Page 1

R55F Series Fiber-Optic Color Mark Sensors

For Plastic and Glass Fiber Optics

Printed in USA

05/01 P/N 57945 rev. B

R55F Series Sensor Features

• Outstanding color contrast sensitivity; detects 16 levels of gray scale.

• Depending on beam color, reliably detects the toughest color mark contrasts,

including 20% yellow against white.

• Fast, 50-microsecond response.

• Choose from infrared or one of four visible beam colors: red, blue, green and

white.

• Fibers mount in small and otherwise inaccessible areas.

• Easy push-button programming options include Static TEACH, Static Single-Point

TEACH, Dynamic TEACH and Remote TEACH; plus manual sensitivity adjustment.

• Non-volatile memory.

• Glass fiber models function well in harsh environments typically associated with

printing processes.

• Plastic fiber models function well in applications that require repeated flexing of

the fibers.

• Fibers install quickly without tools.

• Bipolar (NPN/PNP) outputs with three Delay settings (0, 20 or 40 milliseconds).

• Choice of integral cable or QD connector models.

• Mounts flat or to 35 mm DIN rail; two brackets included with sensor (one for

angle mount, one for flat mount).

R55F Series Sensor Overview

The R55F Fiber-Optic Sensor was developed to provide simplicity of operation and

access to tight areas for color mark (registration) sensing applications. The R55F is a

technological advancement from earlier R55 models.

R55F sensors feature TEACH mode sensitivity adjustment, by presenting the light and

the dark sensing conditions to the sensor. In addition, sensitivity may be fine-tuned at

any time by simply clicking the “+” or “-” buttons on the sensor. The ten-element signal

strength light bar clearly displays the relative received signal strength.

The bipolar (one NPN and one PNP) outputs may be programmed to include a 20 or

40-millisecond pulse stretcher (OFF Delay), if required. Both TEACH mode sensitivity

adjustment and output SETUP are accomplished using the push-buttons on the sensor,

or by supplying input pulses via the Remote Teach input.

TEACH mode has two options: Static TEACH and Dynamic TEACH. Static TEACH is

used to manually set the two sensing conditions individually or to program a specific

condition to be sensed (single-point TEACH). Dynamic TEACH provides a means for

teaching a series of conditions on-the-fly; the R55F “averages” the sensing events and

automatically sets (and periodically updates via the adaptive threshold feature) the

switch point between light and dark conditions.

Page 2

R55F Series Fiber-Optic Color Mark Sensors

page

2

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

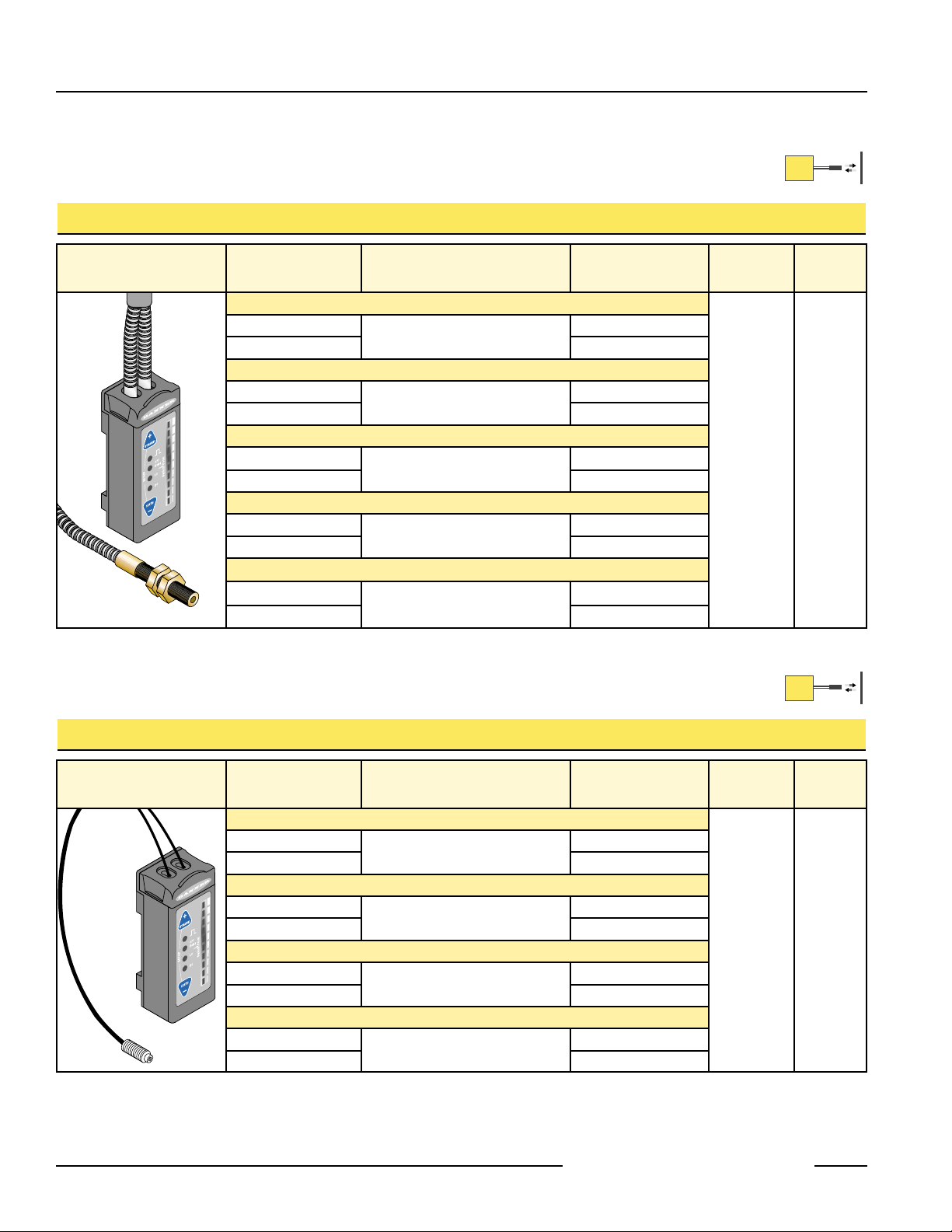

R55F Series Glass Fiber-Optic Sensor Models

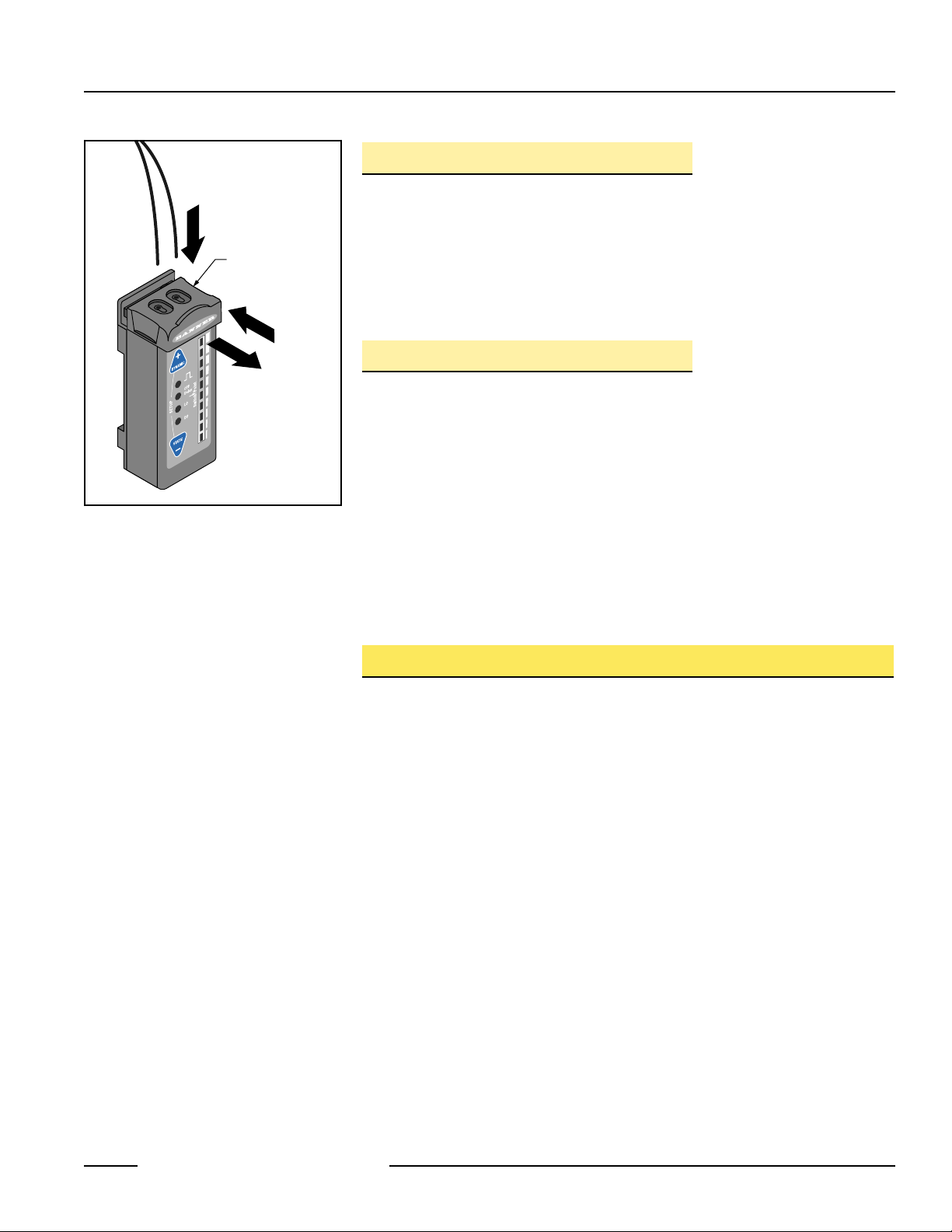

R55F Series Plastic Fiber-Optic Sensor Models

* 9m (30') cables are available by adding suffix “W/30” to the model number of any cabled sensor (e.g., R55FV W/30). A model with a QD

connector requires a mating cable (see page 11).

Advantages of glass fiber optics for color mark sensing:

• Randomly mixed bifurcated fiber bundles produce the best optics for color mark sensing.

• Bundle of small fibers may be shaped at sensing end tip to match the color mark shape.

• Best chemical resistance.

Visible Red, 650 nm

Visible Green, 525 nm

Visible Blue, 475 nm

Visible White, 450-650 nm

Infrared, 880 nm

Visible Red, 650 nm

Visible Green, 525 nm

Visible Blue, 475 nm

Visible White, 450-650 nm

Advantages of plastic fiber optics for color mark sensing:

• Plastic fibers may be repeatedly flexed.

• Low cost.

• Most models may be cut to fit in the field.

Model

Number

Maximum Sensing Distance

For black-to-white contrast

Cable*

Supply

Voltage

Output

Type

Visible Red, 650 nm

10 to 30V dc

Bipolar

NPN/PNP

R55FP

0.040" dia. Fibers: 60 mm (2.4")

5-wire 2 m (6.5') cable

R55FPQ 5-pin Euro-style QD

Visible Green, 525 nm

R55FPG

0.040" dia. Fibers: 28 mm (1.1")

5-wire 2 m (6.5') cable

R55FPGQ 5-pin Euro-style QD

Visible Blue, 475 nm

R55FPB

0.040" dia. Fibers: 28 mm (1.1")

5-wire 2 m (6.5') cable

R55FPBQ 5-pin Euro-style QD

Visible White, 450 - 650 nm

R55FPW

0.040" dia. Fibers: 28 mm (1.1")

5-wire 2 m (6.5') cable

R55FPWQ 5-pin Euro-style QD

Model

Number

Maximum Sensing Distance

For black-to-white contrast

Cable*

Supply

Voltage

Output

Type

Visible Red, 650 nm

10 to 30V dc

Bipolar

NPN/PNP

R55FV

0.060" dia. Bundle: 28 mm (1.1")

0.125" dia. Bundle: 110 mm (4.3")

5-wire 2 m (6.5') cable

R55FVQ 5-pin Euro-style QD

Visible Green, 525 nm

R55FVG

0.060" dia. Bundle: 12 mm (0.5")

0.125" dia. Bundle: 50 mm (2.0")

5-wire 2 m (6.5') cable

R55FVGQ 5-pin Euro-style QD

Visible Blue, 475 nm

R55FVB

0.060" dia. Bundle: 12 mm (0.5")

0.125" dia. Bundle: 50 mm (2.0")

5-wire 2 m (6.5') cable

R55FVBQ 5-pin Euro-style QD

Visible White, 450 - 650 nm

R55FVW

0.060" dia. Bundle: 12 mm (0.5")

0.125" dia. Bundle: 50 mm (2.0")

5-wire 2 m (6.5') cable

R55FVWQ 5-pin Euro-style QD

Infrared, 880 nm

R55F

0.060" dia. Bundle: 40 mm (1.6")

0.125" dia. Bundle: 140 mm (5.5")

5-wire 2 m (6.5') cable

R55FQ 5-pin Euro-style QD

Page 3

R55F Series Fiber-Optic Color Mark Sensors

page

3

Banner Engineering Corp. •

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

B

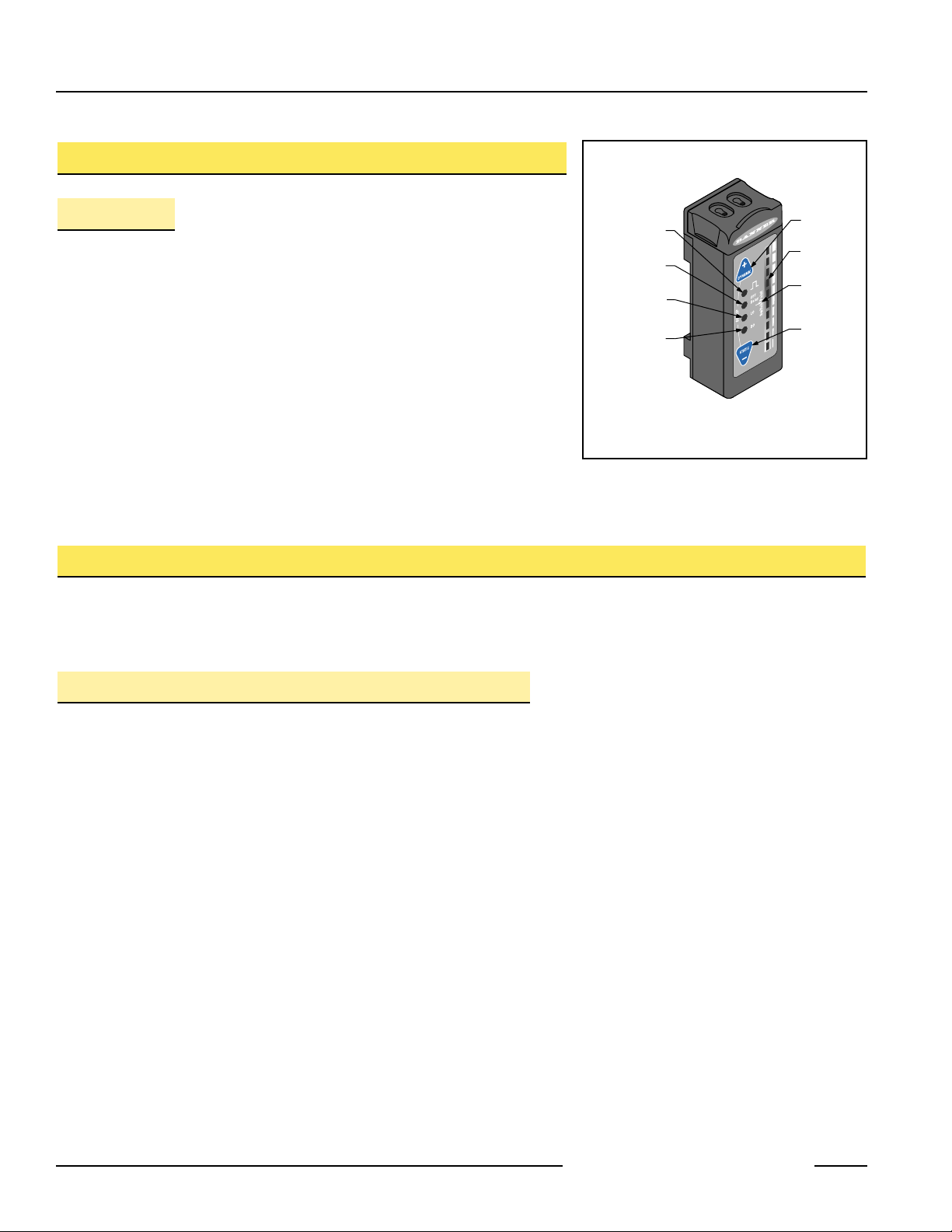

Figure 1. Installing fibers into the R55F

Series sensor

Plastic fibers

shown; procedure

is identical for

glass fibers

Glass Fiber Installation Procedure:

1) Check to see that a rubber o-ring is pre-installed on each fiber control end.

2) Slide the fiber clip to the open position (A).

3) Insert one fiber end into each port (B). Push firmly on the fiber ends to compress

the o-rings and align the grooves in the fiber ends with the slot in the fiber clip.

4) Slide the fiber clip back into place, locking the fibers into position (C).

Plastic Fiber Installation Procedure:

NOTE: R55F sensors accept 0.75, 1.0, and 1.5 mm (0.03", 0.04", and 0.06") core

diameter plastic fibers.

1) Cut the “control ends” (sensor ends) of the plastic fiber(s) to the desired length

per the procedure which accompanies the fiber assembly.

2) If not already done, separate bifurcated fibers by approximately 2" from the control

ends.

3) Slide the fiber clip to the open position (A).

4) Insert the fiber ends into each port and push them in as far as they will go (B).

5) Slide the fiber clip back into place, locking the fibers into position (C).

Fiber Optic Mounting Considerations

Mount the sensing end of the fiber optic assembly so that the light image is totally

contained within the boundaries of the color mark to be sensed. The light image is

made smaller by moving the sensing tip closer to the surface of the material to be

sensed.

When sensing marks on shiny (specular) materials, such as metal, plastic or glossy

paper, mount the sensing tip of the fiber at approximately 15° from perpendicular to

the material surface to minimize strong direct reflections.

Isolate the fiber mounting from vibration. Also, maintain mechanical stability of the

surface to be sensed (e.g., stabilize web flutter at the sensing point).

Fiber

Clip

C

A

Page 4

R55F Series Fiber-Optic Color Mark Sensors

page

4

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Using the R55F Series Sensor

RUN Mode

Normal operation of the R55F is called RUN mode. The LED indicators (see

Figure 2) operate as follows in RUN mode:

Output Conducting LED: ON when outputs are active

Delay Configuration Indicator LED: OFF No OFF Delay is programmed

ON 20 or 40-ms OFF Delay is programmed

Light Operate LED: ON to indicate Light Operate configuration

Dark Operate LED: ON to indicate Dark Operate configuration

(NOTE: Since either one of these is always ON when the sensor is operating, the

combined Light/Dark Operate LEDs also provide a functional Power-ON indication.)

10-Segment Light Bar: indicates signal strength, with respect to the sensing

threshold (“Switch Point”).

TEACH Modes

The sensitivity of the R55F may be quickly optimized by using one of two available TEACH modes: Static TEACH or Dynamic

TEACH. Either may be performed using the push buttons on the sensor, or remotely, using a remote switch or process controller

connected to the sensor’s gray wire(see page 8).Either a sensing window or a specific point may be taught.

Static TEACH

In Static TEACH mode, the sensor learns the light condition and the dark condition, each one time. Sensitivity is automatically set

to place the switch point midway between the two conditions. In addition, the condition taught first becomes the output ON

condition.

Sensitivity may be adjusted at any time when the sensor is in RUN mode by clicking the “+” and “-” buttons. Each click translates

to 1/2 segment on the signal strength light bar. For best sensing reliability, the light and dark conditions should register equally

distant from the switch point on the signal strength light bar.

Single-Point TEACH

The R55F sensor also may be taught a single specific target, using an alternate Static TEACH procedure. The sensor will sense

only the mark taught and will ignore signals both stronger and weaker. The sensitivity to the taught mark then may be adjusted up

or down.

To perform single-point TEACH, place the target in front of the sensor. Press and hold the “Static” button until the LO and DO

LEDs begin to flash, then double-click the Static button. If the single point was successfully taught, the two center sections of the

bar graph will flash.

Manually adjust the sensitivity by clicking either the “+” or “-” button; the bar graph will flash two segments centered about the

sensing point. If the sensitivity is increased (-), the two lighted segments will become closer together, and farther apart if the

sensitivity is decreased (+). If the segments do not flash while the sensitivity is being adjusted, the setting has reached its

maximum and cannot be adjusted further.

Figure 2. R55F Series sensor features

Output

Conducting

LED

Delay

Configuration

Indicator LED

(Light Operate)

(Dark Operate)

* Either LO or DO LED is ON

whenever sensor has power

and is in RUN mode

LO

LED*

DO

LED*

Dynamic

TEACH (+)

Push Button

10-Segment

Light Bar

Switch

Point

Static

TEACH (-)

Push Button

Page 5

Static Single-Point TEACH Procedure - Push Button

Static TEACH Procedure - Push Button

R55F Series Fiber-Optic Color Mark Sensors

page

5

Banner Engineering Corp. •

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Push Button Resulting Indicator Status

Press and hold STATIC button

until LO and DO indicators

alternately flash, then release

button.

LO and DO: Alternately flash green

: ON amber (indicating ready to

teach output ON condition)

Light Bar: Goes OFF

TEACH Condition #1

(Output ON state)

Present the output ON sensing

condition and single-click

STATIC button.

LO and DO: Alternately flash Green

: OFF (indicating ready to teach

output OFF condition)

Light Bar: Remains OFF

TEACH Condition #2

(Output OFF state)

Present the output OFF

sensing condition and singleclick STATIC button.

Contrast accepted: one of the ten

segments flashes for three seconds to

indicate relative contrast, and then the

sensor enters RUN mode.

Contrast too low: every other segment

flashes for three seconds to indicate low

contrast, and the sensor returns to TEACH

Condition #1.

SETUP

DOLOOFF

Delay

Switch Point

+

DYNAMIC

–

STATIC

Press and Hold ≥ 2 seconds

SETUP

DOLOOFF

Delay

Switch Point

+

DYNAMIC

–

STATIC

Single-click

SETUP

DOLOOFF

Delay

Switch Point

+

DYNAMIC

–

STATIC

Single-click

Signal Strength

Light Bar

Push Button Resulting Indicator Status

Press and hold STATIC button

until LO and DO indicators

alternately flash, then release

button.

LO and DO: Alternately flash green

: ON amber (indicating ready to

teach output ON condition)

Light Bar: Goes OFF

TEACH Condition to be

Sensed (Output ON state)

Present the output ON sensing

condition and double-click

STATIC button.

LO or DO: depending on condition of

taught

: OFF

Light Bar: Two center segments are lit

if TEACH was successful.

NOTES:

1) The sensor will return to RUNmode if either TEACH condition is not registered within 90 seconds. Also,

TEACH mode may be cancelled by pressing and holding the push button for ≥ 2 seconds. In either case, the

sensor will revert to the previous conditions taught (i.e., exit without save).

2) If the sensing conditions are accepted at the end of TEACH Condition #2, the signal strength light bar flashes

one of its ten segments for three seconds to indicate relative sensing contrast. The higher the flashing

segment, the higher the measured sensing contrast. High contrast relates directly to sensing reliability. Highcontrast sensing applications are most tolerant of sensing variables, such as web flutter or variations in color

mark color or print density.

See page 8 for Remote

TEACH procedures

Press and Hold ≥ 2 seconds

–

DOLOOFF

Switch Point

+

Delay

DYNAMIC

SETUP

STATIC

Double-click

DYNAMIC

SETUP

STATIC

–

DOLOOFF

Switch Point

+

Delay

Page 6

Dynamic TEACH

Dynamic TEACH is used to program sensitivity during actual machine run conditions. During

Dynamic TEACH, the R55F samples many color marks against their background material and

automatically sets the sensitivity at the optimum level. Dynamic TEACH activates the sensor’s

adaptive threshold system, which continuously tracks minimum and maximum signal levels, and

automatically maintains centering of the switch point between the light and dark conditions. The

adaptive threshold system remains in effect during RUN mode to automatically adjust for changes

in the light or the dark conditions.

When Dynamic TEACH mode is used to program sensitivity, the output ON state must be assigned

to either the light or dark condition using the SETUP mode (see page 7).

Sensitivity may be adjusted at any time when the sensor is in RUN mode by clicking the “+” and “-”

buttons. However, when a manual adjustment is made, the adaptive threshold system is disabled

(cancelled).

Dynamic TEACH Procedure - Push button

R55F Series Fiber-Optic Color Mark Sensors

page

6

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Push Button Resulting Indicator Status

Press and hold DYNAMIC

button until LO and DO

indicators alternately flash.

LO and DO: Alternately flash green

: OFF

Light Bar: Goes OFF

Continue depressing the

DYNAMIC button while

sampling light and dark

sensing conditions.

LO and DO: Alternately flash green

: OFF

Light Bar: Remains OFF

Release the DYNAMIC button

when finished sampling light

and dark sensing conditions.

Contrast accepted: one of the ten

segments flashes for three seconds to

indicate relative contrast, and the sensor

enters RUN mode.

Contrast too low: five light bar segments

flash for three seconds to indicate low

contrast, and sensor reverts to the

previously taught conditions.

NOTES:

1) If the sensing conditions are accepted at the end of Dynamic TEACH, the signal strength light bar flashes one

of its ten segments for three seconds to indicate relative sensing contrast. The higher the flashing segment,

the higher the measured sensing contrast. High contrast relates directly to sensing reliability. High contrast

sensing applications are most tolerant of sensing variables, such as web flutter or variations in color mark

color or print density.

2) If the sensor does not measure enough contrast at the end of Dynamic TEACH, every other segment of the

signal strength light bar flashes in unison for three seconds to warn of unacceptably low contrast, and the

sensor returns to RUN mode with its previously taught conditions.

See page 8 for Remote

TEACH procedures

Press and Hold ≥ 2 seconds

DYNAMIC

SETUP

STATIC

–

Continue to Depress

While Sensor Samples

Light and Dark Conditions

STATIC

–

STATIC

–

DOLOOFF

Switch Point

SETUP

DOLOOFF

Switch Point

SETUP

DOLOOFF

Switch Point

Delay

Delay

Release

Delay

+

DYNAMIC

+

DYNAMIC

+

Page 7

R55F Series Fiber-Optic Color Mark Sensors

page

7

Banner Engineering Corp. •

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

SETUP Mode

SETUP mode is used to configure sensor output response for:

- Light or Dark operate

- 20- or 40-millisecond pulse stretcher (OFF delay), if required.

It will be necessary to access SETUP mode only if the settings which result from

TEACH mode programming are not the settings required for the application. The

status LEDs indicate the output response configuration when the sensor is in RUN

mode, as follows:

- LO indicator ON = output is light operate

- DO indicator ON = output is dark operate

- OFF Delay indicator ON = either 20- or 40-millisecond delay is programmed

- OFF Delay indicator OFF = no output delay is programmed

To change the output response settings;

1) Press and hold BOTH push buttons until the signal strength light bar turns OFF.

2) Click EITHER push button to toggle through the six possible settings

indicated as follows:

Figure 3. SETUP mode

Output Configuration

Delay

IndicatorLOIndicatorDOIndicator

Light operate with no delay

OFF ON OFF

Light operate with 20 ms delay

Flashing ON OFF

Light operate with 40 ms delay

ON ON OFF

Dark operate with no delay

OFF OFF ON

Dark operate with 20 ms delay

Flashing OFF ON

Dark operate with 40 ms delay

ON OFF ON

3) Press and hold both push buttons until the signal strength light bar turns ON,

indicating return to RUN mode.

NOTE: If SETUP mode programming is interrupted and remains inactive for 30

seconds, the sensor returns to RUN mode with the most recent settings

(i.e., exit and save current selection).

Press and Hold

Both Push Buttons

DYNAMIC

SETUP

STATIC

+

OFF

Delay

LO

Switch Point

DO

–

Page 8

R55F Series Fiber-Optic Color Mark Sensors

page

8

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Remote Programming

The gray wire of the R55F may be connected to a remote switch or to a process

controller to:

- Set sensitivity via either Static or Dynamic TEACH mode

- Set output response via SETUP mode

- Disable the push button functions

A remote programming switch is connected between the gray wire and dc common (see

Hookup diagrams on page 11). The switch may be either a normally-open contact, or an

open-collector NPN transistor with its emitter connected to dc common.

Remote programming is accomplished using a specified sequence of input pulses.

The duration of each pulse is defined as:

0.04 seconds < T < 0.8 seconds (40 ms < T< 800 ms)

Remote Static TEACH Mode

1) Present the Output ON condition to the fiber sensing end and pulse the Remote

TEACH input once.

2) Wait at least 0.8 seconds, present the Output OFF condition, and pulse the Remote

TEACH input once.

If sensing contrast is adequate, the sensor flashes one segment of the signal strength

light bar for 3 seconds to indicate relative contrast, and then enters RUN mode.

If contrast is too low, the sensor flashes five segments of the signal strength light bar

in unison to warn of unacceptably low contrast, and returns to re-teach the Output ON

condition (Step 1).

Remote Static Single-Point TEACH

The single-point TEACH may also be performed using the remote wire. Present the

target and single-click the remote wire. Wait for at least 0.8 second, then double-click

the remote wire. If the TEACH is successful, the sensor will flash the middle two LEDs

of the bar graph, and return to RUN mode.

Remote Dynamic TEACH Mode

1) Hold the TEACH input low for > 2 seconds

2) Continue holding the TEACH input low while presenting light and dark sensing

conditions. Open switch when finished teaching.

If sensing contrast is adequate, the sensor flashes one segment of the signal strength

light bar for 3 seconds to indicate relative contrast, and then enters RUN mode.

If contrast is too low, the sensor flashes five segments of the signal strength light bar

in unison to warn of unacceptably low contrast, and returns to RUN mode with its

previously taught conditions.

Figure 4. Input pulse timing

Figure 5. Static TEACH mode

Figure 6. Static Single-Point TEACH mode

Figure 7. Dynamic TEACH mode

0.04 < T < 0.8 sec

Switch Open

Switch Closed

to dc common

Present

Output ON

Condition

TT

Present

Output OFF

Condition

> 0.8 sec

Present

Output ON

Condition

TTT

> 0.8 sec

> 2 sec

Double-Click

T

TEACH Light

and Dark

Conditions

Page 9

R55F Series Fiber-Optic Color Mark Sensors

page

9

Banner Engineering Corp. •

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Remote SETUP Mode

1) To enter SETUPmode, pulse once, wait 0.04 to 0.8 seconds, then pulse again.

2) Wait > 0.8 seconds, then enter sequential pulses to toggle between the six

output configuration choices (see page 7). Spacing between sequential pulses

must be > 0.8 seconds.

3) To exit SETUPmode, hold the TEACH input low for > 2 seconds.

Locking Out (Disabling) the Push Buttons

Pulse four times to disable (or to re-enable) the push buttons.

Figure 8. SETUP mode

Figure 9. Push button lockout

R55F Series Sensor Dimensions

TTTT

Two pulses

to Enter

SETUP

> 0.8 sec

> 0.8 sec

Sequential

pulses to toggle

between configuration choices

TT

T

T

T

TT

Pulse four times to enable

or disable push button

etc.

TT

> 0.8 sec

Plastic Fiber

10.0 mm

(0.39")

35.0 mm

(1.40")

30.0 mm

(1.18")

24.5 mm

(0.97")

Glass Fiber

25.0 mm

(0.99")

12.9 mm

(0.51")

12.9 mm

(0.51")

85.4 mm

(3.36")

11.6 mm

(0.46")

10.0 mm

(0.39")

Quick-Disconnect

Models

+

DYNAMIC

SETUP

STATIC

–

OFF

Delay

LO

DO

Switch Point

4.5 mm

(0.18")

Cabled

Models

+

DYNAMIC

SETUP

STATIC

–

OFF

Delay

LO

DO

Switch Point

Page 10

R55F Series Fiber-Optic Color Mark Sensors

page

10

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

R55F Series Sensor Specifications

Supply Input 10 to 30V dc (10% maximum ripple) at less than 70 mA, exclusive of load

Supply Protection Circuitry Protected against reverse polarity and transient voltages

Output Rating

150 mA max each output @ 25°C (derate ≈ 1 mA per °C increase)

OFF-state leakage current: < 5 µA @ 30V dc

ON-state saturation voltage: PNP Output < 1V @ 10 mA and 1.5V @ 150 mA

NPN Output < 200 mV @ 10 mA and 1V @ 150 mA

Output Response

50 microseconds

NOTE: 100 millisecond delay on power-up; outputs do not conduct during this time.

Indicator LEDs

10-segment (green) light bar indicates signal strength

Light Operate (green)

Dark Operate (green)

Outputs Conducting (yellow)

OFF Delay (green): SETUP Mode: OFF — no delay RUN Mode: OFF — no delay

Flashing — 20 ms delay ON — 20 or 40 ms Delay

ON — 40 ms delay

Construction

Housing: Black ABS/polycarbonate blend; nylon fiber clip

mounts to standard 35 mm DIN rail

1 stainless steel right angle bracket and 1 PBT polyester bracket for mounting to flat surfaces also included

with sensor

Environmental Rating IEC IP67; NEMA 6

Connections

Power: 2 m or 9 m PVC-jacketed 5-conductor cable or 5-pin Euro-style quick-disconnect (QD) connector

Fibers: Fiber clip (no tool required)

Operating Conditions

Temperature: -10° to +55° C (+14° to 131° F)

Maximum Relative Humidity: 90% at 50° C (non-condensing)

Application Notes

• Do not mount the fiber tip directly perpendicular to shiny surfaces; position it at approximately a 15° angle

in relation to the sensing target

• Minimize web or product “flutter” whenever possible to maximize sensing reliability

Output Configuration Bipolar (NPN and PNP)

Output Protection Protected against false pulse on power-up and continuous overload or short-circuit of outputs.

Adjustments

(see pages 4 - 9)

Using push buttons (“+” Dynamic and “-” Static):

Manually adjust Switch Point using “+” or “-” buttons

Dynamic TEACH (teach on-the-fly) sensitivity adjustment

Static TEACH sensitivity adjustment

Light operate/Dark operate

OFF Delay select: 0 milliseconds, 20 milliseconds or 40 milliseconds

Using Remote TEACH input (gray wire):

Dynamic TEACH (teach on-the-fly) sensitivity adjustment

Static TEACH sensitivity adjustment

Light operate/Dark operate

OFF Delay select: 0 milliseconds, 20 milliseconds or 40 milliseconds

Push button lockout for security

Page 11

R55F Series Fiber-Optic Color Mark Sensors

page

11

Banner Engineering Corp. •

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

R55F Series Sensor Hookups

Cabled Models

Quick-Disconnect Models

Mounting Brackets

Both brackets are included with sensor.

SMBR55FRA

• Side-mounting bracket

• 19 ga stainless steel

SMBR55F01

• Flat-mounting bracket

• Molded PBT polyester

Quick-Disconnect (QD) Cables

5-Pin Euro

MQDC1-506

MQDC1-515

MQDC1-530

MQDC1-506RA

MQDC1-515RA

MQDC1-530RA

2 m (6.5')

5 m (15')

9 m (30')

2 m (6.5')

5 m (15')

9 m (30')

Style Model Length Connector

Straight

Straight

Straight

Right-angle

Right-angle

Right-angle

bn

bu

wh

bk

gy

40.0 mm

(1.58")

4.5 mm

(0.18")

Load

Load

Remote Teach

2x ø5.4 mm

(0.21")

35.0 mm

(1.38")

+

10-30V dc

–

20.0 mm

(0.79")

3.5 mm

(0.14")

65.0 mm

(2.56")

29.5 mm

(1.16")

bn

bu

wh

Load

bk

Load

gy

Remote Teach

15.0 mm

(0.59")

4x R2.5

(0.10")

7.2 mm

(0.28")

4x 5.0 mm

(0.20")

+

10-30V dc

–

6.0 mm

(0.24")

35.0 mm

(1.40")

50.8 mm

(2.00")

2.5 mm

(0.10")

4.5 mm

(0.18")

10.0 mm

(0.40")

7.5 mm

(0.30")

30.4 mm

(1.20")

50.8 mm

(2.00")

64.0 mm

(2.52")

Brown Wire

Black Wire

White Wire

Blue Wire

Gray Wire

Page 12

R55F Series Glass and Plastic Fiber-Optic Color Mark Sensors

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

WARNING . . . Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessar y to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current

Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Euro-Style Field-Wireable Connectors

Contacts: Gold-plated; 4-pin models rated 250V ac/dc max., 4 A max.; 5-pin models rated 50V ac/dc max., 4A max.

Cable Diameter: 4.0 to 5.0 mm (0.16 to 0.20")

Temperature: -25° to +90°C (-13° to +194°F)

Environmental Rating: NEMA 6P, IP 67

Style

5-Pin

Right-angle

FIC-M12M5A

5-Pin

Straight

FIC-M12M5 Male

Male

FIC-M12F5A Female

FIC-M12F5 Female

Model Gender

Dimensions Pin-out

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

15.0 mm

(0.59")

15.0 mm

(0.59")

30.5 mm

(1.20")

60 mm

(2.4")

10 mm

(0.4")

M12 x 1

60 mm

(2.4")

10 mm

(0.4")

M12 x 1

41 mm

(1.6")

M12 x 1

15.0 mm

(0.59")

20 mm

(0.8")

20 mm

(0.8")

20 mm

(0.8")

20 mm

(0.8")

!

Loading...

Loading...