baltur BT 75 DSPG, BT 100 DSPG, BT 120 DSPG, BT 300 DSPG, BT 180 DSPG Maintenance, Use And Installation Manual

...

EN

Maintenance,

use and

installation

manual

SP

Manual de

mantenimiento,

uso e

instalación

РУС

Инструкция по

монтажу,

эксплуатации,

техническому

обслуживанию

BT 75 DSPG

BT 100 DSPG

BT 120 DSPG

BT 180 DSPG

BT 250 DSPG

BT 300 DSPG

98319_200910

- Before using the burner for the rst time please carefully read the chapter “WARNINGS NOTES FOR THE USER : HOW

TO USE THE BURNER SAFELY” in this instruction manual, which is an integral and essential part of the product.

- The works on the burner and on the esystem have to be carried out only by competent people.

- Read carefully the instructions before starting the burner and service it.

- The system electric feeding must be disconnected before starting working on it.

- If the works are not carried out correctly it is possible to cause dangerous accidents.

- Antes de empezar a usar el quemador lea detenidamente el folleto “ADVERTENCIAS DIRIGIDAS AL USUARIO PARA USAR CON SEGURIDAD EL QUEMADOR” que va con el manual de instrucciones y que constituye una parte integrante y esencial del producto.

- Lea atentamente las instrucciones antes de poner en funcionamento los quemadores y efectuar las tareas de mantenimiento.

- Los trabajos que se efectúen al quemador y a la instalación deben ser efectuados sólamente por personal cualicado.

- La alimentación eléctrica de la instalación se debe desconectar antes de iniciar los trabajos.

- Si los trabajos no son efectuados correctamente se corre el riesgo de que se produzcan accidentes peligrosos.

E

N

G

L

I

S

H

E

S

P

A

Ñ

- Передначаломэксплуатациигорелки внимательноознакомьтесьс содержанием данной брошюры

“ПРЕДУПРЕЖДЕНИЯ ПОЛЬЗОВАТЕЛЮПО БЕЗОПАСНОЙ ЭКСПЛУАТАЦИИ ГОРЕЛКИ”, которая

входитв комплект инструкции,и, котораяявляетсянеотъемлемойи основной частьюизделия.

- Передпускомгорелкииливыполнениемтехобслуживаниянеобходимовнимательнопрочитатьинструкции.

- Работына горелкеи в системе должнывыполняться квалифицированнымиработниками.

- Перед осуществлением л юбых работ электрическое питание нео бход и мо выключ ить.

- Ра б оты , в ы пол н енные неправиль н ы м образом, могут привести к опа с н ым авариям.

O

L

Р

У

С

С

К

И

Й

3 / 92

98319_200910

Statement of Conformity

We hereby declare under our own responsibility, that our “CE” marked products Series:

Sparkgas…; BTG…; BGN…; TBG...;

Minicomist…; Comist…; RiNOx…, BT…;

BTL…; TBL...; GI…; GI…Mist; PYR…; TS…

Description:

domestic and industrial blown air burners red by gas, oil and dual fuel respect the minimal regulation

of the European Directives:

• 90/396/EEC (G.A.D)

• 92/42/EEC (B.E.D)

• 89/336/EEC (E.M.C. Directive)

• 73/23/EEC (Low Voltage Directive)

• 98/37 EEC (Machinery Directive)

and have been designed and tested in accordance with the European Standards:

• EN 676 (gas and dual fuel, gas side)

• EN 267 (light oil and dual fuel, oil side)

- EN 60335-1:2001:A1:2004+A11:2004 +A2:2006

- EN 60335-2-102:2006

- EN 50165:1997:A1:2001

- EN 55014-1:2000 + A1:2001+A2:2002

- EN 55014-2:1997 + A1:2001

- EN 50366:2004 + A1:2006

- EN 61000-3-2:2000 + A2:2005

E

N

G

L

I

S

H

Surveillance accordingly Gas Appliances Directive 90/396/EEC made by:

CE0085 - DVGW

The Vice President and Managing Director:

Dr. Riccardo Fava

!

Important / note

i

Information

I

Warning / Attention

INDEX

AIR REGULATION SERVOMOTOR ...................................................................................................................................................................19

APPLICATION OF THE BURNER TO BOILER ..................................................................................................................................................11

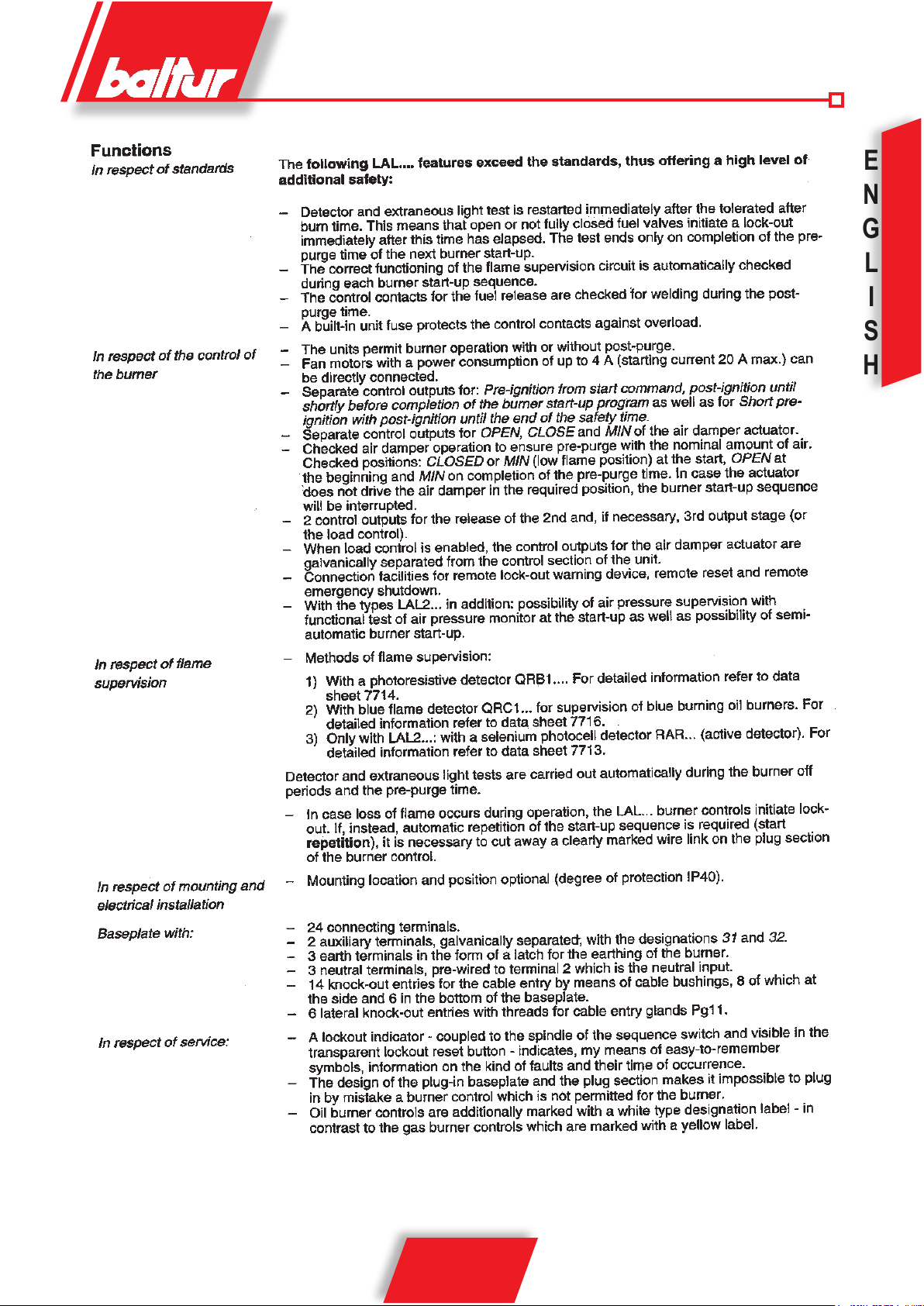

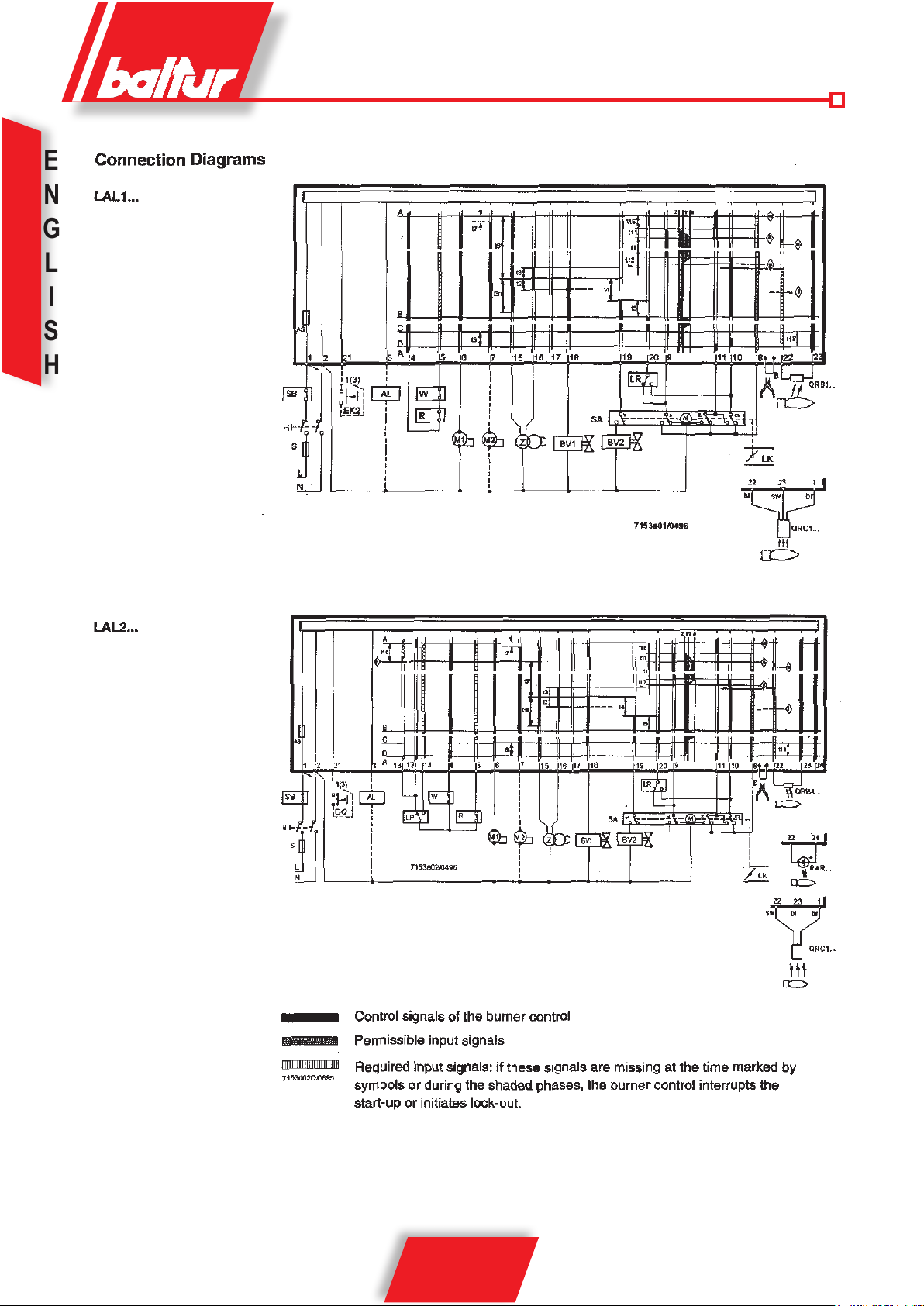

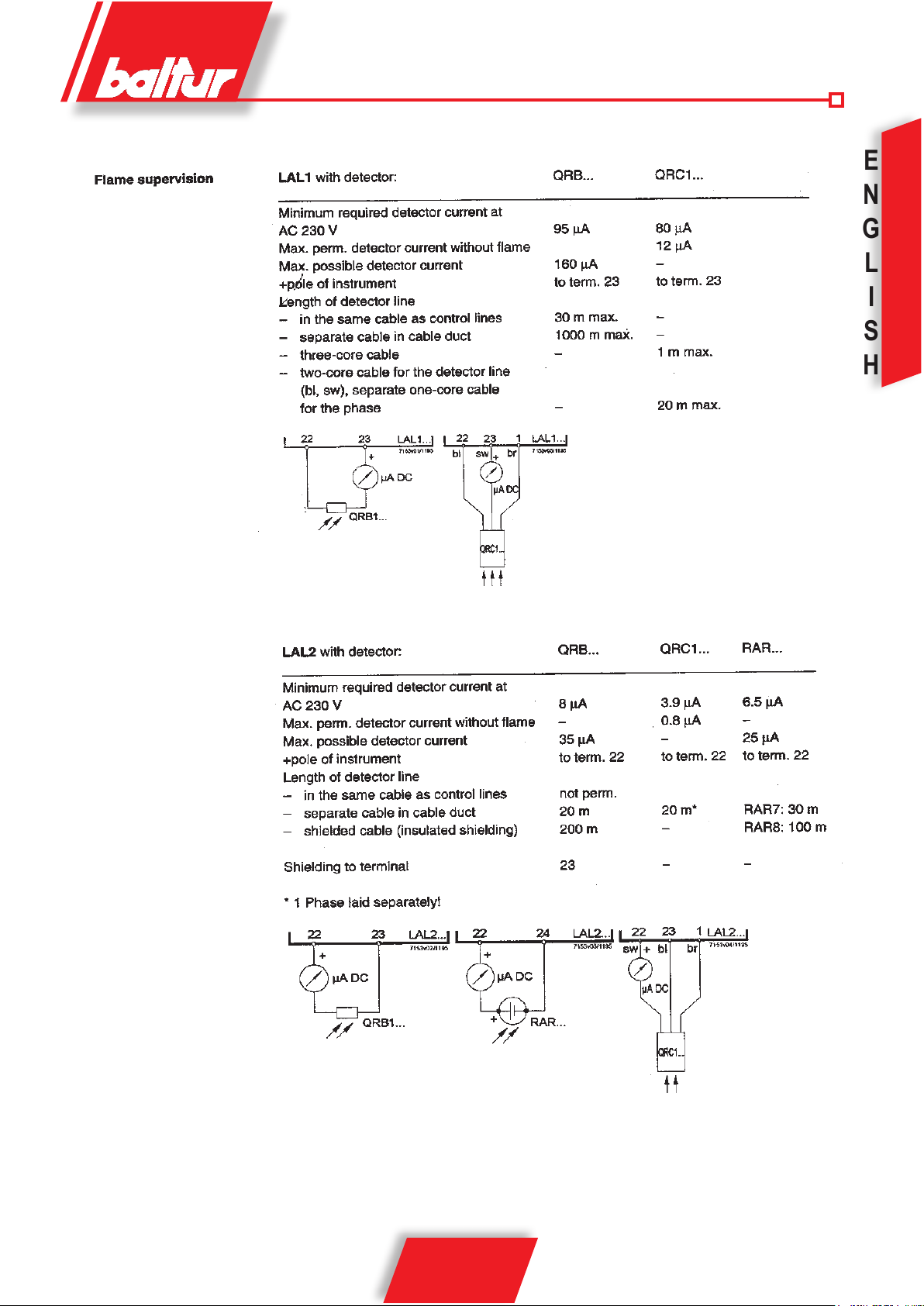

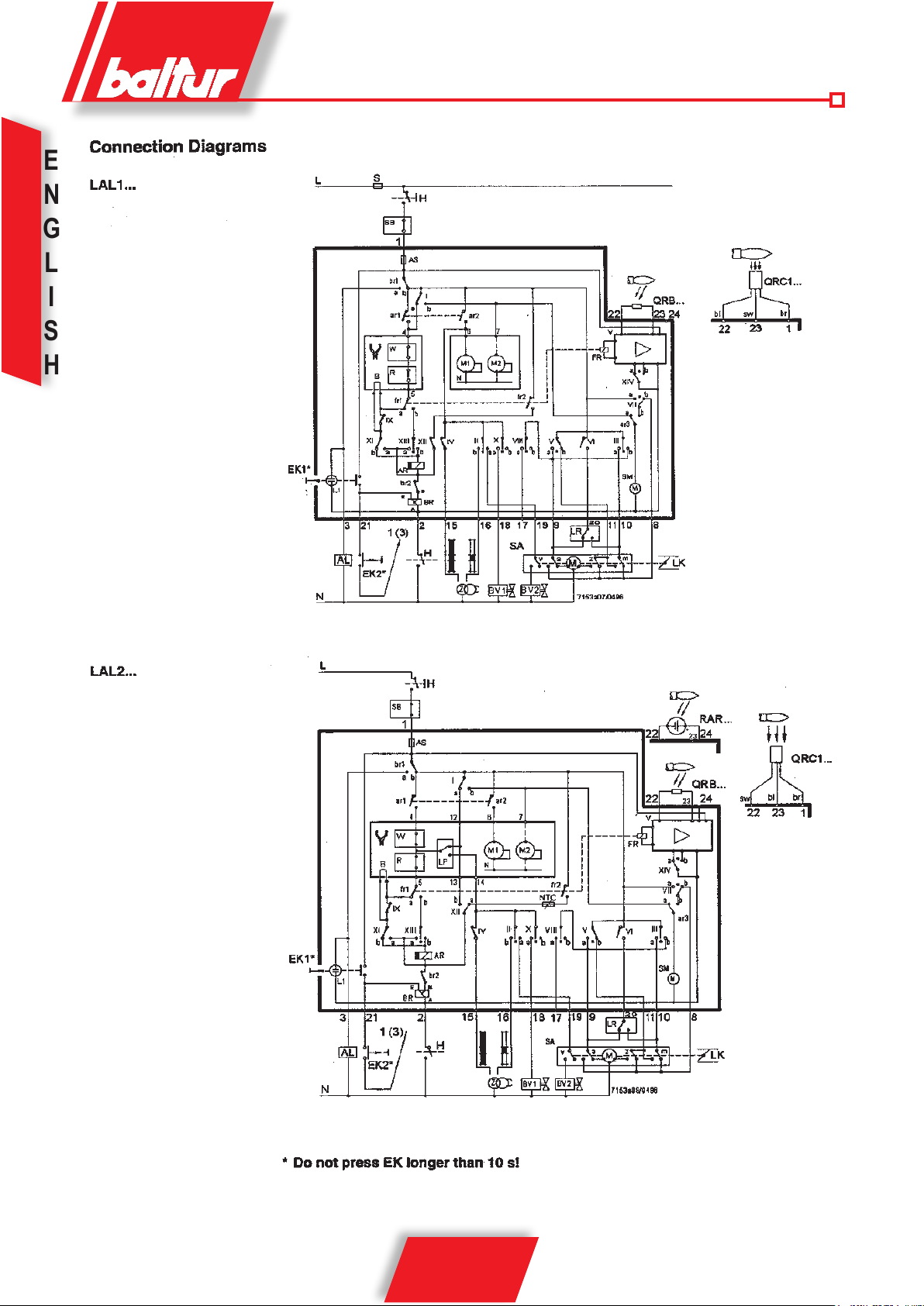

CONTROL BOX ..................................................................................................................................................................................................20

DESCRIPTION OF OPERATION WITH LIGHT OIL ...........................................................................................................................................13

ELECTRICAL CONNECTIONS ..........................................................................................................................................................................11

ESQUEMA ELECTRICO ....................................................................................................................................................................................99

FUEL FEEDING HYDRAULIC DIAGRAM ..........................................................................................................................................................12

FUEL FEED SYSTEM ........................................................................................................................................................................................11

NOZZLE FLOW-RATE TABLE FOR LIGHT OIL .................................................................................................................................................31

REGULATION OF THE COMBUSTION HEAD ..................................................................................................................................................17

STARTING UP AND REGULATION WITH LIGHT OIL .......................................................................................................................................16

TECHNICAL DATA .............................................................................................................................................................................................8

WARNING NOTES FOR THE USER HOW TO USE THE BURNER SAFELY ..................................................................................................6

5 / 32

98319_200910

E

WARNING NOTES FOR THE USER HOW TO

I

USE THE BURNER SAFELY

N

FOREWORD

These warning notes are aimed at ensuring the safe use of the compo-

G

nents of heating systems for civil use and the production of hot water.

They indicate how to act to avoid the essential safety of the components

L

being compromised by incorrect or erroneous installation and by improper

or unreasonable use. The warning notes provided in this guide also seek

I

to make the consumer more aware of safety problems in general, using

necessarily technical but easily understood language. The manufacturer

S

is not liable contractually or extra contractually for any damage caused

by errors in installation and in use, or where there has been any failure to

H

follow the manufacturer’s instructions.

GENERAL WARNING NOTES

• The instruction booklet is an integral and essential part of the product

and must be given to the user. Carefully read the warnings in the booklet as they contain important information regarding safe installation,

use and maintenance. Keep the booklet to hand for consultation when

needed.

• Equipment must be installed in accordance with current regulations,

with the manufacturer’s instructions and by qualied technicians. By

the term ‘qualied technicians’ is meant persons that are competent in

the eld of heating components for civil use and for the production of

hot water and, in particular, assistance centres authorised by the manu-

facturer. Incorrect installation may cause damage or injury to persons,

animals or things. The manufacturer will not in such cases be liable.

• After removing all the packaging make sure the contents are complete

and intact. If in doubt do not use the equipment and return it to the

supplier. The packaging materials (wooden crates, nails, staples, plastic

bags, expanded polystyrene, etc.) must not be left within reach of chil-

dren as they may be dangerous to them. They should also be collected

and disposed on in suitably prepared places so that they do no pollute

the environment.

• Before carrying out any cleaning or maintenance, switch off the equipment at the mains supply, using the system’s switch or shut-off sy-

stems.

• If there is any fault or if the equipment is not working properly, de-activate the equipment and do not attempt to repair it or tamper with it

directly. In such case get in touch with only qualied technicians. Any

product repairs must only be carried out by BALTUR authorised assi-

stance centres using only original spare parts. Failure to act as above

may jeopardise the safety of the equipment. To ensure the efciency

and correct working of the equipment, it is essential to have periodic

maintenance carried out by qualied technicians following the manufacturer’s instructions.

• If the equipment is sold or transferred to another owner or if the owner

moves and leaves the equipment, make sure that the booklet always

goes with the equipment so it can be consulted by the new owner and/

or installer.

• For all equipment with optionals or kits (including electrical), only original accessories must be used.

BURNERS

• This equipment must be used only for its expressly stated use: applied

to boilers, hot air boilers, ovens or other similar equipment and not

exposed to atmospheric agents. Any other use must be regarded as

improper use and hence dangerous.

• The burner must be installed in a suitable room that has ventilation in

accordance with current regulations and in any case sufcient to ensure

correct combustion

• Do not obstruct or reduce the size of the burner’ air intake grills or the

ventilation openings for the room where a burner or a boiler is installed

or dangerous mixtures of toxic and explosive gases may form.

• Before connecting the burner check that the details on the plate correspond to those of the utility supplies (electricity, gas, light oil or other

fuel).

• Do not touch hot parts of the burner. These, normally in the areas near

to the ame and any fuel pre-heating system, become hot when the

equipment is working and stay hot for some time after the burner has

stopped.

• If it is decided not to use the burner any more, the following actions must

be performed by qualied technicians:

a) Switch off the electrical supply by disconnecting the power cable from

the master switch.

b) Cut off the fuel supply using the shut-off valve and remove the control

wheels from their position.

c) Render harmless any potentially dangerous parts.

Special warning notes

• Check that the person who carried out the installation of the burner xed

it securely to the heat generator so that the ame is generated inside

the combustion chamber of the generator itself.

• Before starting up the burner, and at least once a year, have qualied

technicians perform the following operations:

a) Set the burner fuel capacity to the power required by the heat ge-

nerator.

b) Adjust the combustion air ow to obtain combustion yield of at least

the minimum set by current regulations.

c) Carry out a check on combustion to ensure the production of no-

xious or polluting unburnt gases does not exceed limits permitted

by current regulations.

d) Check the adjustment and safety devices are working properly.

e) Check the efciency of the combustion products exhaust duct.

f) Check at the end of the adjustments that all the adjustment devices

mechanical securing systems are properly tightened.

g) Make sure that the use and maintenance manual for the burner is

in the boiler room.

• If the burner repeatedly stops in lock-out, do not keep trying to manually

reset but call a qualied technicians to sort out the problem.

• The running and maintenance of the equipment must only be carried

out by qualied technicians, in compliance with current regulations.

6 / 32

98319_200910

WARNING NOTES FOR THE USER HOW TO

I

USE THE BURNER SAFELY

ELECTRICAL SUPPLY

• The equipment is electrically safe only when it is correctly connected to an

efcient ground connection carried out in accordance with current safety

regulations. It is necessary to check this essential safety requirement.

If in doubt, call for a careful electrical check by a qualied technicians,

since the manufacturer will not be liable for any damage caused by a

poor ground connection.

• Have qualied technicians check that the wiring is suitable for the

maximum power absorption of the equipment, as indicated in the technical

plate, making sure in particular that the diameter of cables is sufcient

for the equipment’s power absorption.

• Adapters, multiple plugs and extension cables may not be used for the

equipment’s power supply.

• An ominpolar switch in accordance with current safety regulations is

required for the mains supply connection.

• The electrical supply to the burner must have neutral to ground

connection. If the ionisation current has control with neutral not to ground

it is essential to make a connection between terminal 2 (neutral) and the

ground for the RC circuit.

• The use of any components that use electricity means that certain

fundamental rules have to followed, including the following:

- do not touch the equipment with parts of the body that are wet or damp

or with damp feet

- do not pull on electrical cables

- do not leave the equipment exposed to atmospheric agents (such as

rain or sun etc.) unless there is express provision for this.

- do not allow the equipment to be used by children or inexpert

persons.

• The power supply cable for the equipment not must be replaced by the

user. If the cable gets damaged, switch off the equipment, and call only

on qualied technicians for its replacement.

• If you decide not to use the equipment for a while it is advisable to switch

off the electrical power supply to all components in the system that use

electricity (pumps, burner, etc.).

Special warning notes when using gas

• Have qualied technicians check the following:

a) that the feed line and the train comply with current law and

regulations.

b) that all the gas connections are properly sealed.

• Do not use the gas pipes to ground electrical equipment.

• Do not leave the equipment on when it is not in use and always close

the gas tap.

• If the user of is away for some time, close the main gas feed tap to the

burner.

• If you smell gas:

a) do not use any electrical switches, the telephone or any other object

that could produce a spark;

b) immediately open doors and windows to create a current of air that

will purify the room;

c) close the gas taps;

d) ask for the help of qualied technicians.

• Do not block ventilation openings in the room where there is gas

equipment or dangerous situations may arise with the build up of toxic

and explosive mixtures.

FLUES FOR HIGH EFFICIENCY BOILERS AND SIMILAR

It should be pointed out that high efciency boilers and similar discharge

combustion products (fumes) at relatively low temperatures into the ue.

In the above situation, traditional ues (in terms of their diameter and heat

insulation) may be suitable because the signicant cooling of the combustion

products in these permits temperatures to fall even below the condensation

point. In a ue that works with condensation there is soot at the point the

exhaust reaches the atmosphere when burning light oil or heavy oil or the

presence of condensate water along the ue itself when gas is being burnt

(methane, LPG, etc.). Flues connected to high efciency boilers and similar

must therefore be of a size (section and heat insulation) for the specic use

to avoid such problems as those described above.

E

N

G

L

I

S

H

GAS, LIGHT OIL, OR OTHER FUEL SUPPLIES

General warning notes

• Installation of the burner must be carried out by qualied technicians

and in compliance with current law and regulations, since incorrect

installation may cause damage to person, animals or things, for which

damage the manufacturer shall not can be held responsible.

• Before installation it is advisable to carry out careful internal cleaning

of all tubing for the fuel feed system to remove any residues that could

jeopardise the proper working of the burner.

• For rst start up of the equipment have qualied technicians carry out

the following checks:

• If you decide not to use the burner for a while, close the tap or taps that

supply the fuel.

98319_200910

7 / 32

TECHNICAL DATA

E

N

G

L

S

H

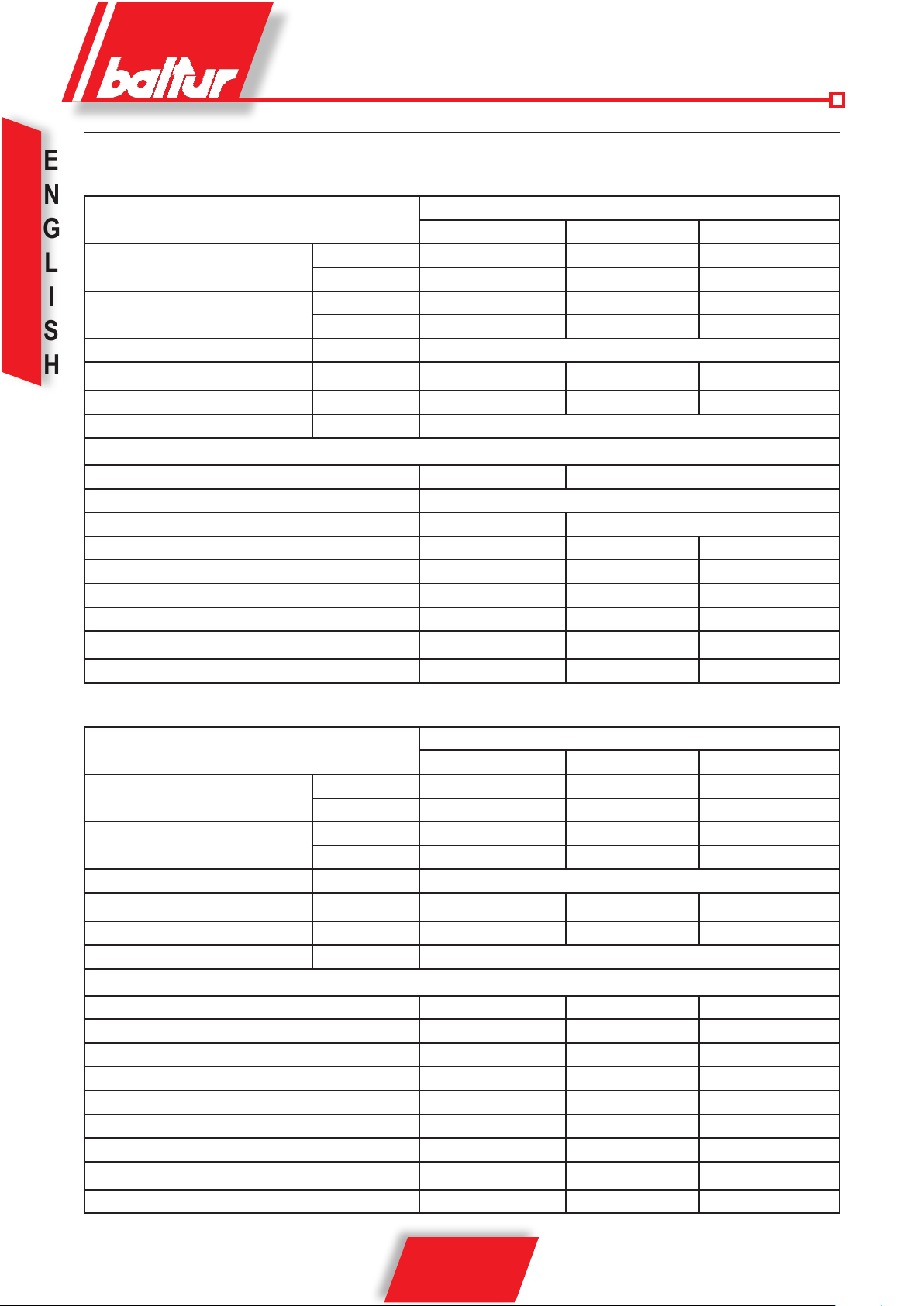

TECHNICAL DATA MODELS

BT 75 DSPG BT 100 DSPG BT 120 DSPG

FLOW RATE

I

THERMAL CAPACITY

FUEL VISCOSITY LIGHT OIL 1,5°E a/at 20°C

FAN MOTOR

TRANSFORMER VOLT 10kV-30mA 10kV-30mA 12kV 30mA

VOLTAGE 3~ 230/400V- 50 Hz

STANDARD ACCESSORIES

BURNER FIXING FLANGE N° 1 N° 2

INSULATING GASKET

ELASTIC COLLAR

STUD BOLTS N°4 M12 N°4 M16 N°4 M16

HEXAGONAL NUTS N°4 M12 N°4 M16 N°4 M16

FLAT WASHERS N°4 Ø12 N°4 Ø16 N°4 Ø16

FLEXIBLE PIPES N°2 - 1” x1" N°2 - 1” x1" N°2 - 1” x1"

NIPPLES

FILTER 1” 1” 1”

MIN. kg/h 35 45 40

MAX. kg/h 75 100 140

MIN. kW 474 533 439

MAX. kW 889 1186 1838

230/400V- 50 Hz 1,1 kW 1,5 kW 2,2 kW

N° 1

- - N° 1

N°2 - 1” x1" N°2 - 1” x1" N°2 - 1” x1"

TECHNICAL DATA MODELS

BT 180 DSPG BT 250 DSPG BT 300 DSPG

FLOW RATE

THERMAL CAPACITY

FUEL VISCOSITY GASOLIO 1,5°E a/at 20°C

FAN MOTOR

TRANSFORMER VOLT 14kV-30mA 14kV-30mA 14kV 30mA

VOLTAGE 3~ 230/400V- 50 Hz

STANDARD ACCESSORIES

BURNER FIXING FLANGE N°1 N°1 N°1

INSULATING GASKET N°1 N°1 N°1

ELASTIC COLLAR - - - - - STUD BOLTS N°4 M12 N°4 M12 N°4 - M20

HEXAGONAL NUTS N°4 M12 N°4 M12 N°4 - M20

FLAT WASHERS N°4 Ø12 N°4 Ø12 N°4 - M20

FLEXIBLE PIPES N°2 - 1”1/4 x 1"1/4 N°2 1" x 1" N°2 - 1”1/4 x 1"1/4

NIPPLES

FILTER 1”1/4 1”1/4 1”1/4

MIN. kg/h 60 74 110

MAX. kg/h 180 270 325

MIN. kW 712 873 1304

MAX. kW 2135 3186 3854

230/400V- 50 Hz 3 kW 7,5 kW 7,5 kW

- - - - - -

8 / 32

98319_200910

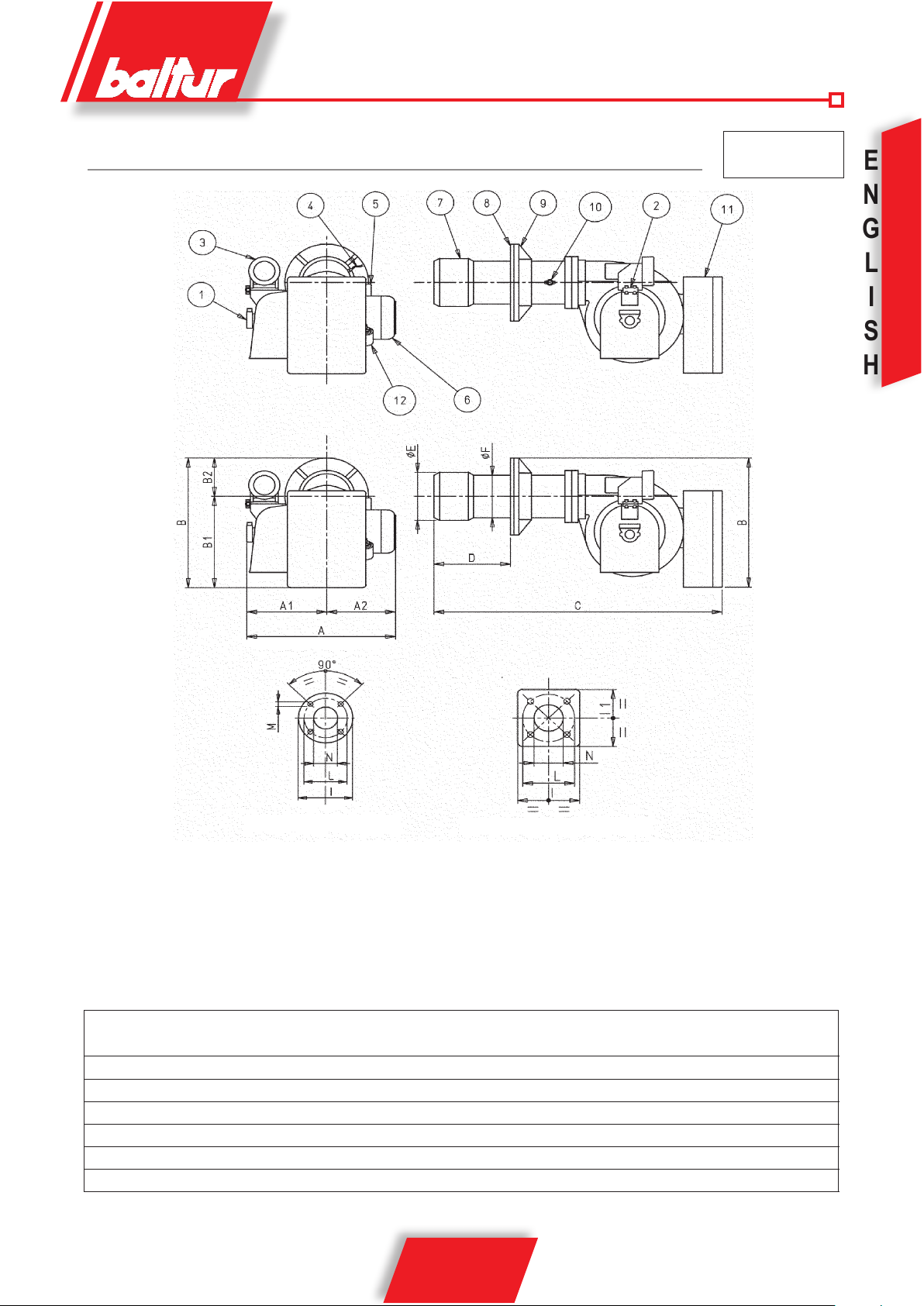

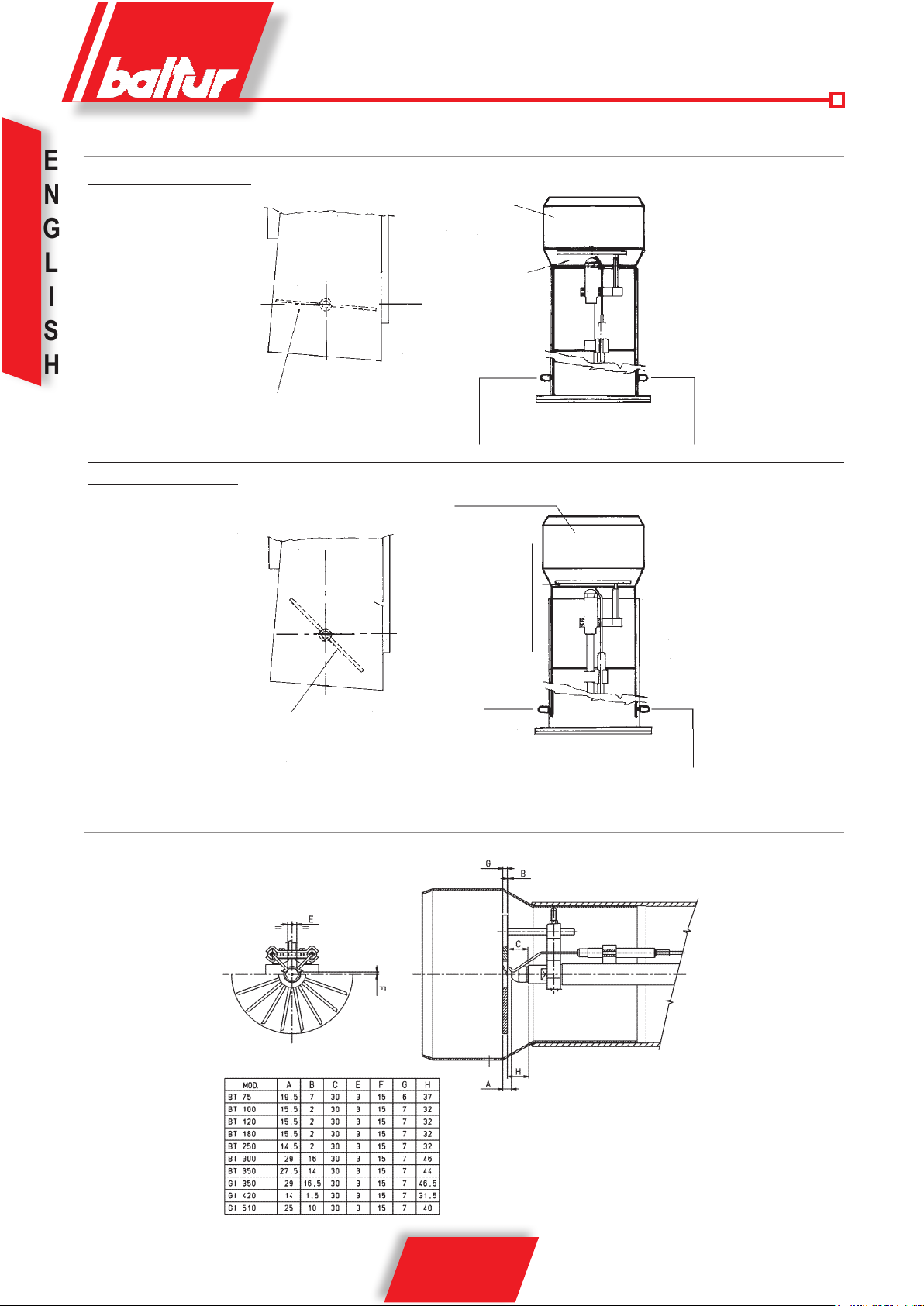

DIMENSIONS

N° 0002270035

E

N

G

L

I

S

H

BT 100 - 120 DSPG

1 - Pump

2 - Pressure regulator valve

3 - Modulator

4 - Photoresistance

5 - Ignition transformer

6 - Fan motor

MOD. A A1 A2 B B1 B2 C D E F I I1 L M N

MIN MAX Ø Ø

BT 75 DSPG 595 310 385 510 365 145 1215 130 ÷ 450 205 160 260 260 225 ÷ 300 M12 170

BT 100 DSPG 670 330 340 525 365 160 1415 210 ÷ 400 230 195 320 - 276 M16 240

BT 120 DSPG 770 390 380 610 450 160 1415 155 ÷ 500 230 195 320 - 276 M16 240

BT 180 DSPG 815 390 425 650 450 200 1700 200 ÷ 535 260 220 320 320 280÷370 M12 230

BT 250 DSPG 1000 520 480 740 580 160 1700 235 ÷ 560 260 220 320 320 280÷370 M12 230

BT 300 DSPG 1000 520 480 800 580 220 1900 245 ÷ 605 360 275 440 440 400÷540 M20 365

98319_200910

BT 75 - 180 - 250 - 300 DSPG

7 - Combustion head

8 - Insulating gasket

9 - Burner xing anges

10 - Combustion head control knob

11 - Electric board

12 - Electromagnet

9 / 32

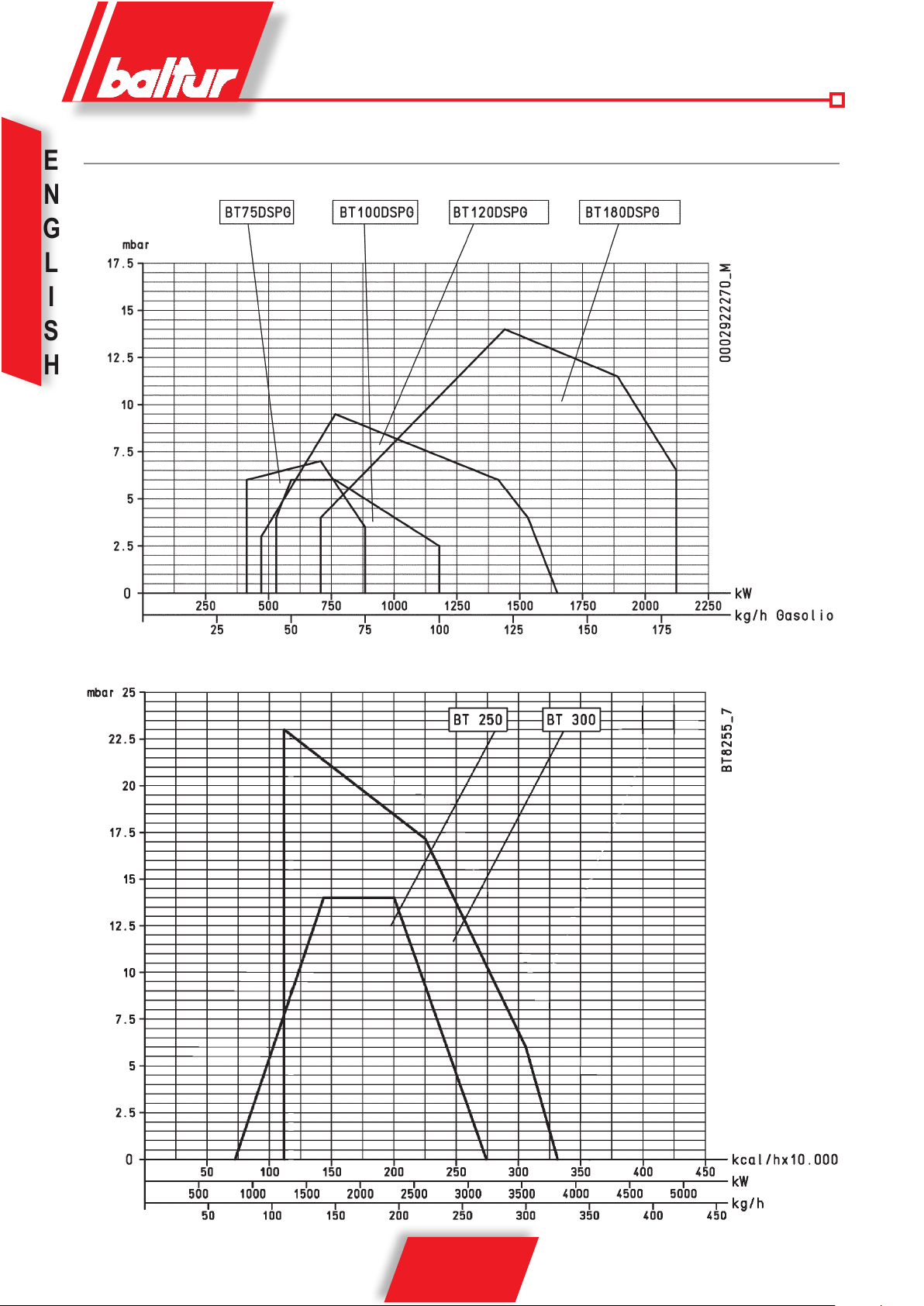

WORKING FIELD

E

N

G

L

I

S

H

10 / 32

98319_200910

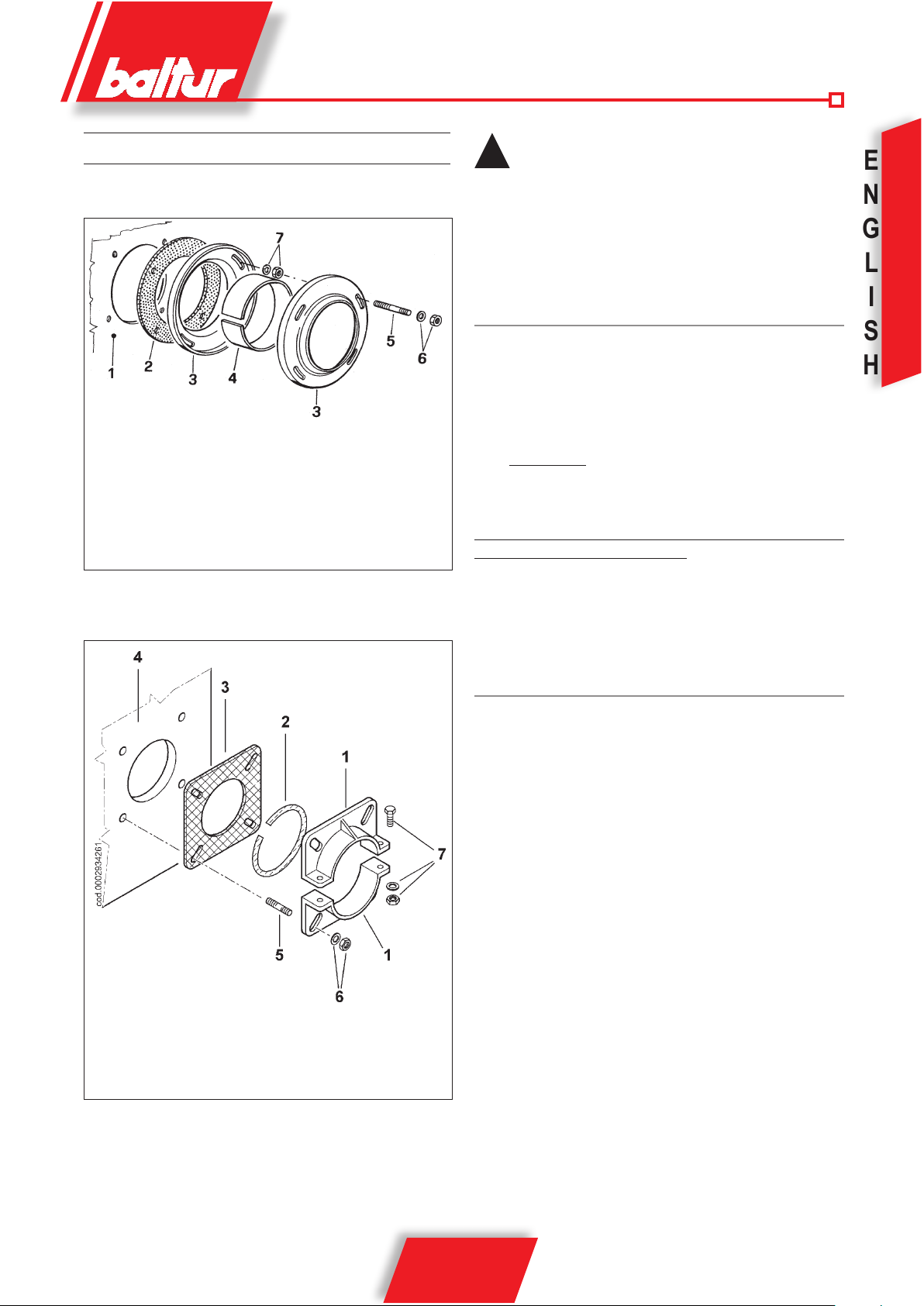

APPLICATION OF THE BURNER TO BOILER

for model BT 75 - 100 - 120 DSPG (steel xing ange)

1 - Boiler plate2 - Insulating gasket

3 - Burner xing ange

4 - Elastic collar

5 - Stud bolt

6 - Locking nut with washer

7 - Nut and washer for fastening the rst ange

for model BT 180 - 250 - 300 DSPG

When tightening the ange, it is important to do it evenly

!

so that the inner faces are parallel between them. Since

the locking system is highly efcient, do not tighten the

nuts too much. During this operation (tightening of the

ange locking nuts) keep the body of the burner lifted

so that the combustion head is kept in a horizontal

position.

N° 0002933330

FUEL FEED SYSTEM

The burner pump should receive fuel from a feed circuit which has

an ancillary pump and, in some cases, a pressure regulator capable

of modifying the pressure value from 0,2 to 1 bar (see drawing N°

0002901120).

In this case, the value of the fuel feed pressure at the burner pump

(0,2 ÷ 1 bar) should not vary when the burner is at a standstill or

when it is operating at the maximum fuel delivery required by the

boiler.

Normally it is possible to realise a circuit without a pressure regulator

as shown in drawing BT 8666/3).

The feed circuit must be realized according to drawing N°

0002901120 or to drawing BT 8666/3.

The dimension of the pipelines should be in function with their length

and with the output of the pump utilized. Our instructions cover the

basic requirements needed to ensure efcient operations. All rules

and regulations existing in the country of installation should be strictly

complied with and the local re brigade should be consulted.

E

N

G

L

I

S

H

1 Burner securing ange

2 Seam with insulating materials

3 Flange with insulating materials

4 Boiler plate

5 Stud bolts,

6 washers and nuts for astening to the boiler

7 Nuts screws and washers to fasten ange the sleeve

ELECTRICAL CONNECTIONS

The burner’s electrical connections are reduced to a minimum.

N° 0002933340

It is advisable to make all connections with exible electric wire.

The electric lines should be at an adequate distance from hot

parts.

Make sure that the electric line to which the unit will be connected

has frequency and voltage ratings suitable for the burner.

Check that the main line, the relevant switch with fuses (essential)

and the current limiter (if required) are capable of with standing the

maximum current absorbed by the burner.

For details, refer to the specic electric diagram for every burner.

11 / 32

98319_200910

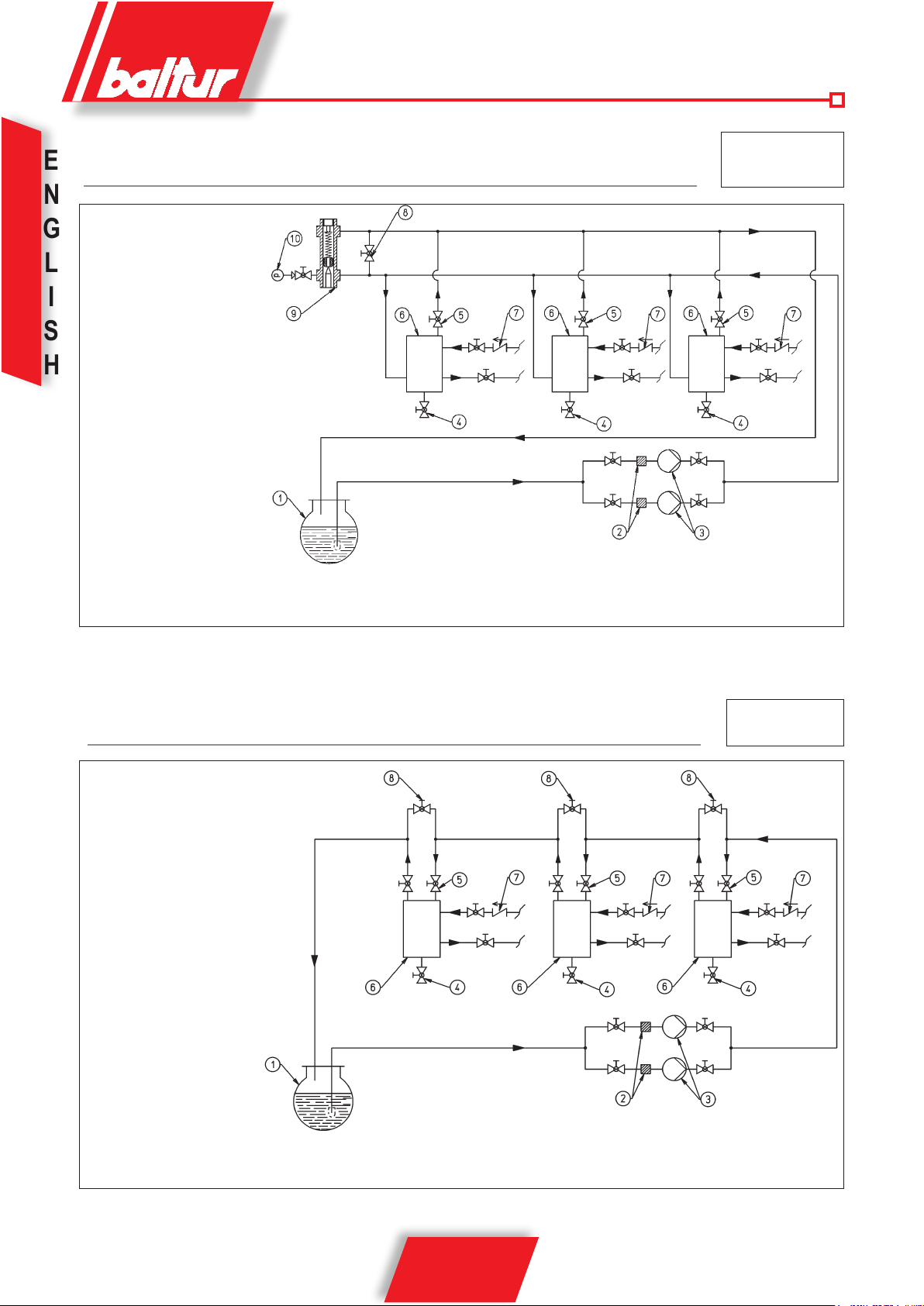

FUEL FEEDING HYDRAULIC DIAGRAM FOR ONE OR MORE LIGHT OIL BURNERS

E

WITH MAXIMUM NOMINAL VISCOSITY (5 °E at 50 °C) FROM 75 TO 300 DSPG

N

1 Main cictern

G

2 Filter

L

3 Circulation pump

4 Water and system drain

I

6 Fuel recovery and degasier

S

7 One-way valve

8 By-pass (usually closed)

H

9 Feeding circuit presure regulator

adjustment range between 0.2 and 1 bar

10 Pressure gauge (0 - 4 bar)

The combustible recovery and degasier tanks (diameter ~ 150, height ~ 400) should be installed as near as possible to the burner

and should be about 0,5 m. higher with respect to the burner's pump.

N° 0002901120

rev.: 19/02/2002

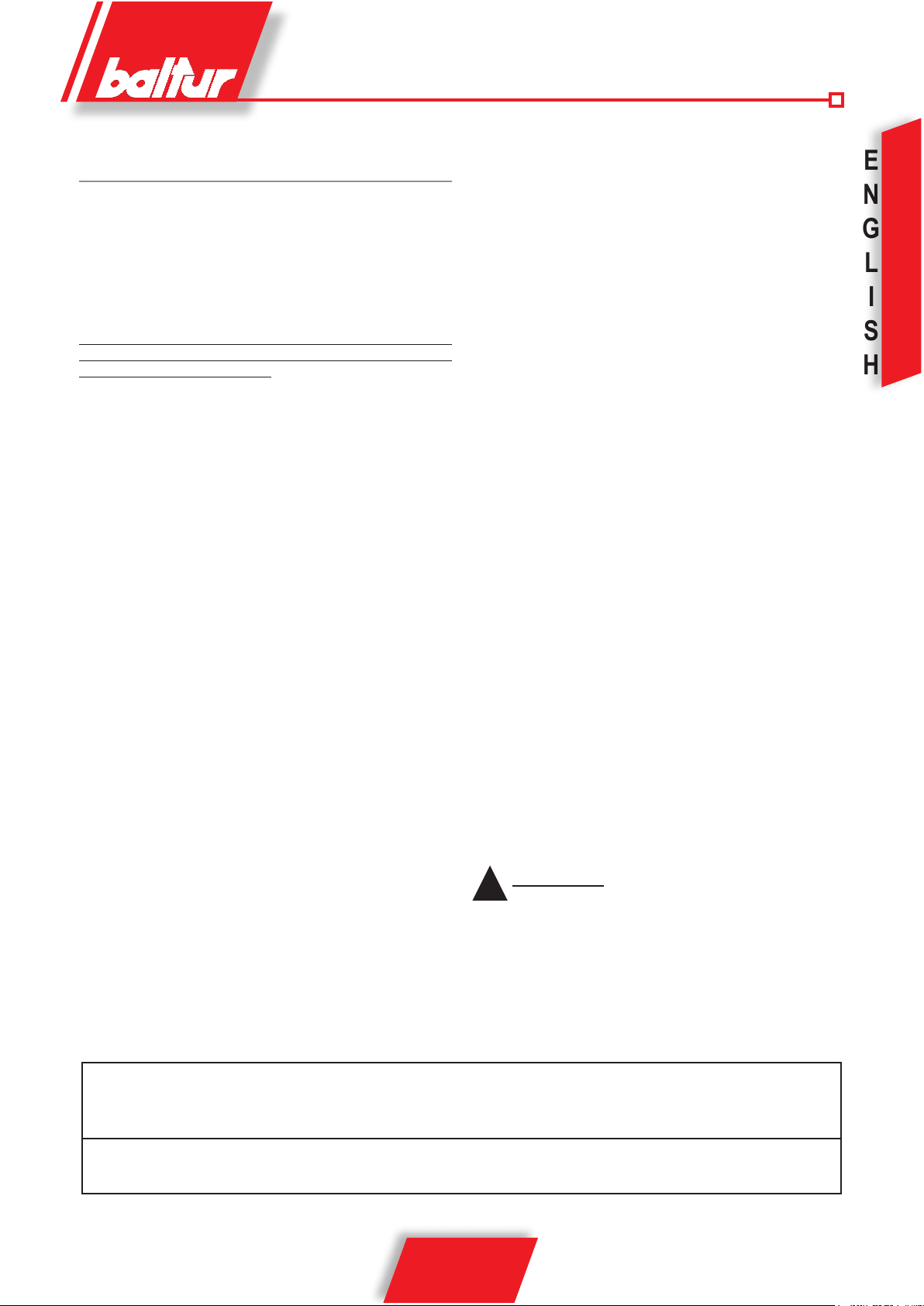

DIAGRAM OF PIPES OF FEED SYSTEM FOR LIGHT OIL BURNERS WITH MAXIMUM

NOMINAL VISCOSITY (5 °E at 50 °C)

1 Main cictern

2 Filter

3 Circulation pumps

4 Water and system drain

5 Air-gas drain usually closed

6 Fuel recovery and degasier

7 One-way valve

8 By-pass (usually closed)

The combustible recovery and degasier tanks (diameter ~ 150, height ~ 400) should be installed as near as possible to the

burner and should be about 0,5 m. higher with respect to the burner's pump.

AL BRUCIATORE

AL BRUCIATORE

N° BT 8666/3

AL BRUCIATORE

12 / 32

98319_200910

DESCRIPTION OF OPERATION WITH LIGHT OIL

(See BT 8714/2)

This is referred as a 2-stage progressive operation because the

passage from the 1st ame to the 2nd ame (from the minimum

rate to the maximum pre-established rate) takes place gradually.

The burner’s control box (cyclic relay) is connected by operating

panel switch ( I ).

The cyclic relay control box carries out the ignition programme by

starting up the fan motor and thus the pump in order to effect the

pre-ventilation and light oil pre-circulation phases.

The pressure of the air supplied by the fan must be sufcient to let

the relative pressure switch come into operation; on the contrary the

control box stops in block position. Oil from the pump reaches the

atomizer unit and is obliged to circulate within it because the passage

leading to the outward and return nozzles are closed.

This closure is carried out by “closing pins” applied to the ends of the

rods. These “pins” are pressed against by strong which are situated

at the apposite ends of the rods. The oil circulates, comes out of the

atomizer unit return and arrives at the return pressure regulator. It

passes through this and reaches the pump return and from there it

is discharged back into the return.

Oil circulation, as described above, should be carried out at a pres-

sure value slightly higher (by some bar) than the minimum pressure

at which the return pressure regulator has been set (10 ÷ 12 bar).

Duration of the pre-ventilation and oil pre-circulation phase is not

22,5 seconds, as foreseen by the control box, because it is effected

when the air shutter is in an open position. The pre-ventilation and

pre-circulation time is calculated by summing together the times of

the following manoeuvres:

the modulation motor’s opening stroke (45 seconds) +

pre-ventilation time foreseen by the control box (22,5 seconds) +

modulation motor’s closing stroke until ignition air position (about

40 seconds)

Therefore, altogether, the duration of the pre-ventilation and oil precirculation phase is about 107 seconds.

Subsequently, the control box continues carrying out the ignition

programme by connecting the ignition transformer which, in turn,

feeds the electrodes with high voltage. High voltage between the

electrodes primes the electric spark for ignition of the fuel/air mixture. 2,5 seconds after the ignition spark appears, the control box

carries voltage to the magnet which, by means of appropriate levers,

moves backwards the two rods which intercept the ow (outward

and return) of light oil to the nozzle. This moving backwards of the

rods also determines a closing of the passage (by-pass) inside the

atomizer unit.

Consequently, the pump pressure is taken to the normal value of

about 20 ÷ 22 bar.

Deviation of the two rods from the closing seat, now permits the

fuel to enter the nozzle at the pressure at which the pump has been

regulated at (20 ÷ 22 bar), and comes out of the nozzle adequately

atomized. The return pressure, which determines delivery to the

furnace, is regulated by the return pressure regulator. The value of

the ignition ow rate (minimum delivery) should be about 10 ÷ 12

bar. The atomized light oil which comes out of the nozzle is mixed

with air supplied by the fan and is then ignited by the spark of the

electrodes. Flame presence is detected by the photoresistance.

The programme proceeds and, after 5 seconds, surpasses the

“shut down” position, disconnects the ignition transformer, and then

connects the modulation circuit. The modulation motor commands

an increase in the delivery of fuel and combustion air at the same

time. The increase in fuel delivery is determined by a disk with a

varied prole which, by rotating, can determine a greater compres-

sion of the return pressure regulator spring and thus an increase

in the pressure itself.

When the return pressure increases, there is also a corresponding

increase in fuel delivery.

There should also be an adequate increase in combustion air to

meet the increase in fuel delivery. Adjustment can be carried out

at rst regulation by operating the screws which vary the prole of

the command disc of the combustion air regulator.

Fuel and combustion air delivery both increase at the same time until

they reach maximum value (light oil pressure at the return pressure

regulator is equal to about 18 ÷ 20 bar if the pressure at the pump

is at the value of 20 ÷ 22 bar).

Fuel and combustion air delivery keeps its maximum value until

the temperature of the boiler (pressure if we have a steam boiler)

approaches the set value on the thermostat (or pressure switch) of

the second stage which determines the return of the delivery regulation servomotor (fuel/air) in the apposite direction to the previous

movement thus gradually reducing the delivery of the gas oil and

of its combustion air to a minimum value.

If even with a minimum fuel and combustion air delivery a maximum

temperature is reached (pressure if we have a steam boiler), at the

set value the thermostat (pressure switch if we have a steam boiler)

determines the complete stop of the burner.

When the temperature lowers (pressure if we have a steam boiler)

below the value causing the activation of the stopping device, the

burner starts up again as described above. Under regular working

conditions, the 2nd stage thermostat (or pressure switch) detects

any variation, in the boiler load and automatically requires the

adjustment of the gas oil delivery and of its combustion air to the

delivery regulation servomotors (fuel/air).

Thus the delivery regulation system (fuel/air) reaches a balance

position corresponding to a fuel delivery and to its combustion air

delivery equal to the heat amount required by the boiler.

As an indication, it should be kept in mind that the eld of

!

variation in output obtainable with a good quality fuel is from

1 to 1/3 of the maximum output given on the rating plate.

E

N

G

L

I

S

H

Control box &

relative Programmer

LAL 1,25

Cyclic relay

Safety Time

in seconds

5

Control box specications

Pre-Ventilation & Oil

Pre-circulation Time

in seconds

22,5

98319_200910

13 / 32

Pre-ignition Time

in seconds

2,5

Post-ignition

Time

in seconds

5

Time between

1st ame & Start of

Modulation

in seconds

15

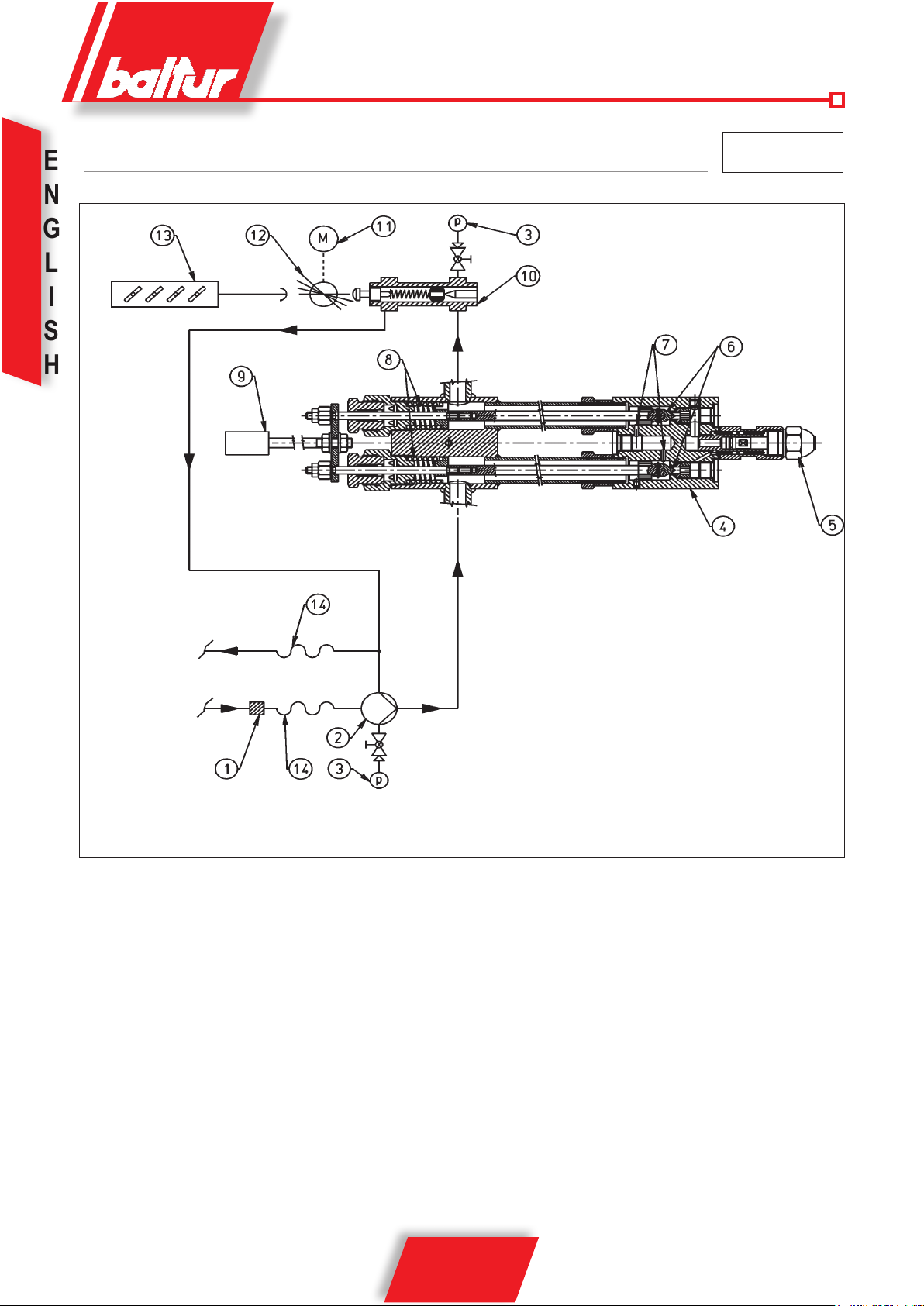

FUEL FEEDING DIAGRAM FOR BURNERS (MAGNET-NOZZLE WITHOUT PIN)

E

N

G

L

I

S

H

1 FILTER

2 BURNER PUMP

3 PRESSURE GAUGE 0 - 40 BAR

4 ATOMIZER UNIT

5 RETURN NOZZLE WITHOUT PIN

CONNECTION AT THE

FUEL FEEDING DIAGRAM FOR ONE OR

MORE BURNERS

(SEE 0002901120)

6 ROD WITH CLOSING PINS

7 BY-PASS HOLES

8 CLOUSING SPRING

9 OPENING ELECTROMAGNET

10 RETURN PRESSURE REGULATOR

11 MODULATION SERVOMOTOR

12 CONTROL DISK FOR VARIATION OF FUEL / AIR DELIERY

13 AIR REGULATION SHUTTERS

14 FLEXIBLE PIPE

N° BT 8714/2

rev.: 19/02/2002

MIN = 10-12 BAR

MAX = 18-20 BAR

14 / 32

98319_200910

DIAGRAM OF A DISMANTLED ( C.B. ) CHARLES BERGONZO NOZZLE (WITHOUT PIN)

Nozzle ID.:

Flow rate kg/h

Spray angle (30° - 45° - 60° - 80°)

Flow ratio (1/3 = B3 - 1/5 = B5)

Air turbolence

chambre

Viton O-ring (oil and teperature resistant)

E

N

G

L

N BT 9353/1

Fuel outlet

Fuel return hole

For the nozzle to operate properly, its "return" section must never be completely closed. This is achived by regulating where the

!

burner is started up for the rst time. In practice, when the nozzle is operating at the maximum ow rate, the difference in pressure

between the "delivery" (pump pressure) and "return" (pressure at the return pressure regulator) pressure (running to and from the

nozzle) must be at least 2 ÷ 3 bar.

Example: Pump pressure 20 bar Pump pressure 22 bar

Return pressure 20 - 2 = 18 bar Return pressure 22 - 3 = 19 bar

Return pressure 20 - 3 = 17 bar Return pressure 22 - 2 = 20 bar

Fuel inlet

Fuel return

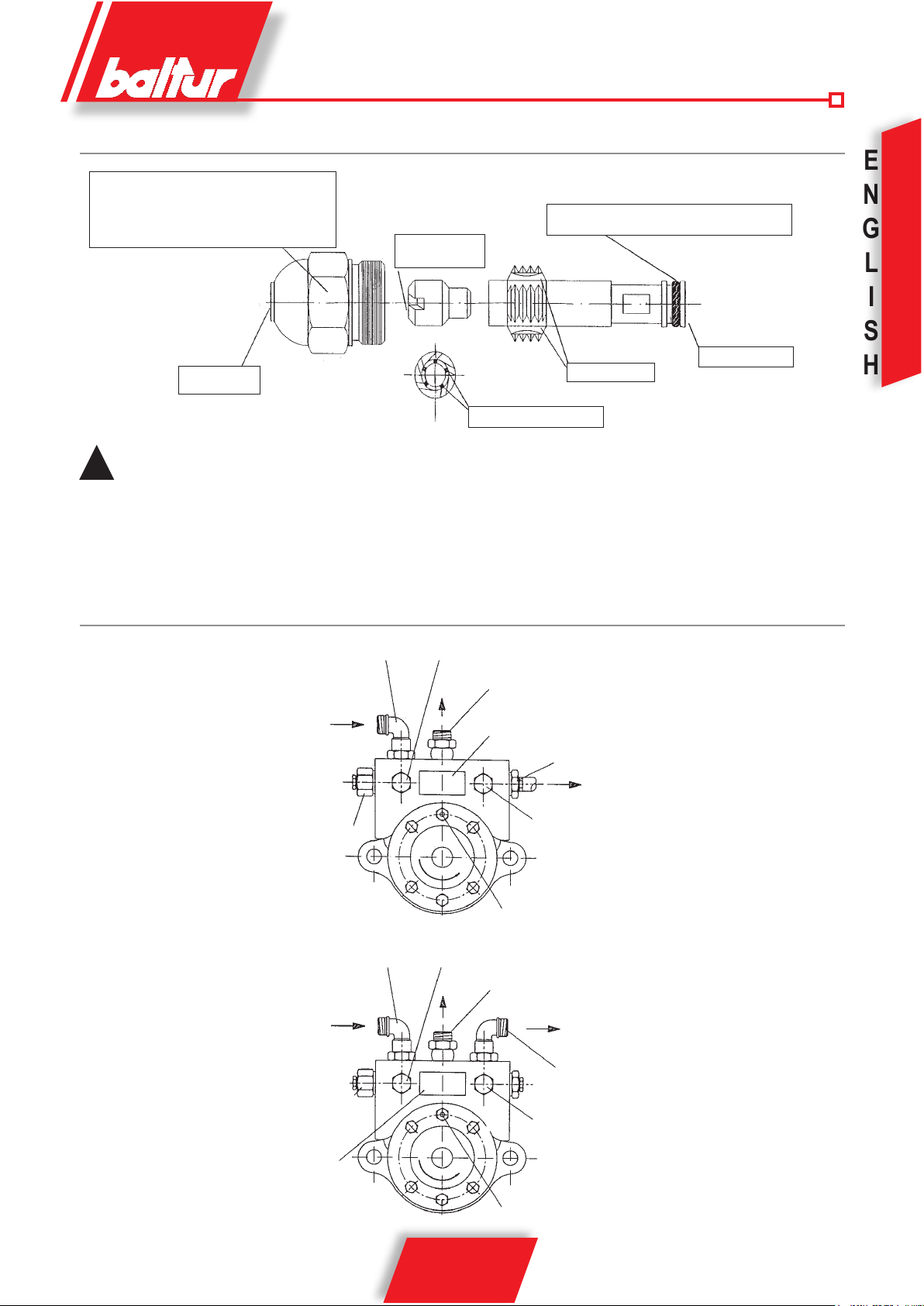

BALTUR PUMP MODEL BT.....

Suction

1/4” Vacuum-meter connection

Return

Pump plate

I

S

H

Pump pressure regulation

(20 ÷ 22 bar)

Pump pressure regulation

(20 ÷ 22 bar)

Pump plate

N° 0002900580

Suction

Delivery (nozzle)

1/4” Pressure gauge connection

Heating element seal

1/4” Vacuum-meter connection

Return

Delivery (nozzle)

1/4” Pressure gauge connection

15 / 32

98319_200910

Heating element seal

STARTING UP AND REGULATION WITH LIGHT OIL

E

1) Check that the characteristics of the nozzle (delivery and

N

G

L

I

S

H

spray angle) are suitable for the furnace (see BT 9353/1).

If not, replace it.

2) Check that there is fuel in the cistern and that it is, at least

visually; suitable for the burner.

3) Check that there is water in the boiler and that the system’s gate

valves are open.

4) Check, with absolute certainty, that the discharge of combustion

products can take place freely (boiler and chimney lock-gates

should be open).

5) Make sure that the voltage of the electric line to which the burner is to be connected, corresponds to that requested by the

manufacturer, and that the motor’s electrical connections have

been correctly prepared to match the voltage rating available.

Also are in accordance with our electric wiring diagram.

6) Make sure that the combustion head enters the furnace to the

extent specied by the boiler manufacturer. Check that the

combustion head is in the position considered necessary for

the fuel delivery required (the air passage between the disk and

the head should be considerably closed when the fuel delivery

is relatively reduced; on the other hand, when the nozzle has

a fairly high delivery, the air passage between the disk and

the head should be relatively (see chapter “Regulation of the

combustion head”).

7) Remove the protective cover from the rotating disk inserted on the modulating motor. On this disk have

been tted adjustable screws which are used to control the fuel

and the relative combustion air.

8) Put the two modulating switches in the “MIN” (minimum) and

“MAN” (manual) positions.

9) Start up the fuel supply auxiliary circuit, check its efciency and

regulate the pressure at about 1 bar (if the circuit is supplied

with a pressure regulator).

10)Remove from the pump the vacuumeter connection point plug

and then open slightly the gate valve tted on the fuel arrival

pipe. Wait until fuel comes out of the hole, without air bubbles,

and then re-close the gate valve.

11) Insert a manometer (end of the scale about 3 bar) into the vacuumeter connection point on the pump and control the value of the

pressure at which the fuel arrives at the burner pump. Insert a

manometer (and of the scale about 30 bar) into the manometer

connection point provided on the pump and control its working

pressure. Insert a manometer (end of the scale about 30 bar) into

the special connection point of the rst ame return pressure.

12) Now open all the gate valves and any other fuel interception

devices tted on the fuel pipelines.

13) Put the switch on the control panel in the “0” (open) position and

give current to the electric lines which the burner is connected

to. Check, by pressing manually on the relative relay, that the

motor rotates in the right direction. If it does not, exchange the

places of two cables of the principle line in order to invert the

sense of rotation.

14) Start operating the burner pump by pressing manually on the

relative relay until the manometer, which measures the working

pressure of the pump, indicates a slight pressure. The presence

of low pressure in the circuit conrms that lling up has taken

place.

15) Insert the switch on the control panel to give current to the control

box. If the thermostats (safety and boiler) are closed, the control

box’s programmer will be connected and will insert the burner’s

component devices according to its-established programme.The

unit starts up in this way, as described in chapter “Description

of Operations”.

16) When the burner is operating at “minimum”, proceed with regulating the air to the quantity considered

necessary to ensure efcient combustion. Tighten or loosen the

adjusting screws situated on the point of contact on the lever,

which transmits the movement to the combustion air regulation

shutter. It is preferable that the quantity of air for the “minimum”

is slightly reduced, in order to ensure a soft ignition even in the

most critical conditions.

17) After having regulated the air for the “minimum”, put the modu-

lation switches in the “MAN” (manual) and “MAX” (maximum)

positions.

18) The modulation motor starts moving; wait until the disk on which

the regulating screws have been tted, has reached an angle

of about 12° (this corresponds to the space taken up by three

screws), stop the modulation motor and return the switch to the

“0” position. Carry out a visual control of the ame and proceed,

if necessary, with regulating the combustion air by operating

as described in point 16. Subsequently, control combustion

with the appropriate instruments and modify, if necessary, the

previous regulation carried out after a visual control only. The

operation described above should be repeated progressively

(by moving forwards the disk by about 12° at a time) and modifying every time, if necessary; the fuel/air ratio during the entire

modulating run. Make sure that the increase in fuel delivery

occurs gradually and that maximum delivery is reached at the

end of the modulation run. This is necessary in order to ensure

that modulation functions with good graduality. The position of

the screws that commend the fuel may need to be modied

in order to obtain the graduality required. Maximum delivery

is obtained when the return pressure is about 2 ÷ 3 bar less

than the delivery pressure (normally 20 ÷ 22 bar). For a correct

Fuel/air ratio, the percentage of Carbon Dioxide (CO

increase with the increase delivery (from a minimum of 10% at

minimum delivery to a maximum of 13% at maximum delivery).

We advise against exceeding 13% of CO2 to avoid operating with

a rather limited excess of air which would cause a considerable

increase in smoke opacity due to unavoidable circumstances

(a variation in the atmospheric pressure; presence of dust

particles in the fan’s air ducts, etc.). Smoke opacity depends

on the type of fuel utilized (the most recent provisions indi-

cate that it should not exceed n. 2 of the Bacharach Scale).

We advise, if possible, maintaining smoke opacity below n. 2 of

the Bacharach Scale even if, as a consequence, the CO2 value

is slightly lower. The lower smoke opacity dirties the boiler less

) should

2

16 / 32

98319_200910

and therefore its average yield is normally higher even when

the CO2 value is slightly inferior. It should be remembered

that, in order to regulate properly, the water in the system

should be at the right temperature and the burner should have

been operating for at least 15 minutes. If the appropriate

instruments are not available, judgement can be based on the

colour of the ame. We advise regulating in such a way as to

obtain a ame bright orange in colour. Avoid a red ame with

smoke in it, or a white ame with an exaggerated excess of air.

After having checked the fuel/air regulation, tighten the locking

screws of the adjustable screws.

19) Now check if the modulation is functioning correctly in the

automatic mode by moving the AUT - 0 - MAN switch to the

“AUT” position and the MIN - 0 - MAX switch “0”. In this way

the modulation is connected only by means of the automatic

control of the boiler probe if we have a modulating burner or

by means of a commend coming from 2° stage thermostat or

pressure switch if we have a two progressive stage burner (BT...

DSPG).

20) Check the efciency of the ame detection device (photoresistance).The photoresistance is a ame control device and,

if the ame should be extinguished during operations, it must

be capable of intervening (this control should be made at least

one minute after start up). The burner should be capable of

blocking itself (shut down), and remaining so; if the ame does

not appear regularly during the start up phase within the time

limit preset on the control box.The shut down causes an imme-

diate interception of the fuel, the burner comes to a standstill

and the red warning light comes on. To check the efciency of

the photoresistance and of the shut down system, proceed as

follows:

a) start up the burner

b) after about one minute, extract the photoresistant cell by

pulling it out of its seat and simulate ame failure (using a

hand or a rag to close the window in the photoresistance

support). The ame should be extinguished.

c) Keep the photoresistant cell in the dark and the burner will

start up again but, as the photoresistance does not see the

light, the burner will go to shut down within the time preset

on the control box’s programme. The control box can only

be unblocked by pressing manually on the appropriate pushbutton. To check the efciency of the shut down device; carry

out this control at least twice.

High air pressure, upstream the disk, might be necessary in order to

avoid ame pulsation’s, and it is considered practically indispensable

when the burner is operating with a pressurized furnace and/or

high thermal load. It is evident from the above, that the position of

the device which regulates the air on the combustion head should

be put in such a position as to always obtain a decidedly high air

pressure value behind the disk.

It is advisable to regulate in such a way as to achieve a throttling

of the air between of the air shutter which regulates the ow to the

burner’s fan suction. Obviously these adjustments should be carried

out when the burner is operating at maximum delivery desired. In

practice, commence regulating with the combustion head in an intermediate position, start up the burner and make a rst adjustment

as previously described.

When maximum delivery desired has been reached, proceed with

correcting the position of the combustion head; move it backwards

and forwards in such a way as to obtain an air ow suitable for the

light oil delivery with the air regulation in suction considerably open.

In the combustion head is pushed forwards (which causes a reduction in the air passage between the head and the disk), avoid closing

it completely. When regulating the combustion head, proceed with

centring it perfectly with respect to the disk. It must be pointed out

that, if perfect centring with respect to the disk is not obtained, bad

combustion and excessive heating of the head could occur which

would result in its rapid deterioration.

A control can be carried out by looking through the spy hole situated

on the back of the burner; then tighten home the screws that lock

the combustion head in position.

Make sure that the ignition is correct because if the

!

regulator has been moved forward, it may happen that

the speed of the exiting air is so high that it impairs the

ignition. If this occurs, gradually move the regulator

backward until it reaches a position which allows to

have a regular ignition and set this position as nal.

Remember furthermore that for the 1° ame it is recommended to limit the amount of air to the minimum

required amount in order to have a safe ignition even

in the most complicated conditions.

E

N

G

L

I

S

H

21) Check the efciency of the boiler’s thermostats or pressure

switches (this operation should stop the burner.

REGULATION OF THE COMBUSTION HEAD

The burner is equipped with a combustion head which can be regulated (by moving it backwards or forwards) in such a way as to close

more or open more the air passage between the disk and the head.

By throttling the passage, it is possible to achieve high pressure

upstream the disk, and therefore high velocity and air turbulence for

low inputs as well. High velocity and air turbulence ensure a better

penetration in the fuel and are therefore an optimum mixture and

allow the burner to operate with good ame stability.

98319_200910

17 / 32

GENERAL DIAGRAM AIR REGULATION

E

INCORRECT REGULATION

N

G

Combustion head

L

I

S

H

CORRECT REGULATION

Combustion air inlet with

very locked shutter

Air ow large

opening

Control and xing knobs of

Combustion head

Air ow quite locked.

Attention:

Avoid complete

locking

N° BT 8608/1

combustion head

Combustion air inlet with

very opened shutter

Control and xing knobs of

combustion head

DRAWING (AS REFERENCE POINT) SHOWING THE PLACING OF NOZZLE - ELECTRODES - FLAME DISK

N° 0002931451

18 / 32

98319_200910

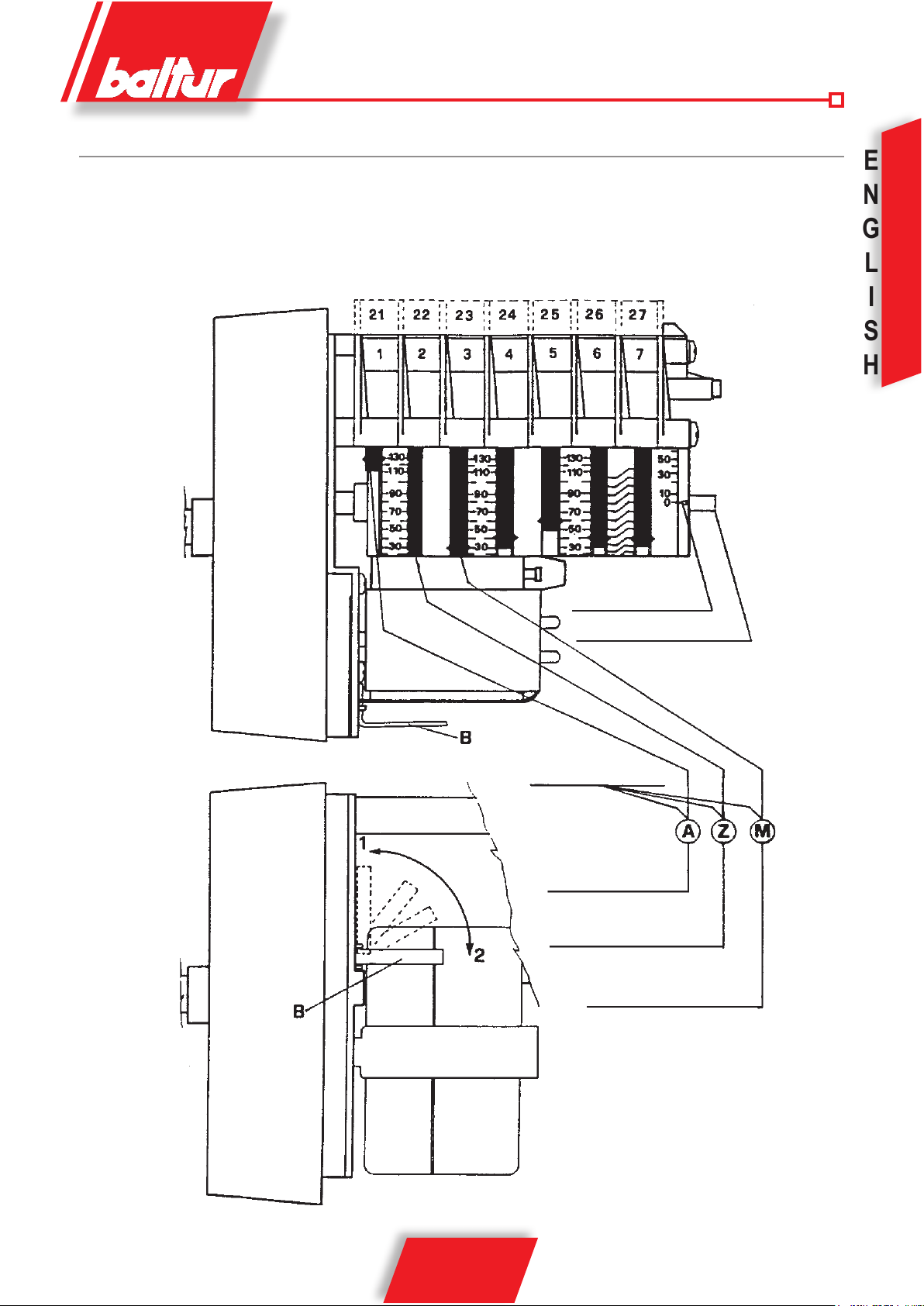

DETAILS OF THE MODULATION CONTROL MOTOR SQM 10 AND SQM 20 FOR REGULATION OF CAMS

To modify the regulation of the 3 cams utilized, operate the respective red rings ( A - Z - M ).

By pushing with enough force, in the direction desired, each red ring will rotate with respect to the reference scale.

The index of the red ring indicates on the respective reference scale the rotation angle taken up for each cam.

N° BT 8562/2

E

N

G

L

I

S

H

Reference Index

Camsshaft

Adjustable Cams

Maximum air opening

end of the run

Complete air closure

(burner not operating)

Air ignition opening

19 / 32

98319_200910

B = Insertion and disinsertion lever

motor connection Camshaft

Position 1 = Disinsertion

Position 2 = Insertion

E

N

G

L

S

H

CONTROL BOX

I

20 / 32

98319_200910

E

N

G

L

S

H

I

21 / 32

98319_200910

E

N

G

L

S

H

I

22 / 32

98319_200910

E

N

G

L

S

H

I

23 / 32

98319_200910

E

N

G

L

S

H

I

24 / 32

98319_200910

E

N

G

L

S

H

I

25 / 32

98319_200910

E

N

G

L

S

H

I

26 / 32

98319_200910

E

N

G

L

S

H

I

27 / 32

98319_200910

E

N

G

L

S

H

I

28 / 32

98319_200910

Loading...

Loading...