Page 1

FI22FP Series

!

Low-Profile, Inline Plastic Fiber Optic Sensor

Features

• Low-profile fiber optic sensors are designed for inconspicuous surface mounting

• 8-segment LED light bar indicates relative received signal strength, sensing contrast,

programming status, and diagnostic warnings

• Easy-to-set automatic Expert-style TEACH options including static, dynamic, and

single-point programming plus manual adjustment for fine-tuning

• Smart power-control algorithms to maximize sensing contrast

• Fast 500-microsecond sensing response

• Programmable 30-millisecond pulse stretcher (OFF delay)

• Extreme programming flexibility via two push buttons or a remote input wire

• Output may be programmed for either light or dark operate

• Bipolar discrete outputs: one current sourcing (PNP) and one current sinking (NPN)

• Visible red (660 nm) light source

• Easy-to-read TEACH and signal strength readout, plus indicators for a continuous

readout of operating status

Models

Model Cable*

2 m (6.5')

FI22FP

FI22FP

* 9 m (30’) cables are available by adding suffix “W/30” to the model number of any cabled sensor

(e.g., FI22FP W/30). A model with a QD connector requires a mating cable (see page 9).

**See page 2 for beam patterns and excess gain curves.

5-wire

integral cable

Integral 6-pin

Q

Pico-style QD

Supply

Voltage

10V dc to

30V dc

Output

Type

Bipolar

NPN/PNP

Maximum Range**

Range varies depending on sensing

mode and fiber optic(s) used; see

below and page 2 for typical values.

Opposed Mode

PIT26U Fiber: 60 mm (2.36")

PIT46U Fiber: 260 mm (10.24")

PIT66U Fiber: 540 mm (21.26")

Diffuse Mode

PBT26U Fiber: 15 mm (0.59")

PBT46U Fiber: 65 mm (2.56")

PBT66U Fiber: 115 mm (4.53")

WARNING . . . Not To Be Used for Personnel Protection

Never use this product as a sensing device for personnel protection. Doing so could lead to serious injury or death.

This product does NOT include the self-checking redundant circuitry necessary to allow its use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your

cur

rent Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Printed in USA 01/12 P/N 108899 rev. C

Page 2

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

FI22FP

PIT26U

PIT46U

PIT66U

Opposed Mode

with PIT26U Fiber

FI22FP

Opposed Mode

with PIT46U Fiber

FI22FP

Opposed Mode

with PIT66U Fiber

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

PIT46U

PIT66U

FI22FP

Opposed Mode

with PIT46U Fiber

FI22FP

Opposed Mode

with PIT66U Fiber

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

PIT66U

FI22FP

Opposed Mode

with PIT66U Fiber

625 mm

25.0 in

500 mm

20.0 in

375 mm

15.0 in

250 mm

10.0 in

125 mm

5.0 in

0

0

50 mm

100 mm

150 mm

50 mm

100 mm

150 mm

0

2.0 in

4.0 in

6.0 in

2.0 in

4.0 in

6.0 in

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

0.20 in

0.40 in

0.60 in

0.20 in

0.40 in

0.60 in

DISTANCE

FI22FP

Opposed Mode

with PIT66U Fiber

300 mm

12.0 in

240 mm

9.6 in

180 mm

7.2 in

120 mm

4.8 in

60 mm

2.4 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

DISTANCE

FI22FP

Opposed Mode

with PIT46U Fiber

75 mm

3.00 in

60 mm

2.40 in

45 mm

1.80 in

30 mm

1.20 in

15 mm

0.60 in

0

0

5 mm

10 mm

15 mm

5 mm

10 mm

15 mm

0

DISTANCE

FI22FP

Opposed Mode

with PIT26U Fiber

PIT26U

PIT46U

PIT66U

625 mm

25.0 in

500 mm

20.0 in

375 mm

15.0 in

250 mm

10.0 in

125 mm

5.0 in

0

0

50 mm

100 mm

150 mm

50 mm

100 mm

150 mm

0

2.0 in

4.0 in

6.0 in

2.0 in

4.0 in

6.0 in

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

DISTANCE

FI22FP

Opposed Mode

with PIT66U Fiber

300 mm

12.0 in

240 mm

9.6 in

180 mm

7.2 in

120 mm

4.8 in

60 mm

2.4 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

DISTANCE

FI22FP

Opposed Mode

with PIT46U Fiber

PIT46U

PIT66U

625 mm

25.0 in

500 mm

20.0 in

375 mm

15.0 in

250 mm

10.0 in

125 mm

5.0 in

0

0

50 mm

100 mm

150 mm

50 mm

100 mm

150 mm

0

2.0 in

4.0 in

6.0 in

2.0 in

4.0 in

6.0 in

DISTANCE

FI22FP

Opposed Mode

with PIT66U Fiber

PIT66U

1

10

100

1 mm

.04 in

10 mm

0.4 in

100 mm

4 in

0.1 mm

.004 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

1

10

100

1 mm

.04 in

10 mm

0.4 in

100 mm

4 in

0.1 mm

.004 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

FI22

Diffuse Mode

with PBT26U Fiber

FI22 FI22

Diffuse Mode

with PBT66U Fiber

PBT66UPBT26U

Diffuse Mode

with PBT46U Fiber

PBT46U

1

10

100

1 mm

.04 in

10 mm

0.4 in

100 mm

4 in

0.1 mm

.004 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

FI22 FI22

Diffuse Mode

with PBT66U Fiber

PBT66UPBT26U

Diffuse Mode

with PBT46U Fiber

PBT46U

1

10

100

10 mm

.4 in

100 mm

4 in

1000 mm

40 in

1 mm

.04 in

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

Diffuse Mode

with PBT66U Fiber

PBT66UPBT26U

125 mm

5.0 in

100 mm

4.0 in

75 mm

3.0 in

50 mm

2.0 in

25 mm

1.0 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

0.08 in

0.16 in

0.24 in

0.08 in

0.16 in

0.24 in

DISTANCE

FI22FP

Diffuse Mode

with PBT66U Fiber

125 mm

5.0 in

100 mm

4.0 in

75 mm

3.0 in

50 mm

2.0 in

25 mm

1.0 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

DISTANCE

FI22FP

Diffuse Mode

with PBT46U Fiber

15 mm

0.56 in

12 mm

0.48 in

9 mm

0.36 in

6 mm

0.24 in

3 mm

0.12 in

0

0

2 mm

4 mm

6 mm

2 mm

4 mm

6 mm

0

DISTANCE

FI22FP

Diffuse Mode

with PBT26U Fiber

PBT66U

PBT26U

PBT46U

125 mm

5.0 in

100 mm

4.0 in

75 mm

3.0 in

50 mm

2.0 in

25 mm

1.0 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

DISTANCE

FI22FP

Diffuse Mode

with PBT66U Fiber

125 mm

5.0 in

100 mm

4.0 in

75 mm

3.0 in

50 mm

2.0 in

25 mm

1.0 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

DISTANCE

FI22FP

Diffuse Mode

with PBT46U Fiber

PBT66U

PBT46U

125 mm

5.0 in

100 mm

4.0 in

75 mm

3.0 in

50 mm

2.0 in

25 mm

1.0 in

0

0

20 mm

40 mm

60 mm

20 mm

40 mm

60 mm

0

0.80 in

1.60 in

2.40 in

0.80 in

1.60 in

2.40 in

DISTANCE

FI22FP

Diffuse Mode

with PBT66U Fiber

PBT66U

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

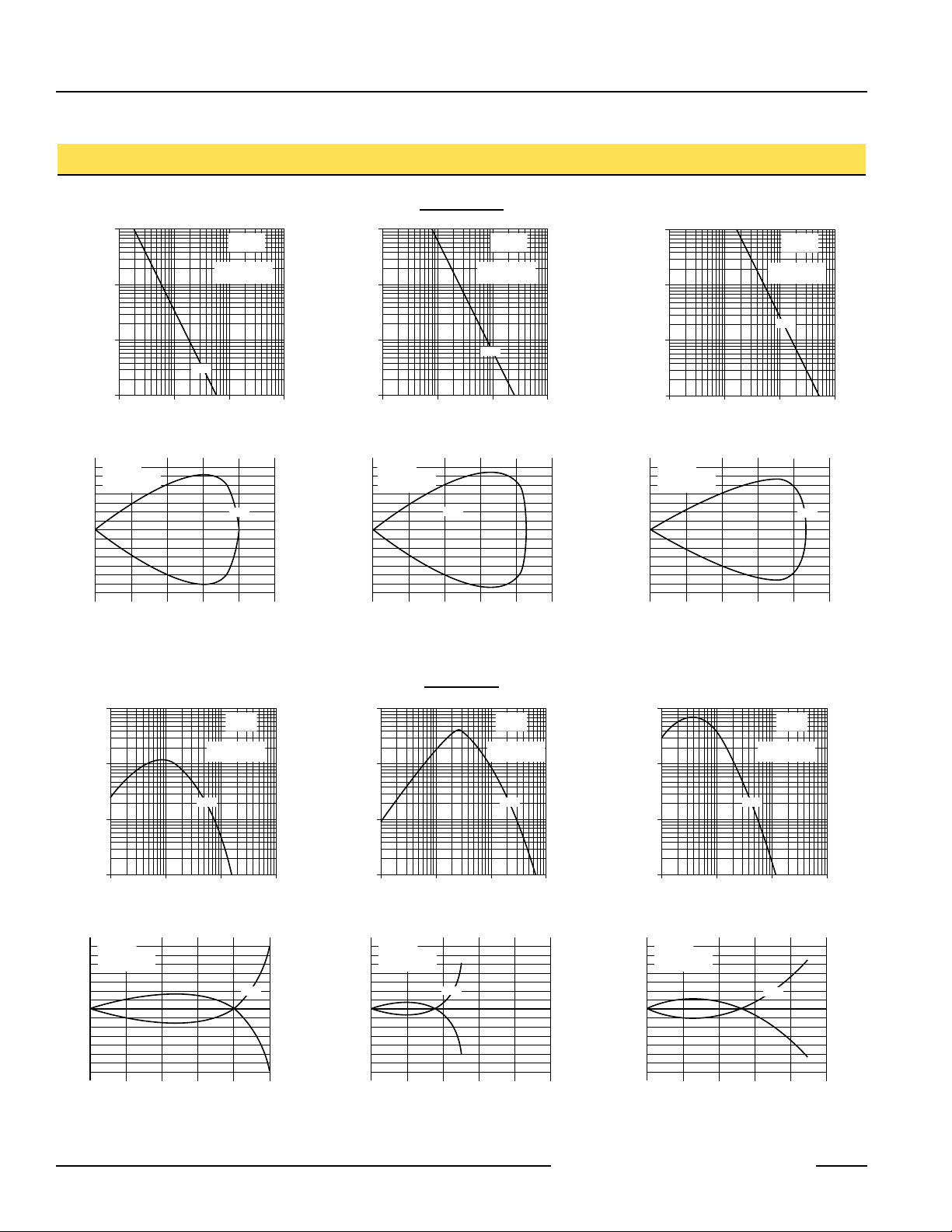

Excess Gain Curves and Beam Patterns

Opposed Mode

Diffuse Mode

2 P/N 108899 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763. 544.3164

Page 3

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

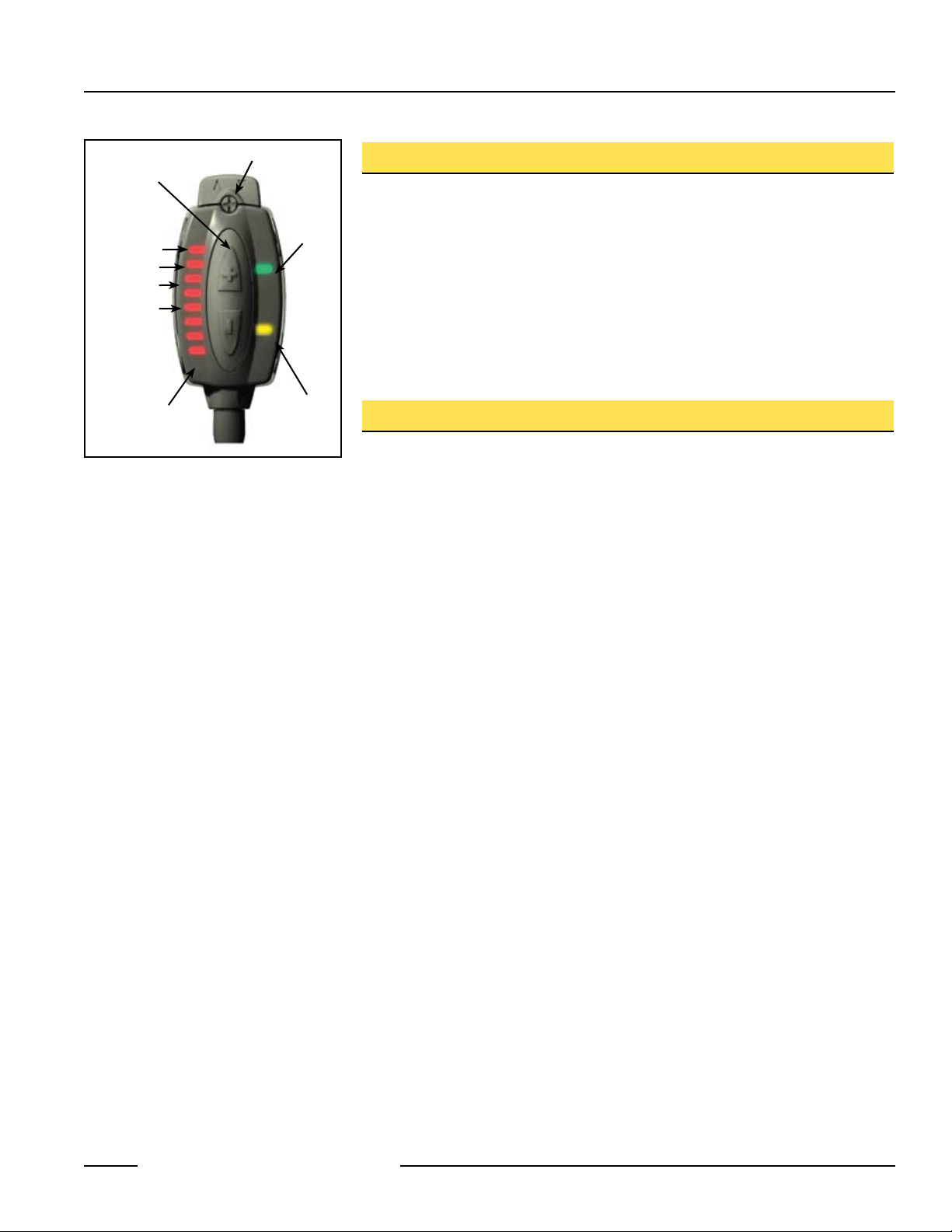

Programming

Push Buttons

SETUP

Status

Indicators:

Light

Dark Operate

Delay

Switching

Point

Bargraph

Display

Figure 1. FI22FP features

Fiber Ports

Yellow Output

Conducting

Indicator

Green

Power ON

Indicator

Overview

The FI22FP is an easy-to-use, low-profile fiber optic sensor. It provides high-performance

sensing in low-contrast applications and its small size lets it mount almost anywhere.

Configuration options include SETUP mode plus static, dynamic and single-point TEACHmode programming, in addition to manual fine adjustment, remote programming and

security lockout options.

The sensor has bipolar outputs, one each NPN and PNP.

The sensor’s compact housing has a large, easy-to-see bargraph display plus bright LEDs

for easy programming and status monitoring during operation. The sensor quickly snapmounts to its custom bracket (included with sensor).

Sensor Programming

Sensor configuration is accomplished through TEACH-mode programming and SETUP

mode. After TEACH mode has defined the sensing parameters, SETUP mode may be used

to enable the delay or to change the light/dark operate status. Manual Adjust may be used

to fine-tune the thresholds (see page 9). Two push buttons, Dynamic (+) and Static (-), or

the remote wire, may be used to access and set programming parameters.

Sensor programming may be accomplished using any of three TEACH methods. A single

switching threshold may be programmed using either dynamic (on-the-fly) or static TEACH.

In addition, single-point static TEACH may be used to define a sensing window, centered on

a single taught condition. Single-point TEACH can be accomplished only statically.

Remote Programming

The Remote Programming function may be used to program the sensor remotely or to

disable the push buttons for security. Connect the gray wire of the sensor to ground (0V

dc), with a remote programming switch connected between them. Pulse the remote line

according to the diagrams in the programming procedures. The length of the individual

gramming pulses is equal to the value T:

ro

p

0.04 seconds ≤ T ≤ 0.8 seconds

Returning to RUN Mode

TEACH and SETUP modes each may be exited either after the 60-second time-out, or by

exiting the process:

static TEACH mode, press and hold the Static (-) button (or hold the remote line) for 2

• In

seconds. The sensor returns to RUN mode without saving any new settings.

• In

SETUP mode, press and hold both the Static (-) and Dynamic (+) buttons (or hold

the remote line) for 2 seconds. The sensor returns to RUN mode and saves the current

setting.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 108899 rev. C 3

www.bannerengineering.com • Tel: 763. 544.3164

Page 4

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

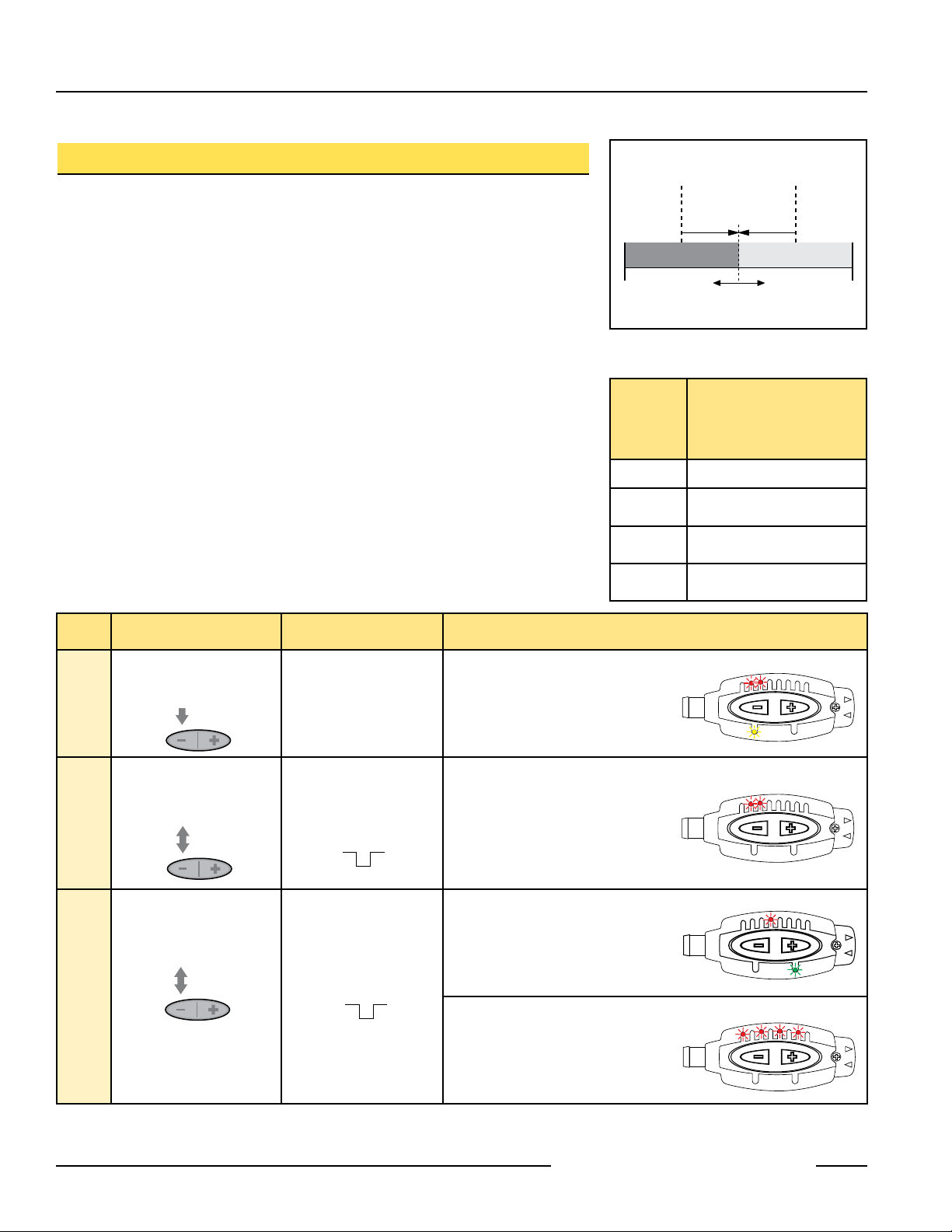

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

2nd Taught

Condition

1st Taught

Condition

Position

adjusted by

Manual Adjust

T

T T

T

T

T T

T

Two-Point Static TEACH (Switch Point)

• Sets a single switching threshold

• Threshold position is adjustable using “+” and “-” buttons (Manual Adjust)

Two-Point TEACH is the traditional setup method, used when two conditions can be

presented by the user. The sensor locates a single sensing threshold (the switch point)

midway between the two taught conditions, with the Output ON condition on one side, and

the Output OFF condition on the other (see Figure 2).

The first condition taught is the ON condition. The Output ON and OFF conditions can be

reversed by changing Light/Dark Operate status in SETUP mode.

Two-Point TEACH and Manual Adjust

Using Manual Adjust with Two-Point TEACH moves the switching threshold. The lighted

LED on the bargraph will move to exhibit the relative amount of received signal.

Figure 2. Two-Point TEACH (Light Operate

Bargraph

LED

Following

TEACH

6 to 8 Excellent: Very stable operation

4 to 5

2 to 3

1

shown)

Relative Signal Difference/

Recommendation

Good: Minor sensing variables

will not affect sensing reliability.

Low: Minor sensing variables

may affect sensing reliability.

Unreliable: Consider an

alternate sensing scheme.

Access

Learn Output

Learn Output

Push Button

0.04 sec. ≤ “click” ≤ 0.8 sec.

• Press and Hold

> 2 seconds

TEACH Mode

• Present Output ON

condition

• Click push button

ON Condition

• Present Output OFF

condition

• Click push button

OFF Condition

Remote Line

0.04 sec. ≤ T ≤ 0.8 sec.

No action required;

sensor is ready for 1st

TEACH condition.

• Present

Output ON

condition

• Single-pulse remote line

• Present

Output OFF

condition

• Single-pulse remote line

Result

Power LED: OFF

Output LED: ON

Status LEDs: #2 & 3 Alternately flashing

Power LED: OFF

Output LED: OFF

Status LEDs: #2 & 3 Alternately flashing

Teach Accepted

Power LED: ON

Bargraph: One LED

relative contrast (good

flashes to show

signal

difference shown; see table above)

Sensor returns to Run mode

Teach Unacceptable

Power LED: OFF

Bargraph: #1, 3, 5,

7 Alternately flash

to show failure

Sensor returns to “Learn Output ON”

condition

4 P/N 108899 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763. 544.3164

Page 5

Sensor positions

threshold midway

between taught conditions

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF

Output ON

Darkest Taught

Condition

Lightest Taught

Condition

Position

adjusted by

Manual Adjust

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

2nd Taught

Condition

1st Taught

Condition

Position

adjusted by

Manual Adjust

Figure 3. Two-Point Dynamic TEACH

T T T T

T

T T

T T T

T T

T T

T

T T T T

T

T T

T T T

T T

T T

T

T T T T

T

T T

T T T

T T

T T

T

(Light Operate shown)

Bargraph

LED

Following

Relative Signal Difference/

Recommendation

TEACH

6 to 8 Excellent: Very stable operation.

4 to 5

2 to 3

1

Good: Minor sensing variables

will not affect sensing reliability.

Low: Minor sensing variables

may affect sensing reliability.

Unreliable: Consider an

alternate sensing scheme.

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

Dynamic TEACH and Adaptive Thresholds

• Teach on-the-fly

• Sets a single switching threshold

reshold position is adjustable using “+” and “-” buttons (Manual Adjust)

• Th

Dynamic TEACH is best used when a machine or process may not be stopped for

teaching. A variation of two-point TEACH, it programs the sensor during actual machine

run conditions, taking multiple samples of the light and dark conditions and automatically

setting the threshold at the optimum level (see Figure 3).

amic TEACH activates the sensor’s adaptive threshold system, which continuously

yn

D

tracks minimum and maximum signal levels, and automatically maintains centering of the

switch point between the light and dark conditions. The adaptive threshold system remains

in effect during RUN mode. The adaptive routine saves to non-volatile memory at least once

per hour.

n Dynamic TEACH mode is used, the output ON state (light or dark operate) will remain

he

W

as it was last programmed. To change the output ON state, use SETUP mode (see page 7).

The

sensing set point may be adjusted (fine-tuned) whenever the sensor is in RUN mode by

clicking the “+” and “-” buttons. However, when a manual adjustment is made, the adaptive

thr

eshold system is disabled (cancelled).

Access

TEACH Mode

Learn Output

ON Condition

Learn Output

OFF Condition

P/N 108899 rev. C 5

Push Button Remote Line Result

• Press and Hold

> 2 seconds

• Hold remote line

(to ground)

low

> 2 seconds

• Continue to hold

• Present Output ON and

OFF conditions

• Present Output ON

OFF conditions

• Continue to hold

line low (to ground)

• Release • Release remote line/

switch

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763. 544.3164

and

remote

Power LED: OFF

Bargraph: #6 & 7 Alternately flashing

Power LED: OFF

Bargraph: #6 & 7 Alternately flashing

Teach Accepted

Power LED: ON

Bargraph: One LED

flashes to show

relative contrast (good signal

difference shown; see table above)

Sensor returns to Run mode with new settings

Teach Unacceptable

Power LED: OFF

Bargraph: #1, 3, 5,

7 Alternately flash

to show failure

Sensor returns to Run mode

without changing settings

Page 6

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

Sensor positions

threshold midway

between taught conditions

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Darkest

(no signal)

Most Light

(saturated

signal)

Most Light

(saturated

signal)

Single

taught

point

Sensing window size

adjusted by

Manual Adjust

Output OFF Output OFF

Output OFF

Output ON

Output ON

Darkest Taught

Condition

Lightest Taught

Condition

Position

adjusted by

Manual Adjust

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

2nd Taught

Condition

1st Taught

Condition

Position

adjusted by

Manual Adjust

T

T T

T

T T

T

Single-Point Static TEACH (Sensing Window)

• Sets a single ON condition

• All other conditions (lighter or darker) result in OFF output

• Sensing window size (sensitivity) is adjustable using “+” and “-” buttons

(Manual Adjust)

Single-Point TEACH is most useful when a product may not always appear in the same

place, or when other signals may appear. Single-point TEACH programs a sensing window,

with the Output ON condition inside the window, and the Output OFF conditions outside the

window (see Figure 4). Output ON and OFF conditions can be reversed by changing Light/

Dark Operate status in SETUP mode.

Single-Point TEACH programming may be accomplished only using Static TEACH. The

sensor learns a single sensing condition, and adds switching thresholds above and below

the taught condition to create a sensing window.

Single-Point TEACH and Manual Adjust

Using Manual Adjust with Single-Point TEACH expands or contracts the size of the window.

The lighted LEDs on the light bar separate to a greater or lesser extent to exhibit the relative

sensing window size.

Figure 4. Single-Point TEACH (Light

Operate shown)

Access

TEACH Mode

Learn Set Point

(Output ON) Condition

Push Button

0.04 sec. ≤ “click” ≤ 0.8 sec.

• Press and Hold

> 2 seconds

• Present Output ON

conditions

• Double-click push button

Remote Line

0.04 sec. ≤ T ≤ 0.8 sec.

• Present Output ON

condition

• Single-pulse

• Double-pulse

remote line

remote line

Result

Power LED: OFF

Output LED: ON (Push Button)

Output LED: OFF (Remote)

Static LEDs: #2 & 3 alternately flashing

Teach Accepted

Power LED: ON

Bargraph: 2 indicators flash together to

show single-point Teach accepted

Sensor returns to Run mode with

new settings

Teach Unacceptable

Power LED: OFF

Bargraph: #1, 3, 5, 7 flash to show failure

Sensor returns to “Teach 1st Condition”

6 P/N 108899 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763. 544.3164

Page 7

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

T T

T T T

T T

T T

T

SETUP Mode

SETUP mode is used to change sensor output response for:

SETUP

Status

Indicators

Figure 5. SETUP mode

{

Press and

hold

both push

buttons > 2

seconds

to access

SETUP mode

• Light or Dark operate

• 30-millisecond pulse stretcher (OFF delay), if required.

The status LEDs, active only during SETUP mode, indicate the output response

figuration when the sensor will be in RUN mode. Four combinations are possible:

con

Light Operate, No Delay

Da

rk Operate, No Delay

Dark Operate, 30 ms Delay

Light Operate, 30 ms Delay

To access SETUP mode and change the output response settings:

1. Press and hold BOTH push buttons (or double-pulse Remote line) until the green LED

indicator turns OFF.

lick EITHER push button (or pulse Remote line) to toggle through the four possible

2. C

setting combinations.

3. P

ress and hold both push buttons (or hold Remote line) until the green LED indicator

turns ON, indicating return to RUN mode.

NOTES: • If SETUP mode programming is interrupted and remains inactive for 60

seconds, the sensor returns to RUN mode with the most recent settings

(i.e., exits and saves current selection).

•

SETUP mode operates in the “background”, while the outputs are active.

Manual Adjust

Use during Run mode, accomplished via push buttons only.

Two-Point TEACH (Static or Dynamic):

• Fine-tunes sensing sensitivity

• Press “+” to increase; press “-” to decrease

Single-Point TEACH:

• Adjusts sensing window size (tolerance) for the single-point target condition

• Press “+” to increase; press “-” to decrease

The lighted bargraph LEDs move to reflect the increase or decrease.

Push Button Disable

In addition to its programming function, Remote Programming may be used to disable the

push buttons for security. Disabling the push buttons prevents undesired tampering with

the programming settings. Connect the gray wire of the sensor as described on page 9, and

ou

r-pulse to either enable or disable the push buttons:

f

P/N 108899 rev. C 7

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763. 544.3164

Page 8

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

Specifications

Sensing Beam

Supply Voltage

Supply Protection Circuitry

Delay at Power Up

Output Configuration

Output Rating

Output Protection

Output Response Time

Repeatability

Adjustments

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

660 nm visible red

10 to 30V dc (10% max. ripple) @ less than 32 mA exclusive of load

Protected against reverse polarity, over voltage, and transient voltages

250 milliseconds max.; outputs do not conduct during this time

Bipolar: 1 current sourcing (PNP) and 1 current sinking (NPN)

100 mA maximum load @25° C (derate 1 mA per °C increase)

OFF-state leakage current: < 50 µA at 30V dc

ON-state saturation voltage:

NPN: < 200 mV @ 10 mA and 1V @ 100 mA load

PNP: < 1.5V @ 10 mA and 2.0V @ 100 mA load

Protected against output short-circuit, continuous overload, transient over-voltages, and false pulse

on power up

500 microseconds

100 microseconds

2 push buttons and remote wire

• Expert Teach programming (two-point static, dynamic, and single-point static)

• Manually adjust (+/–) thresholds (from buttons only)

• LO/DO and Off Delay configurable (from buttons or remote wire)

• Push-button lockout (from remote wire only)

8-segment red bargraph:

Light-to-dark signal difference relative to taught condition (single-point TEACH), or

Sensing contrast (two-point

Green LED: Power On

ellow LED: Output conducting

Y

PC/ABS blend plastic housing; polycarbonate cover

IP67, NEMA 6

5-conductor 2 m (6.5') PVC cable, 9 m (30') PVC cable, or 6-pin integral Pico-style quick-disconnect

Temperature: -10° to +55°C

Relative Humidity: 90% @ 50° C (non-condensing)

TEACH)

Certifications

Banner Engineering Corp. • Minneapolis, MN U.S.A.

8 P/N 108899 rev. C

www.bannerengineering.com • Tel: 763. 544.3164

Page 9

50.0 mm

(1.98")

Pico-style

Quick Disconnect

Integral

Cable

23.0 mm

(0.91")

14.5 mm

(0.57")

7.0 mm

(0.28")

25.0 mm

(0.98")

6.0 mm

(0.24")

12.1 mm

(0.48")

10.5 mm

(0.41")

Sensor

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

Sensor and Bracket Dimensions

Bracket

Figure 6. Installing plastic optical fiber into

the FI22FP fiber ports

Installing the Optical Fibers

To install fibers:

1. Use a small Phillips screwdriver to loosen set screw, as shown in Figure 6.

2. Insert prepared fiber ends (2.2 mm diameter) into emitter and receiver ports, as far as

they will go.

3. H

olding fibers in place, tighten screw to lock in securely.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 108899 rev. C 9

www.bannerengineering.com • Tel: 763. 544.3164

Page 10

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

bn

Remote

Teach

bu

wh

bk

gy

+

10 - 30V dc

–

Load

Load

100 mA max. load

bn

Remote

Teach

bu

wh

bk

gy

+

10 - 30V dc

–

Load

Load

100 mA max. load

28 mm max.

(1.1")

ø 10 mm max.

(0.4")

20 mm

(0.8")

25 mm max.

(1.0")

ø12 mm max.

(0.5")

Brown Wire

Gray Wire

Pink Wire

Blue Wire

Black Wire

White Wire

FI22FP Low-Profile Inline Plastic Fiber Optic Sensor

Hookups

Cabled Models Quick-Disconnect Models

NOTE: Pink wire not used

Accessories

Quick-Disconnect Cables

Style Model Length Dimensions Pinout

6-pin

Pico-style

straight

6-pin

Pico-style

right-angle

PKG6Z-2

PKG6Z-9

PKW6Z-2

PKW6Z-

9

(6.5')

2 m

9 m (30')

2 m

(6.5')

9 m (30')

10 P/N 108899 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763. 544.3164

Page 11

Banner Engineering Corp Limited Warranty

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year

following the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its

manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty

period.This warranty does not cover damage or liability for misuse, abuse, or the improper application or installation of

the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE

THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming

any obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

P/N 108899 rev. C

P/N 63443 rev A.

Page 12

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

P/N 108899 rev. C

P/N 63443 revrA.

Loading...

Loading...