Page 1

PC44 Series Plug-in Fiber Optic Sensing Contr ols

Plastic fiber optic sensor module for printed circuit board mounting

Fiber optic sensor modules for printed circuit

•

board mounting; also compatible with standard I/O

mounting racks

Use with Banner plastic fiber optic assemblies in

•

the opposed and diffuse fiber optic sensing modes

Choice of NPN (sinking) output or PNP (sourcing)

•

output models, selectable light- or dark-operate;

100 mA max. (continuous) load

Separate alarm output warns of marginal excess gain

•

LED indications for

•

ALIGNMENT,

10 to 30V dc operation

•

These are compact visible-red fiber optic sensing modules for

PC-board mounting. PC44 modules are designed for use with all

.040" core diameter Banner cut-to-length plastic fiber optic

assemblies.

PC44s operate from 10-30V dc and draw 25 mA maximum,

exclusive of load current. Model PC44BN6FP has one NPN

(sinking) load output and one NPN (sinking) alarm output. The

PC44BP6FP has one PNP (sourcing) load output and one PNP

(sourcing) alarm output. The load output is selectable for light- or

dark-operate. Alarm outputs are normally open, and conduct

whenever module excess sensing gain falls below 1.5x in the light

condition.

Load outputs and alarm outputs are each capable of 100 mA,

continuous load, except when both outputs are used. When the

alarm output is used, the total combined load (both outputs) may

POWER ON, OUTPUT OVERLOAD,

and LOW GAIN conditions

PC44 Series sensor module

with plastic fiber optic assembly attached.

not exceed 100 mA. PC44 modules can interface to a wide variety

of loads.

Two top-mounted LED indicators light to indicate POWER ON,

OUTPUT OVERLOAD, ALIGNMENT, and EXCESS GAIN 1 to

1.5x (LOW GAIN) conditions. The LOW GAIN indication corresponds to the "on" state of the module's alarm output.

Fiber optic assemblies are available as either coiled or straight fibers,

bifurcated or individual, and with a variety of sensing end styles (see

page 4). Representative sensing range and beam pattern information for the opposed and diffuse sensing modes is given on page 3.

PC44s may be soldered directly to a printed circuit board. Also, a

kit of closed-end jacks is available (model PCJ-25; see specifications) to allow the PC44 module to plug into a printed circuit

board. PC44 modules also plug into standard I/O mounting racks.

Specifications and model listings, PC44 modules:

Sensing range: opposed and diffuse sensing modes; see curves, page 3.

Sensing beam: visible red, 680 nanometers.

Supply voltage: 10 to 30V dc at 25 mA maximum, exclusive of load,

at module pins #2 (+Vdc) and #5 (dc common). 10% maximum ripple.

Module model listing and output configurations:

Solid-state dc outputs, selectable for light- or dark-operate:

PC44BN6FP = NPN sinking load output plus NPN sinking alarm output.

PC44BP6FP = PNP sourcing load output plus PNP sourcing alarm output.

Light operate/dark operate mode selection for the load output (mod-

ule pin #4) is done by either connecting or not connecting module pin #3

to +V dc (see page 2).

Light operate mode: Normally open load output conducts when the

receiver sees the emitter's modulated visible red light.

Dark operate mode: Normally open load output conducts when the

receiver does not see the emitter's modulated light.

The alarm output (at module pin #1) is normally open (N.O.), and

conducts whenever the excess gain in the light condition falls below 1.5x.

Module output rating: 100 mA maximum each output.

No false pulse on power-up. (False pulse protection circuit causes a 100

millisecond delay on power-up.) Short-circuit protected.

Off-state leakage current <1 microamp at 30V dc.

On-state saturation voltage <1V at 10 mA dc; <1.5V at 100 mA dc.

When the alarm output is used, the total load may not exceed 100 mA.

Response time: 1 millisecond "on"; 1 millisecond "off".

Printed in USA

Repeatability is 0.25 milliseconds.

Response time and repeatability are independent of signal strength.

Indicators: Two top-mounted LED indicators, one yellow and one

green. Indications are as follows:

GREEN glowing steadily = dc power "on".

GREEN flashing = output overloaded.

YELLOW glowing steadily = excess gain in light condition is >1.5x.

YELLOW flashing = excess gain in light condition is marginal (<1.5x).

Flashing YELLOW corresponds to a conducting (closed) alarm output.

Adjustments: Single-turn SENSITIVITY control on top of module.

Construction: Polypropylene

pins. Completely sealed, epoxy-encapsulated circuitry. Plated steel

mounting (hold-down) screw.

Mounting: Three options are possible.

1) PC44 modules may be soldered directly to a printed circuit board.

2) A set of socket pins is available for PC board mounting.

Socket pin kit (model PCJ-25) contains 25 socket pins (5 pins are

required per module) and 5 hold-down nuts (1 required per module).

3) PC44 modules plug into standard I/O mounting racks. Contact

Banner's applications engineering department for further informa-

tion.

Operating temperature range: -20° to +55°C (-4° to 131°F).

Maximum relative humidity: 90% at 50°C (non-condensing).

housing; gold-plated copper connecting

P/N 32910F7A

Page 2

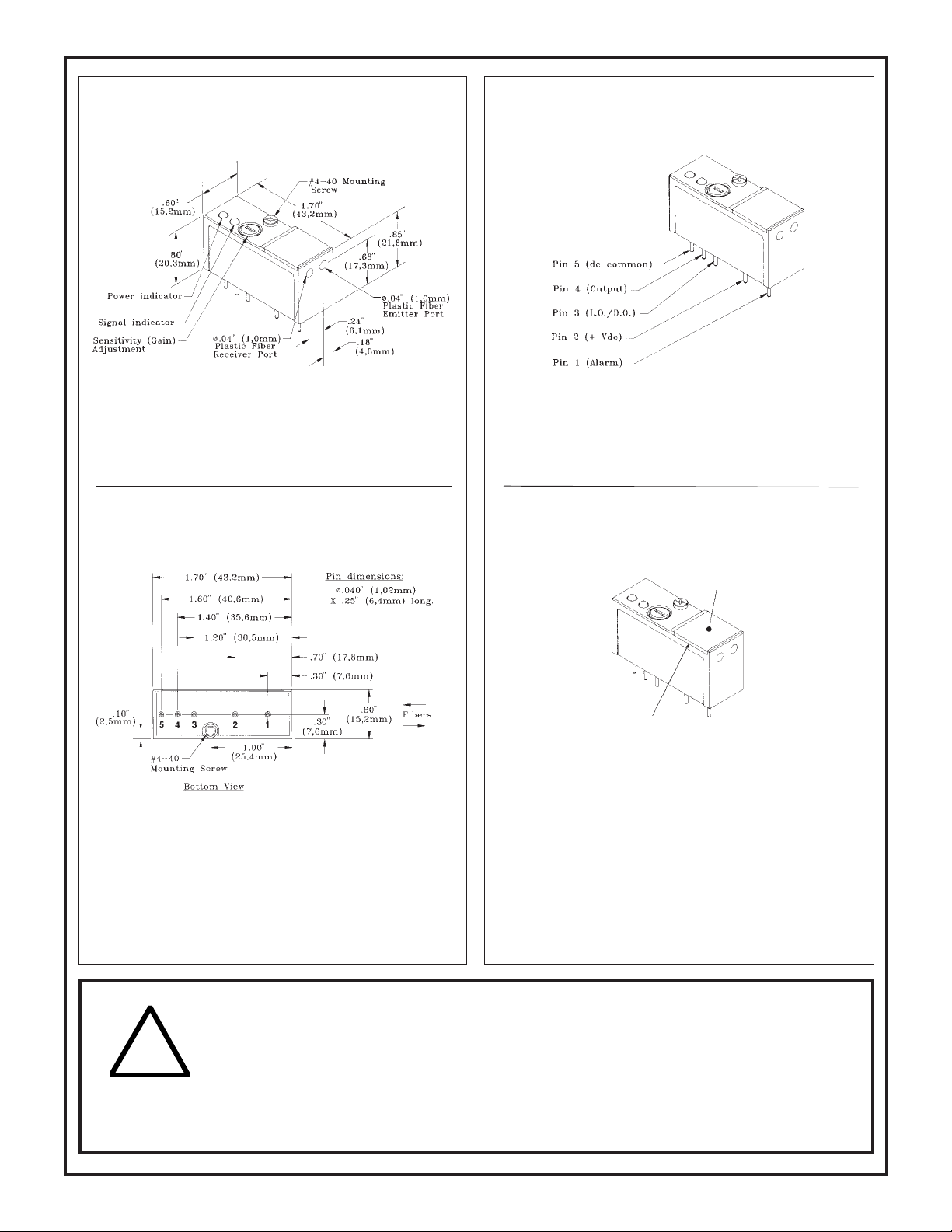

Dimensions & Features, PC44 Series Modules

Pin Identification, PC44 Series Modules

Light/dark operate selection is done at pin #3.

For light operate mode, leave pin #3 unconnected.

For dark operate, connect pin #3 to +V dc.

Dimensions & Pin Locations (module bottom)

Recommended PC-board hole diameters:

Module pins .048" (after plating)

Jacks* .105" (after plating)

Hold-down PEM nut* .166"

*Supplied in kit PCJ-25 (order separately from

module).

Kit PCJ-25 contains 25 jacks and 5 hold-down nuts,

sufficient to mount five PC44 modules.

Fiber Installation

Gripper door

(Lift up here)

Fiber Installation Procedure:

1) Cut fiber to length as described in the data sheet accompanying the fiber.

2) Gently lift up the edge of the gripper door along the "label side" of the

module.

3) Push both fibers into the proper ports* until they stop. While holding the

fibers snugly in place, press the gripper door closed.

*Ports are labeled for emitter and receiver fibers. The difference is not

important when bifurcated fibers are used in the diffuse mode, but may be

a factor when individual fibers are used (opposed sensing mode). The

emitter port is for the fiber on the emitter side of the process; the receiver

port is for the fiber on the receiver side of the process.

WARNING PC44 Series modules do NOT include the self-checking redundant circuitry necessary to allow their use in

personnel safety applications. A sensor failure or malfunction can result in either an energized or a de-energized sensor output

condition.

!

Only MACHINE-GUARD and PERIMETER-GUARD Systems, and other systems so designated, are designed to meet OSHA and ANSI machine safety

standards for point-of-operation guarding devices. No other Banner sensors or controls are designed to meet these standards, and they must NOT be used

as sensing devices for personnel protection.

2

Never use these products as sensing devices for personnel protection. Their use as safety devices may create an unsafe condition

which could lead to serious injury or death.

Page 3

d

Opposed fiber optic sensing mode

1

10

100

10 mm

0.4 in

100 mm

4 in

1000 mm

40 in

1 mm

0.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

PC44

Opposed Mode

PIT46U Fibers

Excess Gain Curve

Beam Pattern

PC44

Opposed Mode

38 mm

25 mm

13 mm

0

13 mm

25 mm

38 mm

50 mm

0

PIT46U Fibers

2 in

100 mm

4 in

DISTANCE

150 mm

6 in

200 mm

8 in

250 mm

10 in

1.5 in

1.0 in

0.5 in

0

0.5 in

1.0 in

1.5 in

In opposed mode sensing, emitter and receiver fiber optics are

set up opposite (and facing) each other, and the object to be

detected passes between the fiber optic sensing tips and breaks

the light beam. Two individual (PI Series) fiber optic assemblies are required: one to carry the emitted light and the other to

carry the received light. The curves (above left) show typical

opposed mode performance of a PC44 module fitted with two

PIT46U fibers in the opposed sensing mode.

Opposed mode sensing range may be extended by using lenses

on both emitter and receiver fibers. The curves (above right)

show the typical performance of PIT46U fibers fitted with L2

lenses. L2RA (right-angled) prisms may be used with threadedtip fibers to provide sensing at right angles to the fiber tips,

although at somewhat reduced sensing range compared to

unlensed fibers.

150 mm

100 mm

50 mm

50 mm

100 mm

150 mm

PC44, .040" fibers

0

0

Beam Pattern

Opposed mode, L2 lenses

1.5 m

1 m

.5 m

20 in

40 in

DISTANCE

60 in

80 in

2.5 m

2 m

100 in

Excess Gain Curve

1000

E

X

C

100

E

S

S

PC44

Opposed Mode,

10

G

PIT46U (.040") fibers,

A

L2 lenses

I

N

1

10 mm

100 mm

4 in

DISTANCE

1 m

40 in

0.4 in

10 m

400 in

L2 and L2RA

L2 lens for extended range operation with opposed mode fibers.

Use with PIT46U or PIT46UC. See sensor excess gain curves

for range information. L2RA (not shown)

provides right-angle sensing at

somewhat reduced range.

.365

9,3

.11 Ø glass lens

2,8

.16 Ø

3,8

M2.5 x 0,45

internal threa

6 in

4 in

2 in

0

2 in

4 in

6 in

Standard models of PI Series individual plastic fiber optic assemblies are included in the list at the bottom of page 4.

Banner Engineering Corp. can custom-design plastic fibers to suit the requirements of your particular application. Contact one

of our application engineers by telephone or FAX for a quote on your design.

Diffuse fiber optic sensing mode

Diffuse mode sensing utilizes bifurcated (PB Series) fibers.

These are paired fibers, one of which carries the light from the

emitter element to the sensing point, while the other carries the

light (reflected from the sensed object) from the sensing point

back to the receiver element.

The curves (right) show typical performance of a PC44 module

fitted with a model PBT46U fiber assembly in the diffuse

sensing mode. Diffuse mode sensing range is referenced to a

white test card of 90% reflectance. Less reflective objects will

shorten the sensing range.

Excess Gain Curve

1000

E

X

C

100

E

S

S

10

G

A

I

N

1

0.1 mm

0.004 in

PBT46U Fiber

1 mm

0.04 in

DISTANCE

Diffuse Mode

10 mm

0.4 in

PC44

100 mm

4 in

Standard models of PB Series bifurcated plastic fiber optic

assemblies are included in the list at the bottom of page 4.

Banner Engineering Corp. can custom-design plastic fibers to suit the requirements of your particular application. Contact one

of our application engineers by telephone or FAX for a quote on your design.

Beam Pattern

PC44

Diffuse Mode

7.5 mm

5 mm

2.5 mm

0

2.5 mm

5 mm

7.5 mm

PBT46U Fiber

50 mm

37.5 mm

25 mm

12.5 mm

0

1.0 in

0.5 in

DISTANCE

1.5 in

2.0 in

Distance to 90% reflectance white test card

62.5 mm

2.5 in

0.3 in

0.2 in

0.1 in

0

0.1 in

0.2 in

0.3 in

3

Page 4

Banner Plastic fiber optic assemblies

Banner plastic fiber optics are an economical alternative to glass

fiber optics for piping photoelectric sensing light into and out of

confined areas where the environmental conditions allow.

They are offered in two general styles: individual and bifurcated.

Individual (PI Series) fibers are used in pairs in the opposed sensing

mode. One fiber transmits the light to the sensing location, while

the other fiber returns the received light to the sensor.

Bifurcated (PB Series) plastic fiber assemblies are "two-way"

fibers having a single sensing end that both emits and receives light

and dual control (sensor) ends which attach separately to the

sensor. Plastic fiber optic assemblies are available in a variety of

sensing end styles. Coiled assemblies may be used successfully on

reciprocating mechanisms for millions of cycles.

Banner plastic fiber optic assemblies are available in two monofilament core diameters: .020-inch and .040-inch. PC44 Series

modules require .040-inch core fibers.

Banner standard plastic fiber optic assemblies are unterminated on

the control (sensor) end. Fiber assemblies are approximately 6 feet

(2m) in length. They can be used "as-is", or they may be cut to a

shorter length. Each assembly is supplied with a cutting device to

allow the fiber to be easily cut to length. Cutting instructions are

included with the fiber assembly.

Due to their light transmission properties, plastic fiber optics are

recommended for use only with visible light fiber optic sensors.

Banner Engineering can custom design plastic fibers to suit your

application requirements. Contact one of our application engi-

neers by telephone or FAX for a quote on your particular design.

Specifications, Banner plastic fiber optic assemblies

SENSING RANGE: refer to the excess gain curves for the fiber optic sensor

to be used. The selection charts at the front of the Banner product catalog list

all self-contained fiberoptic sensors and page references for gain curves.

TEMPERATURE EXTREMES: temperatures below -30° C will cause

embrittlement of the plastic materials but will not cause transmission loss.

Temperatures above +70° C will cause both transmission loss and fiber

shrinkage.

REPEAT BENDING/FLEXING: life expectancy of plastic fiber optic cable

is in excess of one million cycles at bend radii of no less than the minimum

(stated below) and a bend of 90 degrees or less. Avoid stress at the point where

the cable enters the sensor ("control end") and at the sensing end tip. Coiled

plastic fiberoptic assemblies are recommended for any application requiring

reciprocating fiber motion.

OPERATING TEMPERATURE: -30 to +70° C (-20 to +158° F).

CHEMICAL RESISTANCE: the acrylic core of the monofilament optical

fiber will be damaged by contact with acids, strong bases (alkalis) and solvents.

The polyethylene jacket will protect the fiber from most chemical environments. However, materials may migrate through the jacket with long term

exposure. Samples of fiber optic material are available from Banner for testing

and evaluation.

MINIMUM BEND RADIUS: 1.0 inch (25mm) for .040 inch diameter fibers.

CONSTRUCTION:

OPTICAL FIBER: plastic monofilament

PROTECTIVE JACKET: black polyethylene

THREADED END TIPS and HARDWARE: nickel-plated brass

PROBE END TIPS: annealed (bendable) T304 stainless steel

ANGLED END TIPS: hardened T304 stainless steel

FERRULED END TIPS: T303 stainless steel

Banner plastic fiber optic assemblies are available either straight or coiled, individual or

bifurcated, and with a variety of sensing tip styles (see photo). Models compatible with

PIF46U

(2 shown)

PIT46U

(2 shown)

WARRANTY: Banner Engineering Corporation warrants its products to be free from defects for one year. Banner Engineering Corporation will repair or

replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty

does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or implied.

Banner Engineering Corp. 9714 10th Avenue No., Minneapolis, MN 55441 Telephone: (612) 544-3164 FAX (applications): (612) 544-3573

PIT46UC

PBT46U

PBF46U

PC44 Series modules include the full line of Banner .040" core diameter plastic fibers:

PBF46U straight bifurcated fiber, ferruled sensing tip (for diffuse sensing)

PBP46U straight bifurcated fiber, bendable probe sensing tip (for diffuse sensing)

PBP46UC coiled bifurcated fiber, bendable probe sensing tip (for diffuse sensing)

PBT46U straight bifurcated fiber, threaded sensing tip (for diffuse sensing)

PBT46UC coiled bifurcated fiber, threaded sensing tip (for diffuse sensing)

PIF46U straight individual fiber, ferruled sensing tip (for opposed sensing)

PIP46U straight individual fiber, bendable probe sensing tip (for opposed sensing)

PIP46UC coiled individual fiber, bendable probe sensing tip (for opposed sensing)

PIT46U straight individual fiber, threaded sensing tip (for opposed sensing)

PIT46UC coiled individual fiber, threaded sensing tip (for opposed sensing)

NOTES: Individual fibers are sold in pairs. For further information about Banner

plastic fiber optic assemblies, request product data sheet P/N 32881.

Loading...

Loading...