Page 1

SureCross Web Configurator

rev. - 2/14/2012

134421

Page 2

Contents

Contents

Web Configurator ......................................................................................................................................3

Logging into the Web Configurator ......................................................................................................................................3

Changing the Device's IP Address .............................................................................................................................4

Selecting a Host Communication Protocol ..................................................................................................................5

Get ALL .......................................................................................................................................................................5

Change, Refresh, Send, and Update Commands ......................................................................................................6

RF Devices Tab ...................................................................................................................................................................6

Select Models .............................................................................................................................................................6

Configure Points .........................................................................................................................................................9

Expanded Configure Points ......................................................................................................................................11

I/O Linking .................................................................................................................................................................17

Scaling ......................................................................................................................................................................18

Remote I/O ................................................................................................................................................................19

Network Tab ......................................................................................................................................................................25

Modbus Data Submenu ............................................................................................................................................25

Modbus RTU Setup Submenu ..................................................................................................................................29

Modbus TCP Setup Submenu ..................................................................................................................................33

System Tab ........................................................................................................................................................................38

Data Submenu ..........................................................................................................................................................38

Action Rules Submenu .............................................................................................................................................41

Setup Submenu ........................................................................................................................................................45

Advanced Tab ....................................................................................................................................................................50

Scheduler Submenu .................................................................................................................................................50

Data Logger Submenu ..............................................................................................................................................54

E-mail Alerts Submenu .............................................................................................................................................58

Script BASIC Submenu .............................................................................................................................................62

Basic Configuration Examples ...........................................................................................................................................64

Setting up the Devices ..............................................................................................................................................65

Configuring I/O ..........................................................................................................................................................65

Linking I/O .................................................................................................................................................................66

Link Timeouts ............................................................................................................................................................67

System Network Settings ..........................................................................................................................................68

Advanced Configuration ....................................................................................................................................................69

Thresholds ................................................................................................................................................................70

Data and Event Logging ...........................................................................................................................................70

Scheduling ................................................................................................................................................................72

Trending Data ...........................................................................................................................................................73

Scaling ......................................................................................................................................................................74

Troubleshooting .................................................................................................................................................................75

Restoring Factory Default Settings ...........................................................................................................................75

Error Codes ...............................................................................................................................................................75

2 rev. -

Page 3

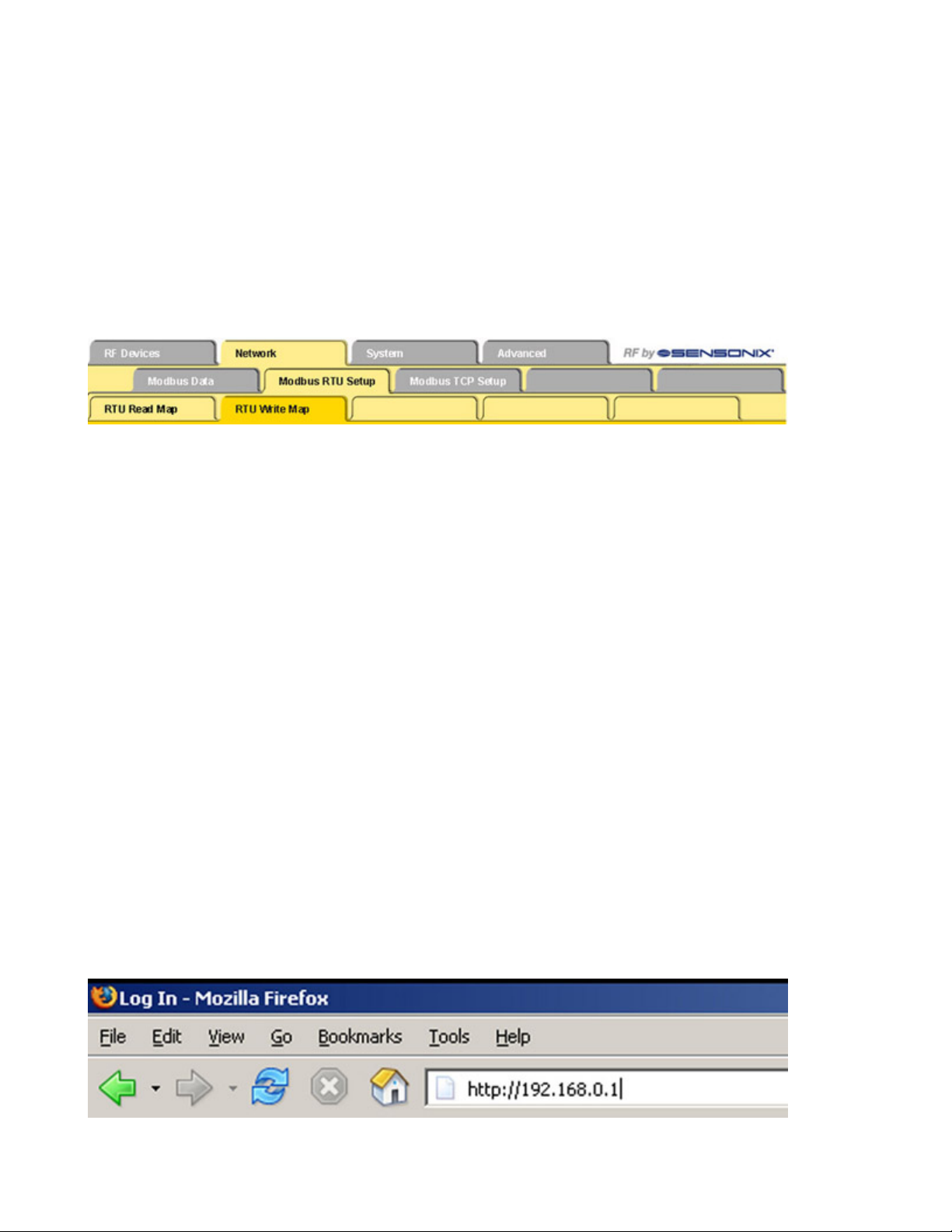

Web Configurator

The SureCross™ DX80 GatewayPro and DX83 Ethernet Bridge devices use an XML file to configure the network. To access the XML

file, use any web browser and enter the device’s IP address into the browser’s address window:

http://192.168.0.1

The web configuration pages are arranged with a hierarchy of index tabs. The upper row of tabs is the top of the hierarchy and selects a

broad topic. Top level tabs open related tabs on the next levels down. The middle tab selects a sub-topic, and the bottom tabs select

individual pages within the sub-topic. The bottom of each page includes a Quick Help section listing usage tips or instructions specific to

that page.

The XML file on any Ethernet Bridge or GatewayPro does not necessarily contain the settings for a specific wireless network. In many

cases, the XML file saved in the Ethernet Bridge or GatewayPro is a default configuration file. Attaching the Ethernet Bridge or GatewayPro to the radio network does not automatically transfer network or device settings to the Ethernet Bridge or to the XML file.

When viewing real-time data returned to the browser by the connected device, the browser displays the data received when the page

displayed. At this time, update data by clicking the Refresh button or the web browser’s Reload or Refresh button. Each time a page

update is requested, new real-time data displays.

For more information on specific SureCross components, please refer to the data sheets for the SureCross devices:

• Gateways

• Line-Powered Nodes

• FlexPower™ Nodes

Logging into the Web Configurator

The SureCross™ Pro and DX83 Ethernet Bridge devices use an XML file to configure the network. To access the XML file, use any web

browser set up for a direct connection to the Internet. If problems occur while connecting, verify the browser is not set to use a proxy

server.

When connecting to the Ethernet Bridge, GatewayPro, or MultiHop Pro directly from a host computer, a crossover Ethernet cable is

required; when connecting through a switch or Ethernet hub, use a standard Ethernet cable.

The factory default IP address for the devices is: 192.168.0.1.

To change the device’s default IP address, first set up the host PC with an IP address different from the Ethernet Bridge, GatewayPro, or

MultiHop Pro IP addresses. (Please refer to Banner document 133116 for detailed instructions on setting up the host computer’s network

IP address.) For example, change the PC host IP address to: 192.168.0.2.

After changing the host’s IP address, open a web browser and log into the Ethernet Bridge, GatewayPro, or MultiHop Pro by typing the IP

address in the browser location window: http://192.168.0.1.

rev. -

www.bannerengineering.com - tel: 763-544-3164 3

Page 4

SureCross Web Configurator

After entering the IP address, the home web page for the SureCross device displays. To log in, click on any tab at the top of the page. To

log out, close the browser.

For user-level access, enter the following as the user name and password.

• User name: system

• Password: admin

For Admin-level access, enter the following as the user name and password:

• User name: root

• Password: sxi

Admin-level access allows administrators to set up system users and their passwords. Admin-level access is also required to change the

IP address of the system.

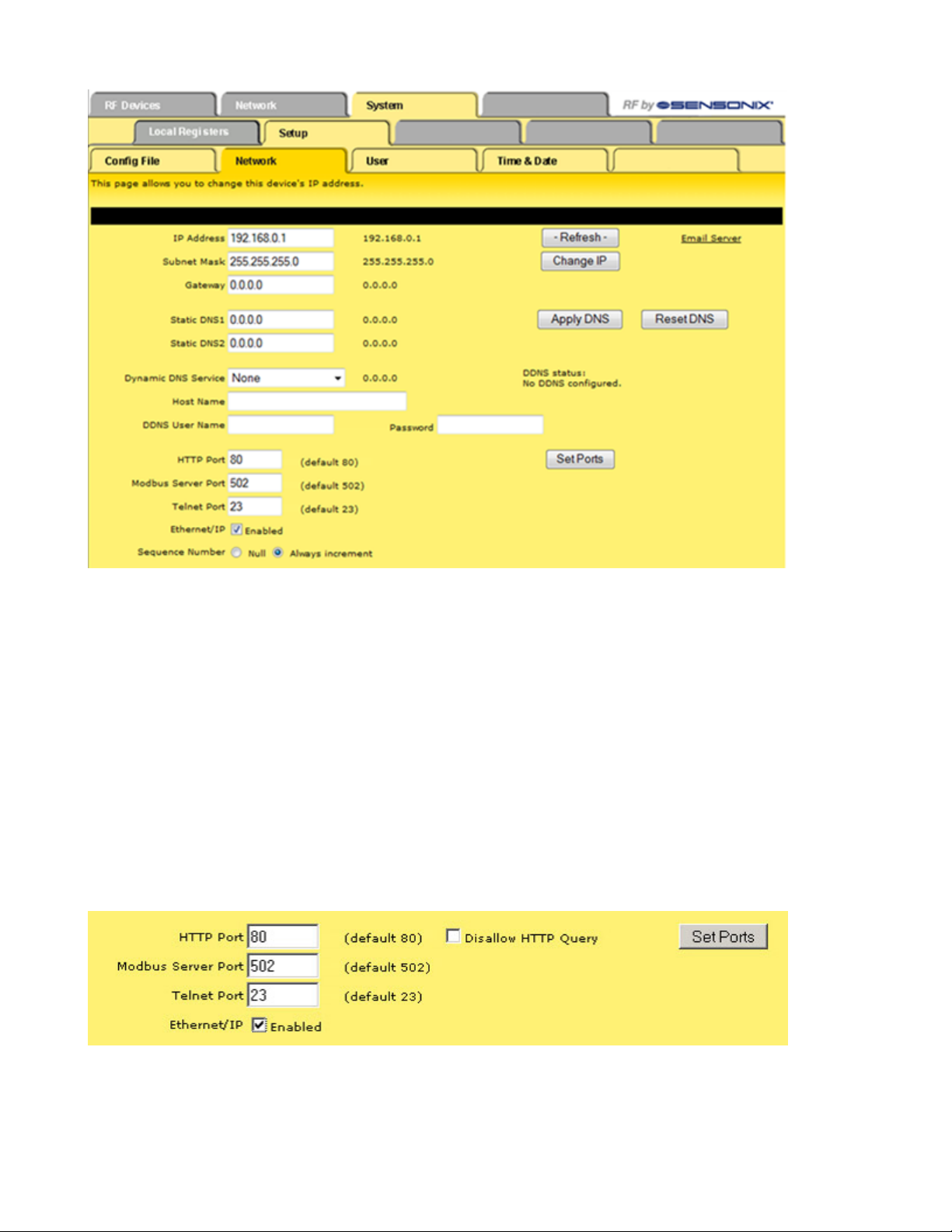

Changing the Device's IP Address

Once logged into the system, use the page tabs at the top of the page to select the path: System > Setup > Network. To change the

Ethernet Bridge or GatewayPro’s IP address:

1. Type in the new IP address

2. Click the Change IP button.

3. Cycle power to the device. The IP address change activates when the device reboots.

4 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 5

SureCross Web Configurator

IMPORTANT! Verify the new IP address is correct before cycling power to the device. After the IP address changes, you must use the

new IP address to access these configuration screens. Print this page and file for your records.

Selecting a Host Communication Protocol

By default the Ethernet Bridge and GatewayPro systems communicate with a host using Modbus/TCP. After establishing the IP address

of the Ethernet Bridge and host, the system is set up to use Modbus/TCP.

The system can also use EtherNet/IP™. To change the system to EtherNet/IP, follow the previous instructions regarding the device and

host IP address, and then:

1. Log in using the following user name and password. User name: root Password: sxi

2. At the bottom of the System > Setup > Network page is a checkbox to enable EtherNet/IP. Only select this box if the GatewayPro

system is running on an EtherNet/IP network. This change cannot be enabled from a login other than the “root” login.

3. After selecting the EtherNet/IP Enabled checkbox, click the Set Ports button to save any changes made to the HTTP Port, Modbus

Server Port, Telnet Port, or EtherNet/IP Enabled settings.

4. Cycle power to the Ethernet Bridge or GatewayPro to complete this update. After the device powers up, the changes should be

registered.

Get ALL

For an existing network, perform a Get ALL for the devices and save the XML file before changing any network parameters. The default

XML file stored on the Ethernet Bridge or GatewayPro may not accurately represent your configured network.

rev. - www.bannerengineering.com - tel: 763-544-3164 5

Page 6

The Get ALL command retrieves the parameters on the Configure Points and I/O Linking pages. These parameters are specific to the

wireless network. The Get ALL command does not retrieve parameters involving the host system or the wired network components.

1. From the RF Devices > Select Models screen, verify the DX80 radio devices are defined using the Models drop-down list and the

device name. If you make any changes to this list, select the Change box, then click the Update button to send the new device list

to the GatewayPro.

2. Select the Get ALL checkbox for each radio device in the wireless network.

3. Click the Update button to retrieve configuration information from each DX80 device.

4. The Get ALL command will take a few minutes to complete. Click on the Check Status button to review the status of the command.

When all devices are "Ready," the command has finished.

SureCross Web Configurator

Saving Changes to the XML File

To permanently save the changes to the XML file, go to the System > Setup > Config File page and click the Save button. Changes made

by clicking an Update button are temporary and only submitted to the Ethernet Bridge or GatewayPro, not the XML file.

Change, Refresh, Send, and Update Commands

Buttons commonly appearing on most configuration screens are the Change, Refresh, Send, and Update buttons. Each of these buttons

performs a slightly different task.

Change If you leave any Web Configurator screen with-

out clicking the Change button to submit the

changes to the Ethernet Bridge or GatewayPro,

all changes are lost.

Refresh Click the Refresh button to refresh the screen

image. This updates any information on the

screen that may have changed on the device.

Send Clicking the Send button transmits device and I/O

parameters to the radio devices. The Send operation usually requires several second to complete.

Update

Clicking the Update button sends information to

the Ethernet Bridge or GatewayPro or retrieves information depending on which checkboxes are selected: Change or Get/Send All. Updating information does not save configuration information permanently to the XML file.

RF Devices Tab

Use the RF Devices tab to configure the radio network devices and I/O points.

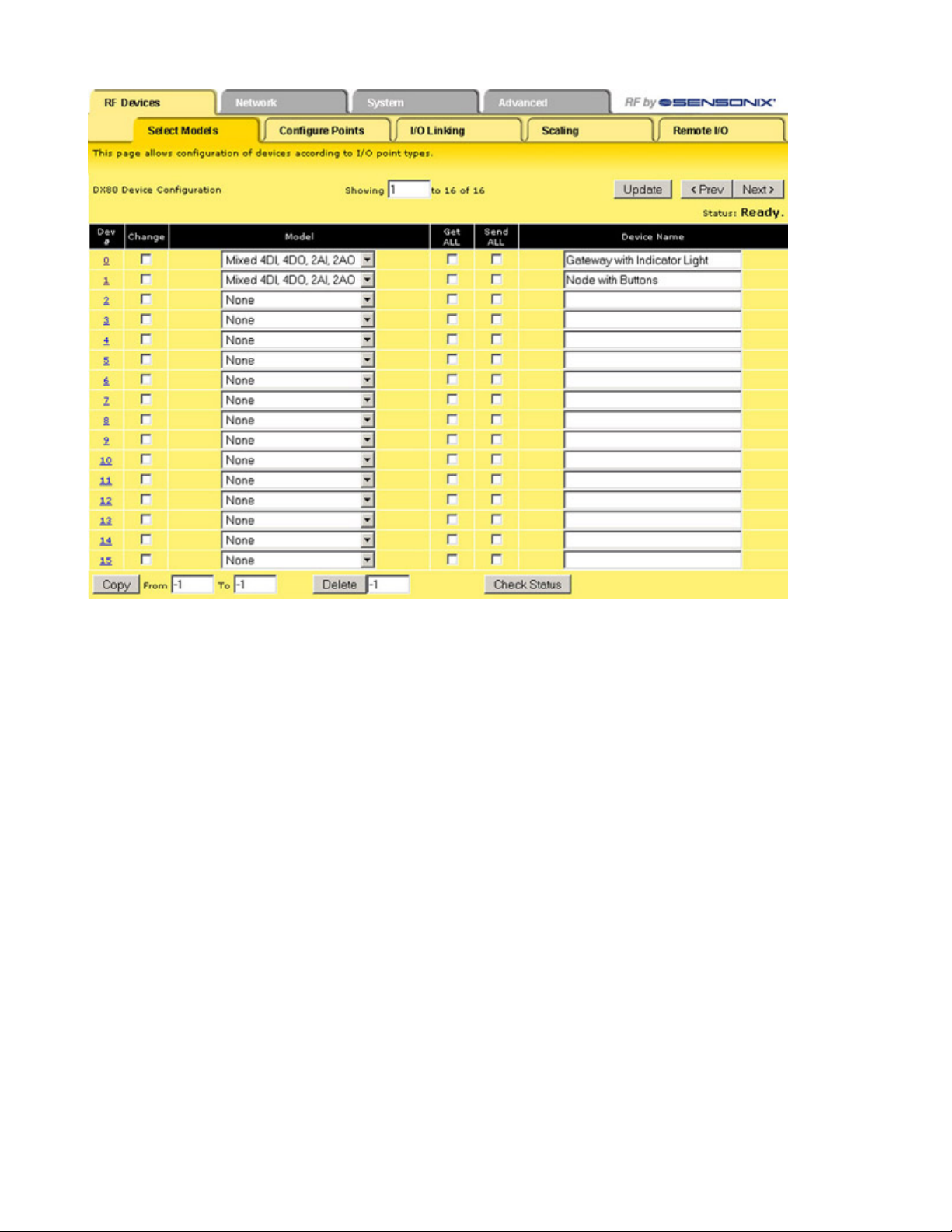

Select Models

The Select Models tab displays the list of devices for the radio network. Use this screen to define the wireless network devices.

6 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 7

SureCross Web Configurator

Defining a Device

To define the DX80 radio network devices:

1. Select the device from the drop-down list, always using device zero for the Gateway. Most device descriptions can apply to either

the Gateway or the Node.

2. Name the device.

3. Select the Change checkbox.

4. Click the Update button to send this information to the Ethernet Bridge.

Using the Change checkbox and Update buttons sends the only device name and model to the Ethernet Bridge/GatewayPro device. This

will not overwrite existing I/O parameter information.

After the devices are defined and named, retrieve any existing parameter configuration information from the DX80 devices and load these

settings into the GatewayPro or Ethernet Bridge:

1. Select the Get ALL checkbox for each device.

2. Click the Update button.

The Get ALL command will take a few minutes to complete. Click on the Check Status button to review the command's status.

Copying a Defined Device

When setting up a radio network that includes devices with the same configuration, set up one device and copy it using the Copy button

at the bottom of the screen. Copying one device’s setup to another device also copies the Configure Points information. To copy device

parameters, fill in the From and To boxes with the appropriate device number (listed on the left side of the table) and click the Copy

button.

Submitting Parameters to the DX80 Devices

After defining the devices in the radio network, including the items from the Configure Points screen, the expanded Configure Points

screen, and the I/O Linking screen, check the Send ALL box for the devices and click the Update button on the Select Models screen.

rev. - www.bannerengineering.com - tel: 763-544-3164 7

Page 8

This sends the I/O point configuration information to the DX80 devices. Once the Send ALL function has begun, click the Check Status

button at the bottom of the screen. A monitoring screen displays each device’s progress.

SureCross Web Configurator

Other Commands

Check

Status

Get

ALL

Prev

and

Next

Click the Check Status button to watch the status of a Get ALL or Send ALL command. Sending or retrieving information from the DX80 devices can take several minutes. Use the Check

Status button to verify the error status of the data transfer. When the list reads "Ready," the

command has finished.

Select the Get ALL checkbox and click the Update button to pull set-up parameters from the

DX80 devices. These parameters will be loaded

into the Web Configurator screens but will not be

automatically saved into the XML file. Before

modifying any existing radio network devices, always perform a Get ALL to update the Web

Configurator with accurate set-up information.

If there are more than 16 devices or rules/maps,

use the Prev and Next buttons to display the

next screen of information.

Send

All

Update

After defining and setting up the devices and I/O

point parameters, select the Send ALL checkbox

and click the Update button to send this information to the radio network devices.

Clicking the Update button sends information to

the Ethernet Bridge or GatewayPro or retrieves information depending on which checkboxes are

selected: Change or Get/Send All. Updating information does not save configuration information

permanently to the XML file.

Saving Changes to the XML File

To permanently save the changes to the XML file, go to the System > Setup > Config File page and click the Save button. Changes made

by clicking an Update button are temporary and only submitted to the Ethernet Bridge or GatewayPro, not the XML file.

Model List

Select from one of the following models to define your device.

None. No device is present

Discrete 4DI, 4DO. Discrete device with four discrete in and four discrete out.

Discrete 6DI, 6DO. Discrete device with six discrete in and six discrete out.

Discrete 8DI, 4DO. Discrete device with eight discrete in and four discrete out.

Discrete 4DI, 8DO. Discrete device with four discrete in and eight discrete out.

Mixed 2DI, 2DO, 2AI, 2AO. Device with two discrete in, two discrete out, two analog in, and two analog out. The term “mixed” refers to a

device with both discrete and analog I/O.

Mixed 4DI, 4DO, 2AI, 2AO. Device with four discrete in, four discrete out, two analog in, and two analog out.

Analog 4AI, 4AO. Device with four analog in and four analog out.

Flex 2DI, 2DO, 2AI. FlexPower™ Node with two discrete in, two discrete out, and two analog in.

Flex 2DI, 2DO, 4AI. FlexPower Node with two discrete in, two discrete out, and four analog in. This description also includes the Thermo-

couple and RTD nodes.

M-GAGE. FlexPower M-GAGE™ Node.

Other. Other model that isn't currently defined.

8 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 9

SureCross Web Configurator

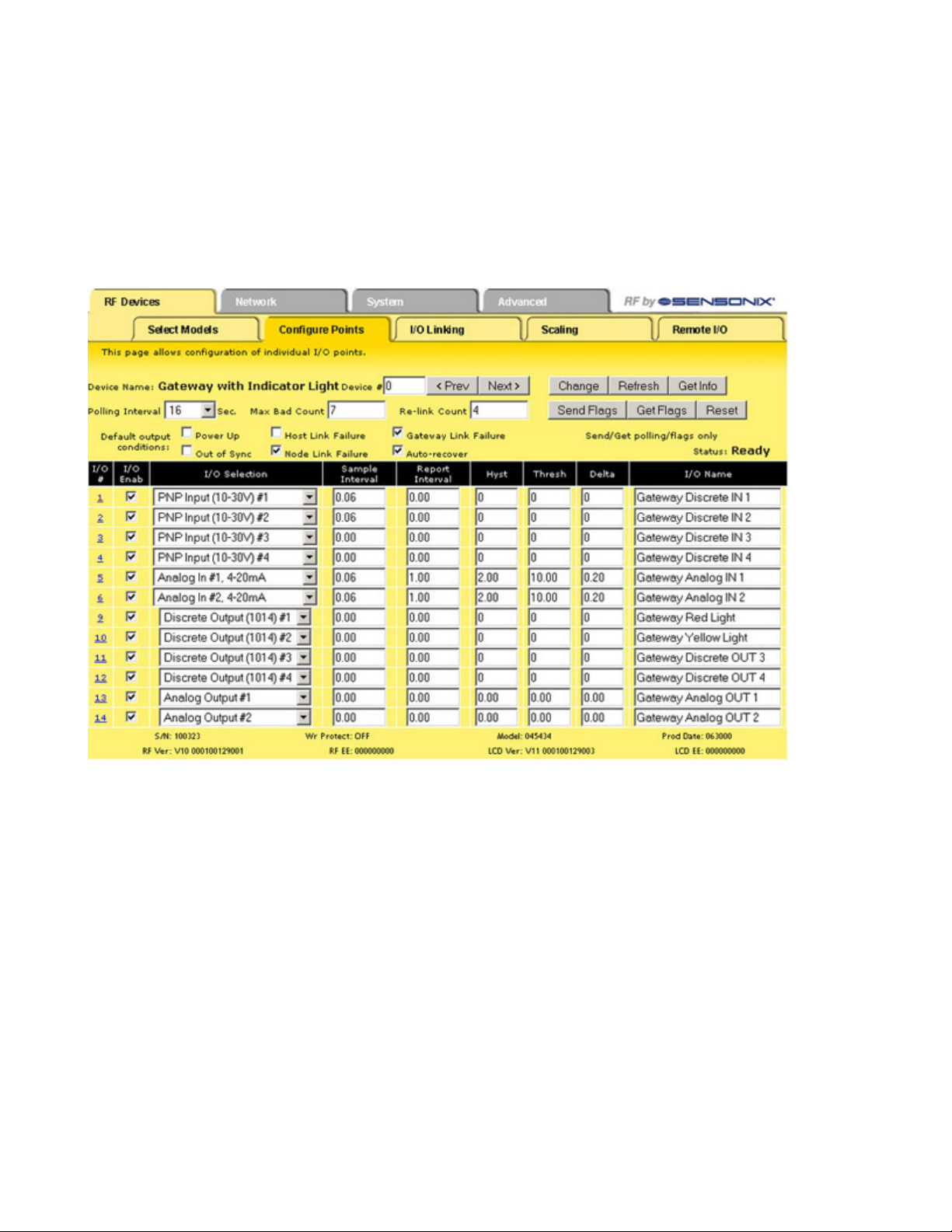

Configure Points

After setting up the basic model for each device, configure the I/O points. There are two ways to access the I/O points configuration

screen:

1. Use the Configure Points tab; or

2. Click on the hyperlinked device number in the left column of the Select Models table to access the Expanded Configure Points

page (see the Expanded Configure Points section).

Refer to the device’s data sheet for factory default information.

Note: If you leave any Web Configurator screen without clicking the Change button to submit the changes to the Ethernet Bridge or

GatewayPro, all changes are lost.

Setting Up I/O Points

To set up an I/O point:

1. Select the I/O Enabled checkbox. Any active I/O point must be enabled or the I/O is ignored.

2. Select an I/O type from the I/O Selection drop-down list.

3. The Configure Points sample screen shows a Gateway defined with four discrete IN, four discrete OUT, two analog IN, and two

analog OUT points. Always refer to the device data sheet to determine which discrete and which analog I/O points are active for a

given device. Note, however, that the NPN and PNP settings for discrete I/O shown on the data sheet are only default configuration

settings and can be changed.

4. Define any applicable parameters, e.g. sample interval, report interval, hysteresis, threshold, or any other parameter displaying on

the main or expanded view screens.

5. After setting up all I/O points using either the Configure Points tab or the expanded Configure Points screen, click the Change

button to submit the changes to the Ethernet Bridge or GatewayPro.

6. To send all I/O data to the devices, use the Select Models screen by selecting the Send ALL checkbox and clicking the Update

button. To send the individual I/O point changes, use the expanded Configure Points screen and the Send button.

rev. - www.bannerengineering.com - tel: 763-544-3164 9

Page 10

I/O Status

SureCross Web Configurator

Parameters

The following parameters are set on the Configure Points screen.

Change If you leave any Web Configurator screen with-

out clicking the Change button to submit the

changes to the Ethernet Bridge or GatewayPro, all changes are lost.

Delta The delta parameter defines the change re-

quired between sample points of an analog input before the analog input reports a new value. To turn off this option, set the Delta value

to 0.

Default

Output

Condition

Flags

The default output conditions are a set of

checkboxes to establish device-based parameters and apply to all outputs on this device. After making changes to the flags, click the Send

Flags button to submit the changes to the device.

Auto-Recover. Selecting the Auto-Recover

option forces the Gateway to attempt to re-establish communications with out-of-sync nodes

after a polling error condition is indicated. The

Gateway polls the failing device and must successfully communicate with the failing node

Re-Link Count times before the error condition

is erased. This parameter is only used on the

Gateway. Without the auto-recover feature selected, the user must manually reset error conditions or the host system must reset the error

condition.

Gateway Link Failure. The Gateway detected

a communication problem with a Node. All

linked outputs of the failing device are set to

the default states.

Prev

and

Next

Refresh

If there are more than 16 devices or rules/maps,

use the Prev and Next buttons to display the next

screen of information.

Click the Refresh button to refresh the screen image. This updates any information on the screen

that may have changed on the device.

Report

Interval/

Rate

The report rate defines how often the Node communicates the I/O status to the Gateway. Change

of state reporting sets the system to report only

when the value crosses the threshold setting. For

FlexPower™ applications, setting the report rate

to a slower rate extends the battery life.

Relink

Count

The re-link count is the number of completed polling messages the Gateway receives from a Node

before a lost RF link is considered re-established

and normal operation resumes.

Reset The Reset button resets any error conditions dis-

played. Until the error message is reset, the device will not start any additional operations.

Sample Interval/

Rate

The sample interval, or rate, defines how often

the SureCross device samples the input. For battery-powered applications, setting a slower rate

extends the battery life.

Host Link Failure. A Modbus timeout forces

all device outputs to the default states. This

parameter applies to every device that sets

this flag.

Node Link Failure. A Node detected an RF

link problem and set its own outputs to the default states.

Out of Sync. When an out-of-sync condition is

detected, all Node outputs are set to the default value. This parameter applies only to the

Nodes.

Power Up. All device outputs are set to the default value on initial power-up.

Get Info The Get Info button retrieves factory informa-

tion for the selected device, such as the model

10 www.bannerengineering.com - tel: 763-544-3164 rev. -

number, serial number, and production date.

Page 11

Are you there?

Yes, I am here.

Threshold

ON point

Time

Input Value

Input

Hysteresis

OFF point

SureCross Web Configurator

I/O Enable

Select the checkbox to enable the individual I/

O point. If the checkbox is not selected, that I/

O point is disabled, regardless of what other

parameters may be defined. For efficient power usage, do not enable I/O points that are not

used.

I/O Name The I/O name field is an optional text field used

to assign names to the individual I/O points for

easy reference. This name may appear in

many other screens relating to the I/O point.

I/O

Number

Click on the I/O # hyperlink on the far left of the

screen to access an additional screen for I/O point

configuration. The expanded screen contains

more I/O point parameters than is displayed on

the primary page.

I/O

Selection or

Type

Select the I/O type from the drop-down list. The

drop-down list includes all options available for the

entire DX80 line. Not all I/O types included in the

drop-down list are applicable for any given device.

Refer to the device data sheet to determine which

options are available for each device.

“Other” Type #: Occasionally some newly designed and released devices will use I/O types not

yet listed in the drop-down list for I/O Type. When

this happens, Banner Engineering applications

engineers will supply the “other” type number. Select Other from the I/O Type drop-down list and

enter the I/O type number supplied by Banner Engineering into this field.

Send

Flags,

Get

Flags

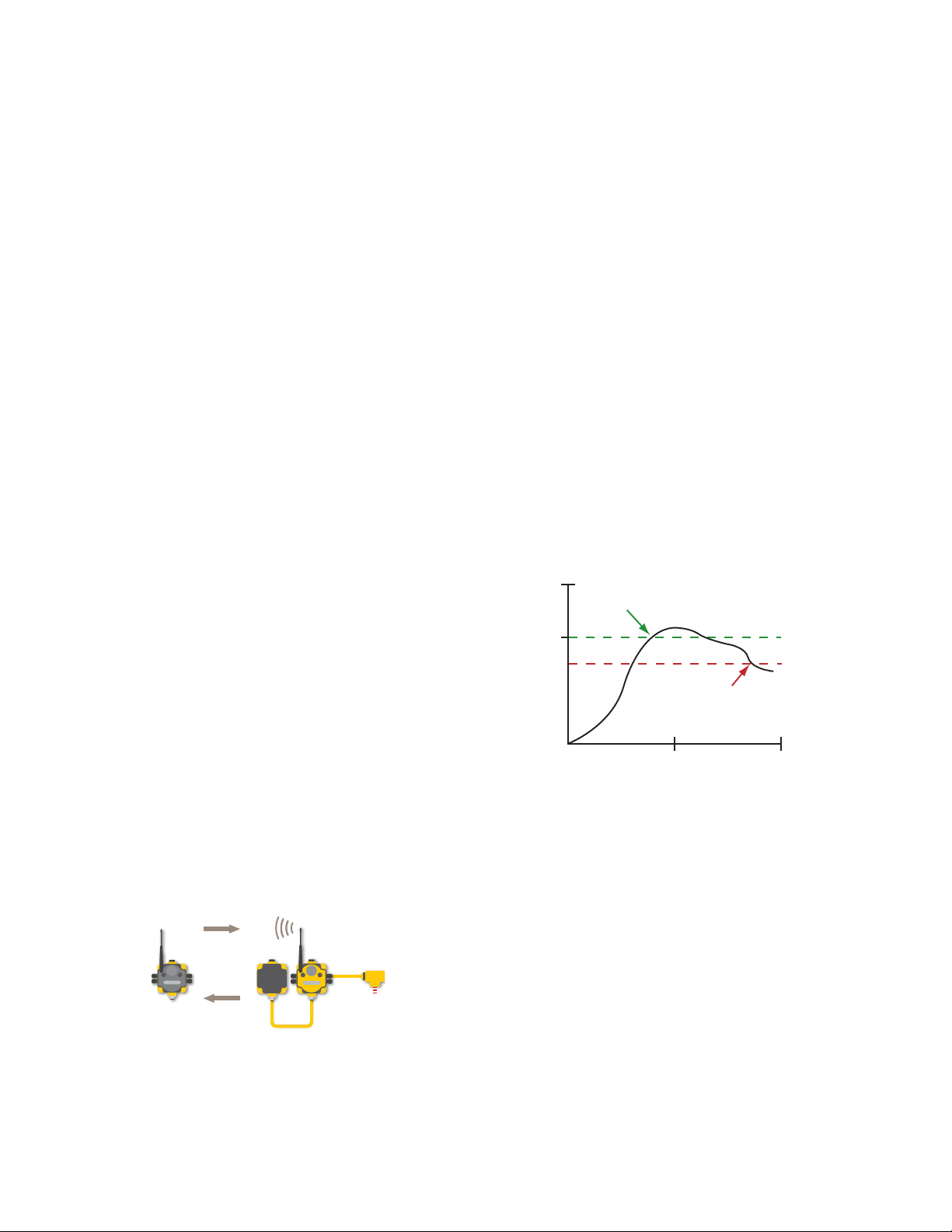

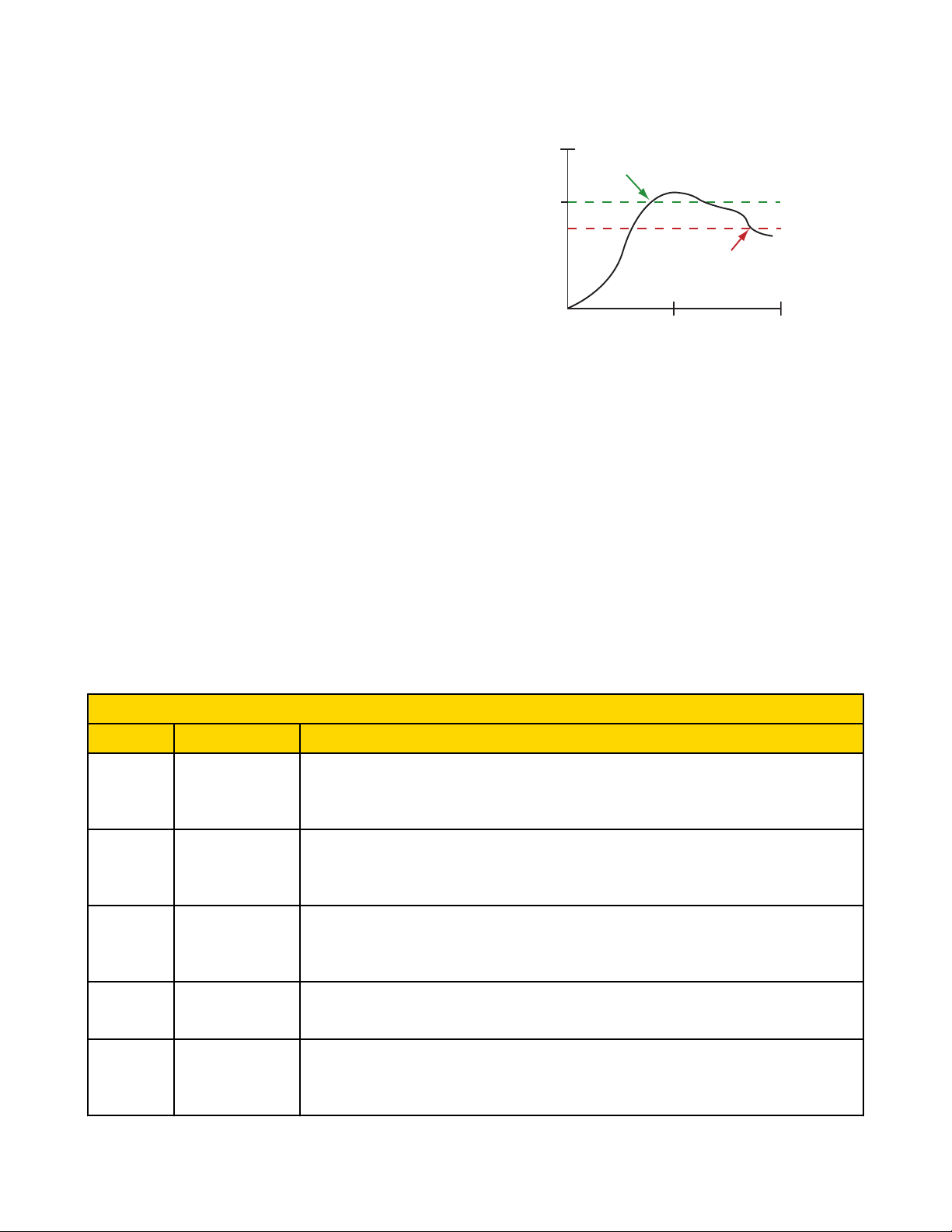

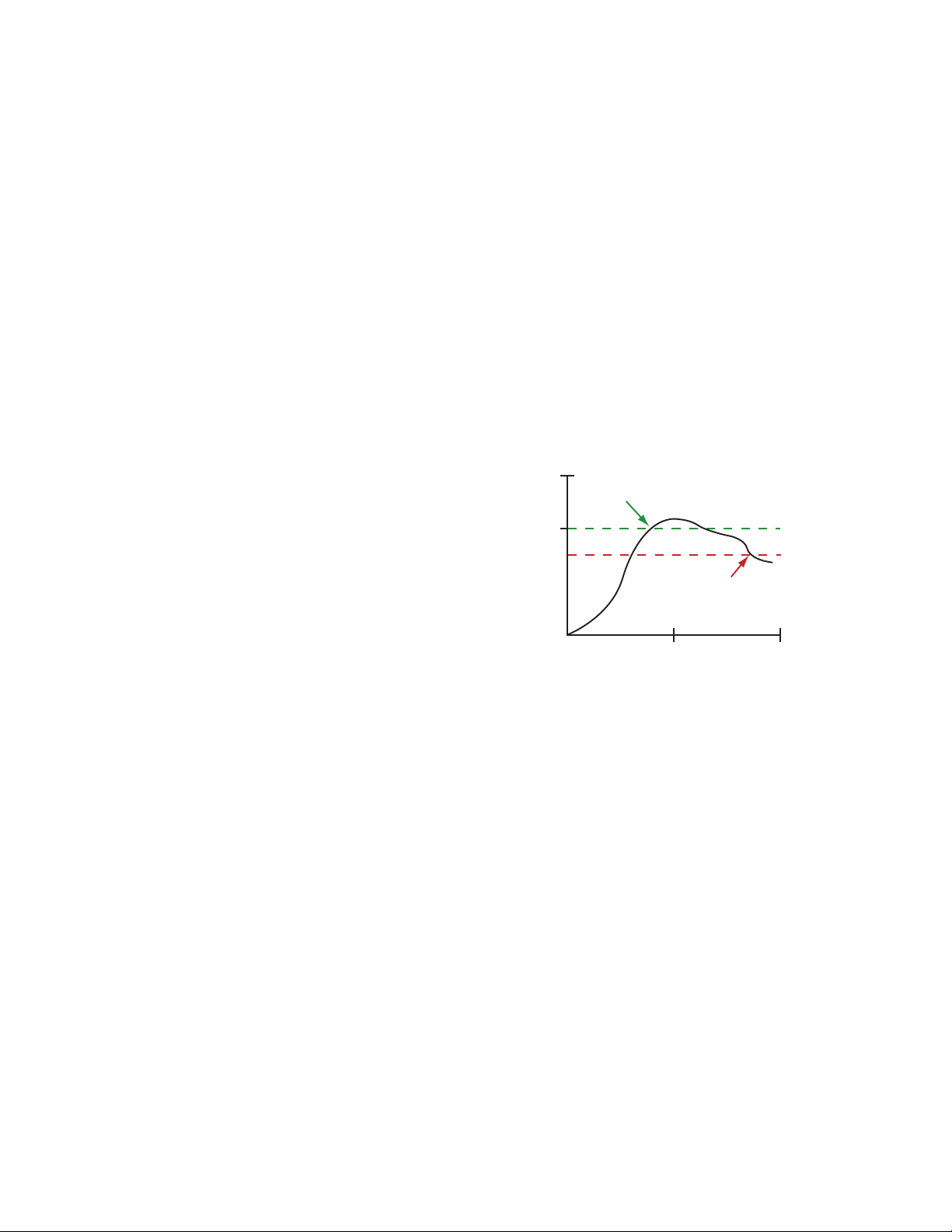

Threshold and

Hysteresis

The Send Flags and Get Flags buttons refer only to the Default Output Conditions flags, not the

I/O parameters.

Threshold and hysteresis work together to establish the ON and OFF points of an analog input. The threshold defines a trigger point or reporting threshold (ON point) for a sensor input.

The hysteresis value establishes how much below the active threshold (ON point) an analog input is required to be before the input is considered OFF. A typical hysteresis value is 10% to

20% of the unit’s range.

Maximum

Bad

Count

Polling Interval/

Rate

The max bad count refers to a user-established

maximum count of consecutive failed polling attempts before the Gateway considers the RF link

to have failed.

To monitor network health, the Gateway communicates with, or polls, each Node to determine if

the radio link is active. The polling rate defines

how often the Gateway communicates with each

Node. Polling is always initiated by the Gateway

and only verifies radio signal communications.

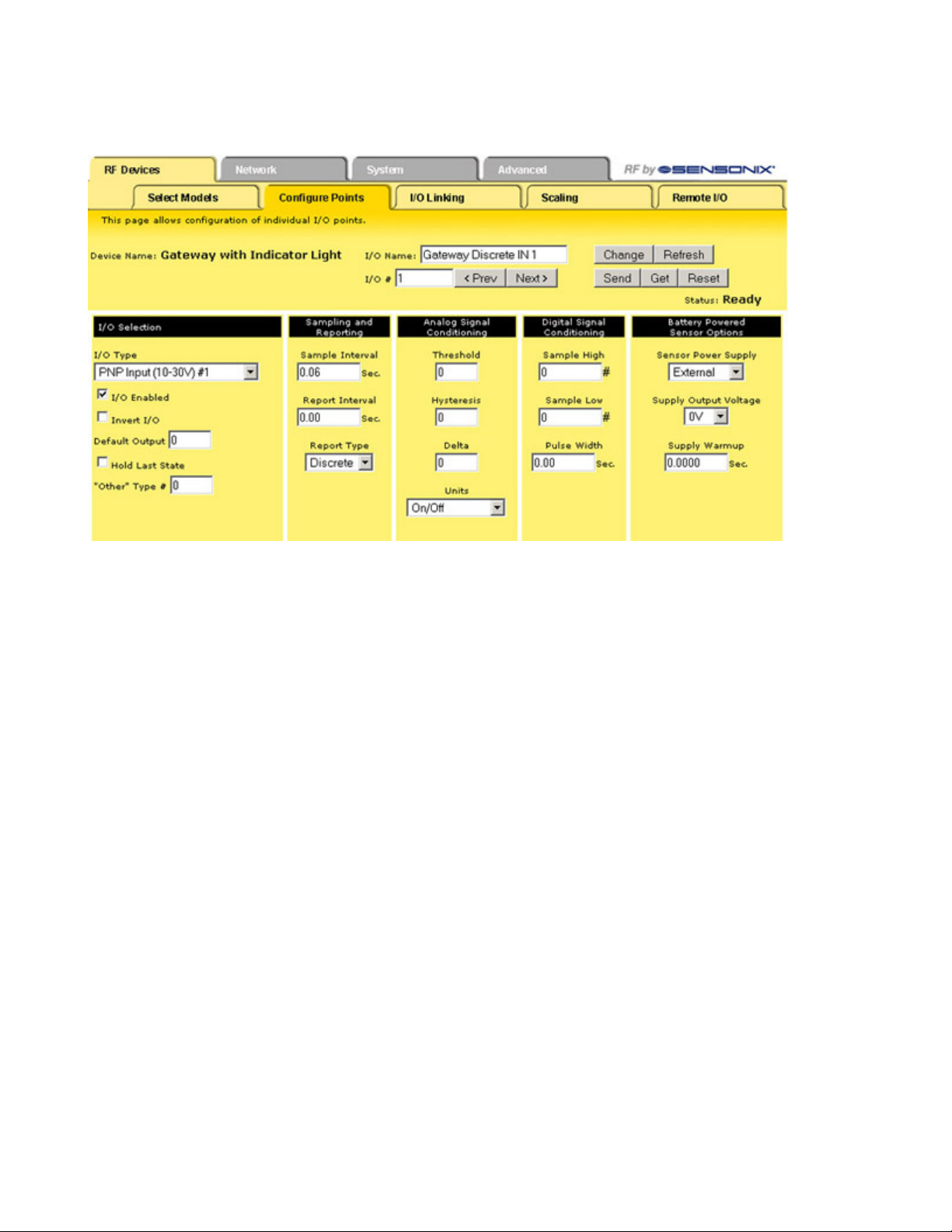

Expanded Configure Points

Most I/O point parameters are changed using the expanded view of the Configure Points tab.

rev. - www.bannerengineering.com - tel: 763-544-3164 11

In the example shown graphically, the input is

considered on at 15 mA. To consider the input

off at 13 mA, set the hysteresis to 2 mA. The input will be considered off when the value is 2

mA less than the threshold.

Page 12

SureCross Web Configurator

To access this expanded view, which displays all parameters for the I/O point selected, click on the I/O number hyperlink from the Configure Points tab. Several parameters on the expanded view also appear in the standard Configure Points screen and can be modified from

either screen.

After making changes to the parameters screen:

1. Click the Change button to submit the changes to the Ethernet Bridge or GatewayPro.

2. Click the Send button to update the radio devices.

Change If you leave any Web Configurator screen

without clicking the Change button to submit

the changes to the Ethernet Bridge or GatewayPro, all changes are lost.

Get Click the Get button to read all device and I/O

parameters from the DX80 device and load

them into the Web Configurator screens. This

does not save the parameters to the XML file.

Prev and

Next

If there are more than 16 devices or rules/

maps, use the Prev and Next buttons to display the next screen of information.

Refresh Click the Refresh button to refresh the screen

image. This updates any information on the

screen that may have changed on the device.

Reset The Reset button resets any error conditions

displayed. Until the error message is reset,

the device will not start any additional operations.

Saving

Changes to

the XML

File

To permanently save the changes to the

XML file, go to the System > Setup > Config

File page and click the Save button.

Changes made by clicking an Update button

are temporary and only submitted to the

Ethernet Bridge or GatewayPro, not the XML

file.

Send Clicking the Send button transmits device

and I/O parameters to the radio devices. The

Send operation usually requires several second to complete.

I/O Selection

Default

Output

Value

Default output values are specific values written to output registers. For discrete outputs,

this is a 1 (on) or 0 (off) value. For analog outputs the value can be any valid register value.

I/O Enable

Select the checkbox to enable the individual I/O

point. If the checkbox is not selected, that I/O

point is disabled, regardless of what other parameters may be defined. For efficient power usage,

do not enable I/O points that are not used.

12 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 13

I/O Status

SureCross Web Configurator

When a default condition occurs, these default

output values are written to the output register.

Hold

Last

State

The I/O point retains the last value recorded instead of the default output value during selected default conditions.

Invert I/O Selecting this checkbox inverts the digital rep-

resentation of the I/O.

Sampling and Reporting

Report

Interval/

Rate

The report rate defines how often the Node communicates the I/O status to the Gateway. Change

of state reporting sets the system to report only

when the value crosses the threshold setting. For

FlexPower™ applications, setting the report rate to

a slower rate extends the battery life.

I/O Selection

or

Type

Sample

Interval/

Rate

Select the I/O type from the drop-down list. The

drop-down list includes all options available for

the entire DX80 line. Not all I/O types included in

the drop-down list are applicable for any given device. Refer to the device data sheet to determine

which options are available for each device.

“Other” Type #: Occasionally some newly designed and released devices will use I/O types

not yet listed in the drop-down list for I/O Type.

When this happens, Banner Engineering applications engineers will supply the “other” type number. Select Other from the I/O Type drop-down list

and enter the I/O type number supplied by Banner Engineering into this field.

The sample interval, or rate, defines how often the

SureCross device samples the input. For batterypowered applications, setting a slower rate extends the battery life.

Report

Type

Select from discrete or analog format reporting

types. Analog data requires sixteen bits while discrete data uses only one bit per I/O point. Selecting

double from the list uses two consecutive registers,

each consisting of sixteen bits.

Analog Signal Conditioning

Delta The delta parameter defines the change required be-

tween sample points of an analog input before the

analog input reports a new value. To turn off this option, set the Delta value to 0.

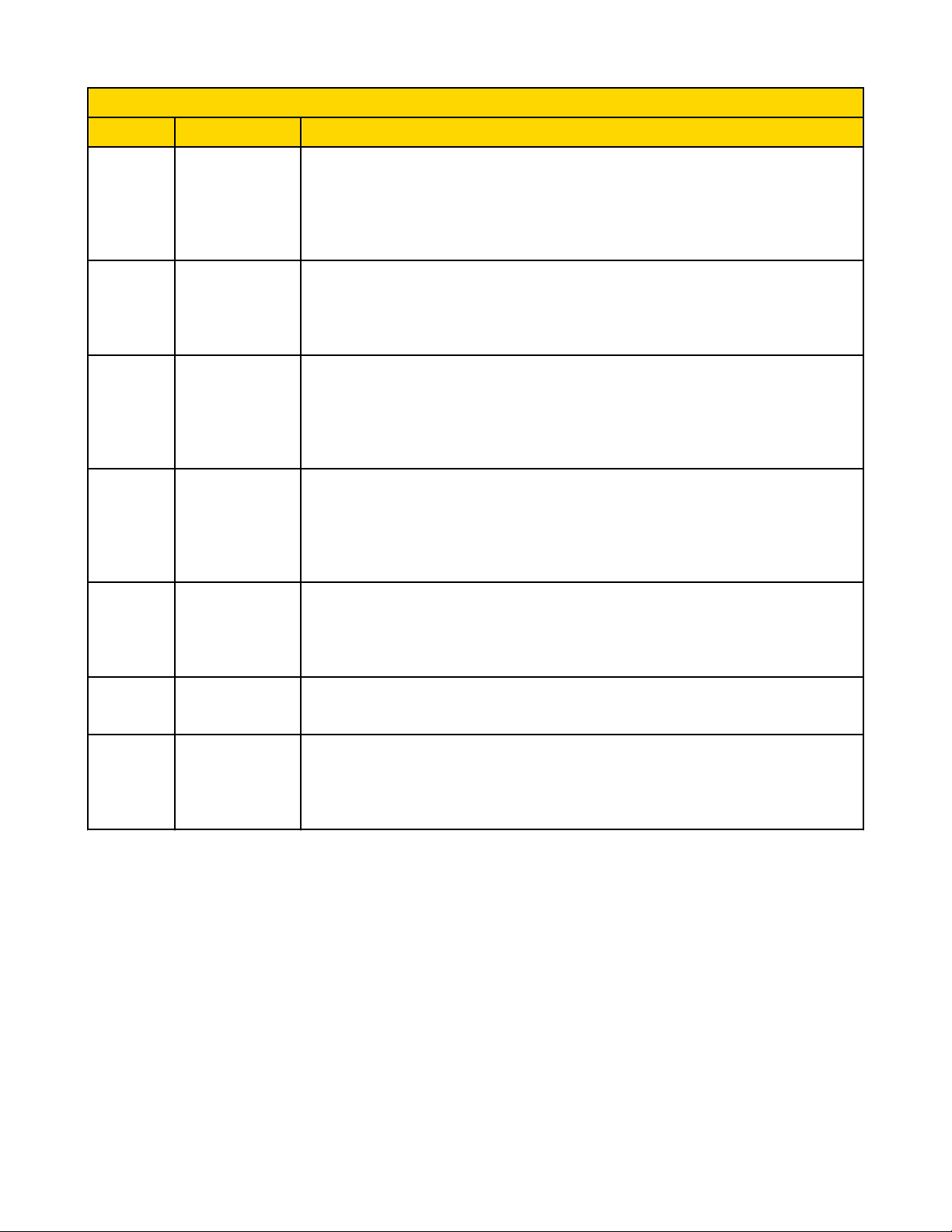

Digitial Signal Conditioning

Sample

High/

Sample

Low

(Dis-

For discrete inputs, the sample high parameter

defines the number of consecutive samples the

input signal must be high before a signal is considered active. Sample low defines the number

of consecutive samples the input signal must be

low before a signal is considered low. The sam-

Threshold and

Hysteresis

Threshold and hysteresis work together to establish the ON and OFF points of an analog input. The threshold defines a trigger point or reporting threshold (ON point) for a sensor input.

The hysteresis value establishes how much below the active threshold (ON point) an analog input is required to be before the input is consid-

rev. - www.bannerengineering.com - tel: 763-544-3164 13

Page 14

Threshold

ON point

Time

Input Value

Input

Hysteresis

OFF point

SureCross Web Configurator

crete I/O)ple high and sample low parameters are used

to create a filter to avoid unwanted input transi-

ered OFF. A typical hysteresis value is 10% to

20% of the unit’s range.

tions. The default value is 0, which disables this

feature. The value range is 1 through 255.

Pulse

Width

The pulse width determines the length of time,

in seconds, that a digital output is active (1) before returning to zero. Select 0 to disable this

feature.

In the example shown graphically, the input is

considered on at 15 mA. To consider the input

off at 13 mA, set the hysteresis to 2 mA. The in-

put will be considered off when the value is 2

mA less than the threshold.

Units Defined

The units parameter defines the range and/or type of data value associated with an input or output.

Selecting Units from within any configuration tool changes the units definition of several parameters, including threshold, hysteresis, and

delta. For example, if the units are 0-20 mA, the threshold, hysteresis, and delta values are entered as milliampere values. Selecting

Temp C changes the threshold, hysteresis, and delta units to degrees Celsius.

Signed values range from −32768 to +32767 and allow for the measurement of negative values. Signed values are typically used for

measuring temperatures. Signed values are stored as two's complement values.

Unsigned values range from 0 to 65535 and are used to measure values that do not go below zero, such as 4 to 20 mA, distance, or a

counter.

Input Units

Units Description Definition

0 Raw Displays the raw A/D conversion data with data ranges from 0 to 65535. This units type is typical-

ly used only for factory calibration.

LCD: Raw A/D hex value

1 4 to 20 mA Analog unit. Modbus register contents are scaled such that 0 represents 4 mA and 65535 repre-

sents 20 mA.

LCD: 4.00mA–20.00mA

2 0 to 20 mA Default analog input unit. Modbus register contents are scaled such that 0 represents 0 mA and

65535 represents 20 mA.

LCD: 0.00mA–20.00mA

3 Discrete (ON/OFF) Default discrete input unit.

LCD: ON/OFF

4 0 to 10V (Volts) Analog input using 0 to 10V instead of current. Modbus register contents are scaled such that 0

14 www.bannerengineering.com - tel: 763-544-3164 rev. -

represents 0V and 65535 represents 10V.

LCD: 0.00V–10.00V

Page 15

SureCross Web Configurator

Input Units

Units Description Definition

6 Temp °C Celsius, high resolution. Analog input for temperature devices such as thermocouples, RTD, and

thermistors. In high resolution mode, temperature = (Modbus register value) ÷ 20.

LCD: 0000.0C

7 Temp °F Fahrenheit, high resolution. Analog input for temperature devices such as thermocouples, RTD,

and thermistors. In high resolution mode, temperature = (Modbus register value) ÷ 20.

LCD: 0000.0F

8 Temp °C (Low Res) Celsuis, low resolution. To measure a greater temperature range, use the low resolution unit. In

low resolution mode, temperature = (Modbus register value) ÷ 2.

LCD: 0000.0C

9 Temp °F (Low Res) Fahrenheit, low resolution. To measure a greater temperature range, use the low resolution unit.

In low resolution mode, temperature = (Modbus register value) ÷ 2.

LCD: 0000.0F

10 Asynchronous

Counter, 32-bit

11 Asynchronous

Counter, 16-bit

The 32-bit counter value records counts up to 4.29 billion.

LCD: 0000 0000

The 16-bit counter value records counts up to 65535.

LCD: 0000

Output Units

Units Description Definition

0 Raw Displays the raw A/D conversion data with data ranges from 0 to 65535. This units type is typical-

ly used only for factory calibration.

LCD: Raw A/D hex value

1 4 to 20 mA Analog unit. Modbus register contents are scaled such that 0 represents 4 mA and 65535 repre-

sents 20 mA.

LCD: 4.00mA–20.00mA

2 0 to 20 mA Default analog input unit. Modbus register contents are scaled such that 0 represents 0 mA and

65535 represents 20 mA.

LCD: 0.00mA–20.00mA

3 Discrete (ON/OFF) Default discrete unit.

LCD: ON/OFF

4 0 to 10V (Volts) Analog unit using 0 to 10V instead of current. Modbus register contents are scaled such that 0

represents 0V and 65535 represents 10V.

LCD: 0.00V–10.00V

5 Signed Analog, 0 to

10V

For a signed value, such as temperature, that is to be converted to a voltage out value. Use null

to set the start point and span to define the range. The null value is the starting temperature to be

associated with 0V. The span is the entire temperature range that is to be associated with 0 to

10V.

LCD: 0.00V–10.00V

rev. - www.bannerengineering.com - tel: 763-544-3164 15

Page 16

SureCross Web Configurator

Units Description Definition

Output Units

6 Signed Analog, 0 to

20 mA

7 Unsigned Analog, 0

to 20 mA

8 Signed Analog, 4 to

20 mA (A)

9 Signed Analog, 4 to

20 mA (B)

10 Unsigned Analog, 0

to 10V

For a signed value, such as temperature, that is to be converted to a mA out value. Use null to

set the start point and span to define the range. The null value is the starting temperature to be

associated with 0 mA. The span is the entire temperature range that is to be associated with 0 to

20 mA.

LCD: 0.00mA–20.00mA

For unsigned values, such as a counter, that is to be converted to a mA out value. Use the null to

set the start point and span to define the range. The null value is the distance to be associated

with 0 mA. The span is the entire distance range that is to be associated with 0 to 20 mA.

LCD: 0.00mA–20.00mA

In older models, this units type is for degree Celsius conversions only. Use null to set the start

point and span to define the range. The null value is the starting temperature to be associated

with 4 mA. The span is the entire temperature range that is to be associated with 4 to 20 mA. For

newer firmware models, type codes 8 and 9 are treated the same.

LCD: 4.00mA–20.00mA

In older models, this units type is for degree Fahrenheit conversions only. Use null to set the start

point and span to define the range. The null value is the starting temperature to be associated

with 4 mA. The span is the entire temperature range that is to be associated with 4 to 20 mA. For

newer firmware models, type codes 8 and 9 are treated the same.

LCD: 4.00mA–20.00mA

For an unsigned value, such as 0 to 20 mA, that is to be converted to a voltage out value. Use the

null to set the start point and span to define the range. The null value is the distance to be associated with 0V. The span is the entire distance range that is to be associated with 0 to 10V.

LCD: 0.00V–10.00V

11 Counter, 16-bit The 16-bit counter value records counts up to 65535.

LCD: 0000

12 Unsigned Analog, 4

to 20 mA

For an unsigned value, such as 0 to 10V, that is to be converted to a mA out value. Use the null

to set the start point and span to define the range. The null value is the distance to be associated

with 4 mA. The span is the entire distance range that is to be associated with 4 to 20 mA.

LCD: 4.00mA–20.00mA

Battery Powered Sensor Options

Sensor Power Supply

Select a power supply for the sensor device. Select Supply 1 through 4 to indicate the external device is powered from one of the Node’s

supplied switch power connectors.

External. The sensor is powered from outside the Node.

Supply #1. Switched power 1 (SP1)

Supply #2. Switched power 2 (SP2)

Supply #3. Switched power 3 (SP3)

Supply #4. Switched power 4 (SP4)

16 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 17

Warmup Time

0 Volts

Switch Power

Sample point

Sample point

Sample interval

Voltage

SureCross Web Configurator

Supply Output Voltage

The Supply Output Voltage sets the voltage required for the sensor device. This parameter is only applicable when using the supplied

switch power option.

Supply Warmup

Supply Warmup defines the length of time the switch power should be turned on before examining the sensor’s input.

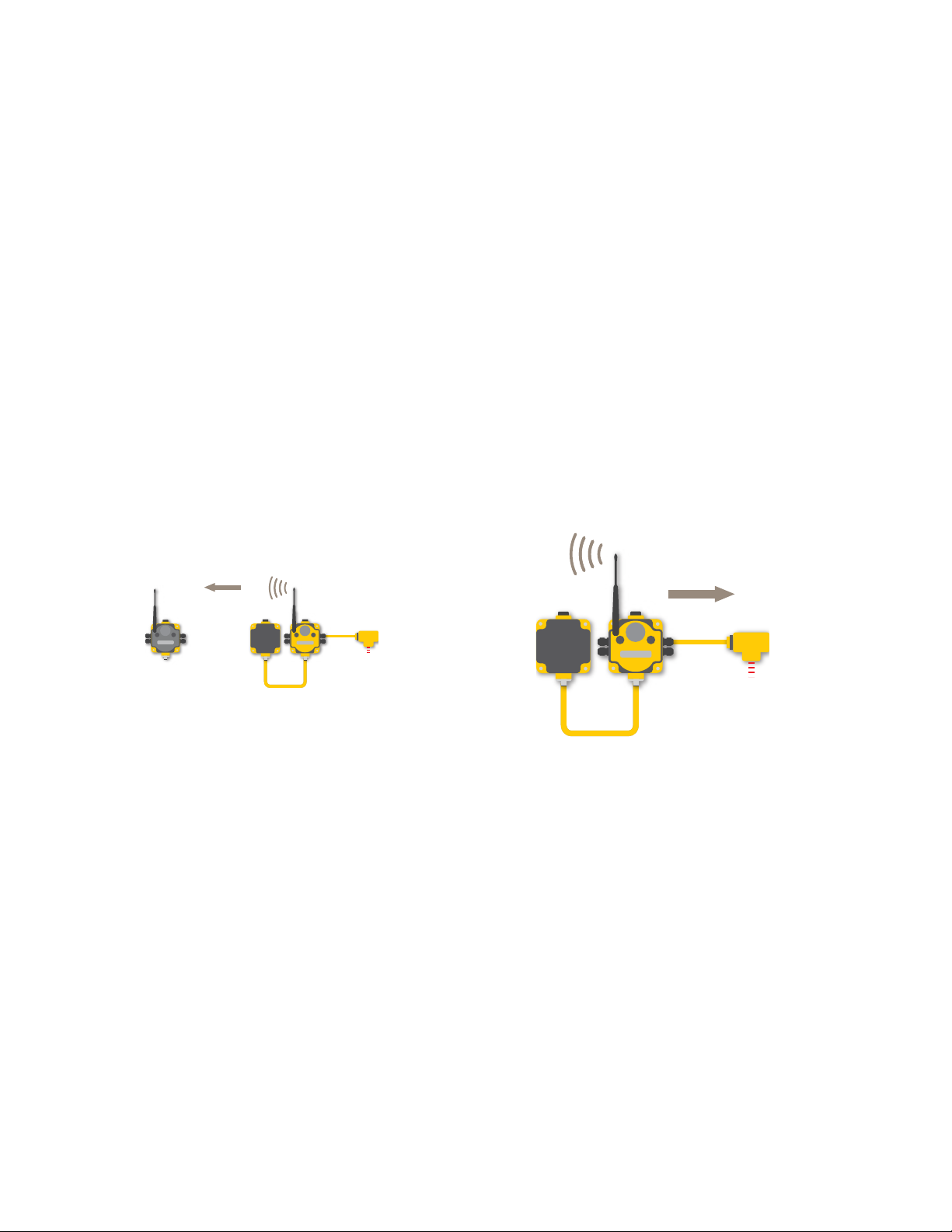

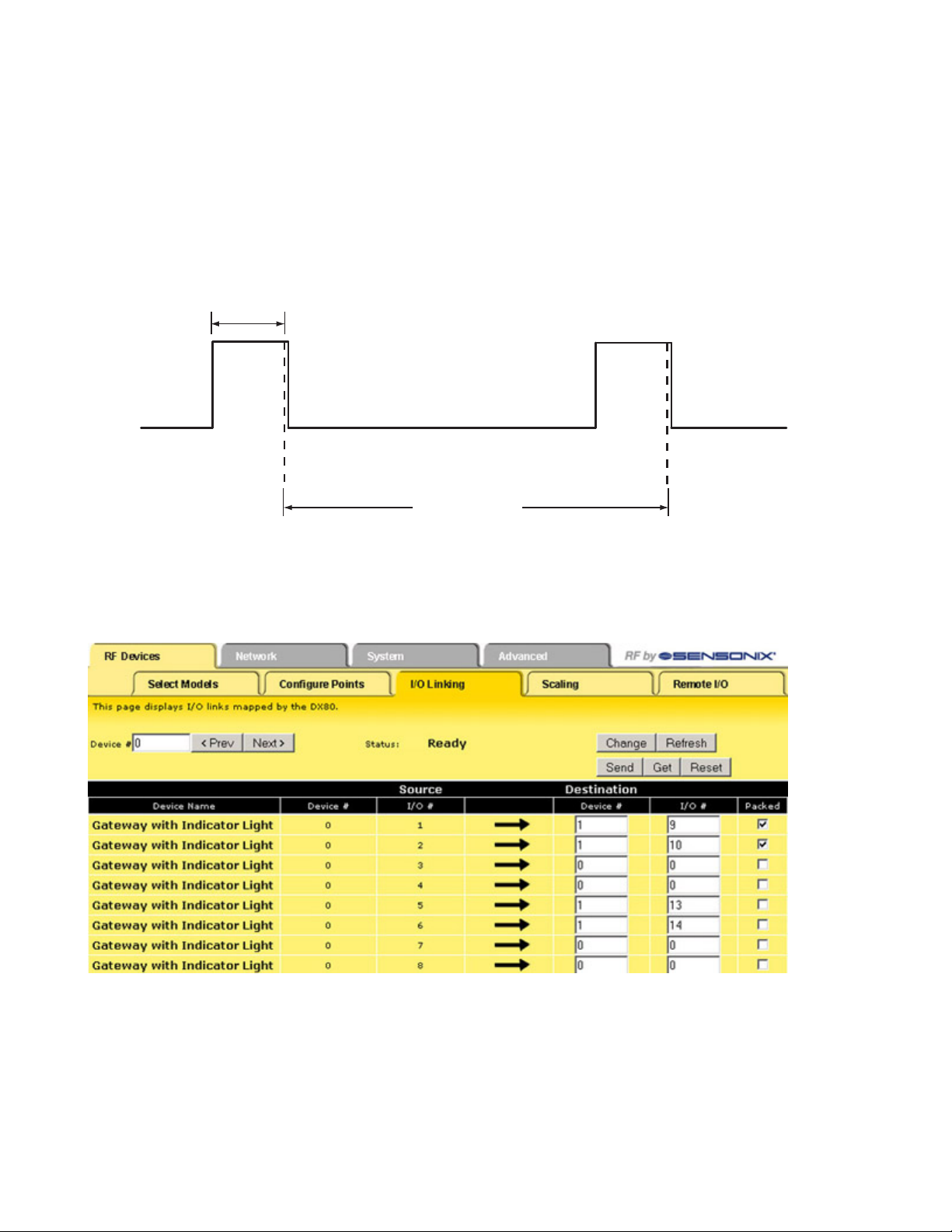

I/O Linking

Each device input point can be linked or connected to any output point in the system. An output link defined as zero for the device and

zero for the output point is not connected. Valid output points on all devices are nine through fourteen; valid devices are one through

fifteen with zero reserved for the Gateway (or GatewayPro).

In the sample screen shown, the Gateway input points can be mapped to any Node’s outputs. Manually enter the device number in the

Destination Device # box, then enter the I/O point number for that destination device.

After making changes to this screen:

1. Click on the Change button to send the changes to the DX83 Ethernet Bridge or the GatewayPro

2. Click on the Send button to send these changes to the device.

rev. - www.bannerengineering.com - tel: 763-544-3164 17

Page 18

SureCross Web Configurator

Change If you leave any Web Configurator screen with-

out clicking the Change button to submit the

changes to the Ethernet Bridge or GatewayPro,

all changes are lost.

Get Click the Get button to read all device and I/O

parameters from the DX80 device and load

them into the Web Configurator screens. This

does not save the parameters to the XML file.

Packed

Flag

Setting the Packed flag communicates discrete

output point information more efficiently. Instead

of sending one message for each output

change, discrete values are packed into one

message sent to the destination device. The

packing data reduces the wireless device traffic

and improves the timing in critical applications

when multiple inputs from a single device are

connected to outputs on one other device.

The Packed flag only affects the output point

messages, the input message communication is

defined by each device I/O point. If a device I/O

point Report Type parameter is defined as discrete, the input reporting messages for this

point are packed into one wireless message.

For greatest efficiency, all discrete inputs

should be defined as a discrete Report Type.

Refresh Click the Refresh button to refresh the

screen image. This updates any information

on the screen that may have changed on the

device.

Reset The Reset button resets any error conditions

displayed. Until the error message is reset,

the device will not start any additional operations.

Saving

Changes to

the XML

File

To permanently save the changes to the

XML file, go to the System > Setup > Config

File page and click the Save button.

Changes made by clicking an Update button

are temporary and only submitted to the

Ethernet Bridge or GatewayPro, not the XML

file.

Send Clicking the Send button transmits device

and I/O parameters to the radio devices. The

Send operation usually requires several second to complete.

Prev

and

Next

If there are more than 16 devices or rules/maps,

use the Prev and Next buttons to display the

next screen of information.

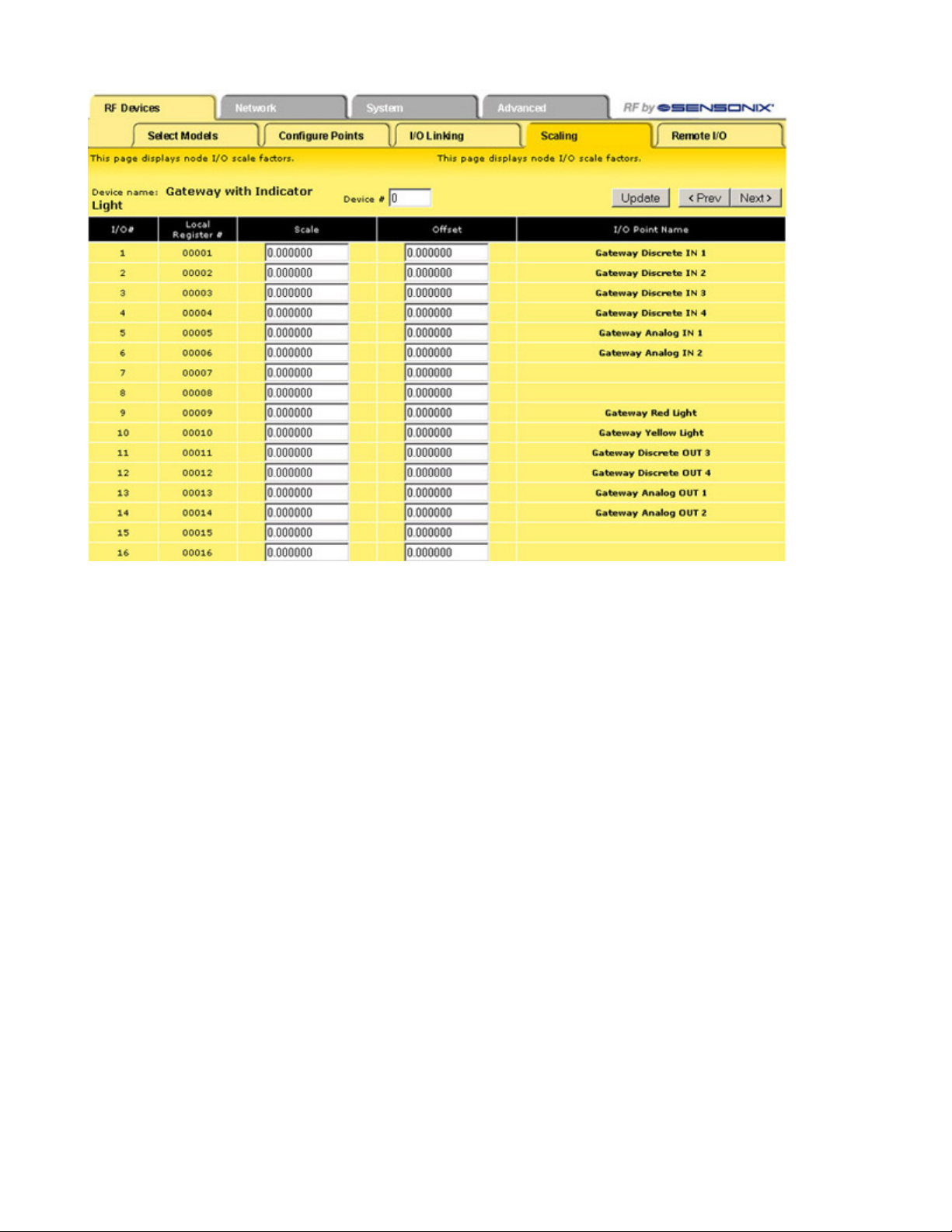

Scaling

The Scaling screen is used for converting data.

Raw data is multiplied by the Scale and added to the Offset to produce the data appearing in the floating point register associated with

the I/O point. The floating point registers start at register 1001.

18 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 19

SureCross Web Configurator

For example, thermocouple inputs are multiplied by 20 before being written to the Modbus register. To convert this register value back to

a temperature reading use the Scaling screen.

The Offset value can be used to account for errors introduced into the sensor system, such as errors introduced because of wiring

lengths in a thermocouple input system.

Other Commands

Prev and

Next

If there are more than 16 devices or rules/

maps, use the Prev and Next buttons to display

the next screen of information.

Update

Clicking the Update button sends information to the

Ethernet Bridge or GatewayPro or retrieves information depending on which checkboxes are selected: Change or Get/Send All. Updating information

does not save configuration information permanently to the XML file.

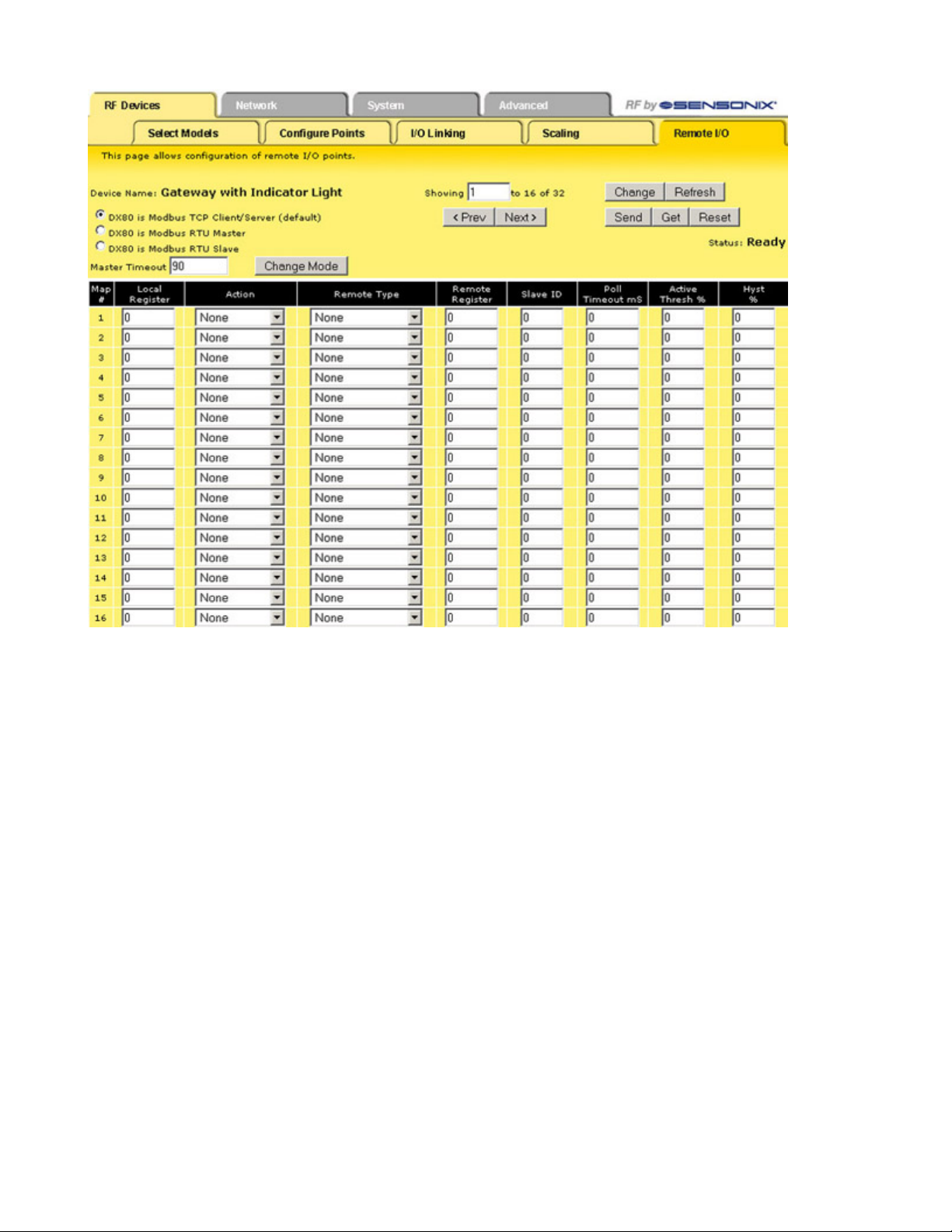

Remote I/O

The Remote I/O configuration page defines up to 32 external communication registers when the DX80 Gateway is defined as a Modbus

RTU Master.

This table is used only when the Gateway is a Modbus RTU master and it is communicating with Modbus slave devices, typically DX85

Expanded Remote I/O devices.

rev. - www.bannerengineering.com - tel: 763-544-3164 19

Page 20

SureCross Web Configurator

After power-up, the DX80 Gateway is a slave device (to the Ethernet Bridge) for the time defined in the Master Timeout field, defined in

seconds with a 90 second minimum. During this time, the operating mode can be changed using the browser interface. To change the

mode:

1. Click one of the radio buttons to select how the DX80 Gateway functions.

• Select Modbus/TCP Client/Server mode (default) when you are connecting a DX80 to an external PLC or similar equipment.

• Select Modbus RTU Master mode if the DX80 Gateway is to be a Modbus master device communicating to other slave devices using

a Modbus RS485 serial connection. The Gateway enters master mode after the Master Timeout period has elapsed.

• Select Modbus RTU Slave if the DX80 GatewayPro or a Ethernet Bridge and Gateway pair is operating as a slave on a Modbus serial

connection.

2. Set the Master Timeout field, then click the Change Mode button. When the timeout expires, the DX80 Gateway begins to operate as

selected. The Master Timeout determines how long the DX80 Gateway waits before changing modes.

3. After making changes, click on the Change button to send the changes to the DX83 Ethernet Bridge or the GatewayPro and then click

on the Send button to send these changes to the device.

Saving Changes to the XML File

To permanently save the changes to the XML file, go to the System > Setup > Config File page and click the Save button. Changes made

by clicking an Update button are temporary and only submitted to the Ethernet Bridge or GatewayPro, not the XML file.

Other Commands

Change If you leave any Web Configurator screen with-

out clicking the Change button to submit the

Reset The Reset button resets any error conditions dis-

played. Until the error message is reset, the device

will not start any additional operations.

20 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 21

SureCross Web Configurator

changes to the Ethernet Bridge or GatewayPro,

all changes are lost.

Get Click the Get button to read all device and I/O

parameters from the DX80 device and load them

into the Web Configurator screens. This does not

save the parameters to the XML file.

Refresh Click the Refresh button to refresh the screen

image. This updates any information on the

screen that may have changed on the device.

DX80 Modes

Setting Gateway GatewayPro Ethernet

Bridge

DX80 is Modbus/

Slave Master Master Default mode. The Gateway is a Modbus slave device and the EtherTCP Client/Server

(default)

DX80 is Modbus

Master Master Ignored The Ethernet Bridge can only communicate with a slave device. In

RTU Master

Send Clicking the Send button transmits device and I/O

parameters to the radio devices. The Send operation usually requires several second to complete.

net Bridge is the master device.

this mode, any communications sent to the Bridge from the Web

Configurator is ignored. To resume communications, cycle power to

the Gateway. When power is cycled, the Ethernet Bridge begins

again as a master device until the timeout lapses.

DX80 is Modbus

RTU Slave

Slave Slave Ignored Similar to the default mode, but a device other than the Ethernet

Bridge acts as the Modbus master device. The Ethernet Bridge still

communicates with the Gateway and can read and write to registers,

but another device is the master device.

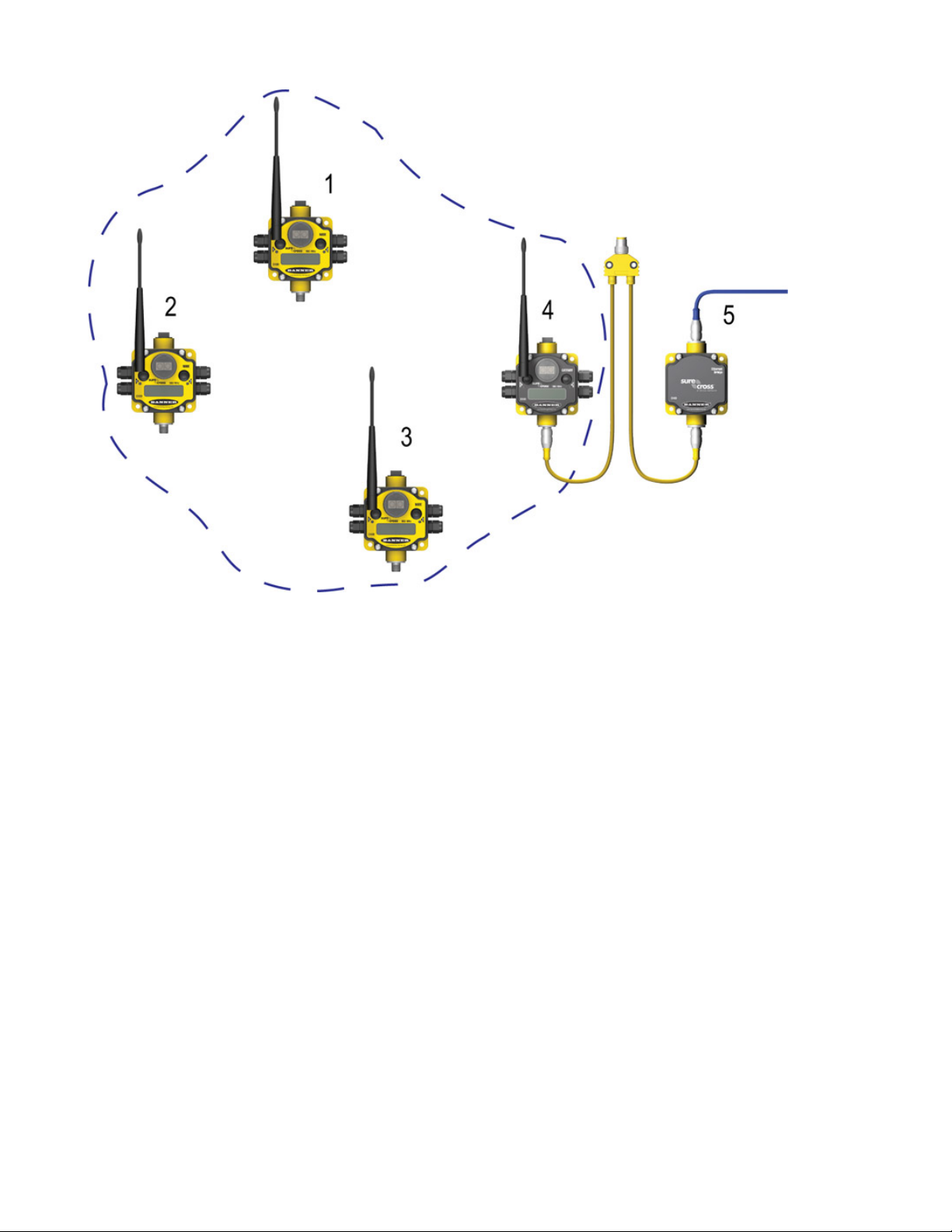

DX80 is a Modbus/TCP Client/Server (default)

The default configuration is DX80 is Modbus/TCP Client/Server. The DX83 Ethernet Bridge is the Modbus master device and only

communicates with the device configured as Slave ID 1: the Gateway.

rev. - www.bannerengineering.com - tel: 763-544-3164 21

Page 22

SureCross Web Configurator

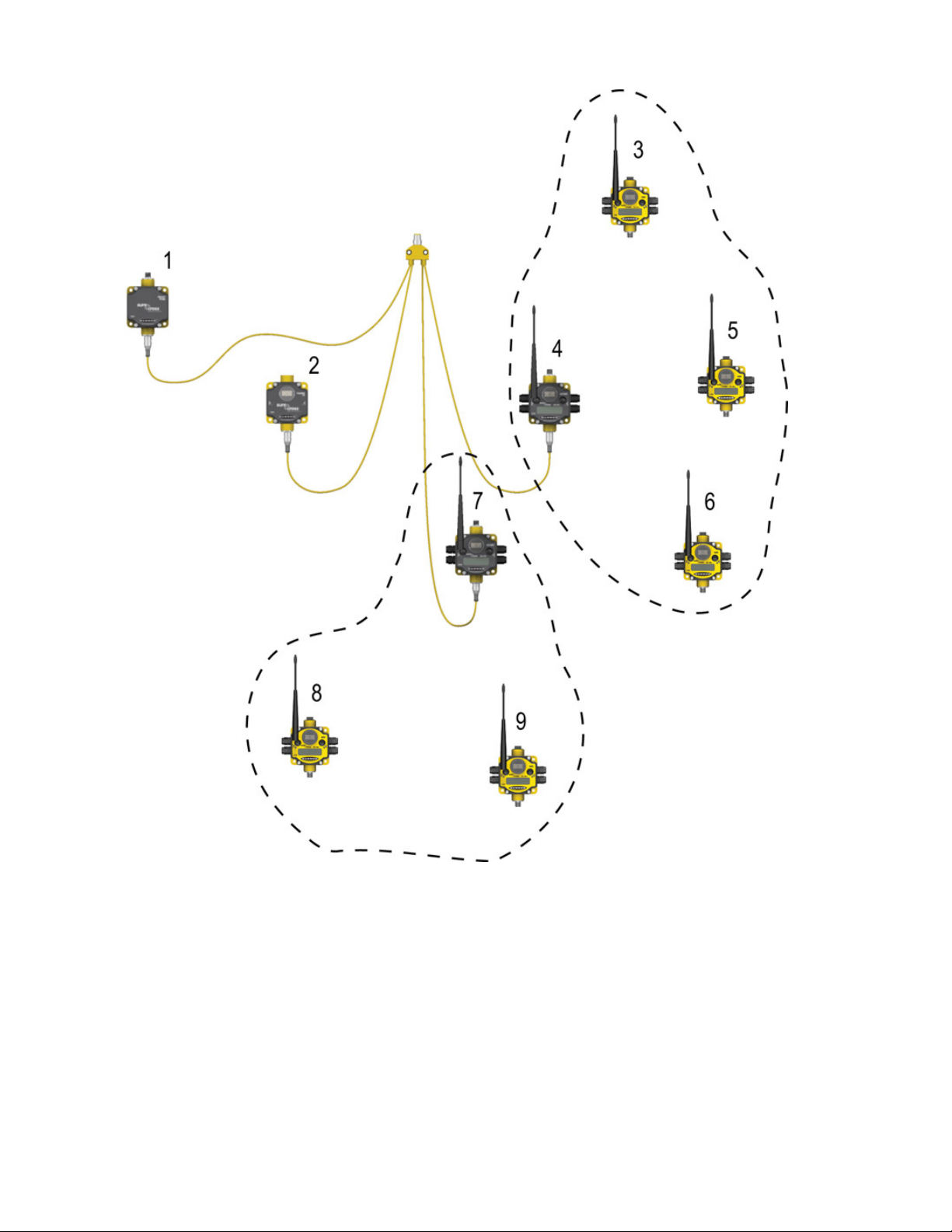

1. Node 1, registers 17 through 32.

2. Node 2, registers 33 through 48.

3. Node 3, registers 49 through 64.

4. Gateway, Slave ID 1, registers 1 through 16.

5. DX83 Ethernet Bridge

DX80 Gateway is Modbus RTU Master

When a DX80 Gateway is set up as a Modbus RTU master device, the communication between the DX83 Ethernet Bridge (used to

configure the network) and the Gateway is ignored. The Gateway acts as the Modbus RTU master device for the system, which may

include other slave Gateways or DX85 Remote I/O slave devices. All communication must go through the master device.

The master table entries define the register-to-register communication for remote I/O points. Each line represents a register/point connection between the master device and a Modbus slave device with up to 32 table entries possible. For each table entry, specify the local

Modbus register, action to perform, type of external point, external register number, external slave number, and a Modbus timeout value

for that register access. Active threshold and hysteresis are optional parameters that may be applied to registers.

After making changes:

1. Click on the Change button to send the changes to the DX83 Ethernet Bridge or the GatewayPro.

2. Click on the Send button to send these changes to the radio devices.

3. To save the changes to the XML file, go to the System > Setup > Config File page and click the Save button.

This sample network shows a DX80 Gateway as the Modbus RTU Master device. Once the Gateway is set as the master, communication is ignored between the Ethernet Bridge (normally the master) and the Gateway.

22 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 23

SureCross Web Configurator

1. DX83 Ethernet Bridge

2. Slave ID 2, DX85 Modbus RTU Remote I/O

3. Node 1, registers 17 through 32

4. Master Device, DX80 Gateway, registers 1 through 16.

5. Node 2, registers 22 through 48.

6. Node 3, registers 49 through 64.

7. Slave ID 5, DX80 Gateway, registers 1 through 16.

8. Node 2, registers 33 through 48

9. Node 1, registers 17 through 32.

rev. - www.bannerengineering.com - tel: 763-544-3164 23

Page 24

Threshold

ON point

Time

Input Value

Input

Hysteresis

OFF point

Parameters

SureCross Web Configurator

Action Select an action from the following: None, Reads

From, or Writes To. Select None to perform no

action, Reads From reads the parameter from

the remote register and copies the contents into

the local register, and Writes To writes the data

from the local register to the remote register.

Get Click the Get button to read all device and I/O

parameters from the DX80 device and load them

into the Web Configurator screens. This does not

save the parameters to the XML file.

Local

Register

Map

Number

The Local Register entry is the from register in

the I/O mapping. I/O points are linked from the

local register to the remote register.

Each map entry is defined with a map number,

one through 32. The master table entries define

the register-to-register communication for remote

I/O points. Each line represents a register/point

connection to another Modbus slave device. Up

to 32 table entries are possible.

Poll

Timeout

The poll timeout refers to the time limit, in milliseconds, to communicate with a specific slave

device. When this time limited is exceeded, the

system begins communicating with the next device in the table. The Poll Timeout setting prevents the system from stopping when a slave device is not responding.

Reset The Reset button resets any error conditions

displayed. Until the error message is reset, the

device will not start any additional operations.

SlaveIDThe slave ID is an identifying number used for

devices within a Modbus system. By default,

Gateways are set to Modbus Slave ID 1. When

using more than one Modbus slave, set each

slave to a unique ID number.

Threshold and

Hysteresis

Threshold and hysteresis work together to establish the ON and OFF points of an analog input. The threshold defines a trigger point or reporting threshold (ON point) for a sensor input.

The hysteresis value establishes how much below the active threshold (ON point) an analog input is required to be before the input is considered OFF. A typical hysteresis value is 10% to

20% of the unit’s range.

Refresh

Remote

Regis-

Click the Refresh button to refresh the screen image. This updates any information on the screen

that may have changed on the device.

The Remote Register entry is the to register in

the I/O mapping. I/O points are linked from the

local register to the remote register.

In the example shown graphically, the input is

considered on at 15 mA. To consider the input

off at 13 mA, set the hysteresis to 2 mA. The input will be considered off when the value is 2

mA less than the threshold.

ter

Remote

Type

Select a type from the following drop-down list:

none, coil (output), discrete input, input register,

or holding register. DX80 device registers are all

holding registers. Banner Engineering’s SureCross™ slave devices use only input registers

and holding registers. When using slave devices

from other manufacturers, please refer to the

manufacturer’s documentation to determine what

I/O types they use.

Coil (output). 1xxxx - Other slave devices, write

only, 1 bit

Discrete Input. 3xxxx - Other slave devices,

24 www.bannerengineering.com - tel: 763-544-3164 rev. -

read only, 1 bit

Input Register. 3xxxx - SureCross™ slave devi-

ces, read only, 16 bit

Page 25

SureCross Web Configurator

Holding Register. 4xxxx - SureCross slave devices, read/write, 16 bit

Selecting None for remote type negates the rule

though it remains in the list until deleted. Unused

rules at the end of the list always show None as

the remote type.

DX80 is Modbus RTU Slave

The third option, DX80 is Modbus RTU Slave, sets up a Gateway and Ethernet Bridge or GatewayPro as a slave device. This selection

stops the communication between the Ethernet interface and the DX80 Gateway.

DX80 is Modbus RTU Slave mode was created for special configurations of GatewayPro or Ethernet Bridge devices. Contact Banner

Wireless Support for more information.

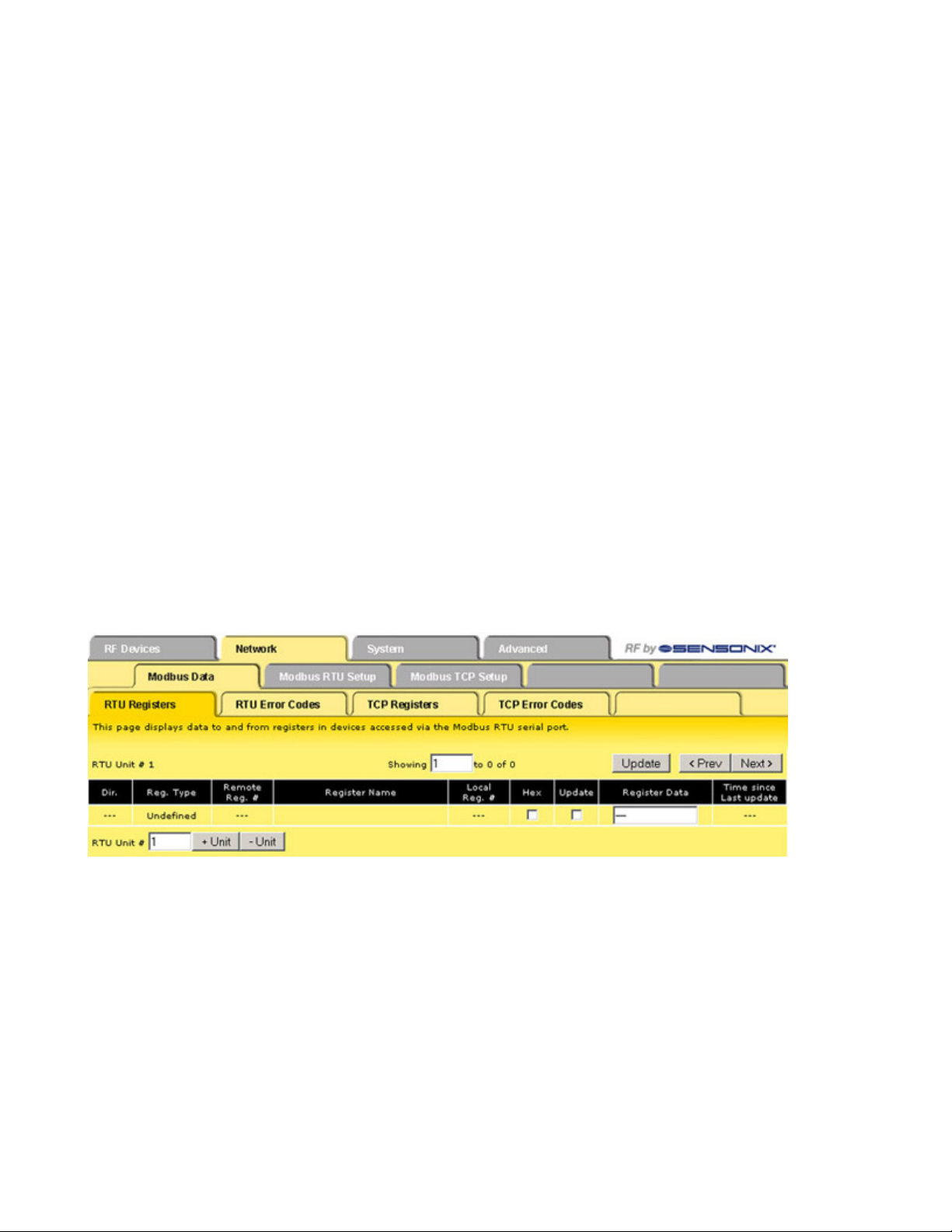

Network Tab

Use the Network main tab to configure the communications outside the radio network.

Modbus Data Submenu

The Ethernet processor in a GatewayPro or Ethernet Bridge can serve as a Modbus master device. The tables configured under the

Network page define the Master communication settings for Modbus RTU and Modbus/TCP clients and servers. Use the Modbus Data

submenu to view Modbus register data defined under the Modbus RTU set-up page.

RTU Registers

The RTU Registers screen displays the Modbus register contents for RTU slave devices defined under the Modbus RTU set-up page.

To change the register data:

1. Enter a new register data value

2. Select the Update checkbox.

3. Click the Update button to send the new data to the device.

Hex checkbox

Prev and

Next

Select the Hex checkbox to view the data in

hexidecimal form (not recommended for

floating point values).

If there are more than 16 devices or rules/

maps, use the Prev and Next buttons to display the next screen of information.

Unit + and

Unit–

Update Clicking the Update button sends information

Scrolls through the list of RTU slave devices.

to the Ethernet Bridge or GatewayPro or retrieves information depending on which

checkboxes are selected: Change or Get/

Send All. Updating information does not save

rev. - www.bannerengineering.com - tel: 763-544-3164 25

Page 26

SureCross Web Configurator

Showing Lists the pages of registers for the selected

slave (RTU unit).

Update

checkbox

configuration information permanently to the

XML file.

Unless the Update checkbox is selected, this

register data will not be submitted to the

Ethernet Bridge or GatewayPro.

RTU Error Codes

The first occurrence of read and write errors are shown along with the map number that was processing when the error occurred.

Select the Reset checkbox to the left of the error codes and click the Update button to clear the error. If more than one error is active, the

next error code displays.

The right four columns display a count of errors for all maps for each device. Select the Reset checkbox left of the Total Messages

column and click Update to reset the counts. Click Update to view the most recent values.

RTU and TCP Error Codes (A/B Format)

Error codes (A/B format) indicate the following errors with the first number:

1. n/a for RTU (Transaction ID out of sync)

2. Exception code returned by remote device

3. Function code mismatch (bad packet)

4. Insufficient data (bad packet)

5. No response from remote device, timed out

6. CRC error in received packet

When A is code 2, indicating an exception code was returned, B indicates the exception as follows:

1. Illegal function code

2. Illegal data address (the requested register does not exist in the device)

3. Illegal data value

26 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 27

SureCross Web Configurator

TCP Registers

The TCP Registers page displays data mapped by the virtual server user map defined under Network > Modbus/TCP Setup > Server

Map.

This is a snapshot of what the remote client sees when the user map is enabled. The diagnostic info displays the connection status for

each available connection. A code of A/B where A is zero is an available connection, and B indicates the reason for closing (may be

normal TCP close). A value of A greater than zero and B equal to zero indicates an active connection.

TCP Error Codes

The TCP Error Codes page displays error codes encountered when processing Modbus Client reads and writes via the Modbus/TCP

connection.

rev. - www.bannerengineering.com - tel: 763-544-3164 27

Page 28

SureCross Web Configurator

Resetting Error Codes

The first occurrence of read and write errors are shown along with the map number that was processing when the error occurred. Check

the Reset box to the left of the error column and click the Update button to clear the error. If more than one error is active, the next error

code displays.

The right three columns display an error count for all maps for each device. Check the Reset box to the left of the Total Messages column

and click Update to reset the counts. Click Update to view the most recent data values.

RTU and TCP Error Codes (A/B Format)

Error codes (A/B format) indicate the following errors with the first number:

1. n/a for RTU (Transaction ID out of sync)

2. Exception code returned by remote device

3. Function code mismatch (bad packet)

4. Insufficient data (bad packet)

5. No response from remote device, timed out

6. CRC error in received packet

When A is code 2, indicating an exception code was returned, B indicates the exception as follows:

1. Illegal function code

2. Illegal data address (the requested register does not exist in the device)

3. Illegal data value

28 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 29

SureCross Web Configurator

Modbus RTU Setup Submenu

The Modbus RTU Setup submenu contains the read and write map screens for setting up the Modbus RTU Slave option. The two

screens contained within the Modbus RTU Setup tab apply only to the Ethernet processor on the GatewayPro or a DX83 device.

RTU Read Map

The RTU Read Map screen creates a map entry to read data from one or more remote Modbus RTU serial devices. Click on the map

number in the left column to view more detail and to insert or delete maps.

Maps entered on the RTU Read Map page only read data from remote devices into local registers. To write data to those remote devices,

go to the RTU Write Map tab.

This screen displays an abbreviated list of maps. Any parameter shown may be changed. To view and/or modify the complete set of

parameters, click on the map number shown in the left column and use the expanded RTU Read Map page. To submit changes, click the

Update button.

For each remote register to be read, enter the register type, remote register format, register number, remote unit number, and local

register number.

Local Register Number

Name The name is optional and used only for dis-

Prev and

Next

Remote

Register

Format

Remote

Register

Number

After the remote register is read and the data

multiplied by the scale factor, the data is written to the Local Register number.

play purposes. The name acts as an identifier

for a specific register map. Type in the name

in this screen.

If there are more than 16 devices or rules/

maps, use the Prev and Next buttons to display the next screen of information.

Select the format of the remote register from

integer, unsigned, double, float, or bit. An integer is a 16-bit (signed) number, an unsigned format is a 16-bit unsigned number, a

double refers to a double precision (32-bit)

value, a floating value is a floating point number, and a bit value is a single bit that can either be a 0 or a 1 (discrete value.)

The Remote Register entry is the register being read.

Remote

Type

Scale The raw data in the remote register is multiplied

Select a type from the following drop-down list:

none, coil (output), discrete input, input register,

or holding register. Banner Engineering’s SureCross™ slave devices use only input registers

and holding registers. When using slave devices

from other manufacturers, please refer to the

manufacturer’s documentation to determine what

I/O types they use.

• Coil (output). 1xxxx - Other slave devices,

write only, 1 bit

• Discrete Input. 3xxxx - Other slave devices,

read only, 1 bit

• Input Register. 3xxxx - SureCross™ slave

devices, read only, 16 bit

• Holding Register. 4xxxx - SureCross slave

devices, read/write, 16 bit

Selecting None for remote type negates the rule

even though it continues to appear in the list until

deleted. Unused rules at the end of the list always show None as the remote type. To prevent

these from displaying, reduce the number of

maps enabled.

by the scale factor to produce the data appearing

rev. - www.bannerengineering.com - tel: 763-544-3164 29

Page 30

SureCross Web Configurator

Remote

Unit #

(Slave ID)

The Remote Unit number is the slave ID of

the remote unit to be read. The value in this

register is then written to the local register listed.

Swapped

in the floating point register associated with the I/

O point.

Check the Swapped box to swap the byte orientation.

Update Clicking the Update button sends information to

the Ethernet Bridge or GatewayPro or retrieves

information depending on which checkboxes are

selected: Change or Get/Send All. Updating information does not save configuration information permanently to the XML file.

Expanded RTU Read Map

The expanded view of the RTU Read Map contains the same parameters as on the original page in addition to a few more parameters.

For each remote register to be read, enter the register type, remote register format, remote register number, and device number (remote

unit number). Referring to the screen image, the following parameters may be set using this screen:

Parameter Parameter

1 Register type 8 Offset

2 Remote register format 9 Local register number

3 Remote register number 10 Name

4 Device number (remote unit number) 11 Periodic poll time

5 Doubles swapper 12 Default value

6 Bit mask 13 Read fail count

7 Scale

When the remote register is read, data may be manipulated before being written to the local register. If a bit mask is entered (in hexadecimal), and the remote register type is signed or unsigned (16-bit data), the mask will be bit-wise logical AND-ed with the data, and the

30 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 31

SureCross Web Configurator

retained bits will be right justified in the result. The result is multiplied by the scale factor and added to the offset. The final result is written

to the local register number selected.

Delete

and Insert

Periodic Poll

Time

Prev

and

Next

Clicking the Delete button removes the rule or

map number shown in the Rule # or Map # box.

Clicking the Insert button inserts a new map

ahead of the map number shown. It is not necessary to use the Insert button to add maps to the

bottom of the list or to define any rule with None

as the register type. To add a map/rule to the

bottom of the list, increase the number of rules or

maps enabled.

Determines how often the Gateway Pro or Gateway/Ethernet Bridge pair read the remote registers of the Modbus slave device. Setting the periodic poll time to zero sets the Gateway Pro or

Gateway/Ethernet Bridge pair to read the remote

registers continually.

If there are more than 16 devices or rules/maps,

use the Prev and Next buttons to display the

next screen of information.

Read

Fail

Count

When the read fail count is not zero, the default

value is stored in the local register after the given number of read failures. Setting the read fail

count to zero disables the default and the register retains the most recent value.

Register

Type

Selecting None for register type negates the

map though it remains in the list until deleted.

Unused maps always show None as the type. If

the displayed maps are used and more are needed, increase the RTU Read Maps Enabled

number.

Update Clicking the Update button sends information to

the Ethernet Bridge or GatewayPro or retrieves

information depending on which checkboxes are

selected: Change or Get/Send All. Updating information does not save configuration information permanently to the XML file.

RTU Write Map

The RTU Write Map page creates a map entry that writes data to one or more remote Modbus RTU serial devices.

Maps on the RTU Write Map page only write data from the local register to the remote register listed. Use the RTU Read Map page to

read data from those remote devices.

Any parameters shown may be changed and submitted by clicking the Update button, but this screen displays only an abbreviated list of

the map parameters. To view and/or modify the complete set of parameters, click on the hyperlinked map number in the left column and

use the expanded RTU Write Map page.

For each local register, enter the register number, scale, remote type, remote register format, remote register number, and remote unit

number (device).

Delete

and Insert

Clicking the Delete button removes the rule or

map number shown in the Rule # or Map #

box. Clicking the Insert button inserts a new

map ahead of the map number shown. It is not

necessary to use the Insert button to add maps

to the bottom of the list or to define any rule

with None as the register type. To add a map/

Remote

Type

Select a type from the following drop-down list:

none, coil (output), discrete input, input register,

or holding register. Banner Engineering’s SureCross™ slave devices use only input registers

and holding registers. When using slave devices

from other manufacturers, please refer to the

manufacturer’s documentation to determine what

I/O types are used.

rev. - www.bannerengineering.com - tel: 763-544-3164 31

Page 32

SureCross Web Configurator

rule to the bottom of the list, increase the number of rules or maps enabled.

Local

Register

The data in the local register is multiplied by

the scale factor, then written to the remote register.

Name The name is optional and used only for display

purposes. The name acts as an identifier for a

specific register map. Type in the name in this

screen.

Prev and

Next

If there are more than 16 devices or rules/

maps, use the Prev and Next buttons to display the next screen of information.

Remote

Register

Format

Select the format of the remote register from

integer, unsigned, double, float, or bit. An integer is a 16-bit (signed) number, an unsigned

format is a 16-bit unsigned number, a double

refers to a double precision (32-bit) value, a

floating value is a floating point number, and a

bit value is a single bit that can either be a 0 or

a 1 (discrete value.)

Remote

Register

The Remote Register entry is the register being written to in the map.

Number

Remote

Slave ID

The Remote Unit number is the slave ID of the

remote unit to be written to.

(Unit #)

• Coil (output). 1xxxx, Other slave devices,

write only, 1 bit

• Discrete Input. 3xxxx, Other slave devices,

read only, 1 bit

• Input Register. 3xxxx, SureCross™ slave

devices, read only, 16 bit

• Holding Register. 4xxxx, SureCross slave

devices, read/write, 16 bit

Selecting None for remote type negates the rule

though it remains in the list until deleted. Unused

rules at the end of the list always show None as

the remote type. To prevent these from displaying, reduce the number of maps enabled on the

expanded view screen.

Scale The raw data in the local register is multiplied by

the scale factor to produce the data written to the

remote register.

Swapped

Check the Swapped box to swap the byte orientation.

Update Clicking the Update button sends information to

the Ethernet Bridge or GatewayPro or retrieves

information depending on which checkboxes are

selected: Change or Get/Send All. Updating information does not save configuration information permanently to the XML file.

Expanded RTU Write Map

Like the RTU Read Map expanded view, the RTU Write Map expanded view contains some of the same parameters as the RTU Write

Map primary view in addition to a few more parameters.

Refer to the Expanded RTU Read Map section for more information about these parameters (GUID-5EBD5A53-1BF9-4F16-

B92D-60E91D2E058C.xml).

32 www.bannerengineering.com - tel: 763-544-3164 rev. -

Page 33

SureCross Web Configurator

Modbus TCP Setup Submenu

Use the Modbus TCP Setup pages to specify the network address and optional device parameters of a remote Modbus/TCP device.

Example remote Modbus/TCP devices may include another Gateway device or any remote device using Modbus/TCP to communicate.

Devices

Use the Devices page to set up the network address and optional device parameters for a remote Modbus/TCP device that is linked to for

remote input and/or output.

Map the remote Modbus/TCP device’s input and/or output using the Client Read and Client Write Maps.

Connection Status. Connection status displays a non-zero error code when a socket error occurs. Possible errors include:

• 104 - Connection reset by peer

• 111 - Connection refused

• 113 - Connection aborted

• 114 - Network is unreachable

• 116 - Connection timed out

• 118 - Host is unreachable

• 119 - Connection in progress (connect unsuccessful and still trying)

• 205 - Could not get host IP by name

Default

Poll Period

Domain

Name

IP Address

Local

Name

Port If port is left set to zero, port 502 is used. To

The polling period defines how often, in seconds, this device (GatewayPro or Ethernet

Bridge) contacts the device listed and solicits

data.

The system may also look up an IP address

when given a domain name. If the IP address

is set to zero, the system attempts to find the

host by name.

Specify the IP address of the remote Modbus/

TCP device.

The local name is an optional field and is used

to refer to this device in other Web Configurator pages.

use a non-standard port number, enter the

number.

Swap

Double

Registers

The term swapped applies only to double or float

formats. Modbus registers are, by definition, 16

bits of data per register. Access to 32-bit data,

either 32-bit integer (double) or IEEE 754 floating point (float), is supported using two consecutive registers. Modbus protocol is inherently “big

endian,” therefore Modbus defaults to having the

high order register first for double and float formats. If the low order register comes first on the