baltur COMIST 72 DSPGM, COMIST 180 DSPGM, COMIST 122 DSPGM, COMIST 250 DSPGM, COMIST 300 DSPGM Instruction

- Instruction for burners model

COMIST 72 DSPGM

COMIST 122 DSPGM

en

COMIST 180 DSPGM

COMIST 250 DSPGM

COMIST 300 DSPGM

- The works on the burner and on the system have to

be carried out only by competent people.

- Read carefully the instructions before starting the

burner and service it.

- The system electric feeding must be disconnected

before starting working on it.

- If the works are not carried out correctly it is

possible to cause dangerous accidents.

Edition

2003/11

Cod. 0006080115

Dichiarazione del Costruttore

Dichiariamo che i bruciatori di gas, gasolio, olio combustibile e misti (gas/gasolio oppure gas/olio combustibile)

sono da noi prodotti a regola d’arte in conformità alle Norme CE - CEI - UNI vigenti al momento della costruzione.

• La BAL TUR garantisce la certificazione “CE” sul prodotto solo se il bruciatore viene inst allato con la ramp a

gas “CE” fornita dalla BALTUR e con accessori di linea gas certificati “CE” (forniti su richiesta).

NOTA : la presente dichiarazione non è valida, relativamente alla Norma CE oppure UNI, per i bruciatori di gas e per la

parte gas dei bruciatori misti (gas/gasolio oppure gas/olio combustibile) quando, gli stessi, ci vengono ordinati non

conformi alla Norma CE oppure UNI, perché destinati ad uso speciale, non previsto nelle norme sopra indicate.

Manufacturer’s declaration

We hereby declare that our gas, light oil, heavy oil, and combination (gas/light oil or gas/heavy oil)

burners are manufactured in conformance with current CE, CEI and UNI standards.

• BALTUR guarantees the “CE” certification provided that the burner is coupled to the “CE” gas train supplied

by BAL TUR and the “CE” gas line accessories (on request).

NOTE: this declaration is not valid with regard to EC or UNI Standards for gas burners or the gas p art of

duel-fuel burners (gas/light oil or gas/heavy oil) when such burners have been ordered in non-compliance

with the EC St andard or It alian UNI Standard because they are to be used for special purposes not provided

for in the above-mentioned standards.

Declaración del fabricante

Declaramos que la empresa fabrica los quemadores de gas, gasóleo, fuel y mixtos (gas/gasóleo o

gas/fuel) ajustándose a las Normas CE - CEI - UNI vigentes en el momento de su fabricación.

• La firma “BALTUR” garantiza la certificación “CE” sombre el producto sólo si el quemador viene instalado

con la rampa gas “CE” suministrada por la “BALTUR” misma y con los accesorios de linea gas

certificados “CE” (suministrables a pedido).

NOTA: la presente declaración no tiene validez, respecto a la Norma CE o UNI, para los quemadores de

gas y para la parte de gas de los quemadores mixtos (gas/gasóleo o gas/fuel) cuando, los mismos, se

piden no conformes a la Norma CE o a la norma italiana UNI, porque están destinados a un uso especial,

no previsto en las normas arriba mencionadas.

Déclaration du constructeur

Nous déclarons que les brûleurs à gaz, fioul, fioul lourd et mixtes (gaz/fioul ou gaz/fioul lourd) sont

produits selon les règles de l’art, conformément aux Normes CE – CEI – UNI en vigueur au moment de la

fabrication.

• La BALTUR garantit la certification “CE” seulement si les brûleur sont installé avec les rampes de gaz “CE”

produites par la BALTUR et les accessoires de ligne gaz “CE” (fournis sur demande).

NOTE: la présente déclaration n’est pas valable, correspondante à la Norme CE ou bien UNI, pour les

brûleurs à gaz et pour la partie gaz des brûleurs mixtes (gaz/fioul ou bien gaz/fioul lourd) lorsque, ces

derniers, nous sont commandés sans être conformes à la Norme CE ou bien à la norme italienne UNI, parce

qu’ils sont destinés à une utilisation spéciale qui n’est pas prévue par les normes indiquées ci-dessus.

Herstellererklärung

Wir erklären, dass die Gas-, Heizöl-, Schweröl- und Wechselbrenner (Gas/Heizöl oder Gas/Schweröl)

von uns fachgerecht und in Übereinstimmung mit den zum Zeitpunkt der Fertigung geltenden Normen CE CEI - UNI hergestellt wurden.

• Die “CE”-Zertifizierung der von BALTUR hergestellten Produkte ist nurin Verbindung mit einer von BALTUR

gelieferten CE-Gasarmatur und unter Verwendung von CE-zertifizierten Bauteilen in der Gaszufürhrung gültig.

HINWEIS: Die vorliegende Erklärung im Hinblick auf die EU- oder UNI-Normen ist nicht gültig für

Gasbrenner und für den Gasteil von Wechselbrennern (Gas/Öl oder Gas/Schweröl), wenn solche bei uns

ohne Konformität mit den EU-Normen oder mit der italienischen Norm UNI bestellt werden, weil sie eine für

spezielle Verwendung bestimmt sind, die von den oben genannten Normen nicht vorgesehen ist.

L' Amministratore delegato

Dott. Riccardo Fava

2

CARA TTERISTICHE TECNICHE

Ó

R

TECHNICAL DA T A

CARACTIRÍSTICAS TÉCNICAS

N° 0002570030

Rev.

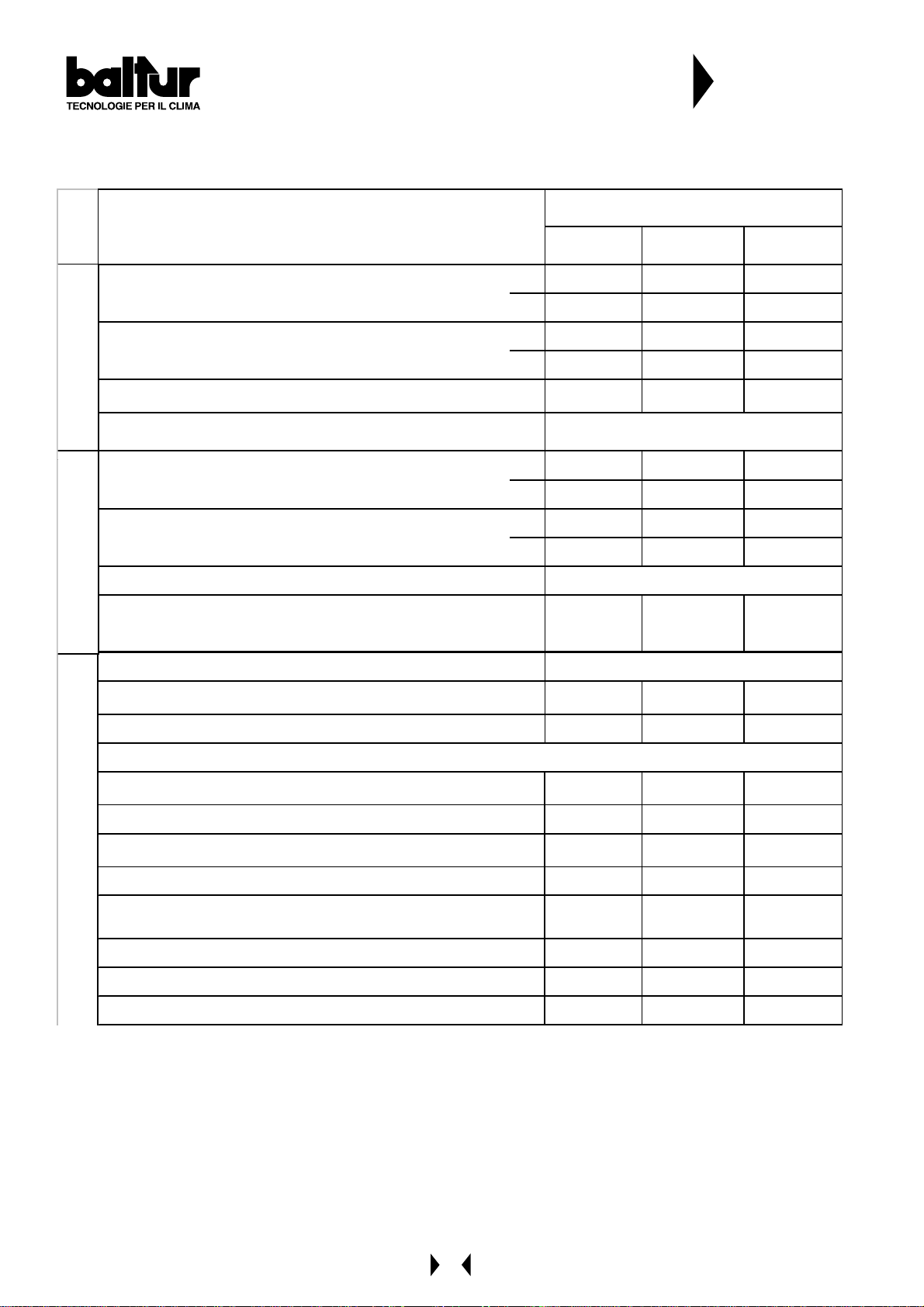

CARATTERIS T I CHE TECNICHE / T ECHNICAL DAT A

CARACTERÍST ICAS T ÉCNICAS / T ECHNIS CHE DAT EN

POTENZA TERMICA / THERMIC CA PACITY /

POTENCIA TÉRMICA / HEIZLEISTUNG

PORTATA / FLOW RA TE / CAUDAL / DURCHSA TZ

PRESSIONE MIN.(*) / MIN. PRESSURE (*) /

PRESIÓN META NO MÍN. (*) / DRUCK MIN. (*)

METANO /

NATURAL GAS

TRASFORMATORE METANO / NAT. GAS TRANSFORMER /

TRANSFORMA DORES DE ENCENDIDO ME TANO

POTENZA TERMICA / THERMIC CA PACITY /

POTENCIA TÉRMICA / HEIZLEISTUNG

PORTATA / FLOW RA TE / CAUDAL / DURCHSA TZ

VISCOSITA' COMBUSTIBILE / FUEL VISCOSITY / VISCOSIDAD COMBUSTIBLE

TRASFORMATORE GASOLIO / LI GHT OIL TRANSFORMER

GASÓLEO / HEIZÖL

GASOLIO /LIGHT OIL

TRANSFORMA DORES DE ENCENDIDO GA SÓLEO / ZÜNDTRA FO

TENSIONE / VOLTAGE / TENSIÓN / SPANNUNG

MOTORE VENTOLA / FAN MOTOR / MOTORES VENTILADOR / LÜFTERMOTOR

MOTORE POMPA / PUMP MOTOR / MOTORES BOMBA / PUMPMOTOR

MODELLO / MODEL /

MO DELO / M O DEL L

COM IST 72 COM IST 122

MM - DSPGM MM - DSPGM

MAX kW 916 1364

MIN kW 348 652

MAX m³/h

MIN m³/h

CE mbar

93 137

35 65,5

20 23

8 kV - 20 mA

MAX kW

MIN kW

MAX kg/h

MIN kg/h

916 1364

348 652

78 115

30 55

1,5°E a/ at 20°C

10 kV - 20 mA 12 k V - 30 mA

Volt

kW

kW / r.p.m.

230/ 400 - 50 Hz

1,1 - 50Hz 2,2 - 50Hz

0,55 - 1420 0,75 - 2800

MAT ERIALE A CORREDO / ST AND ARD AC CES SORI ES / M AT ERIAL EN DOTACI

FLANGIA ATTACCO BRUCIAT. / BURNER FIXING FLANGE /

BRIDA UNIÓN / BEFESTIGUNGSFLANSCH

COLLARE ELASTICO / ELASTIC COLLAR / COLLARÍN ELÁSTICO / FEDER

GUARNIZIONE ISOLANTE / INSULATING GASKET /

EMPAQUETADURA / ISOLIERDICHTUNG

FILTRO / FILTER 1" 1"1/4

TUBI FLESSIBILI / FLEXIBLE PIPE / TUBOS FLEXIBLES / SCHLÄUCHE

NIPPLO / NIPPLE / ENTRERROSCA S / NIPPEL

PRIGIONIERI / STUD BOLTS / ESPÁRRAGOS / STIFTSCHRAUBEN

DADI / EXAGONAL NUTS / TUERCAS / SEC HSKANTMUTTERN

RONDELLE PIANE / FLAT WASHERS / ARANDELAS / FLACHSCHEIBEN

N / STANDARD ZUBEHÖ

22

11

11

N°2 - 1"x1" N°2 - 1"¼ x1"¼

N°1 - 1"x1" - -

N°4 M16 N°4 M16

N°8 M16 N°8 M16

N° 8 ø16 N° 8 ø16

3

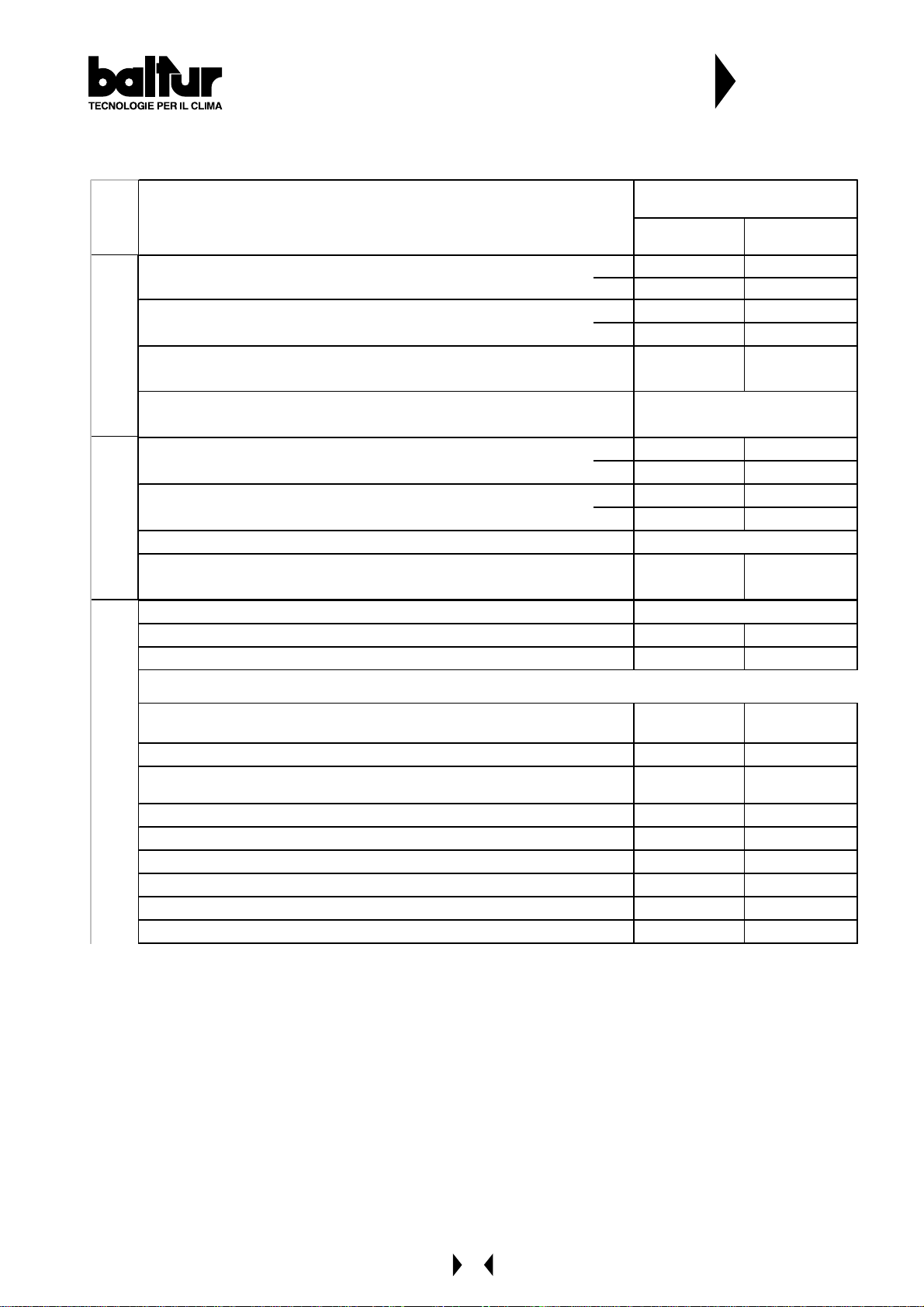

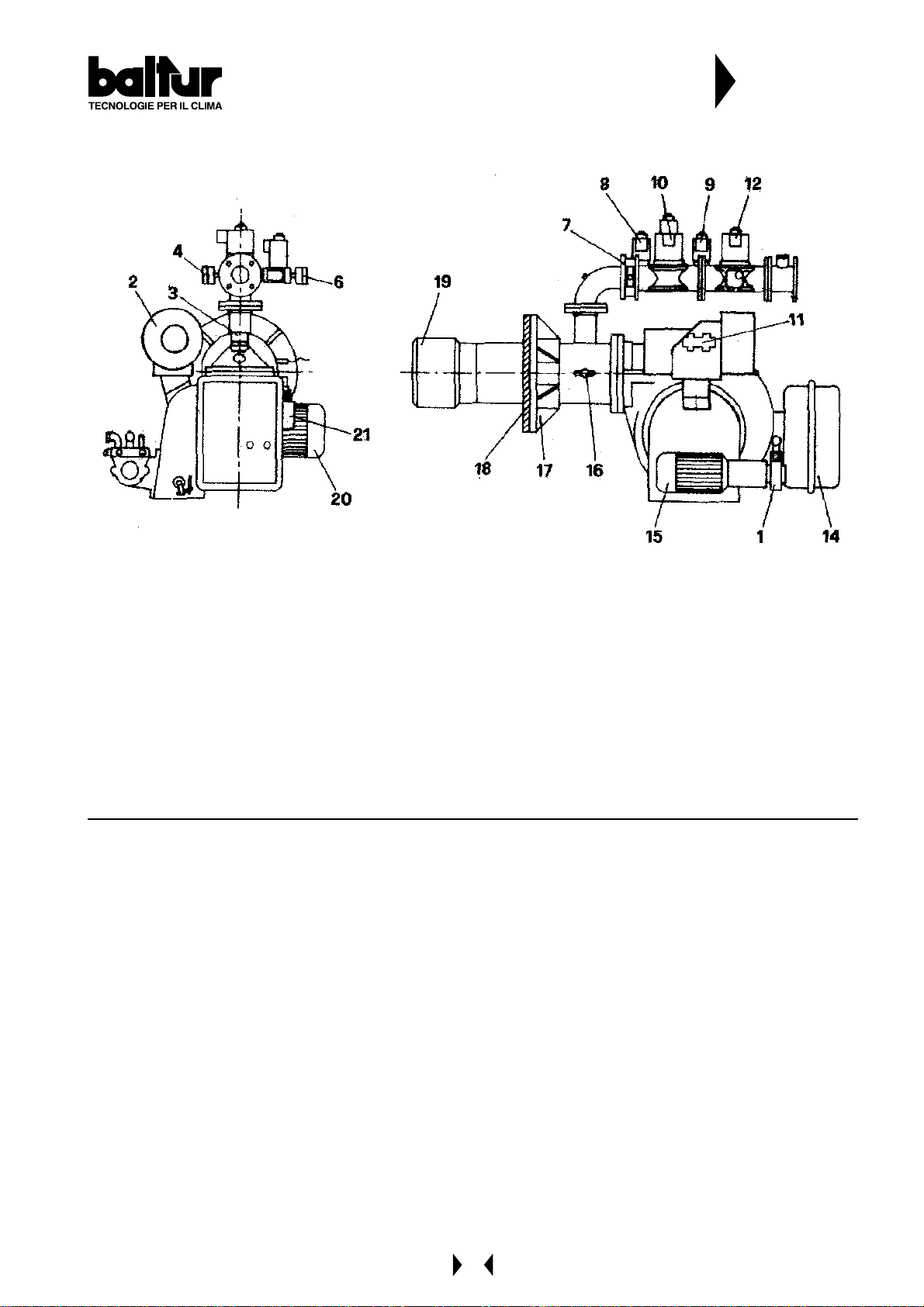

Elenco componenti

Component List

Lista de los componentes

N° 0002570030

Rev.

1 - Pompa

2 - Modulatore

3 - Pressostato aria

4 - Pressostato gas minima

5 - Pressostato gas massima

6 - Pressostato gas massima

7 - V alvola a farfalla

8 - Valvola funzionamento rampa pilot a

9 - Cerniera

10 - Valvola funzionamento

1 - Pump

2 - Modulator

3 - Aire pressure switch

4 - Gas pressure switch min.

5 - Gas pressure switch max.

6 - Gas pressure switch max.

7 - Butterfly

8 - Pilot main valve

9 - Hinge

10 - Main valve

1 1 - Regulation valve return pressure

12 - Safety valve

14 - Electric board

15 - Pump motore

16 - Combustion head air control knob

17 - Burner fixing flange

18 - Gasket

19 - Combustion head

20 - Fan motor

21 - Electromagnet

11 - Valvola regolatrice di pressione

12 - V alvola di sicurezza

14 - Quadro elettrico

15 - Motore pompa

16 - Vite regolazione aria alla testa di combustione

17 - Flangia attacco bruciatore

18 - Guarnizione isolante

19 - Testa di combustione

20 - Motore ventola

21 - Elettromagnete

1 - Bomba

2 - Modulator

3 - Presóstato aire

4 - Presóstato gas mínima

5 - Presóstato gas máxima

6 - Presóstato gas máxima

7 - Válvula de mariposa

6 - Válvula funcionamiento tren piloto

9 - Bisagra

10 - Válvula de funcionamiento

1 1 - Válvula de regulación presión

12 - Válvula de seguridad

14 - Cuadro eléctrico

15 - Motor bomba

16 - Tornillo regulaciónaire en el cabezal de combustión

17 - Brida unión quemador

18 - Empaquetadura aislante

19 - Cabezal de combustión

20 - Motor ventilador

21 - Electroimán

4

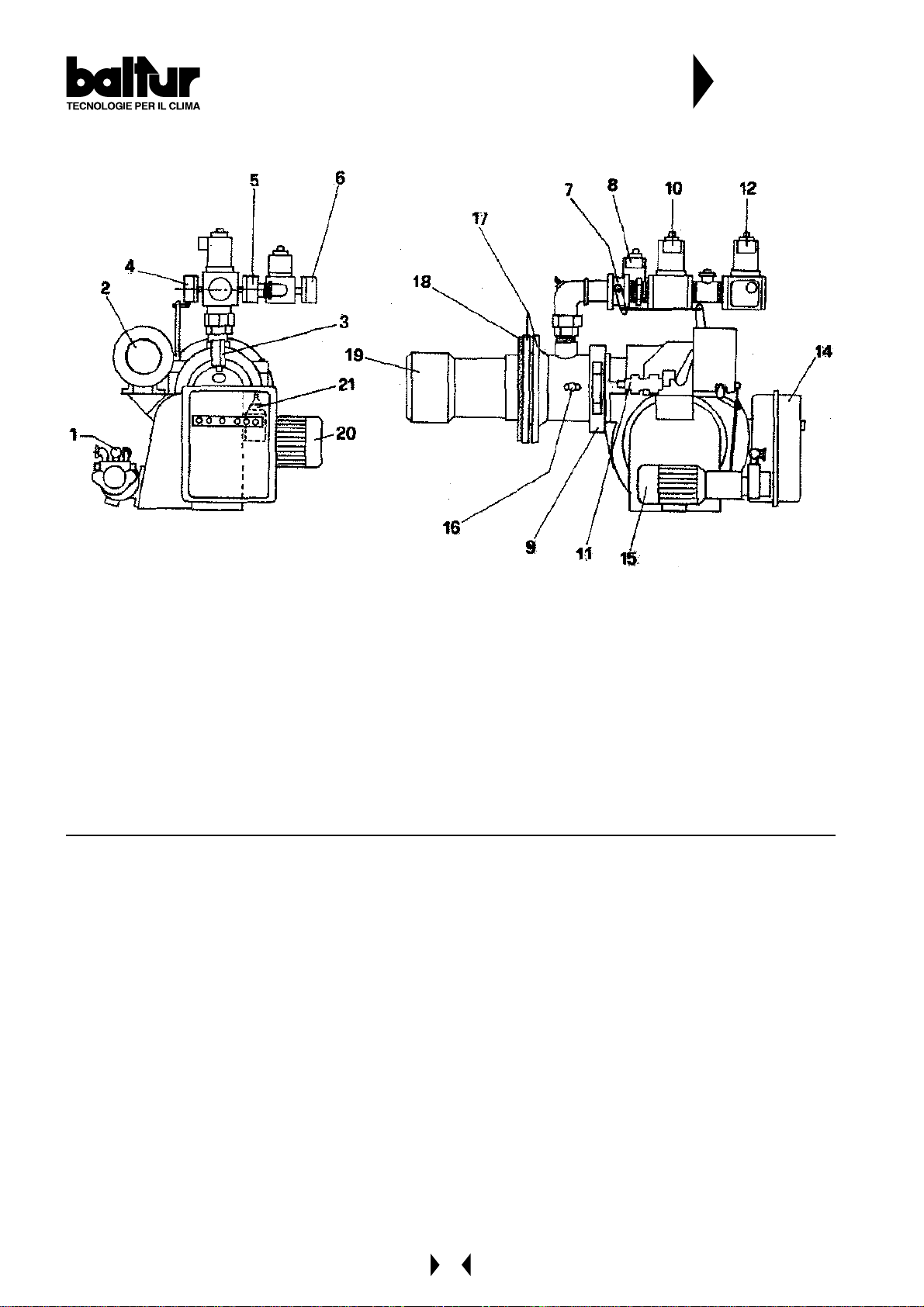

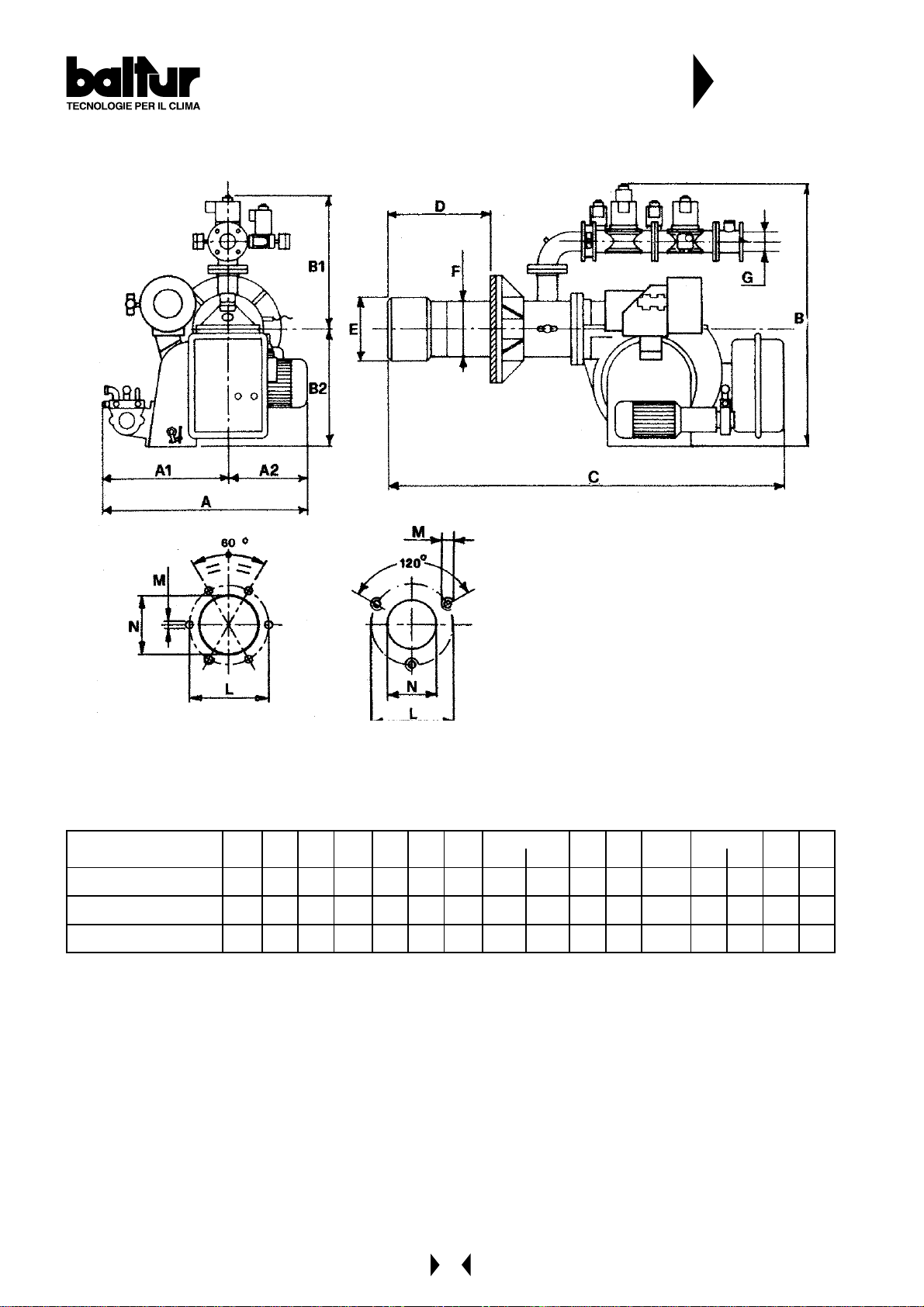

Dimensioni / Dimensions / Dimensiones

N° 0002570030

Rev.

MOD.

COM IST 7 2 DSPG M

COMI S T 122 DS P GM

A A1 A2 B B1 B2 B3 C D E F G L M N

MIN MAX Ø Ø Ø Ø

670 400 270 810 375 43 5 265 1410 185 445 227 220 2" 240 M16 240

830 460 370 1170 455 715 - 1500 195 455 227 220 2"1/2 240 M16 240

5

CARA TTERISTICHE TECNICHE

W

W

TECHNICAL DA T A

CARACTIRÍSTICAS TÉCNICAS

N° 0002570100

Rev.

CARATTERIS T ICHE TECNICHE / T ECHNICAL DAT A

CARACTERÍST ICAS T ÉCNICAS / T ECHNIS CHE DAT EN

POTENZA TERMICA / THERMIC CA PACITY /

POTENCIA TÉRMICA / HEIZLEISTUNG

PORTATA / FLOW RATE / CAUDAL / DURCHSATZ

PRESSIONE MIN.(*) / MIN. PRESSURE (*) /

METANO /

PRESIÓN METANO MÍN. (*) / DRUCK MIN. (*)

NATURAL GAS

TRASFORMATORE METANO / NAT. GAS TRANSFORMER /

TRANSFORMADORES DE ENCENDIDO METANO

POTENZA TERMICA / THERMIC CA PACITY /

POTENCIA TÉRMICA / HEIZLEISTUNG

PORTATA / FLOW RATE / CAUDAL / DURCHSATZ

VISC OSIT A ' COMBUSTIBILE / FU EL VISCO SITY / VISCOSIDAD COMBUSTIBLE

TRASFORMATORE GASOLIO / LI GHT OIL TRANSFORMER

GASÓLEO / HEIZÖL

GASOLIO /LIGHT OIL

TRANSFORMADORES DE ENCENDIDO GASÓLEO / ZÜNDTRAFO

MODELL O / M O DEL /

MODELO / MODELL

COMIST 180 COMIST 250 COMIST 300

DSPGM DSPGM DSPGM

MAk

MI k

MAX m³/h 199 340 390

MIN m³/h 69 113 131

CE

bar 37 150 150

1981 33 80 3878

688 1127 1304

8 kV - 20 mA

MAX kW 1981 3380 3878

MIN kW 688 1127 1304

MAX kg/h 167 285 327

MIN kg/h 58 95 110

1,5° E a/at 20° C

12 kV - 30 mA

14 kV - 30 mA 14 kV - 30 mA

TENSIONE / VOLTA GE / TENSIÓN / SPANNUNG

MOTORE VENTOLA / FAN MOTOR /

MOTORES VENTILA DOR / LÜFTERMOTOR

MOTORE POMPA / PUMP MOTOR / MOTORES BOMBA / PUMPM OTOR

Vol

kW/r.p.m.

kW/r.p.m.

230/ 400 - 50 Hz

3 - 2870 7, 5 - 2870 7,5 - 2870

0,75 - 28 00 1, 5 - 2800 1,5 - 2800

MAT ERI A L E A CO RREDO / S T ANDARD ACCESSO RIES / MATERI AL EN DOTACIÓN / STANDAR DZUBEHÖR

FLANGIA ATTACCO BRUCIAT. / BURNER FIXING FLANGE /

BRIDA UNIÓN / BEFESTIGUNGSFLANSCH

COLLARE ELASTICO / ELASTIC COLLAR / COLLARÍN ELÁSTICO / FEDER

GUARNIZIONE ISOLANTE / INSULATING GASKET /

EMPAQUETADURA / ISOLIERDICHTUNG

FILTRO / FILTE R

TUBI FLESSIBILI / FLEXIBLE PIPE / TUBOS FLEXIBLES / SCHLÄUCHE

PRIGIONIERI / STUD BOLTS / ESPÁRRAGOS / STIFTSCHRAUBEN

DADI / EXAGONAL NUTS / TUERCAS / SECHSKANTMUTTERN

RONDELLE PIA NE / FLA T WA SHERS / A RANDELA S / FLACHSCHEIBEN

111

- - 1 1

222

1"¼ 1"¼ 1"1/4

N°2

1"¼x1"¼

N°2

1"¼x1"¼

N°2

1"¼x1"¼

N°6 M20N°3 M20N°3 M20

N°6 M20N°3 M20N°3 M20

N°6 ø20N°3 ø20N°3 ø20

6

CARA TTERISTICHE TECNICHE

TECHNICAL DA T A

CARACTIRÍSTICAS TÉCNICAS

N° 0002570100

Rev.

1 - Pompa

2 - Modulatore

3 - Pressostato aria

4 - Pressostato gas minima

5 - Pressostato gas massima

6 - Pressostato gas massima

7 - Valvola a farfalla

8 - Valvola funzionamento rampa pilot a

9 - Valvola sicurezza rampa pilot a

10 - Valvola funzionamento

1 - Pump

2 - Modulator

3 - Aire pressure switch

4 - Gas pressure switch min.

5 - Gas pressure switch max.

6 - Gas pressure switch max.

7 - Butterfly

8 - Pilot main valve

9 - Pilot safety valve

10 - Main valve

1 1 - Regulation valve return pressure

12 - Safety valve

14 - Electric board

15 - Pump motore

16 - Combustion head air control knob

17 - Burner fixing flange

18 - Gasket

19 - Combustion head

20 - Fan motor

21 - Electromagnet

1 1 - V alvola regolatrice di pressione

12 - Valvola di sicurezza

14 - Quadro elettrico

15 - Motore pompa

16 - Vite regolazione aria alla testa di combustione

17 - Flangia attacco bruciatore

18 - Guarnizione isolante

19 - Testa di combustione

20 - Motore ventola

21 - Elettromagnete

1 - Bomba

2 - Modulator

3 - Presóstato aire

4 - Presóstato gas mínima

5 - Presóstato gas máxima

6 - Presóstato gas máxima

7 - Válvula de mariposa

6 - Válvula funcionamiento tren piloto

9 - Válvula de seguridad tren piloto

10 - Válvula de funcionamiento

1 1 - Válvula de regulación presión

12 - Válvula de seguridad

14 - Cuadro eléctrico

15 - Motor bomba

16 - T ornillo regulaciónaire en el cabezal de combustión

17 - Brida unión quemador

18 - Empaquetadura aislante

19 - Cabezal de combustión

20 - Motor ventilador

21 - Electroimán

7

Dimensioni / Dimensions / Dimensiones

M

M

M

N° 0002570100

Rev.

Mod.

COMIST 1 80 DSP G

COMIST 2 50 DSP G

COMIST 3 00 DSP G

AA1A2BB1B2CDEFGLMN

min max min max

875 460 415 1225 510 715 1725 330 520 260 245 2”1/ 2G 400 400 M 20 300

1075 540 535 1300 580 720 1750 320 500 320 273 3”G 490 490 M 20 340

1075 540 535 1300 580 720 1750 320 500 320 273 3”G 490 490 M 20 350

8

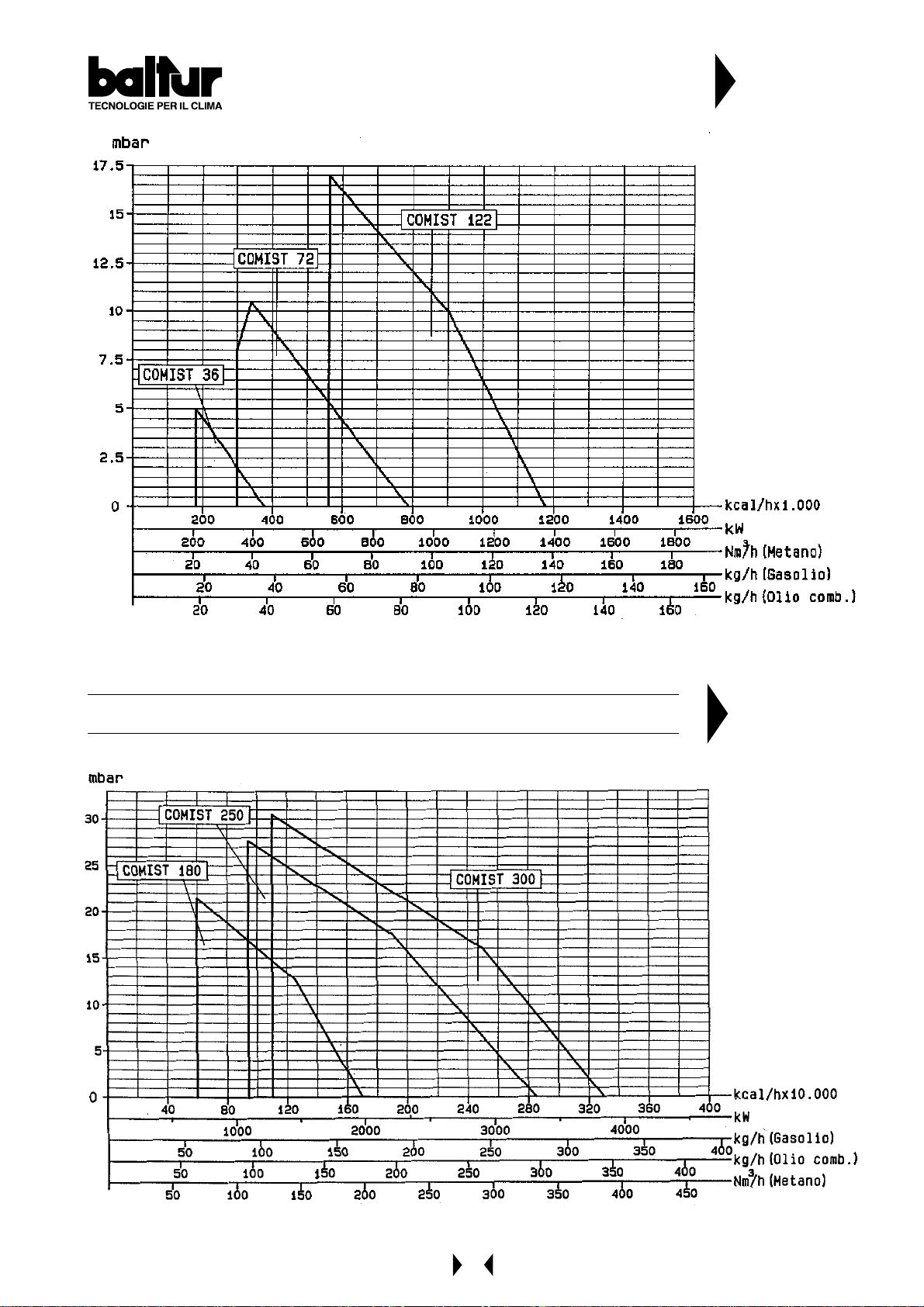

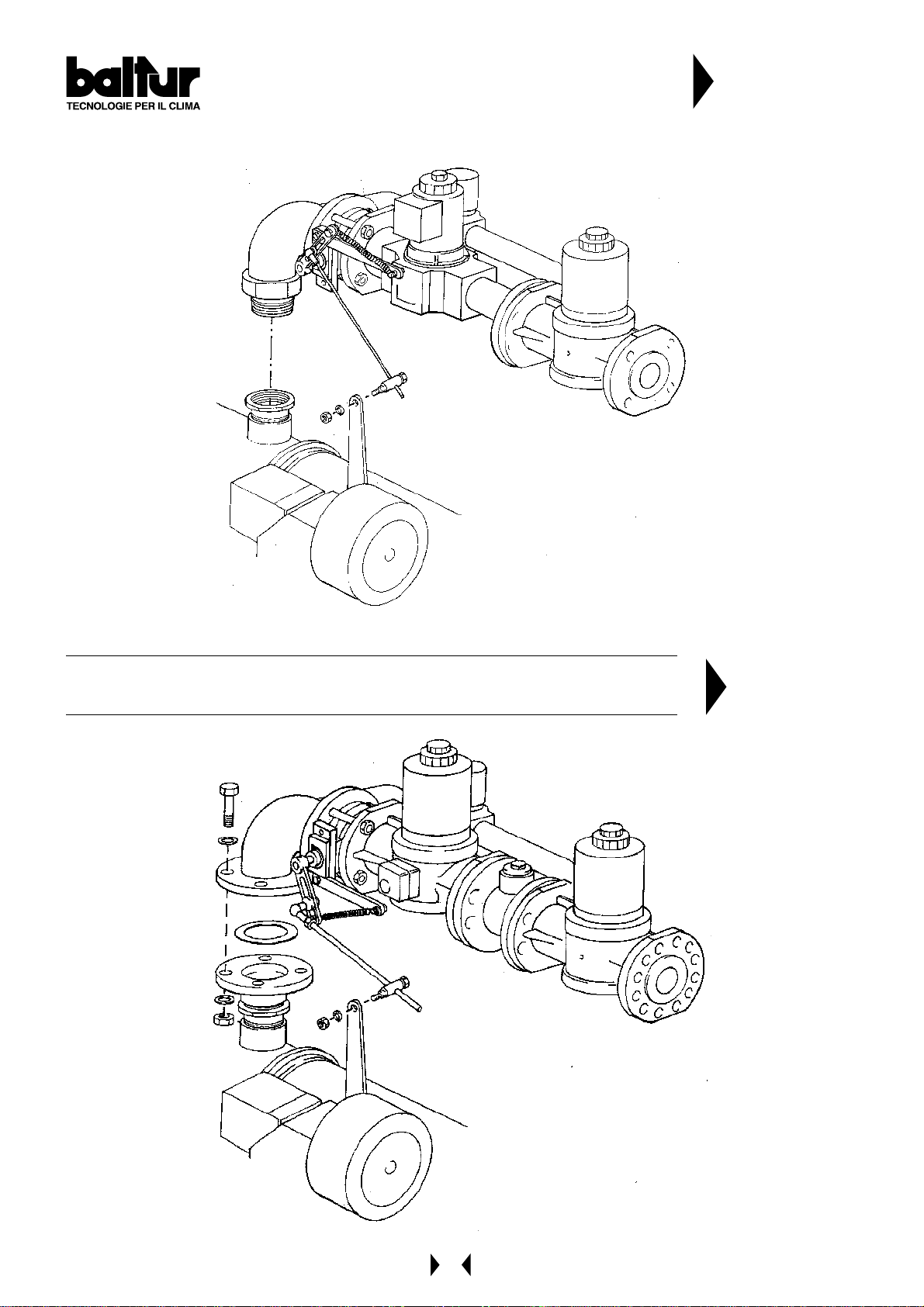

COMIST 36 - 72 - 122

N° 8187/1

Rev.

COMIST 180 - 250 - 300

N° 8111/2

Rev.

9

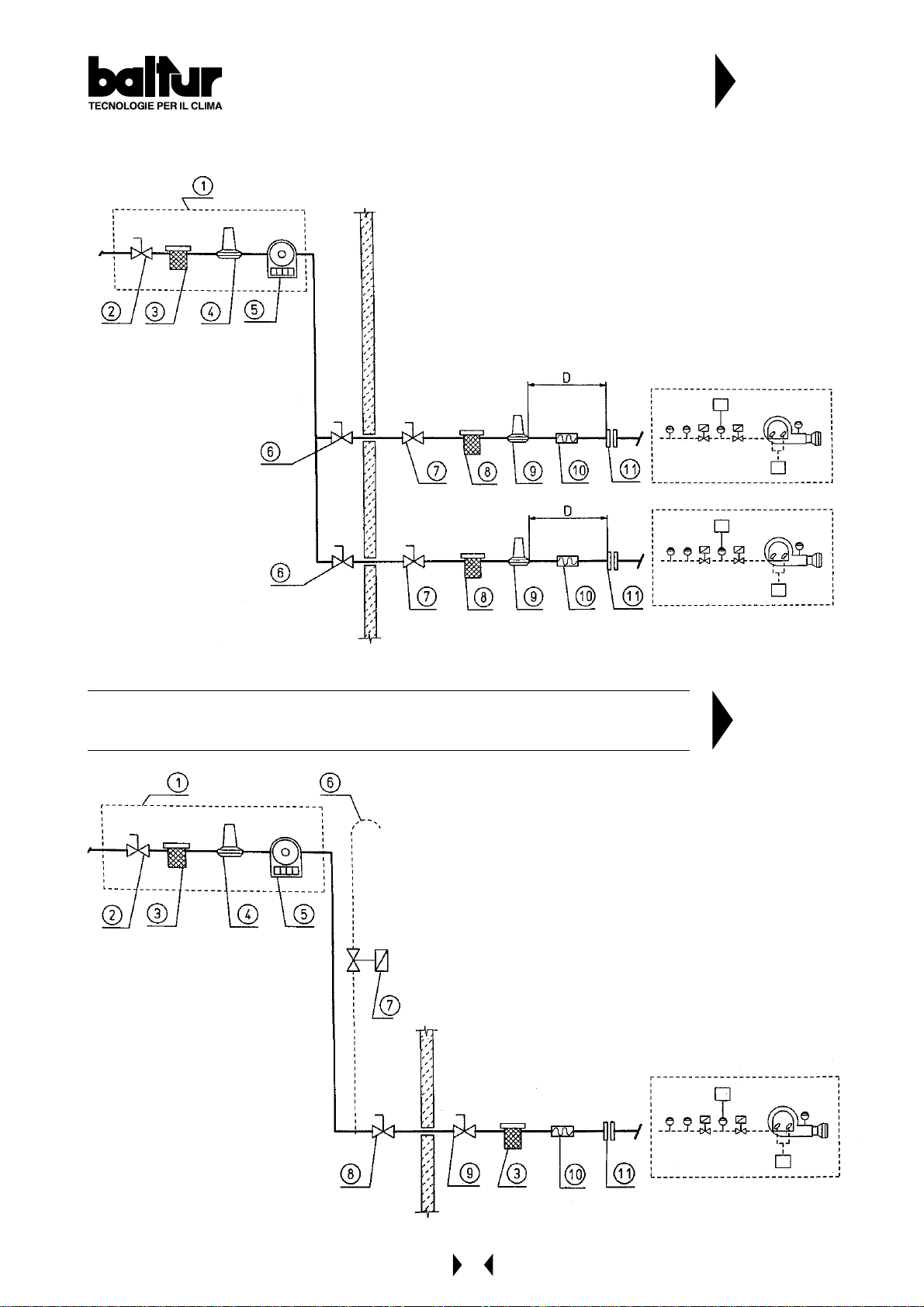

DRAWING SHOWING THE GAS TRAIN ASSEMBL Y

COMIST 72 MG - DSPGM

N° 8805

Rev.

DRAWING SHOWING THE GAS TRAIN ASSEMBL Y

COMIST 122 - 180 - 250 - 300 MG - DSPGM - DSPNM

N° 8797

Rev.

10

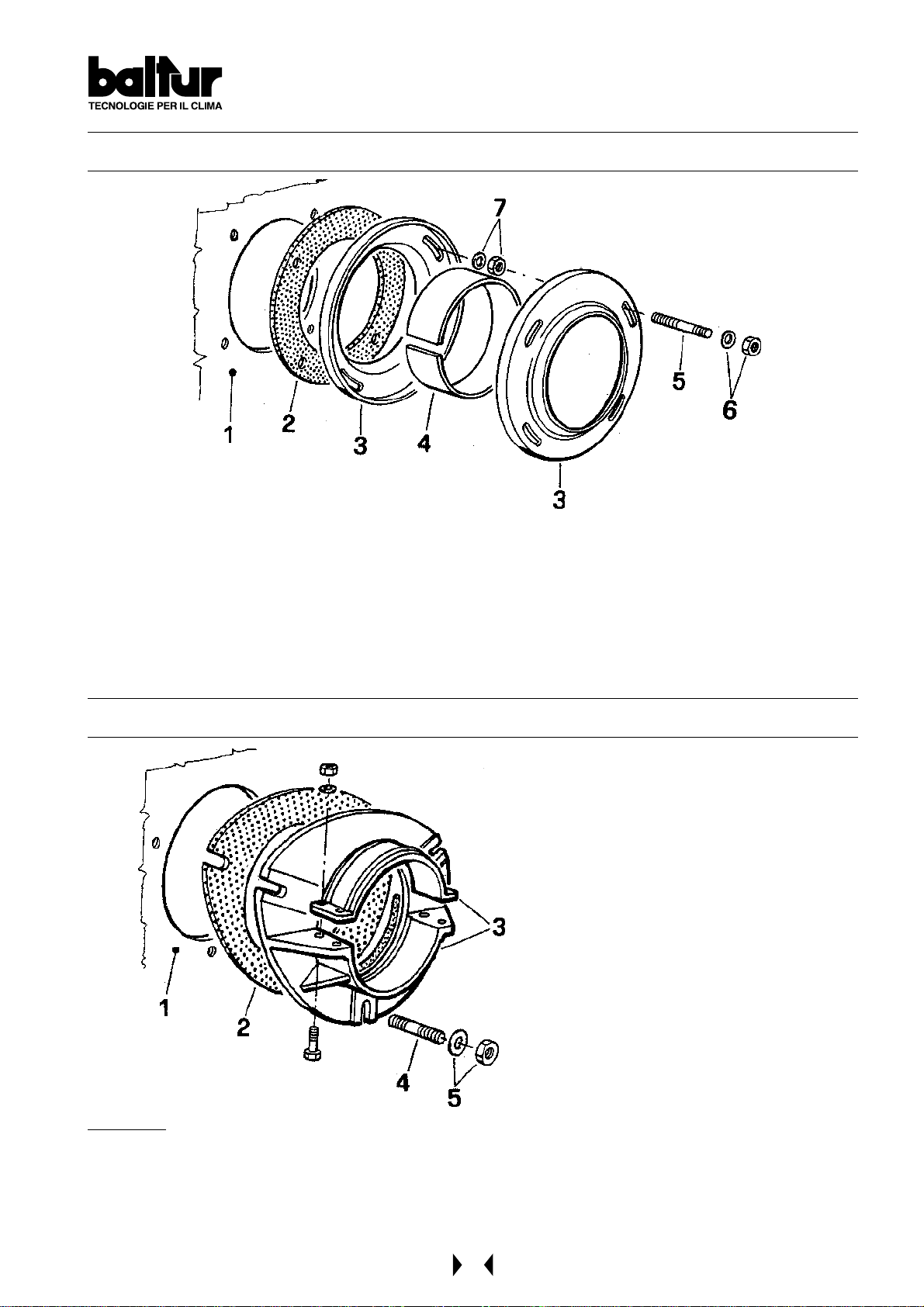

APPLICATION OF THE BURNER TO BOILER

for model COMIST 72 - 122 DSPGM (steel fixing flange)

1 - Boiler plate

2 - Insulating gasket

3 - Burner fixing flange

4 - Elastic collar

for model COMIST 250 - 300 DSPGM

5 - Stud bolt

6 - Locking nut with washer

7 - Nut and washer for fastening the first flange

1 - Boiler plate

2 - Insulating gasket

3 - Burner fixing flange

4 - Stud bolt

5 - Locking nut with washer

REMARKS

When tightening the flange, it is important to do it evenly so that the inner faces are parallel between them.

Since the locking system is highly efficient, do not tighten the nuts too much.

During this operation (tightening of the flange locking nuts) keep the body of the burner lifted so that the

combustion head is kept in a horizontal position.

11

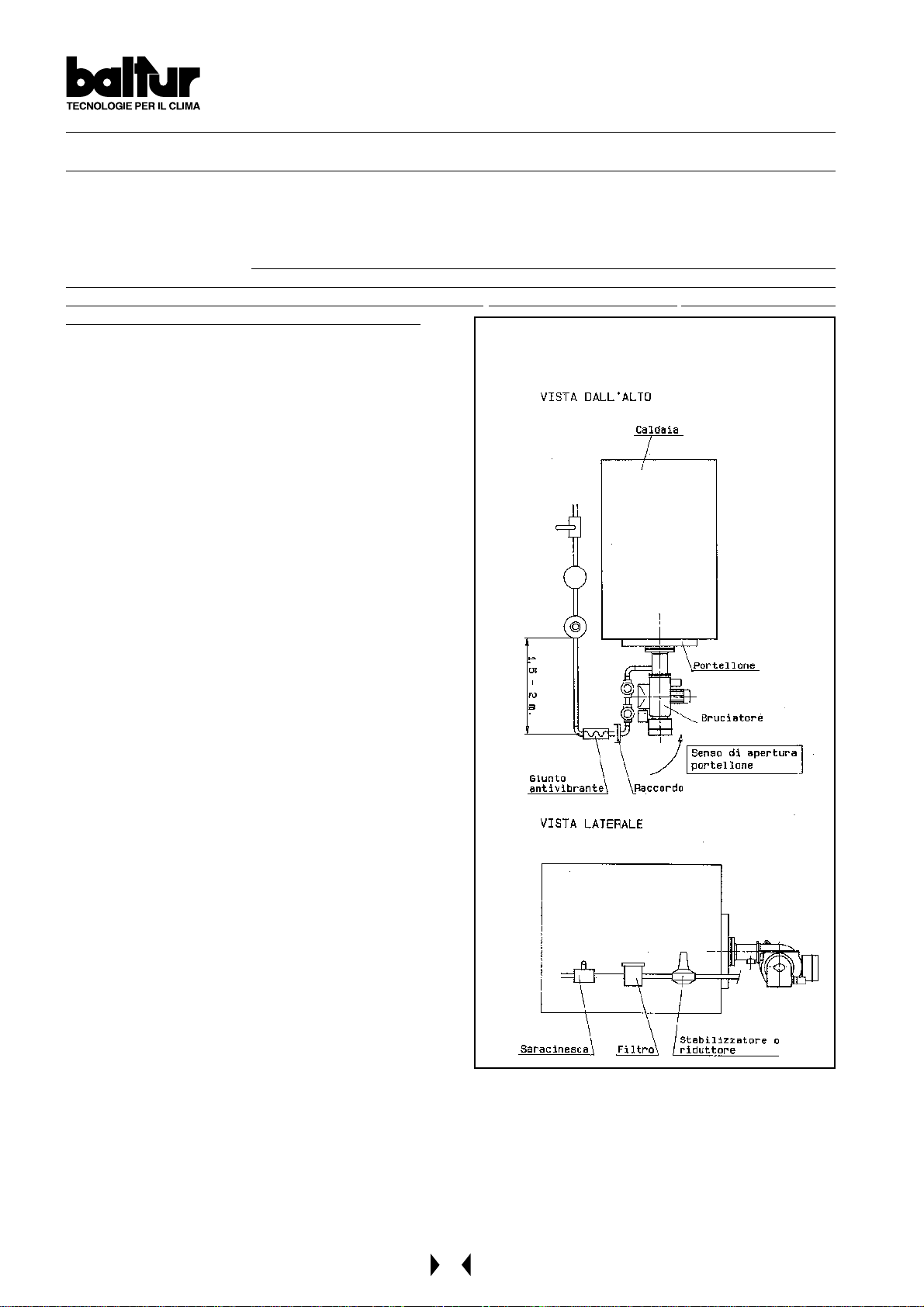

GAS FEED SYSTEM AT LOW PRESSURE ( max. 400 mm.C.A )

When the burner has been correctly fastened to the boiler, proceed with connecting it to the gas pipeline

(see BT 8780 and BT 1387). The dimension of the gas adduction pipeline should be in proportion to its length and

to gas delivery and the load loss should not exceed 5 mm W. C. (see diagram). It must also be perfectly hermetic

and adequately tested before the burner’s general inspection. It is indispensable to install a proper fitting on the

pipeline, in proximity to the burner, to allow for easy disassembling of the burner and/or opening of the boiler door .

In addition, the following should be installed: a cut -off cock, a gas filter , a st abilizer or a pressure regulator (when

the feed pressure is superior to 400 mm W. C. = 0,04 Kg/cm2), and an antivibration joint. These parts should be

installed as described in our drawing (see BT 8780).

We consider it useful to give the following practical tips for

installing the essential accessories on the gas pipeline near

to the burner:

1) To avoid big drops in pressure on ignition, the length of

the pipeline between the point where the stabilizer or

reducer is fitted and the burner should be from 1,5 to 2

m. This pipe must have a diameter equal or superior to

that of the burner attachment fitting.

2) The fitting must be applied on horizontal pipes.

This is to avoid any impurities falling into the pipes or

entering the stabilizer during cleaning.

3) T o get the best performance out of the pressure st abilizer,

it is advisable to fit it onto horizontal pipes, after the filter .

In this way, the vertical movement of the entire mobile

part (shutter) of the stabilizer is rapid. (If the movement

of the mobile part were horizontal - with the stabilizer

fitted into vertical pipes - friction to the guide bush/es of

the pin to which the entire mobile part is fitted would

delay movement).

GENERAL DIAGRAM FOR INSTALLATION OF

GATE-FILTER-STABILIZER-ANTIVIBRA TION JOINT

OPENABLE PITTING

N° BT 8780

4) We advise installing a bend directly onto the burner gas

ramp before applying the removable fitting. This layout

makes it possible to open the boiler door, if there is one,

after the pipe fitting itself has been opened. The above

information is clearly illustrated in drawing BT 8780.

12

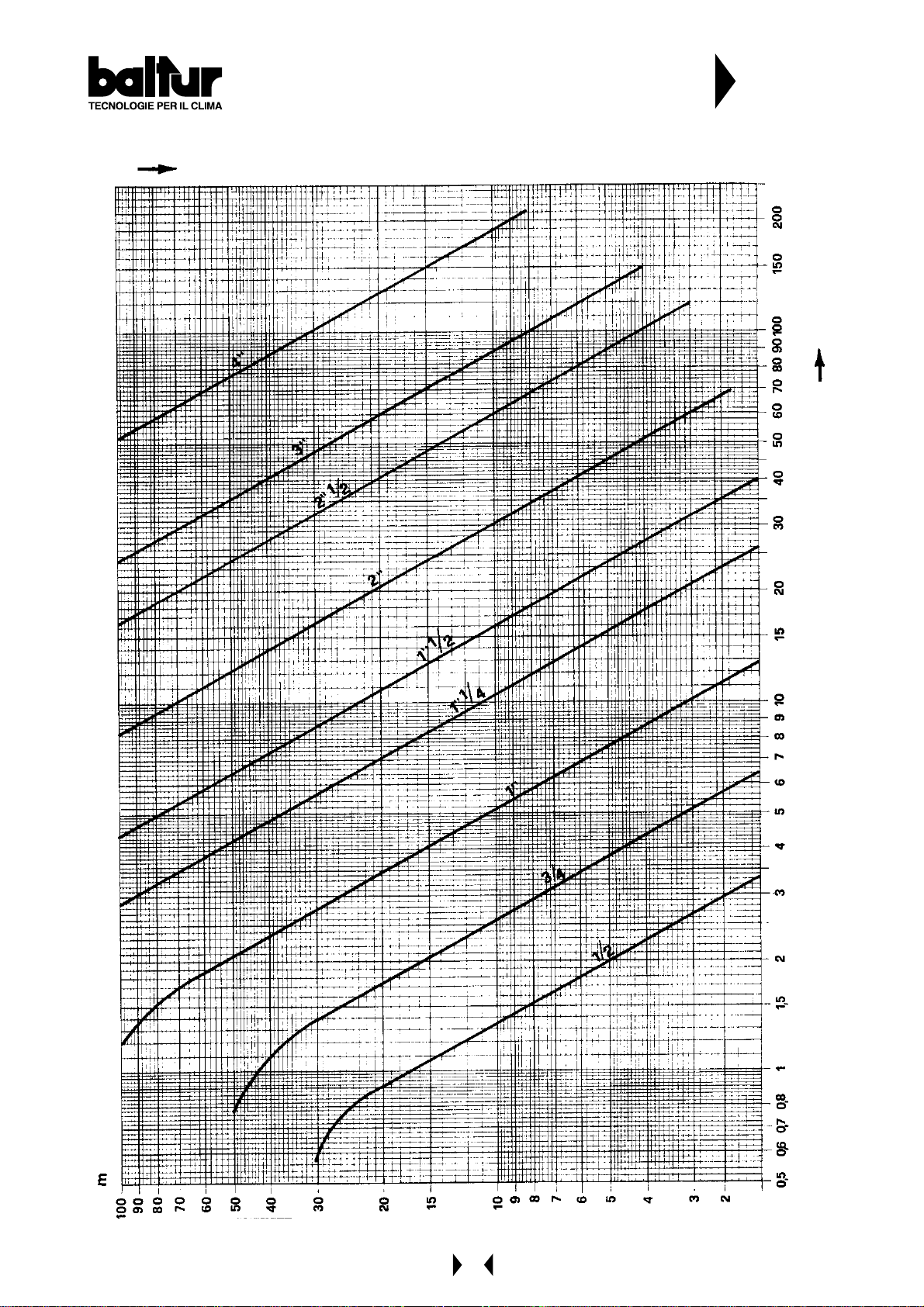

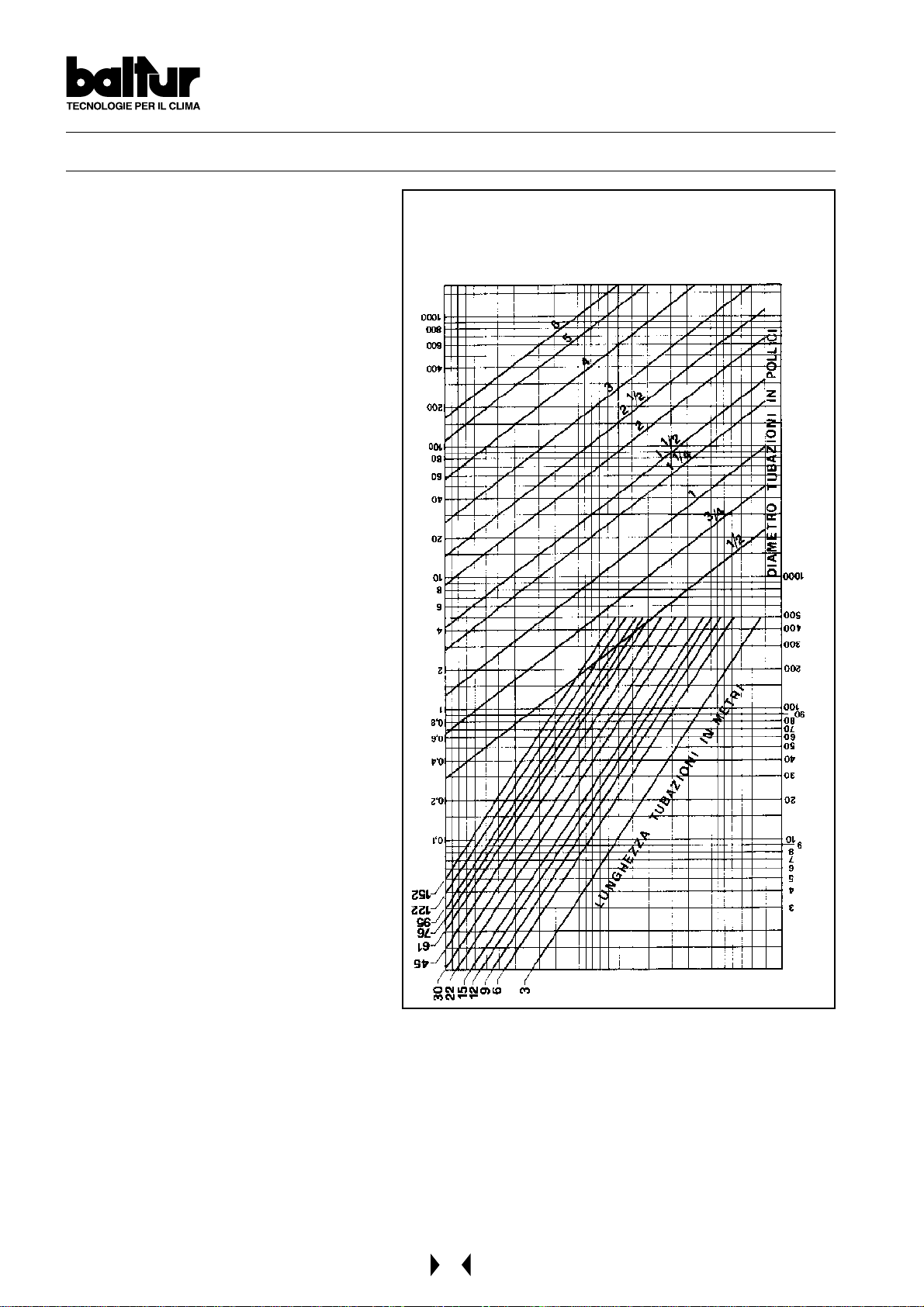

FLOW (m3/h) METHANE GAS (d=0,85) IN

COMMERCIAL GAS PIPES (UNI 3824-68)

LOAD LOSS MAX. 5 mm W . C.

VIRTUAL LENGTH IN METERS

N° BT 1387

/h

3

FLOW m

13

GAS FEED SYSTEM AT AVERAGE PRESSURE a few bars (see BT 8058-BT 8530/1-8531/1)

When high delivery is required, the Gas

Distributing Company requests the installation of

a unit comprising a pressure reducer and a meter,

and then connects it to the gas pipe network at

average pressure (a few bars).

This unit can be supplied by the Gas Distributing

Company or by the user , but should be according

to the Gas Company’s precise instructions.

The unit’s pressure reducer should be large

enough to supply the maximum gas delivery

required by the burner at the rate of pressure

normally estimated for it.

From experience, we would recommend utilising

a large-scale reducer in order to attenuate the

notable increase in pressure which occurs when

the burner comes to a standstill, with a high

delivery . (Regulations require that the gas valves

close in less than one second).

As an indication, we would advise using a reducer

capable of producing at delivery (m3/h) about

double that of the maximum amount estimated

for the burner.

If several burners are to be used, each one should

have its own pressure reducer; this will enable

the gas feed pressure to the burner to be

maintained at a constant level even if only one

burner is operating at the time.

Consequently , it is possible to accurately regulate

the delivery and therefore the combustion, and

thus improve yield.

The dimension of the gas pipeline should be in

function with the quantity of gas it has to deliver.

We advise maintaining the load loss at a low level

(not more than 10% of the gas pressure value at

the burner); it should be kept in mind that the

load loss is added to the pressure existing when

the burner stops and therefore a subsequent start

up will occur at a pressure that rises in

accordance with an increase in the pipe’s load

loss. Should the gas pressure reach

unacceptable values when the burner stops

(rapid closure of the gas valves), it is necessary

to install between the reducer and the first valve

of the burner an automatic overflow valve and

relative conveying pipe, of suitable section, in the

open air.

The end of conveying pipe in the open air should terminate in a suitable place, be protected from rain and have a

flame trap. The overflow valve should be regulated in such a way as to completely unload excessive pressure.

See diagram BT 8058 for gas pipeline dimensions.

Near to the burner should also be fitted a cut-off ball cock, a gas filter , an anti-vibration joint and a flanged fitting

(see BT 8530/1 and BT 8531/1).

DIAGRAM FOR CALCULATING THE DIAMETER OF THE

PIPES IN RELATION TO THEIR LENGTH AND GAS FLOW

/h OF METHANE p.a. 0,60

c

FLOW IN m

LENGTH OF PIPES IN METERS

DIAMETER OF PIPES IN INCHES

O

2

PRESSURE DROP IN mm OF H

N° BT 8058

14

DIAGRAM OF CONNECTING MORE THAN ONE

BURNER TO THE GAS PIPE NETWORK

A T A VERAGE PRESSURE

1 - Measuring and reducing unit

2 - Interception

3 - Filter

4 - Reducer

5 - Meter

6 - Emergency interception (installed outside)

7 - Ball cock

8 - Filter

9 - Final reducer or stabilizer

10- Anti-vibration joint

11- A couple of flane

D = Distance between pressure stabilizer and valve about 1,5 ÷ 2 m

N° BT 8530/1

DIAGRAM OF CONNECTING A BURNER TO THE GAS PIPE NETWORK AT

A VERAGE PRESSURE

1 - Measuring and reducing unit

2 - Interception

3 - Filter

4 - Reducer

5 - Meter

6 - Wire gauze flame trap

7 - Eventual automatic overflow valve (it should obviously

unload outside in a suitable place)

8 - Emergency interception installed outside

9 - Ball cock

10- Anti-vibration joint

11- A couple of flange

N° BT 8531/1

15

ELECTRICAL CONNECTIONS

It is advisable to make all connections with flexible electric wire.

The electric lines should be at an adequate distance from hot parts.

Make sure that the electric line to which the unit will be connected has frequency and voltage ratings suitable for

the burner.

Check that the main line, the relevant switch with fuses (essential) and the current limiter (if required) are capable

of withstanding the maximum current absorber by the burner .

For details, refer to the specific electric diagram for each single burner .

FUEL FEED SYSTEM

The burner pump should receive fuel from a feed circuit which has an ancillary pump and, in some cases, a

pressure regulator capable of modifying the pressure value 0,2 to 1 bar (see drawing BT 0002901120).

In this case, the value of the fuel feed pressure at the burner pump (0,2 ÷ 1 bar) should not vary when the burner

is at a standstill or when it is operating at the maximum fuel delivery required by the boiler.

Normally it is possible to realize a circuit without a pressure regulator as shown in drawing n° BT 8666/3.

The feed circuit must be realized according to drawing 0002901 120 or to drawing BT 8666/3.

The dimension of the pipelines should be in function with their length and with the output of the pump utilized.

Our instructions cover the basic requirements needed to ensure efficient operations.

All rules and regulations existing in the country of installation should be strictly complied with and the local fire

brigade should be consulted.

FURTHER INSTRUCTIONS TO START A MIXED BURNER

It is advisable to first carry out the starting with the liquid fuel because in this case the delivery is conditioned by the

available nozzle whereas the delivery of methane be varied as you like by working on its delivery regulator .

16

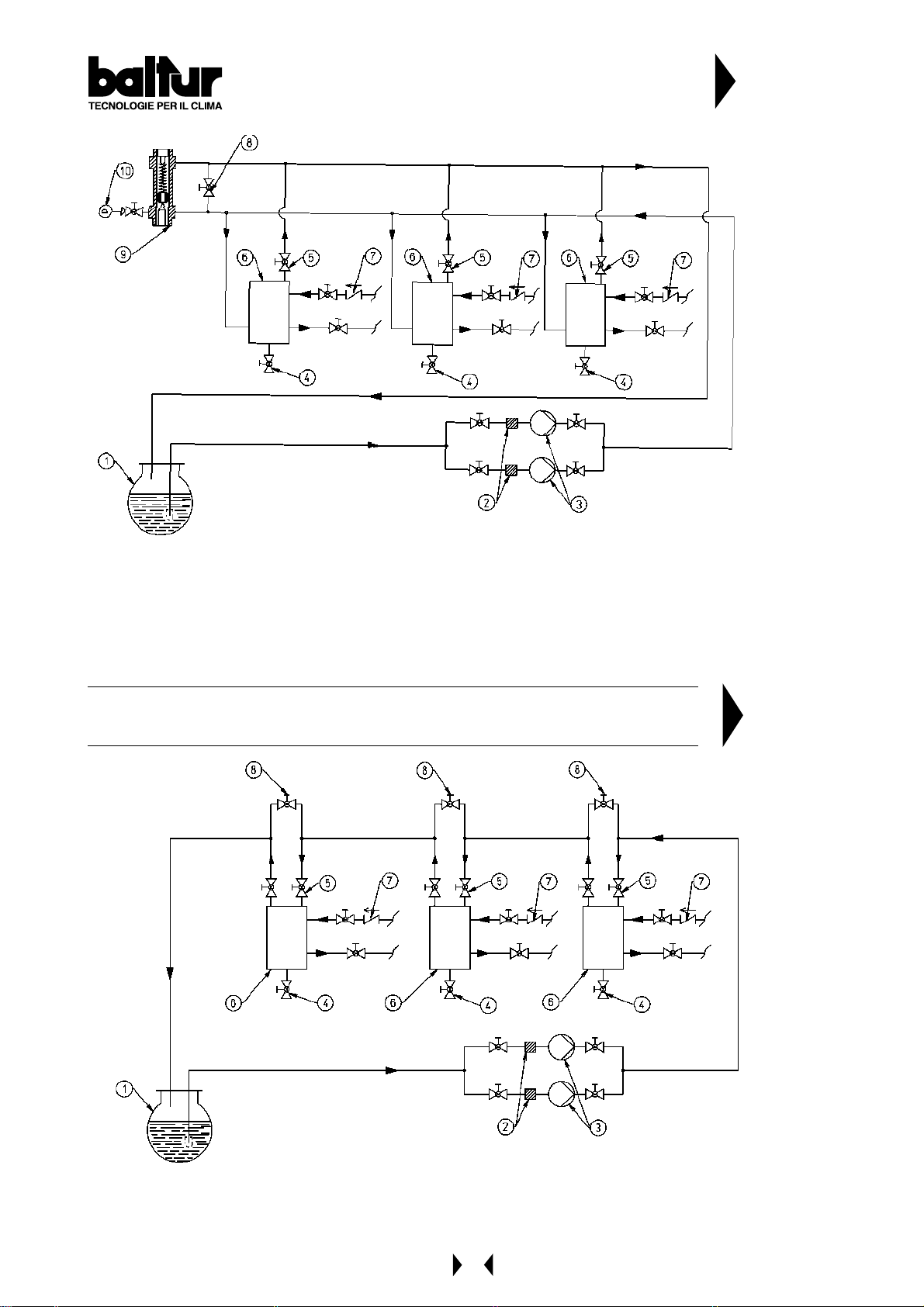

FUEL FEEDING HYDRAULIC DIAGRAM FOR ONE

OR MORE LIGHT OIL BURNERS

WITH MAXIMUM NOMINAL VISCOSITY (5 °E at 50 °C)

1 Main cictern

2 Filter

3 Circulation pump

4 Water and system drain

6 Fuel recovery and degasifier

7 One-way valve

8 By-pass (usually closed)

9 Feeding circuit presure regulator adjustment range between 0.2 and 1 bar

10 Pressure gauge (0 - 4 bar)

The combustible recovery and degasifier

tanks (diameter ~ 150, height ~ 400)

should be installed as near as possible

to the burner and should be about 0,5 m.

higher with respect to the burner's pump.

N° 0002901 120

rev.:19/02/2002

DIAGRAM OF PIPES OF FEED SYSTEM FOR LIGHT OIL BURNERS

WITH MAXIMUM NOMINAL VISCOSITY (5 °E at 50 °C)

1 Main cictern

2 Filter

3 Circulation pumps

4 Water and system drain

5 Air-gas drain usually closed

6 Fuel recovery and degasifier

7 One-way valve

8 By-pass (usually closed)

The combustible recovery and degasifier tanks (diameter

~ 150, height ~ 400) should be installed as near as

possible to the burner and should be about 0,5 m. higher

with respect to the burner's pump.

N° BT 8666/3

17

DESCRIPTION OF TWO ST AGE PROGRESSIVE OPERATIONS WITH LIGHT OIL

COMIST...DSPGM (See BT 8714/2)

This is referred to as a 2-stage progressive operation because the passage from the 1st flame to the 2nd flame

(from the minimum rate to the maximum pre-established rate) takes place gradually both as delivery of combustion

air and of fuel. The burner’s control box (cyclic relay) is connected by operating panel switch ( I ).

Control box specifications

Control box

& relative

Programmer

LFL 1.333

Cyclic relay

The cyclic relay control box carries out the ignition programme by starting up the fan motor and thus the pump in

order to effect the pre-ventilation and light oil pre-circulation phases.

It is necessary that the air pressure supplied by the fan is sufficient to cause the intervention of the relative

pressure switch, if not, the control box will go to “shut down”.

Oil from the pump reaches the atomizer unit and circulates within it because the passages leading to the outward

and return nozzles are closed. This closure is carried out by “closing pins” applied to the ends of the rods.

These “pins” are pressed against their seats by strong springs which are situated at the opposite ends of the rods.

The oil circulates, comes out of the atomizer unit return and arrives at the return pressure regulator.

It passes through this and reaches the pump return and from there it is discharged back into the return.

Oil circulation, as described above, should be carried out at a pressure value slightly higher (by some bar) than the

minimum pressure at which the return pressure regulator has been set (10 ÷ 12 bar).

Duration of the pre-ventilation and oil pre-circulation phase is not as foreseen by the control box, because it is

effected when the air shutter is in an open position.

The pre-ventilation and pre-circulation time is calculated by summing together the times of the following manoeuvres:

- the delivery regulation servomotor’s opening stroke (fuel/air) +

- preventilation time foreseen by the control box +

- the closing stroke of the delivery regulation servomotor (fuel/air) until ignition air position.

Subsequently , the control box continues carrying out the ignition programme by connecting the ignition transformer

which feeds the electrodes with high voltage. The voltage between the electrodes primes the electric spark for

ignition of the fuel/air mixture. After the insertion spark appears, the control box carries voltage to the magnet

which, by means of appropriate levers, moves backwards the two rods which intercept the flow (outward and

return) of light oil to the nozzle. This moving backwards of the rods also determines a closing of the passage (bypass) inside the atomizer unit. Consequently , the pump pressure is taken to the normal value of about 20 ÷ 22 bar .

Deviation of the two rods the closing seat, now permits the fuel to enter the nozzle at the pressure at which the

pump has been regulated at (20 ÷ 22 bar), and comes out of the nozzle adequately atomized.

The return pressure, which determines delivery to the furnace, is regulated by the return pressure regulator.

The value of the ignition flow rate (minimum delivery) should be about 10 ÷ 12 bar.

The atomized light oil which comes out of the nozzle is mixed with air supplied by the fan and is then ignited by the

spark of the electrodes. Flame presence is detected by the photocell UV.

The programme proceeds and surpasses the “shut down” position, disconnects the ignition transformer and by

this point on the burner is operating at minimum output.

If the boiler thermostat (or pressure switch) of the 2nd stage allows it (regulated at a temperature or pressure value

superior to that existing in the boiler), the servomotor which regulates the delivery starts turning and determines a

gradual increase in the fuel delivery and in the relative combustion air until it reaches the maximum delivery value

at which the burner has been regulated. The increase in fuel delivery is determined by a disk with a varied profile

which, by rotating, can determine a greater compression of the return pressure regulator spring and thus an

increase in the pressure itself. When the return pressure increases, there is also a corresponding increase in fuel

delivery . There should also be an adequate increase in combustion air to meet the increase in fuel delivery.

Adjustment can be carried out at first regulation by operating the screws which vary the profile of the commend

disk of the combustion air regulator.

Safety

time in

seconds

3

Pre-Ventilation &

Oil Pre-circulation

Time

in seconds

31,5

Pre-ignition

Time

in seconds

6

Post-ignition

Time

in seconds

3

Time between

1st flame & Start

of Modulation

in seconds

12

18

Fuel and combustion air delivery both increase at the same time until they reach maximum value (light oil pressure

at the return pressure regulator is equal to about 18 ÷ 20 bar if the pressure at the pump is at the value of 20 ÷ 22

bar). The burner remains in the maximum delivery position until the temperature or pressure reaches the limit set

for the intervention of the boiler thermostat (or pressure switch) of the 2nd stage and makes the servomotor

regulating fuel/air delivery rotate in the opposite sense of direction, a causing gradual reduction in fuel delivery and

a relative reduction in combustion air until they reach minimum value.

Should the maximum temperature (pressure, if steam boiler), be reached even with fuel and combustion air

delivery at a minimum, the thermostat (pressure switch, if steam boiler) will intervene when the value at which it

has been set is reached, and bring the burner to a standstill. When the temperature (pressure, if steam boiler)

drops below the intervention limit of the “shut down” device, the burner will start up again as previously described.

During normal operations, the boiler thermostat / pressure switch of the 2nd stage fitted to the boiler detects the

variations requested and automatically proceeds with adapting the fuel and combustion air delivery by inserting

the servomotor which regulates delivery (fuel/air). This will rotate in such a way as to obtain an increase or a

decrease. In this way , the delivery regulating system (fuel/air) reaches a position of equilibrium which corresponds

to a fuel delivery and a relative combustion air delivery equal to the quantity of heat required by the boiler.

As in indication, it should be kept in mind that the field of variation in output obtainable with good combustion is

from 1 to 1/3 of the maximum output given on the rating plate.

Note: The air pressure switch must be set when the burner is started up and must be in function with the pressure

value verified during operations with the ignition flame; otherwise the control box will go to “shut down”.

DESCRIPTION OF MODULATING OPERATIONS WITH LIGHT OIL (COMIST...MM) (See BT 8714/2)

The burner’s control box (cyclic relay) is connected by operating panel switch ( I ).

Control box specifications

Control box

& relative

Programmer

LFL 1.333

Safety Time

in seconds

3

Pre-Ventilation &

Oil Pre-circulation

Time

in seconds

31,5

Pre-ignition

Time

in seconds

6

Post-ignition

Time

in seconds

3

Time between

1st flame & Start

of Modulation

in seconds

12

Cyclic relay

The cyclic relay control box carries out the ignition programme by starting up the fan motor and thus the pump in

order to effect the pre-ventilation and light oil pre-circulation phases.

It is necessary that the air pressure supplied by the fan is sufficient to cause the intervention of the relative

pressure switch, if not, the control box will go to “shut down”.

Oil from the pump reaches the atomizer unit and circulates within it because the passages leading to the outward

and return nozzles are closed.

This closure is carried out by “closing pins” applied to the ends of the rods.

These “pins” are pressed against their seats by strong springs which are situated at the opposite ends of the rods.

The oil circulates, comes out of the atomizer unit return and arrives at the return pressure regulator.

It passes through this and reaches the pump return and from there it is discharged back into the return.

Oil circulation, as described above, should be carried out at a pressure value slightly higher (by some bar) than the

minimum pressure at which the return pressure regulator has been set (10 ÷ 12 bar).

Duration of the pre-ventilation and oil pre-circulation phase is not as foreseen by the control box, because it is

effected when the air shutter is in an open position.

The pre-ventilation and pre-circulation time is calculated by summing together the times of the following manoeuvres:

- the delivery regulation servomotor’s opening stroke (fuel/air) +

- pre-ventilation time foreseen by the control box +

- the closing stroke of the delivery regulation servomotor (fuel/air) until ignition air

position .

Subsequently , the control box continues carrying out the ignition programme by connecting the ignition transformer

which feeds the electrodes with high voltage.

The voltage between the electrodes primes the electric spark for ignition of the fuel/air mixture.

19

After the insertion spark appears, the control box carries voltage to the magnet which, by means of appropriate

levers, moves backwards the two rods which intercept the flow (outward and return) of light oil to the nozzle.

This moving backwards of the rods also determines a closing of the passage (by-pass) inside the atomizer unit.

Consequently , the pump pressure is t aken to the normal value of about 20 ÷ 22 bar.

Deviation of the two rods from the closing seat, now permits the fuel to enter the nozzle at the pressure at which

the pump has been regulated at (20 ÷ 22 bar), and comes out of the nozzle adequately atomized.

The return pressure, which determines delivery to the furnace, is regulated by the return pressure regulator.

The value of the ignition flow rate (minimum delivery) should be about 10 ÷ 12 bar.

The atomized light oil which comes out of the nozzle is mixed with air supplied by the fan and is then ignited by the

spark of the electrodes. Flame presence is detected by the photocell UV.

The programme proceeds and surpasses the “shut down” position, disconnects the ignition transformer , and then

connects the modulation circuit. The modulation motor commands an increase in the delivery of fuel and combustion

air at the same time. The increase in fuel delivery is determined by a disk with a varied profile which, by rotating,

can determine a greater compression of the return pressure regulator spring and thus an increase in the pressure

itself. When the return pressure increases, there is also a corresponding increase in fuel delivery.

There should also be an adequate increase in combustion air to meet the increase in fuel delivery .

Adjustment can be carried out at first regulation by operating the screws which vary the profile of the commend

disk of the combustion air regulator. Fuel and combustion air delivery both increase at the same time until they

reach maximum value (light oil pressure at the return pressure regulator is equal to about 18 ÷ 20 bar if the

pressure at the pump is at the value of 20 ÷ 22 bar). Fuel and combustion air delivery remain at maximum value

until the boiler temperature (pressure, if steam boiler), approaches the value at which it has been set and causes

the servomotor regulating fuel/air delivery to reverse its previous sense of movement. The return movement of the

modulation causes a reduction in light oil delivery and a relative reduction in combustion air.

The modulation system reaches a position of equilibrium which corresponds to a fuel delivery and a relative

combustion air delivery equal to the quantity of heat required by the boiler. With the boiler operating, the probe in

the boiler is aware of load variation in the boiler and automatically commands the modulation motor to make an

adjustment in the light oil delivery and in the relative combustion air.

Should the maximum temperature (pressure, if steam boiler), be reached even with fuel and combustion air

delivery at a minimum, the thermostat (pressure switch, if steam boiler) will intervene when the value at which it

has been set is reached, and bring the burner to a standstill. When the temperature (pressure, if steam boiler)

drops below the intervention limit of the “shut down” device, the burner will start up again as previously described.

The air pressure switch must be regulated at the burner ignition, in relation to the pressure value obtained whit

ignition flame; on the contrary the control box stops in lock position.

Note: As an indication, it should be kept in mind that the field of variation in output obtainable with a good quality

fuel is from 1 to 1/3 of the maximum output given on the rating plate.

20

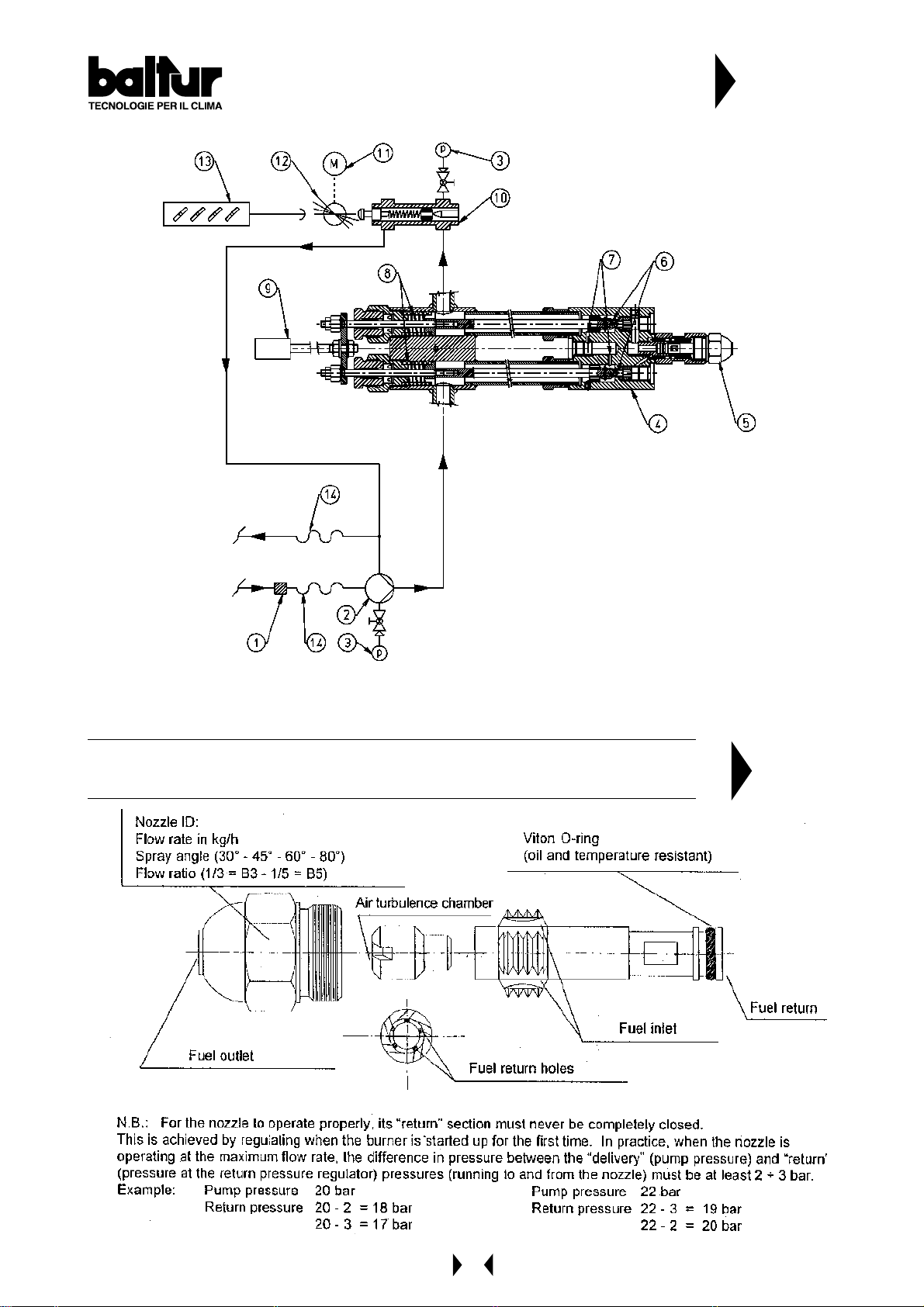

CONNECTION AT THE

FUEL FEEDING

DIAGRAM FOR ONE

OR MORE BURNERS

(SEE 0002901120)

DIAGRAM OF LIGHT OIL MODULATING

BURNERS ( MAGNET - NOZZLE WITHOUT PIN)

1 FILTER

2 BURNER PUMP

3 PRESSURE GAUGE 0 - 40 BAR

4 ATOMIZER UNIT

5 RETURN NOZZLE WITHOUT PIN

6 ROD WITH CLOSING PINS

7 BY-PASS HOLES

8 CLOUSING SPRING

9 OPENING ELECTROMAGNET

10 RETURN PRESSURE REGULATOR

11 MODULATION SERVOMOTOR

12 CONTROL DISK FOR VARIATION OF FUEL / AIR DELIERY

13 AIR REGULATION SHUTTERS

14 FLEXIBLE PIPE

N° BT 8714/2

REV .: 19/02/2002

MIN = 10-12 BAR

MAX = 18-20 BAR

DIAGRAM OF A DISMANTLED ( C.B. ) CHARLES BERGONZO NOZZLE

(WITHOUT PIN)

N° BT 9353/1

21

Loading...

Loading...