Page 1

U-GAGE QT50UVR Series Sensors

117764

Datasheet

• Fast, easy-to-use TEACH-Mode programming; no potentiometer

adjustments

• SPDT electromechanical relay for high-capacity switching

• Universal supply voltage: 85 to 264 V ac / 48 to 250 V dc

• Rugged encapsulated design for harsh environments

• Models available with factory-installed Teflon® flange and film coating

bonded over the transducer for protection from harsh environments

• Unique housing design allows for multiple mounting configurations

• Choose models with integral 2 m (6.5 ft) or 9 m (30 ft) cable, or with

Figure 1. Standard Model

Teflon® is a registered trademark of Dupont

Information about dc-voltage models is available on Banner’s website:

www.bannerengineering.com

Figure 2. Teflon-Protected Model

Mini-style or Micro-style quick-disconnect fitting

• Wide operating range of –20 °C to 70 °C (–4 °F to 158 °F)

• Temperature compensation

™

Models Sensing Range Cable

QT50UVR3W

QT50UVR3WQ 5-pin Mini-style QD

QT50UVR3F 5-wire, 2 m (6.5 ft) cable

QT50UVR3FQ1 5-pin Micro-style QD

QT50UVR3FQ 5-pin Mini-style QD

200 mm to 8 m (8 inches

to 26 ft)

5-wire, 2 m (6.5 ft) cable

1

Operation Model

Window-limit (N.O.and N.C.)QT50UVR3WQ1 5-pin Micro-style QD

Fill-level control (pump-in and

pump out)

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to

serious injury or death. This device does not include the self-checking redundant circuitry necessary

to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an

energized or de-energized sensor output condition.

Overview

Ultrasonic sensors excel in position-monitoring applications and in applications involving clear or multi-colored targets.

QT50UVR sensors are available in a variety of models: dc sensors with either analog or two discrete outputs, or universal

voltage models that feature an SPDT electromechanical relay for switching larger loads. Programming and setup for the

universal voltage models are accomplished using the sensor’s two push buttons.

Models are available with Teflon sensor face and hex nut, plus Teflon-coated transducer and special o-rings for use in

harsh environments, such as fill-level monitoring in an acidfilled tank.

1

To order the 9 m cable models, add suffix W/30 to the model number of a cabled sensor (for example, QT50UVR3W w/30).

Models with a QD connector require a mating cable.

Original Document

117764 Rev. F

21 April 2014

Page 2

C

m/s

= 20 √

273 + T

C

ft/s

=

49 √460 + T

F

C

U-GAGE QT50UVR Series Sensors

Principles of Operation

Ultrasonic sensors emit one or multiple pulses of ultrasonic energy, which travel through the air at the speed of sound. A

portion of this energy reflects off the target and travels back to the sensor. The sensor measures the total time required

for the energy to reach the target and return to the sensor. The distance to the object is then calculated using the

following formula: D = ct ÷ 2

D = distance from the sensor to the target

c = speed of sound in air

t = transit time for the ultrasonic pulse

To improve accuracy, an ultrasonic sensor may average the results of several pulses before outputting a new value.

Temperature Effects

The speed of sound is dependent upon the composition, pressure and temperature of the gas in which it is traveling. For

most ultrasonic applications, the composition and pressure of the gas are relatively fixed, while the temperature may

fluctuate.

In air, the speed of sound varies with temperature according to the following approximation:

In metric

units:

C

= speed of sound in meters per second C

m/s

TC = temperature in °C TF = temperature in °F

In English units:

= speed of sound in feet per second

ft/s

Temperature Compensation

The speed of sound changes roughly 1% per 6° C (10° F). QT50U series ultrasonic sensors have temperature

compensation available; temperature compensation will reduce the error due to temperature by about 90%.

Changes in air temperature affect the speed of sound, which in turn affects the distance reading measured by the sensor.

An increase in air temperature shifts both sensing window limits farther away from the sensor. Conversely, a decrease in

air temperature shifts both limits closer to the sensor. This shift is approximately 3.5% of the limit distance for a 20° C

change in temperature. With temperature compensation enabled, the sensor will maintain the window limits to within

1.8% over the entire -20° to +70° C (−4° to +158° F) range.

NOTE:

• If temperature compensation is enabled, exposure to direct sunlight can affect the sensor’s

ability to accurately compensate for changes in temperature..

• If the sensor is measuring across a temperature gradient, the compensation will be less

effective.

• With temperature compensation enabled, the temperature warmup drift upon power-up is less

than 1.0% of the sensing distance. After 30 minutes, the apparent switchpoint will be within

0.5% of the actual position. After 60 minutes, the apparent switchpoint will be within 0.3% of

the actual position.

Configuration

The sensor can be configured for one of three output response times and to enable or disable temperature compensation.

Both are accomplished using the sensor’s Speed push button, using the procedures described below. A button click is

defined as: 0.04 ≤ Click ≤ 0.8 sec.

1. Select the output response time.

Action

Click the Speed button until the desired output response time is

selected.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 117764 Rev. F

Result

Response LED cycles throughSolid Red, Solid Amber, and OFF

to indicate selected Output Response Time.

• Solid Red — Slow Response (1600 ms)

• Solid Amber — Medium Response (400 ms) (factory

default)

• OFF — Fast Response (100 ms)

Page 3

U-GAGE QT50UVR Series Sensors

Action Result

No further action required; sensor stores selection and remains in

RUN mode.

2. Enable or disable the temperature compensation.

Action Result

Push and hold the Speed push button for 10 seconds to enter

programming mode.

Click the Speed button to toggle between enable and disable. Response LED flashes:

Push and hold the Speed button for 10 seconds to return to Run

mode.

Response LED flashes:

• Flashing Amber — Temperature Compensation is

enabled (default).

• Flashing Red — Temperature Compensation is disabled.

• Flashing Amber — Temperature Compensation is

enabled (default).

• Flashing Red — Temperature Compensation is disabled.

• Sensor stores selection.

• Sensor returns to Run mode.

• Response LED returns to a solid color or OFF to indicate

current Output Response Time setting.

Status Indicators

Power ON/OFF LED (Green) — ON when sensor power is ON.

Signal LED (Red) — indicates incoming signal strength and condition.

Signal LED Status

ON Bright Good signal

ON Dim Marginal signal strength

OFF No signal is received 2 or target is beyond the sensor's range limitations

Output LED (Amber or Red) — indicates the target position relative to the window limits, or TEACH mode status.

Output LED Status

RUN Mode Window-Limit Sensor Models Fill-Level Control Sensor Models

ON Amber Target is within window limits Level has dropped below far limit

OFF Target is outside window limits Level has risen above near limit

TEACH Mode

ON Red Waiting for first limit to be taught

Flashing Red Waiting for second limit to be taught

Response LED (Amber or Red) — indicates sensor output response time selection.

Indicates

Indicates

Response LED Status

ON Red Slow response (1600 ms)

ON Amber Medium response (400 ms)

OFF Fast response (100 ms)

2

If no signal is received, the output reacts as if the target is beyond the far limit. The normally open output will be OFF, and the

normally closed output will be ON.

P/N 117764 Rev. F www.bannerengineering.com - tel: 763-544-3164 3

Indicates

Page 4

A

B

C

D

E

F

Output OFF Output ON Output OFF

Minimum

Limit

Maximum

Limit

Output ON Output ONOutput OFF

Minimum

Limit

Maximum

Limit

Normally Closed Output

Normally Open Output

U-GAGE QT50UVR Series Sensors

Sensor Programming

Two TEACH methods may be used to program the sensor, using the TEACH button:

• Teach individual minimum and maximum limits.

• Use the Auto-Window feature to center a sensing window around the taught position.

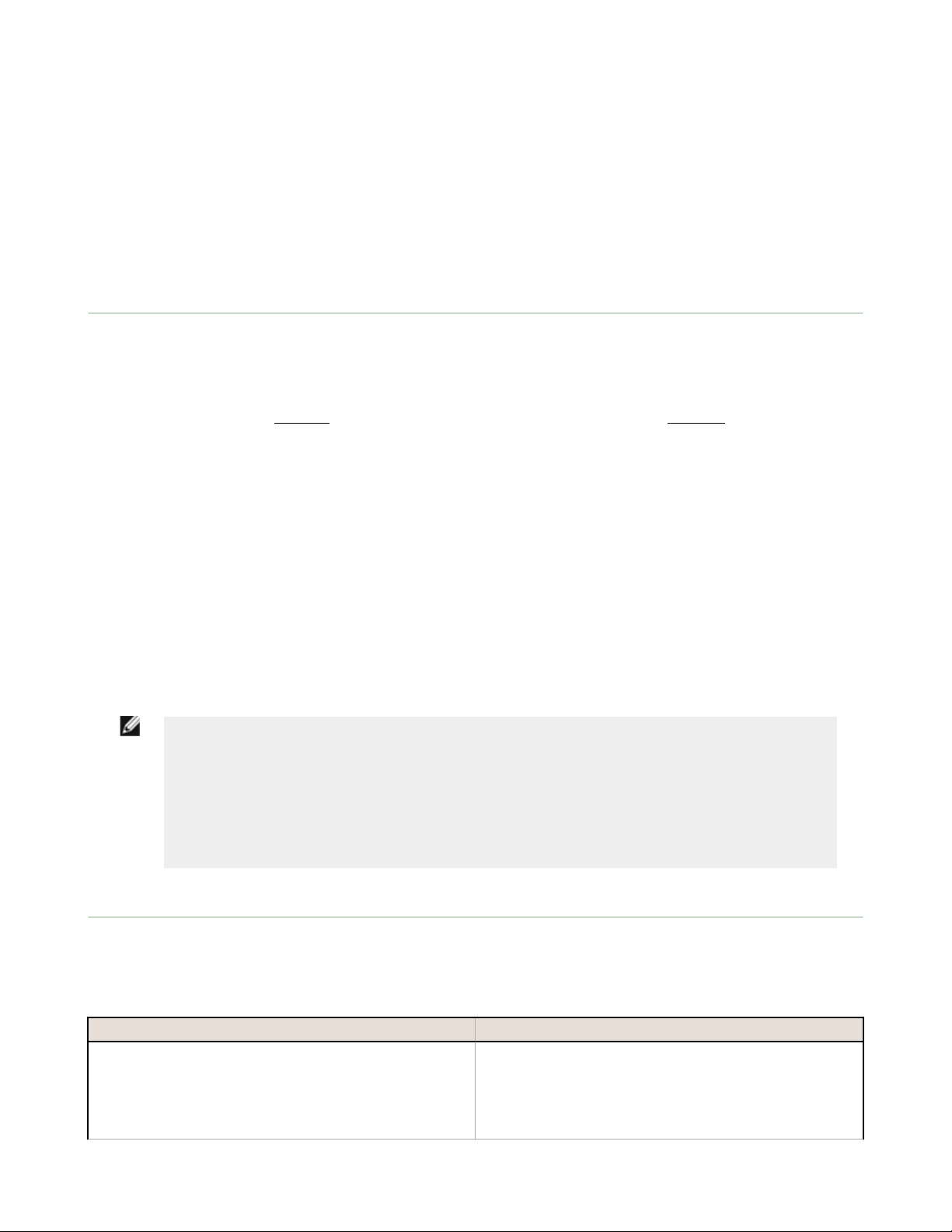

A - TEACH button

B - Sensor power indicator

C - Target signal strength indicator

D - Speed button

E - Output response time indicator

F - Output ON indicator

Figure 3. Sensor features

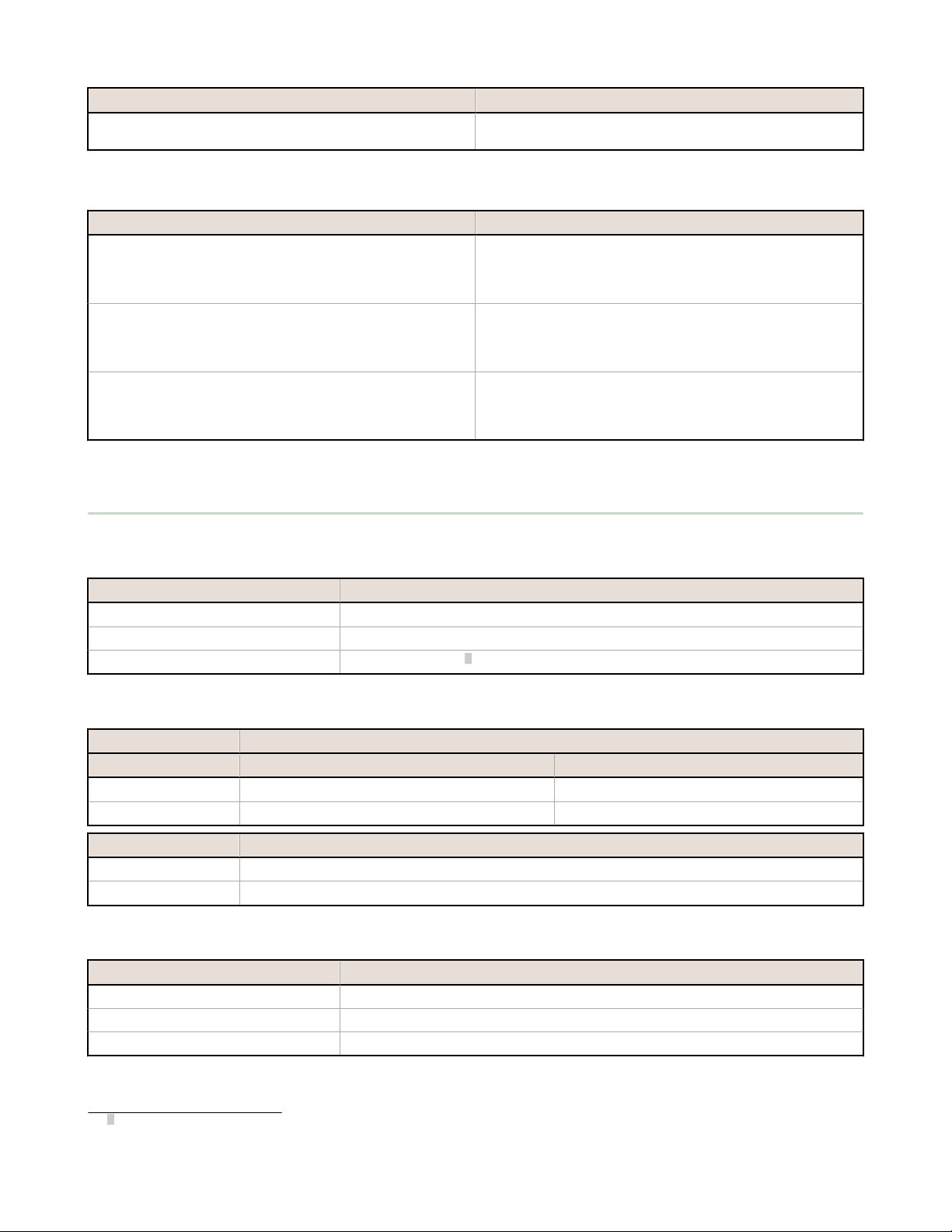

Teaching Minimum and Maximum Limits

Teach procedures are identical for window-limit and filllevel control models. Window-limit models function as

shown in the figure on the right, and fill-level control

models function as shown in Figure 5 on page 5. To

readjust minimum or maximum limits, repeat the teach

procedure.

A button click is defined as: 0.04 s. ≤ Click ≤ 0.8 s.

Figure 4. Teaching independent minimum and maximum limits —

1. Enter programming mode.

Action

Push and hold TEACH button for 2 seconds Output LED turns solid red and the sensor waits for first limit

window limit models

Result

2. Teach the first limit.

Action

Position the target for the first limit.

Click the TEACH button. The sensor learns the first limit position and the Output LED

3. Teach the second limit.

4 www.bannerengineering.com - tel: 763-544-3164 P/N 117764 Rev. F

Result

changes to flashing red

Page 5

Pump-In Application

(using Normally Open Output)

Pump-Out Application

(using Normally Closed Output)

Initial Tank Level -

Outputs are INACTIVE

Level Drops Below Far Limit -

Outputs ACTIVATE

Level Rises Above Near Limit -

Outputs DEACTIVATE

1

Flow

Flow

Initial Tank Level -

Outputs are INACTIVE

Level Rises Above Near Limit -

Outputs ACTIVATE

Level Drops Below Far Limit -

Outputs DEACTIVATE

Pump Control

Pump Control

Level Rises Above Near Limit -

Output DEACTIVATES

Level Rises Above Near Limit -

Outputs DEACTIVATE

Initial Tank Level -

Output is INACTIVE

Level Rises Above Near Limit -

Outputs DEACTIVATE

Level Drops Below Far Limit -

Output ACTIVATES

Initial Tank Level -

Outputs are INACTIVE

Level Drops Below Far Limit -

Outputs ACTIVATE

Level Rises Above Near Limit -

Outputs DEACTIVATE

Level Rises Above Near Limit -

Output ACTIVATES

Level Rises Above Near Limit -

Outputs DEACTIVATE

Initial Tank Level -

Output is ACTIVE

Level Rises Above Near Limit -

Outputs DEACTIVATE

Level Drops Below Far Limit -

Output DEACTIVATES

Output OFF Output ON Output OFF

Position

+ 100 mm

Position

- 100 mm

Taught Position

Output ON Output ON

Output OFF

Position

+ 100 mm

Position

- 100 mm

Taught Position

Normally Closed Output

Normally Open Output

U-GAGE QT50UVR Series Sensors

Action Result

Position the target for the second limit.

Click the TEACH button. The sensor stores both limits and Output LED turns solid amber.

The sensor returns to Run mode.

The Fill-Level Control mode provides the switching logic required for fill-level, web tensioning control, and similar

applications. In this mode, the output energizes when the target reaches the first sensing window limit, and stays

energized until the target moves to the second limit. The output then de-energizes at the second limit and does not reenergize until the target moves, again, to the first limit.

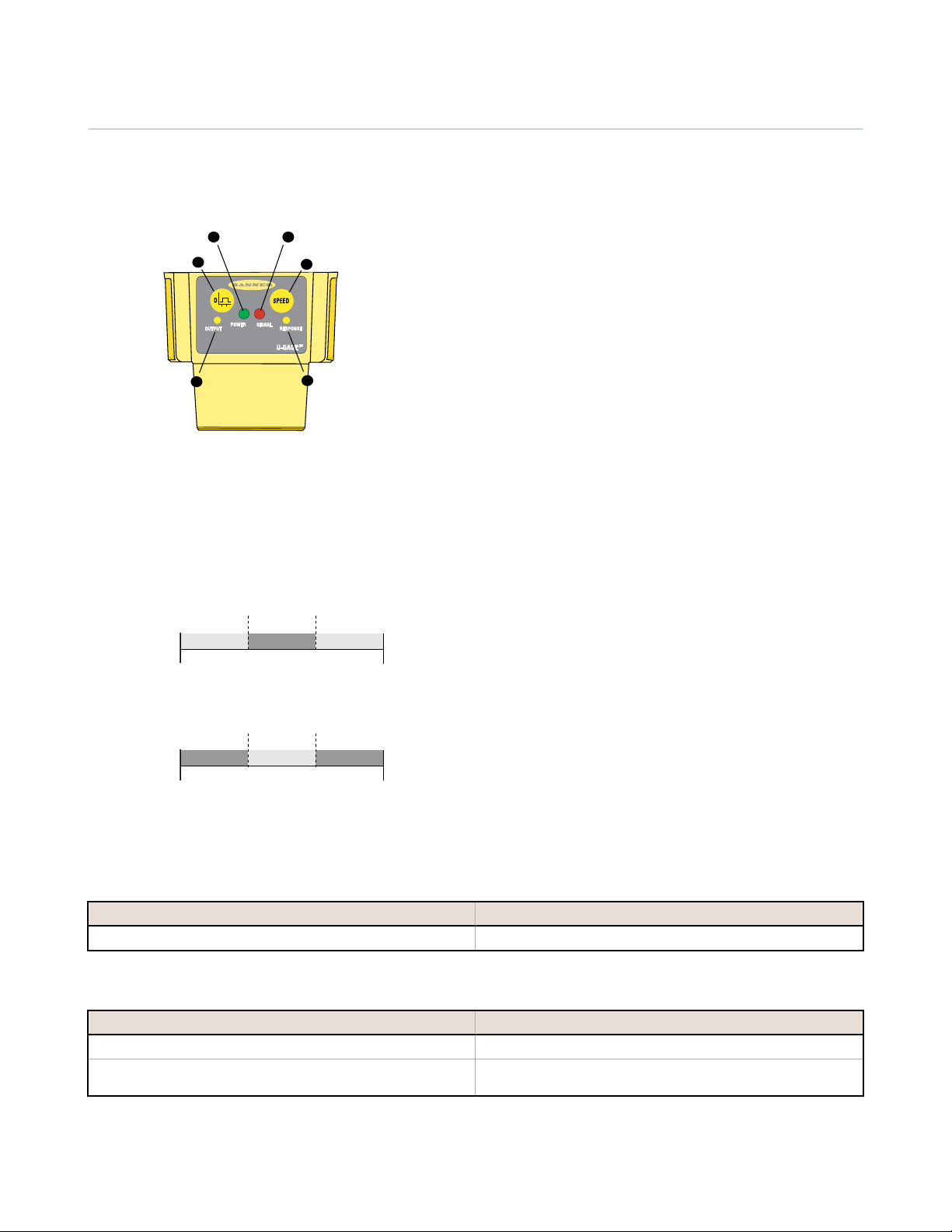

Teaching Limits Using the Auto-Window Feature

Figure 6. Using the Auto-Window feature for programming

1. Enter programming mode.

Action

Push and hold TEACH push button for 2 seconds. Output LED turns solid red and the sensor waits for first limit.

Figure 5. Fill-Level Control

Teach procedures are identical for window-limit and filllevel control models. Teaching the same limit twice

automatically centers a 200 mm window on the taught

position. To readjust the sensing midpoint, repeat the teach

procedure.

A button click is defined as: 0.04 s. ≤ Click ≤ 0.8 s.

Result

2. Teach the first limit.

P/N 117764 Rev. F www.bannerengineering.com - tel: 763-544-3164 5

Page 6

Output OFF

Taught Position

(e.g., wall or floor)

Position

-100 mm

Position

+100 mm

Sensor

Output

ON

Sensor

Output

OFF

Any object in this area will switch the output,

whether or not the object returns a good signal to the sensor.

Sensing Range

200 mm

Output ON

QT50U Chemical-Resistant Sensor

Tank Section

O-Ring

O-Ring

Threaded Teflon

Nut (included)

U-GAGE QT50UVR Series Sensors

Action Result

Position the target at the desired midpoint for the sensing

window.

Click the TEACH button. Output LED changes to flashing red

3. Teach the second limit.

Action Result

Without moving the target, click the button again. The sensor stores sensing window and the Output LED turns solid

amber. The sensor returns to Run mode.

Figure 7. An application for Auto-Window feature (retroreflective mode)

Installing the Chemical-Resistant Models

The sensor may be threaded directly into the side of a tank (see dimensions for hole diameter and thread specifications),

or into a non-threaded hole, using the included threaded nut. Recommended through-hole size: 56.5 ± 0.5 mm.

For a non-threaded hole, install an o-ring onto the flange, and insert the flange completely into the hole until the sensor

front surface is against the tank’s exterior surface. Place the other o-ring into the groove on the Teflon nut, and thread the

nut onto the flange. Tighten enough to eliminate gaps between the flange and the tank surface. This will ensure that the orings are fully compressed.

Figure 8. Installing a chemical-resistant sensor model into a threaded hole in a tank

6 www.bannerengineering.com - tel: 763-544-3164 P/N 117764 Rev. F

Page 7

Effective Beam Width

Target Distance

-200 mm

-400 mm

-600 mm

200 mm

400 mm

0

600 mm

800 mm

1000 mm

-800 mm

-1000 mm

0 1 m

(3.3')

2 m

(6.6')

3 m

(9.8')

4 m

(13.1')

5 m

(16.4')

6 m

(19.6')

7 m

(22.9')

8 m

(26.2')

8"

-8"

0

16"

-16"

24"

-24"

31"

-31"

-40"

40"

25 mm Rod

500 mm Plate

-10

-20

-30

10

0

20

30

40

-40

0

Target Distance (m)

Target Rotation (deg)

1 m

(3.3’)

2 m

(6.6’)

3 m

(9.8’)

4 m

(13.1’)

5 m

(16.4’)

6 m

(19.6’)

7 m

(22.9’)

8 m

(26.2’)

U-GAGE QT50UVR Series Sensors

Specifications

Sensing Range

200 mm to 8 m (8 inches to 26 feet)

Supply Voltage

Universal Voltage: 85 to 264 V ac, 50/60 Hz / 48 to 250 V dc (1.5

watts maximum, exclusive of load)

Supply Protection Circuitry

Protected against transient over-voltages; DC wiring is without regard

to polarity

Ultrasonic Frequency

75 kHz burst, rep. rate 96 ms

Delay at Power-up

1.5 seconds

Output Configuration

SPDT (Single-Pole, Double-Throw) electromechanical relay output

Output Ratings

Max. switching power (resistive load): 2000 VA, 240 W (1000 VA,

120 W for sensors with Micro-style QD)

Max. switching voltage (resistive load): 250 V ac, 125 V dc

Max. switching current (resistive load): 8 A at 250 V ac, 8 A at 30

V dc derated to 200 mA at 125 V dc (4 A max. for sensors with Microstyle QD)

Min. voltage and current: 5 V dc, 10 mA

Mechanical life of relay: 50,000,000 operations

Electrical life of relay at full resistive load: 100,000 operations

Output Response Time

Selectable 1600 ms, 400 ms or 100 ms

Temperature Effect

Uncompensated: 0.2% of distance/°C

Compensated: 0.02% of distance/°C

Hysteresis

Window-Limit Sensor Models: 5 mm

Fill-Level Control Sensor Models: 0 mm

Repeatability

1.0 mm

Minimum Window Size

20 mm

Adjustments

Sensing Limits: TEACH-Mode programming of near and far limits

Sensor Configuration: Output response time and temperature

compensation mode

Factory Default Settings: 400 ms output response; Temperature

compensation enabled

Indicators

Green Power On LED: Indicates power is ON.

Red Signal LED: Indicates target is within sensing range, and the

condition of the received signal.

Output indicator (bicolor amber/red): Indicates output status or TEACH

mode.

Response indicator (bicolor amber/red): Indicates output response time

selection.

Construction

Transducer: Ceramic/Epoxy composite

Housing: ABS

Membrane Switch: Polyester

CRFV Models: Teflon face, flange, hex nut and transducer coating;

Viton® o-ring

Operating Conditions

Temperature: −20 °C to +70 °C (−4 °F to +158 °F)

Maximum Relative Humidity: 100%

Connections

2 m (6.5 ft) or 9 m (30 ft) shielded 5-conductor (with drain) PVC

jacketed attached cable or 5-pin Micro-style quick-disconnect or 5-pin

Mini-style quick-disconnect fitting.

Environmental Rating

Leakproof design is rated IEC IP67; NEMA 6P

Vibration and Mechanical Shock

All models meet Mil Std. 202F requirements. Method 201A (vibration:

10 to 60 Hz max., double amplitude 0.06", maximum acceleration

10G). Also meets IEC 947-5-2 requirements: 30G 11 ms duration, half

sine wave.

Temperature Warmup Drift

Less than 1.0% of sensing distance upon power-up with Temperature

Compensation enabled

Application Notes

Objects passing inside the specified minimum sensing distance (200

mm) may produce a false response.

Certifications

Performance Curves

QT50U Effective Beam Pattern

P/N 117764 Rev. F www.bannerengineering.com - tel: 763-544-3164 7

QT50U (with 500 mm Plate) Maximum Target

Rotation Angle

Page 8

67.4 mm

[2.66”]

38.1 mm

[1.5”]

18 mm

[0.71”]

66 mm

[2.6”]

84.2 mm

[3.32”]

33 mm

[1.3”]

Temperature

Sensor Location

Internal thread 1/2” NPSM

External thread M30 x 1.5

37 mm

[1.46”]

4x 4.4 mm dia

[0.17” dia]

50.8 mm

[2”]

50.8 mm

[2”]

34.2 mm

[1.35”]

34.2 mm

[1.35”]

U-GAGE QT50UVR Series Sensors

Dimensions

Cabled Models 5-pin Mini-style Models

Chemical-Resistant Models

5-pin Euro-style

Models

74.1 mm (2.92")

67.0 mm (2.64")

M56 x 1.5

35.0 mm (1.38")

10.0 mm (0.39")

8 www.bannerengineering.com - tel: 763-544-3164 P/N 117764 Rev. F

73.1 mm (2.88")

66.0 mm (2.60")

Page 9

Load

bk

ye

bn

bu

wh

85-264V ac, 50/60 Hz

48-250V dc**

shield*

Output Current

8A Max.

bk

ye

bn

bu

wh

shield*

Output Current

(4A or 8A Max.)***

Load

85-264V ac, 50/60 Hz

48-250V dc**

bk

ye

bn

bu

wh

shield*

Output Current

8A Max.

Load

85-264V ac, 50/60 Hz

48-250V dc**

bk

ye

bn

bu

wh

shield*

Load

Output Current

(4A or 8A Max.)***

85-264V ac, 50/60 Hz

48-250V dc**

7/8-16UN-2B

ø 28 mm max.

(1.1")

61 mm max.

(2.4")

4

3

1

5

2

U-GAGE QT50UVR Series Sensors

Wiring

Cabled Models QD Models

Normally Open/Pump-In Normally Open/Pump-In

Normally Closed/Pump-In

* Banner recommends that the shield wire be connected to earth ground.

** DC wiring is without regard to polarity

*** 4 A max. for sensors with Micro-style QD; 8 A max. for sensors with Mini-style QD.

Normally Closed/Pump-In

Accessories

5-Pin Mini-Style Cordsets with Shield

Model Length Style Dimensions Pinout (Female)

MBCC2-506 1.83 m (6 ft)

MBCC2-515 4.57 m (15 ft)

Straight

MBCC2-530 9.14 m (30 ft)

P/N 117764 Rev. F www.bannerengineering.com - tel: 763-544-3164 9

1 = Brown

2 = White

3 = Blue

4 = Black

5 = Yellow

Page 10

42 Typ.

ø 14.5

1/2-20 UNF-28

3

2

5

1

4

38 mm max.

1/2-20UNF-2B

ø 15 mm

38 mm

max.

67

58

29

B

A

70

57

A

B

C

57

ø 49.8 mm

(1.96")

49.4 mm

1.94"

25.0 mm

(0.98")

10.0 mm

(0.39")

65.0 mm

(2.56")

64.0 mm

(2.52")

2" NPT Threads

U-GAGE QT50UVR Series Sensors

5-Pin Micro-Style Cordsets with Shield

Model Length Style Dimensions Pinout (Female)

MQVR3S-506 1.83 m (6 ft)

MQVR3S-515 4.57 m (15 ft)

Straight

MQVR3S-530 9.14 m (30 ft)

MQVR3S-506RA 1.83 m (6 ft)

1 = Brown

2 = White

3 = Yellow

4 = Black

5 = Blue

MQVR3S-515RA 4.57 m (15 ft)

Right Angle

MQVR3S-530RA 9.14 m (30 ft)

Brackets

SMB30SC

• Swivel bracket with 30 mm

mounting hole for sensor

• Black reinforced

thermoplastic polyester

• Stainless steel mounting and

swivel locking hardware

included

Hole center spacing: A=ø 50.8

Hole size: A=ø 7.0, B=ø 30.0

SMB30MM

• 12-ga. stainless steel bracket

with curved mounting slots

for versatile orientation

• Clearance for M6 (¼ in)

hardware

• Mounting hole for 30 mm

sensor

Hole center spacing: A = 51, A to B = 25.4

Hole size: A = 42.6 x 7, B = ø 6.4, C = ø 30.1

SAFQT50U • PVC mounting flange mounts to the front of a QT50U sensor (not

for use with chemical-resistant models).

• Adapts sensor to thread into standard 50.8 mm (2 in) NPT female

threads

10 www.bannerengineering.com - tel: 763-544-3164 P/N 117764 Rev. F

Page 11

U-GAGE QT50UVR Series Sensors

SAFQT50U • PVC mounting flange mounts to the front of a QT50U sensor (not

for use with chemical-resistant models).

• Adapts sensor to thread into standard 50.8 mm (2 in) NPT female

threads

1. Place o-ring in flange groove.

2. Assemble sensor onto threaded flange as shown, using the M4 screws

supplied with the QT50U sensor.

3. Using the supplied hex wrench, torque screws to approximately 1.1 kg/m

(10 in/lbs).

4. Mount sensor/flange assembly into the 50.8 mm (2 in) NPT fitting.

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...