Page 1

Model PPE-G/PPE-P Enclosure Kit

®

Dust-Resistant Enclosure for PresencePLUS® Pro Vision System Camera w/o Light

Features

• Small size encloses PresencePLUS Pro camera and lens only, when ring light is not

required

• Protects camera from damage caused by accidental bumps and scratches

• Helps maintain lens focus by enclosing the lens and camera

• Keeps dust and dirt off camera and lens in applications not requiring washdown

and/or aggressive corrosion protection

• Glass or polycarbonate window models available (see Specifications)

• Can be mounted directly through base plate, or with optional flat or right-angle

mounting bracket

• Allows fine adjustment for aiming camera up and down, and from side to side

Printed in USA 01/04 P/N 115342 rev. A

Page 2

Model PPE-G/PPE-P Enclosure Kit

Model PPE-G/PPE-P Enclosure Kit

P/N 115342 rev. A 3

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation

Remove Enclosure Housing from Base

NOTE: It is not necessary to remove the end cap and window to install the camera.

1. Remove five screws from around base of housing using a #2 Phillips head

screwdriver.

2. Lift back of housing up off the base, slide housing forward until it clears the front

end cap, and separate the housing from the base.

Install the PresencePLUS Pro Camera

1. Verify that the lens is mounted on the camera.

2. Check the fit of the camera/lens assembly. The lens should be positioned about

flush with the base’s front edge. When using lenses of greater than 25 mm focal

length, remove the camera bracket and mount it in reverse position so the camera

can be moved further back.

3. Mount the camera on the camera bracket, using the four supplied M3x6 socket head

screws, lock washers and flat washers. Tighten the camera screws with the included

2.5 mm hex wrench.

4. Slide the camera and bracket so the front of the lens is approximately flush with the

front of the base, and tighten the two bracket screws on the bottom of the base.

Mounting the Enclosure Base – Without the Optional Mounting Bracket

1. Drill four holes for #8 screws into the mounting surface. Use the base as a template

or see the dimension drawing on page 4. (Mounting holes may be clearance drilled

or tapped.)

2. Mount the base using four #8 screws of sufficient length (user-supplied).

Mounting the Enclosure Base – Using the Optional Mounting Bracket

1. Assemble the bracket to the enclosure base (to either side of the enclosure), using

the hardware supplied with the bracket.

2. Drill two holes for " screws into the mounting surface. Use the bracket as a

template. (Mounting holes may be drilled or tapped.)

3. Mount the base using two " screws of sufficient length (user-supplied).

For Applications with Vibration

If the Right-Angle Bracket is to be used

to mount the enclosure in a vibration

application, the optional Front Bracket

(SMBPPEF) is required. Use it to stabilize

the front of the enclosure after it is

mounted, aimed, and assembled.

1. The Front Bracket fastens to the PEM nut

on the bottom of the enclosure, using the

#10 screw and washers supplied with the

bracket. Remove the clear dust seal over

the PEM nut first.

2. To mount the side of the bracket to the

mounting surface, use the bracket as a

template to mark the hole location. Drill

a hole for a " screw in the mounting

surface.

3. The slots in the Front Bracket allow some

additional adjustment after mounting, if

needed.

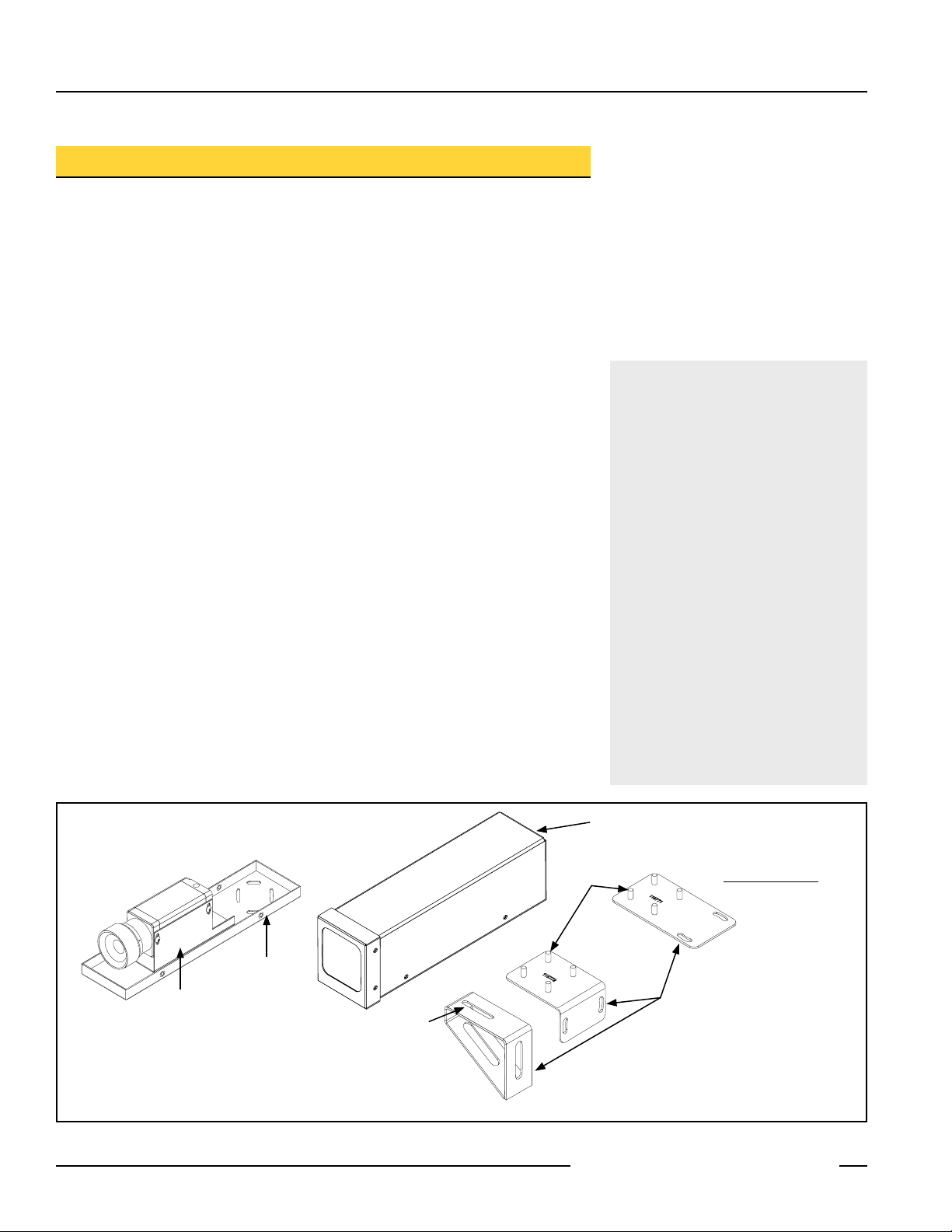

Enclosure Housing

washers and nuts

included

Enclosure Base

Camera Bracket

screw and washer

included

Model SMBPPEF

Front Bracket for Vibration Applications

Figure 1. Assembling the enclosure

2 P/N 115342 rev. A

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Clearance for " screws

Model SMBPPEA

Right-Angle Bracket

Optional Enclosure

Mounting Brackets

Model SMBPPES

Flat Bracket

Page 3

Model PPE-G/PPE-P Enclosure Kit

Connect the Camera

1. Push the camera cable’s round connector through the black grommet in the back of

the enclosure housing.

2. Connect the cable to the camera, but do not install the enclosure housing now.

3. Power up the camera.

4. Adjust horizontal aim using the mounting screws on the base (or straight bracket, if

used).

5. If right-angle bracket is not used, adjust vertical aim on the camera bracket.

If right-angle bracket is used, tighten screws in center of camera bracket slots and

use the vertical face of the right-angle bracket for adjustment.

6. Adjust the lens focus and aperture.

7. Verify that the front of the lens does not extend past the front edge of the base;

adjust camera bracket on base, if needed.

Assemble the Enclosure

1. Verify that there are no smudges on the window (especially on the inside) that could

cause imaging problems. (The window can be cleaned with standard glass cleaner

and a soft, non-abrasive cloth.)

2. Place the enclosure housing over the camera so the housing’s front end cap wraps

around the base’s front edge. Push the housing back until it clears the rear of the

base and drops down.

3. Reinstall the five screws.

Damaged Window Replacement

1. Remove the (4) Phillips screws on the sides of the end cap.

2. Remove the end cap with window and gasket.

3. Place the new window in the end cap and place gasket on top (it will be between the

window and the enclosure housing).

4. Place the end cap assembly onto housing and push down to compress gasket. Hold

down while reinserting (4) screws.

5. Tighten screws.

Specifications

Environmental Rating

Construction

NEMA 1, IEC IP40

Enclosure: 20 gauge cold rolled steel with clear zinc plate,

including edges

Screws and nuts: 18-8 stainless steel

Gasket: Cellular urethane foam

Window: Model PPE-G: Glass;

Model PPE-P: Polycarbonate

Cord Grommet: 6/6 Nylon and Buna/N Nitrile

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 115342 rev. A 3

www.bannerengineering.com • Tel: 763.544.3164

Page 4

Model PPE-G/PPE-P Enclosure Kit

®

L

61.7 mm

(2.43")

207.5 mm

(8.17")

55.4 mm

(2.18")

2 x 4.47 mm (0.18")

Wide Slots

28.7 mm

(1.13")

131.4 mm

(5.17")

28.7 mm

(1.13")

14.7 mm

(0.58")

12 mm

(0.47")

C

Dimensions

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair

or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

P/N 115342 rev. A

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...