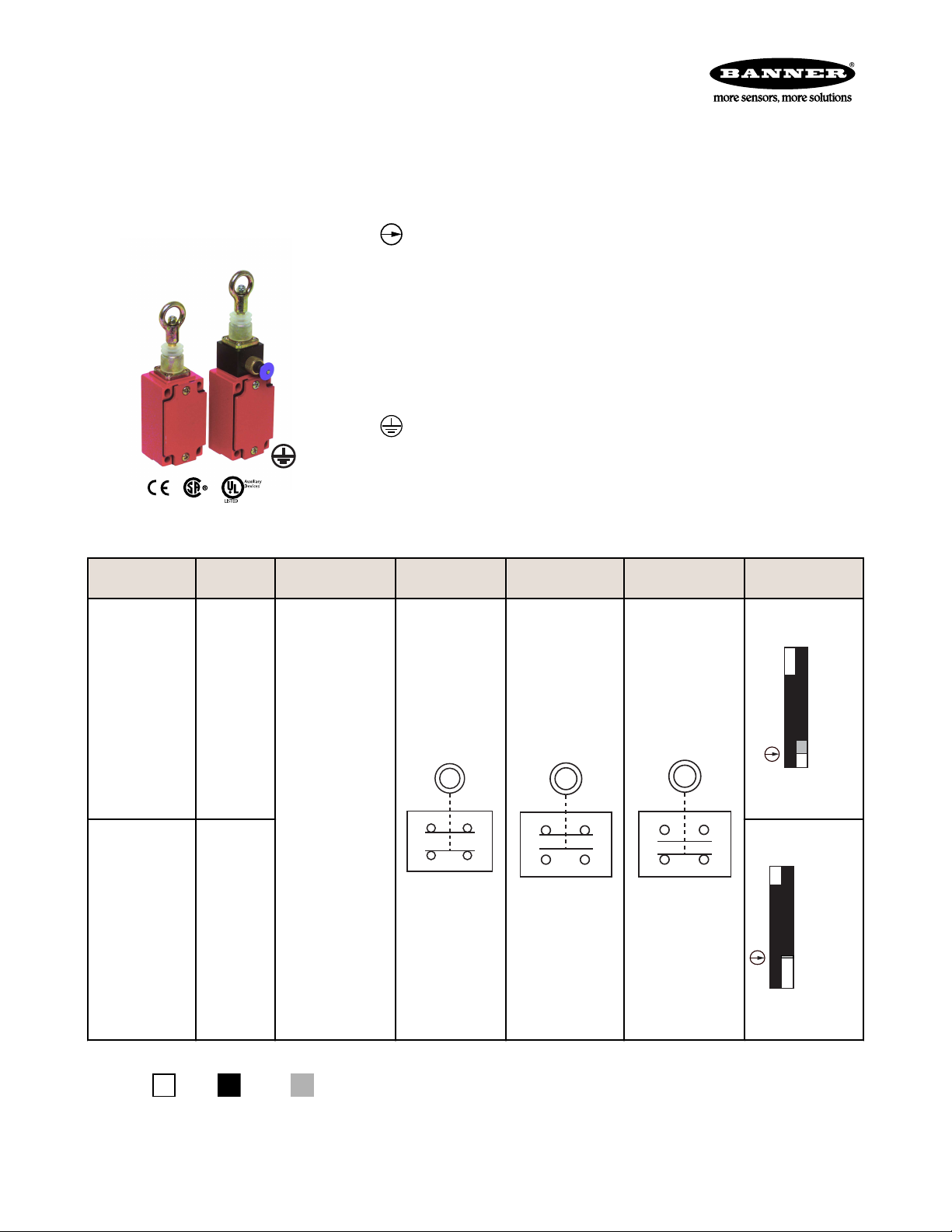

RP-LM40 Series Rope Pull Switches

Datasheet

RP-LM40 Series 40 mm Limit-Switch-Style Switches with Rope Actuators

Model

•

• Standard limit-switch housing (EN 50041)

• Heavy-duty die cast metal housing, rated IP65, suitable for demanding

• Rope spans up to 6 m (20 ft)

• Both safety contacts are closed with normal rope tension; one contact

• Long life, switch rated at 1 million mechanical operations, minimum

• Two available models, trip and latch

•

Actuation Max. Rope

Length

Positive-opening safety contacts (IEC 60947-5-1), not dependent upon

springs

industrial environments

opens when rope is pulled, the other contact opens if rope breaks (or if

tension is reduced from normal amount)

Protective Earth Terminal (IEC 60947-1)

Run Position Cable Pulled Cable Break Switching

Diagram

RP-LM40D-6 Trip

RP-LM40D-6L Latch

Contacts: Open Closed Transition

6 m (20 ft)

P/N 62082 Rev. C 23 January 2014

Page 2

RP-LM40 Series Rope Pull Switches

NOTE: This symbol for a positive-opening safety contact (IEC 60947-5-1) is used in the switching

diagram to identify the point in actuator travel where the normally-closed safety contact is fully open.

Important... Read This First

Regarding the Use of Rope Pull Switches. In the United States, the functions that Banner rope pull switches are

intended to perform are regulated by the Occupational Safety and Health Administration (OSHA). Whether or not any

particular rope pull switch installation meets all applicable OSHA requirements depends upon factors that are beyond the

control of Banner Engineering Corp. These factors include the details of how the switches are applied, installed, wired,

operated, and maintained.

Banner Engineering Corp. has attempted to provide complete application, installation, operation, and maintenance

instructions in this document. Direct any questions regarding the use or installation of rope pull switches to the factory

applications department.

Banner Engineering Corp. recommends that rope pull switches be applied according to the guidelines set forth in the

standards listed below. In addition, the user is responsible for ensuring all local, state, and national laws, rules, codes, and

regulations relating to the use of Banner rope pull switches in each application are satisfied. Extreme care is urged that all

legal requirements are met and that all installation and maintenance instructions are followed.

Applicable U.S. Standards

OSHA Code of Federal Regulations: Title 29, Parts 1900 to 1910

Available from: Superintendent of Documents, Government Printing Office, P.O. Box 371954, Pittsburgh, PA 15250-7954,

Tel: 202-512-1800

ANSI B11 Standards for Machine Tools Safety

Contact: Safety Director, AMT – The Association for Manufacturing Technology, 7901 Westpark Drive, McLean, VA 22102,

Tel.: 703-893-2900

Applicable European and International Standards

ISO/TR 12100-1 (EN 292-1 & -2) Safety of Machinery – Basic Concepts, General Principles for Design

ISO 13852 (EN 294) Safety of Machinery—Safety Distances to Prevent Danger Zones Being Reached by the Upper Limbs

ISO 13853 (EN 811) Safety of Machinery—Safety Distances to Prevent Danger Zones Being Reached by the Lower Limbs

ISO 13849-1 (EN 954-1) Safety-Related Parts of Control Systems

ISO 13855 (EN 999) The Positioning of Protective Equipment in Respect to Approach Speeds of Parts of the Human Body

ISO 14119 (EN 1088) Interlocking Devices Associated with Guards – Principles for Design and Selection

IEC 60204-1 Electrical Equipment of Machines Part 1: General Requirements

IEC 60947-5-1 Low Voltage Switchgear – Electromechanical Control Circuit Devices

Contact: Global Engineering Documents, 15 Inverness Way East, Englewood, CO 80112-5704, Tel.: 800-854- 7179

Overview

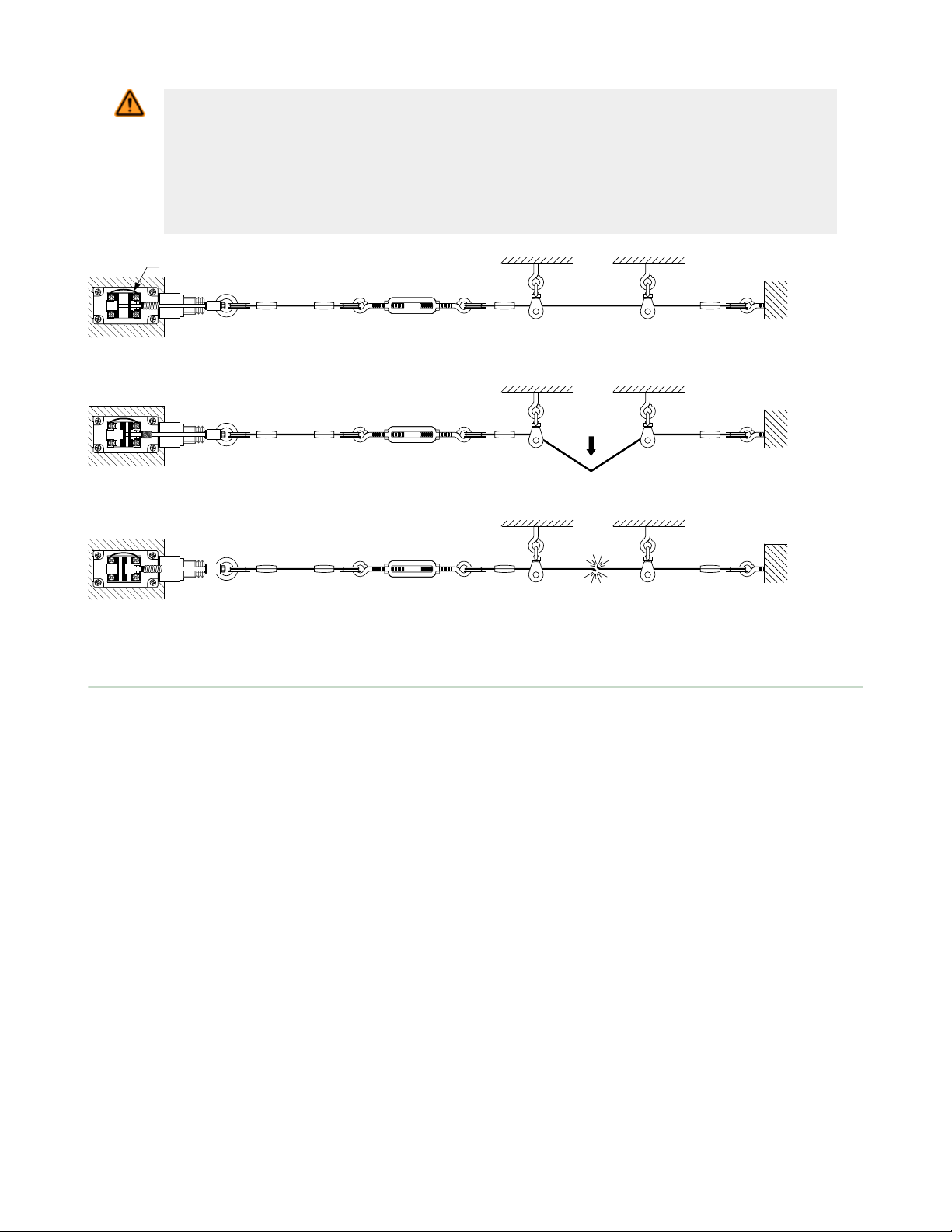

Models RP-LM40D-6 and RP-LM40D-6L are rope pull switches in compact, limit switch-style housings. When used with steel

wire rope, they can provide machine stop actuation along conveyors and similar machinery. Red PVC-covered 2 mm

diameter wire rope, up to 6 m (20 ft) long is recommended.

When the rope is properly tensioned (using a turnbuckle), both contacts of the switch are closed. When the rope is pulled,

the positive-break contacts between terminals 25–26 open. If the rope breaks or goes slack, the contacts between

terminals 13–14 open. These two contacts typically should be wired together, in series.

These rope pull switches are not safeguarding devices; they do not protect personnel from injury. They provide the same

function as other types of stop switches.

The two switch models differ in their switching operation. Model RP-LM40D-6 is a momentary switch, which returns

immediately to the Run condition (i.e., both contacts close) after releasing the rope, following a Pull condition. When using

this model, a separate latching circuit is required. Model RP-LM40D-6L latches contacts 25–26 open with each Pull

condition, and must be reset by pulling the integral reset button.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 62082 Rev. C

Page 3

Wire in Series

RP-LM40 Series Rope Pull Switches

WARNING: Not a Safeguarding Device

An Emergency Stop Device is not considered a safeguarding device because it requires an

overt action by an individual to stop machine motion or hazards.

A safeguarding device limits or eliminates an individual's exposure to a hazard without action by the

individual or others. Because an individual must actuate the device for it to function, these devices do

not fit the definition of a safeguarding device and cannot be substituted for required safeguarding. Refer

to the relevant standards to determine those requirements.

Figure 1. Run Position: Proper Rope Tension

Figure 2. Rope Pulled: Contact 25-26 Opens

Figure 3. Rope Break or Slack: Contact 13-14 Opens

Mechanical Installation

Installation Guidelines

• The rope should be easily accessible and visible along its entire length. Markers or flags may be fixed on the rope

to increase its visibility

• Mounting points, including support points, must be rigid and allow sufficient space around the rope to allow easy

access

• The rope should be free of friction at all supports. Pulleys are recommended

• Use only pulleys (not eye bolts) when routing the rope around a corner or whenever direction changes, even

slightly

• Never run rope through conduit or other tubing

• Never attach weights to the rope

• Temperature affects rope tension. The rope expands (lengthens) when temperature increases, and contracts

(shrinks) when temperature decreases. Significant temperature variations require frequent checks of the tension

adjustment

• Do not exceed the maximum specified total rope length. Banner offers models for other spans; contact Banner

Engineering or visit www.bannerengineering.com for model selection

Installation Procedure

1. Mount the switch securely on a solid, stationary surface.

2. Fasten an eye bolt at the opposite end of the rope span, up to 6 m (20 ft) from the switch. The anchor for the eye

bolt also must be solid and stationary, to withstand the constant tension of the rope.

3. Assemble the rope as shown. Keep the rope’s PVC cover intact along its complete length.

4. Use pulleys (recommended) or eye bolts at each support point. A pulley must be used when routing the rope

around a corner, regardless of the angle.

5. Connect a continuity tester (or ohmmeter) between terminals 25–26 of the switch. Adjust the turnbuckle to tighten

the rope, until contact 25–26 closes. This indicates sufficient rope tension.

6. Pull hard on the rope several times. If contact 25–26 remains open (following reset, for model RP-LM40D-6L),

further tighten the turnbuckle, until contact 25–26 closes.

7. Repeat step 6 until contact 25–26 remains closed for the Run condition.

P/N 62082 Rev. C www.bannerengineering.com - tel: 763-544-3164 3

Page 4

150 mm

(6") max.

6 m

(20') max.

3 m

(10') max.

25 mm

(1") min.

400 mm (16") max.

for Actuation of Switch

NOTE: Force to actuate must not exceed 200 N (45 lbf)

Reset Button—

Pull to Reset

Install

Jumper Wire

Between

Contacts

132514

26

To

Machine

Control

Stop

Circuit

RP-LM40 Series Rope Pull Switches

Figure 4. Assembly of Rope and Hardware

All hardware is supplied by the user. The switch mounting holes are on a standard limit switch mounting pattern of 30 x 60

millimeters, and accept M5 (#10) hardware. Wire rope and associated hardware may be ordered separately; see

Accessories.

Electrical Installation

Access to the Wiring Chamber. The wiring chamber is accessed via a

cover plate (remove two screws). A conduit adapter is supplied to convert

the 20 millimeter threaded entrance to 1/2" NPT. An accessory cable gland

which fits the M20 thread is also available.

Wiring. Install a jumper wire to place the two switch contacts in series, as

shown.

Important: Model RP-LM40D-6 does not latch contacts

25–26 open when the rope is pulled. The contacts close

when the rope is released. When using model RPLM40D-6, a latch circuit must be included in the

machine control circuitry.

Figure 5. Wire the two switch contacts in series

Maintenance/Checkout

At switch installation or replacement and at machine set up, a Designated Person1 must test each switch for proper

machine shutdown response and check the switch(es) and installation for proper operation, physical damage, mounting

(looseness), and excessive environmental contamination. This must also take place on a periodic schedule determined by

the user, based on the severity of the operating environment and the frequency of switch actuations. Adjust, repair, or

replace components as needed. If inspection reveals contamination on the switch, thoroughly clean the switch and

eliminate the cause of the contamination. Replace the switch and/or appropriate components when any parts or

assemblies are damaged, broken, deformed, or badly worn; or if the electrical/mechanical specifications (for the

environment and operating conditions) have been exceeded. Always test the control system for proper functioning under

machine control conditions after performing maintenance, replacing the switch, or replacing any component of the switch.

Additional items that should be included in the checkout and/or regularly scheduled maintenance of a rope pull system:

• Check for proper rope tension and adjust as needed

• Verify free operation (no binding) of the rope and proper tripping when the rope is pulled

• Periodically lubricate the pulleys and other moving parts associated with the rope

1

A Designated Person is identified in writing by the employer as being appropriately trained to perform a specified checkout procedure.

4 www.bannerengineering.com - tel: 763-544-3164 P/N 62082 Rev. C

Page 5

RP-LM40 Series Rope Pull Switches

• Repair any loose or damaged hardware, worn/frayed rope (cable), missing red rope sheathing or flags/markers (if

used)

• Remove or clean off any contamination and eliminate its cause

Repairs

Contact Banner Engineering for troubleshooting of this device. Do not attempt any repairs to this Banner device; it

contains no field-replaceable components. If the device or a device component is determined to be defective by a

Banner Applications Engineer, they will advise you of Banner's RMA (Return Merchandise Authorization) procedure.

Important: If instructed to return the device, pack it with care. Damage that occurs in return shipping

is not covered by warranty.

Specifications

Contact Rating

10 A at 24 V ac

10 A at 110 V ac

6 A at 230 V ac

6 A at 24V dc

2.5 kV max. transient tolerance

NEMA A300 P300

European Rating

Utilization categories: AC15 and DC13

Switches with 1 and 2 contact pairs: Ui = 500V ac; Ith

= 10A

40-60 Hz

Ue (A) Ie/AC-15 (A) Ie/DC-13 (A)

24 10 6

110 10 1

230 6 0.4

Contact Material

Silver-nickel allow

Maximum Switching Speed

50 operations per minute

Recommended Rope Size

2 mm diameter steel rope

Maximum Rope Pull Length

6 m (20 ft)

Short Circuit Protection

10 amp Slow Blow, 15 amp Fast Blow. Recommended

external fusing or overload protection.

Mechanical Life

1 million operations

Wire Connections

Screw terminals with pressure plates accept the

following wire sizes –

Stranded and solid: 20 AWG (0.5 mm2) to 16 AWG

(1.5 mm2) for one wire

Stranded: 20 AWG (0.5 mm2) to 18 AWG (1.0 mm2)

for two wires

Cable Entry

M20 x 1.5 threaded entrance. Adapter supplied to

convert M20 x 1.5 to ½"-14 NPT threaded entrance

Construction

Aluminum alloy die-cast

Environmental Rating

IEC IP65

Operating Conditions

Temperature: –30 to 80 °C (–22 to 176 °F)

Weight

RP-LM40D-6: 0.22 Kg (0.49 lbs)

RP-LM40D-6L: 0.26 Kg (0.57 lbs)

Certifications

P/N 62082 Rev. C www.bannerengineering.com - tel: 763-544-3164 5

Page 6

30.0 mm

(1.18")

40.0 mm

(1.58")

Ø5.2 mm

(0.20")

M20 x 1.5

60.0 mm

(2.36")

74.5 mm

(2.94")

7.5 mm

(0.30")

50.0 mm

(1.97")

Ø25.0 mm

(0.99")

Ø15.0 mm

(0.59")

2.0 mm

(0.08")

5.2 mm

(0.20")

37.5 mm

(1.48")

33.0 mm

(1.30")

15.0 mm

(0.60")

16.0 mm

(0.63")

5.0 mm

(0.20")

30.0 mm

(1.18")

40.0 mm

(1.58")

Ø5.2 mm

(0.20")

M20 x 1.5

60.0 mm

(2.36")

74.5 mm

(2.94")

2.0 mm

(0.08")

5.2 mm

(0.20")

37.5 mm

(1.48")

33.0 mm

(1.30")

15.0 mm

(0.60")

7.5 mm

(0.30")

73.0 mm

(2.88")

Ø25.0 mm

(0.99")

Ø15.0 mm

(0.59")

16.0 mm

(0.63")

5.0 mm

(0.20")

52 mm

(2.05")

Ø15.0 mm

(0.59")

8.6 mm

(0.34")

M20 x 1.5

24.0 mm

(0.94")

35.5 mm

(1.40")

RP-LM40 Series Rope Pull Switches

Dimensions

Figure 6. Model RP-LM40D-6

Figure 7. Model RP-LM40D-6L

Accessories

Cable Glands

Model

SI-QM-CGM20 M20 × 1.5 Metal

6 www.bannerengineering.com - tel: 763-544-3164 P/N 62082 Rev. C

Size

For Cable

Diameter

5.0 to 12.0 mm

(0.20 to 0.47

inches)

Dimensions Used With

SI-LM40 Safety Interlock

Switches

SI-QM100 Safety Interlock

Switches

RP-RM83 Rope Pull Switches

RP-LM40 Rope Pull Switches

RP-QM72/QMT72 Rope Pull

Switches

RP-QM90 Rope Pull Switches

Page 7

23.0 mm

(0.91")

M20 x 1.5

24.0 mm

(0.94")

1/2"-14 NPT

Internal Thread

O-ring

Thimble Clamp

Pulley

Turnbuckle Eye Bolt

RP-LM40 Series Rope Pull Switches

Conduit Adapters

Model Size Thread Conversion Dimensions Used With

SI-LM40 Safety Interlock

Switches

SI-QM100 Safety Interlock

SI-QM-M20

½ in-14 NPT

Metal

M20 × 1.5 to ½

in-14 NPT

Switches

RP-RM83 Rope Pull Switches

RP-LM40 Rope Pull Switches

RP-QM72/QMT72 Rope Pull

Switches

RP-QM90 Rope Pull Switches

One conduit adapter is supplied with each switch.

Assembly Components

Figure 8. Components for Wire Rope Assembly Components

Model

Length Description Wire Rope

RPA-C1-10 10 m (33 ft)

RPA-C1-20 20 m (66 ft)

2 mm steel wire rope with 0.5 mm red PVC jacket

(unterminated)

RPA-C1-100 100 m (330 ft)

Model Quantity Description Thimble

RPA-T1-4 4 Thimble for 2 mm wire rope

Model Quantity Clamp

RPA-CC1-4 4 Clamp for 2 mm wire rope

Model Quantity Description Turnbuckle

RPA-TA1-1 1 #4 Turnbuckle

P/N 62082 Rev. C www.bannerengineering.com - tel: 763-544-3164 7

Page 8

Model Quantity Description Eye Bolt

RPA-EB1-1 1 ¼"-20 Eye bolt (3" bolt shaft)

Model Quantity Description Pulley

RPA-P1-1 1 Hanging pulley for in-line use

RP-LM40 Series Rope Pull Switches

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...