Page 1

Height

(See table

below)

Figure 1. Assembled enclosure

MSA-TE Series Tubular Enclosures

For MINI-SCREEN® Sensors Mounted in Washdown Environments

Features

• FDA-grade polycarbonate tubing and acetal end caps

• Stainless steel mounting components

• Brackets and fasteners included

• Ideal for high-pressure washdown applications

• NEMA 4X, IP67

• 12 models available to accommodate MINI-SCREEN® sensors 4" to 48" long

Banner MSA-TE Series Tubular Enclosures are designed specifically for use with Banner

MINI-SCREEN emitters and receivers. The enclosures are constructed of FDA-approved

rugged polycarbonate tubing with FDA-approved acetal end caps. The enclosures are

mounted with stainless steel mounting brackets and fasteners. The enclosures are

available in 12 lengths.

Use of the enclosure affects the sensing range of the MINI-SCREEN used: when wired

in pairs, range can be reduced by 50%. It is recommended to use MINI-SCREEN LongRange sensors (MSXLE/R) in the tubular enclosure.

CAUTION... Reduced

Sensing Range

Sensing Range is reduced

50% due to tubular construction.

WARNING...

Maintain Required

Separation Distance

The light screen produced by the

optical safety system sensors

must be placed at a minimum safe

distance from the dangerous motion

of the machine being guarded.

This necessary minimum distance

is called the separation distance,

and is discussed in Section 3 of the

appropriate instruction manuals.

Failure to calculate this distance

correctly and to maintain minimum

separation distance can result in

serious injury.

Figure 3 shows how the enclosure is assembled. Components are bagged together for

easier assembly.

Models

Enclosure

Model

MSA-TE-4

MSA-TE-8

MSA-TE-12

MSA-TE-16

MSA-TE-20

MSA-TE-24

MSA-TE-28

MSA-TE-32

MSA-TE-36

MSA-TE-40

MSA-TE-44

MSA-TE-48

Enclosure Height

(Figure 1)

338 mm (13.3")

439 mm (17.3")

541 mm (21.3")

643 mm (25.3")

744 mm (29.3")

846 mm (33.3")

947 mm (37.3")

1049 mm (41.3")

1151 mm (45.3")

1252 mm (49.3")

1354 mm (53.3")

1455 mm (57.3")

For MINI-SCREEN

Sensor Models

MSXLE/R 4

MSXLE/R 8

MSXLE/R 12

MSXLE/R 16

MSXLE/R 20

MSXLE/R 24

MSXLE/R 28

MSXLE/R 32

MSXLE/R 36

MSXLE/R 40

MSXLE/R 44

MSXLE/R 48

Printed in USA 06/05 P/N 109307 rev. B

Page 2

MSA-TE Series Tubular Enclosures

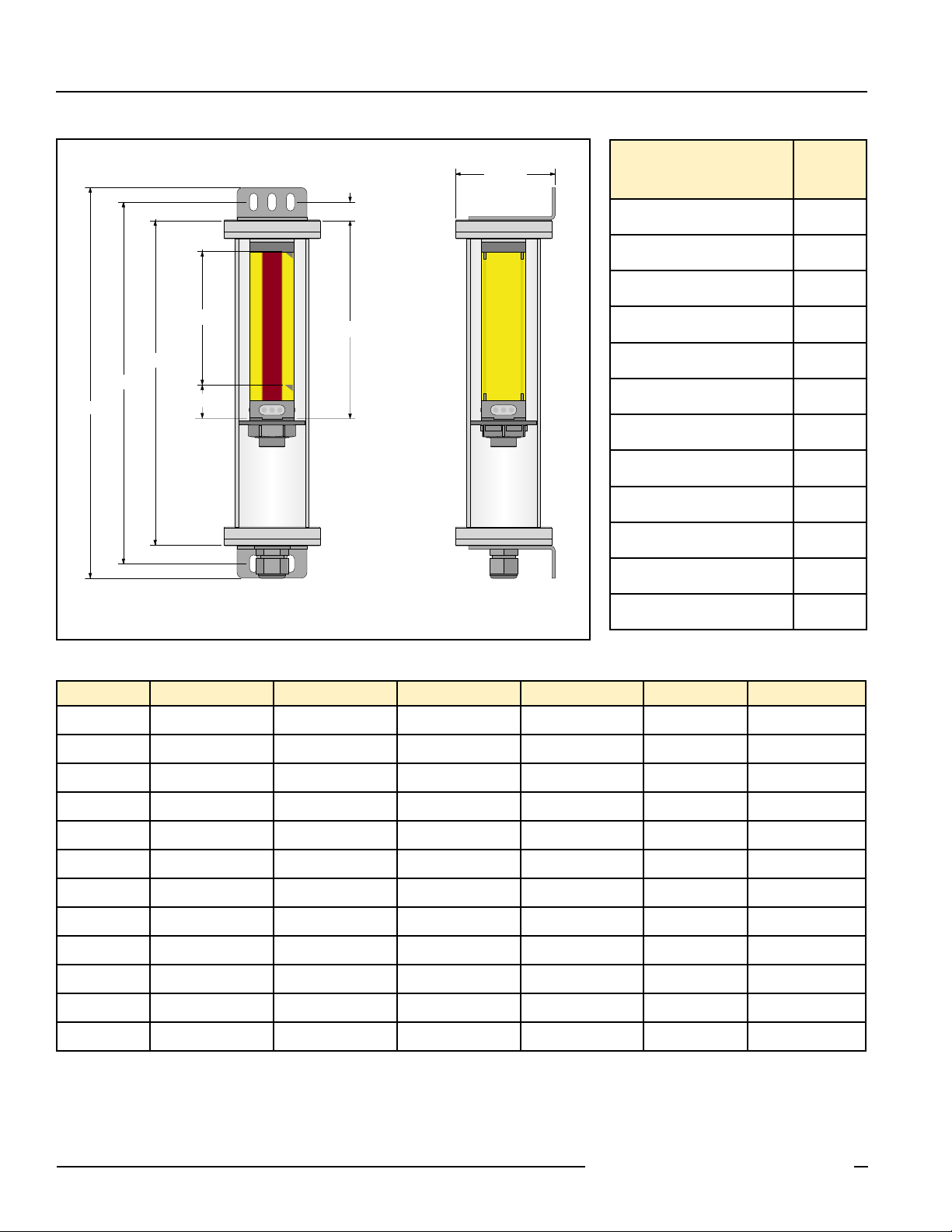

L1

L2

L3

16.8 mm

(0.66")

L4

Y

X

86.4 mm

(3.40")

Included with Each

MSA-TE Series Tubular

Enclosure

Spacer 1

Top End Cap 1

Bottom End Cap 1

Polycarbonate Tube 1

O-Ring (#142) 2

Mounting Bracket 2

M4 Screw 2

M4 Lockwasher 2

#6-32 Screw 8

Quantity

Figure 2. Enclosure/MINI-SCREEN dimensions

Model L1 L2 L3 L4 X Y

MSA-TE-4

MSA-TE-8

MSA-TE-12

MSA-TE-16

MSA-TE-20

MSA-TE-24

MSA-TE-28

MSA-TE-32

MSA-TE-36

MSA-TE-40

MSA-TE-44

338 mm (13.3") 312 mm (12.3") 279 mm (11.0") 170 mm (6.7") 28 mm (1.1") 114 mm (4.5")

439 mm (17.3") 414 mm (16.3") 381 mm (15.0") 272 mm (10.7") 28 mm (1.1") 215 mm (8.5")

541 mm (21.3") 516 mm (20.3")

643 mm (25.3")

744 mm (29.3") 719 mm (28.3") 686 mm (27.0") 577 mm (22.7") 30 mm (1.2") 508 mm (20")

846 mm (33.3") 820 mm (32.3") 787 mm (31.0") 678 mm (26.7") 30 mm (1.2") 610 mm (24")

947 mm (37.3") 922 mm (36.3") 889 mm (35.0") 780 mm (30.7") 33 mm (1.3") 711 mm (28")

1049 mm (41.3") 1024 mm (40.3") 991 mm (39.0") 879 mm (34.6") 33 mm (1.3") 813 mm (32")

1151 mm (45.3") 1125 mm (44.3") 1092 mm (43.0") 980 mm (38.6") 33 mm (1.3") 914 mm (36")

1252 mm (49.3") 1227 mm (48.3") 1194 mm (47.0") 1082 mm (42.6") 33 mm (1.3") 1016 mm (40")

1354 mm (53.3") 1328 mm (52.3") 1295 mm (51.0") 1184 mm (46.6") 33 mm (1.3") 1118 mm (44")

617 mm (24.3")

#6 Split Ring Lockwasher 8

#10-32 Screw 4

#10 Lockwasher 4

483 mm (19.0") 373 mm (14.7")

30 mm (1.2") 305 mm (12")

584 mm (23.0") 475 mm (18.7") 30 mm (1.2") 406 mm (16")

MSA-TE-48

2 P/N 109307 rev. B

1455 mm (57.3") 1430 mm (56.3") 1397 mm (55.0") 1285 mm (50.6") 33 mm (1.3") 1219 mm (48")

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

MSA-TE Series Tubular Enclosures

Lockwasher

Assembly Instructions

A. Place spacer disk on the QD end of the MINI-SCREEN sensor,

using the plastic mounting nut and lockwasher (supplied with

MINI-SCREEN).

O-ring

A

B

(backside)

B. Screw the top cap onto the non-QD end of the MINI-SCREEN

using the two M4 screws and lockwashers (make sure o-ring

is in place on top cap). Torque: 6 in-lbs max.

C. Being careful not to scratch the tubular housing, slide the

terminated end of the cordset into the labeled end of the clear

tube and push it through, so it comes out the other end.

D. Connect the cordset to the MINI-SCREEN.

E. Slide the MINI-SCREEN into the clear tube until the top cap

mates with the tube flange. Make sure the o-ring seals against

the flat surface of the flange.

C

D

F. Screw the top cap to the tube flange using four 6-32 screws

and lockwashers. Torque: 15 in-lbs max.

G. Slide the bottom end cap over the unterminated end of the

cordset, making sure the o-ring is in place on the bottom cap.

H. Screw the bottom cap to the tube flange, using four 6-32

screws and lockwashers. Make sure the o-ring seals against

the flat surface of the flange. Torque: 15 in-lbs max. Tighten

the strain relief nut over the cordset cable.

E

F

I. Place the mounting bracket on the top cap and secure with

two 10-32 screws and lockwashers. Torque: 50 in-lbs max.

J. Place the mounting bracket over the cordset cable and to

the bottom end cap; secure with two 10-32 screws and

lockwashers. Torque: 50 in-lbs max.

O-ring

(backside)

G

I

Figure 3. MSA-TE Series Tubular Enclosure assembly steps

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 109307 rev. B 3

H

J

Page 4

MSA-TE Series Tubular Enclosures

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair

or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

P/N 109307 rev. B

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...