Banner PresencePLUS P4 COLOR User Manual

PresencePLUS® P4 OMNI/OMNI

1.3/OMNI Color

User's Manual

P/N 125808 rev. D — 2010R1

Contents

Chapter 1: Product Support and Maintenance..........................................7

Chapter 2: System Description ..................................................................9

Chapter 3: Getting Started.........................................................................19

1.1 Product Support........................................................................................................7

1.2 Maintenance..............................................................................................................8

2.1 P4 Vision Sensors.....................................................................................................9

2.1.1 Typical P4 Vision Application...........................................................................9

2.1.2 PresencePLUS® P4 Components.................................................................10

2.1.3 P4 Cable Connections..................................................................................11

2.2 Software Overview..................................................................................................12

2.2.1 Main Menu Toolbar .......................................................................................12

2.2.2 Image Window...............................................................................................13

2.2.3 Navigation/Results Window...........................................................................14

2.2.4 Configuration Window...................................................................................16

2.2.5 Status Window..............................................................................................17

3.1 Installing the PresencePLUS Software...................................................................19

3.1.1 Installing the Software...................................................................................19

3.1.2 Starting Up the Software...............................................................................19

3.2 Typical Setup and Startup Sequence......................................................................23

3.3 Startup and Troubleshooting....................................................................................23

3.3.1 General Troubleshooting...............................................................................24

3.4 Setting Up Hardware Parameters............................................................................25

3.5 Building an Inspection.............................................................................................25

Chapter 4: Setup.........................................................................................27

4.1 Setup Screen...........................................................................................................27

4.2 Capturing a Reference Image.................................................................................27

4.3 Focus Tab................................................................................................................27

4.3.1 Reference Image Source..............................................................................28

4.3.2 Focus Value...................................................................................................29

4.3.3 Auto Exposure...............................................................................................29

4.4 Trigger Tab...............................................................................................................30

4.4.1 Trigger Settings.............................................................................................31

4.4.2 Resolution.....................................................................................................31

4.5 Advanced Tab..........................................................................................................32

4.6 Considerations When Setting up Color Inspections................................................33

4.6.1 Primary Colors..............................................................................................33

4.6.2 Setting up a Color Inspection........................................................................34

Chapter 5: Tools Screen ...........................................................................39

5.1 Overview.................................................................................................................39

5.2 Typical Build/Modify Procedure...............................................................................39

5.2.1 Choosing a Tool.............................................................................................39

5.2.2 Adding a Tool.................................................................................................40

5.2.3 Adding a Test Tool.........................................................................................40

5.2.4 Renaming Tools.............................................................................................40

5.2.5 Removing a Tool............................................................................................40

5.3 Quick Teach.............................................................................................................40

5.4 Load Tab..................................................................................................................41

5.4.1 Flexible Inspection Loading...........................................................................42

5.4.2 Inspection Storage Capacity.........................................................................43

5.4.3 Opening an Inspection from the Sensor or a Library....................................43

iiiMinneapolis, MN USABanner Engineering Corp.

2/2010PresencePLUS® P4 OMNI/OMNI 1.3/OMNI Color

Chapter 6: System Setup Dialog...............................................................45

6.1 Sensor Select Tab...................................................................................................45

6.1.1 Change Sensor IP Address...........................................................................46

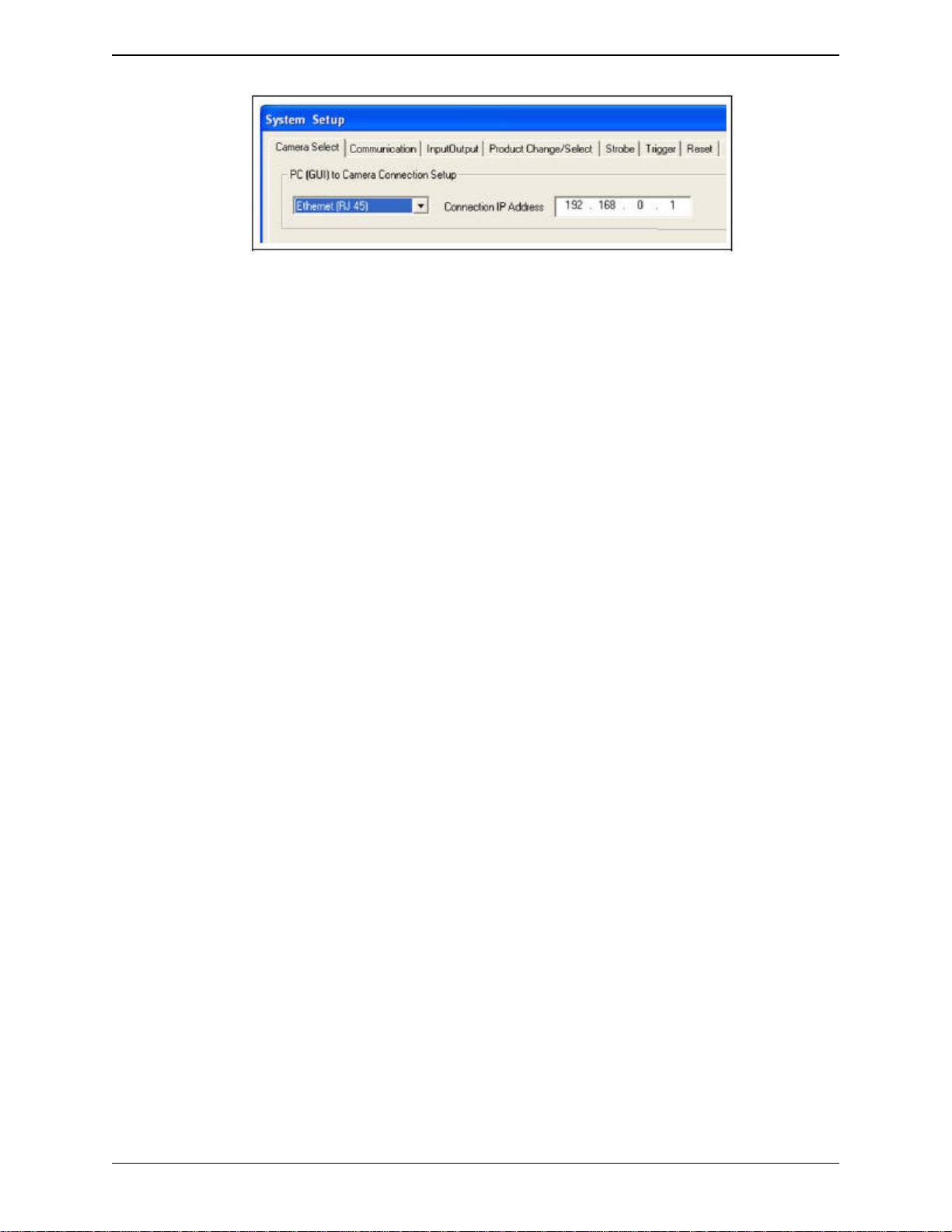

6.1.2 PC (GUI) to Sensor Connection Setup.........................................................47

6.1.3 IP Address History........................................................................................48

6.2 Communication Tab.................................................................................................49

6.2.1 Communication Setup...................................................................................50

6.2.2 Remote Command Channel Configuration ..................................................54

6.2.3 PresencePLUS/Kawasaki Vision Guidance and Inspection..........................61

6.2.4 Using Custom_ASCII to Communicate with an External Device Over Ethernet.75

6.3 Input/Output Tab......................................................................................................76

6.3.1 P4 Input/Output Tab......................................................................................78

6.4 Strobe Tab...............................................................................................................80

6.4.1 Strobe Width..................................................................................................81

6.4.2 Level..............................................................................................................82

6.5 Units Tab..................................................................................................................82

6.5.1 Select Conversion Units................................................................................83

6.5.2 Configure with Known Distance....................................................................84

6.6 Reset Tab................................................................................................................86

6.7 Start-Up Inspection Tab...........................................................................................87

6.8 NTSC Tab................................................................................................................88

6.9 Language Tab..........................................................................................................89

6.10 Tools Configuration................................................................................................90

6.10.1 Standard Mode............................................................................................91

6.10.2 Enhanced Mode..........................................................................................91

6.10.3 Custom Mode..............................................................................................91

6.10.4 Tool Licensing..............................................................................................92

Chapter 7: PresencePLUS Software Tools...............................................93

7.1 ROI Types................................................................................................................93

7.1.1 Linear ROI.....................................................................................................93

7.1.2 Area ROI.......................................................................................................93

7.1.3 Search ROI...................................................................................................93

7.2 Location Tools..........................................................................................................94

7.2.1 Locate Tool....................................................................................................94

7.2.2 Geometric Find Tool....................................................................................101

7.2.3 Pattern Find Tool.........................................................................................108

7.2.4 Blob Find Tool..............................................................................................111

7.3 Vision Gray Scale Tools.........................................................................................122

7.3.1 Average Gray Scale Tool.............................................................................122

7.3.2 Blob Detect Tool..........................................................................................125

7.3.3 Circle Detect Tool........................................................................................137

7.3.4 Edge Tool....................................................................................................142

7.3.5 Geometric Count Tool .................................................................................149

7.3.6 Line Detect Tool...........................................................................................155

7.3.7 Object Tool..................................................................................................158

7.3.8 Pattern Count Tool.......................................................................................167

7.4 Vision Color Tools..................................................................................................170

7.4.1 Average Color Tool......................................................................................170

7.4.2 Color Blob Tool............................................................................................174

7.4.3 Color Match Tool.........................................................................................187

7.5 Premium Vision Tools............................................................................................190

7.5.1 Barcode Tool...............................................................................................190

7.5.2 Barcode Tool Advanced Tab........................................................................193

7.5.3 Barcodes Read by Banner BCR.................................................................196

7.5.4 Bead Tool....................................................................................................200

7.5.5 Optical Character Recognition (OCR) Tool.................................................206

7.5.6 Trainer.........................................................................................................208

7.5.7 Advanced Tab..............................................................................................223

7.5.8 Optical Character Verification (OCV) Tool...................................................224

7.5.9 Trainer.........................................................................................................227

7.5.10 Advanced Tab............................................................................................242

7.5.11 OCV Tool and the Remote Command Channel........................................243

7.6 Analysis Tools........................................................................................................244

Banner Engineering Corp.Minneapolis, MN USAiv

PresencePLUS® P4 OMNI/OMNI 1.3/OMNI Color2/2010

7.6.1 Communication Tool....................................................................................244

7.6.2 Coordinate Tool...........................................................................................259

7.6.3 Math Tool.....................................................................................................263

7.6.4 Measure Tool...............................................................................................268

7.6.5 String Tool...................................................................................................290

7.6.6 Test Tool......................................................................................................297

Chapter 8: Communication Tool Setup...................................................317

8.1 Ethernet Connection.............................................................................................317

8.2 Serial Connection..................................................................................................318

8.3 Overview of Testing the Communication Tool........................................................319

8.4 Detailed Steps for Testing the Communication Tool..............................................319

8.4.1 Testing Ethernet Communications...............................................................319

8.4.2 Testing Serial Communications...................................................................320

8.5 Troubleshooting Ethernet Connections..................................................................320

8.6 Troubleshooting Serial Connections......................................................................321

8.7 Remote Command Channel Configuration ..........................................................321

8.7.1 Remote Command Set ...............................................................................321

8.7.2 RCC Return Values.....................................................................................324

8.7.3 Frame Tag Numbers ...................................................................................325

8.7.4 Command Processing ................................................................................325

8.7.5 RCC Log ....................................................................................................326

8.7.6 Frame and Field Delimiters.........................................................................326

Chapter 9: Teach......................................................................................329

9.1 Quick Teach...........................................................................................................329

9.2 Teach.....................................................................................................................329

9.3 Teach Screen.........................................................................................................329

9.3.1 Teaching an Inspection................................................................................330

9.4 Remote Teach.......................................................................................................332

9.4.1 Understanding Remote Teach.....................................................................332

9.4.2 Remotely Teaching a Tool...........................................................................332

9.4.3 Timing Sequence........................................................................................332

9.4.4 Remote Teach Results................................................................................333

Chapter 10: Run Screen...........................................................................335

10.1 Selected Inspection.............................................................................................336

10.2 Display.................................................................................................................336

10.3 Capture Control...................................................................................................336

10.4 Results................................................................................................................337

10.5 Inputs...................................................................................................................337

10.6 Outputs................................................................................................................337

10.7 Product Select.....................................................................................................338

10.8 System................................................................................................................338

10.9 Start/Stop............................................................................................................338

10.10 Select Tab..........................................................................................................338

10.11 Log Tab..............................................................................................................339

10.12 Run Results.......................................................................................................341

10.13 Run Player/Recorder.........................................................................................343

10.13.1 Record.....................................................................................................345

10.13.2 Playback..................................................................................................347

Chapter 11: Product Change...................................................................349

11.1 Product Change Specifications...........................................................................349

11.2 Product Select Input Specifications.....................................................................350

Chapter 12: P4 Product Change and Product Select Timing...............351

12.1 One Pulse Set Overview.....................................................................................351

12.1.1 Product Select in One-Pulse Configuration...............................................352

12.2 Three Pulse Set Overview...................................................................................352

12.2.1 Product Select in Three-Pulse Configuration............................................352

Chapter 13: Saving Inspections..............................................................355

13.1 Saving Inspections to a Vision Sensor................................................................356

vMinneapolis, MN USABanner Engineering Corp.

13.2 Saving Inspections to a PC or Network Drive.....................................................357

Chapter 14: Backing Up and Restoring Vision Sensor Data................359

14.1 Backing up Vision Sensor Data...........................................................................359

14.2 Restoring Vision Sensor Data.............................................................................363

Chapter 15: Dimensions and Specifications.........................................367

15.1 Sensor Dimensions.............................................................................................367

15.1.1 Right-Angle Sensor Dimensions...............................................................367

15.1.2 Right-Angle Sensor Mounting Bracket Dimensions..................................367

15.1.3 In-Line Sensor Dimensions.......................................................................368

15.1.4 In-Line Sensor Mounting Bracket Dimensions..........................................368

15.2 Sensor Specifications..........................................................................................369

15.3 Monitor Specifications - 9" CRT..........................................................................370

15.4 Monitor Specifications - Flat Panel 8" LCD Color................................................371

15.5 Ethernet Communication Specifications..............................................................372

15.6 Serial Port Communication Specifications..........................................................373

...................................................................................................................375

Product Support and Maintenance

This section provides general Banner resources and specific documentation for installers and operators of this

PresencePLUS Vision Sensor.

Attention: Not to be Used for Personal Protection.

Never use these products as sensing devices for personel protection. Doing so could lead to serious injury or

death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition.

Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI, and IEC standards

for personnel protection.

Chapter 1

1.1 Product Support

Banner provides the following resources for quickly setting up and operating the sensor.

Documentation

Online Help

The PresencePLUS online help is available from the from the Help menu item within the PresencePLUS software.

You can also get targeted help while on any system tab or dialog by pressing the <F1> key.

PDF Documentation

The PresencePLUS Sensor documentation is available in a convenient printable format (PDF) on the installation CD

or on the Banner Web site

Banner Website

The most current PresencePLUS information, documentation, and software updates are available at the following

Banner website page:

www.bannerengineering.com

Warranty Service

The PresencePLUS Vision Sensor is designed for reliability. Do not open the housing; it contains no field-replaceable

components. If repair is necessary, do not attempt to repair the sensor yourself; return the unit to the factory. Should

it become necessary to return a sensor to the factory, please do the following:

1. Contact the Banner Factory Application Engineering group at the address or numbers listed below. They will

attempt to trouble shoot the system from your description of the problem. If they conclude that a component is

defective, they will issue an RMA (Return Merchandise Authorization) number for your paperwork and give you

the proper shipping address.

2. Pack the sensor carefully. Damage which occurs during return shipping is not covered by warranty.

Factory Support

Call, e-mail, fax, or write your local Banner representative or a Banner Applications Engineer for support. Applications

Engineers are available from 8:00 A.M. to 5:00 P.M. Central Time, Monday through Friday, excluding holidays.

7Minneapolis, MN USABanner Engineering Corp.

Phone

Local: 763.544.3164

Toll Free: 1.888.3.SENSOR (1.888.373.6767)

763.544.3213Fax

sensors@bannerengineering.comE-mail

Address

To help Banner better assist you, be ready to provide the following information:

• PresencePLUS software version (to find version number, click Help in the Main Menu toolbar and choose About)

• Operating system of your PC

• Sensor Model Number and Date Code. Model Number is on top of Sensor, Date Code is either on the bottom or the

side

• Exact wording of any messages that appeared on your screen

• A description of what you were doing and what happened

• A description of how you tried to solve the problem

See Maintenance on page 8

Banner Engineering Corp.

9714 10th Avenue North, Minneapolis, MN 55441 USA

1.2 Maintenance

Maintenance tasks include keeping the hardware free of dust and dirt and possibly updating the PresencePLUS software

as new versions become available.

Cleaning the Sensor

Regularly remove any dust or dirt from the Sensor using a soft cloth. If needed, slightly dampen the cloth with a weak

solution of neutral detergent. Avoid getting dirt on the imager (the area behind the lens). If the imager is dirty, use

anti-static compressed air to blow off the dust.

Cleaning the Lens

Regularly remove dust, dirt, or fi

use a lens cloth and lens cleaner or window cleaner to wipe off remaining debris.

Do not use any other chemicals for cleaning.

Updating the PresencePLUS Software

The current version of PresencePLUS software is available for download from the Banner website. See Banner Website

for the software downloads link.

ngerprints from the lens. Use anti-static compressed air to blow off dust. If necessary,

System Description

The PresencePLUS ProII and P4 sensor families are easy-to-use camera systems with advanced visual inspection

capability. With minimal knowledge of vision systems, a user can quickly set up a PresencePLUS ProII or P4 and run

an inspection that tests products accurately, rejecting bad products on a production line.

Inspections are set up using a personal computer (PC). A digital camera inside the Vision sensor captures images, and

the sensor software analyzes the images using one or more Vision tools to pass or fail the product. The PC is not

required for running inspections after the inspection files have been stored in the sensor’s memory.

Inspection setup involves focusing the camera and selecting the appropriate Location, Vision, and Analysis tools. The

full range of inspection tolerances can be established either automatically or manually. The automatic Teach function

eliminates the iterative process of determining correct tolerances.

The PresencePLUS ProII and P4 Sensor families accommodate both translational and rotational variation. Parts moving

down a production line or web need not be oriented in exactly the same way.

The Sensor is easy to operate, with both basic and advanced options. New users can follo w the guided Setup sequence.

Advanced users can override automatic settings and create highly customized inspections.

Chapter 2

2.1 P4 Vision Sensors

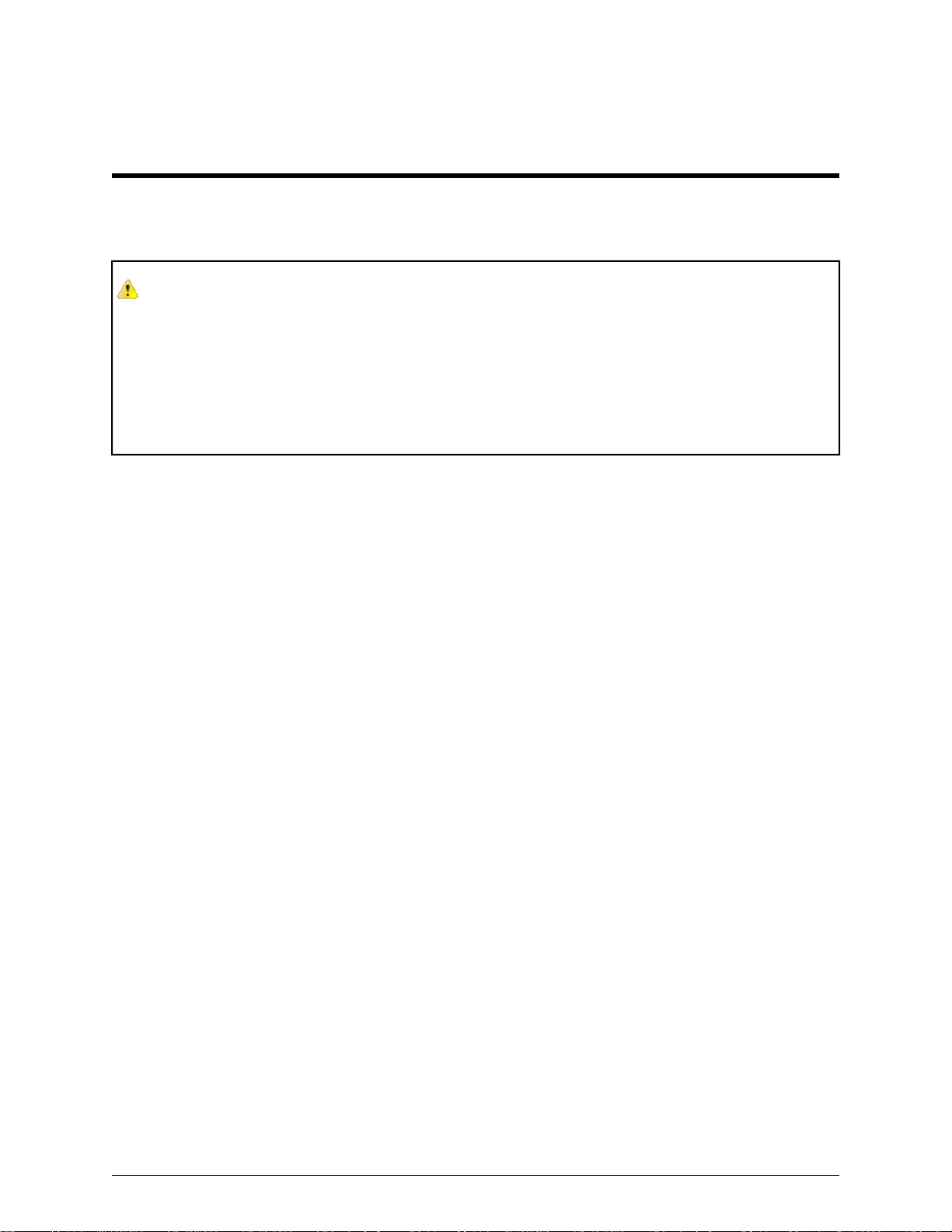

2.1.1 Typical P4 Vision Application

A typical PresencePLUS P4 application is shown below.

9Minneapolis, MN USABanner Engineering Corp.

2/2010System Description

In the application shown above, as each plastic formed part comes past the Vision sensor, an inspection is performed.

If the part is not shaped correctly as shown here, the inspection fails.

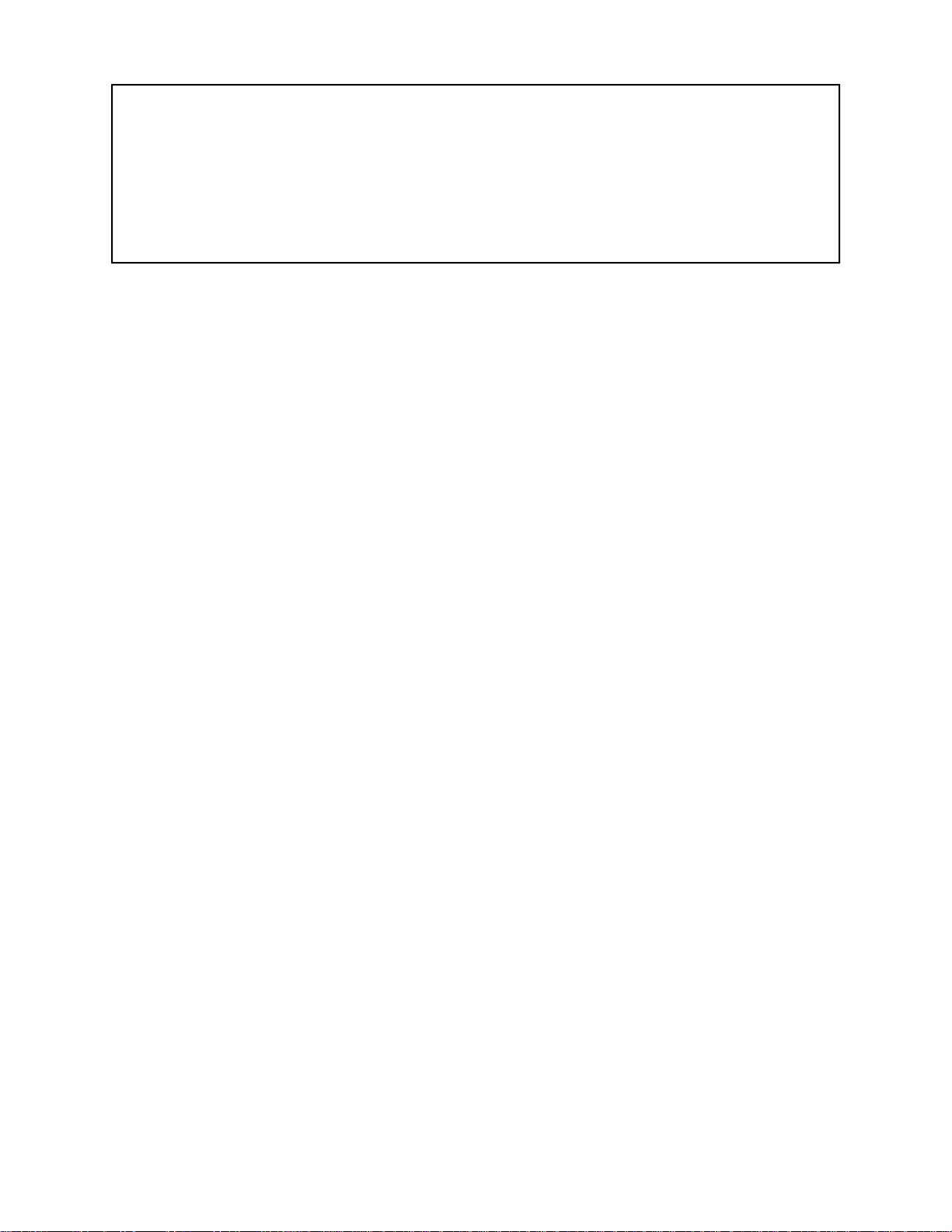

2.1.2 PresencePLUS® P4 Components

The PresencePLUS P4 system consists of the Sensor and a PC with PresencePLUS software and the appropriate

connections. The Sensor requires lighting and a trigger device, and an optional video monitor can be connected.

Note: The trigger device can be any 10-30V dc photoelectric sensor (PNP or NPN) or a device with a similar

output.

Banner Engineering Corp.Minneapolis, MN USA10

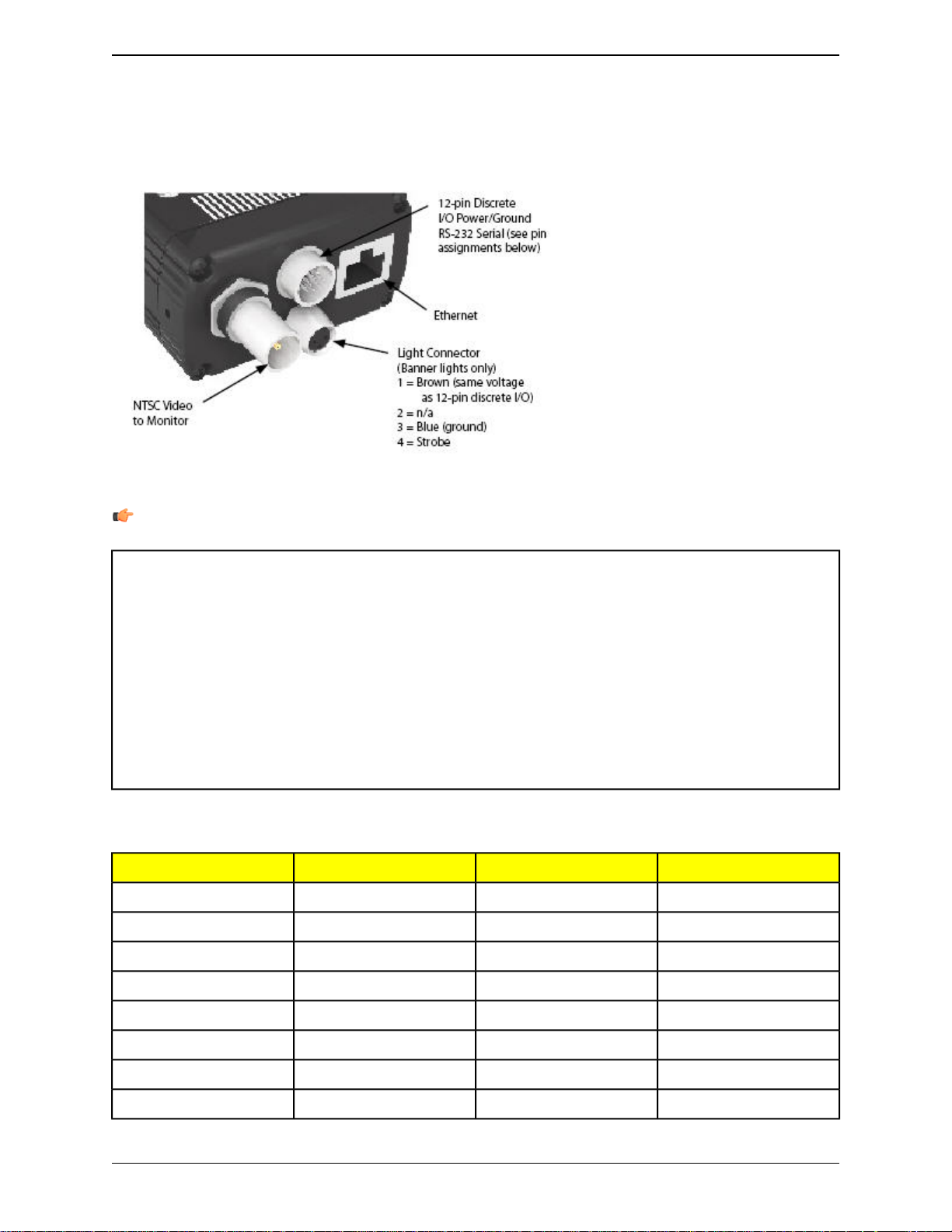

2.1.3 P4 Cable Connections

System Description2/2010

Note: The sensor power must be 24V dc ± 10% if a light source is powered by the sensor.

Monitor Cable (to Video Monitor, optional)Crossover Ethernet Cable (to PC Ethernet Port)*

BNC06 —2 m (6')STPX07 — 2.1 m (7')

BNC15 — 5 m (15')STPX25 — 7.6 m (25')

BNC30 — 9 m (30')or

Serial Cable (to PC serial Port)*Standard Ethernet Cable (to PC via Network Hub or

Switch

STP07 — 2.1 m (7')

STP25 — 7.6 m (25')

*The Sensor can be connected to the PC via a serial cable or an Ethernet network; Ethernet provides faster

communication.

DB9P06 — 2 m (6')

DB9P15 — 5 m (15')

DB9P30 — 9 m (30')

DirectionDescriptionWire ColorPin #

OutputRS-232 TX**Yellow1

InputRemote TeachGray2

InputProduct ChangeOrange3

InputExternal TriggerPink4

In/OutDiscrete I/O #1Black5

In/OutDiscrete I/O #2Red6

In/OutDiscrete I/O #3White7

In/OutDiscrete I/O #4Light Blue8

11Minneapolis, MN USABanner Engineering Corp.

DirectionDescriptionWire ColorPin #

InputRS-232 RX**Violet9

OutputRS-232 Signal Ground**Green10

InputCommon (Signal Ground)Blue11

Input10-30V dcBrown12

** These three wires make up the RS-232 serial connection.

Note: All unused inputs and outputs should be connected to ground if configured as PNP, and connected to +24V

dc if configured as NPN. Serial input pins should be connected to ground.

2.2 Software Overview

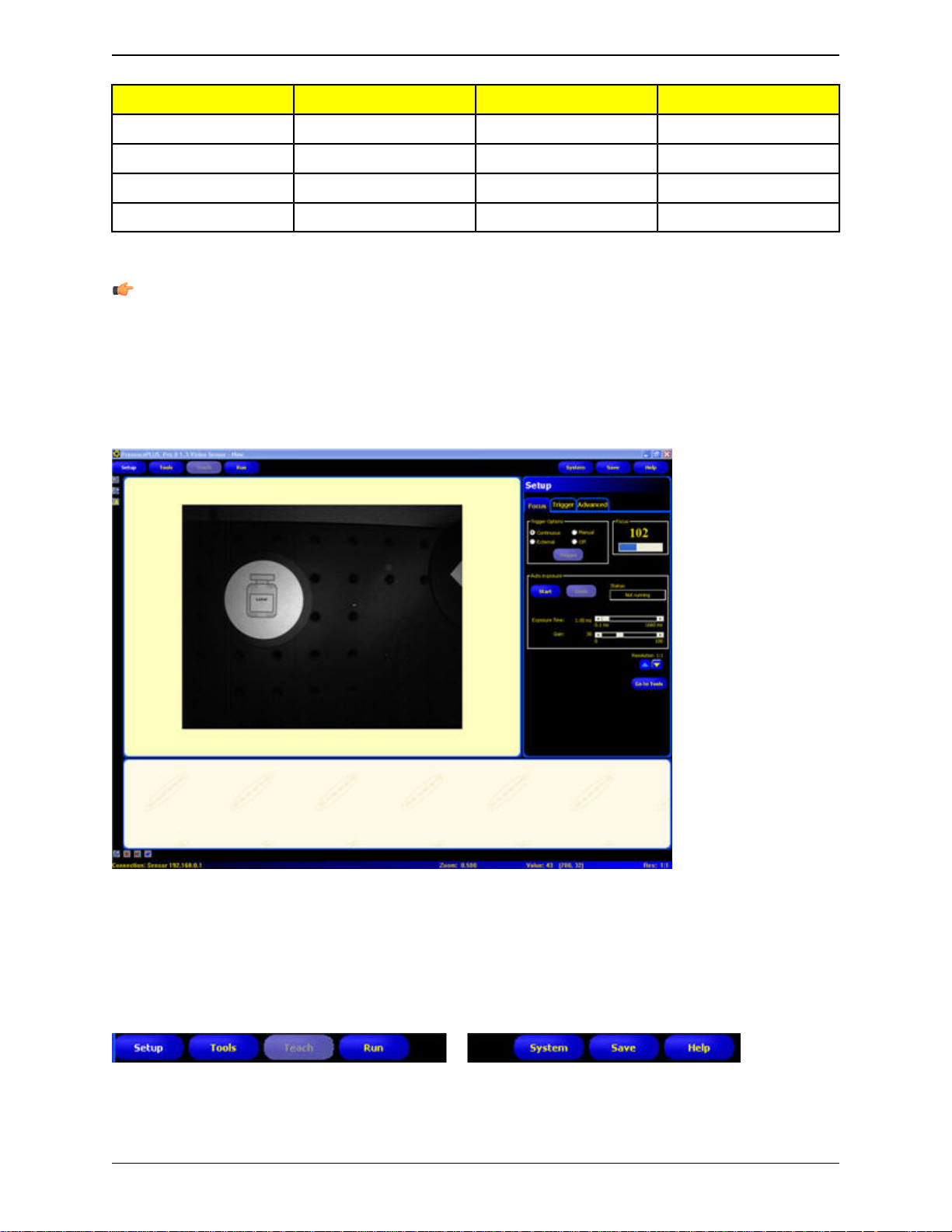

The PresencePLUS application window is shown below.

2/2010System Description

2.2.1 Main Menu Toolbar

Use the Main Menu toolbar to navigate between the Sensor options. Proceeding from left to right, the buttons in the

Main Menu toolbar step through the process of creating and controlling an inspection. Each button is explained in the

illustration below and in the table that follows.

The following table describes the screen associated with each button in the Main Menu.

Banner Engineering Corp.Minneapolis, MN USA12

Inspection-Specific Screens

System Description2/2010

Setup

Tools

Teach

System

Set up the camera, lens, trigger, and lighting to acquire images. Create a reference image to be

used later.

Add tools to an inspection. Build the inspection from scratch, or load tools from a previous

inspection file saved on the controller or a PC.

Teach the Sensor good products. This screen automatically configures the parameters chosen in

the Tools screen.

Choose which inspection file the Sensor will run, and view the results of the inspectionRun

System-Wide Screens

Set up the discrete inputs and outputs and communication configuration. This screen also has the

Sensor diagnostic tools.

Name the current inspection files and save them to the controller or a PC for future use.Save

Call the Help window or the About window.Help

2.2.2 Image Window

The Image window, on the left side of the screen, displays images acquired from the camera or the reference image

that is set for the current inspection. The toolbar buttons in the Image window are explained below.

Note: The reference image is used as a template for dev eloping an inspection; it establishes the initial values for

the Vision tools. The reference image also is used by Quick Teach.

13Minneapolis, MN USABanner Engineering Corp.

2/2010System Description

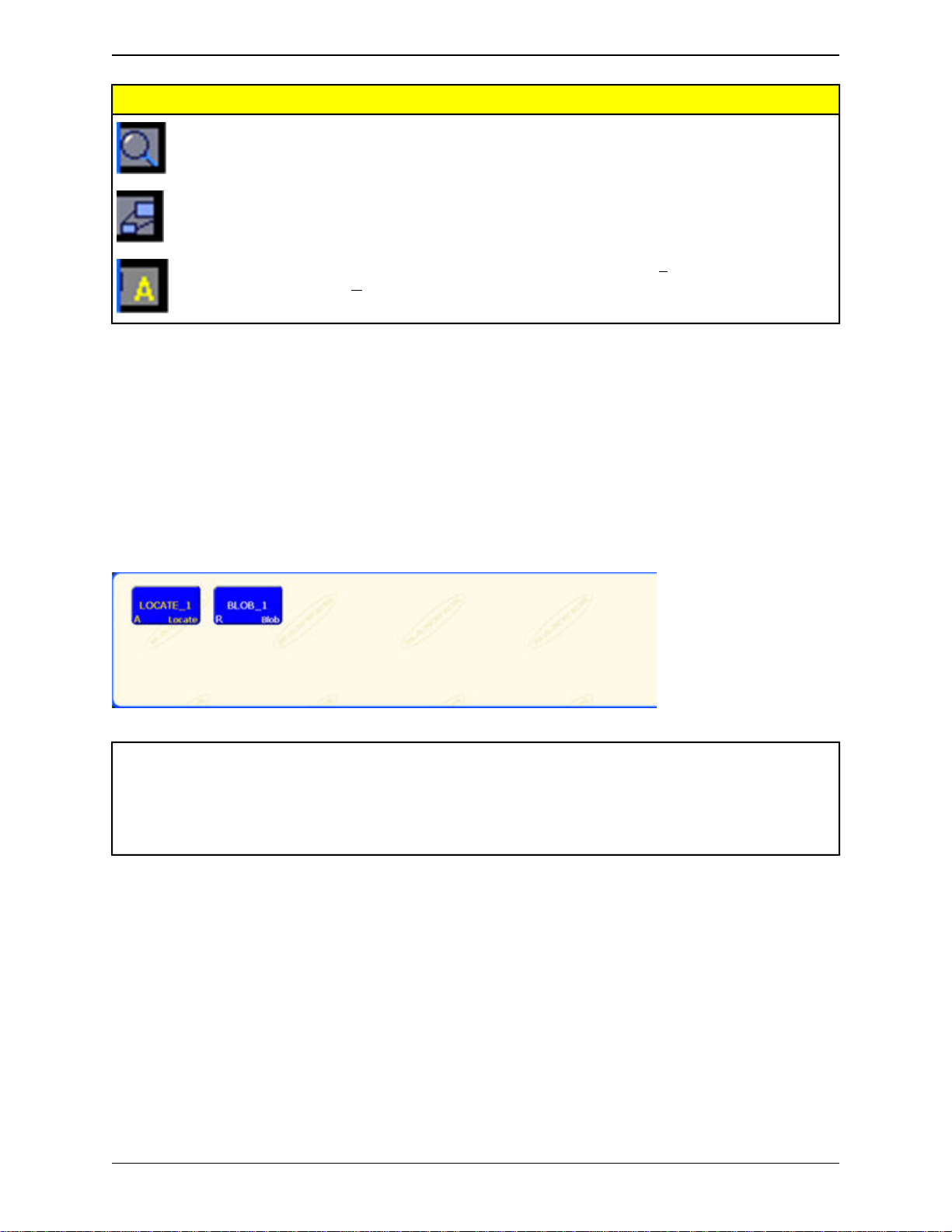

DescriptionIcon

Zoom -- toggles zoom control. When enabled, click on the image window to zoom in and

right-click to zoom out. This button is active when an image is displayed in the Image

window.

Expand Image -- toggles the size of the Image window between maximum and minimum.

Selected ROI / ALL ROIs -- toggles between the currently S elected Region of Interest

(ROI) and A ll ROIs.

2.2.3 Navigation/Results Window

The Navigation/Results window, at the bottom of the screen, displays tool navigation buttons or inspection results

files.

Navigation Buttons

Clicking on the Tools button in the Main Menu toolbar brings up the tool navigation b uttons in the Navig ation/Results

window. When setting up or using tools, click on any tool navigation button to get the corresponding tab in the

Configuration window.

Tool nameLOCATE_1 (or BLOB_1)

AbsoluteA

RelativeR

Tool typeLocate (or Blob)

Absolute and Relative Tools

An absolute tool’s Region of Interest (ROI) does not move in the image window. A relative tool shifts the ROI from

the previous tool, relative to the position of the part.

The Location tools (for example, Locate) track parts in the Image window , and the V ision tools that follo w (for example,

A verage Gray Scale and Blob Detect) are relati ve. A Vision tool that precedes all Location tools will be absolute. Rules

governing whether a tool is absolute or relative are as follows:

• The first Location tool is always absolute.

• All tools following a Location tool are relative to that tool unless they are made absolute themselves, in which case

the chain is broken, and a new chain is started.

• For a Vision tool to be absolute, it must be placed before any Location tools.

Banner Engineering Corp.Minneapolis, MN USA14

System Description2/2010

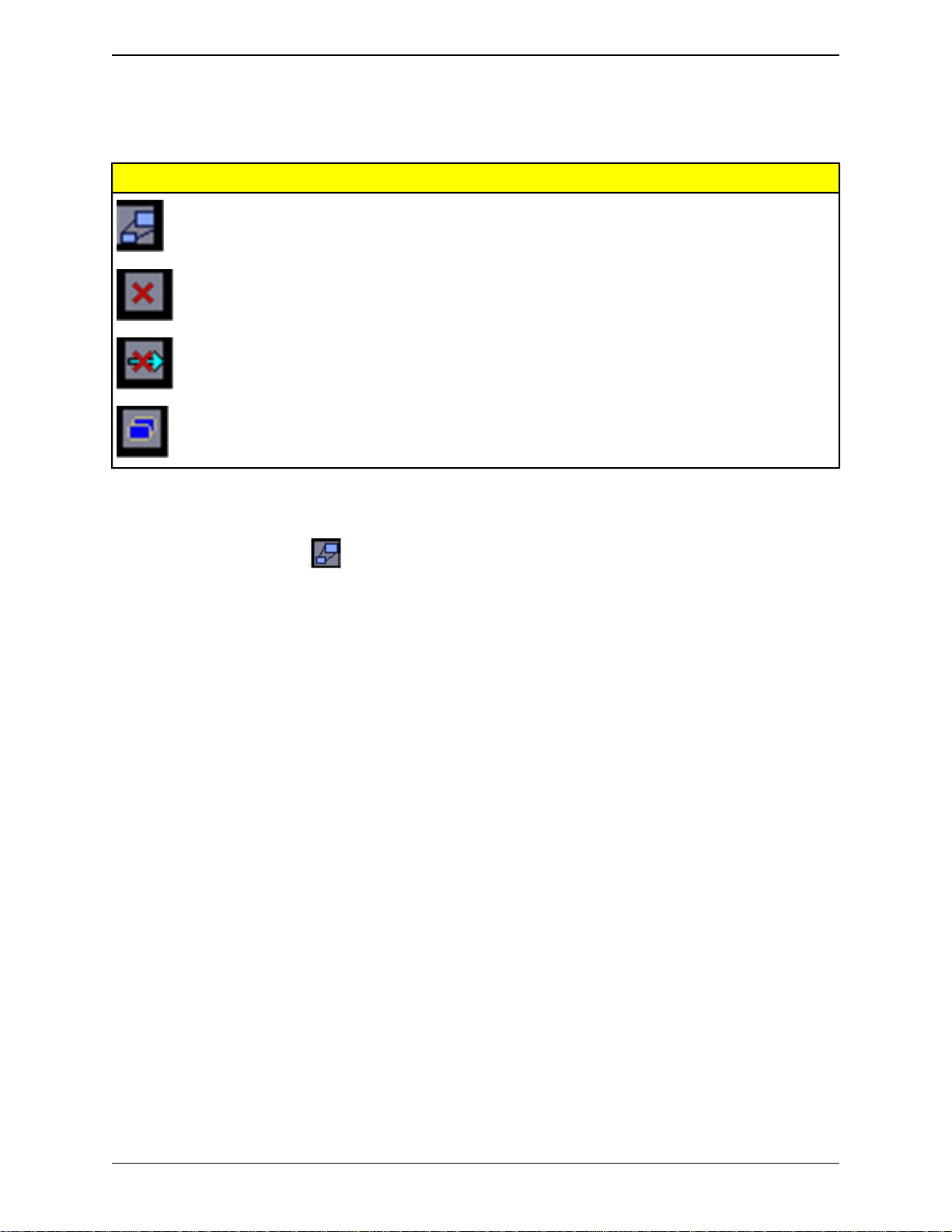

Navigation/Results Toolbar Buttons

Using the Navigation/Results toolbar buttons, the Navig ation/Results window size can be set, and tools can be deleted.

DescriptionIcon

Expand Results -- toggles the size of the Navigation/Results window between

maximum and minimum.

Delete Selected Tool -- deletes the selected tool from the current inspection.

Delete Selected Tools -- deletes the selected tool and all the tools to the right of

the selected tool.

Copy Selected Tool -- clones the selected tool.

Expand Button

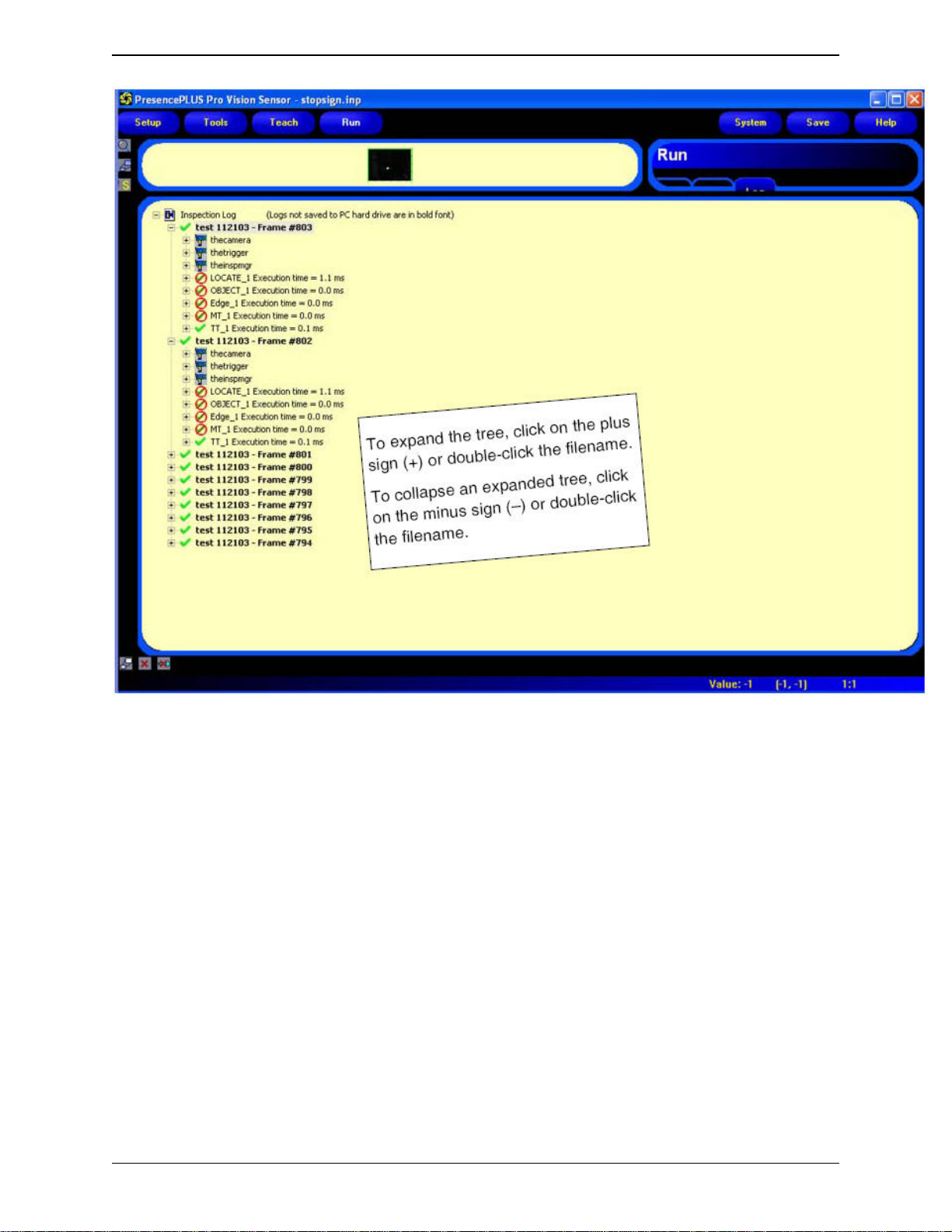

Clicking on the Expand button ( ) toggles the size of the Navigation/Results window to accommodate an expanded

list of inspection results files, as shown below.

15Minneapolis, MN USABanner Engineering Corp.

2/2010System Description

2.2.4 Configuration Window

The Configuration window, on the right side of the screen, displays the currently selected options with multiple tabs.

Clicking the Setup, Tools, Teach, Run, System, Save, or Help buttons on the Main Menu toolbar changes the contents

of the Configuration window accordingly.

Banner Engineering Corp.Minneapolis, MN USA16

System Description2/2010

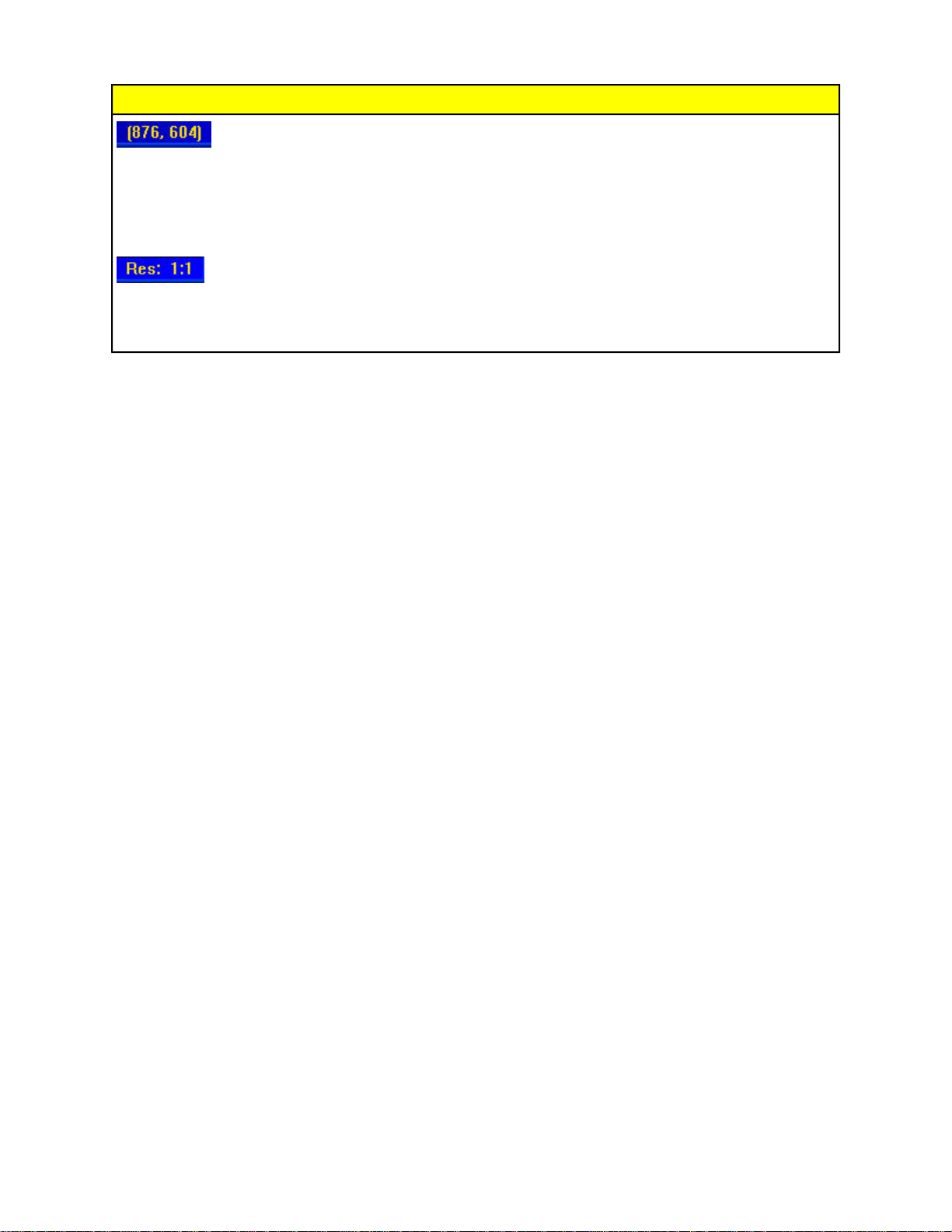

2.2.5 Status Window

The Status window, shown below, provides the following Sensor feedback.

The following table provides descriptions of each region in the Status window:

DescriptionRegion

Connection info -- current sensor to which the PC is

connected.

Image update completion -- progress bar shows relative

image update completion when an image is being

transferred from the camera to the PC (this flickers, and

is next to Connection: Sensor 192.168.0.1).

Current zoom value - works with the Zoom icon

(magnifying glass).

Current grayscale value -- the 0-255 gray scale value of

the pixel under the cursor.

17Minneapolis, MN USABanner Engineering Corp.

DescriptionRegion

Cursor position -- displays the x, y coordinates of the

pixel under the cursor relative to the upper-left corner

(origin, which is 0,0) of the field of view. Note that you

must have the mouse pointer hovering over the image to

get this information, otherwise, it displays

(-1,-1).

Current image display resolution -- displays the

user-specified value, which can be from 1:1 to 64:1. Note

that this does not affect how the sensor operates; it only

affects sensor-to-GUI image communication speed, and

is more useful when using Serial communication.

Getting Started

This section begins with some Vision basics, then provides a brief overview of how to install the software, and the

general steps to creating an inspection.

Chapter 3

3.1 Installing the PresencePLUS Software

The PresencePLUS software CD includes the sensor software and this documentation.

3.1.1 Installing the Software

To install the PresencePLUS software:

1. Close all active programs.

2. Make sure that no previous installations of PresencePLUS are installed.

3. Insert the PresencePLUS CD into the CD R OM drive of the personal computer. If you ha v e auto-start enabled, the

CD should automatically start. If it doesn't start --

a. Double-click on the My Computer icon on the desktop.

b. Double-click on the CD Drive in the list that appears.

c. Double-click on the PresencePLUS autorun file.

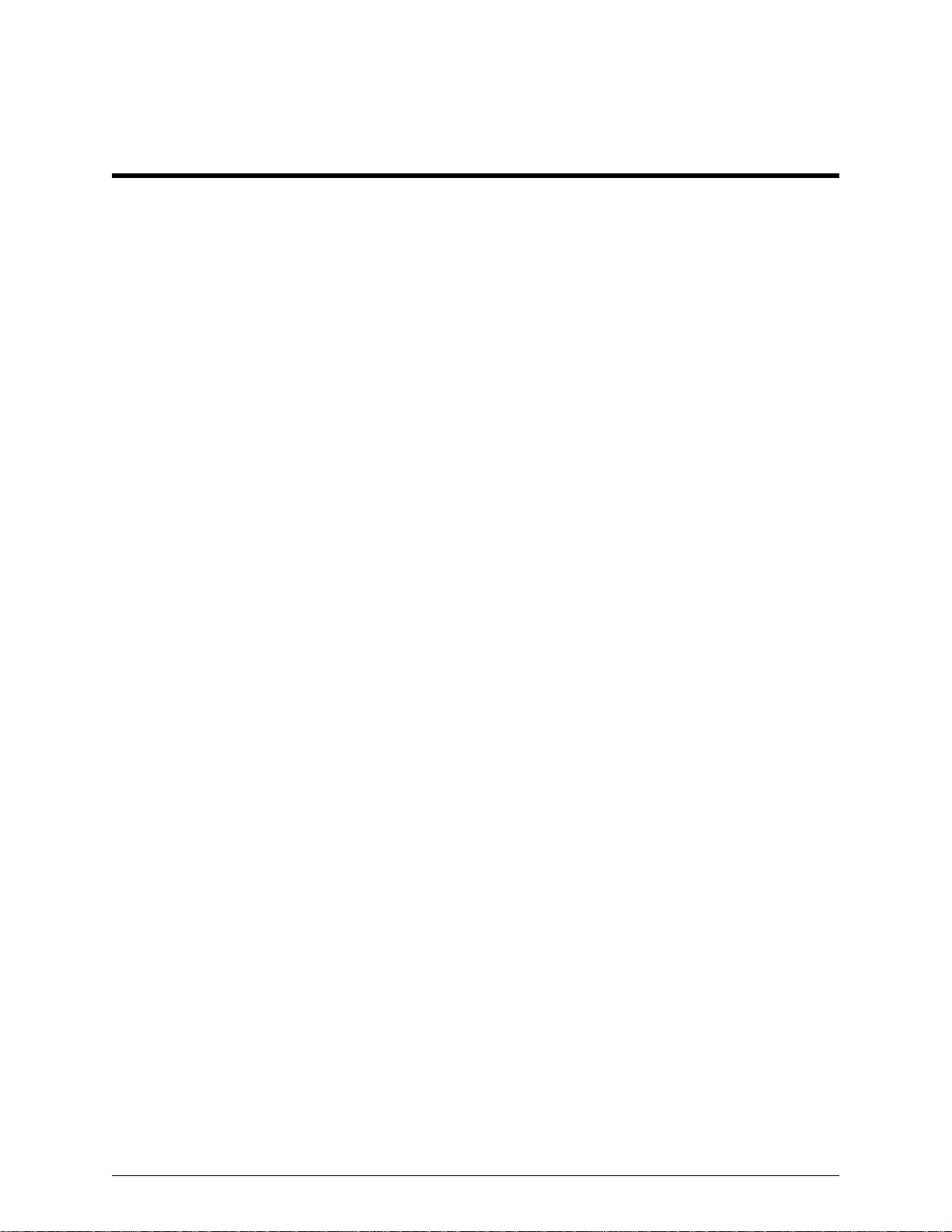

4. When the Install screen appears, click PresencePLUS PC Software.

5. Follow the instructions on the screen.

6. When the installation completes, reboot the PC.

3.1.2 Starting Up the Software

1. Power up the PC.

2. Install the software if it has not been installed. The installation screen of the PresencePLUS Pro software CD is

shown below.

19Minneapolis, MN USABanner Engineering Corp.

2/2010Getting Started

Note: The following instructions assume you are installing the software on Windows XP.

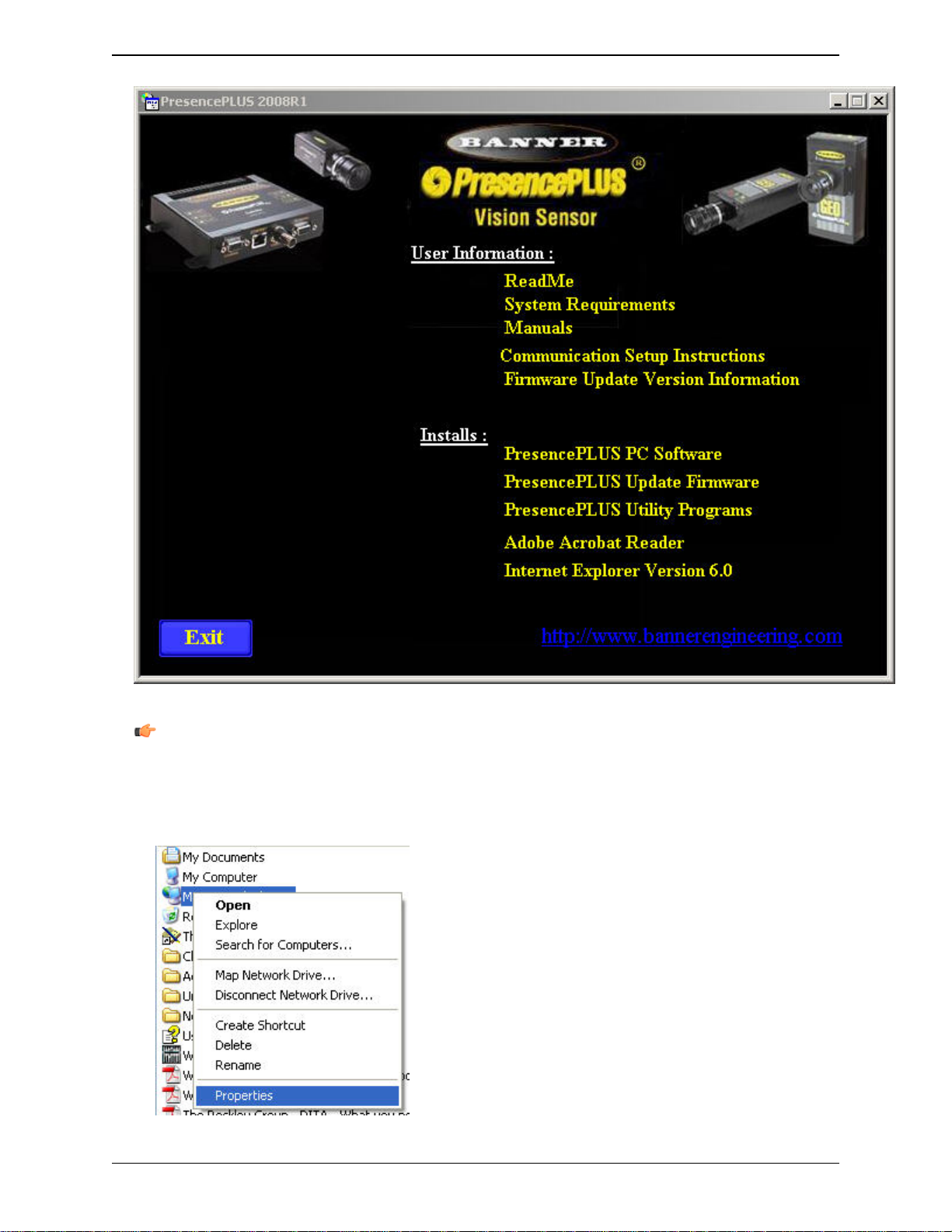

3. If using an Ethernet communication cable, configure the IP address as follows:

a. Open Network Properties on the PC (right-click on the Network Neighborhood icon).

Banner Engineering Corp.Minneapolis, MN USA20

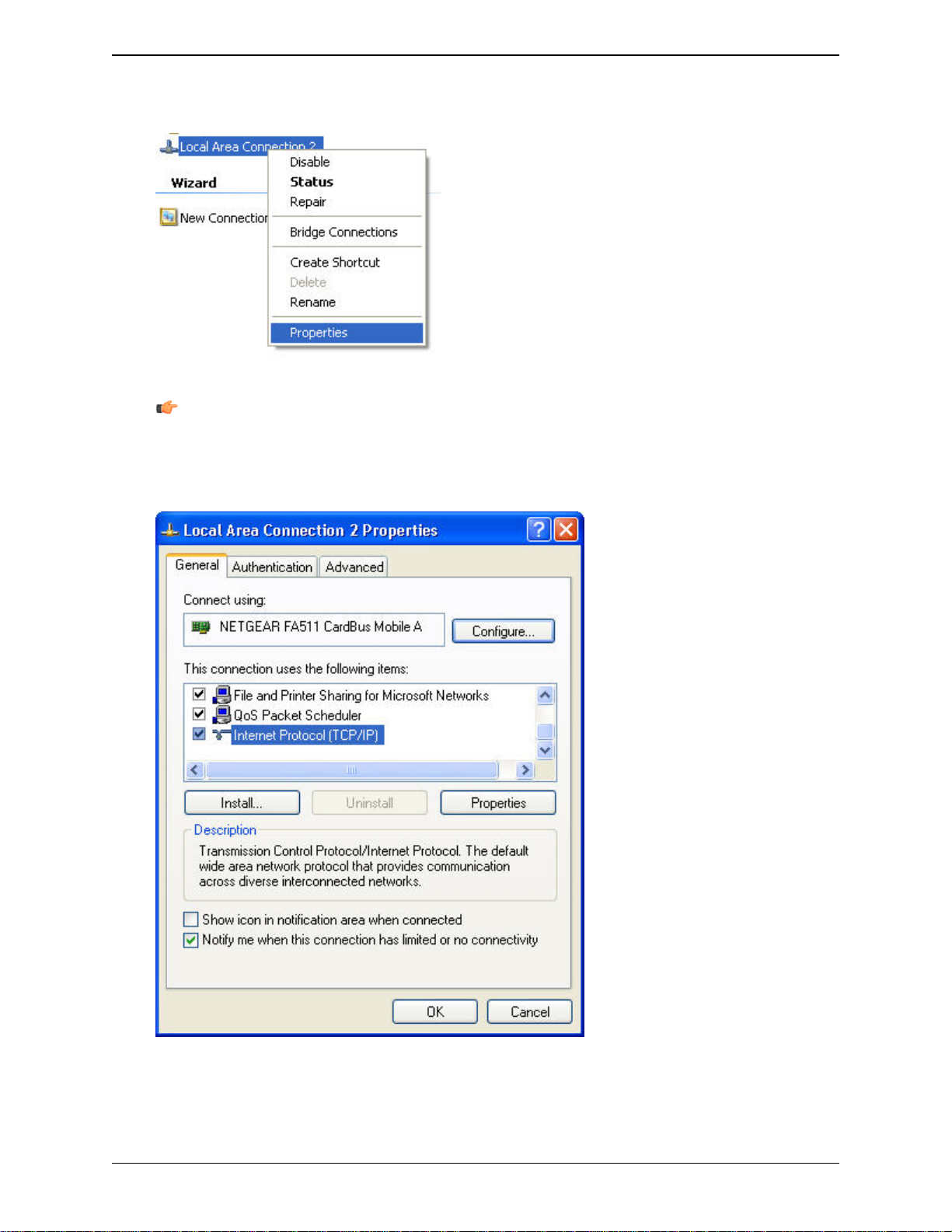

b. On the Local Area Connection, right-click on Properties.

Note: The PC in the example abov e has a second netw ork card which is used to connect to the camera so

it is using Local Area Connection 2.

c. In the dialog, click on Internet Protocol (TCP/IP) and click the Properties button.

Getting Started2/2010

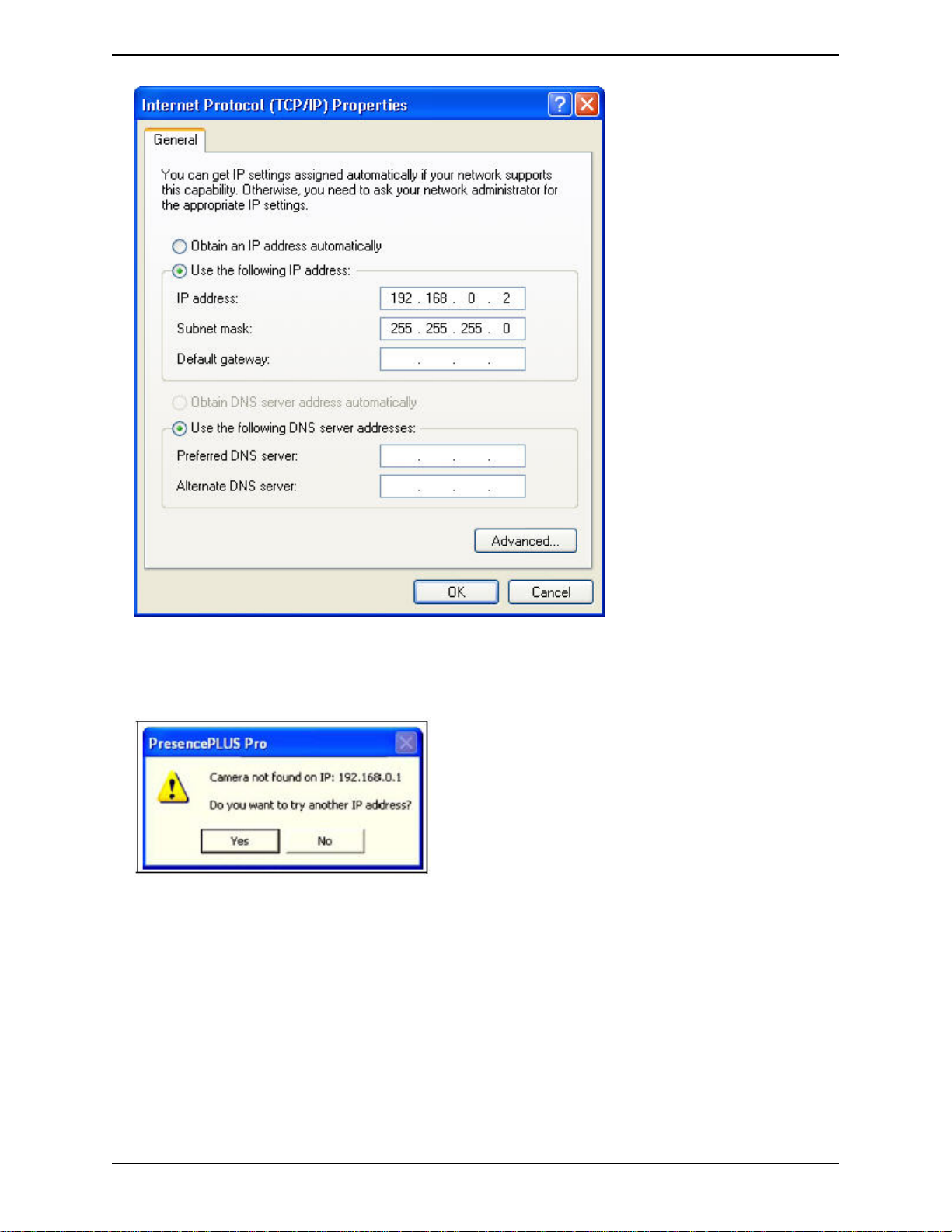

4. In the Internet Protocol (TCP/IP) Properties dialog, select Use the following IP address and make sure that the

the IP address is 192.168.0.2, and the subnet mask is 255.255.255.0.

21Minneapolis, MN USABanner Engineering Corp.

2/2010Getting Started

5. Start the sofware.

6. Upon initial startup, the software communication is not configured, and the following error message is displayed.

7. Click Yes to open the Communication screen.

8. Establish communications as follows:

Ethernet

Connection

1. When the software is started for the first time, the IP address is "Localhost." Choose Ethernet

(RJ 45).

2. Change the IP address to 192.168.0.1 (default IP address of the sensor).

3. Click OK.

Banner Engineering Corp.Minneapolis, MN USA22

3.2 Typical Setup and Startup Sequence

The following subsections proceed through a typical Sensor setup and startup sequence

1. Connect and power up the hardware.

2. Start up the software.

3. Set up hardware parameters.

4. Build and run an inspection.

Getting Started2/2010

3.3 Startup and Troubleshooting

The following explains how to verify connections and start the PresencePLUS software.

1. Verify cable connections.

• The sensor is connected to a PC with an Ethernet crossover cable ofr a serial cable.

• The monitor, if used, is connected to the sensor's video port.

2. Thread the lens onto the sensor.

3. Verify electrical connections.

• +V is connected to Pin 12, brown were, 10-30V dc (24V dc ± 10% if a light is powered by the sensor).

• -V is connected to Pin 11, blue wire (dc common).

• The trigger device is connected to Pin 4 (pink wire, Trigger In).

• Any additional connections are made as required.

4. Verify power. Ensure that the sensor is powered by 10-30V dc (24V dc ± 10% if a light is po wered by the sensor).

5. Verify PC configuration.

• Ethernet connection: IP address of PC is 192.168.0.2.

• Serial connection: A dial-up network has been established, and the network is a point-to-point protocol (PPP).

6. Power up the hardware and verify that the Error LED turns off.

• During powerup, all the sensor LEDs illuminate for 15 to 20 seconds.

• After the Red Error LED turns OFF, verify that the Green power LED is flashing.

7. Launch the Software.

• Click Start > PresencePLUS to start the program.

• If the sensor has a different IP address than the default address (192.168.0.1), or if it is connected through a serial

connection, the following error message will display:

Sensor not found on specified IP address 192.168.0.1.

Do you want to try another IP address?

• Click Yes to access the System Setup window.

23Minneapolis, MN USABanner Engineering Corp.

2/2010Getting Started

• Click on the Sensor select tab, and change the conection setup as follows:

Ethernet Connection --

1. Select Ethernet (RJ45) in the drop-down menu.

2. Change the IP address to the address of the sensor to which the PC is connected.

3. Click OK.

Serial Connection --

1. Select PC Serial in the drop-down menu.

2. Click OK.

3.3.1 General Troubleshooting

The following table describes solutions to the most common problems in using the PresencePLUS softw are. For further

assistance, contact Banner Engineering.

Cause/SolutionProblem

• Green Power LED on sensor is not ON.

• Interface cannot connect to the sensor.

• No image on the monitor.

• No image on PC or monitor.

• Green Ready LED on sensor is OFF.

• The software seems to be working correctly, but the

image is missing.

• Error message "Failed to capture a full-resolution image.

Please try again." • Restart the PresencePLUS software.

• •Image is frozen on the PC and monitor. Check all connections.

Green Ready LED on sensor is OFF

• Error message "Failed to capture a full-resolution image.

Please try again." • Reconnect the cable.

• •Image is frozen on PC, but image on monitor updates

properly.Image is frozen on PC, but image on monitor

updates properly.

• Indicator lights on RJ-45 port are OFF.

Sensor not getting enough power.

• Check the connection to the power supply.

Run display set to "None"

• Ensure that the sensor is receiving trigger signals.

Sensor not receiving triggers

• If the connections are secure, call a Banner Applications

Engineer.

Software restart needed or there are loose connections.

•• If a software restart does not correct the problem and the

connections are secure, call a Banner Applications

Engineer.

Ethernet connection lost.

Check the cable for breaks, then power down and back

up.

• Replace the cable.

• Attempt to close and reopen PresencePLUS software.

• If none of these actions fix the problem, call a Banner

Applications Engineer.

• Focus number does not update.

• QuickStart fails.

• Errors when saving inspections to the sensor.

Error code is displayed on PC.

FTP communications is blocked.

• Disable TCP/IP Firewall software on the PC.

•• A list of error codes and potential causes and solutions

are available in the main help.

Banner Engineering Corp.Minneapolis, MN USA24

Getting Started2/2010

3.4 Setting Up Hardware Parameters

If the Sensor is being run for the first time, or if changes have been made to the hardware, then you may need to set

or modify hardware parameters.

1. Click on System in the Main Menu toolbar.

2. Configure the Trigger parameter according to the trigger de vice being used. F or e xample, if using the QS18V6ND

as the trigger device, then select NPN.

3. Configure the six discrete inputs/outputs.

4. If the controller triggers a strobe light source, set the strobe trigger options.

5. If using the product select, configure the product select and product change lines to be NPN or PNP as required.

6. Click on Setup in the Main Menu toolbar, select Trigger tab, and configure the remaining parameters:

• Polarity

• Minimum Trigger Width

• Trigger delay

• Trigger Divide

3.5 Building an Inspection

The automatic screen sequence starts with the Setup screen, hich results from the first button (Setup) in the Main Menu

toolbar. Subsequent screens are shown below in the Main Menu toolbar layout.

1. Setup screen:

a. Set up the camera, lens, and lighting.

b. Choose trigger option Continuous for a live image.

c. Click Auto-exposure to adjust the image brightness.

d. Focus the lens by turning the lens focusing ring until the focus value is maximized.

e. When the desired image is shown, click Next to proceed to the Tools screen.

2. Tools screen:

a. Add Location tool(s) to find the target to adjust the Regions of Interest (ROI) for translational and rotational

changes.

b. Required: Add Vision tool(s) to inspect the part.

c. Add Measure tools(s) to create distance measurements from points found.

d. Required: Add Test tool(s) to set the Pass/Fail criteria (Vision and Measure tools are inputs to the Test tool).

e. Click Quick Teach to automatically set all the selected parameters in the Test tool and to proceed to the Run

screen, or click Next to proceed to the Teach screen and to teach a sample set of good products.

25Minneapolis, MN USABanner Engineering Corp.

Note: To keep specific, user-defined parameters in a Test tool, skip Teach and go directly to Run.

3. Teach screen:

The Teach screen automatically configures the parameters chosen in the Tools screen.

a. Chooose the sample size.

b. Click Start.

c. Trigger the controller with the external trigger device.

d. Click Stop.

Note: Before entering Run, save inspection file to one of the memory locations on the controller.

e. Click Next to proceed to the Run screen.

Note: Save a backup copy of the inspection to the host PC.

4. Run screen:

Select an inspection fo run, and review the results of the inspection.

• To select an inspection (in the Select tab), enable Software Override, and select the inspection file from the list

of stored inspections on the camera.

• An alternate method is to use Hardware input to select an inspection via discrete inputs to the controller.

5. Begin inspection:

To begin inspecting, click the Start button in the Run screen.

Setup

Chapter 4

4.1 Setup Screen

The Vision sensor has two modes: running and idle. If the sensor is idle when you start up the PresencePLUS software

while your PC is connected, the software starts in the Setup screen. If the sensor is running, then the software starts in

the Run screen.

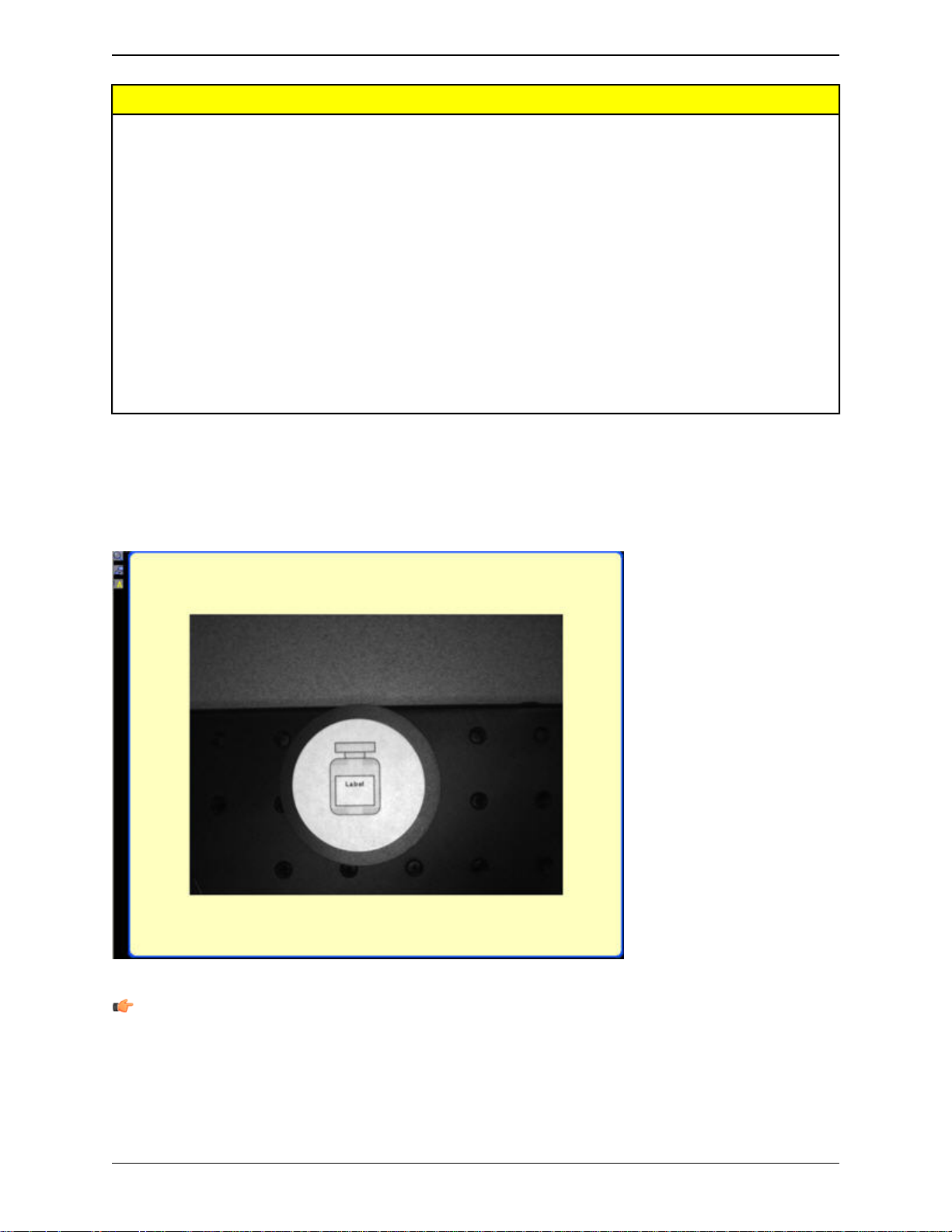

4.2 Capturing a Reference Image

The reference image is used as a template for developing an inspection. The Vision tools use this image to acquire the

critical information needed for the inspection.

Acquiring a quality image is crucial for a successful inspection. A quality image shows a measurable and repeatable

difference between good products (which pass inspection) and bad products (which fail inspection). Most commonly,

what determines the quality of the image is the illumination.

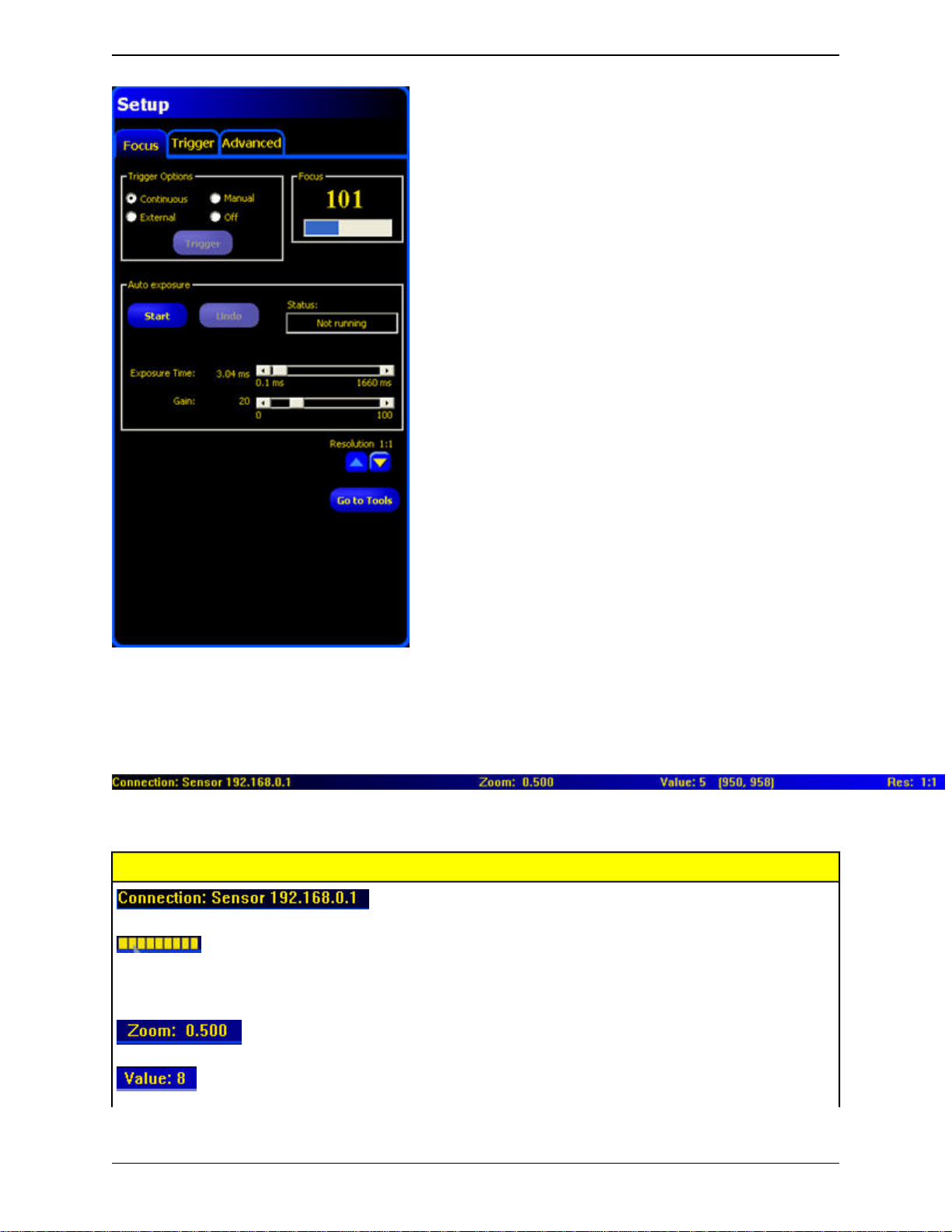

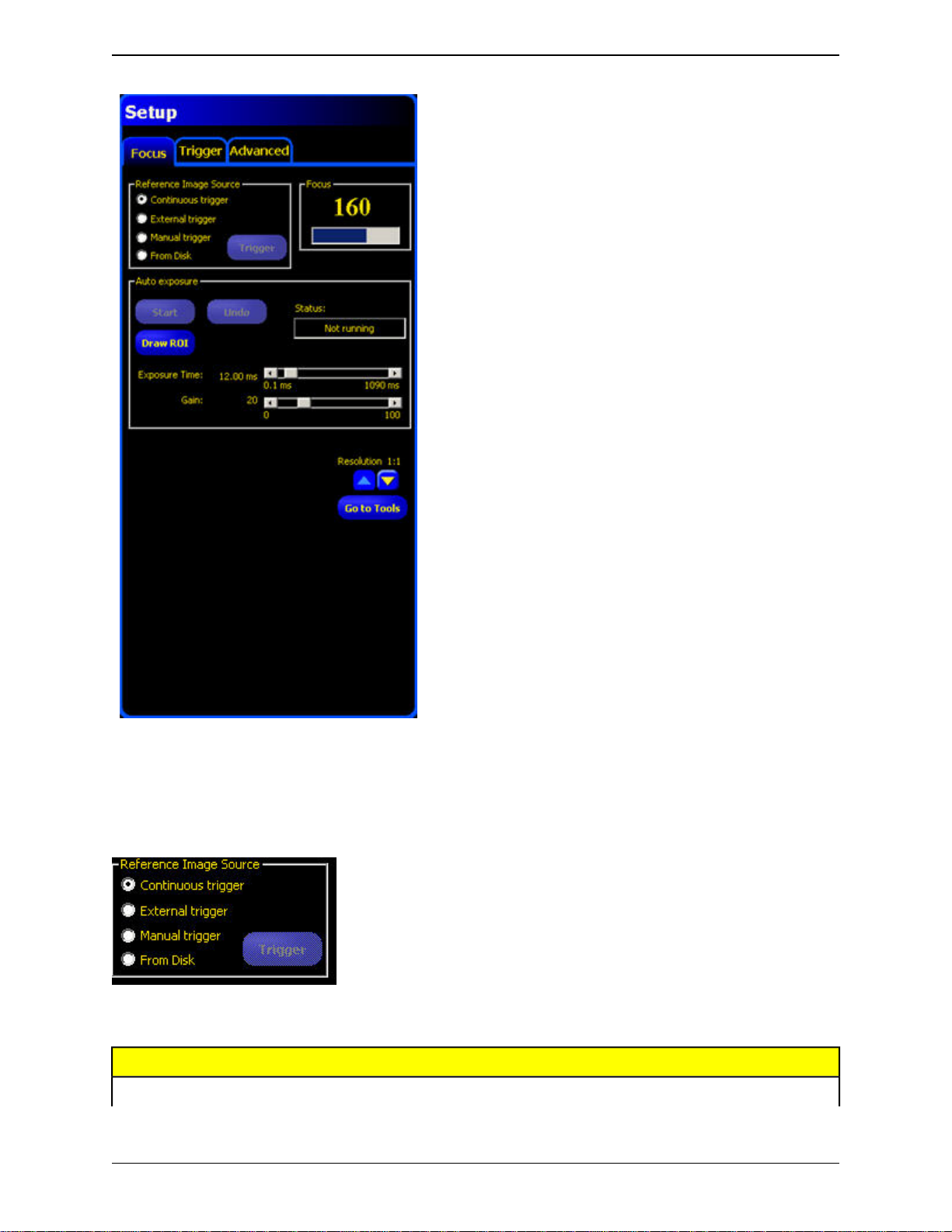

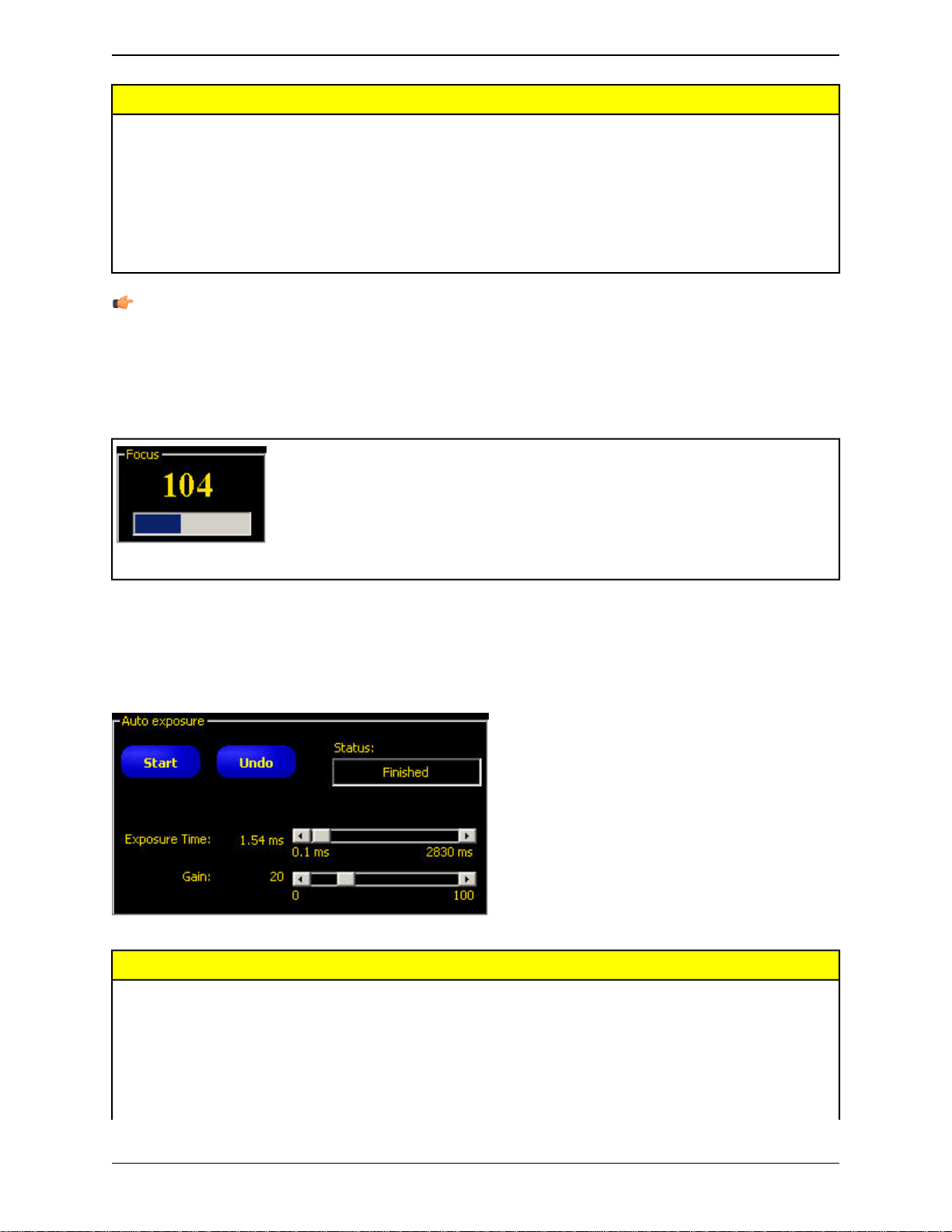

4.3 Focus Tab

The Focus tab on the Setup screen is used to:

• Reference Image Source on page 28

• Focus Value on page 29

• Auto Exposure on page 29

Focus tab

27Minneapolis, MN USABanner Engineering Corp.

2/2010Setup

4.3.1 Reference Image Source

Before capturing an image, you need to determine what will trigger the Sensor to capture and image.

The Sensor can be triggered to capture an image in one of the following ways.

DescriptionTrigger Option

The sensor will update continuously in Setup mode.Continuous

Banner Engineering Corp.Minneapolis, MN USA28

Setup2/2010

DescriptionTrigger Option

External

Manual

From Disk

Note: The trigger options described above are used only in the Setup routine. Note, though, that Run mode does

require an external trigger.

Images are acquired only in reponse to a signal from an external source as configured on the

Trigger tab. Choose External if the part will be moving during the inspection to capture an

image with the same conditions as the inspection conditions.

Images are acquired only then the Trigger button is clicked. The Trigger button is grayed

out when any trigger option other than Manual is selected.

If you check this option, the a Trigger button allows you to browse for an image to load

from disk.

4.3.2 Focus Value

The Focus value on the Focus tab is a number between 1 and 255.

T o focus the lens, place the target object so that the area to be focused appears

on the center of the displayed image. You can use the image on the PC to

determine when the image is sharp enough, or you can use this Focus value

as a guide. Turn the focus ring on the lens until the F ocus value is at the highest

possible number between 1 and 255. Note there is no optimal value for this

number, but it can be used as a guide if setting up more than one camera

focused on the same target.

4.3.3 Auto Exposure

When you click Start in Auto Exposure, the exposure time and gain are optimized for the current inspection and the

Status field provides feedback.

DescriptionField

The following are status possibilities:Status

• Not running -- Auto exposure has not been activated since entering this screen.

• Running -- Auto exposure is currently running.

• Finished -- Auto exposure has run and is complete.

• Image too dark -- Auto e xposure could not brighten the image enough. Add more light

to the inspection, or increase the exposure manually.

29Minneapolis, MN USABanner Engineering Corp.

2/2010Setup

DescriptionField

• Image too bright -- Auto exposure could not darken the image enough. Remove light

to the inspection, or decrease the exposure manually.

Exposure Time

Gain

Exposure time is the amount of time the camera allows light to energize the image chip.

Increasing the exposure time (that is, moving the slider to the right) allows more light to

energize the image chip, which brightens the image.

Gain is an electronic boost to the image signal. Increasing gain (that is, moving the slider

to the right) increases image brightness without increasing exposure time.

Note: Gain brightens both the light pixels and dark pixels. High gain values will

make the image appear grainy.

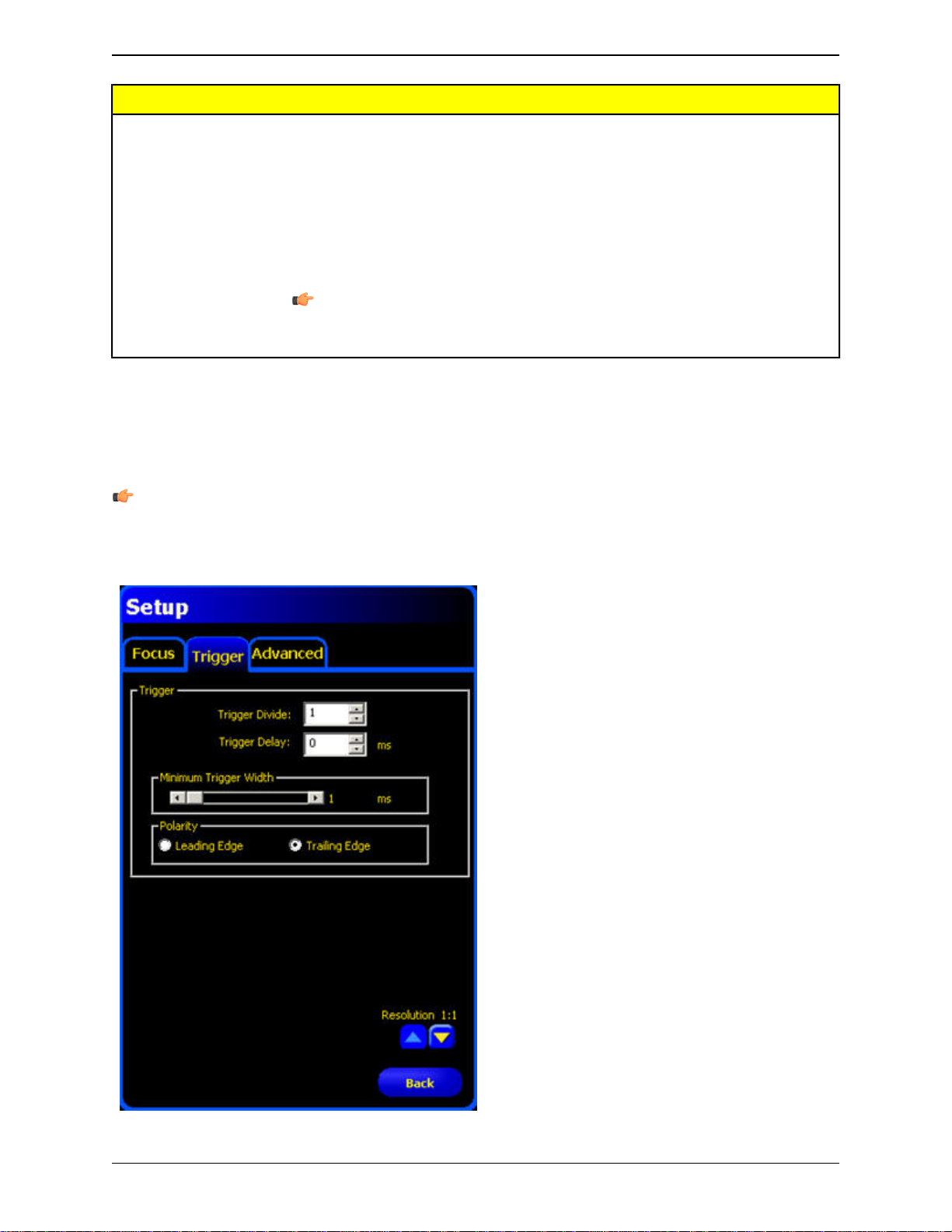

4.4 Trigger Tab

An external trigger is used to tell the Sensor when to capture an image. You can modify the validity and timing of the

trigger by setting the parameters on the Trigger tab.

Note: Parameters set in the Trigger tab are stored in the inspection file and can be different for each inspection.

Trigger tab

Banner Engineering Corp.Minneapolis, MN USA30

Loading...

Loading...