Page 1

Models included:

Models included:

• GEO

• GEO/GEO 1.3

• EDGE

• EDGE/EDGE 1.3

• BCR/BCR 1.3

• AREA/AREA 1.3

• OMNI/OMNI 1.3

Printed in USA 12/04 P/N 118000 rev. A

Printed in USA 02/06 P/N 118000 rev. D

Page 2

WARNING . . .

Never use this product as a sensing device for personnel protection. Doing so could

lead to serious injury or death.

This product does NOT include the self-checking redundant circuitry necessary to allow its use in

personnel safety applications. A sensor failure or malfunction can cause either an energized or deenergized sensor output condition. Consult your current Banner Safety Products catalog for safety

products which meet OSHA, ANSI and IEC standards

Not To Be Used for Personnel Protection

for personnel protection.

CAUTION . . . Electrostatic Discharge

Avoid the damage that electrostatic discharge (ESD) can cause to the Sensor.

Always use a proven method for preventing electrostatic discharge when installing a lens or attaching

a cable.

2 P/N 118000 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

Start

Hook Up the Hardware

Install the Software and

Establish Communications

Acquire an Image of the Part

Being Inspected

Choose Vision Tool(s) to

Find the Feature or Flaw

Add a Test Tool To Set Up

Pass/Fail Criteria

Teach Good Examples

Run

Finish

Install the Lens

(and Filters, if used)

Introducing PresencePLUS P4

The PresencePLUS P4 (or the Sensor) is an easy-to-use

vision sensor with advanced visual inspection capabilities.

With minimal knowledge of vision, a user can quickly set up

the Sensor to run an inspection that tests all products and

accurately rejects bad products on a production line.

Inspections are set up using a personal computer (PC) or by

activating the Remote Teach input. The Sensor captures images

and analyzes them using one or more Vision tools to pass or fail

the product. The PC is not required for running inspections after

the inspection files have been stored in the Sensor’s memory.

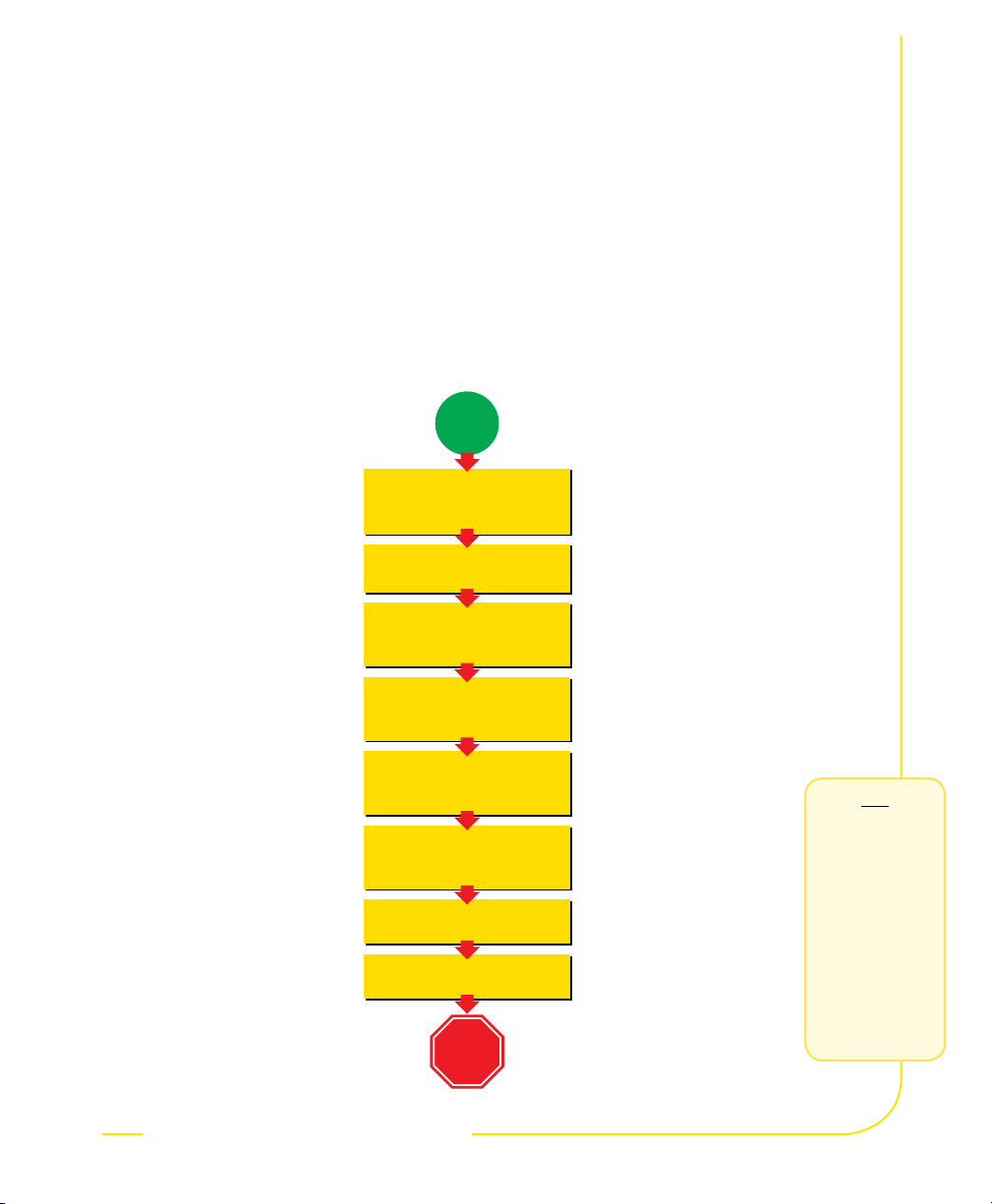

Quick Start Overview

This guide is designed to

provide – even to those

new to vision sensing

– the information needed

to use this sensor. It

provides an overview of

the PresencePLUS P4 and

illustrates how to easily set

up the Sensor to inspect a

product. The flow chart at

left provides an overview of

the process.

introduction

introduction

sensor

sensor

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

TIPS

For more detailed

instructions, refer

to the User’s

Manual on the

installation CD.

P/N 118000 rev. D 3

Page 4

step 1

step 1

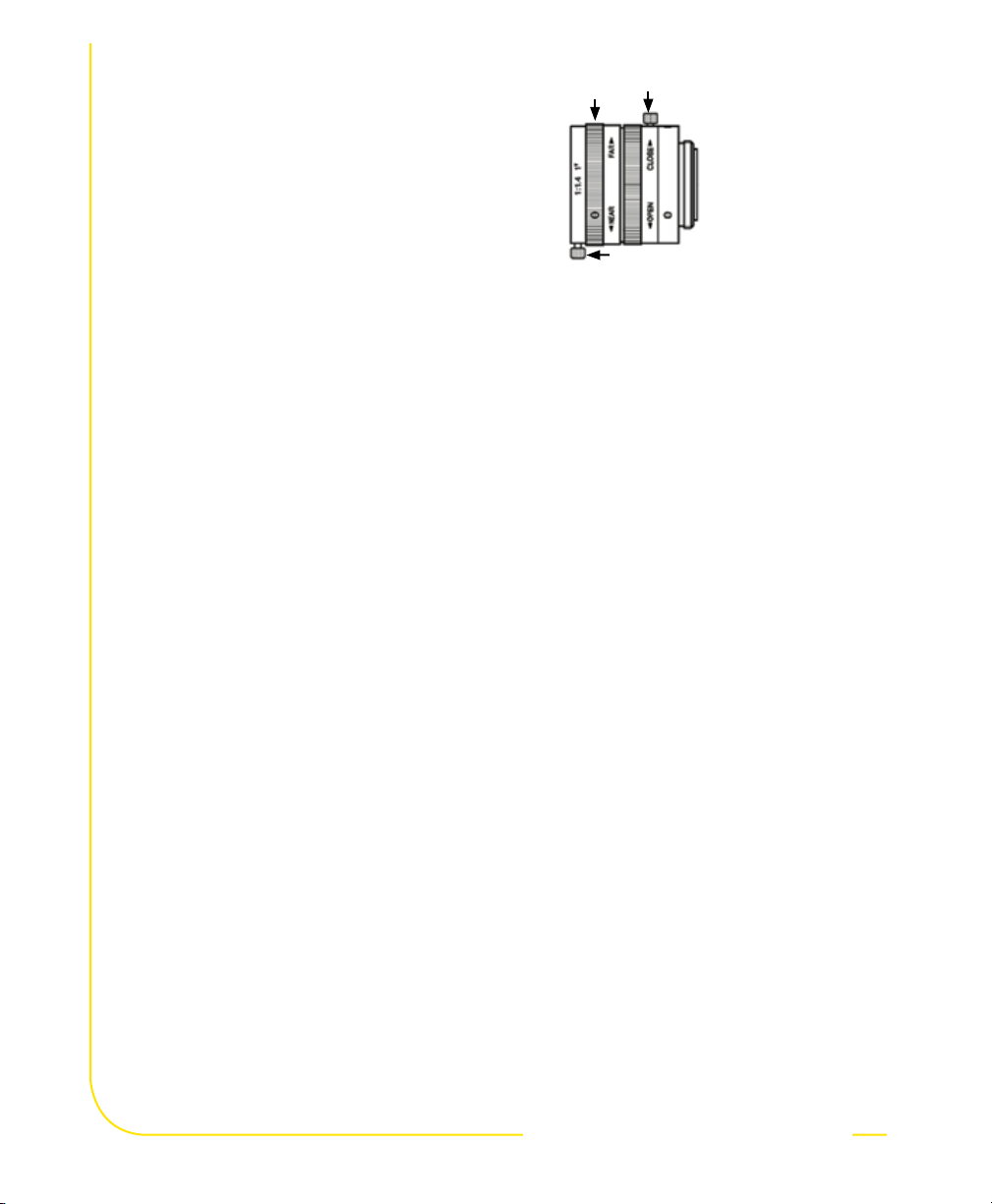

1. Install the lens (and filters, if used).

For EDGE, GEO, BCR, AREA, and OMNI any

lens may be used. For EDGE 1.3, GEO 1.3,

AREA 1.3, BCR 1.3, and OMNI 1.3 use only

Megapixel lenses. For non-Banner lenses,

follow the lens manufacturer’s unpacking

and installation instructions.

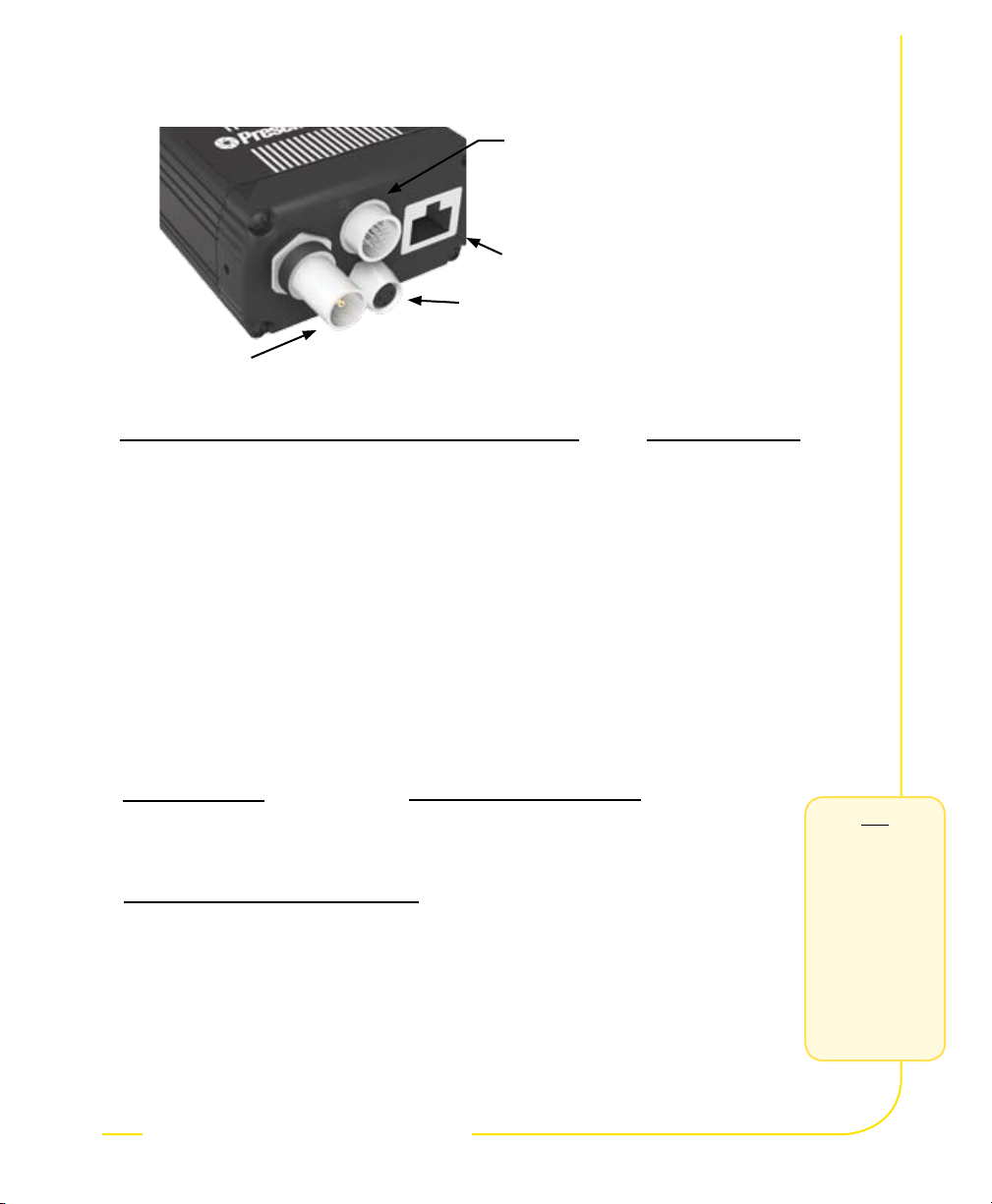

Cable Connections

1. If a light will be powered by the Sensor,

connect it to the

Light connector.

connections

connections

step 2

step 2

a. Caution: If the light is powered by the Sensor, the

Sensor power source must be 24V dc.

b. Caution: This connection is for Banner lights only!

2. If an NTSC monitor is used, connect it to the Sensor via a

BNC-to-BNC cable to the NTSC Video connector.

3. Connect the Ethernet cable from your PC to the Sensor at

the RJ-45 connector.

a. If connecting directly from the PC, use a crossover

cable (such as Banner Model No. STPX07).

b. If connecting the Sensor to a hub or router, use

components/

components/

straight cables (such as Banner Model No. STP07) to

the Sensor as well as to the PC.

4. Push the connector end of the supplied 12-wire cable

onto the 12-pin connector on the Sensor.

Focusing

Ring

Aperture Lock

Screw

NOTE: If the lens has a focus

lock screw, loosen the

screw before focusing

the lens. Some lenses

also have an aperture

lock screw.

Focus

Lock Ring

4 P/N 118000 rev. D

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

5. Connect the leads on the 12-wire cable to the appropriate

locations (see pin assignments below).

12-pin Discrete

I/O Power/Ground

RS-232 Serial (see pin

assignments below)

Ethernet (RJ-45)

Light Connector (3-pin Pico Style)

(Banner lights only)

NTSC Video

(BNC)

12-Wire Cable Pin Assignments

Pin # Wire Color Description Direction

1 Yellow RS-232 TX Output

2 Gray Remote Teach Input

3 Orange Product Change Input

4 Pink External Trigger Input

5 Black Discrete I/O #1 In/Out

6 Red Discrete I/O #2 In/Out

7 White Discrete I/O #3 In/Out

8 Light Blue Discrete I/O #4 In/Out

9 Violet RS-232 RX Input

10 Green RS-232 Signal Ground Output

11 Blue Common (Signal Ground) Input

12 Brown 10-30V dc Input

Crossover Ethernet Cable

(to PC Ethernet Port)

STPX07 — 2.1 m (7')

— 7.6 m (25')

STPX25

Monitor Cable (to Video Monitor, optional)

BNC06 — 2 m (6')

— 5 m (15')

BNC15

BNC30 — 9 m (30')

or

Standard Ethernet Cable

(to PC via Network Hub or Switch)

STP07 — 2.1 m (7')

STP25

1 = Brown 24V

2 = n/a

3 = Blue (ground)

4 = Strobe

— 7.6 m (25')

12-Wire Cable Models

P4C06

— 2 m (6')

— 7 m (23')

P4C23

— 10 m (32')

P4C32

— 16 m (50')

P4C50

— 23 m (75')

P4C75

TIPS

The trigger device

can be any

10-30V dc

photoelectric

sensor, or a

device with a

similar output.

connections

connections

components/

components/

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 118000 rev. D 5

Page 6

step 3

step 3

PC Configuration

1. Ethernet communication, configure the

IP address of your computer.

Typical IP Address:

192.168.0.2

Write down the existing address of your PC before changing it: _ _ _ • _ _ _ • _ _ _ • _ _ _

To change the IP address of your PC, do the following:

The following screen captures are from Windows XP. For earlier Windows versions, see Banner’s Supplemental

configuration

configuration

sensor

sensor

Information at http://info.bannersalesforce.com/xpedio/groups/public/documents/trainingjobaid/vr_01_00_e.pdf.pdf

b. Double-click the Local

a. Select Start

> Settings

> Network

Connections.

Sensor

Default IP Address

192.168.0.1

Area Connection used by

PresencePLUS.

c. Click the Properties

button.

d. Highlight Internet Protocol

6 P/N 118000 rev. D

TCP/IP, and click the

Properties button.

e. Choose Use the following IP address, and:

• Change the IP address to 192.168.0.2

• Change the Subnet mask to 255.255.255.0

• Click the OK button.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

2. Install the PresencePLUS software.

a. Insert the Installation CD.

b. Click Install PresencePLUS PC Software.

step 4

step 4

Starting the PresencePLUS P4

1. Power up the hardware and verify

that the Power/Error light turns

Green. This may take up to 20

seconds.

2. Verify that the yellow LED on

the Ethernet port is ON.

If it is not ON, see

Cable Connections

on page 4.

Green = Power

Red = Error

Green = Pass

Red = Fail

Green = Ready

Yellow = Trigger

Green = Pass

Red = Fail

Green = Power

Red = Error

Green = Ready

Yellow = Trigger

startup

startup

sensor

sensor

step 5

step 5

In-Line Sensor

Launching Software

1. Start the PresencePLUS program by clicking

Start > Program Files > PresencePLUS.

2. At start-up, PresencePLUS will try to communicate with the Sensor.

If communication with the Sensor is successful, the application will launch and

display the Setup or Run screen. If communication was not successful:

• Verify that the Ethernet cable is the correct type (see Cable Connections on

page 4).

• Verify that the TCP/IP settings are correct (see PC Configuration on

page 6).

3. If using an optional NTSC video monitor, verify that the monitor is displaying an

image. You may not see an image until the camera is given the first trigger.

4. When the software launches, create an inspection, configure the discrete I/O,

and begin running inspections.

NOTE: Initially, all discrete I/O are configured as inputs. Go to the System window

to change the discrete I/O. For detailed configuration information, refer to

the User’s Manual (under the Help button in the GUI; see back cover for part

number).

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Right-Angle

Sensor

P/N 118000 rev. D 7

Page 8

step 6

step 6

Software Setup

Use the Main Menu toolbar to navigate the PresencePLUS P4 options. Proceeding from left to

right, the buttons in the Menu toolbar step through the process of creating an inspection file.

Inspection Work Flow

1.

inspections

inspections

creating

creating

2.

TIPS

Before creating an

inspection file, set

up the electrical

configuration

of the external

trigger. (Click

System button,

select

Trigger tab.)

Required

Required

Set up the Sensor, lens, and lighting, to acquire a reference image.

a. Set up the Sensor lens and lighting.

Choose Trigger option Continuous for a live image.

b.

c. Click Auto Exposure to adjust the brightness.

d. Focus the Sensor lens by turning the lens until the Focus Number is

maximized.

NOTE: While still in the Setup screen, verify that the trigger works by

selecting External in the Trigger Options. When in Run mode, the

Sensor uses only the external trigger.

e. When you have the desired image, click Next to proceed to the Tools

screen to acquire the reference image.

Add tools to the inspection. Build the tools from scratch or add tools from

a previous inspection file saved on the PC or the Sensor. To add a Vision

tool, click the Tool button. To remove a tool, click the “X” in the lower left

corner of the screen.

a. Add Location tool(s) to find the target to adjust the following Regions

of Interest (ROI) for transitional and rotational changes.

Add Vision or Bar Code tool(s) to inspect the part.

b.

c. Add Measure tool(s) to create distance measurements from points

found.

d. Add

NOTES: • Click Quick Teach to automatically set all the selected

Test tool(s) to set the Pass/Fail criteria. (The Vision, Bar Code, and

Measure tools are inputs to the Test tool.)

parameters in the Test tool and proceed to the Run screen, or

click Next to proceed to the Teach screen, to teach a sample set

of good products.

8 P/N 118000 rev. D

• To manually set min/max parameters in a Test tool, skip Teach

and go directly to Run.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 9

Tool Options

NOTE: Tool availability depends on P4 model; see back page.

Tool Name Function Description

Location Tools

Vision Tools

Bar Code

Analysis Tools

Reader

GEO Find

Locate

GEO Count

Edge

Object

Average Gray

Scale

BLOB

Bar Code

Measure

Test Logic

Translation and rotation Locates the target by searching for a taught

pattern and compensates for translation and

rotation.

Translation and rotation Finds the edge of the part and compensates

for translation and rotation (if selected).

Finds one or more patterns Locates and counts a taught pattern.

Counts and locates edges Detects and counts transitions between

bright and dark pixels. The total number of

edges can be counted, and the position of

each edge can be found.

Locates and counts objects,

determines midpoints, and

measures widths

Determines presence,

absence, and shades of gray

Counts/measures areas and

counts, sizes, and locates

objects

Decodes bar code markings Finds and decodes DataMatrix, PDF-417,

Measures between points Measures distance between two prescribed

input/output

Detects the edges of dark and bright

objects, locates their midpoints, counts dark

and bright objects, and measures the width

of each dark and bright object.

Determines average gray scale value in the

Region of Interest (ROI)

Detects groups of connected light or dark

pixels within the ROI and designates them

as BLOBs. After BLOBs are found, they can

be counted, sized, and located.

and Linear bar code types in user-selectable

decoder modes, color schemes, and viewer

schemes.

points.

Evaluates results of selected Vision and

Analysis tools to determine whether an

inspection passes or fails. It also performs

logical operations and activates outputs.

TIPS

• Each inspection

must contain at

least one Vision

tool and one

Test tool.

• Save a backup

copy of your

inspection to

the host PC.

inspections

inspections

creating

creating

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 118000 rev. D 9

Page 10

3.

This screen automatically configures the parameters chosen in the

Tools screen.

Choose the sample size

a.

Click Start

b.

c. Trigger the controller with the external trigger device

d. Click Stop

e. Click Next to proceed to Run

Before entering Run, save the inspection file to one of the 12 memory

locations on the Sensor.

4.

inspections

inspections

running

running

TIPS

When using the

Hardware input,

pulse the Product

Change and

Product Select

inputs to initiate

an inspection

change. See the

User’s Manual in

the Help menu

for complete

information.

Click + to

expand and

– to contract

category

Passing

Tool

Failing

Tool

Select an inspection to run, and view the results of the inspection.

To select an inspection, (in the Select tab) enable Software Override and

select the inspection file from the list of stored inspections.

Alternate method: Use Hardware Input to select an inspection via Product

Change and Product Select lines.

Viewing Results

Display Options

Next Pass

Next Fail

Next RT

Next RT Fail

Next

None

Display only the next passing inspection.

Display only the next failing inspection.

Display the next remote teach.

Display the next unsuccessful remote teach.

Continuously display inspections.

Don’t display any inspections.

Click on

tool name

to show

the ROI

10 P/N 118000 rev. D

To begin inspecting, click the Start button in the Run screen.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 11

step 7

step 7

System Setup

Use the System Setup screen to change discrete I/O, the communication port, the product

change, the strobe output (for external lighting control), the trigger input, and to view

diagnostic information.

NOTE: To select the polarity of the

outputs, set one of the four

I/O pins to an output.

configuration

configuration

sensor

sensor

InputOutput Configuration Tab

Save inspections to the Sensor or to a folder on the PC.

Provides: Operation Help

Installation Help

Lens Selection Help

Lighting Help

Error Codes

About (GUI Software version, Sensor

Firmware version, Hardware version,

Sensor’s physical address)

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

TIPS

Use Help > About

in the GUI to look

up the software,

firmware,

and hardware

versions. The

information will

be helpful if you

call Banner for

support.

P/N 118000 rev. D 11

Page 12

Maintenance

Maintenance tasks include keeping the hardware free of dust and

dirt and updating the PresencePLUS software as new versions

become available.

Cleaning the Sensor

Regularly remove any accumulated dust or dirt from the Sensor

using a soft cloth. If needed, slightly dampen the cloth with a

weak solution of neutral detergent. Avoid getting dirt on the

Sensor’s imager (the area behind the lens). If the imager is dirty,

use anti-static compressed air to blow off the dust.

Cleaning the Sensor Lens

Regularly remove dust, dirt, or fingerprints from the lens. Use

maintenance

maintenance

sensor

sensor

anti-static compressed air to blow off dust. If necessary, use

a lens cloth and lens cleaner or window cleaner to wipe off

remaining debris. Do not use any other chemicals for cleaning.

Updating PresencePLUS Software

The current version of PresencePLUS software is available for

download from the Banner website:

www.bannerengineering.com

Click on Literature/Resources.

Click on Software and Electronic Data Sheets.

Select PRESENCEPLUSP4 from the Vision Product Line pulldown menu, and click on Go!

Download the latest Firmware, PC software, or both.

NOTE: If you upgrade the PC software only, new features may

12 P/N 118000 rev. D

not be available until you load the latest firmware to the

Sensor.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 13

Troubleshooting

Problem Cause/Solution

• Error Code is displayed on PC. • A list of error codes and potential causes and

solutions are available under Help/About on the

PresencePLUS software CD.

• Power light is not ON.

• Interface cannot connect to Sensor.

• No image on monitor.

• No image on PC or monitor.

• Sensor Ready/Trigger LED is Green.

• The software seems to be working

correctly, but the image is missing.

• Error message, “Failed to capture a full-

resolution image. Please try again.”

• Image is frozen on PC and monitor.

• Sensor Power/Error LED is Red.

• Image is frozen on PC, but image on

monitor properly updates.

• Error message, “Failed to capture full-

resolution image.”

• Indicator lights on RJ-45 port are OFF.

• Focus number does not update.

• QuickStart fails.

• Errors when saving inspections to the

Sensor.

Sensor not getting enough power

• Verify that the power supply is 10–30V dc with

maximum current of

550 mA (GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3,

and OMNI 1.3)

500 mA (GEO, EDGE, and AREA)

650 mA (BCR and OMNI)

NOTE: If light source is powered by the Sensor,

power supply must be 24V dc.

• Check the connection to the power supply.

Run display set to “None”

• Verify that the Sensor is receiving triggers.

Sensor not receiving triggers

• If the connections are secure, call a Banner

Applications Engineer.*

Software restart needed or loose connections

• Restart the PresencePLUS software.

• If the connections are secure, call a Banner

Applications Engineer.*

Ethernet connection lost

• Reconnect the cable.

• Check the cable for any breaks, then power down

and back up.

• Replace the cable.

• Attempt to close and reopen the

PresencePLUS software.

• If still not resolved, call a Banner Applications

Engineer.*

FTP communications blocked

• Disable TCP/IP Firewall software on the PC.

troubleshooting

troubleshooting

sensor

sensor

* Support is available from your local Banner representative or a Banner Applications Engineer. Call,

e-mail, fax, or write for support. Applications Engineers are available from 8:00 A.M. to 5:00 P.M.

Central Time, Monday through Friday, excluding holidays.

Local: 763.544.3164

Toll free: 1.888.3.SENSOR (1.888.373.6767)

Fax: 763.544.3213

sensors@bannerengineering.com

Banner Engineering Corp. • 9714 10th Avenue North • Minneapolis, MN 55441 • USA

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 118000 rev. D 13

Page 14

Specifications

Load

–

+

10-30V dc

NPN Hookup

Load

+

–

10-30V dc

PNP Hookup

Right-Angle Housing In-Line Housing

GEO: P4GR

GEO 1.3: P4G1.3R

EDGE: P4ER

Models

Dimensions

* Measured length does not

include connectors or cables

specifications

specifications

sensor

sensor

Mechanical

Display Options

Discrete I/O

EDGE 1.3: P4E1.3R

BCR: P4BCR

BCR 1.3: P4BC1.3R

AREA: P4AR

AREA 1.3: P4A1.3R

OMNI: P4OR

OMNI 1.3: P4O1.3R

H x W x L:

55.6 x 66.8 x 124.5* mm

(4.9" x 2.63" x 2.2")

Construction: Black anodized aluminum

Weight: Approximately 0.29 kg (0.642 lb.)

Environmental Rating: IEC IP20; NEMA 1

Operating Temperature: 0˚ C to +50˚ C (+32˚ F to +122˚ F)

Maximum Relative Humidity: 90%, non-condensing

PC or NTSC video (9 m [30'] max. cable length)

1 Remote Teach IN (pin 2) 4 Programmable I/O (pin 5-8)

1 Product Change IN (pin 3) 1 Strobe OUT (light connector pin 4)

1 Trigger IN (pin 4)

GEO: P4GI

GEO 1.3: P4G1.3I

EDGE: P4EI

EDGE 1.3: P4E1.3I

BCR: P4BCI

BCR 1.3: P4BC1.3I

AREA: P4AI

AREA 1.3: P4A1.3I

OMNI: P4OI

OMNI 1.3: P4O1.3I

H x W x L:

34.3 x 66.8 x 147.3* mm

(1.35" x 2.63" x 5.8")

14 P/N 118000 rev. D

Output Configuration

Output Rating

Communication

NPN or PNP software selectable

150 mA (each)

ON-State Saturation Voltage: < 1V at 150 mA max. NPN

> V+ - 2 volts

OFF-State Leakage Current: <100 microamps NPN or PNP

• 1 RJ-45 Ethernet

• RS-232 flying leads

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 15

Specifications, continued

Memory

Power

Acquisition

Exposure Time

Imager

Stores up to 12 inspection files, depending on the P4 model

Voltage: 10-30V dc

Current:

GEO, EDGE, AREA: 500 mA max.

BCR, OMNI: 650 mA max.

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3: 550 mA max.

Frames Per Second:

GEO, EDGE, AREA: 500 max.

BCR, OMNI: 48 max.

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3: 26.8 max.

Image Size:

GEO, EDGE, AREA: 128 x 100 pixels

BCR, OMNI: 640 x 480 pixels

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3: 1280 x 1024 pixels

Levels of Gray Scale: 256

GEO, EDGE, AREA: 0.01 ms to 20.47 ms

BCR, OMNI: 0.1 to 2830 ms

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3: 0.1 ms to 1670 ms

GEO, EDGE, AREA:

2.56 x 2.00 mm, 3.2486 mm diagonal CMOS; 128 x 100 pixels

BCR, OMNI:

4.736 x 3.552 mm, 5.9200 mm diagonal CCD; 640 x 480 pixels

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3:

8.576 x 6.861 mm, 10.9829 mm diaganol CMOS; 1280 x 1024 pixels

specifications

specifications

sensor

sensor

GEO, EDGE, AREA: 20 x 20 micrometers

Pixel Size

Lens Mount

Certifications

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

BCR, OMNI: 7.4 x 7.4 microns

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3: 6.7 x 6.7 micrometers

GEO, EDGE, BCR, AREA, OMNI: C-mount

GEO 1.3, EDGE 1.3, AREA 1.3, BCR 1.3, OMNI 1.3: Megapixel C-mount

P/N 118000 rev. D 15

Page 16

Models/Tools

PresencePLUS

P4 Models

GEO/GEO 1.3

EDGE/EDGE 1.3

BCR/BCR 1.3

AREA/AREA 1.3

OMNI/OMNI 1.3

User’s

Manual

Part

Number*

117020 X X X X X X

120413 X X X X X X

122800 X X X X X

125439 X X X X X X

125808 X X X X X X X

Locate

Avg.

Gray

BLOB

GEO

Find

GEO

Count

*Available on enclosed CD or online at www.bannerengineering.com.

Tools

EDGE Object

Bar Code

Reader

X

(optional)

Measure Test Comm.

X X X

P/N 118000 rev. D

Banner Engineering Corp.,

9714 Tenth Ave. No.

Minneapolis, MN 55441

Phone: 763.544.3164

www.bannerengineering.com

Email: sensors@bannerengineering.com

Loading...

Loading...