Page 1

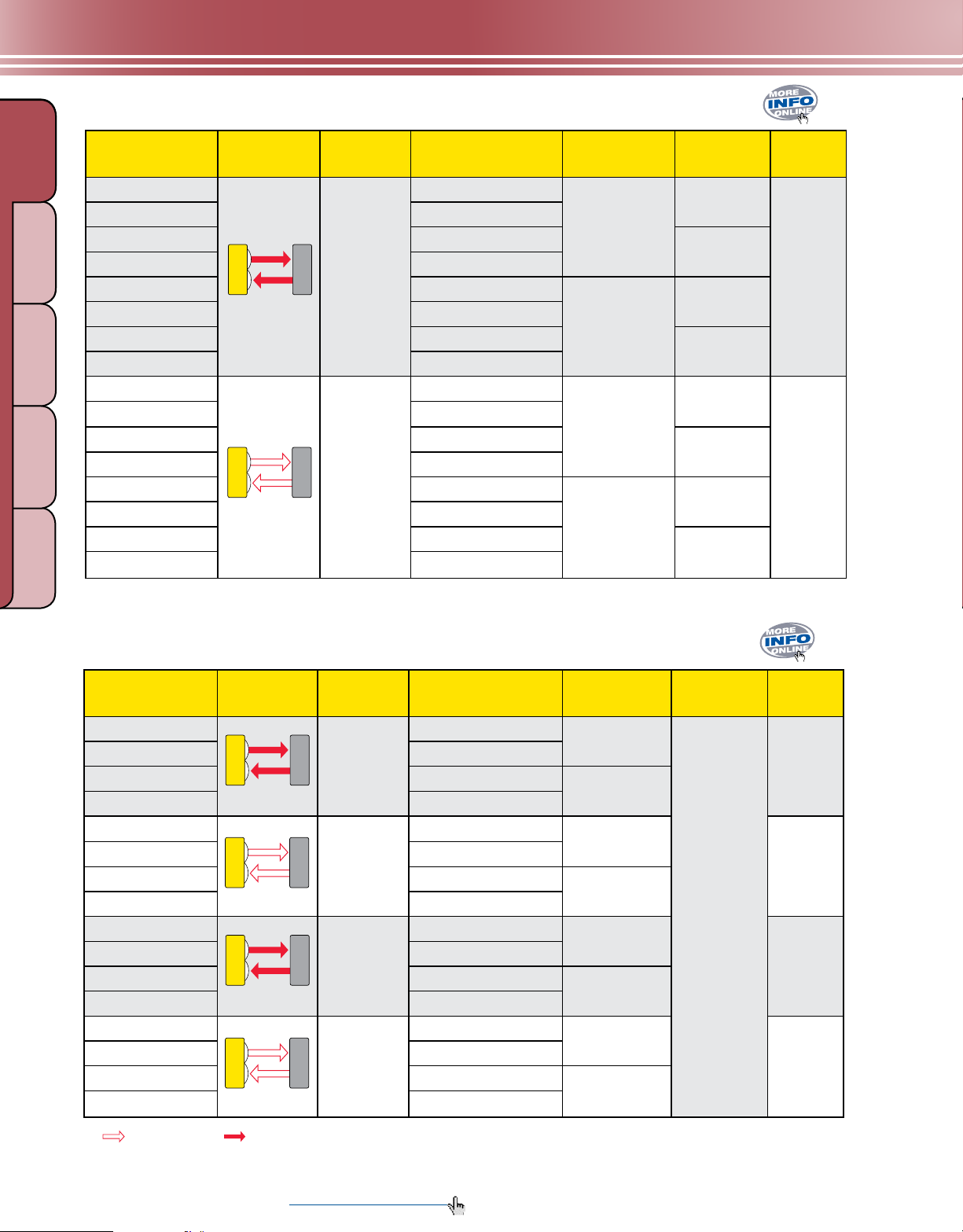

MEASUREMENT & INSPECTION

®

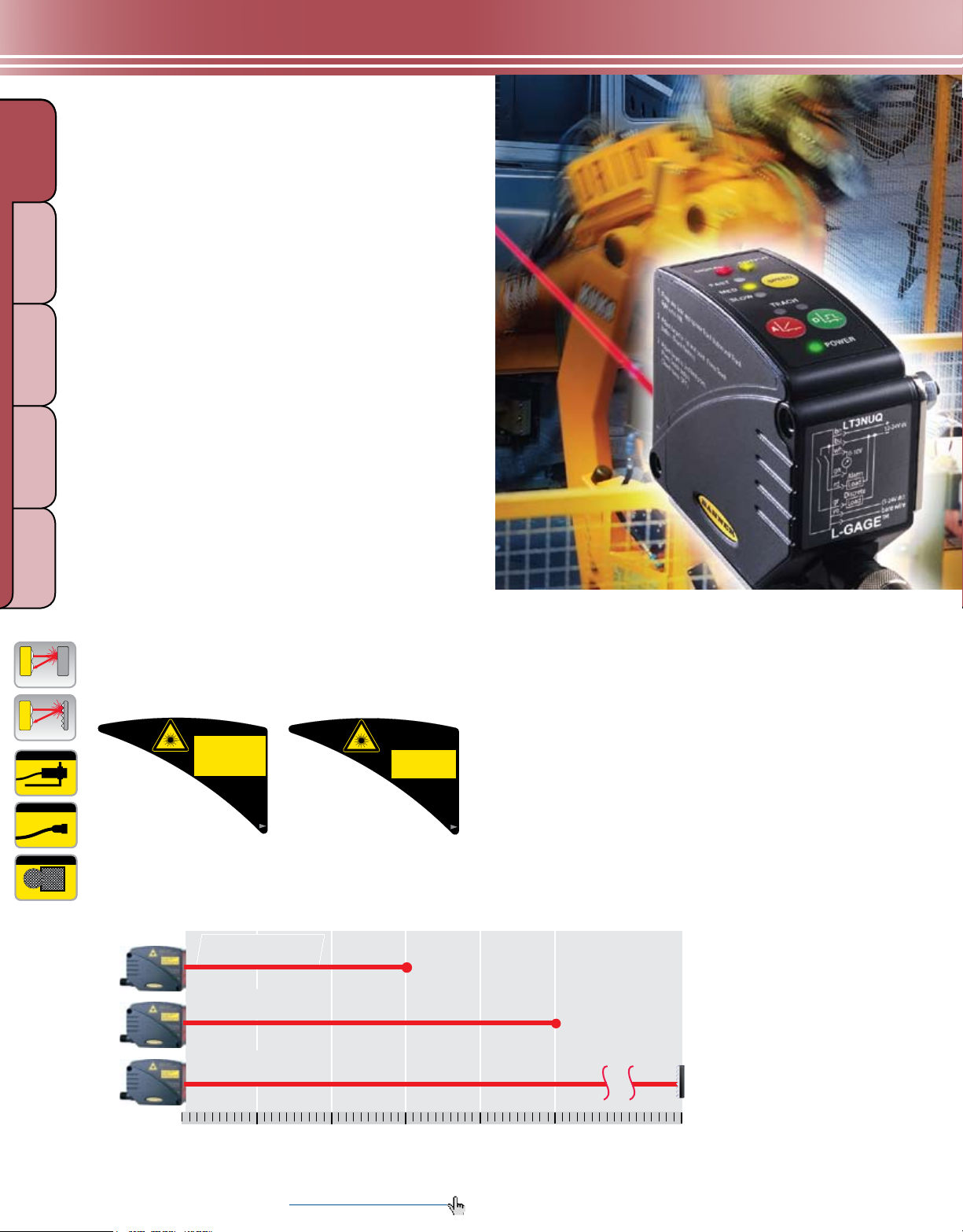

L-GAGE

Light Gauging Sensors

LT3 page 244

• Exceptionally accurate advanced time-of-flight

sensing technology provides precise measurements

over long ranges.

• Retroreflective mode sensor has 50 m range.

• Ranges with diffuse mode sensor are 5 m for white

targets and 3 m for gray targets.

• Sensors offer either analog and discrete, or

dual-discrete output, with independent window limits.

GAUGI NG

LIGHT

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

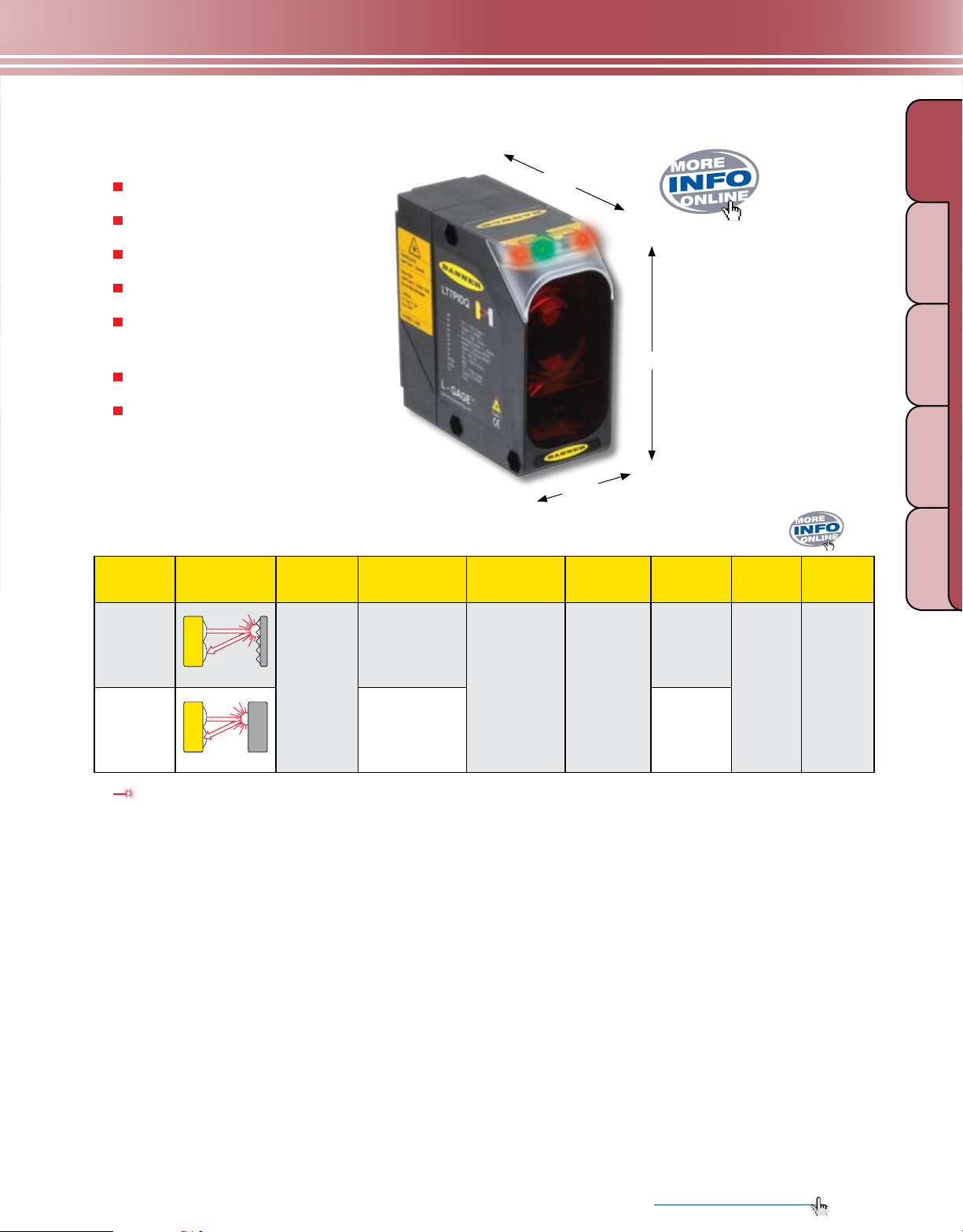

LT7 page 248

• Extremely long-range sensor uses a

Class 1 laser beam for accuracy over long

distances.

• Retroreflective mode sensor has

250 m range.

• Ranges with diffuse mode sensor are up

to 10 m for white, 7 m for gray and 3 m for

black targets.

• Models are available with discrete output

only or with discrete and analog output.

• RS-422 or SSI compatible serial

connections are provided.

LG page 252

• One-piece laser gauging system requires

no separate controller.

• Ultra narrow beam delivers precise

distance, height and thickness

measurement and gauging.

• Two sensing ranges are available:

45 to 60 mm and 75 to 125 mm.

RADAR

Q50 page 256

• LED sensor delivers laser-like performance

in a compact, low-cost package.

• Models are available to gauge distances

either from 100 to 400 mm or 50 to 200 mm,

with analog or discrete output.

• Features include high resolution and a fast,

selectable response time.

More information online at bannerengineering.com

243

Page 2

MEASUREMENT & INSPECTION

QD CABLES

REFLECTORS

LASE R R ETRO

LASER DIFFU SE

BRACKETS

RADIANT POWER 0.15mW

10ns PULSE, 1MHz

650 - 670

nm

Complies with IEC 60825-1:

and 21 CFR 1040.10 & 1040.

except for deviations purs

Laser Notice No. 50, date

d

July 26, 2001

LASER LIGHT

CLASS 1 LASER PRODUCT

Laser ligh

t

emitted fr

o

this apertue

RADIANT POWER 0.5mW

10ns PULSE, 1MHz

650 - 670 nm

COMPLIES TO 21 CFR PART

1040.10 AND EN60825-1:1994

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

Av oid exposure- las

e

light emit

t

thisture

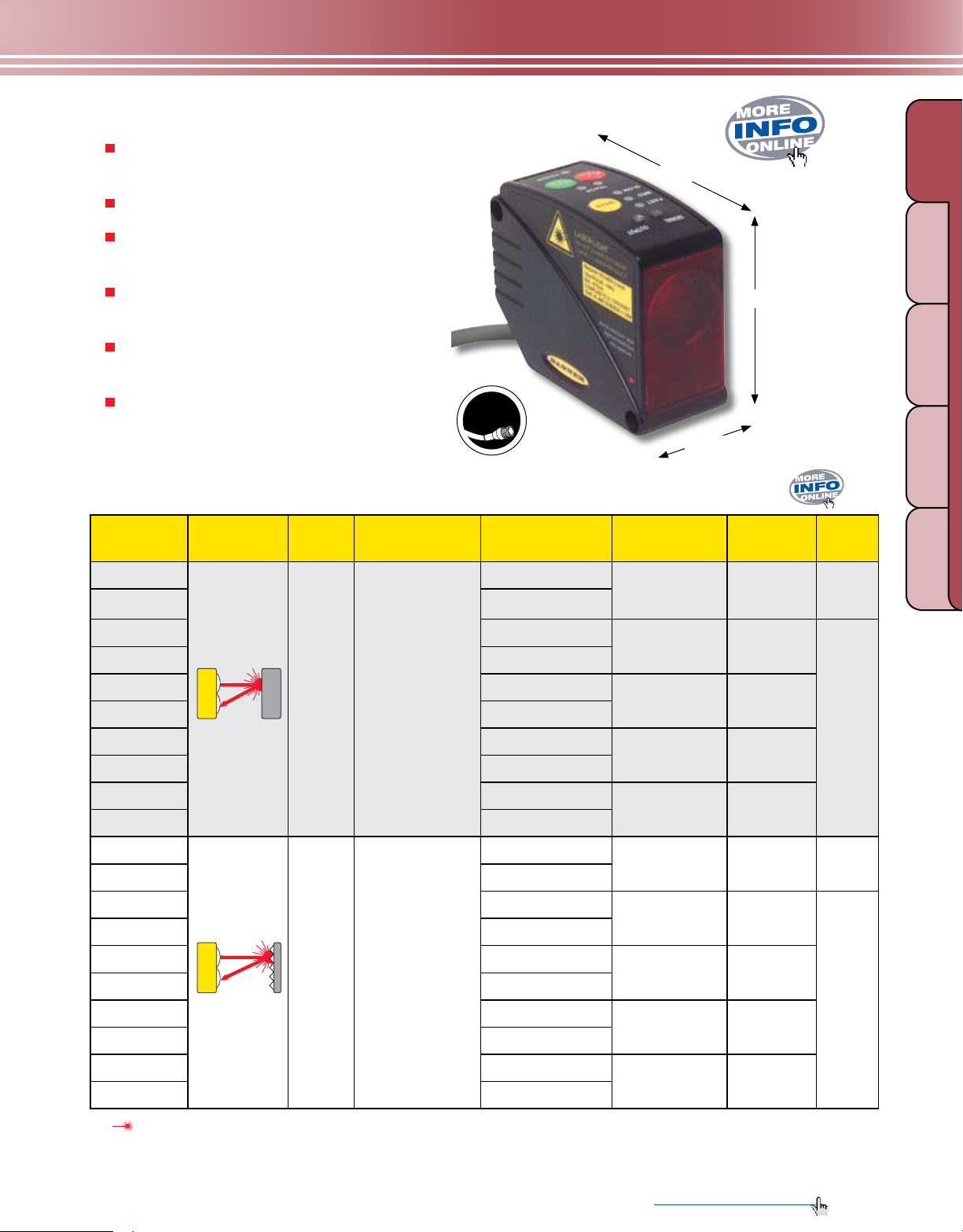

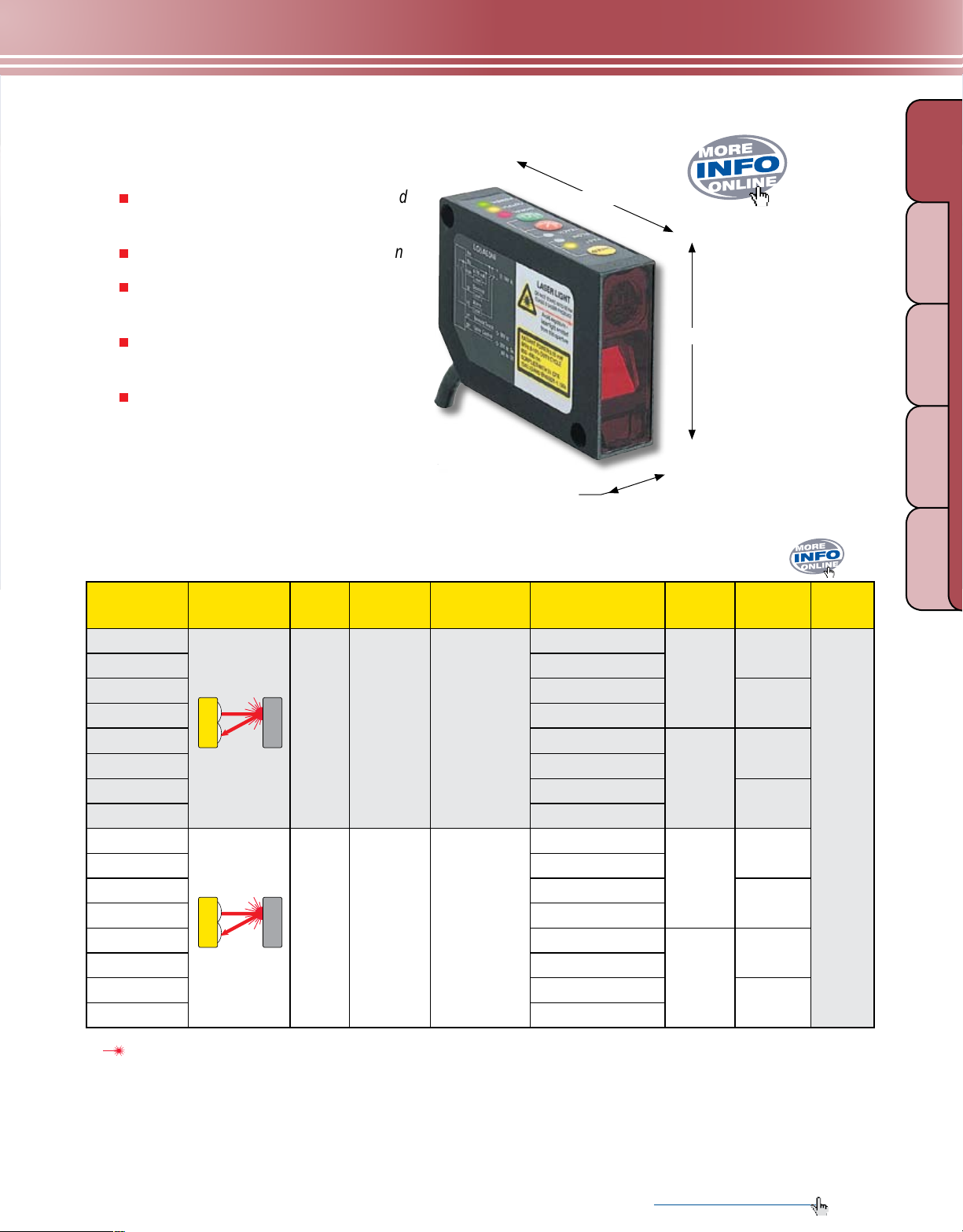

L-GAGE® LT3

LIGHT

ULTRASONIC

MEASURING

TE MP ER ATU RE

RADAR

GAUGI NG

SLOT & LABEL PART & AREA

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

Laser DistanceGauging Sensors

Advanced time-of-flight technology at less cost

The L-GAGE® LT3 sensor uses “time-of-ight” technology

for precise, long-distance gauging at the speed of light.

The microprocessor-controlled laser distance-gauging

sensor features a unique design for exceptional accuracy

and range at a much lower cost than competitive lasergauging devices. Precise performance and low price

make the LT3 an ideal solution for a variety of precision

inspection applications.

lUMINESCENCE

• Available in accurate diffuse-mode models with ranges

to 5 m and retroreflective models with a 50 m range

• Emits one million pulses per second

• Reliably detects angled targets

Analog & discrete outputs, or dual-discrete models

The LT3 can include both a discrete (switched) output

and an analog output in the same unit, with independently

programmable window limits. For added exibility, the

analog output is available in a choice of 4 to 20 mA

or 0 to 10V dc. You can also choose models with two

independent discrete outputs, selectable PNP (sourcing)

or NPN (sinking).

Compact, self-contained design

• The LT3’s design conserves production space and

decreases setup time.

• The self-contained system measures just 68.5 by 35.3

by 87.0 mm, to fit and function in tighter spaces than

competitive systems.

PAGE 370

8-Pin Euro

PAGE 416

PAGE 425

Class 1 Label Class 2 Label

LT3 Sensing Ranges

Diffuse models with

gray targets: 0.3 - 3 m

Diffuse models with

white targets: 0.3 - 5 m

Retroreective models with

retroreector: 0.5 - 50 m

244 More information online at bannerengineering.com

Meters

1 2 3 4 5 . . . 50

Simple 3-step programming

Programming the LT3 takes just three short steps, which

are conveniently printed on the side of the sensor. In

addition, push-button TEACH-mode programming sets

custom sensing windows. And remote programming

offers added security and convenience.

Page 3

MEASUREMENT & INSPECTION

Detailed

Dimension

s

LASER DIFFUSE

LASER RETRO

Dow nlo a

d

PDF

QPMA

E

U

R

O

-

S

T

Y

L

E

•

P

I

G

T

A

I

L

•

P

U

R

•

C

A

B

L

E

C

A

L

L

F

A

C

T

O

R

Y

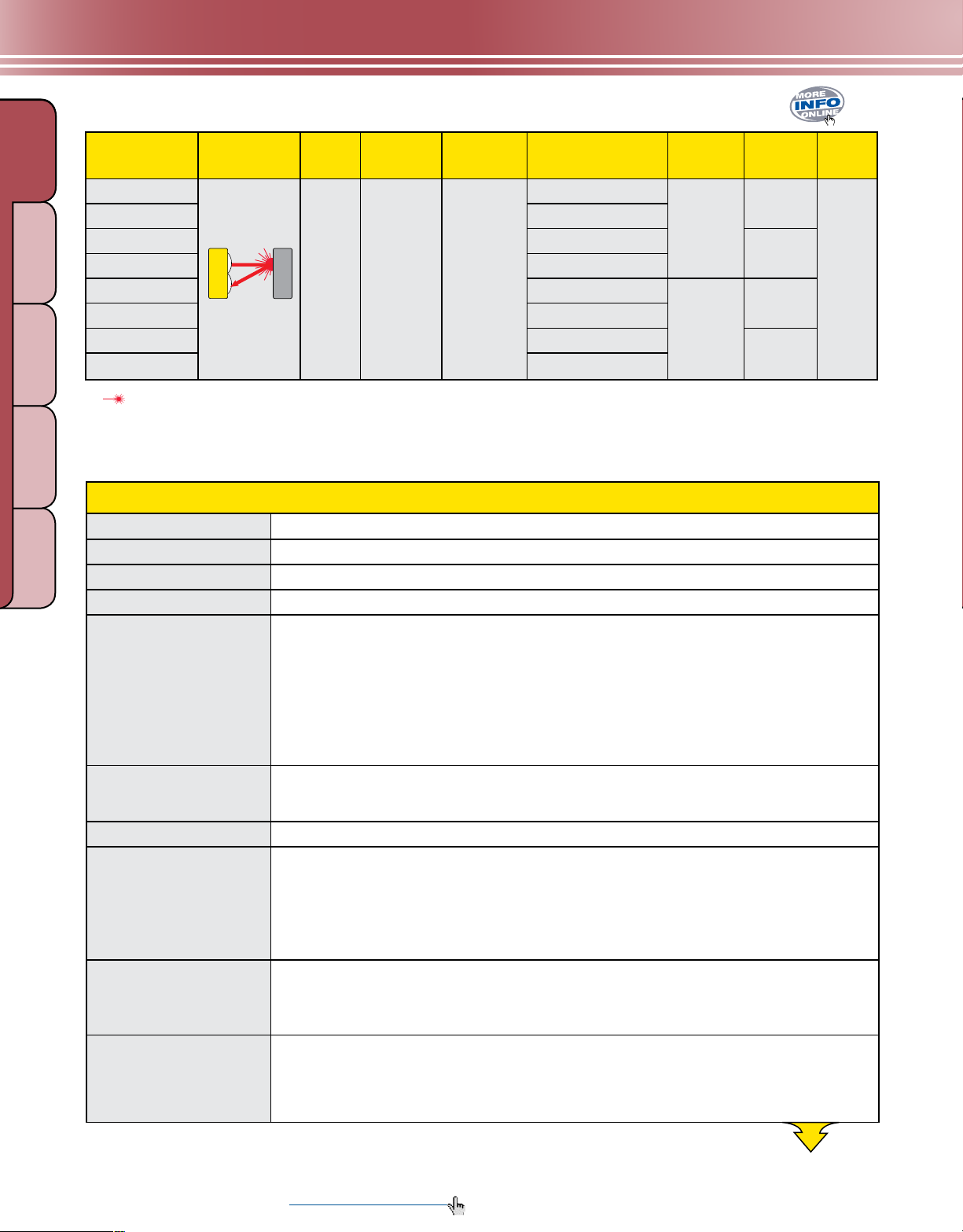

L-GAGE® LT3 Sensors

Programmable output response for three

speeds using simple push-button TEACH

Bright, visible laser spot to simplify alignment

Analog outputs in a choice of 0 to 10V dc or

4 to 20 mA sourcing

Rugged construction to withstand demanding

sensing environments; rated IEC IP67, NEMA 6

2 m or 9 m attached cable, or 8-pin Euro-style

quick-disconnect

8-pin Euro-style QD cables with shield ordered

separately (see page 416)

L-GAGE® LT3, 12-24V dc

Models

LT3BD

LT3BDQ

Sensing

Mode/LED*

Laser

Class

Sensing

Distance Cable**

2 m

8-pin Euro QD

87.0 mm

35.3 mm

Discrete

Output

Dual NPN or

PNP Selectable

68.5 mm

Analog

Output

None

Data

Sheet

68503

GAUGI NG

LIGHT

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

LT3PU

LT3PUQ

LT3NU

LT3NUQ

LT3PI

LT3PIQ

LT3NI

LT3NIQ

LT3BDLV

LT3BDLVQ

LT3PULV

LT3PULVQ

LT3NULV

LT3NULVQ

LT3PILV

LT3PILVQ

LT3NILV

LT3NILVQ

Class 2

Class 1

0.3 to 5 m

for 90% reectivity

white card

(see Performance

Curve RRC-1 on

page 510 for more

information)

0.5 to 50 m

†

(see Performance

Curve RRC-2 on

page 510 for more

information)

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

2 m

8-pin Euro QD

PNP 0 to 10V dc

NPN 0 to 10V dc

PNP 4 to 20 mA

NPN 4 to 20 mA

Dual NPN or

PNP Selectable

PNP 0 to 10V dc

NPN 0 to 10V dc

PNP 4 to 20 mA

NPN 4 to 20 mA

None

65742

68503

68504

Visible Red Laser

*

** For 9 m cable, add suffix W/30 to the 2 m model number (example, LT3BD W/30). A model with a QD requires a mating cable (see page 416).

†

Retroref lective range specified using included model BRT-TVHG -8X10P high-grade target.

More information online at bannerengineering.com

245

Page 4

LIGHT

ULTRASONIC

MEASUREMENT & INSPECTION

Sensing Beam

GAUGI NG

Sensing Range

SLOT & LABEL PART & AREA

Supply Voltage and Current

Supply Protection Circuitry

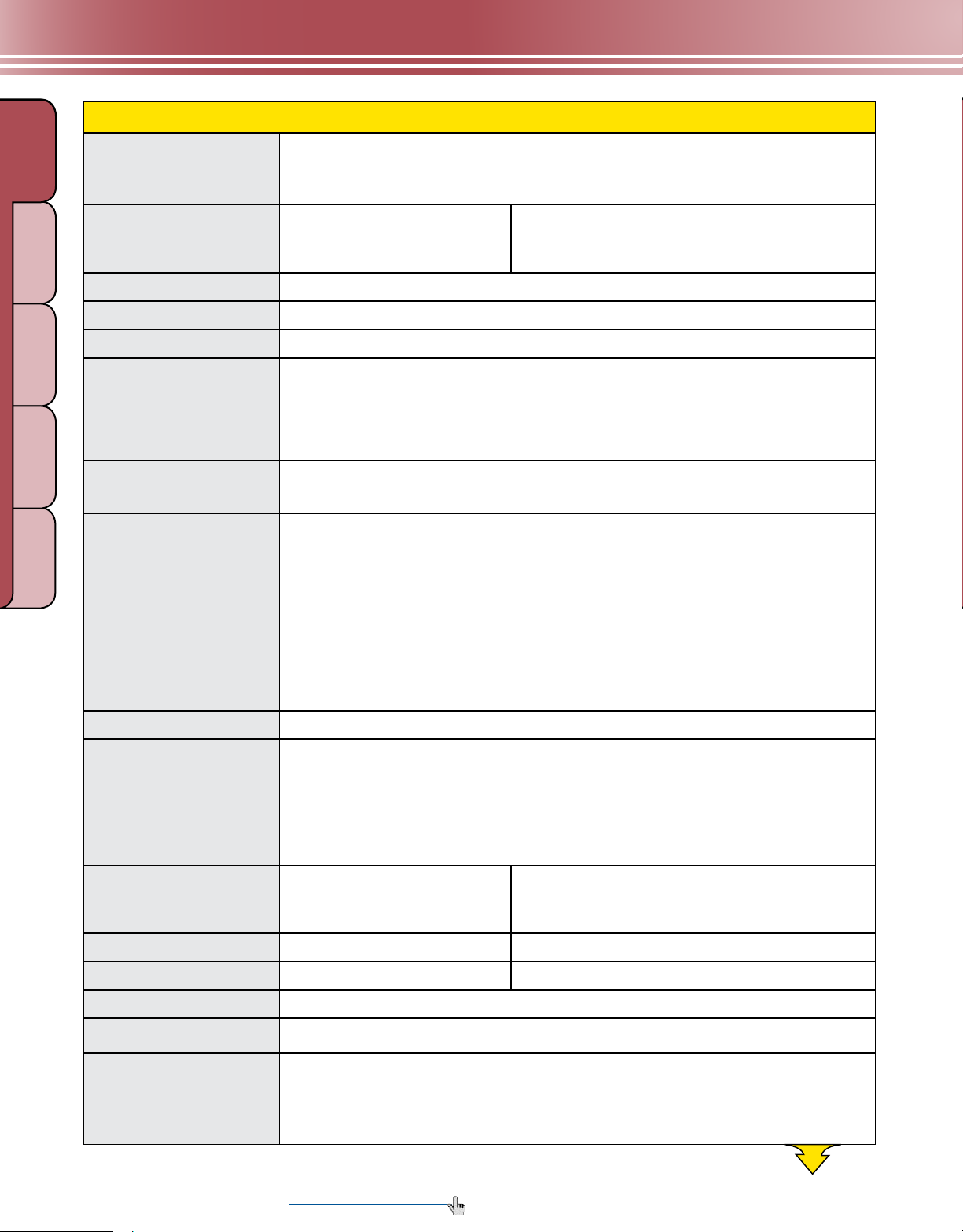

L-GAGE® LT3 Specifications

Typical beam dia: 6 mm @ 3 m

Typical laser lifetime: 75,000 hours

Diffuse: 658 nm visible red IEC and CDRH Class 2 laser; 0.5 mW max. radiant output power

Retroreflective: 658 nm visible red IEC and CDRH Class 1 laser, 0.15 mW max. radiant output power

Diffuse:

90% white card: 0.3 to 5 m

18% gray card: 0.3 to 3 m

6% black card: 0.3 to 2 m

12 to 24V dc (10% max. ripple); 108 mA max. @ 24V dc or [2600/V dc] mA

Protected against reverse polarity and transient voltages

Retroreflective:

0.5 to 50 m (using supplied target)

MEASURING

TE MP ER ATU RE

RADAR

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

Delay at Power-up

Output Rating

lUMINESCENCE

Output Configuration

Output Protection

Output Response Time

Resolution/Repeatability

Color Sensitivity (typical)

Analog Linearity

1 second; outputs do not conduct during this time

Discrete (switched) output: 100 mA max.

OFF-state leakage current: less than 5 µA

Output saturation NPN: less than 200 mV @ 10 mA; less than 600 mV @ 100 mA

Output saturation PNP: less than 1.2V at 10 mA; less than 1.6V at 100 mA

Analog voltage output: 2.5 kΩ min. load impedance (voltage sourcing)

Analog current output: 1 kΩ max. @ 24V; max. load resistance = [Vcc-4.5/0.02 Ω] (current sourcing)

Discrete (switched): Solid-state switch; NPN (current sinking) or PNP (current sourcing), depending on

model. Dual-discrete models feature selectable NPN or PNP, depending on wiring hookup.

Analog output: 0 to 10V dc or 4 to 20 mA

Protected against short circuit conditions

Discrete output

Fast: 1 millisecond ON/OFF Medium: 10 milliseconds ON/OFF Slow: 100 milliseconds ON/OFF

Diffuse Analog Voltage output (-3 dB)

Fast: 450 Hz (1 millisecond average/1 millisecond update rate)

Medium: 45 Hz (10 milliseconds average/2 milliseconds update rate)

Slow: 4.5 Hz (100 milliseconds average/4 milliseconds update rate)

Retroreflective Analog Voltage output (-3 dB)

Fast: 114 Hz (6 milliseconds average/ 1 millisecond update rate)

Medium: 10 Hz (48 milliseconds average/ 1 millisecond update rate)

Slow: 2.5 Hz (192 milliseconds average/ 1 millisecond update rate)

See charts RRC-1 and RRC-2 on page 510.

Diffuse: 90% white to 18% gray: less than 10 mm; 90% white to 6% black: less than 20 mm.

See chart CSC-1 on page 511.

Retroreflective: ± 60 mm from 0.5 to 50 m (0.12% of full scale)

(Specied @ 24V dc, 22° C using supplied BRT-TVHG-8X10P retroreector)

Diffuse: ± 30 mm from 0.3 to 1.5 m; ± 20 mm from 1.5 to 5 m

(Specied @ 24V dc, 22° C using a 90% reectance white card)

Discrete Output Hysteresis

Diffuse

Fast: 10 mm

Medium: 5 mm

Slow: 3 mm

Temperature Effect

Minimum Window Size

Remote TEACH Input

Remote TEACH

Adjustments

Diffuse: less than 2 mm/ ° C Retroreflective: less than 3 mm/° C

Diffuse: 20 mm Retroreflective: 40 mm

18 kΩ min. (65 kΩ at 5V dc)

To teach: Connect yellow wire to +5 to 24V dc

To disable: Connect yellow wire to 0 to +2V dc (or open connection)

Response speed: Push button toggles between fast, medium and slow (see Output Response Time)

Window limits (analog or discrete): TEACH-mode programming of near and far window limits.

Limits may also be taught remotely using TEACH input.

Analog output slope:

The rst limit taught is assigned to minimum output current or voltage (4 mA or 0V dc)

246 More information online at bannerengineering.com

Retroreflective

Fast: 20 mm

Medium: 10 mm

Slow: 6 mm

More on

next page

Page 5

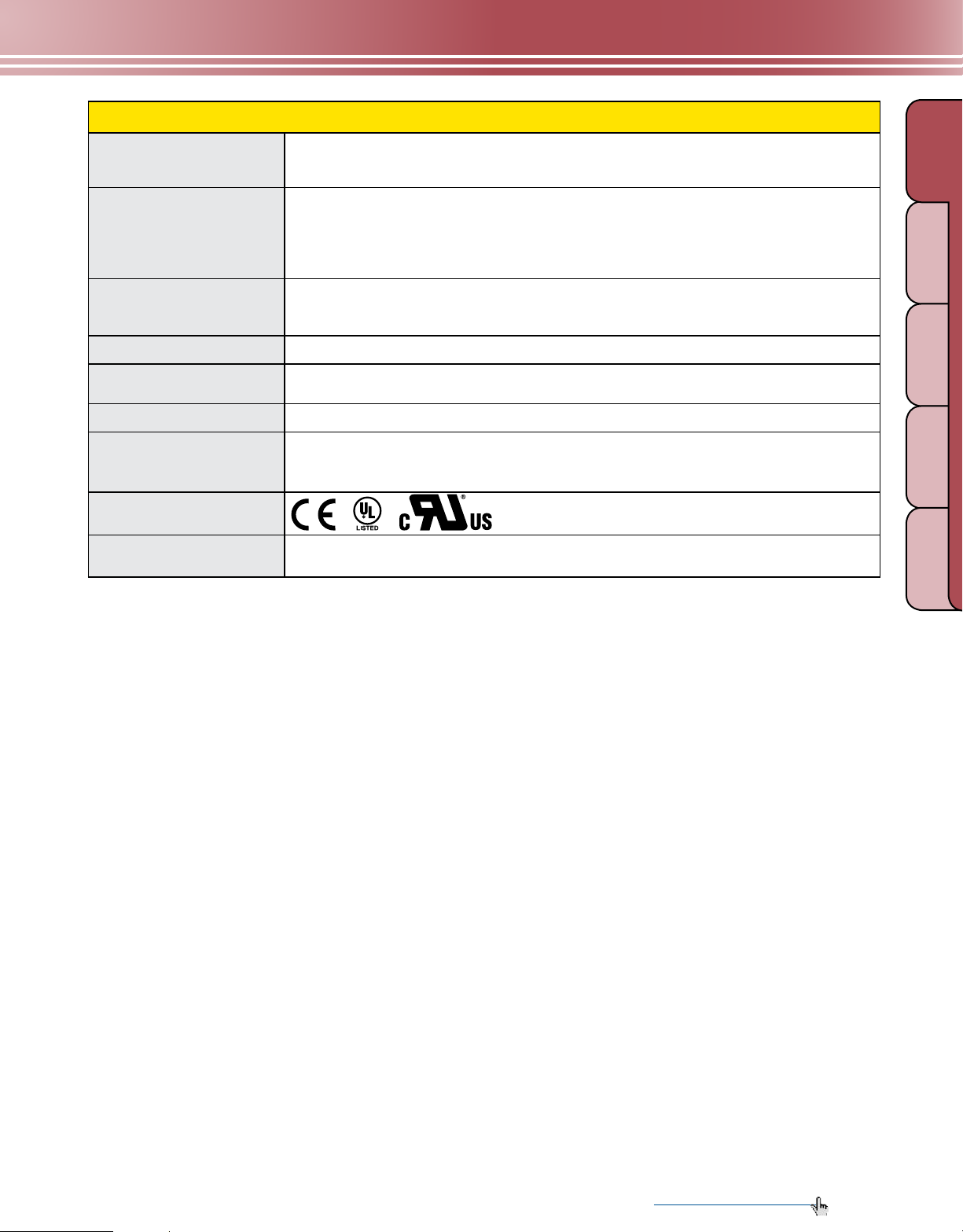

MEASUREMENT & INSPECTION

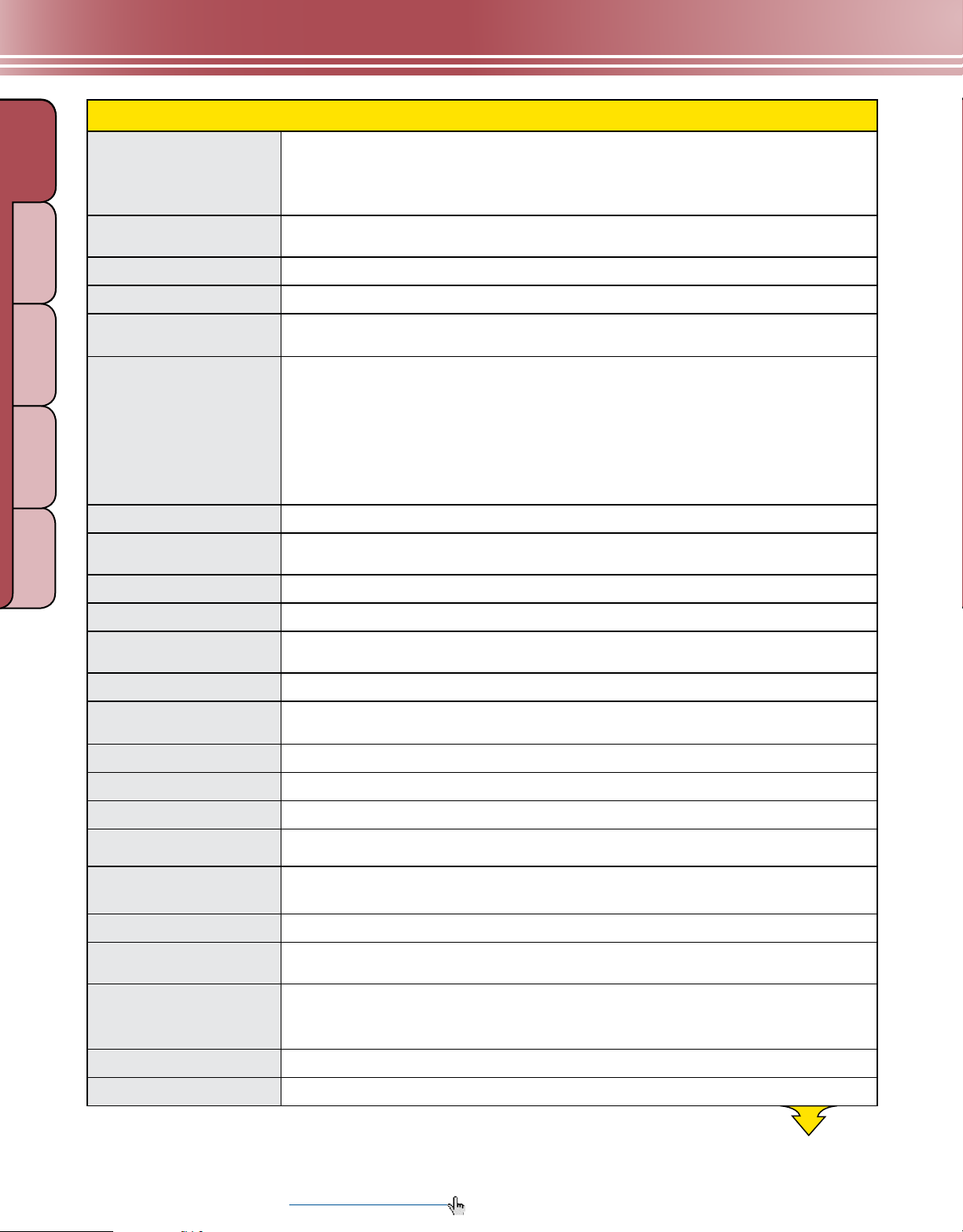

Laser Control

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

Application Notes

Certifications

Hookup Diagrams

L-GAGE® LT3 Specifications

Connect red wire to +5 to 24V dc to enable laser beam; connect to 0 to +1.8V dc

(or open connection) to disable; when sensor is powered laser enable time is 100 millisecond delay on

enable, when sensor is powered.

Green Power ON LED: Indicates when power is ON, overloaded output and laser status

Yellow Output LED: Indicates when discrete load output is conducting

Red Signal LED: Indicates target is within sensing range and the condition of the received light signal

Yellow Speed LED: Indicates the response speed setting

Red/Yellow TEACH LEDs: In programming mode; indicate active output(s)

Housing: ABS/polycarbonate blend

Window: Acrylic

Quick-disconnect: ABS/polycarbonate blend

IP67; NEMA 6

2 m or 9 m shielded 7-conductor (with drain) PVC-jacketed attached cable, or 8-pin Euro-style

quick-disconnect. QD cables are ordered separately. See page 416.

Temperature: 0° to +50° C Relative humidity: 90% at 50° C (non-condensing)

• For best accuracy, allow 30-minute warm-up before programming or operating

• Retroreective performance specications are based on use with supplied BRT-TVHG-8X10P

high-grade target. Results may vary with other retroreective target materials.

R

Discrete/Analog Models: NPN: MI01 (p. 532) PNP: MI02 (p. 532)

Dual-Discrete Models: NPN: MI03 (p. 532) PNP: MI04 (p. 532)

(cont’d)

GAUGI NG

LIGHT

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

More information online at bannerengineering.com

247

Page 6

MEASUREMENT & INSPECTION

QD CABLES

Operating Mode

Laser Class 1

Setup Mode

Laser Class 2

Do not stare into beam

LASE R R ETR O

LASER DIFFUSE

BRACKETS

REFLECTORS

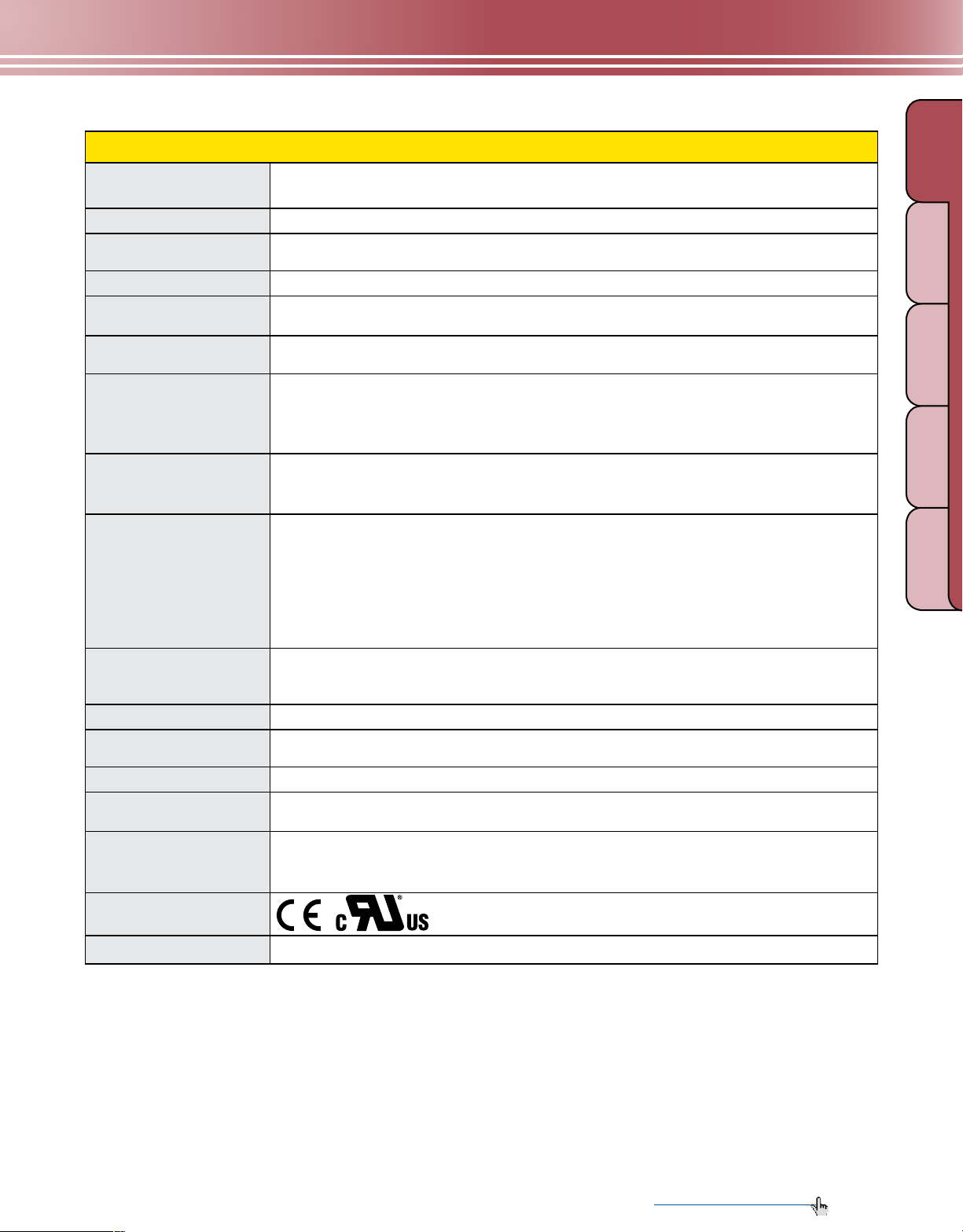

L-GAGE® LT7

LIGHT

ULTRASONIC

MEASURING

TE MP ER ATU RE

RADAR

PAGE 372

12-Pin M16

PAGE 418

PAGE 425

GAUGI NG

SLOT & LABEL PART & AREA

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

Highly Accurate

Time-of-Flight Laser

Gauging Sensors

• Available in extremely long-range retroreflective

models with ranges to 250 m or in diffuse models with

ranges to 10 m

• Features TEACH-mode programming, using either

integrated push buttons or a serial interface

• Provides ongoing LCD display of sensing distance in

lUMINESCENCE

millimeters or hundredths of an inch

• Delivers excellent ±10 mm linearity

• Offers choice of RS-422 or SSI-compatible serial

connection

• Uses visible Class 2 alignment laser for

accurate alignment

• Provides quick warmup to minimize drift

Discrete outputs or analog and discrete models

• Diffuse models provide 2 discrete outputs (PNP) and one 4 to 20 mA

output for long-range precision background suppression up to 10 m.

• Retroreflective models offer two discrete outputs (PNP) for extremely

long-range sensing.

• All models offer two alarm outputs with ongoing LCD display for

easy troubleshooting.

Retroreflective models

• Ideal for long-range automated storage and retrieval applications

• Features ±2 mm resolution

Diffuse models

• Features dark-color performance, ideal for automotive applications

• Offers ±4 mm resolution

2-line digital display

of sensing distance

Programming

push buttons

Integral 12-pin

M16 QD connector

Status

Indicator

LED

LT7 Sensing Ranges

Diffuse models with

gray targets: 0.5 - 7 m

Diffuse models with

white targets: 0.5 - 10 m

Retroreflective models with

specified reflector: 0.5 - 250 m

Meters

250 . . . 10 9 8 7 6 5 4 3 2 1

248 More information online at bannerengineering.com

Page 7

L-GAGE® LT7 Sensors

Detailed

Dimension

s

LASER RETRO

LASER DIFFUSE

Dow nlo a

d

PDF

Status Indicator LEDs

2-line digital display

Programming push buttons

MEASUREMENT & INSPECTION

95.0 mm

GAUGI NG

LIGHT

ULTRASONIC

Integral 12-pin M16 QD connector

Class 1 sensing laser and Class 2

visible alignment laser

2 PNP Alarm Outputs

RS-422 or SSI-compatible

serial connection

L-GAGE® LT7, 18-30V dc

Models

LT7PLVQ

LT7PIDQ

Sensing

Mode/LED*

Laser

Class

Class 1

Sensing

Laser

(Class 2

Alignment

Laser)

Sensing

Distance*** Cable**

0.5 to 250 m

12-pin

M16 QD

0.5 to 10 m

42.0 mm

Discrete

Output

2 PNP

93.0 mm

Analog

Output Serial

—

4-20 mA

RS-422

or

SSI

Data

Sheet

120244

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

*

** A model with a Q D requires a mating c able (see page 418).

*** Diffuse-mode range specified using a 90% reflectance white card.

Infrared Laser

Retroreflective-mode range specified using a BRT-250, BRT-540 or BRT-700 retroreflective target (see page 429).

More information online at bannerengineering.com

249

Page 8

LIGHT

MEASUREMENT & INSPECTION

Sensing Range

GAUGI NG

L-GAGE® LT7 Specifications

LT7PLVQ: 0.5 to 250 m (using specified reflector)

LT7PIDQ: 6% Black card: 0.5 to 3 m

18% Gray card: 0.5 to 7 m

90% White card: 0.5 to 10 m

ULTRASONIC

MEASURING

TE MP ER ATU RE

RADAR

SLOT & LABEL PART & AREA

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

Supply Voltage and

Current

Power Consumption

Measuring Laser

Laser Control

Spot Size

lUMINESCENCE

Pilot Laser (Alignment)

Discrete & Analog

Output Protection

Discrete Outputs

Discrete Switch Points

Discrete Output

Hysteresis

Alarm Outputs

Analog Output

Maximum Cable Length

18 to 30V dc (10% max. ripple)

Less than 4.5 W @ 25º C

Infrared, 900 nm, Class 1

Measurement laser is ON when sensor is ON. Pilot (visible) laser enabled during Programming mode;

alternates with measurement laser.

Distance Spot Size

LT7PLVQ: 10 m ø 20 mm

50 m ø 100 mm

100 m ø 200 mm

250 m ø 500 mm

LT7PIDQ: 4 m 3 x 10 mm

6 m 4 x 12 mm

10 m 10 x 20 mm

Visible red, 650 nm, Class 2

Protected against continuous overload and short circuit

(2) 100 mA, PNP

Adjustable in 1 mm steps

Adjustable, 10 mm min.

50 mA, PNP (NO)

LT7PLVQ: None

LT7PIDQ: 4-20 mA

100 m

Output Response Time

Linearity

Resolution/Repeatability

Color Sensitivity

Temperature Effect

Minimum Analog

Window Size

Adjustments

Serial Interface

Serial Measurement Speed

12 milliseconds

±10 mm

LT7PLVQ: ±2 mm

LT7PIDQ: ±4 mm

LT7PLVQ: Not Applicable

LT7PIDQ: Contact Factory

Less than ± 5 mm over the total sensing range

LT7PLVQ: Not Applicable

LT7PIDQ: 300 mm

Push-button-directed password enable/disable, measurement unit select, offset value select, output

limits set, output mode select, analog output slope select (diffuse models only) and output limit manual

adjust. See data sheet for information.

RS-422 or SSI compatible

SSI: 1.4 milliseconds (SSI cycle 80 microseconds) RS-422: 2.9 milliseconds @ 57.6 kBaud

250 More information online at bannerengineering.com

More on

next page

Page 9

MEASUREMENT & INSPECTION

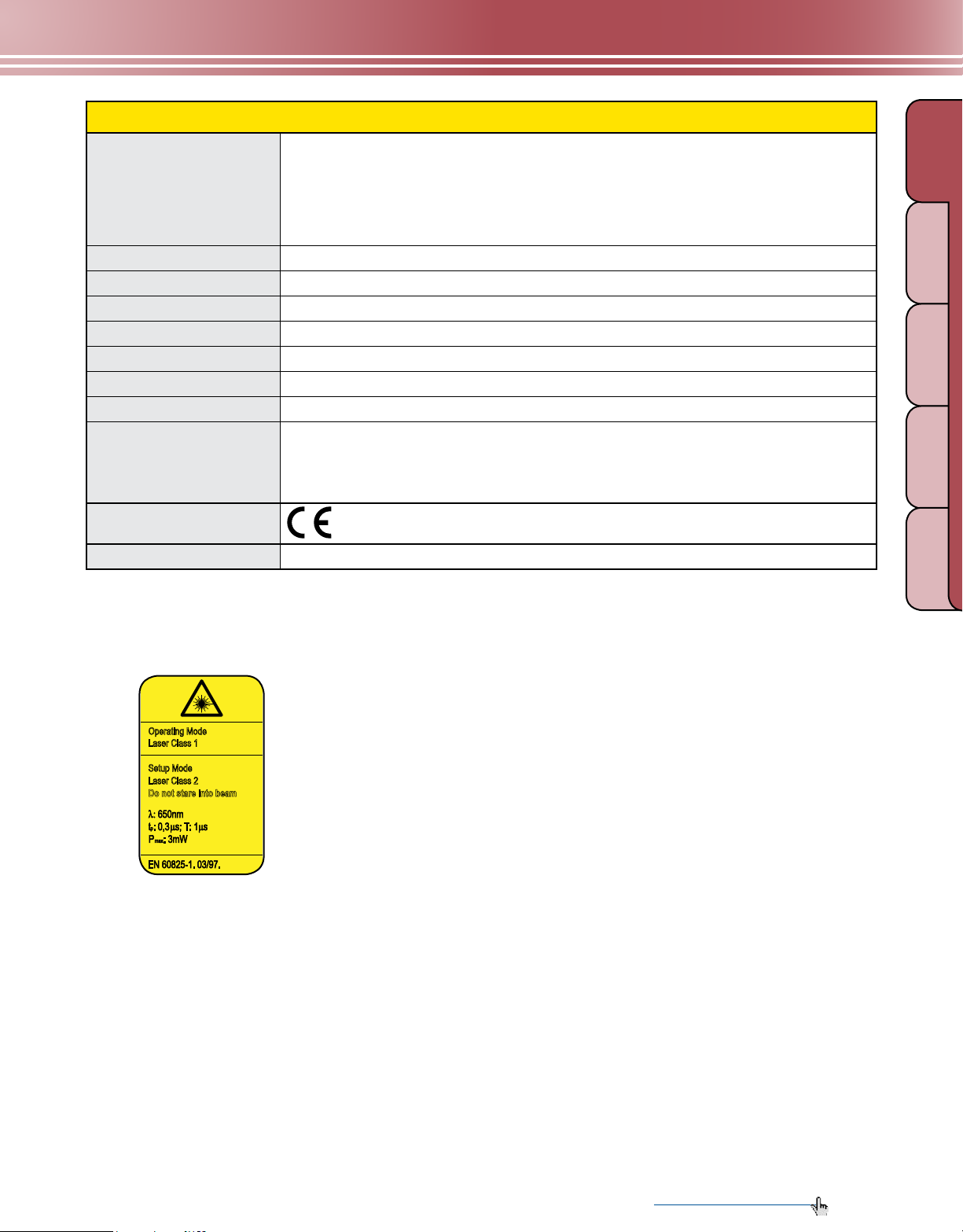

Operating Mode

Laser Class 1

Setup Mode

Laser Class 2

Do not stare into beam

Indicators

Construction

Weight

Environmental Rating

Connections

Operating Conditions

Storage Temperature

Vibration/Shock

Application Notes

Certifications

Hookup Diagrams

L-GAGE® LT7 Specifications

4 LEDs:

Green: Power ON/OFF

Red: Alarm (Error) LED

Orange: Output 1 and Output 2 conducting LEDs

2-line digital LCD display. See data sheet for more information.

ABS shock-resistant housing; PMMA window; polycarbonate displays

Approximately 230 g

IEC IP67

12-pin M16 connector; 100 m max. cable length; use only cables listed on page 418.

Temperature: -10° to +50° C in continuous operation

-30° to +75° C

EN 60947-5-2

• All specifications are based on the specified surface at constant ambient conditions and following a

minimum operating time of 15 minutes.

• For best accuracy, allow a 15-minute warmup before programming or operating

• Crosstalk avoidance: Light spots must be separated by at least 200 mm.

MI05 (p. 533)

(cont’d)

GAUGI NG

LIGHT

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

Class 1 (Infrared Sensing Laser)

Lasers that are safe under reasonably

foreseeable conditions of operation,

including the use of optical instruments

for intrabeam viewing. Reference

60825-1 Amend. 2 © IEC:2001(E),

section 8.2.

Class 2 (Visible Alignment Laser)

Lasers that emit visible radiation in

the wavelength range from 400 to 700

nm where eye protection is normally

afforded by aversion responses,

including the blink reex. This reaction

may be expected to provide adequate

protection under reasonably foreseeable

conditions of operation, including the

use of optical instruments for intrabeam

viewing. Reference 60825-1 Amend. 2

© IEC:2001(E), section 8.2.

More information online at bannerengineering.com

251

Page 10

MEASUREMENT & INSPECTION

RADIANT POWER 0.2 mW

9.8KHz 11-20% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure laser light emitted

from this aperture

BRACKETS

LASER DIFFU SE

QD CABLES

L-GAGE® LG

LIGHT

MEASURING

PAGE 372

8-Pin Euro

PAGE 416

ULTRASONIC

SLOT & LABEL PART & AREA

COLOR &

TE MP ER ATU RE

PICK-TO-LIGHT

RADAR

Short-range Laser Sensors

GAUGI NG

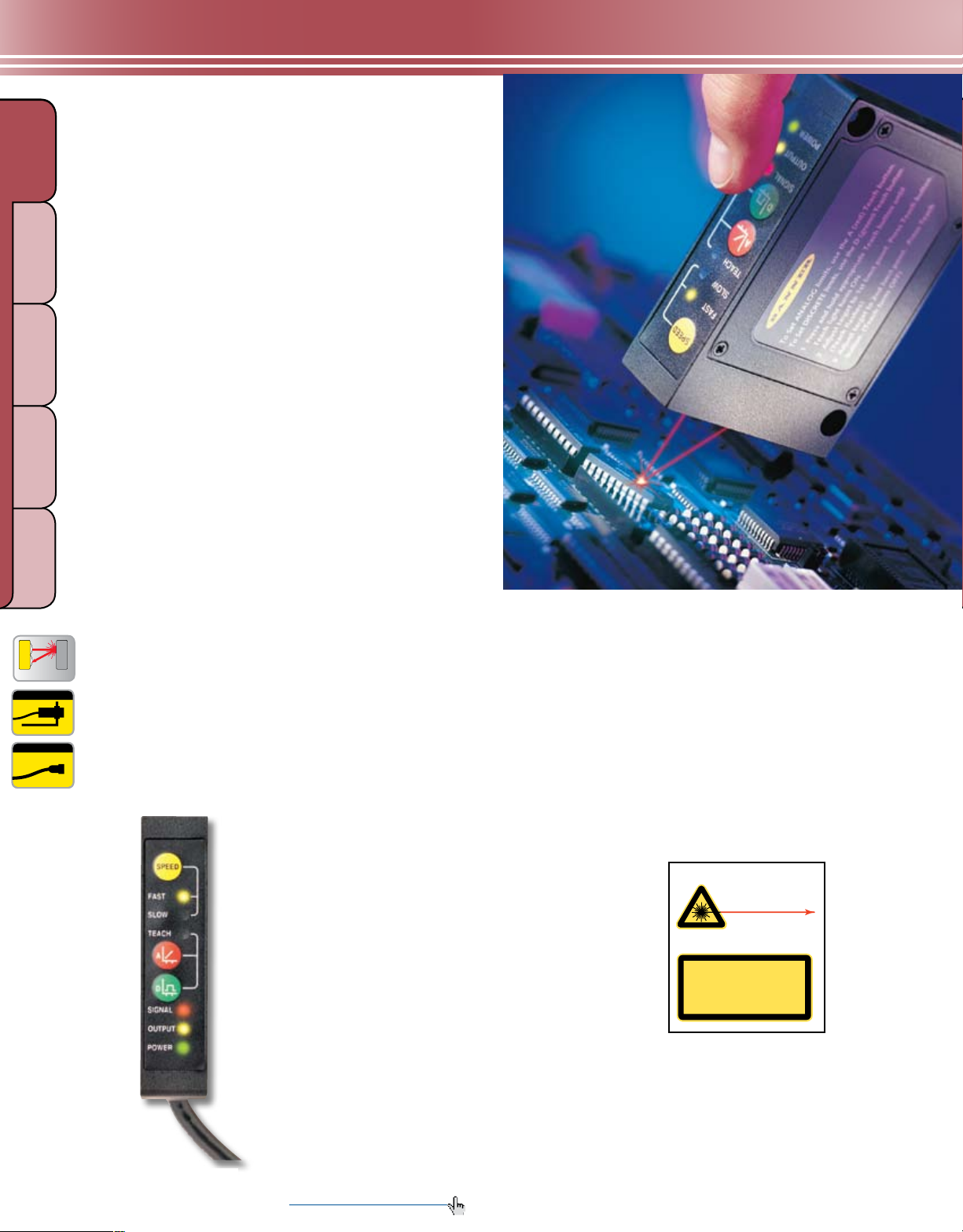

Extremely compact, self-contained design

The Banner L-GAGE

®

LG Series replaces large, two-piece

laser gauging sensors with a completely self-contained,

compact housing measuring only 55 x 82 x 20 mm.

• Features a one-piece design to conserve

production space

• Wires easily, decreasing setup time

• Provides a highly accurate solution at a much lower cost

LIGHT SCR EENS

• Does not touch parts it measures, so can be used with

lUMINESCENCE

moving processes, hot parts and sticky parts

Ultra-precise & flexible, with analog & discrete outputs

Advanced digital signal processing algorithms make

the LG Series Class 2 modulated visible laser gauging

sensor a powerhouse of performance for a wide range of

measurement applications.

• Features an outstanding maximum resolution of 3 µm for

flat white targets

• Uses an ultra-narrow beam for applications requiring

precise measurement of distance, height or thickness as

well as gauging applications

• Lets you pick the exact range you need with the

push of a button

• Houses discrete (switched) and analog outputs in

the same unit, each independently programmable

252 More information online at bannerengineering.com

Push-button setup for custom-sized sensing windows

Unlike older, inflexible, fixed-range technology, Banner’s

TEACH-mode programming lets you set your own

custom-sized sensing windows anywhere within the

measuring range, using just one push button.

• Available ranges of 45 to 60 mm and 75 to 125 mm

• Can be programmed for analog output, discrete

output or both simultaneously with independently

controlled sensing window limits

Page 11

LASER DIFFUSE

LASER DIFFUSE

L-GAGE® LG Sensors

Detailed

Dimension

s

Dow nlo a

d

PDF

MEASUREMENT & INSPECTION

GAUGI NG

LIGHT

Choice of NPN or PNP discrete output and

either voltage or current analog output

Push-button setup or remote configuration

LED indicators and output programming

push buttons

2 m or 9 m attached cable, or

8-pin Euro-style quick-disconnect

8-pin Euro-style QD cables with shield

ordered separately (see page 416)

L-GAGE® LG5, 12-30V dc

Models

LG5A65PU

LG5A65PUQ

LG5A65PI

LG5A65PIQ

LG5A65NU

LG5A65NUQ

LG5A65NI

LG5A65NIQ

LG5B65PU

LG5B65PUQ

LG5B65PI

LG5B65PIQ

LG5B65NU

LG5B65NUQ

LG5B65NI

LG5B65NIQ

Sensing

Beam/LED*

Laser

Class

Class 2 45-60 mm

Class 2 45-60 mm

82.3 mm

20.2 mm

Sensing

Distance Beam Size Cable**

2 m

At 53 mm:

0.4 mm

x

0.6 mm

Focus

70 mm

At 53 mm:

0.1 mm

Focus

53 mm

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

2 m

8-pin Euro Pigtail QD

55.3 mm

Discrete

Output

PNP

NPN

PNP

NPN

Analog

Output

0-10V dc

4-20 mA

0-10V dc

4-20 mA

0-10V dc

4-20 mA

0-10V dc

4-20 mA

Data

Sheet

59786

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

Visible Red Laser

*

** For 9 m cable, add suffix W/30 to the 2 m model number (example, LG5A65PU W/30). A model with a QD requires a mating cable (see page 416).

More information online at bannerengineering.com

253

Page 12

MEASUREMENT & INSPECTION

Dow nlo a

d

PDF

LASER DIFFUSE

L-GAGE® LG10, 12-30V dc

LIGHT

ULTRASONIC

MEASURING

TE MP ER ATU RE

RADAR

GAUGI NG

SLOT & LABEL PART & AREA

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

Sensing

Models

LG10A65PU

LG10A65PUQ

LG10A65PI

LG10A65PIQ

LG10A65NU

LG10A65NUQ

LG10A65NI

LG10A65NIQ

Visible Red Laser

*

lUMINESCENCE

** For 9 m cable, add suffix W/30 to the 2 m model number (example, LG10A65PU W/30). A model with a QD requires a mating cable (see page 416).

Beam/LED*

Laser

Class

Class 2 75-125 mm

Sensing

Distance

Beam

Size Cable**

At 125 mm:

0.6 mm

x

0.8 mm

Focus

180 mm

8-pin Euro Pigtail QD

8-pin Euro Pigtail QD

8-pin Euro Pigtail QD

8-pin Euro Pigtail QD

2 m

2 m

2 m

2 m

L-GAGE® LG5 and LG10 Specifications

Sensing Beam

Supply Voltage and Current

Supply Protection Circuitry

Delay at Power-up

Output Rating

Output Configuration

Output Protection

Output Response Time

Analog Resolution and

Repeatability of Discrete

Trip Point

Analog Linearity*

*Resolution and linearity

specied @ 24V dc, 22° C, using

a white ceramic test surface (see

Application Notes)

650 nm visible Red IEC and CDRH Class 2 laser; 0.20 mW max. radiant output power

12 to 30V dc (10% max. ripple); 50 mA max @ 24V dc (exclusive of load)

Protected against reverse polarity and transient overvoltages

1.25 second

Discrete (switched) and Alarm outputs: 100 mA max.

OFF-state leakage current: less than 5 µA

Output saturation voltage

PNP outputs: less than 1.2V at 10 mA and less than 1.6V at 100 mA

NPN outputs: less than 200 mV at 10 mA and less than 600 mV at 100 mA

Analog Current output: 1 kΩ max @ 24V dc, max load resistance = [(Vcc - 4.5)/0.02]Ω (current

sourcing)

Analog Voltage output: 2.5 kΩ min. load impedance (voltage sourcing)

Discrete (switched) & alarm outputs: Solid-state switch; choose NPN (current sinking) or

PNP (current sourcing) models

Analog output: 4 to 20 mA (current sourcing), 0 to 10V dc (voltage sourcing)

Discrete and alarm outputs are protected against continuous overload and short circuit

Discrete Outputs (ON/OFF)

Fast: 2.0 milliseconds Medium: 10 milliseconds Slow: 100 milliseconds

Analog Output (-3dB)

Fast: 450 Hz (1 millisecond average/1 millisecond update rate)

Medium: 45 Hz (10 millisecond average/2 millisecond update rate)

Slow: 4.5 Hz (100 millisecond average/5 millisecond update rate)

LG5: Fast: Less than 40 µm @ 50 mm LG10: Fast: Less than 150 µm @ 100 mm

Medium: Less than 12 µm @ 50 mm Medium: Less than 50 µm @ 100 mm

Slow: Less than 3 µm @ 50 mm Slow: Less than 10 µm @ 100 mm

See chart RRC-3 on page 510 See chart RRC-4 on page 510

LG5: +/- 60 µm LG10: +/- 200 µm

over 45 to 60 mm sensing window over 75 to 125 mm sensing window

+/- 10 µm +/- 20 µm

over 49 to 51 mm sensing window over 95 to 100 mm sensing window

Discrete

Output

PNP

NPN

Analog

Output

0-10V dc

4-20 mA

0-10V dc

4-20 mA

Data

Sheet

59786

More on

next page

254 More information online at bannerengineering.com

Page 13

Minimum Window Size

(Analog or Discrete)

Discrete Output Hysteresis

Color Sensitivity (typical)

Temperature Effect

Remote TEACH and Laser

Control Input Impedance

Remote TEACH

Adjustments

Laser Control

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and

Mechanical Shock

Application Notes

Certifications

Hookup Diagrams

MEASUREMENT & INSPECTION

L-GAGE® LG5 and LG10 Specifications

LG5: 1.5 mm LG10: 5 mm

LG5: Less than 0.2 mm LG10: Less than 1.0 mm

LG5: Less than 75 µm LG10: Less than 100 µm

for white to dark gray ceramic target for white to dark gray ceramic target

LG5: +/- 7 µm/° C LG10: +/- 25 µm/° C

18 kΩ min. (65 kΩ min. at 5V dc)

To teach: Connect yellow wire to +5 to 30V dc

To disable: Connect yellow wire to 0 to +2V dc (or open connection)

Response speed: Push button toggles between Slow, Medium, and Fast (see Output Response Time)

Window limits (analog or discrete): TEACH-mode programming of near and far window limits. Limits

may also be taught remotely using TEACH wire.

Analog output slope: The first limit taught is assigned to the minimum analog output (0V dc or 4 mA).

To enable laser: Connect green wire to +5 to 30V dc

To disable laser: Connect green wire to 0 to +2V dc (or open connection)

250 millisecond delay upon enable/disable

Green Power ON LED: Indicates when power is ON, overloaded output and laser status.

Yellow Output LED: Indicates when discrete load output is conducting.

Red Signal LED: Indicates when target is within sensing range and the condition of the received light

signal.

Tri-color Red/Green/Yellow TEACH LED: Indicates sensor is ready for programming each limit

(indicates Red for analog output, Green for discrete, and Yellow for simultaneous analog and discrete.)

Yellow Fast/Slow LEDs: Combination of 2 lights ON or OFF indicates 1 of 3 response speeds

Housing: Zinc alloy die-cast, plated and painted finish

Cover plate: aluminum with painted finish

Lens: acrylic

IP67; NEMA 6

2 m or 9 m 7-conductor shielded PVC-jacketed attached cable, or 150 mm 8-pin Euro-style pigtail quick-

disconnect. Mating QD cables are purchased separately. See page 416.

Temperature: -10° to +50° C Relative humidity: 90% at 50° C (non-condensing)

Vibration: 60 Hz, 30 minutes, 3 axes

Shock: 30G for 11 milliseconds, half sine wave, 3 axes

For comparison, a white ceramic test surface has approximately 91% of the reflectivity of a white Kodak

test card with a matte finish. A dark gray ceramic test surface has approximately 11% of the reflectivity of

a white Kodak test card with a matte finish. (Allow 15-minute warm-up for maximum linearity.)

NPN Models: MI06 (p. 533) PNP Models: MI07 (p. 533)

(cont’d)

GAUGI NG

LIGHT

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

More information online at bannerengineering.com

255

Page 14

MEASUREMENT & INSPECTION

QD CABLES

BRACKETS

DIFFUSE

DIFFUSE

L-GAGE® Q50

LIGHT

MEASURING

PAGE 372

5-Pin Euro

PAGE 416

ULTRASONIC

SLOT & LABEL PART & AREA

COLOR &

TE MP ER ATU RE

PICK-TO-LIGHT

RADAR

Low-cost LED-based

GAUGI NG

Distance Measurement

Sensors

A low-cost alternative to laser measurement sensors

The compact, self-contained L-GAGE

tion sensor combines laser-like performance with LED

safety and economy. The Q50 features analog outputs

with programmable sensing window limits, and a unique

tightly collimated emitter that enables it to operate in tight

LIGHT SCR EENS

lUMINESCENCE

spaces or on small targets. The Q50 is an appealing laser

alternative for many applications, including dry-bulk level

measurement, package lling, roll-diameter measurement,

loop control and dimensional measurement.

Patented scalable analog output

• Automatically scales the analog output over the

width of the programmed sensing window

• Streamlines setup and maximizes resolution in

electrically noisy environments

• Offers 4 to 20 mA (current sourcing) or 0 to 10V

(voltage sourcing) output configurations

• Available with discrete output

Reliable sensing for varied targets

• 50 to 300 mm range visible red beam models

• 50 to 400 mm range infrared beam models

• Sensor linearity less than 1 percent of full scale

®

Q50 triangula-

Programmable features

• Offers TEACH programming and remote programming

• Requires no potentiometer adjustments

• Offers choice of positive or negative analog output slope

• Allows choice of output response speed from

4 to 64 milliseconds

• Provides remote location programming for maximum

security and convenience

256 More information online at bannerengineering.com

Page 15

MEASUREMENT & INSPECTION

DIFFUSE

DIFFUSE

Dow nlo a

d

PDF

Detailed

Dimension

s

GAUGI NG

LIGHT

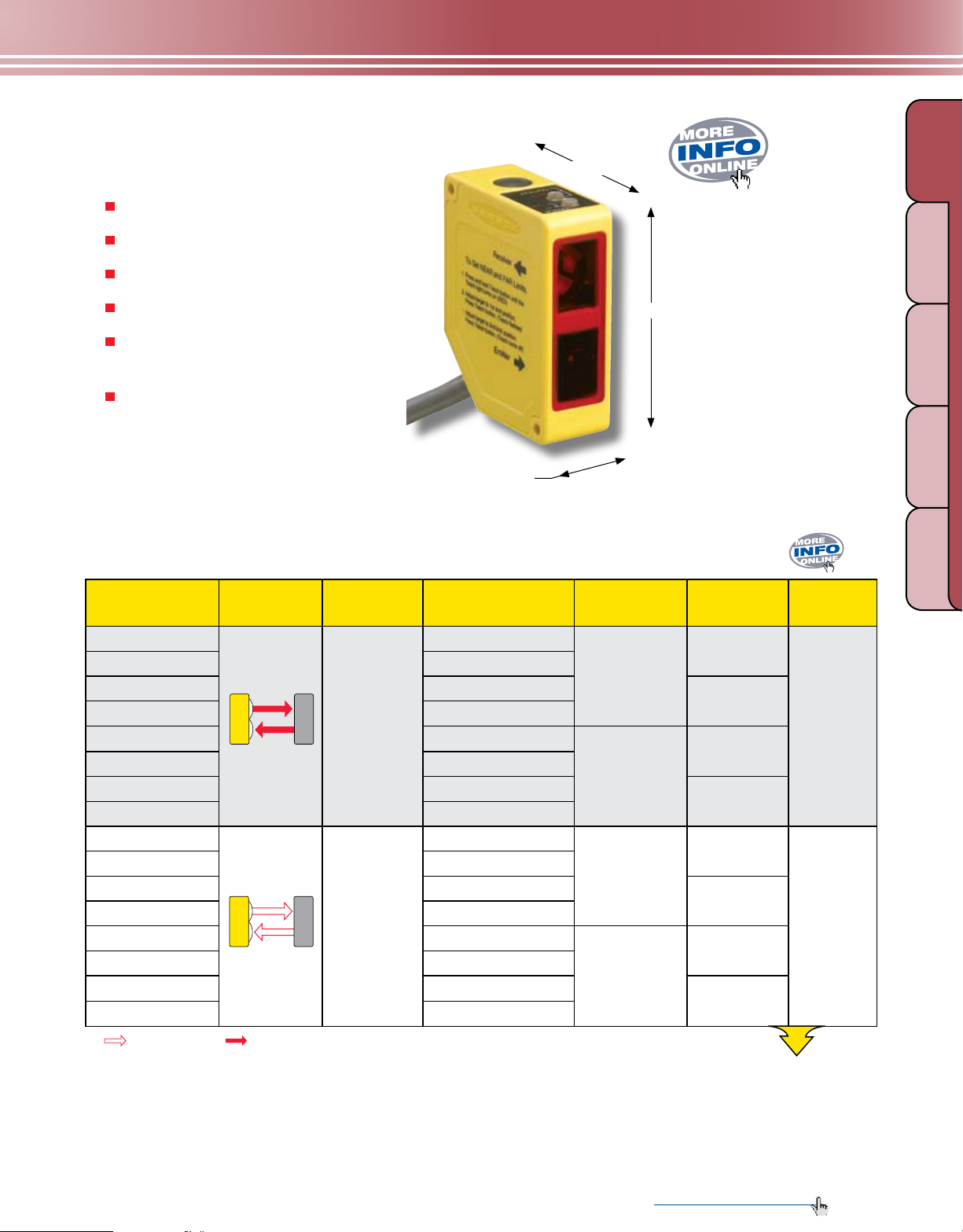

L-GAGE® Q50 Sensors

49.8 mm

Simple push-button TEACH programming

Range indicator LED

High resolution of less than 1 mm

Fast response, to 4 milliseconds

60.0 mm

2 m or 9 m attached cable, or swivel

5-pin Euro-style quick-disconnect

5-pin Euro-style QD cables with shield,

ordered separately (see page 416)

19.7 mm

L-GAGE® Q50 Discrete Output, 12-30V dc

Sensing

Models

Q50AVN

Q50AVNQ

Q50AVNY

Q50AVNYQ

Q50AVP

Q50AVPQ

Q50AVPY

Q50AVPYQ

Q50AN

Q50ANQ

Q50ANY

Q50ANYQ

Q50AP

Q50APQ

Q50APY

Q50APYQ

Infrared LED Visible Red LED

*

** For 9 m cable, add suffix W/30 to the 2 m model number (example, Q50AVN W/30). A model with a QD requires a mating cable (see page 416).

Beam/LED* Range Cable**

2 m

5-pin Euro QD

2 m

50-150 mm

50-200 mm

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

Output

Type

NPN

PNP

NPN

PNP

Response

Time

48 ms

4 ms

48 ms

4 ms

48 ms

4 ms

48 ms

4 ms

Data

Sheet

67417

67417

More on

next page

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

More information online at bannerengineering.com

257

Page 16

MEASUREMENT & INSPECTION

Dow nlo a

d

PDF

DIFFUSE

DIFFUSE

DIFFUSE

DIFFUSE

Dow nlo a

d

PDF

DIFFUSE

DIFFUSE

L-GAGE® Q50 Discrete Output, 12-30V dc (cont’d)

LIGHT

ULTRASONIC

MEASURING

TE MP ER ATU RE

RADAR

GAUGI NG

SLOT & LABEL PART & AREA

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

lUMINESCENCE

Models

Q50BVN

Q50BVNQ

Q50BVNY

Q50BVNYQ

Q50BVP

Q50BVPQ

Q50BVPY

Q50BVPYQ

Q50BN

Q50BNQ

Q50BNY

Q50BNYQ

Q50BP

Q50BPQ

Q50BPY

Q50BPYQ

Sensing

Beam/LED* Range Cable**

2 m

5-pin Euro QD

2 m

100-300 mm

100-400 mm

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

Output

Type

NPN

PNP

NPN

PNP

Response

Time

48 ms

4 ms

48 ms

4 ms

48 ms

4 ms

48 ms

4 ms

Data

Sheet

65741

65741

L-GAGE® Q50 Analog Output, 15-30V dc

Sensing

Models

Q50AVI

Q50AVIQ

Q50AVU

Q50AVUQ

Q50AI

Q50AIQ

Q50AU

Q50AUQ

Q50BVI

Q50BVIQ

Q50BVU

Q50BVUQ

Q50BI

Q50BIQ

Q50BU

Q50BUQ

Beam/LED* Range Cable**

5-pin Euro QD

50-150 mm

5-pin Euro QD

5-pin Euro QD

50-200 mm

5-pin Euro QD

5-pin Euro QD

100-300 mm

5-pin Euro QD

5-pin Euro QD

100-400 mm

5-pin Euro QD

2 m

2 m

2 m

2 m

2 m

2 m

2 m

2 m

Output

Type

4 to 20 mA

0 to 10V

4 to 20 mA

0 to 10V

4 to 20 mA

0 to 10V

4 to 20 mA

0 to 10V

Response

Time

4 ms

or 64 ms

selectable

Data

Sheet

67416

67416

64323

64323

Infrared LED Visible Red LED

*

** For 9 m cable, add suffix W/30 to the 2 m model number (example, Q50BVN W/30). A model with a QD requires a mating cable (see page 416).

258 More information online at bannerengineering.com

Page 17

L-GAGE® Q50 Discrete Output Specifications

Sensing Beam

Sensing Range

Supply Voltage and Current

Supply Protection Circuitry

Output Configuration

Delay at Power-up

Output Rating

Output Protection

Output Response Time

Output Hysteresis

Sensing Repeatability

Color Sensitivity (typical)

Temperature Effect

Remote TEACH Input

Impedance

Remote TEACH Input

Adjustments

Indicators

Ambient Light Immunity

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and

Mechanical Shock

Application Notes

Certifications

MEASUREMENT & INSPECTION

Wavelength: Q50..V: 685 nm (typical) Q50..: 880 nm (typical)

Beam Size: Q50..V: 20 mm dia. (max.) Q50..: 20 mm dia. (max.)

Q50AV: 50 to 150 mm Q50A: 50 to 200 mm

Q50BV: 100 to 300 mm Q50B: 100 to 400 mm

12 to 30V dc (10% max. ripple); 70 mA max. (exclusive of load)

Protected against reverse polarity and transient overvoltages

Solid-state Complementary; Choose NPN (current sinking) or PNP (current sourcing) models.

2 seconds

Complementary Discrete Output 150 mA max., per output

OFF-state leakage current: Less than 10 µA

ON-state saturation voltage: Less than 1V @ 10 mA and less than 1.5V @ 100 mA

Protected against false pulse on power-up and continuous overload or short circuit of outputs.

2-second delay on power-up:

Fast: 4 milliseconds ON/OFF Slow: 48 milliseconds ON/OFF

See charts HC-5 and HC-6 on page 512.

Slow Response (Q50..): 0.5% of sensing distance

Fast Response (Q50..Y): 1.0% of sensing distance

See charts CSC-2 and CSC-3 on page 511.

Q50B.. models: From 0° to 50° C: 0.25 mm/° C From -10° to 55° C: 0.35 mm/° C

Q50A.. models: From 0° to 50° C: 0.08 mm/° C From -10° to 55° C: 0.11 mm/° C

15 kΩ

To TEACH: Connect gray wire to +5 to 30V dc

To Disable: Connect gray wire to 0 to +2V dc (or open connection)

Sensing Window Limits: TEACH-mode programming of near and far window limits may be set using

the TEACH push button or remotely using the gray TEACH wire.

Range LED Green — Target is within sensing range

Indicator Red — Target is outside sensing range

(Green/Red) Flashing Green — Outputs are overloaded

OFF — Sensor Power OFF

Teach/Output Yellow (window limits) — Target is within taught window limits

LED Indicator Yellow (fixed field) — Target is closer than cutoff limit

(Yellow/Red) OFF — Target is outside taught window limits

Red — Sensor is in TEACH mode

< 10,000 LUX

Housing: Molded ABS/Polycarbonate Window Lens: Lens: Acrylic

Hardware: M3 hardware is included

IEC IP67; NEMA 6P

2 m or 9 m 5-conductor PVC-covered attached cable, or 5-pin Euro-style quick-disconnect.

See page 416.

Temperature: -10° to +55° C Relative humidity: 90% at +50° C (non-condensing)

All models meet Mil. Std. 202F requirements. Method 201A (Vibration: 10 to 60 Hz max. double

amplitude 0.06”, maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G,

11 milliseconds duration, half sine wave.

Allow 15-minute warm-up for maximum performance

GAUGI NG

LIGHT

ULTRASONIC

LIGHT SCR EENS

MEASURING

TE MP ER ATU RE

RADAR

Hookup Diagrams

MI08 (p. 533)

More information online at bannerengineering.com

259

Page 18

LIGHT

ULTRASONIC

MEASURING

TE MP ER ATU RE

RADAR

MEASUREMENT & INSPECTION

Sensing Beam

GAUGI NG

Sensing Range

Supply Voltage and Current

Supply Protection Circuitry

Output Configuration

SLOT & LABEL PART & AREA

COLOR &

LIGHT SCR EENS

PICK-TO-LIGHT

Delay at Power-up

Output Protection

Output Response Time

lUMINESCENCE

Resolution

Linearity

Color Sensitivity (typical)

Temperature Effect

Remote and Speed Input

Impedance

Remote TEACH Input

Adjustments

Indicators

L-GAGE® Q50 Analog Output Specifications

Wavelength: Q50..V: 685 nm (typical) Q50..: 880 nm (typical)

Beam Size: Q50..V: 20 mm dia. (max.) Q50..: 20 mm dia. (max.)

Q50AV: 50 to 150 mm Q50A: 50 to 200 mm

Q50BV: 100 to 300 mm Q50B: 100 to 400 mm

15 to 30V dc (10% max. ripple); 70 mA max. (exclusive of load)

Protected against reverse polarity and transient overvoltages

4-20 mA current sourcing models: 1 kΩ max. load @ 24V dc. Max. load = [(Vcc -4.5)/0.02]Ω

0-10V voltage sourcing models: 15 mA max.

2 seconds

Protected against short circuit conditions

Analog Output Average Interval Update Rate -3 dB Frequency Response

Fast: 4 milliseconds 1 millisecond 112 Hz

Slow: 64 milliseconds 4 milliseconds 7 Hz

See RRC-5 and RRC-6 on page 510 for typical value.

Q50B models:

Target Distance: 200 mm Slow Response: 1 mm (max) Fast Response: 4 mm (max)

Q50A models:

Target Distance: 100 mm Slow Response: 0.5 mm (max) Fast Response: 2 mm (max)

Q50B.. models: ±3 mm Q50A.. models: ±1.5 mm

See charts CSC-4 and CSC-5 on page 511.

Q50B.. models:

From 0° to 50° C: 0.25 mm/° C From -10° to 55° C: 0.35 mm/° C

Q50A.. models:

From 0° to 50° C: 0.08 mm/° C From -10° to 55° C: 0.11 mm/° C

15 kΩ

To Teach: Connect gray wire to +5 to 30V dc

To Disable: Connect gray wire to 0 to +2V dc (or open connection)

Fast Speed: Connect black wire to +5 to 30V dc

Slow Speed: Connect black wire to 0 to +2V dc (or open connection)

Range LED Green — Target is within sensing range

Indicator Red — Target is outside sensing range

(Green/Red) OFF — Sensor Power OFF

Teach/Output Yellow — Target is within taught window limits

LED Indicator OFF — Target is outside taught window limits

(Yellow/Red) Red — Sensor is in TEACH mode

Ambient Light Immunity

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and

Mechanical Shock

Application Notes

< 10,000 LUX

Housing: Molded ABS/Polycarbonate Hardware: M3 hardware is included. Window Lens: Acrylic

IEC IP67; NEMA 6P

2 m or 9 m 5-conductor PVC-covered attached cable, or 5-pin Euro-style quick-disconnect.

See page 416.

Temperature: -10° to +55° C Relative humidity: 90% at +50° C (non-condensing)

All models meet Mil. Std. 202F requirements. Method 201A (Vibration: 10 to 60Hz max. double amplitude

0.06”, maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G,

11 milliseconds duration, half sine wave.

Allow 15-minute warm-up for maximum performance

Certifications

Hookup Diagrams

MI09 (p. 534)

260 More information online at bannerengineering.com

Page 19

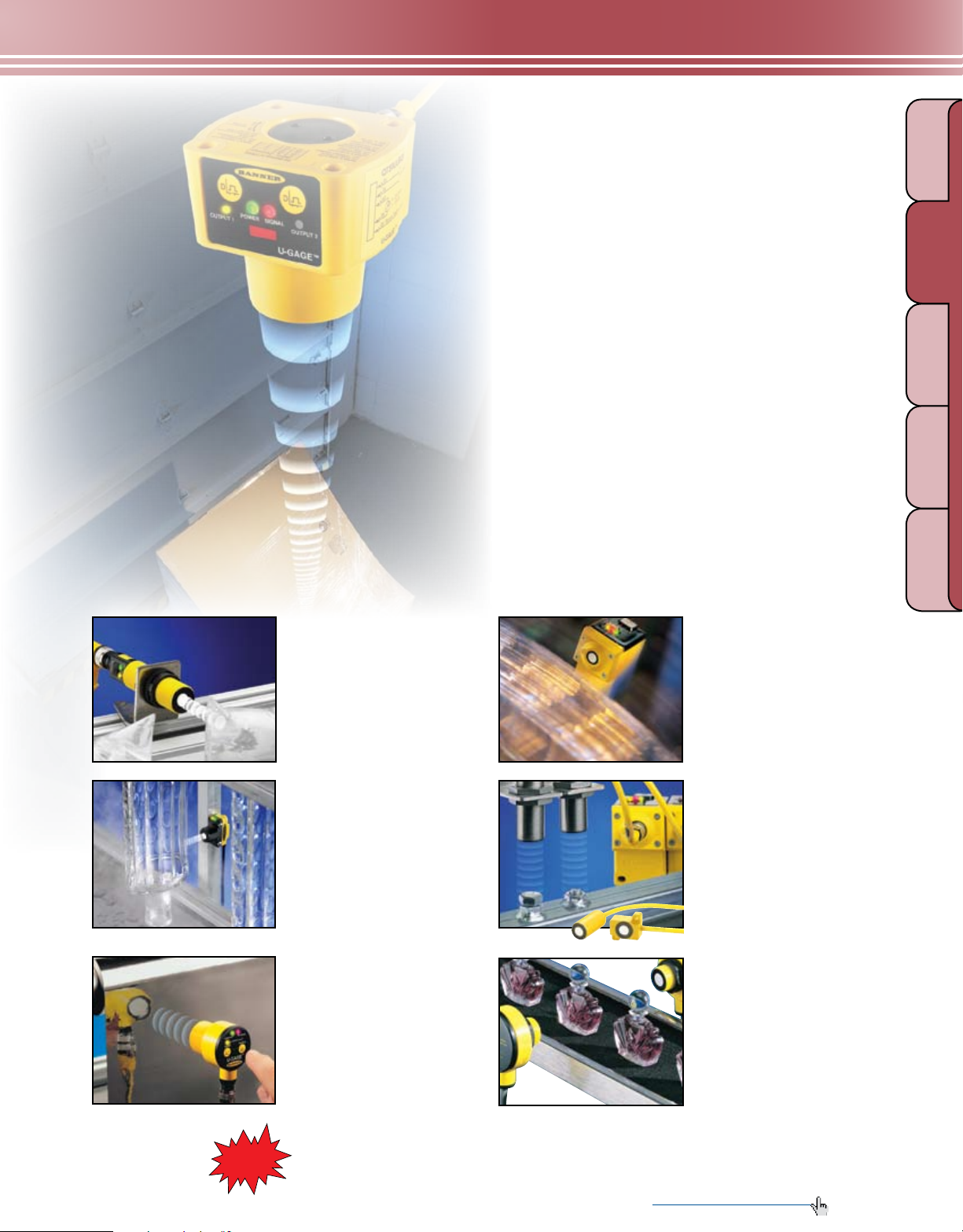

MEASUREMENT & INSPECTION

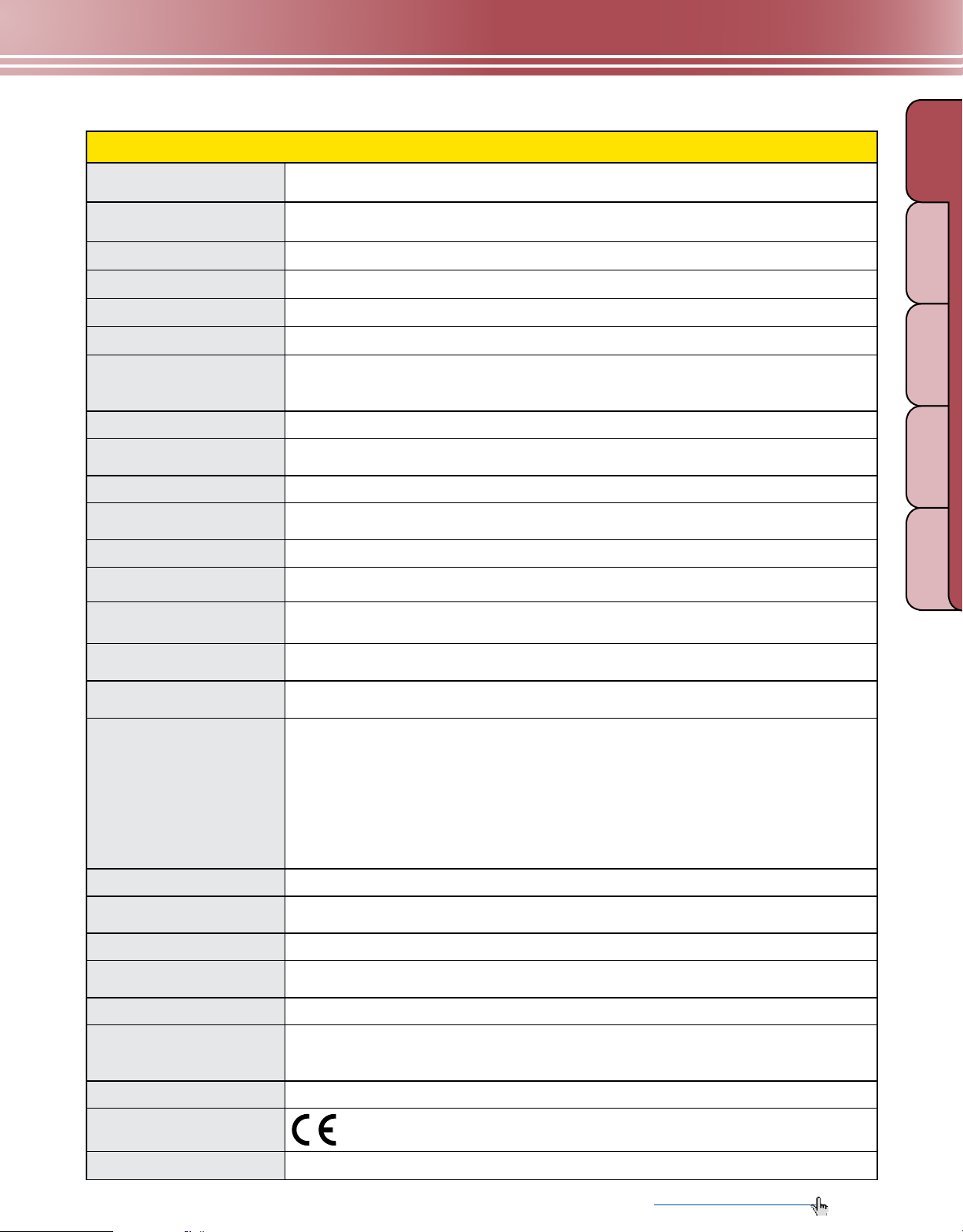

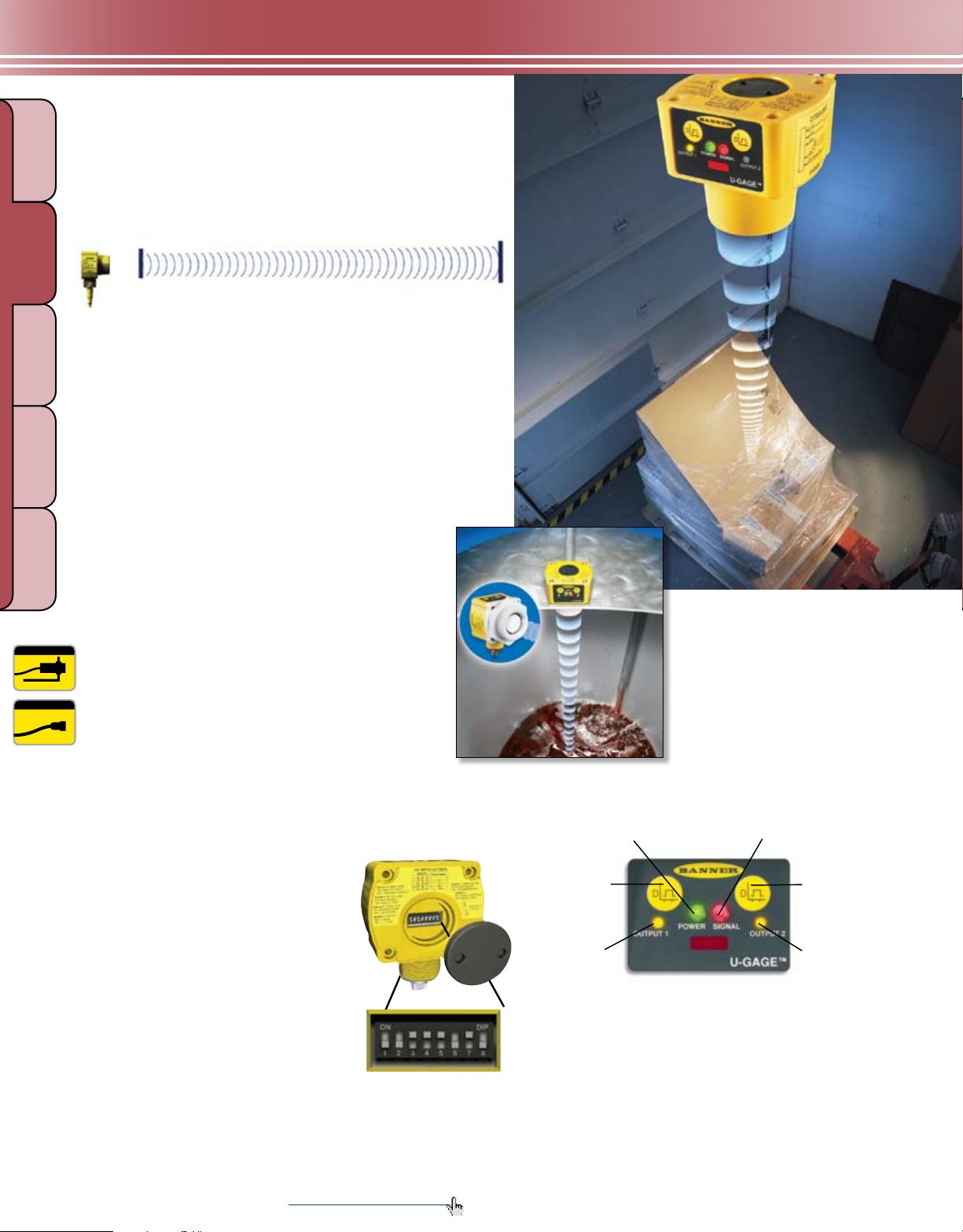

U-GAGE

®

GAUGING

LIGHT

S18U page 266

• Compact 18 mm straight or

right-angle housing

• Highly accurate detection from

30 to 300 mm

• Wide range of mounting options

Ultrasonic Sensors

QT50U page 262

• Long-range ac or dc sensor covers 8 m, with minimal

dead zone.

• Advanced programming capability includes a unique

temperature compensation feature.

• Retrosonic mode has reduced dead zone.

• Each output has two independent near and far limits.

• Optional Teflon

®

coating resists harsh chemicals.

Q45U page 276

• Operating window limits from

100 mm to 3 m

• Discrete output models for ON/OFF

presence detection or HIGH/LOW

level control

• Programmable response time

ULTRASONIC

MEASURING LIGHT

SCREENS

TEMPERATURE

RADAR

Teflon® is a registered

trademark of Dupont

QS18U page 269

• Compact 18 mm universal housing

• Compensation for air temperature

fluctuations

• Optional encapsulation for

resistance to harsh chemicals

(IP68)

T30U page 272

• Right-angle T-style housing with

30 mm threaded lens

• Analog and discrete outputs in

the same sensor

• Programmable sensing windows

with 150 mm to 1 m range or

300 mm to 2 m range

• Optional Teflon

™

.

Coming

Soon!

resistance to harsh chemicals

T30U models with temperature

compensation, longer sensing

ranges, shorter dead zones and

improved linearity.

®

coating for

More information online at bannerengineering.com

Q45UR page 280

• Ultra-accurate remote gauging

• Compact housing with choice of

three remote sensing heads

• Compensation for temperature

variations at remote head

T18U page 284

• Dual range, opposed ultrasonic sensors

• Two combinations of range and

response time in the same unit

• Ideal for sensing under bright

lighting and for clear materials

• T-style sensor with 18 mm threaded lens

261

Page 20

LIGHT

BRACKETS

QD CABLES

ULTRASONIC

MEASURING LIGHT

TEMPERATURE

GAUGING

SLOT & LABEL

SCREENS

COLOR &

PICK-TO -LIGH T

MEASUREMENT & INSPECTION

U-GAGE® QT50U

Long-range

Ultrasonic Sensor

Dead

Zone

200 mm

Minimum Range

Enhanced long-range sensing

• Senses extended range of up to 8 m

lUMINESCENCE

• Features ultrasonic dead-zone of only 2.5% of the

total range—75% less than comparable products

• Available in analog or discrete dc models and in ac/dc

universal voltage models with electromechanical relay output

• Offers retrosonic sensing mode

8 m

Maximum Range

RADAR

PAGE 372

5-Pin Euro + 5-Pin Micro

+ 5-Pin Mini

PAGE 415, 419 & 421

Designed for challenging applications

• Features a completely sealed, shock-resistant

housing that is ideal for monitoring levels of

liquids as well as solids

• Uses a narrow sensing beam to detect targets at

long range within confined areas—such as a

storage tank—without interference from

the tank walls

• Available in a chemically resistant model with a

Teflon

®

coating to protect the transducer

• Provides continuous monitoring (analog model)

• Offers dual-discrete option for setting independent

near and far limits for both outputs, for applications

requiring high and low-limit sensing

Engineered for flexibility

• Offers a multitude of configurations

in the same analog or discrete unit,

using an advanced microprocessor

and 8 DIP switches (dc models only)

• Compensates for temperature, for

greatest sensing accuracy

• Reduces dead zone and detects

objects of any size, shape and

orientation (retrosonic mode)

™

Teflon® is a registered trademark of Dupont

.

Chemically resistant models

Sensor Power

Indicator

Output 1

Push Button

Output 1

Indicator

Push-button programming

• Simplifies setup with push-button and remote

TEACH-mode programming

• Shows status during setup and operation,

using highly visible LEDs indicators

* Discrete dc model shown.

Target Signal

Strength Indicator

Output 2

Push Button

Output 2

Indicator

262 More information online at bannerengineering.com

Page 21

MEASUREMENT & INSPECTION

Detailed

Dimension

s

Dow nlo a

d

PDF

Dow nlo a

d

PDF

74.1 mm

73.1 mm

85.2 mm

M56 x 1.5

U-GAGE® QT50U Sensors

Push-button TEACH programming for

easy setup

Rugged encapsulated design for

harsh environments

Cabled or quick-disconnect models

Bright LED status indicators for

setup and operation

QD cables with shield, ordered separately

(see pages 415, 419 and 421)

74.1 mm

DC and Universal Voltage Models

67.4 mm

84.2 mm

®

Teflon

-protected Models

(Suffix -CRFV)

GAUGING

LIGHT

ULTRASONIC

MEASURING LIGHT

SCREENS

TEMPERATURE

RADAR

U-GAGE

®

QT50U, 10-30V dc

Models* Range Cable** Output Data Sheet

QT50ULB

QT50ULBQ

QT50ULBQ6

QT50UDB

QT50UDBQ

QT50UDBQ6

U-GAGE

200 mm - 8 m

200 mm - 8 m

®

QT50U Universal Voltage, 85-264V ac/24-250V dc

2 m

5-pin Mini QD

5-pin Euro QD

2 m

5-pin Mini QD

5-pin Euro QD

Selectable:

0 to 10V dc

or 4 to 20 mA

Selectable

Dual NPN

or PNP

70137

110 112

Output

Models* Range Cable*

QT50UVR3W

QT50UVR3WQ1

200 mm - 8 m

QT50UVR3WQ

QT50UVR3F

QT50UVR3FQ1

200 mm - 8 m

QT50UVR3FQ

* For sensors with Teflon®-protected face and transducer, add suffix -CRF V to the model number (example, QT50ULB-CRFV). See data sheet par t number 122155 for additional info.

** For 9 m cable, add suff ix W/30 to the 2 m model number (example, QT50ULB W/30). A model with a QD requires a mating cable (see pages 415, 419 and 421).

2 m

5-pin Micro QD

5-pin Mini QD

2 m

5-pin Micro QD

5-pin Mini QD

Operation Mode Output Data Sheet

Window-limit

(complementary

outputs)

Pump/level control

(pump-in and

pump-out logic)

SPDT

e/m relay

SPDT

e/m relay

117764

117764

Teflon® is a registered trademark of Dupont

™

.

More information online at bannerengineering.com

263

Page 22

LIGHT

ULTRASONIC

MEASURING LIGHT

TEMPERATURE

RADAR

GAUGING

SLOT & LABEL

SCREENS

COLOR &

PICK-TO -LIGH T

MEASUREMENT & INSPECTION

Effective Beam

Supply Voltage and Current

Ultrasonic Frequency

Supply Protection Circuitry

Output Protection

Delay at Power-up

Output Configuration

Output Ratings

lUMINESCENCE

Temperature Effect

Linearity (Analog Models)

Resolution/Repeatability

Hysteresis

Output Response Time

Minimum Window Size

Adjustments

Indicators

Remote TEACH

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and

Mechanical Shock

Temperature Warmup Drift

Application Notes

U-GAGE® QT50U DC Specifications

See charts EBPC-1, EBPC-2 and EBPC-3 on page 513.

Analog models: 10 - 30V dc (10% max. ripple); 100 mA max @ 10V, 40 mA max. @ 30V (exclusive of load)

Dual-discrete models: 10 to 30V dc (10% max. ripple); 100 mA max. @ 10V,

40 mA @ 30V (exclusive of load)

75 kHz burst, rep. rate 96 milliseconds

Protected against reverse polarity and transient overvoltages

Protected against short circuit conditions

1.5 seconds

Analog models: Voltage sourcing: 0 to 10V dc Current sourcing: 4 to 20 mA

Dual-discrete models: Dual PNP or NPN, selectable using DIP switch

Analog Voltage Output: 0 to 10V dc

Minimum load resistance = 500 Ω

Minimum required supply voltage for full 0-10V output span = (

Analog Current Output: 4 to 20 mA

Maximum load resistance = 1 kΩ or (

Minimum required supply voltage for full 4-20 mA output span = 10V dc or

[(RLoad x 0.02)+5]V dc, whichever is greater. 4-20 mA output calibrated at 25° C with

250 Ω load.

Discrete Output: 150 mA max.

OFF-State leakage current: less than 5 µA

Output saturation: NPN: less than 200 mV @ 10 mA; less than 650 mV @ 150 mA

PNP: less than 1.2V @ 10 mA; less than 1.65V @ 150 mA

Uncompensated: 0.2% of distance/° C

Compensated: 0.02% of distance/° C

+/- 0.2% of span from 200 to 8000 mm; +/- 0.1% of span from 500 to 8000 mm (1 mm minimum)

1.0 mm

5 mm

Analog models: 100 to 2300 milliseconds

Dual-discrete models: 100 to 1600 milliseconds

20 mm

Sensing window limits: TEACH-Mode programming of near and far window limits may be set using

the push buttons or remotely using TEACH input.

Green Power ON LED: Indicates power is ON

Red Signal LED: Indicates target is within sensing range, and the condition of the received signal.

Teach/Output indicator (bicolor Yellow/Red):

Yellow–Target is within taught limits Yellow OFF (Discrete)–Target is outside taught window limits

Red–Sensor is in TEACH mode Yellow Flashing (Analog)–Target is outside taught window limits

See data sheet p/n 70137 (Analog) and p/n 110112 (Discrete)

Transducer: Ceramic/Epoxy composite Housing: ABS/Polycarbonate

Membrane Switch: Polyester Lightpipes: Acrylic

Leakproof design is rated IEC IP67; NEMA 6P

2 m or 9 m shielded 5-conductor (with drain) PVC jacketed attached cable, or 5-pin Euro-style

quick-disconnect or 5-pin Mini-style quick-disconnect. QD cables are ordered separately.

See pages 415 and 421.

Temperature: -20° to +70° C Relative humidity: 100%

All models meet Mil Std. 202F requirements. Method 201A (vibration: 10 to 60Hz max.,

double amplitude 0.06", maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G 11

milliseconds duration, half sine wave

Less than 0.8% of sensing distance upon power-up with Temperature Compensation enabled

• Objects passing inside the specied near limit (200 mm ) may produce a false response

• For best accuracy, allow 30 minute warm-up before programming or operating

V supply - 5

0.02

) Ω, whichever is lower

1000

RLOAD

+ 13)V dc

More on

next page

264 More information online at bannerengineering.com

Page 23

MEASUREMENT & INSPECTION

Certifications

Hookup Diagrams

U-GAGE

Effective Beam

Supply Voltage

Ultrasonic Frequency

Supply Protection

Circuitry

Output Protection

Delay at Power-up

Output Configuration

Output Ratings

Temperature Effect

Repeatability

Hysteresis

Output Response Time

Minimum Window Size

Adjustments

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and

Mechanical Shock

Temperature Warmup Drift

Application Notes

Certifications

Hookup Diagrams

Teflon® is a registered trademark of Dupont

U-GAGE® QT50U DC Specifications

Analog Models: MI11 (p. 534) Discrete Models: MI10 (p. 534)

®

QT50U Universal Voltage Specifications

See charts EBPC-1, EBPC-2 and EBPC-3 on page 513.

85 to 264V ac, 50/60 Hz / 24 to 250V dc (1.5 watts max., exclusive of load)

75 kHz burst, rep. rate 96 milliseconds.

Protected against transient over voltages. DC hookup is without regard to polarity.

Protected against short circuit conditions

1.5 seconds

SPDT (Single-Pole, Double-Throw) electromechanical relay output.

One normally open (NO) and one normally closed (NC).

Max. switching power (resistive load): 2000 VA, 240 W (1000 VA, 120 W for sensors with Micro QD)

Max. switching voltage (resistive load): 250V ac, 125V dc

Max. switching current (resistive load): 8A @ 250V ac, 8A @ 30V dc derated to 200 mA @ 125V dc

(4A max. for sensors with Micro QD)

Min. voltage and current: 5V dc, 10 mA

Mechanical life of relay: 50,000,000 operations

Electrical life of relay at full resistive load: 100,000 operations

NOTE: Transient suppression is recommended when switching inductive loads.

Uncompensated: 0.2% of distance/° C Compensated: 0.02% of distance/° C

1.0 mm

Window-limit sensor models: 5 mm Fill-level control sensor models: 0 mm

Selectable 1600, 400 or 100 milliseconds

20 mm

Sensing limits: TEACH-Mode programming of near and far limits may be set using the TEACH push button.

Sensor configuration: Output response time and temperature compensation mode may be set using

the Speed push button.

Factory default settings: 400 milliseconds output response time; temperature compensation enabled

Green Power ON LED: Indicates power is ON

Red Signal LED: Indicates target is within sensing range, and the condition of the received signal.

Output indicator (bicolor Yellow/Red): Indicates output status or TEACH mode

Response indicator (bicolor Yellow/Red): Indicates output response time selection

Transducer: Ceramic/Epoxy composite Housing: ABS

Membrane Switch: Polyester

Leakproof design is rated IEC IP67; NEMA 6P

2 m or 9 m shielded 5-conductor (with drain) PVC jacketed attached cable, or 5-pin Micro-style

quick-disconnect or 5-pin Mini-style quick-disconnect. QD cables are ordered separately.

See pages 419 and 421.

Temperature: -20° to +70° C Relative humidity: 100%

All models meet Mil Std. 202F requirements. Method 201A (vibration: 10 to 60Hz max.,

double amplitude 0.06", maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G

11 milliseconds duration, half sine wave

Less than 1.0% of sensing distance upon power-up with Temperature Compensation enabled

Objects passing inside the specied minimum sensing distance (200 mm) may produce a false response.

Contact factory for more information.

UN05 (p. 529)

™

More information online at bannerengineering.com

(cont’d)

265

GAUGING

LIGHT

ULTRASONIC

MEASURING LIGHT

SCREENS

TEMPERATURE

RADAR

Page 24

LIGHT

BRACKETS

QD CABLES

ULTRASONIC

MEASURING LIGHT

TEMPERATURE

RADAR

GAUGING

SLOT & LABEL

SCREENS

COLOR &

PICK-TO -LIGH T

MEASUREMENT & INSPECTION

U-GAGE® S18U

Compact

Ultrasonic Sensor

On-board diagnostics

®

The highly accurate U-GAGE

rst compact ultrasonic sensor with push-button TEACH

programming and diagnostic LEDs integrated right into the

housing. The S18U small size doesn’t limit its accuracy. It is

unaffected by target color and has all the features of much

larger sensors:

lUMINESCENCE

• Integrated diagnostic LEDs and push-button

programming

• Minimal dead zone

• Retrosonic sensing mode

• Temperature compensation circuitry

• Programmable background

suppression

• Analog and discrete versions

S18U is the industry’s

5-Pin Euro

PAGE 373

PAGE 415

Two housing styles

• Available in straight or right-angle versions with a

wide variety of mounting hardware for enhanced

sensing versatility

• Ideal for material handling and packaged goods

applications, such as bottling or liquid level detection

and control for small containers

• Senses from 30 to 300 mm

Straight Right Angle

Accessory wave guides are available

for narrowing sensing beam.

(see page 445)

Integrated push-button programming

Program the unit with its integrated TEACH-mode push

button or remote TEACH wire. Bright LEDs indicate status

during setup and offer visual diagnostics during operation.

Congure a set sensing window, background suppressed

sensing or retrosonic mode for detecting any object

regardless of shape, angle or size.

Power/Signal Strength

TEACH Push

Button

Output/TEACH Indicator

266 More information online at bannerengineering.com

Page 25

MEASUREMENT & INSPECTION

Detailed

Dimension

s

18.0 mm

85.1 mm

Dow nlo a

d

PDF

U-GAGE® S18U Sensors

Push-button TEACH programming for easy setup

18 mm threaded barrel housing

Straight or right-angle housing

Rugged encapsulated design for

harsh environments

Bright diagnostic LEDs on sensor housing

5-pin Euro-style QD cables with shield,

ordered separately (see page 415)

Optional wave guides for narrowing

sensing beam (see page 444)

U-GAGE

S18UUA

S18UUAQ

S18UIA

S18UIAQ

S18UUAR

S18UUARQ

S18UIAR

S18UIARQ

S18UBA

S18UBAQ

S18UBAR

S18UBARQ

®

S18U, 10-30V dc

Models Range Cable* Output

2 m

30 - 300 mm

30 - 300 mm

30 - 300 mm

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

2 m

5-pin Euro QD

Straight Models

0 to 10V dc

4 to 20 mA

0 to 10V dc

4 to 20 mA

Bipolar

NPN/PNP

80.8 mm

Configuration

S18U Right-angle Models

18.0 mm

Housing

Straight

Right-Angle

Straight

Right-Angle

Data

Sheet

110738

110738

108964

GAUGING

LIGHT

ULTRASONIC

MEASURING LIGHT

SCREENS

TEMPERATURE

RADAR

* For 9 m cable, add suffix W/30 to the 2 m model number (example, S18UUA W/30). A model with a QD requires a mating cable (see page 415).

U-GAGE® S18U Specifications

Effective Beam

Supply Voltage and Current

Ultrasonic Frequency

Supply Protection Circuitry

Output Protection

See charts EBPC-4 and EBPC-5 on page 513.

10 to 30V dc (10% max. ripple); 65 mA max. (exclusive of load), 40 mA typical @ 25V input

300 kHz, rep. rate 2.5 milliseconds

Protected against reverse polarity and transient voltages

Protected against short circuit conditions

More information online at bannerengineering.com

More on

next page

267

Page 26

LIGHT

ULTRASONIC

MEASURING LIGHT

TEMPERATURE

GAUGING

SLOT & LABEL

SCREENS

COLOR &

PICK-TO -LIGH T

MEASUREMENT & INSPECTION

Output Ratings

Output Configuration

Output Response Time

lUMINESCENCE

Delay at Power-up

Linearity*

(Analog output models)

Resolution*

(Analog output models)

Repeatability

U-GAGE® S18U Specifications (cont’d)

Analog:

Analog Voltage Output: 2.5 kΩ min. load resistance

Minimum supply for a full 10V output is 12V dc (for supply voltages

between 10 and 12, V out max is at least V supply -2)

Analog Current Output: 1 kΩ max @ 24V input

Max load resistance = (Vcc-4)/0.02 Ω

Discrete: 100 mA max.

OFF-state leakage current: less than 5 µA

NPN saturation: less than 200 mV @ 10 mA and less than 600 mV @ 100 mA

PNP saturation: less than 1.2V @ 10 mA and less than 1.6V @ 100 mA

Analog: 0 to 10V dc or 4 to 20 mA, depending on model

Discrete: Bipolar: One NPN (current sinking) and one PNP (current sourcing) output in each model.

Solid-state switch conducts when target is sensed within sensing window.

Analog: 30 milliseconds: Black wire at 0-2V dc (or open) Discrete: 5 milliseconds

2.5 milliseconds: Black wire at 5-30V dc

300 milliseconds

2.5 milliseconds response: ± 1 mm

30 milliseconds response: ± 0.5 mm

2.5 milliseconds response: 1 mm

30 milliseconds response: 0.5 mm

0.5 mm

Temperature Effect

RADAR

Temperature Warmup Drift

Minimum Window Size

Switching Hysteresis

(Discrete output models)

Adjustments

Indicators

Remote TEACH Input

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and

Mechanical Shock

Application Notes

0.02% of distance/ ° C

Less than 1.7% of sensing distance upon power-up

5 mm

0.7 mm

Sensing window limits: TEACH-Mode programming of near and far window limits may be set using

the push-button or remotely using TEACH input.

Power/Signal Strength (Red/Green)

Green—Target is within sensing range

Red—Target is outside sensing range

OFF—Sensing power is OFF

TEACH/Output Indicator (Yellow/Red)

Yellow —Target is within taught limits

OFF—Target is outside taught window limits

Red—Sensor is in TEACH mode

Impedance: 12 kΩ

Threaded Barrel: Thermoplastic polyester Push-Button Housing: ABS/PC

Push Button: Santoprene Lightpipes: Acrylic

Leakproof design is rated IEC IP67; NEMA 6P

2 m or 9 m shielded 5-conductor (with drain) PVC jacketed attached cable, or 5-pin Euro-style

quick-disconnect. QD cables are ordered separately. See page 415.

Temperature: -20° to +60° C Relative humidity: 100%

All models meet Mil. Std. 202F requirements. method 201A (vibration: 10 to 60 Hz max.,

double amplitude 0.06”, maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G

11 milliseconds duration, half sine wave

Objects passing inside the specied near limit may produce a false response.

Certifications

Hookup Diagrams

Analog Models: MI13 (p. 535) Discrete Models: MI12 (p. 534)

*Linearity and resolution are specified using a 50 x 50 mm aluminum plate at 22° C under fixed sensing conditions.

268 More information online at bannerengineering.com

Page 27

MEASUREMENT & INSPECTION

BRACKETS

QD CABLES

QS18U

Ultrasonic

®

WORLD-BEAM

• Senses clear or transparent material and color variations

• Senses within a 50 to 500 mm window with a

15 millisecond response time

• Delivers high accuracy in wet or dirty environments

• Available in encapsulated IP68 models rated for a

range of harsh conditions

• Features push-button TEACH for easy programming at

the sensor or remotely

Features

• TEACH setup using on-board push-button or remote wire

• 2 m or 9 m integral cable, 4-pin Euro- or Pico-style

integral quick-disconnect, or 150 mm threaded pigtail

QD cable options

• Wide operating range of -20° to 60° C

• Retrosonic sensing mode

Sensor

GAUGING

LIGHT

ULTRASONIC

MEASURING LIGHT

SCREENS

TEMPERATURE

RADAR

Applications

• Sense clear web materials in confined areas

• Detect clear or shiny bottles in a filling line

• Detect highly reflective surfaces

• Verify liquid or dry bulk levels from inside

cramped locations

Choice of pre-wired cable, Pico- or

Euro-style integral QD connector,

or pigtail QD (not shown)

Accessory wave guides are

available for narrowing sensing

beam. (see page 444.)

Simple push-button

programming

Rugged,

ultra-compact

housing

Bright LED bicolor operating status

indicators visible from 360°

Universal 18 mm

threaded nose or side

mounting formats

PAGE 373

4-Pin Euro +

4-Pin Pico

PAGE 411 & 412

More information online at bannerengineering.com

269

Page 28

MEASUREMENT & INSPECTION

Detailed

Dimension

s

Dow nlo a

d

PDF

LIGHT

ULTRASONIC

MEASURING LIGHT

TEMPERATURE

RADAR

GAUGING

SLOT & LABEL

SCREENS

COLOR &

PICK-TO -LIGH T

WORLD-BEAM® QS18U Sensors

Bicolor LED indicator for power and signal strength

Bicolor LED indicator for TEACH/output

Choice of cables and connectors

Rugged, ultra-compact housing

4-pin Pico- or Euro-style QD cables with shield

ordered separately (see pages 411 and 412)

lUMINESCENCE

Optional wave guides for narrowing

sensing beam (see page 444)

WORLD-BEAM® QS18U, 12-30V dc

Model Range Cable*

41.5 mm

15.0 mm

33.5 mm

TEACH

Options Output

Data

Sheet

QS18UNA

2 m

NPN

QS18UNAQ8 4-pin Euro QD

50 - 500 mm

QS18UPA 2 m

Integral push button

and remote TEACH

(IP67; NEMA 6P)

PNP

QS18UPAQ8 4-pin Euro QD

QS18UNAE

QS18UNAEQ8

QS18UPAE

QS18UPAEQ8

* For 9 m cable, add suffix W/30 to the 2 m model number (example, QS18UNA W/30). A model with a QD requires a mating cable (see pages 411 and 412).

QD mod els:

• For 4-pin integral Euro-style QD, add suffix Q8 (example, QS18UNAQ8). • For 4-pin 150 mm Euro-style pigtail, add suff ix Q5 (example, QS18UNAQ5).

• For 4-pin integral Pico-style QD, add suffix Q7 (example, QS18UNAQ7). • For 4-pin 150 mm Pico-st yle pigtail, add suf fix Q (example, QS18UNAFQ).

†

Models are epoxy-encapsulated, IP68; NEMA 6P with remote TEACH programming

†

†

†

†

50 - 500 mm

2 m

4-pin Euro QD

2 m

4-pin Euro QD

NPN

Remote TEACH

(epoxy-encapsulated,

IP68; NEMA 6P)

PNP

119287

119287

270 More information online at bannerengineering.com

Page 29

Sensing Range

Sensing Beam

Supply Voltage

Ultrasonic Frequency

Supply Protection Circuitry

Output Protection

Delay at Power-Up

Output Configurations

Temperature Effect

Repeatability

Hysteresis

Output Ratings

Output Response Time

Minimum Window Size

Adjustments

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

Vibration and Mechanical

Shock

Temperature Warmup Drift

Application Notes

Certifications

Hookup Diagrams

MEASUREMENT & INSPECTION

WORLD-BEAM® QS18U Specifications

50 to 500 mm

See charts EBPC-6 and EBPC-7 on pages 513-514.

12 to 30V dc (10% max. ripple); 25 mA max. (exclusive of load)

300 kHz, rep. rate 7.5 milliseconds

Protected against reverse polarity and transient voltages

Protected against short circuit conditions

300 milliseconds

Solid-state switch conducts when target is sensed within sensing window;

One NPN (current sinking) or one PNP (current sourcing), depending on model.

Non-encapsulated models: ± 0.05% per ° C from -20° to +50° C, ± 0.1% per ° C from +50° to +60° C

Encapsulated models: ± 0.05% per ° C from 0° to +60° C, ± 0.1% per ° C from -20° to 0° C

0.7 mm

1.4 mm

100 mA max.

OFF-state leakage current: less than 10 µA (sourcing); less than 200 µA (sinking)

NPN ON-state saturation voltage: less than 1.6V @ 100 mA

PNP ON-state saturation voltage: less than 2.0V @ 100 mA

15 milliseconds

5 mm

Sensing window limits: TEACH-Mode programming of near and far window limits may be set using

the push button or remotely using TEACH input.

Range Indicator (Red/Green)

Green—Target is within sensing range

Red—Target is outside sensing range

OFF—Sensing power is OFF

Housing: ABS Push-Button Housing: ABS

Push Button: TPE Lightpipes: Polycarbonate

Leakproof design, rated IEC IP67 or IP68; NEMA 6P, depending on model

2 m or 9 m 4-conductor PVC jacketed attached cable, or 4-pin Euro-style integral QD (Q8), or 4-pin

Pico-style integral QD (Q7), or 4-pin Euro-style 150 mm pigtail QD (Q5), or 4-pin Pico-style 150 mm

pigtail QD (Q), depending on model. See pages 411 and 412.

Temperature: -20° to +60° C Relative humidity: 100% (non-condensing)

All models meet Mil. Std. 202F requirements method 201A (vibration: 10 to 60 Hz max., double

amplitude 0.06", maximum acceleration 10G). Also meets IEC 947-5-2 requirements: 30G 11

milliseconds duration, half sine wave.

See data sheet p/n

119287 for more information.

Objects passing inside the specied near limit may produce a false response.

MI14 (p. 535)

Teach/Output Indicator (Yellow/Red)

Yellow—Target is within taught limits

OFF—Target is outside taught window limits

Red—Sensor is in TEACH mode

GAUGING

LIGHT

ULTRASONIC

MEASURING LIGHT

SCREENS

TEMPERATURE

RADAR

More information online at bannerengineering.com

271

Page 30

LIGHT

BRACKETS

QD CABLES

ULTRASONIC

MEASURING LIGHT

TEMPERATURE

GAUGING

SLOT & LABEL

SCREENS

COLOR &

PICK-TO -LIGH T

MEASUREMENT & INSPECTION

U-GAGE® T30U

Compact Sensors in

Universal Housing

Incredible versatility

The U-GAGE® T30U sets new standards for ultrasonic sensor

versatility by including discrete (switched) and analog outputs

in the same compact sensor. Dual-discrete models also are

available.

Two model types

lUMINESCENCE

• Combined analog and discrete output models:

- Offers choice of either NPN or PNP

discrete output and either 0-10V dc

or 4-20 mA sourcing analog

output—in the same compact sensor

- Features outputs that are

independently configurable

PAGE 373

5-Pin Euro

PAGE 415

RADAR

• Dual-discrete output:

- Features two NPN or two PNP

discrete outputs

- Offers independently

programmable outputs

- Available in models for direct liquid

level control (pump in/pump out)

Patented, ultra-short T-shaped package

The T30U is the shortest 30 mm diameter ultrasonic sensor

available and is less than half the length of comparable

competitive sensors.

• Four LED indicators keep you constantly informed of

programming and operating status.

• Strength of ashing red LED indicates the strength of the

COMING

SOON!

Push-button TEACH-mode programming

• Features simple 3-step push-button setup for accurate,