Page 1

R55 Expert™ Color Mark Sensors

Parallel to sensor length

Perpendicular to sensor length

Perpendicular to sensor length

CONVERGENT

Color Registration Mark Sensor with Solid-State Light Source

Features

• Outstanding color contrast sensitivity; detects 16 levels of gray scale.

• Reliable detection of the toughest color mark contrasts, including 20% yellow

against white

• Three sensing beam colors: blue, green and white, depending on model

• Fast, 50-microsecond response

• Easy-to-set automatic

Expert-style configuration options: Static and Dynamic TEACH

and Window SET, plus Manual Adjust for fine tuning via push button or remote input

• Non-volatile memory

• Ten-element light bar for clear display of received signal strength

• Fixed-convergent sensing at 10 ±3 mm (0.39" ±0.12")

• Rectangular 1.2 mm x 3.8 mm (0.05" x 0.15") sensing image at 10 mm from the lens

• Horizontal or vertical sensing image, depending on model (see table below)

• Rugged zinc alloy die-cast housing with high-quality acrylic lens suitable for food

processing applications; rated IP67, NEMA 6

• Bipolar (NPN/PNP) discrete outputs with three delay settings (0, 20 or 40 ms)

• 0 to 10 mA analog output; value provides an indication of signal strength.

• Integral cable or QD connector, depending on model

Models Beam Color Cable* Focus

R55ECG1

R55ECG1Q 6-pin Euro-Style QD

R55ECB1

R55ECB1Q 6-pin Euro-Style QD

R55ECW1

R55ECW1Q 6-pin Euro-Style QD

R55ECG2

R55ECG2Q 6-pin Euro-Style QD

R55ECB2

R55ECB2Q 6-pin Euro-Style QD

R55ECW2

R55ECW2Q 6-pin Euro-Style QD

* 9 m (30') cables are available by adding suffix “W/30” to the model number of the cabled version (e.g., R55ECG1 W/30). A model with a QD

connector requires an accessory mating cable. See page 12.

Printed in USA 12/06 P/N 59574 rev. B

Green

525 nm

Blue

475 nm

White

450-650 nm

Green

525 nm

Blue

475 nm

White

450-650 nm

6-wire 2 m (6.5')

6-wire 2 m (6.5')

6-wire 2 m (6.5')

6-wire 2 m (6.5')

6-wire 2 m (6.5')

6-wire 2 m (6.5')

Models

10 mm

(0.39")

Supply

Voltage

10-30V dc

Output

Type

Bipolar

NPN/PNP

and

Analog

0-10 mA

Sensing Image Orientation

Page 2

R55 Expert™ Color Mark Sensors

SETUP

DO

LO

OFF

Delay

Switch Point

+

DYNAMIC

–

STATIC

Dynamic (+)

Push Button

Switch Point

10-Segment

Bargraph Display

Static (–)

Push Button

DO

(Dark Operate) LED*

* Either LO or DO LED is ON

Whenever sensor has power

and is in RUN Mode

LO

(Light Operate) LED*

Delay Configuration

Indicator LED

Output Conducting

LED

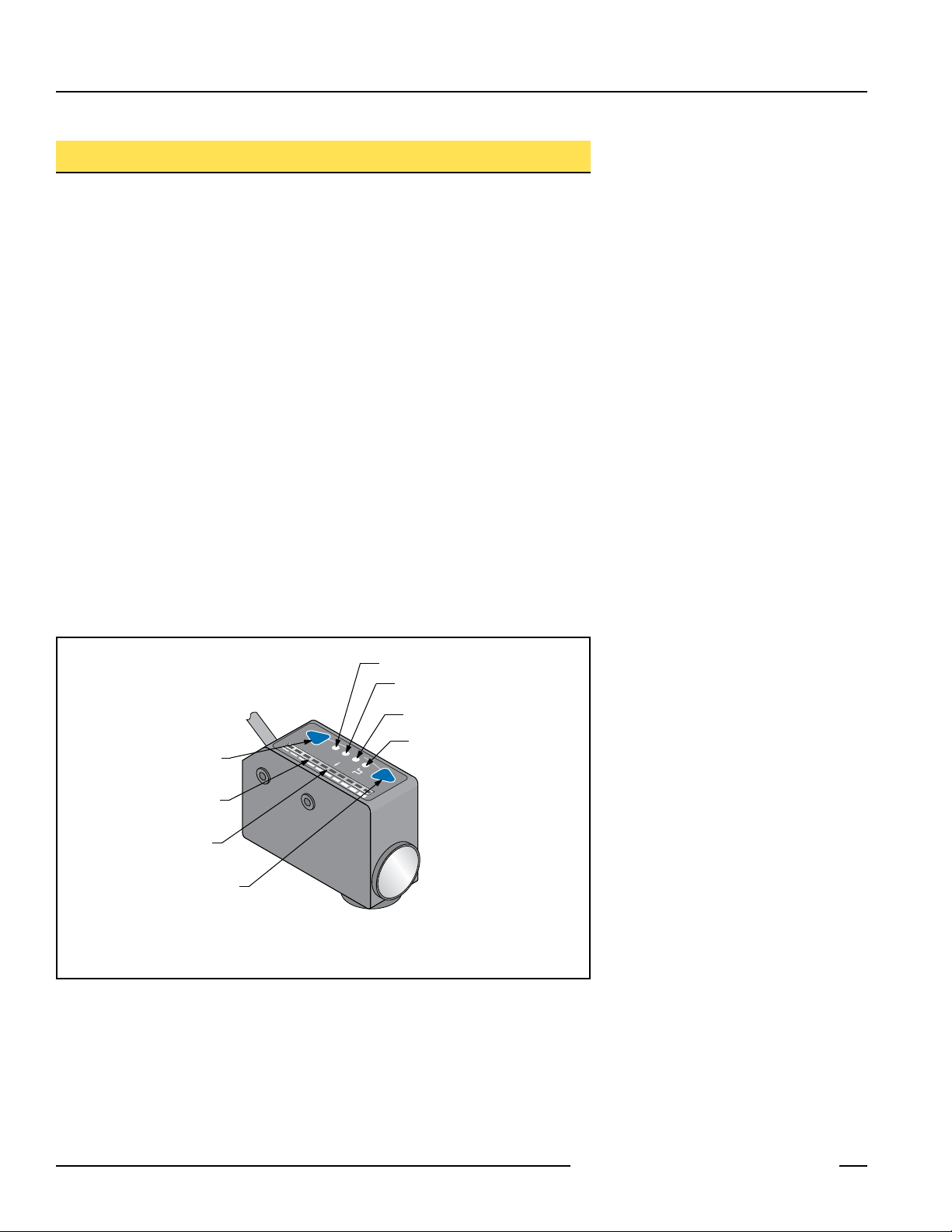

Overview

R55 Expert (R55E) offers maintenance-free, solid-state reliability for all color contrasts found

in common product and material registration applications. Fast 50-microsecond sensing

response produces excellent registration repeatability, even in ultra-high-speed applications.

This fast response, coupled with the small 1.2 x 3.8 mm (0.05" x 0.15") sensing image, allows

color marks to be made small and inconspicuous, while being reliably sensed.

The construction of the R55E is extremely robust, with a die-cast metal housing, plastic

optics, and IP67 and NEMA 6 leakproof design for harsh sensing environments. The sensor's

10-segment bargraph display and the individual indicator LEDs provide easy configuration

and status monitoring.

Indicators

The LED indicators (see Figure 1) operate as follows in RUN mode (normal operation):

Output Conducting LED: ON when outputs are active

Delay Configuration Indicator LED: OFF No OFF-delay is programmed

ON 20- or 40-ms OFF-delay is programmed

Light Operate LED: ON to indicate Light Operate configuration

Dark Operate LED: ON to indicate Dark Operate configuration

(NOTE: Since either one of these is always ON when the sensor is operating, the

combined Light/Dark Operate LEDs also provide a functional Power-ON indication.)

10-Segment Bargraph Display: indicates signal strength, with respect to the sensing

threshold (“switchpoint”).

Figure 1. R55E Series sensor features

2 P/N 59574 rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

R55 Expert™ Color Mark Sensors

Sensor Configuration

Sensor configuration is accomplished via TEACH, SET and SETUP modes. After the

sensing parameters are defined (using either TEACH or SET mode), SETUP mode may

be used to enable the delay or to change the light/dark operate status. Manual Adjust

may be used to fine-tune the thresholds (see page 7). Two push buttons, Dynamic

(+) and Static (-), or the remote wire, may be used to access and set the sensing

parameters. The ten-element signal strength bargraph display clearly displays the relative

received signal strength.

Sensor sensitivity may be configured using any of three methods. A single switching

threshold may be achieved using either Dynamic (on-the-fly) or Static TEACH, or Window

SET may be used to define a sensing window, centered on a single sensing condition.

The discrete bipolar (one NPN and one PNP) outputs may be programmed in SETUP

mode to include a 20- or 40-millisecond pulse stretcher (OFF-delay), if required. A

third, dedicated, 0 to 10 milliamp analog output may be used for applications such as

measuring or monitoring of surface brightness or texture.

Both sensing sensitivity and output setup are accomplished either by using the sensor push

buttons, or by supplying input pulses via the remote input.

Remote Configuration

The remote configuration function may be used to configure the sensor remotely or to

disable the push buttons for security. Connect the gray wire of the sensor to ground

(0V dc), with a remote programming switch connected between them. Pulse the remote

line according to the diagrams in the configuration procedures. The duration of the

individual pulses is equal to the value T:

0.04 seconds ≤ T ≤ 0.8 seconds

Returning to RUN Mode

Some TEACH and SET modes may be exited after the 90-second time-out or by exiting

the process:

• In Static TEACH or Window SET mode, press and hold the Static (-) button (or hold the

remote line) for 2 seconds. The sensor returns to RUN mode without saving any new

settings.

SETUP mode may be exited after the 30-second time-out or by exiting the process:

• In SETUP mode, press and hold both the Static (-) and Dynamic (+) buttons (or hold

the remote line) for 2 seconds. The sensor returns to RUN mode and saves the current

setting.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 59574 rev. B 3

www.bannerengineering.com • Tel: 763.544.3164

Page 4

R55 Expert™ Color Mark Sensors

+

DYNAMIC

–

STATIC

+

DYNAMIC

+

DYNAMIC

–

STATIC

–

STATIC

+

DYNAMIC

+

DYNAMIC

–

STATIC

–

STATIC

T

T T

T

T T

T T

T

T

T T

T

T T

T T

T

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

2nd Taught

Condition

1st Taught

Condition

Position

adjusted by

Manual Adjust

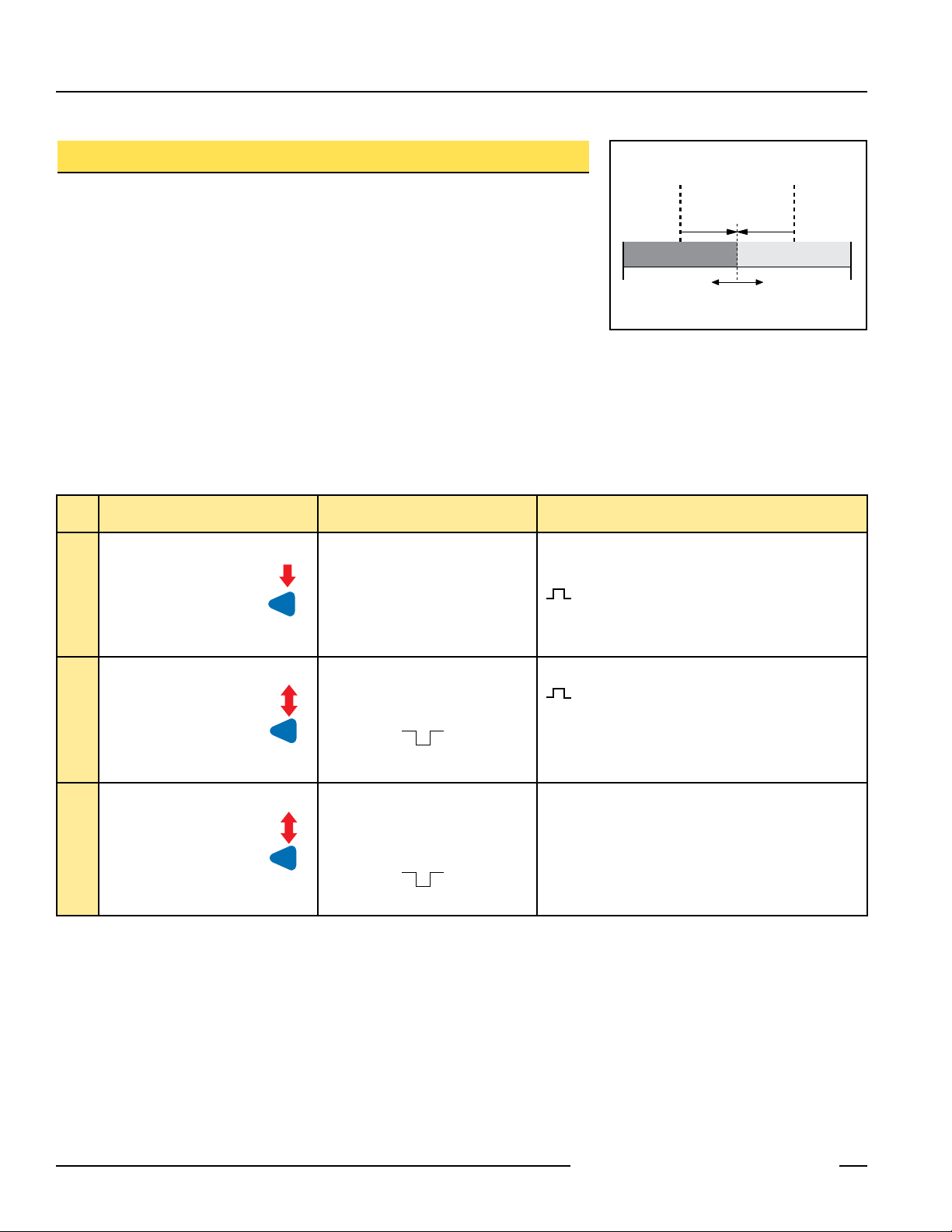

Static TEACH

• Establishes a single switching threshold

• Threshold position is adjustable using “+” and “-” buttons (Manual Adjust)

Static TEACH is the traditional setup method, used when two conditions can be

presented by the user. The sensor locates a single sensing threshold (the switchpoint)

midway between the two taught conditions, with the Output ON condition on one side,

and the Output OFF condition on the other (see Figure 2).

The first condition taught is the ON condition. The Output ON and OFF conditions can be

reversed by changing Light/Dark Operate status in SETUP mode (see page 7).

Static TEACH and Manual Adjust

Using Manual Adjust with Static TEACH moves the switching threshold. Sensitivity may

be adjusted at any time when the sensor is in RUN mode by clicking the “+” and “-”

buttons. Each click translates to 1/2 segment on the signal strength light bar. For best

sensing reliability, the light and dark conditions should register equally distant from the

switchpoint on the bargraph display.

Push Button

0.04 seconds ≤ “Click” ≤ 0.8 seconds

• Press and hold Static button

≥ 2 seconds until LO and DO

indicators alternately flash,

then release button.

Access

TEACH Mode

• Present the output ON

sensing condition.

• Single-click Static button.

Condition

TEACH Output ON

• No action required; sensor is ready

for 1st TEACH condition.

• Present output ON sensing

condition.

• Single-pulse the remote line.

Remote Line

0.04 seconds ≤ T ≤ 0.8 seconds

Push Button TEACH only:

LO and DO: Alternately flash green

: ON yellow

Light Bar: Goes OFF

LO and DO: Alternately flash green

: OFF

Light Bar: Remains OFF

Figure 2. Static TEACH (Light Operate

shown)

Result

(ready to teach output ON condition)

(ready to teach output OFF condition)

Condition

TEACH Output OFF

NOTES:

1. The sensor will return to RUN mode if either TEACH condition is not registered within 90 seconds. Also, TEACH mode may be cancelled by

pressing and holding the push button for ≥ 2 seconds. In either case, the sensor will revert to the previous conditions taught (i.e., exit without

save).

2. If the sensing conditions are accepted at the end of TEACH Output OFF Condition, the signal strength light bar flashes one of its ten segments

for three seconds to indicate relative sensing contrast. The higher the flashing segment, the higher the measured sensing contrast. High contrast

relates directly to sensing reliability. High-contrast sensing applications are most tolerant of sensing variables, such as web flutter or variations in

color mark color or print density.

4 P/N 59574 rev. B

• Present the output OFF

sensing condition.

• Single-click Static button.

• Wait 0.8 seconds.

• Present the output OFF sensing

condition.

• Single-pulse the remote line.

Contrast accepted: One light bar segment flashes for

three seconds to indicate relative contrast, and then

sensor enters RUN mode.

Contrast too low: Every other segment flashes for three

seconds to indicate low contrast, and the sensor returns

to TEACH Output ON Condition.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

Sensor positions

threshold midway

between taught conditions

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF

Output ON

Darkest Taught

Condition

Lightest Taught

Condition

Position

adjusted by

Manual Adjust

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

2nd Taught

Condition

1st Taught

Condition

Position

adjusted by

Manual Adjust

Figure 3. Dynamic TEACH (Light Operate

+

DYNAMIC

+

DYNAMIC

+

DYNAMIC

+

DYNAMIC

+

DYNAMIC

+

DYNAMIC

T

TTT

T

T T

T T T

T T

T T

T

T T

T T

T

T

TTT

T

T T

T T T

T T

T T

T

T T

T T

T

T

TTT

T

T T

T T T

T T

T T

T

T T

T T

T

shown)

R55 Expert™ Color Mark Sensors

Dynamic TEACH

• Teach on-the-fly

• Establishes a single switching threshold

• Threshold position is adjustable using “+” and “-” buttons (Manual Adjust)

Dynamic TEACH is used to configure the switching threshold during actual sensing

conditions. During Dynamic TEACH, the R55E takes multiple samples of the color mark

against its background material and automatically sets the threshold at the optimum level.

Dynamic TEACH activates the sensor’s adaptive threshold system, which continuously

tracks minimum and maximum signal levels, and automatically maintains centering of

the switchpoint between the light and dark conditions. The adaptive threshold system

remains in effect during RUN mode to automatically adjust for changes in the light or

the dark conditions. The adaptive routine saves to non-volatile memory at least once per

hour.

When Dynamic TEACH mode is used to configure sensitivity, the output ON state (light

or dark operate) will remain as it was last programmed. To change to either the light or

the dark condition, use SETUP mode (see page 7).

Dynamic TEACH and Manual Adjust

Sensitivity may be adjusted at any time when the sensor is in RUN mode by clicking the

“+” and “-” buttons. However, when a manual adjustment is made, the adaptive threshold

system is disabled (cancelled).

Access

TEACH Output ON

Return to

NOTE: If the sensing conditions are accepted at the end of Dynamic TEACH, the signal strength light bar flashes one of its ten segments for three

P/N 59574 rev. B 5

Push Button Remote Line Result

• Press and hold Dynamic button

≥ 2 seconds until LO and DO

indicators alternately flash.

TEACH Mode

• Continue depressing the

Dynamic button while

sampling light and dark

sensing conditions.

and OFF Condition

• Release the Dynamic button when

finished sampling

light and dark sensing

conditions.

Run Mode

seconds to indicate relative sensing contrast. The higher the flashing segment, the higher the measured sensing contrast. High contrast

relates directly to sensing reliability. High contrast sensing applications are most tolerant of sensing variables, such as web flutter or

variations in color mark color or print density.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

• Hold remote line low (to ground)

> 2 seconds.

• Present Output ON and OFF

sensing conditions.

• Continue to hold remote line low.

• Release remote line switch.

LO and DO: Alternately flash green

: OFF

Light Bar: Remains OFF

LO and DO: Alternately flash green

: OFF

Light Bar: Remains OFF

Contrast accepted: One light bar segment flashes for

three seconds to indicate relative contrast, and then

sensor enters RUN mode.

Contrast too low: Every other segment flashes for three

seconds to indicate low contrast, and the sensor reverts

to the previously taught conditions.

Page 6

R55 Expert™ Color Mark Sensors

Sensor positions

threshold midway

between taught conditions

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Darkest

(no signal)

Most Light

(saturated

signal)

Most Light

(saturated

signal)

Single

sensing

condition

Sensing window size

adjusted by

Manual Adjust

Output OFF Output OFF

Output OFF

Output ON

Output ON

Darkest Taught

Condition

Lightest Taught

Condition

Position

adjusted by

Manual Adjust

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

2nd Taught

Condition

1st Taught

Condition

Position

adjusted by

Manual Adjust

+

DYNAMIC

–

STATIC

+

DYNAMIC

+

DYNAMIC

+

DYNAMIC

–

STATIC

–

STATIC

–

STATIC

Present

Output ON

Condition

Double-Pulse

> 0.8 sec

T TTT

Window SET

• Establishes a single ON condition

• All other conditions (lighter or darker) result in OFF output

• Sensing window size (sensitivity) is adjustable using “+” and “-” buttons

(Manual Adjust)

The R55 Expert sensor also may be configured for a single specific target. Window SET

is most useful when a product may not always appear in the same place, or when other

signals may appear. Window SET designates a sensing window, with the Output ON

condition inside the window, and the Output OFF conditions outside the window (see

Figure 4). The sensor accepts a single sensing condition and adds switching thresholds

above and below that condition to create a sensing window. Output ON and OFF

conditions can be reversed by changing Light/Dark Operate status in SETUP mode.

Window SET and Manual Adjust

Using Manual Adjust with Window SET expands or contracts the size of the window. The

lighted LEDs on the light bar separate to a greater or lesser extent to exhibit the relative

sensing window size.

Manually adjust the sensitivity by clicking either the “+” or “-” button; the bar graph will

flash two segments centered about the sensing point. If the sensitivity is increased (-),

the two lighted segments will become closer together, and farther apart if the sensitivity

decreased (+). If segments do not flash while the sensitivity is being adjusted, the setting

has reached its maximum and cannot be adjusted further.

Figure 4. Window SET (Light Operate

shown)

Access

SET Mode

Learn Switchpoint

(Output ON Condition)

Push Button

0.04 seconds ≤ “Click” ≤ 0.8 seconds

• Press and hold Static button

≥ 2 seconds until LO and DO

indicators alternately flash.

• Release button.

• Present the Output ON sensing

condition.

• Double-click Static button.

Remote Line

0.04 seconds ≤ T ≤ 0.8 seconds

• No action required; sensor is

ready for sensing condition to be

presented.

• Present the target (output ON)

condition.

• Single-pulse the remote wire.

• Wait ≥ 0.8 second, then doublepulse the remote wire.

Result

LO and DO: Alternately flash green

: ON yellow (indicating ready to teach Output ON

condition)

Light Bar: Goes OFF

LO and DO: ON depending on condition taught

: OFF

Light Bar: Two center segments are lit if TEACH was

successful.

6 P/N 59574 rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

SETUP

DOLOOFF

Delay

Switch Point

+

DYNAMIC

–

STATIC

Press and Hold

both push buttons

≥ 2 seconds

Figure 5. SETUP Mode

T

T

T

T T

T T T

T T

T T

T T T

T T

T T

T

T T

T T

T

R55 Expert™ Color Mark Sensors

SETUP Mode

SETUP mode is used to configure discrete sensor output response for:

• Light or Dark operate

• 20- or 40-millisecond pulse stretcher (OFF-delay), if required.

It will be necessary to access SETUP mode only if the settings that result from

TEACH mode are not the settings required for the application. The status LEDs indicate

the output response configuration when the sensor is in RUN mode (see table below).

To change the output response settings;

1. Press and hold both push buttons for at least two seconds (or double-pulse the

remote line), until the signal strength light bar turns OFF.

2. Click either push button (or pulse the remote line) to toggle through the six possible

settings, indicated as follows:

Output Configuration

Delay

Indicator

LO

Indicator

DO

Indicator

Light operate with no delay OFF ON OFF

Light operate with 20 ms delay Flashing ON OFF

Light operate with 40 ms delay ON ON OFF

Dark operate with no delay OFF OFF ON

Dark operate with 20 ms delay Flashing OFF ON

Dark operate with 40 ms delay ON OFF ON

3. Press and hold both push buttons (or hold the remote line) until the signal strength

light bar turns ON, indicating return to RUN mode.

NOTE: If SETUP mode configuration is interrupted and remains inactive for 30 seconds,

the sensor returns to RUN mode with the most recent settings (i.e., exits and

saves current selection).

Locking Out (Disabling) the Push Buttons

In addition to its configuration function, the remote input may be used to disable the push

buttons for security. Disabling the push buttons prevents undesired tampering with the

configuration settings. Connect the gray wire of the sensor as described on page 3, and

four-pulse to either enable or disable the push buttons:

P/N 59574 rev. B 7

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

NOTE: Push buttons can be disabled/enabled from the remote line only.

Page 8

R55 Expert™ Color Mark Sensors

90º

Roller or

Tension Bar

Opaque,

Non-reflective

Web Material

Focus Distance

10.0 mm (0.39")

R55E

Mount the R55E perpendicular to

non-reflective (matte) materials

Approximately 15º

Focus Distance

10.0 mm (0.39")

Mount the R55E at approximately 15°

from perpendicular to transparent

and opaque reflective materials

Roller or

Tension Bar

Transparent or

Opaque Reflective

Web Material

R55E

Lens

Cap

10 ± 3 mm

Cap

Surface of

Material

Lens

10 ± 3 mm

Installation Notes

Lens Location

The lens of the R55E may be installed at either of two lens ports (see Figure 6). The lens

and the lens port cap are both threaded and may be exchanged by hand; no tools are

required. The lens and cap both include an o-ring seal.

NOTE: Lens port cap must be installed for reliable operation.

Mounting the Sensor

The R55E includes a total of eight M5 threaded holes used for mounting (see dimension

drawing on page 10). These threaded holes are positioned to match the mounting hole

patterns common to other color mark sensors. The R55E includes four

M5 x 0.8 x 6 mm stainless steel cap screws and a hex key wrench.

The R55E focus is located at 10 mm (0.39") ahead of the lens surface. The R55E must

be mounted within 3 mm (0.12") of this distance from the surface of the material for

reliable sensing (Figure 7).

Mounting Considerations

1. Whenever possible, it is a good idea to sense a web material at a location where it

passes over a tension bar or roller, to minimize the adverse effects of web “flutter” or

sag (Figure 7).

2. When sensing a color mark on a reflective (shiny) material, mount the R55E at

an angle that places the lens centerline at approximately 15° off perpendicular to

the material’s surface (see Figure 8). This “skew angle” will minimize strong direct

reflections (which tend to overwhelm the sensor), and allow the sensor to discern the

relatively small optical contrast offered by difference in colors.

3. Clear materials are poor reflectors of light. When sensing a mark printed on a clear

material (e.g., a clear poly web), position a reflective surface directly behind the clear

material that will return light to the R55E. The printed mark, regardless of its color,

then becomes the dark condition, as it blocks the light from reaching the reflective

surface. Most clear materials are also shiny; it is important also to include a 15° skew

angle when sensing clear materials (Figure 8).

Figure 6. R55E Lens Positions

Figure 7. Mounting for sensing opaque

non-reflective materials

8 P/N 59574 rev. B

Figure 8. Mounting for sensing opaque

reflective and transparent

materials

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 9

R55 Expert™ Color Mark Sensors

Specifications

Supply Input 10 to 30V dc (10% maximum ripple) at less than 80 mA, exclusive of load.

Supply Protection Circuitry Protected against reverse polarity and transient voltages.

Output Configuration Digital outputs: Bipolar. One current sourcing (PNP) and one current sinking (NPN) open-collector transistor

Analog output: Current source proportional to the received light level, updated in real time (every 50 microseconds)

Output Rating Digital outputs are 100 mA maximum (each)

Off-state leakage current < 10 microamps at 30V dc

Saturation voltage (NPN output) < 1.5V at 150 mA dc

Saturation voltage (PNP output) < 2.0V at 150 mA dc

Current Sourcing Analog output: 0 to 10 mA

Maximum load voltage drop is ≤ 2 volts

Output Protection Protected against false pulse on power-up and continuous overload or short-circuit of outputs.

Output Response 50 microseconds NOTE: 1 second delay on power-up; outputs do not conduct during this time.

Adjustments

(see pages 3–7)

Indicator LEDs 10-segment (green) light bar indicates signal strength

Construction Zinc alloy die-cast and steel housing with black acrylic polyurethane finish

Environmental Rating IEC IP67; NEMA 6

Connections PVC-jacketed 6-conductor 2 m (6.5') or 9 m (30') attached cable with internal strain relief, or 6-pin Euro-style

Operating Conditions Temperature: -10° to +55° C (+14° to 131° F)

Vibration and

Mechanical Shock

Application Notes • Do not mount the sensor directly perpendicular to shiny surfaces; position it at approximately a 15° angle in

Using push buttons (“+” Dynamic and “-” Static):

Manually adjust discrete output switchpoint using “+” or “-” buttons

Dynamic TEACH (teach on-the-fly) sensitivity adjustment

Static TEACH sensitivity adjustment

Light operate/Dark operate

OFF-delay select: 0 milliseconds, 20 milliseconds or 40 milliseconds

Using Remote TEACH input (gray wire):

Dynamic TEACH (teach on-the-fly) sensitivity adjustment

Static TEACH sensitivity adjustment

Light operate/Dark operate

OFF-delay select: 0 milliseconds, 20 milliseconds or 40 milliseconds

Lockout of push buttons for security

Light Operate: green

Dark Operate: green

Outputs Conducting: yellow

OFF-Delay (green): SETUP Mode RUN Mode

OFF — no delay OFF — no delay

Flashing — 20 ms delay ON — 20 or 40 ms Delay

ON — 40 ms delay

Lens and lens port cap are o-ring sealed

Lens is acrylic

Lens port cap and lens holder are ABS

quick-disconnect. Mating QD cables are purchased separately. See Cables, page 10.

Maximum Relative Humidity: 90% at 50° C (non-condensing)

All models meet IEC 68-2-6 and IEC 68-2-27 testing criteria.

relation to the sensing target (see page 8).

• Minimize web or product “flutter” whenever possible to maximize sensing reliability.

• The analog output is proportional to the received light signal. The analog output is unaffected by + or

– manual sensitivity adjustments.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 59574 rev. B 9

www.bannerengineering.com • Tel: 763.544.3164

Page 10

R55 Expert™ Color Mark Sensors

SETUP

DOLOOFF

Delay

Switch Point

+

DYNAMIC

–

STATIC

21.0 mm

(0.83")

30.0 mm

(1.18")

30.4 mm

(1.20")

5.0 mm

(0.20")

3.0 mm (0.12")

15.0 mm

(0.59")

80.0 mm

(3.15")

43.0 mm

(1.69")

15.0 mm (0.59")

28.0 mm

(1.10")

M5 x 0.8 Thread

x 6.3 mm Deep (8 Holes),

max. torque 45 in./lbs.

25 mm

(1.0")

39.0 mm

(1.54")

28.0 mm

(1.10")

55.5 mm

(2.19")

15 mm

(0.59")

3 mm (0.12")

18.0 mm

(0.71")

bn

wh

bu

+

–

bk

pk

Load

0-10mA

Load

10-30V dc

Remote Input

gy

bn

wh

bu

+

–

bk

Load

Load

10-30V dc

Remote Input

gy

pk

0-10mA

38 mm max.

(1.5")

M12 x 1

ø 15 mm

(0.6")

38 mm max.

(1.5")

M12 x 1

ø 15 mm

(0.6")

44 mm max.

(1.7")

White Wire

Blue Wire

Pink Wire

Black Wire

Gray Wire

Brown Wire

Dimensions

Euro-style QD Models

Style Model Length Dimensions Pinout

6-Pin

Euro-Style

Straight

6-Pin

Euro-Style

Right-Angle

10 P/N 59574 rev. B

MQDC-606

MQDC-615

MQDC-630

MQDC-606RA

MQDC-615RA

MQDC-630RA

Cabled Models

Quick-Disconnect (QD) Cables

2 m (6.5')

5 m (15')

9 m (30')

2 m (6.5')

5 m (15')

9 m (30')

Hookups

Quick-Disconnect Models

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 11

R55 Expert™ Color Mark Sensors

15.0°

50.8 mm

(2.00")

31.8 mm

(1.25")

8 x R 3.3 mm

(0.13")

12.7 mm

(0.50")

15.2 mm

(0.60")

11.4 mm

(0.45")

13.3 mm

(0.53")

24.1 mm

(0.95")

12 x R 2.6 mm

(0.10")

2.6 mm

(0.10")

2 x 12.4 mm

(0.49")

24.8 mm

(0.98")

27.9 mm

(1.10")

C

L

2 x 5.6 mm

(0.22")

2 x 7.6 mm

(0.30")

5.4 mm

(0.21")

50.8 mm

(2.00")

25.4mm

(1.00")

4 x R 6.4 mm

(0.25")

2 x 12.4 mm

(0.49")

24.8 mm

(0.98")

27.9 mm

(1.10")

C

L

2 x 5.6 mm

(0.22")

2 x 7.6 mm

(0.30")

8 x R 3.3 mm

(0.13")

12.7 mm

(0.50")

15.2 mm

(0.60")

11.4 mm

(0.45")

13.3 mm

(0.53")

24.1 mm

(0.95")

12 X R 2.6 mm

(0.10")

5.4 mm

(0.21")

50.8 mm

(2.00")

25.4mm

(1.00")

2.6 mm

(0.10")

82.6 mm

(3.25")

4 x R 6.4 mm

(0.25")

8 x R 3.3 mm

(0.13")

12.7 mm

(0.50")

15.2 mm

(0.60")

11.4 mm

(0.45")

13.3 mm

(0.53")

24.1 mm

(0.95")

2.6 mm

(0.10")

2 x 12.4 mm

(0.49")

27.9 mm

(1.10")

C

L

2 x 5.6 mm

(0.22")

2 x 7.6 mm

(0.30")

12 X R 2.6 mm

(0.10")

5.4 mm

(0.21")

50.8 mm

(2.00")

25.4mm

(1.00")

24.8 mm

(0.98")

4 x R6.4 mm

(0.25")

4x R6.4 mm (0.25")

4x R2.6

(0.10")

28.0 mm

(1.10")

8.2 mm

(0.32")

7.9 mm

(0.31")

3.8 mm

(0.15")

44.5 mm

(1.75")

15.0°

34.3 mm

(1.35")

25.4 mm

(1.00")

2.6 mm

(0.10")

8x R3.3 mm (0.13")

2x 10.2 mm

(0.40")

7.1 mm

(0.28")

8.1 mm

(0.32")

30.5 mm

(1.20")

10.2 mm

(0.40")

Accessory Mounting Brackets

SMB55A

SMB55RA

• 15° offset bracket

• 12-gauge stainless steel

• Right-angle bracket

• 12-gauge stainless steel

shown

with R58

sensor

shown

with R58

sensor

SMB55F

shown

with R58

sensor

SMB55S

• Flat mount bracket

• 12-gauge stainless steel

• 15° offset bracket

• 12-gauge stainless steel

shown

with R58

sensor

Replacement Lens

P/N 59574 rev. B 11

Models Description

UC-R55 Replacement lens for R55E

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 12

R55 Expert™ Color Mark Sensors

WARNING . . . Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A sensor failure

or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products catalog for

safety products which meet OSHA, ANSI and IEC standards for personnel protection.

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or replace,

free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty

does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or

implied.

P/N 59574 rev. B

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...