Page 1

BVC Direct Drive

Air-Cooled

Condenser

PRODUCT DATA &

INSTALLATION

Bulletin B50-BVC-PDI-10

1068833

Model

BVC = Bally Vertical air flow Condenser

BCH = Bally Horizontal air flow Condenser

Tubing

1 = 3/8 OD smooth 2 = 1/2 OD smooth

Motor & Fan Type

A = 30” fan with 850 RPM motor (Standard)

B = 30” fan with 550 RPM motor

C = 30” fan with 1140 RPM motor

Fan Configuration

First number = number of fans wide

Second number = number of fans in length

26 = 2 fans wide x 6 fans length (total 12 fans)

11 = 1 fan wide x 1 fan length (total 1 fan)

One to Twelve Fan Motors

NOMENCLATURE

BVC 2 A 26 206 A - T3 C

Generation

C = Latest series (A, B older series)

Electrical Code

S2 = 208-230/1/60 S6 = 200-220/1/50

T3 = 208-230/3/60 T7 = 200-220/3/50

T4 = 460/3/60 T9 = 380-400/3/50

T5 = 575/3/60

Fin Material & Spacing

A = Aluminum 12 FPI (Standard), B = 10, C = 8

D = Gold Coat Alum 12 FPI, E = 10, F = 8

G = Copper 12 FPI, H = 10, J = 8

K = Heresite Coat Alum 12 FPI, L = 10, M = 8

Nominal Capacity (Tons - THR)

Rated at 25

12” FPI, smooth tubing, 0° Subcooling, Sea Level, 60 Hz

o

F (14 oC) TD, 30” Fan / 850 RPM Motor,

CONTENTS

PAGE

SPECIFICATIONS

Nomenclature........................................... Front

850 RPM Data:

Capacity, General Specs, Elec. Specs... 2-5

Dimensional Data...................................... 6, 7

Wiring Data.............................................. 8-11

550 RPM Data:

Capacity, General Specs, Elec. Specs... 12-15

1140 RPM Data:

Capacity, General Specs, Elec. Specs.... 16-19

DESIGN & SELECTION

Condenser Theory..................................... 20

Glossary of Terms..................................... 21, 22

Condenser Selection & Worksheets............ 23-29

Low Ambient Operation.............................. 30-34

INSTALLATION

Inspection, Location & Placement............... 35

Piping & Wiring......................................... 36

System Check & Maintenance................... 37

Service Parts............................................ 38

Project Information.................................... Back

• THERMOSPAN

TM

coil design feature eliminates

tube failure on tube sheets.

• Standard 850 RPM quiet low speed dual

voltage (230/460) fan motors with male electrical

plug, moisture slinger, and rainshield for complete

weather protection.

• Optional 550 ultra low and 1140 RPM high

speed motors available.

• Rugged heavy-gauge galvanized steel rail

motor mounts/support.

• All fan sections individually baffled with full

height partitions, and clean-out panels.

• Complete selection of electrical fan cycling and

speed control options.

• Heavy-gauge galvanized steel cabinet

construction assembled with zinc plated huck

bolts supported on heavy-duty legs.

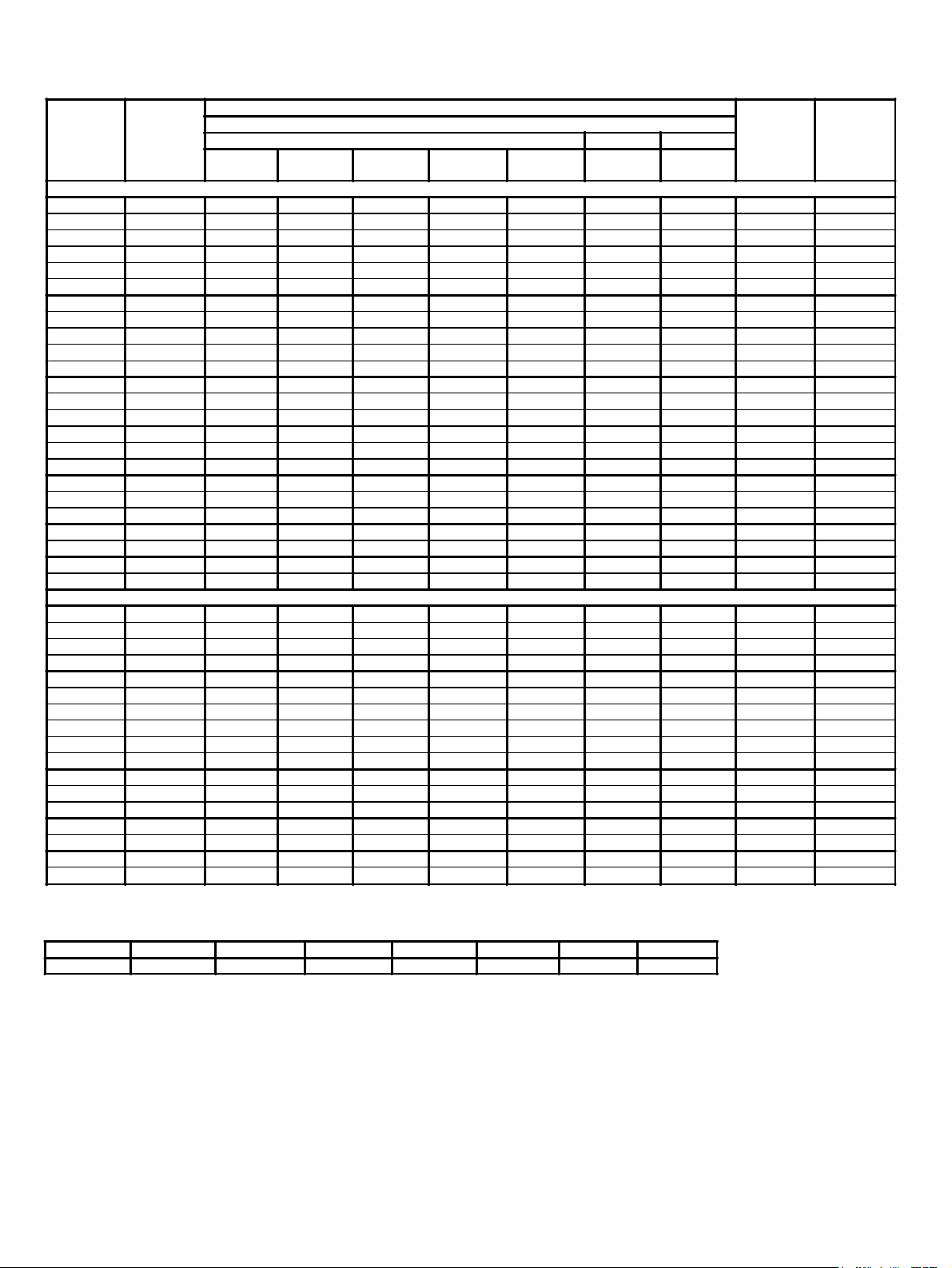

Page 2

CAPACITY DATA - 850 RPM MODELS - R22

BVC

MODEL

NUMBER

007

009

010

011

012

013

017

019

022

024

027

029

034

037

041

043

048

056

063

068

079

085

095

103

039

045

049

054

058

067

073

081

086

096

112

126

137

158

172

190

206

TOTAL HEAT OF REJECTION CAPACITY (MBH)

Fan Rows

1°F

(0.56°C)

1 x 1 3.165 31.7 47.5 63.3 95.0 2.912 2.595 7 0.45

1 x 1 4.135 41.4 62.0 82.7 124 3.846 3.515 8 0.52

1 x 1 4.655 46.6 69.8 93.1 140 4.329 3.957 9 0.52

1 x 1 5.365 53.7 80.5 107 161 5.097 4.721 12 0.45

1 x 1 5.875 58.8 88.1 118 176 5.581 5.170 12 0.49

1 x 1 6.465 64.7 97.0 129 194 6.336 5.948 15 0.43

1 x 2 8.265 82.7 124 165 248 7.686 7.025 14 0.59

1 x 2 9.265 92.7 139 185 278 8.616 7.875 18 0.51

1 x 2 10.74 107 161 215 322 10.20 9.447 24 0.45

1 x 2 11.77 118 176 235 353 11.18 10.35 24 0.49

1 x 2 12.94 129 194 259 388 12.68 11.90 30 0.43

1 x 3 13.97 140 209 279 419 12.90 11.87 27 0.52

1 x 3 16.07 161 241 321 482 15.26 14.14 36 0.45

1 x 3 17.64 176 265 353 529 16.75 15.52 36 0.49

1 x 3 19.40 194 291 388 582 19.01 17.85 45 0.43

1 x 3 20.64 206 310 413 619 19.61 18.17 36 0.57

1 x 3 23.01 230 345 460 690 22.55 21.17 45 0.51

1 x 4 26.34 263 395 527 790 24.50 22.39 22 1.20

1 x 4 30.29 303 454 606 909 28.77 26.65 30 1.01

1 x 4 32.55 326 488 651 977 31.90 29.95 37 0.88

1 x 5 37.95 379 569 759 1138 36.05 33.39 30 1.26

1 x 5 40.70 407 610 814 1221 39.88 37.44 37 1.10

1 x 6 45.54 455 683 911 1366 43.26 40.07 30 1.52

1 x 6 48.84 488 733 977 1465 47.85 44.93 37 1.32

2 x 2 18.60 186 279 372 558 17.30 15.81 36 0.52

2 x 2 21.47 215 322 429 644 20.39 18.89 48 0.45

2 x 2 23.50 235 353 470 705 22.33 20.68 48 0.49

2 x 2 25.84 258 388 517 775 25.32 23.77 60 0.43

2 x 3 27.90 279 419 558 837 25.95 23.72 54 0.52

2 x 3 32.17 322 482 643 965 30.56 28.31 72 0.45

2 x 3 35.24 352 529 705 1057 33.47 31.01 72 0.49

2 x 3 38.77 388 581 775 1163 37.99 35.66 90 0.43

2 x 3 41.29 413 619 826 1239 39.22 36.33 72 0.57

2 x 3 46.02 460 690 920 1381 45.10 42.34 90 0.51

2 x 4 53.89 539 808 1078 1617 50.11 45.80 45 1.20

2 x 4 60.57 606 909 1211 1817 57.54 53.30 60 1.01

2 x 4 65.99 660 990 1320 1980 64.67 60.71 75 0.88

2 x 5 75.90 759 1138 1518 2277 72.10 66.79 60 1.26

2 x 5 82.50 825 1237 1650 2475 80.85 75.90 75 1.10

2 x 6 91.08 911 1366 1822 2732 86.52 80.15 60 1.52

2 x 6 98.99 990 1485 1980 2970 97.01 91.07 75 1.32

10°F

(5.56°C)

TEMPERATURE DIFFERENCE (TD)

12 FPI 10 FPI 8 FPI

15°F

(8.3°C)

20°F

(11.1°C)

Single Row Models

Double Row Models

30°F

(16.7°C)

1°F

(0.56°C)

1°F

(0.56°C)

Maximum

No. of

Feeds

MBH

@ 1° F TD

Per Feed

(12 FPI)

Correction Factors for Other refrigerants - Use R22 Values Multiplied By

R134a R12 R507 R404A R407A R407B R502 R407C

0.94 0.95 0.97 0.97 0.97 0.97 0.98 1.00

NOTES: (1) Above capacity data based on 0°F subcooling and at sea level.

(2) TD = Condensing temperature - ambient temperature

(3) Standard fin spacing is 12 FPI except models 056 and 112 (13 FPI).

(4) For High Altitude applications apply the following correction factors:

0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

(5) For 50Hz capacity multiply by 0.92.

- 2 -

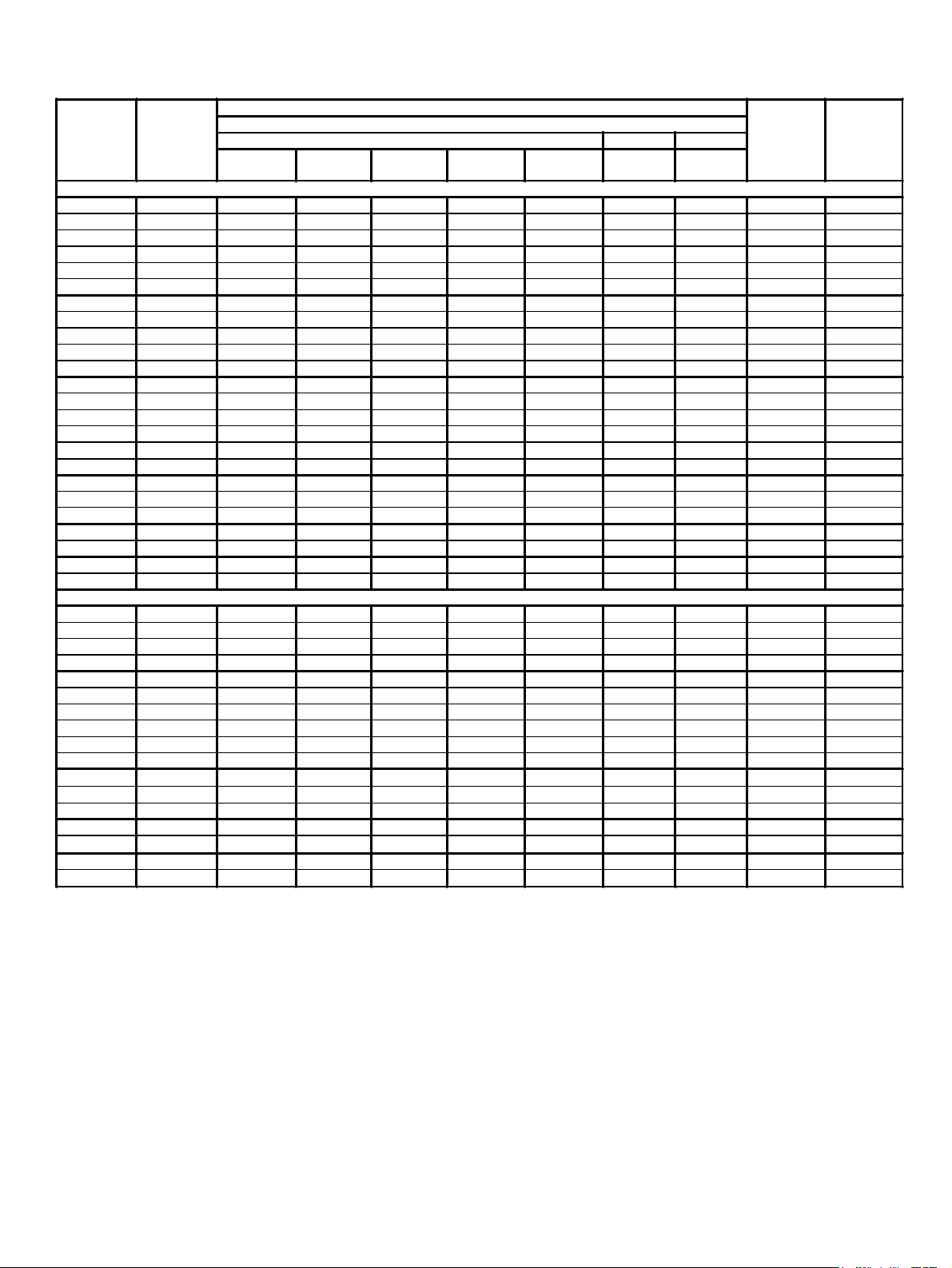

Page 3

CAPACITY DATA - 850 RPM MODELS - R404A

TOTAL HEAT OF REJECTION CAPACITY (MBH)

BVC

MODEL

NUMBER

007

009

010

011

012

013

017

019

022

024

027

029

034

037

041

043

048

056

063

068

079

085

095

103

039

045

049

054

058

067

073

081

086

096 2 x 3 44.64 446 670 893 1339 43.75 41.07 90 0.50

112

126

137

158

172

190

206

Fan Rows

1°F

(0.56°C)

1 x 1 3.070 30.7 46.1 61.4 92.1 2.825 2.517 7 0.44

1 x 1 4.011 40.1 60.2 80.2 120 3.731 3.410 8 0.50

1 x 1 4.515 45.2 67.7 90.3 135 4.199 3.838 9 0.50

1 x 1 5.204 52.0 78.1 104 156 4.944 4.579 12 0.43

1 x 1 5.699 57.0 85.5 114 171 5.414 5.015 12 0.47

1 x 1 6.271 62.7 94.1 125 188 6.146 5.770 15 0.42

1 x 2 8.017 80.2 120 160 241 7.455 6.814 14 0.57

1 x 2 8.987 89.9 135 180 270 8.358 7.639 18 0.50

1 x 2 10.41 104 156 208 312 9.892 9.164 24 0.43

1 x 2 11.41 114 171 228 342 10.84 10.04 24 0.48

1 x 2 12.55 125 188 251 376 12.30 11.54 30 0.42

1 x 3 13.55 135 203 271 406 12.51 11.51 27 0.50

1 x 3 15.58 156 234 312 467 14.80 13.71 36 0.43

1 x 3 17.11 171 257 342 513 16.25 15.05 36 0.48

1 x 3 18.82 188 282 376 565 18.44 17.31 45 0.42

1 x 3 20.02 200 300 400 601 19.02 17.62 36 0.56

1 x 3 22.32 223 335 446 670 21.87 20.53 45 0.50

1 x 4 25.55 256 383 511 767 23.77 21.72 22 1.16

1 x 4 29.38 294 441 588 881 27.91 25.85 30 0.98

1 x 4 31.58 316 474 632 947 30.94 29.05 37 0.85

1 x 5 36.81 368 552 736 1104 34.97 32.39 30 1.23

1 x 5 39.48 395 592 790 1184 38.69 36.32 37 1.07

1 x 6 44.17 442 663 883 1325 41.96 38.87 30 1.47

1 x 6 47.37 474 711 947 1421 46.41 43.58 37 1.28

2 x 2 18.04 180 271 361 541 16.78 15.34 36 0.50

2 x 2 20.82 208 312 416 625 19.78 18.32 48 0.43

2 x 2 22.80 228 342 456 684 21.66 20.06 48 0.47

2 x 2 25.06 251 376 501 752 24.56 23.05 60 0.42

2 x 3 27.06 271 406 541 812 25.17 23.00 54 0.50

2 x 3 31.20 312 468 624 936 29.64 27.46 72 0.43

2 x 3 34.18 342 513 684 1025 32.47 30.08 72 0.47

2 x 3 37.60 376 564 752 1128 36.85 34.59 90 0.42

2 x 3 40.05 400 601 801 1201 38.04 35.24 72 0.56

2 x 4 52.27 523 784 1045 1568 48.61 44.43 45 1.16

2 x 4 58.75 588 881 1175 1763 55.82 51.70 60 0.98

2 x 4 64.01 640 960 1280 1920 62.73 58.88 75 0.85

2 x 5 73.62 736 1104 1472 2209 69.94 64.78 60 1.23

2 x 5 80.02 800 1200 1600 2401 78.42 73.62 75 1.07

2 x 6 88.34 883 1325 1767 2650 83.93 77.74 60 1.47

2 x 6 96.02 960 1440 1920 2881 94.10 88.34 75 1.28

10°F

(5.56°C)

TEMPERATURE DIFFERENCE (TD)

12 FPI 10 FPI 8 FPI

15°F

(8.3°C)

Single Row Models

Double Row Models

20°F

(11.1°C)

30°F

(16.7°C)

1°F

(0.56°C)

1°F

(0.56°C)

Maximum

No. of

Feeds

MBH

@ 1° F TD

Per Feed

(12 FPI)

To calculate capacities with other refrigerants, multiply the R22 capacity by the appropriate correction factor.

Refer to the table accompanying each of the R22 tables.

NOTES: (1) Above capacity data based on 0°F subcooling and at sea level.

(2) TD = Condensing temperature - ambient temperature

(3) Standard fin spacing is 12 FPI except models 056 and 112 (13 FPI).

(4) For High Altitude applications apply the following correction factors:

0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

(5) For 50Hz capacity multiply by 0.92.

- 3 -

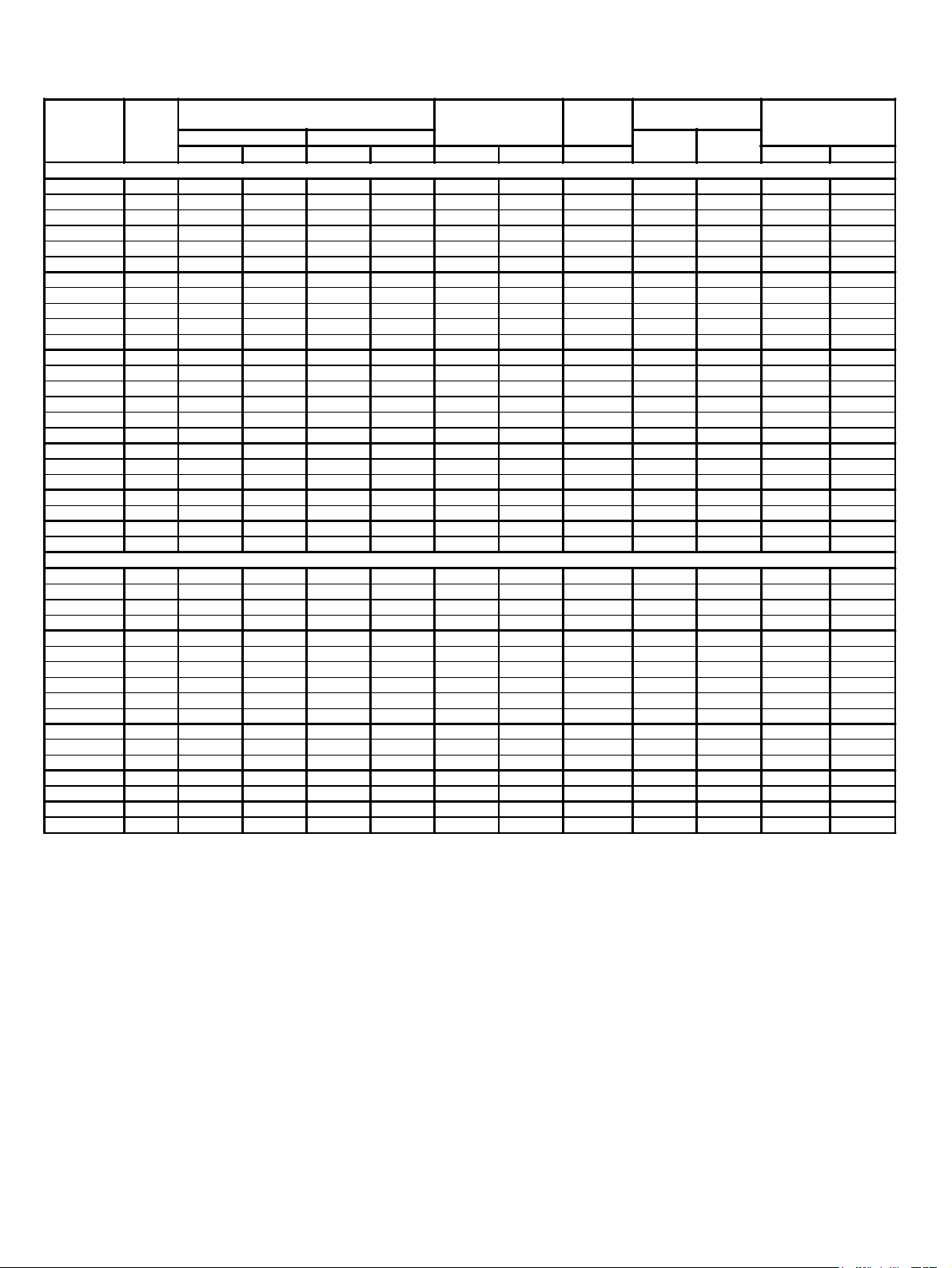

Page 4

GENERAL SPECIFICATIONS - 850 RPM MODELS

BVC

MODEL

NUMBER

Total

No. of

Feeds

R22 Refrigerant Charge

(2)

Normal

lbs kg lbs kg CFM m3/h dBA lbs kg

(1)

90% FULL

Sound

(3)

Air Flow Rate

(4)

Level

Piping Connections

(5)

Inlet

Qty - OD

Outlet

Qty - OD

Condenser

Weight

(6)

Single Row Models

1A11007 7 1.7 0.8 11.0 5.2 7150 12200 63.5 1 - 1 1/8 1 - 7/8 360 163

1A11009 8 2.2 1.0 17.0 7.5 6280 10700 63.5 1 - 1 3/8 1 - 7/8 375 170

1A11010 9 2.8 1.3 21.0 9.5 7150 12200 63.5 1 - 1 3/8 1 - 7/8 420 191

1A11011 12 3.9 1.8 27.0 12.0 6880 11700 63.5 1 - 1 3/8 1 - 1 1/8 440 200

1A11012 12 4.3 2.0 31.0 14.0 7200 12200 63.5 1 - 1 3/8 1 - 1 1/8 480 218

1A11013 15 5.2 2.4 39.0 18.0 6930 11800 63.5 1 - 1 5/8 1 - 1 1/8 505 229

1A12017 14 4.1 1.9 31.0 14.0 12500 21300 66.5 1 - 1 5/8 1 - 1 1/8 565 256

1A12019 18 6.1 2.8 44.0 20.0 14300 24300 66.5 1 - 2 1/8 1 - 1 3/8 630 286

1A12022 24 7.4 3.4 55.0 25.0 13700 23300 66.5 1 - 2 1/8 1 - 1 3/8 675 306

1A12024 24 8.3 3.8 62.0 28.0 14400 24500 66.5 1 - 2 1/8 1 - 1 3/8 740 336

1A12027 30 10.0 4.5 75.0 34.0 13900 23600 66.5 1 - 2 1/8 1 - 1 3/8 790 358

1A13029 27 9.0 4.1 61.0 28.0 21400 36400 67.7 1 - 2 1/8 1 - 1 5/8 840 381

1A13034 36 10.0 4.5 78.0 35.0 20600 35000 67.7 1 - 2 1/8 1 - 1 5/8 905 410

1A13037 36 12.0 5.4 94.0 42.0 21600 36700 67.7 1 - 2 5/8 1 - 1 5/8 1000 454

1A13041 45 14.0 6.4 113 51.0 20800 35400 67.7 1 - 2 5/8 1 - 1 5/8 1070 485

1A13043 36 17.5 7.9 128 57.8 26500 45100 67.7 1 - 2 5/8 1 - 1 5/8 1055 479

1A13048 45 20.5 9.3 152 68.9 25800 43800 67.7 1 - 2 5/8 1 - 1 5/8 1150 522

2A14056 22 25.9 11.8 183 83.2 35900 61000 69 1 - 2 5/8 1 - 2 1/8 1600 726

2A14063 30 32.5 14.7 239 108 35300 59900 69 1 - 2 5/8 1 - 2 1/8 1650 748

2A14068 37 38.0 17.2 286 130 34300 58300 69 1 - 2 5/8 1 - 2 1/8 1750 794

2A15079 30 38.5 17.5 290 131 44100 74900 70.3 1 - 2 5/8 1 - 2 1/8 2063 936

2A15085 37 48.8 22.2 356 161 42900 72900 70.3 1 - 2 5/8 1 - 2 5/8 2188 992

2A16095 30 53.5 24.3 365 165 52900 89900 71 1 - 3 1/8 1 - 3 1/8 2475 1123

2A16103 37 61.2 27.7 436 198 51500 87500 71 1 - 3 1/8 1 - 3 1/8 2625 1191

Double Row Models

1A22039 36 16.0 7.3 104 47.0 28600 48600 69.5 2 - 2 1/8 2 - 1 3/8 1060 481

1A22045 48 19.0 8.6 126 57.0 27500 46800 69.5 2 - 2 1/8 2 - 1 3/8 1145 519

1A22049 48 21.0 9.5 141 64.0 28800 49000 69.5 2 - 2 1/8 2 - 1 3/8 1255 569

1A22054 60 23.0 10.0 167 76.0 27700 47100 69.5 2 - 2 1/8 2 - 1 3/8 1350 612

1A23058 54 22.0 10.0 141 64.0 42800 72800 71 2 - 2 1/8 2 - 1 5/8 1420 644

1A23067 72 26.0 12.0 174 79.0 41200 70000 71 2 - 2 1/8 2 - 1 5/8 1550 703

1A23073 72 30.0 14.0 212 96.0 43200 73400 71 2 - 2 5/8 2 - 1 5/8 1710 776

1A23081 90 35.0 16.0 251 114 41600 70700 71 2 - 2 5/8 2 - 1 5/8 1865 846

1A23086 72 35.0 16.0 255 116 53000 90100 71 2 - 2 5/8 2 - 1 5/8 2110 957

1A23096 90 41.0 19.0 304 138 51500 87600 71 2 - 2 5/8 2 - 1 5/8 2300 1043

2A24112 45 53.0 24.0 375 170 71800 122100 72.5 2 - 2 5/8 2 - 2 1/8 3200 1451

2A24126 60 65.0 30.0 477 217 70500 119900 72.5 2 - 2 5/8 2 - 2 1/8 3300 1497

2A24137 75 77.0 35.0 579 263 68600 116600 72.5 2 - 2 5/8 2 - 2 1/8 3500 1588

2A25158 60 77.0 35.0 579 263 88100 149800 73.3 2 - 2 5/8 2 - 2 1/8 4125 1871

2A25172 75 99.0 45.0 721 327 85800 145800 73.3 2 - 2 5/8 2 - 2 5/8 4375 1984

2A26190 60 107.0 49.0 729 331 106000 179800 74 2 - 3 1/8 2 - 3 1/8 4950 2245

2A26206 75 124.0 56.0 883 401 102900 174900 74 2 - 3 1/8 2 - 3 1/8 5250 2381

(1) For R407A, R507 use R22 Charge x 0.87. For R407-C use R22 Charge x 0.97.

For R134a and R502 use R22 Charge. For R12 use R22 Charge X 1.1.

(2) Normal Charge is the refrigerant charge for warm ambient or summer operation. For low ambient or winter charge with

flooded head pressure control and fan cycling see Page 33 and Page 34.

(3) 90% FULL is the liquid refrigerant weight at 90% of internal volume and is for reference ONLY.

(4) For 50Hz Fan Data use 60Hz CFM (m3/h) X 0.83.

(5) Sound Pressure Level at ten meter distance.

(6) Less weight of refrigerant charge.

- 4 -

Page 5

ELECTRICAL DATA - 850 RPM MODELS 60Hz

Not available on 4 and 5 fan single row models

Not available on 4 and 5 fan single row models

NO.

OF

FANS

1 3.4 4.3 15 5.9 7.4 15 2.9 3.6 15 2.3 2.9 15

2 6.8 7.7 15 11.8 13.3 20 5.8 6.5 15 4.6 5.2 15

3 10.2 11.1 15 17.7 19.2 25 8.7 9.4 15 6.9 7.5 15

4 13.6 14.5 20 23.6 25.1 30 11.6 12.3 15 9.2 9.8 15

5 N/A N/A N/A 29.5 35.1 40 14.5 15.2 20 11.5 12.1 15

6 20.4 21.3 30 35.4 36.9 45 17.4 18.1 25 13.8 14.4 20

8 NA NA NA 47.2 48.7 60 23.2 23.9 30 18.4 19.0 25

10 NA NA NA 59 60.5 70 29 29.7 40 23 23.6 30

12 NA NA NA 70.8 72.3 80 34.8 35.5 45 27.6 28.2 40

M.C.A. = Minimum Circuit Ampacity (AMPS)

M.O.P. = Maximum Overcurrent Protection (AMPS)

208-230/1/60* 208-230/3/60 460/3/60 575/3/60

TOTAL

FLA

MCA MOP

TOTAL

FLA

MCA MOP

TOTAL

FLA

MCA MOP

TOTAL

*

and 6 fan models 183” and longer.

FLA

MCA MOP

ELECTRICAL DATA - 850 (700) RPM MODELS 50Hz

NO.

OF

FANS

1 3.6 4.5 15 6.5 8.1 15 2.7 3.4 15

2 7.2 8.1 15 13 14.6 20 5.4 6.1 15

3 10.8 11.7 15 19.5 21.1 25 8.1 8.8 15

4 14.4 15.3 20 26 27.6 40 10.8 11.5 15

5 N/A N/A N/A 32.5 34.1 40 13.5 15.1 20

6 21.6 22.5 30 39 40.6 45 16.2 16.9 20

8 NA NA NA 52 53.6 60 21.6 22.3 30

10 NA NA NA 65 66.6 80 27 27.7 40

12 NA NA NA 78 79.6 90 32.4 33.1 45

TOTAL

FLA

M.C.A. = Minimum Circuit Ampacity (AMPS)

M.O.P. = Maximum Overcurrent Protection (AMPS)

200-220/1/50 200-220/3/50* 380-400/3/50

MCA MOP

TOTAL

FLA

MCA MOP TOTAL FLA MCA MOP

*

and 6 fan models 183” and longer.

- 5 -

Page 6

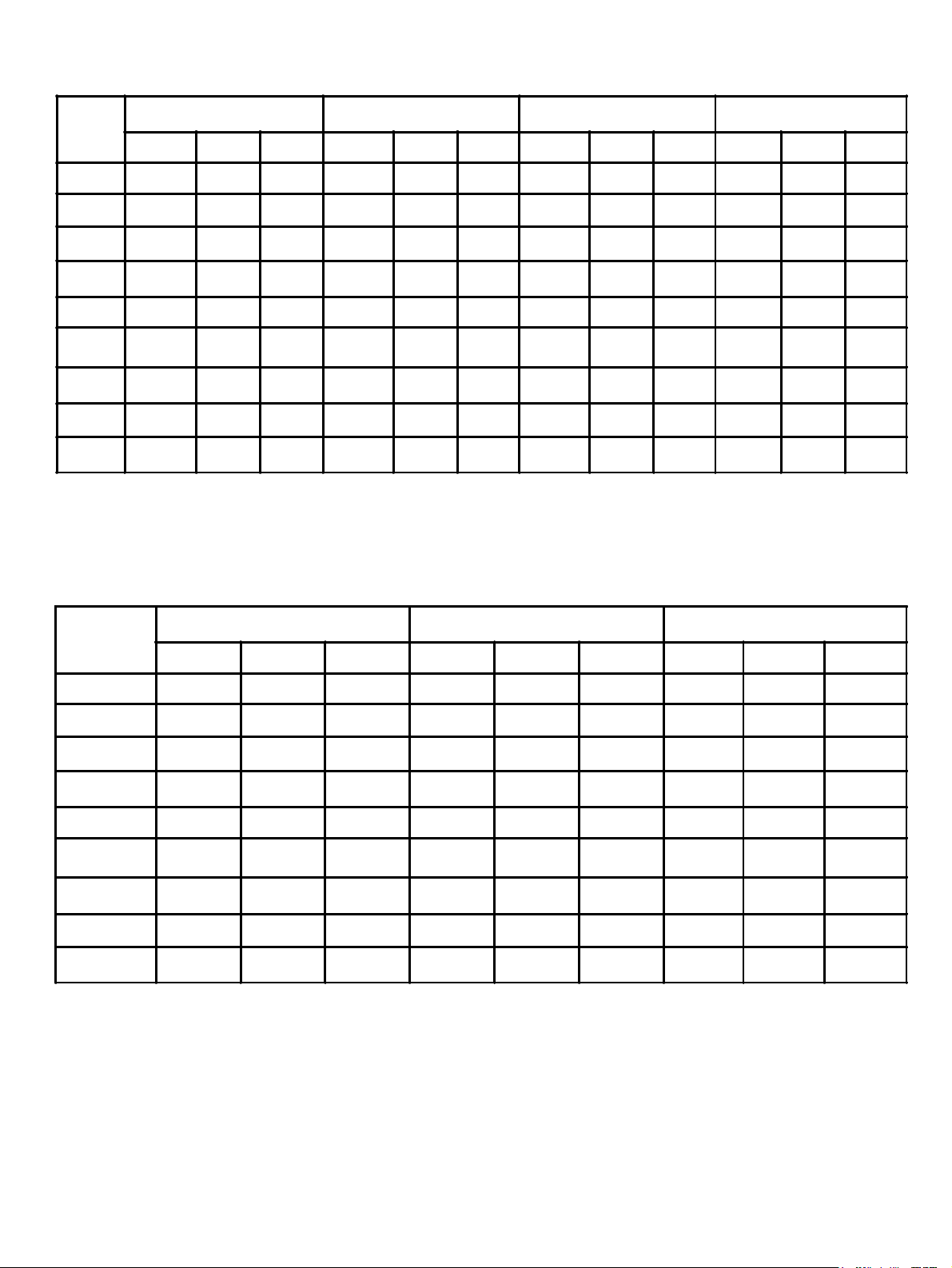

DIMENSIONAL DATA - SINGLE ROW BVC MODELS

DIMENSIONS - Inches (mm)

SINGLE ROW

MODEL

11 007

11 009

11 010 48 1/8 (1222) 43 (1092) 41 1/8 (1045) 36 (914) - -

11 011

11 012

11 013 48 1/8 (1222) 50 (127) 41 1/8 (1045) 43 (1092) - 12 017

12 019

12 022

12 024

12 027 48 1/8 (1222) 97 1/8 (2467) 41 1/8 (1045) 90 1/8 (2289) - 13 029

13 034

13 037

13 041 48 1/8 (1222) 144 1/4 (3664) 41 1/8 (1045) 137 1/4 (3486) - 13 043

13 048

14 056 48 1/8 (1222) 243 (6172) 41 1/8 (1045) 236 5/16 ( 6002) 116 3/16 (2951) 14 063

14 068

15 079

15 085 48 1/8 (1222) 303 (7696) 41 1/8 (1045) 296 5/16 (7526) 116 3/16 (2951) 176 3/16 (4475)

16 095

16 103

WIDTH

W

38 1/8 (968) 43 (1092) 31 1/8 (791) 36 (914) - 38 1/8 (968) 43 (1092) 31 1/8 (791) 36 (914) - -

48 1/8 (1222) 43 (1092) 41 1/8 (1045) 36 (914) - 48 1/8 (1222) 50 (127) 41 1/8 (1045) 43 (1092) - -

38 1/8 (968) 83 1/8 (2111) 31 1/8 (791) 76 1/8 (1934) - 48 1/8 (1222) 83 1/8 (2111) 41 1/8 (1045) 76 1/8 (1934) - 48 1/8 (1222) 83 1/8 (2111) 41 1/8 (1045) 76 1/8 (1934) - 48 1/8 (1222) 97 1/8 (2467) 41 1/8 (1045) 90 1/8 (2289) - -

48 1/8 (1222) 123 1/4 (3131) 41 1/8 (1045) 116 1/4 (2953) - 48 1/8 (1222) 123 1/4 (3131) 41 1/8 (1045) 116 1/4 (2953) - 48 1/8 (1222) 144 1/4 (3664) 41 1/8 (1045) 137 1/4 (3486) - -

48 1/8 (1222) 183 (4648) 41 1/8 (1045) 176 1/4 (4477) - 48 1/8 (1222) 183 (4648) 41 1/8 (1045) 176 1/4 (4477) - -

48 1/8 (1222) 243 (6172) 41 1/8 (1045) 236 5/16 ( 6002) 116 3/16 (2951) 48 1/8 (1222) 243 (6172) 41 1/8 (1045) 236 5/16 ( 6002) 116 3/16 (2951) 48 1/8 (1222) 303 (7696) 41 1/8 (1045) 296 5/16 (7526) 116 3/16 (2951) 176 3/16 (4475)

48 1/8 (1222) 363 (9220) 41 1/8 (1045) 356 5/16 (9050) 116 3/16 (2951) 236 3/16 ( 5999)

48 1/8 (1222) 363 (9220) 41 1/8 (1045) 356 5/16 (9050) 116 3/16 (2951) 236 3/16 ( 5999)

LENGTH

L

M1 M2 M3 M4

MOUNTING LEG CENTRES

- 6 -

Page 7

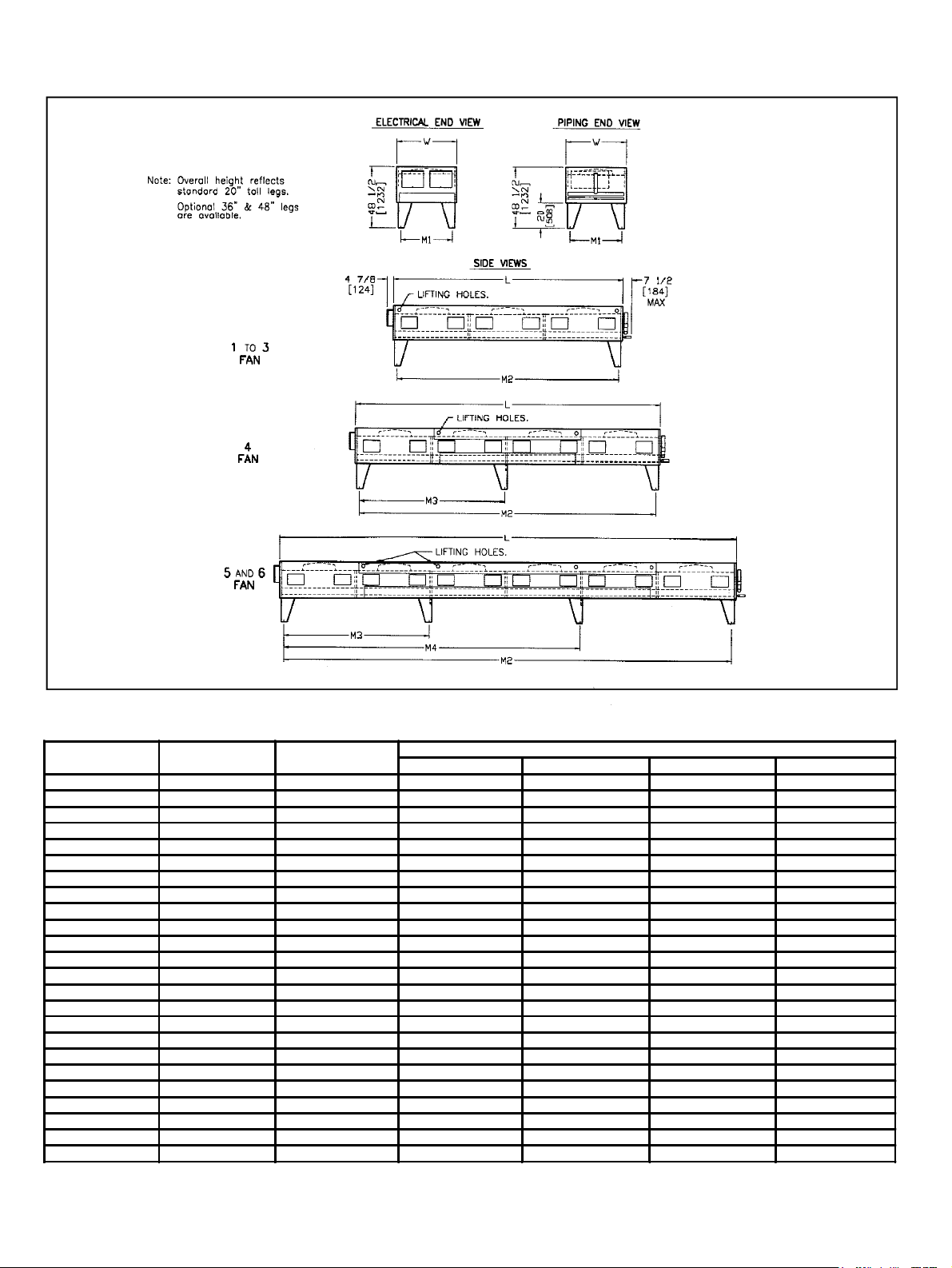

DIMENSIONAL DATA - DOUBLE ROW BVC MODELS

DIMENSIONS - Inches (mm)

DOUBLE ROW

MODEL

22 039

22 045

22 049 97 1/8 (2467) 86 1/8 (2188) 90 1/8 (2289) - 22 054

23 058

23 067

23 073

23 081

23 086

23 096

24 112 243 (6172) 86 7/16 (2196) 236 5/16 ( 6002) 116 3/16 (2951) 24 126

24 137

25 158

25 172 303 (7696) 86 7/16 (2196) 296 5/16 (7526) 116 3/16 (2951) 176 3/16 (4475)

26 190

26 206

LENGTH

L

83 1/8 (2111) 86 1/8 (2188) 76 1/8 (1934) - 83 1/8 (2111) 86 1/8 (2188) 76 1/8 (1934) - -

97 1/8 (2467) 86 1/8 (2188) 90 1/8 (2289) - 123 1/4 (3131) 86 1/8 (2188) 116 1/4 (2953) - 123 1/4 (3131) 86 1/8 (2188) 116 1/4 (2953) - 144 1/4 (3664) 86 1/8 (2188) 137 1/4 (3486) - 144 1/4 (3664) 86 1/8 (2188) 137 1/4 (3486) - -

183 (4648) 86 7/16 (2196) 176 1/4 (4477) - 183 (4648) 86 7/16 (2196) 176 1/4 (4477) - -

243 (6172) 86 7/16 (2196) 236 5/16 ( 6002) 116 3/16 (2951) 243 (6172) 86 7/16 (2196) 236 5/16 ( 6002) 116 3/16 (2951) 303 (7696) 86 7/16 (2196) 296 5/16 (7526) 116 3/16 (2951) 176 3/16 (4475)

363 (9220) 86 7/16 (2196) 356 5/16 (9050) 116 3/16 (2951) 236 3/16 ( 5999)

363 (9220) 86 7/16 (2196) 356 5/16 (9050) 116 3/16 (2951) 236 3/16 ( 5999)

M1 M2 M3 M4

MOUNTING LEG CENTRES

- 7 -

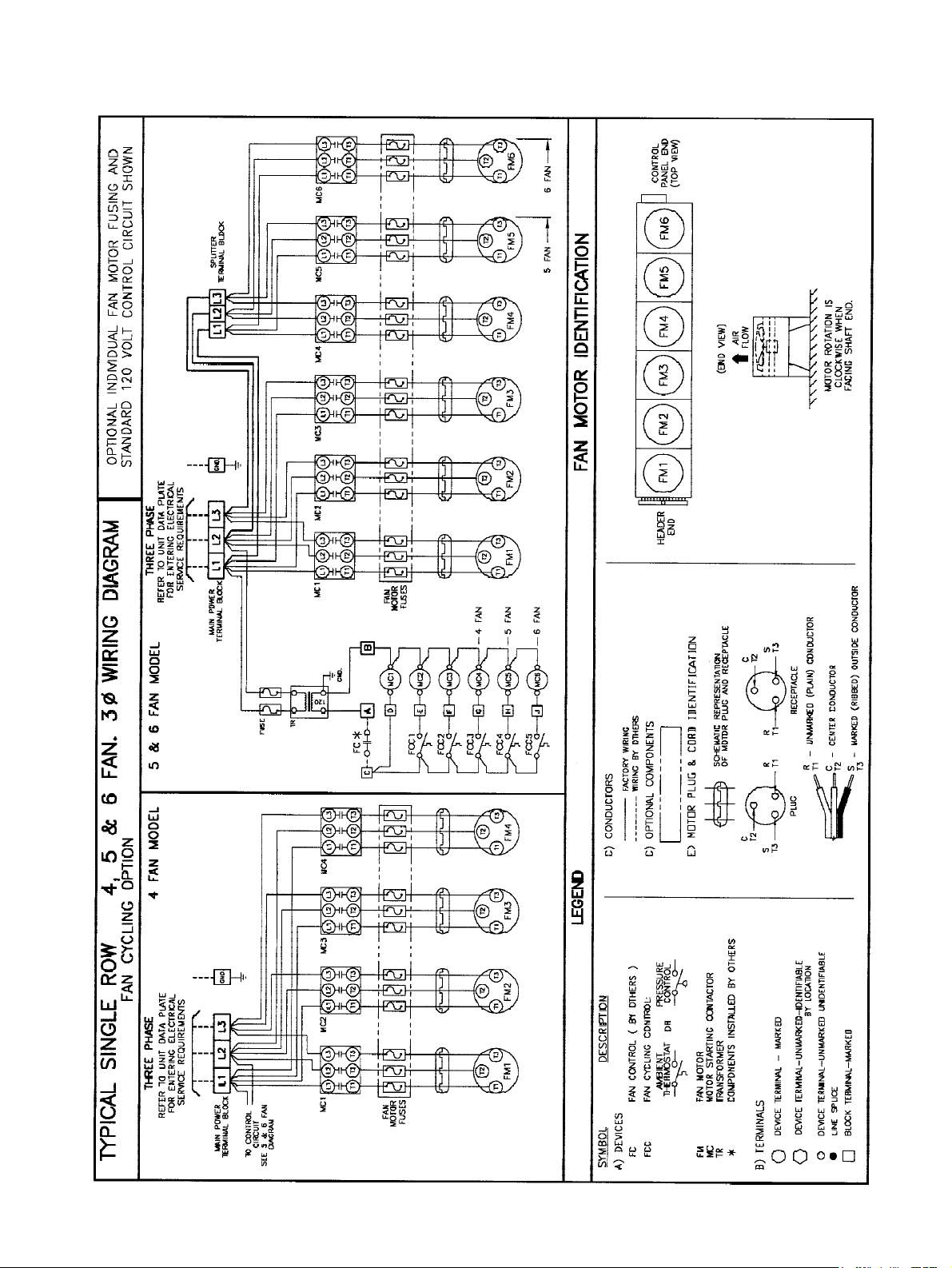

Page 8

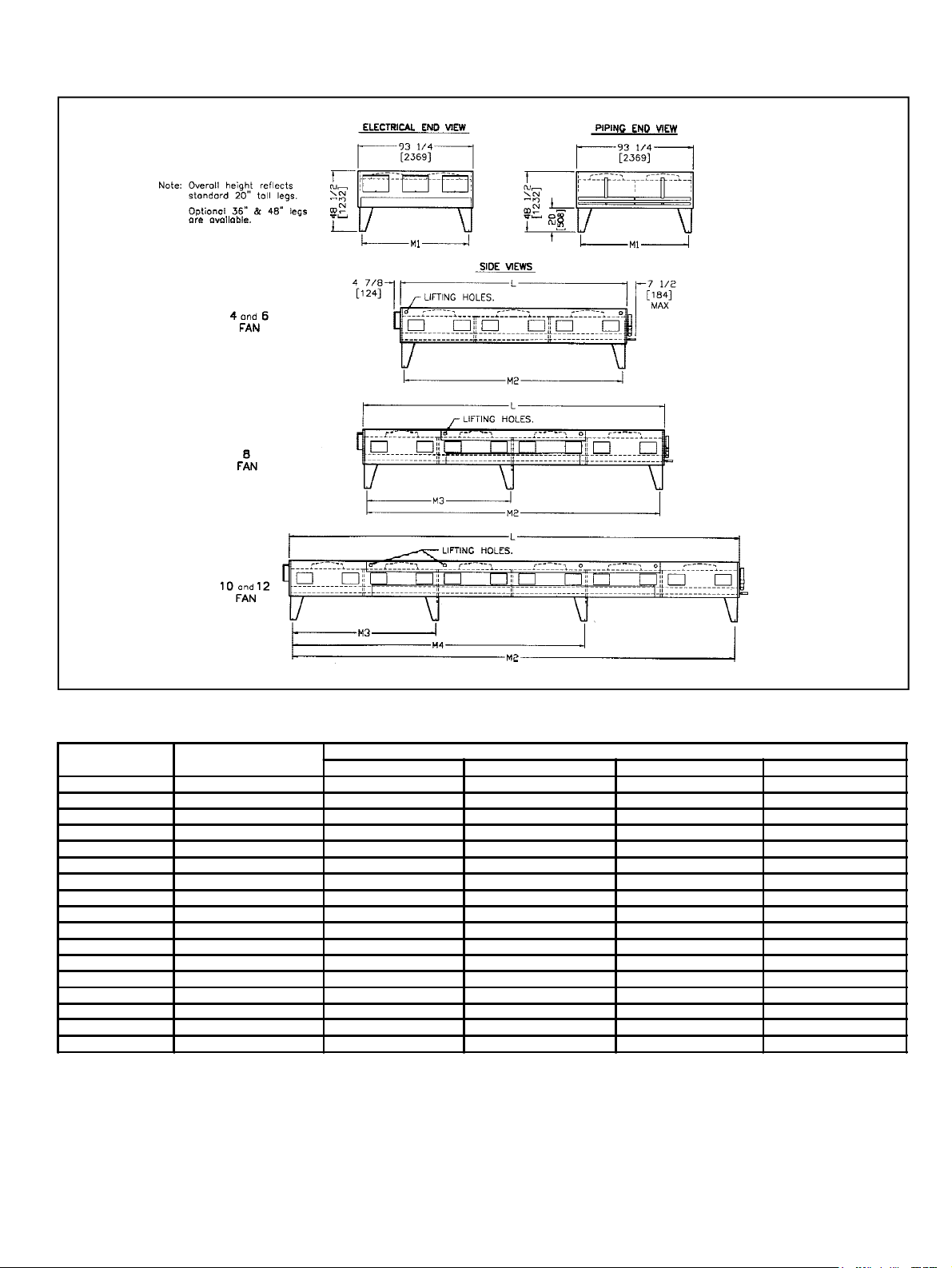

WIRING DIAGRAMS

(SINGLE ROW MODELS)

Note: 1∅ Motors not available

on 183” long models.

- 8 -

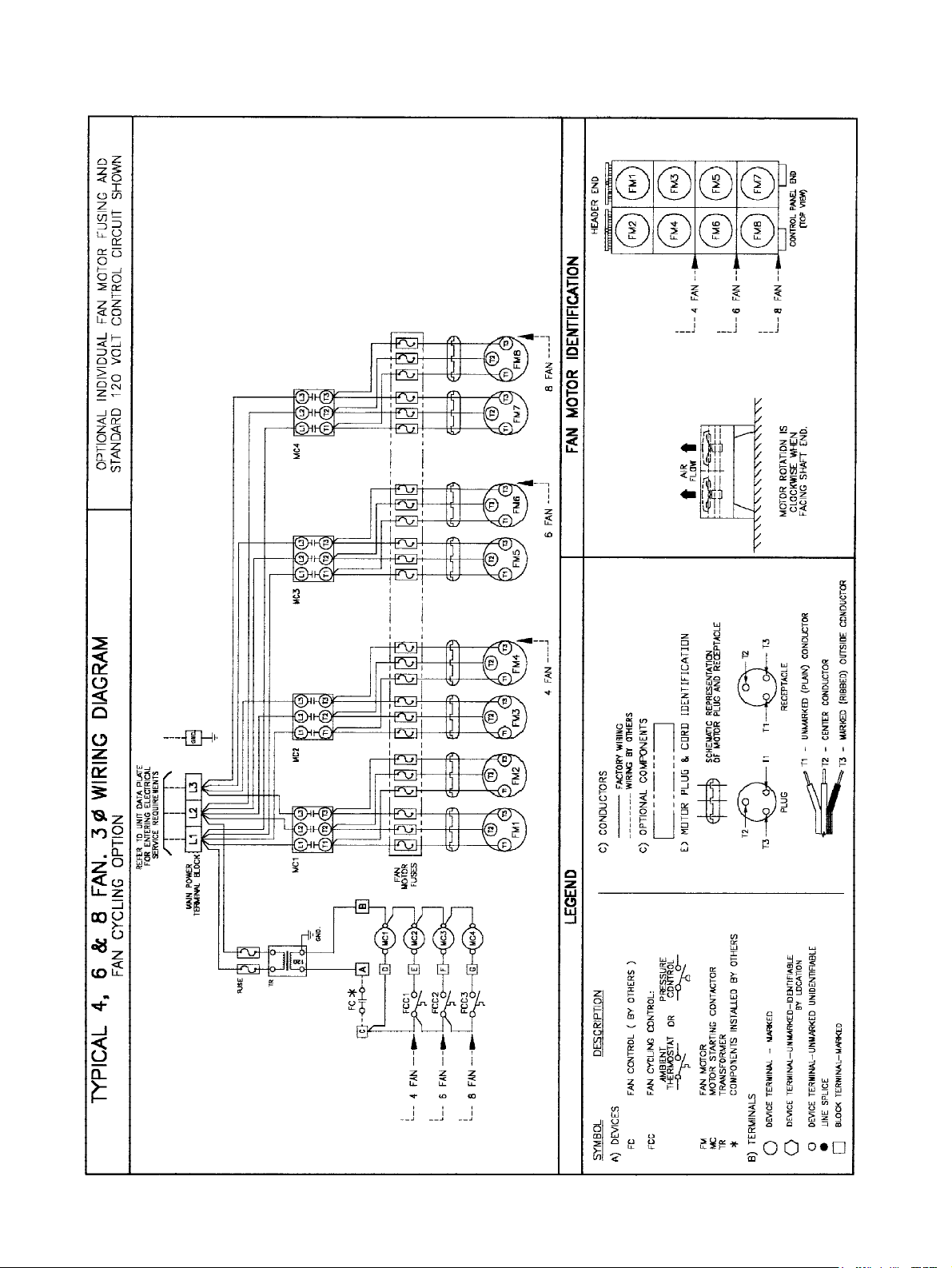

Page 9

WIRING DIAGRAMS

(SINGLE ROW MODELS)

- 9 -

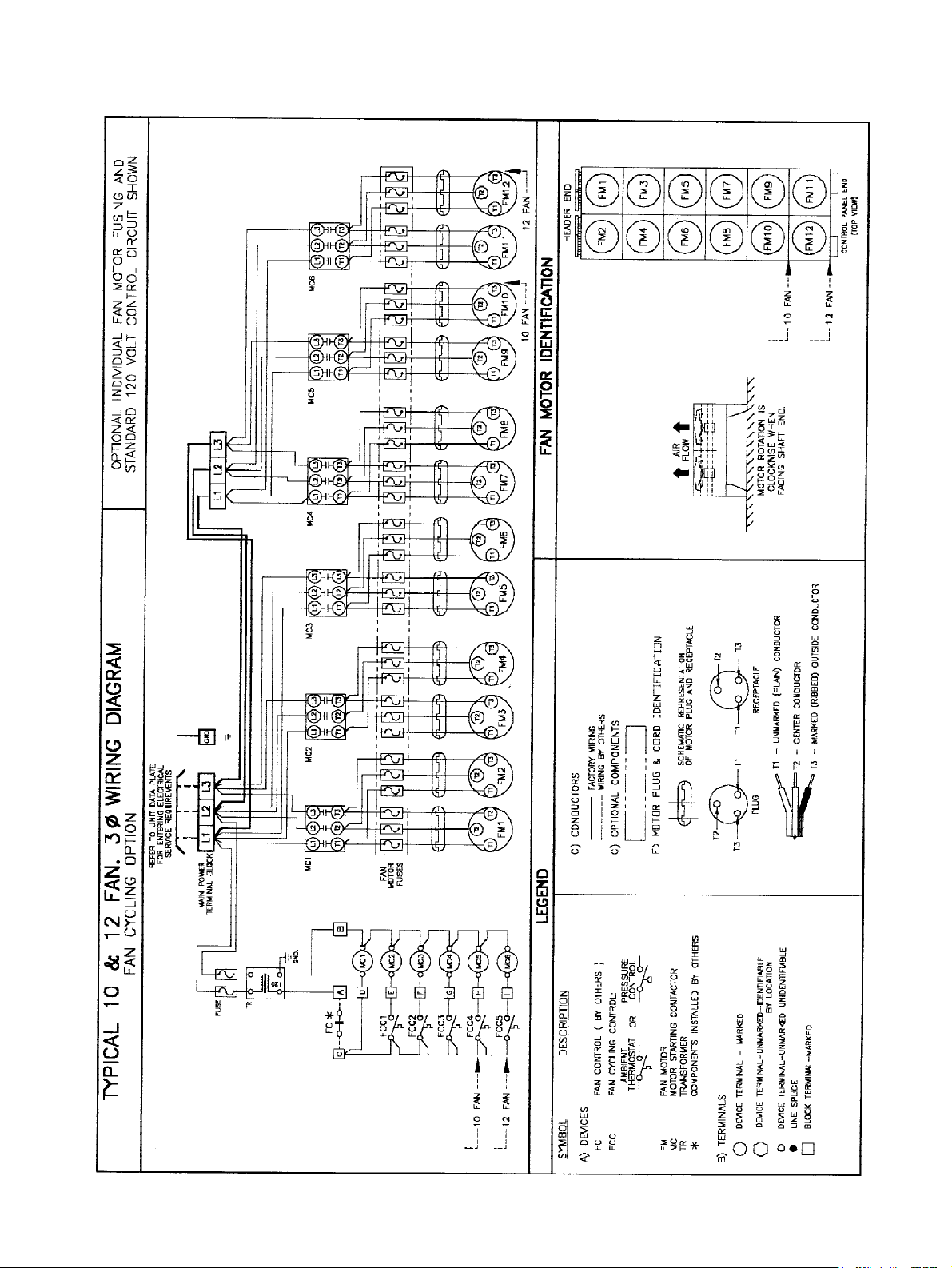

Page 10

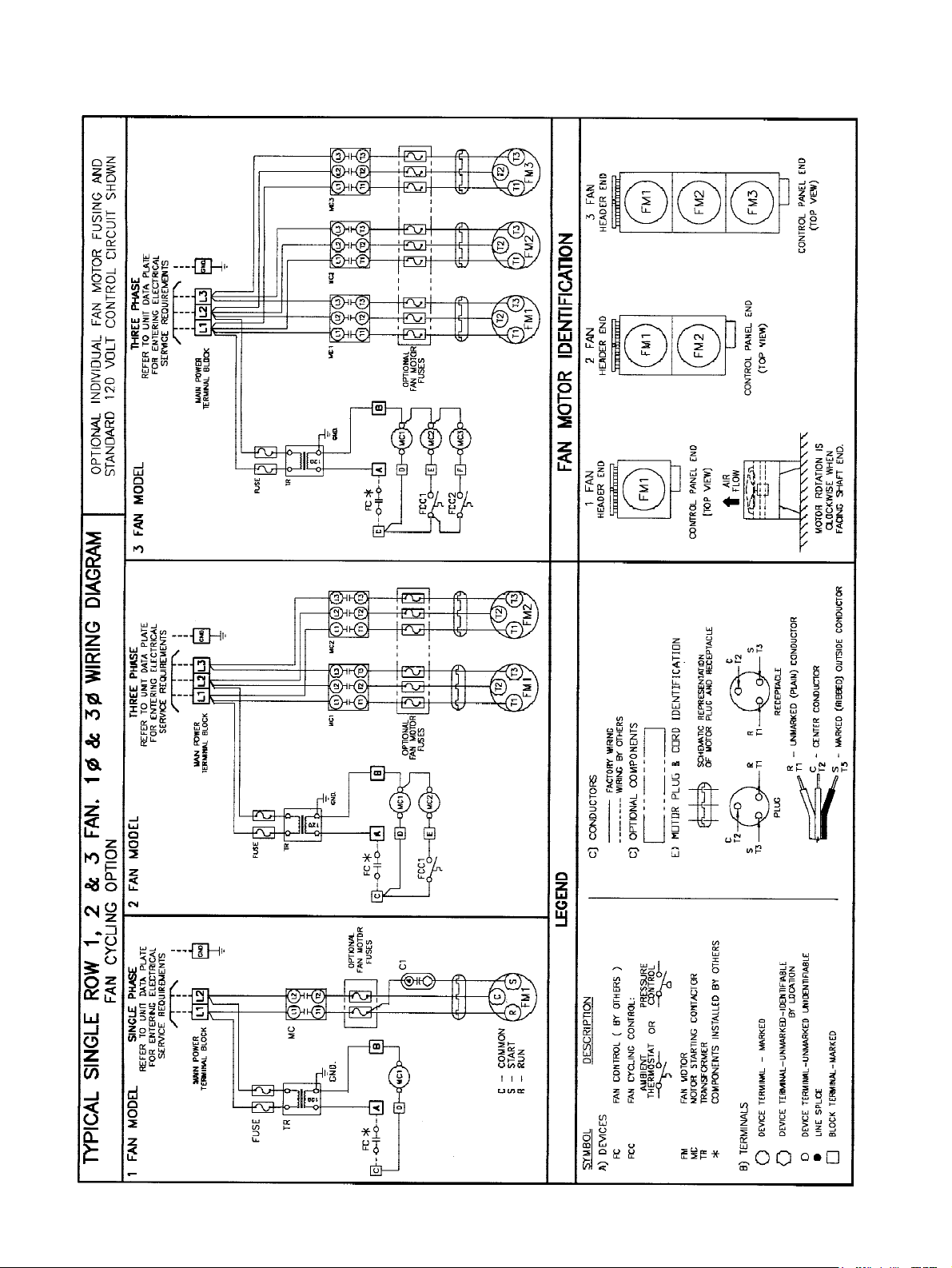

WIRING DIAGRAMS

(DOUBLE ROW MODELS)

- 10 -

Page 11

WIRING DIAGRAMS

(DOUBLE ROW MODELS)

- 11 -

Page 12

CAPACITY DATA - 550 RPM MODELS - R22

BVC

MODEL

NUMBER

007

009

010

011

012

013

017

019

022

024

027

029

034

037

041

043

048

056

063

068

079

085

095

103

039

045

049

054

058

067

073

081

086

096

112

126

137

158

172

190

206

TOTAL HEAT OF REJECTION CAPACITY (MBH)

Fan Rows

1°F

(0.56°C)

1 x 1 2.540 25.4 38.1 50.8 76.2 2.324 2.059 4 0.63

1 x 1 3.162 31.6 47.4 63.2 94.8 3.011 2.760 8 0.40

1 x 1 3.523 35.2 52.8 70.5 106 3.312 3.014 9 0.39

1 x 1 3.949 39.5 59.2 79.0 118 3.822 3.568 8 0.49

1 x 1 4.298 43.0 64.5 86.0 129 4.104 3.835 8 0.54

1 x 1 4.580 45.8 68.7 91.6 137 4.503 4.288 10 0.46

1 x 2 6.316 63.2 94.7 126 189 6.015 5.514 14 0.45

1 x 2 7.008 70.1 105 140 210 6.589 5.997 18 0.39

1 x 2 7.898 79.0 118 158 237 7.644 7.136 18 0.44

1 x 2 8.603 86.0 129 172 258 8.215 7.677 18 0.48

1 x 2 9.159 91.6 137 183 275 9.006 8.575 18 0.51

1 x 3 10.56 106 158 211 317 9.930 9.037 18 0.59

1 x 3 11.82 118 177 236 355 11.44 10.68 24 0.49

1 x 3 12.89 129 193 258 387 12.31 11.51 24 0.54

1 x 3 13.73 137 206 275 412 13.50 12.86 30 0.46

1 x 3 15.24 152 229 305 457 14.17 13.32 36 0.42

1 x 3 16.20 162 243 324 486 15.59 14.92 45 0.36

1 x 4 20.23 202 303 405 607 19.02 17.32 15 1.35

1 x 4 22.53 225 338 451 676 21.52 20.10 20 1.13

1 x 4 23.66 237 355 473 710 23.26 22.15 25 0.95

1 x 5 28.24 282 424 565 847 26.97 25.19 30 0.94

1 x 5 29.18 292 438 592 887 28.69 27.32 37 0.79

1 x 6 33.88 339 508 678 1017 32.36 30.23 30 1.13

1 x 6 35.02 350 525 710 1065 34.42 32.78 37 0.95

2 x 2 14.06 141 211 281 422 13.22 12.03 27 0.52

2 x 2 15.79 158 237 316 474 15.28 14.27 36 0.44

2 x 2 17.18 172 258 344 515 16.40 15.33 36 0.48

2 x 2 18.29 183 274 366 549 17.98 17.12 45 0.41

2 x 3 21.09 211 316 422 633 19.83 18.05 36 0.59

2 x 3 23.66 237 355 473 710 22.90 21.37 48 0.49

2 x 3 25.76 258 386 515 773 24.60 22.99 48 0.54

2 x 3 27.44 274 412 549 823 26.98 25.69 60 0.46

2 x 3 30.48 305 457 610 914 28.34 26.63 72 0.42

2 x 3 32.39 324 486 648 972 31.18 29.85 90 0.36

2 x 4 40.46 405 607 809 1214 38.03 34.63 30 1.35

2 x 4 45.07 451 676 901 1352 43.04 40.20 40 1.13

2 x 4 47.32 473 710 946 1420 46.52 44.29 50 0.95

2 x 5 56.47 565 847 1129 1694 53.93 50.38 60 0.94

2 x 5 59.16 592 887 1183 1775 58.15 55.37 75 0.79

2 x 6 67.77 678 1017 1355 2033 64.72 60.45 60 1.13

2 x 6 70.98 710 1065 1420 2129 69.78 66.44 75 0.95

10°F

(5.56°C)

TEMPERATURE DIFFERENCE (TD)

12 FPI 10 FPI 8 FPI

15°F

(8.3°C)

Double Row Models

20°F

(11.1°C)

Single Row Models

30°F

(16.7°C)

1°F

(0.56°C)

1°F

(0.56°C)

Maximum

No. of

Feeds

MBH

@ 1° F TD

Per Feed

(12 FPI)

Correction Factors for Other refrigerants - Use R22 Values Multiplied By

R134a R12 R507 R404A R407A R407B R502 R407C

0.94 0.95 0.97 0.97 0.97 0.97 0.98 1.00

NOTES: (1) Above capacity data based on 0°F subcooling and at sea level.

(2) TD = Condensing temperature - ambient temperature

(3) Standard fin spacing is 12 FPI except models 056 and 112 (13 FPI).

(4) For High Altitude applications apply the following correction factors:

0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

(5) For 50Hz capacity multiply by 0.92.

- 12 -

Page 13

CAPACITY DATA - 550 RPM MODELS - R404A

BVC

MODEL

NUMBER

007

009

010

011

012

013

017

019

022

024

027

029

034

037

041

043

048

056

063

068

079

085

095

103

039

045

049

054

058

067

073

081

086

096

112

126

137

158

172

190

206

TOTAL HEAT OF REJECTION CAPACITY (MBH)

Fan Rows

1°F

(0.56°C)

1 x 1 2.464 24.6 37.0 49.3 73.9 2.254 1.998 4 0.62

1 x 1 3.067 30.7 46.0 61.3 92.0 2.921 2.677 8 0.38

1 x 1 3.417 34.2 51.3 68.3 103 3.213 2.924 9 0.38

1 x 1 3.830 38.3 57.5 76.6 115 3.707 3.461 8 0.48

1 x 1 4.169 41.7 62.5 83.4 125 3.981 3.720 8 0.52

1 x 1 4.442 44.4 66.6 88.8 133 4.368 4.159 10 0.44

1 x 2 6.126 61.3 91.9 123 184 5.834 5.348 14 0.44

1 x 2 6.798 68.0 102 136 204 6.391 5.817 18 0.38

1 x 2 7.661 76.6 115 153 230 7.415 6.922 18 0.43

1 x 2 8.345 83.5 125 167 250 7.969 7.447 18 0.46

1 x 2 8.885 88.8 133 178 267 8.736 8.318 18 0.49

1 x 3 10.24 102 154 205 307 9.632 8.766 18 0.57

1 x 3 11.46 115 172 229 344 11.09 10.36 24 0.48

1 x 3 12.51 125 188 250 375 11.94 11.16 24 0.52

1 x 3 13.32 133 200 266 400 13.10 12.47 30 0.44

1 x 3 14.78 148 222 296 443 13.75 12.92 36 0.41

1 x 3 15.71 157 236 314 471 15.12 14.48 45 0.35

1 x 4 19.19 192 288 392 589 18.44 16.80 15 1.28

1 x 4 21.86 219 328 437 656 20.87 19.50 20 1.09

1 x 4 22.64 226 340 459 689 22.56 21.48 25 0.91

1 x 5 27.39 274 411 548 822 26.16 24.43 30 0.91

1 x 5 28.31 283 425 574 861 27.82 26.50 37 0.77

1 x 6 32.87 329 493 657 986 31.39 29.32 30 1.10

1 x 6 33.97 340 510 689 1033 33.39 31.80 37 0.92

2 x 2 13.64 136 205 273 409 12.82 11.67 27 0.51

2 x 2 15.31 153 230 306 459 14.82 13.84 36 0.43

2 x 2 16.66 167 250 333 500 15.91 14.87 36 0.46

2 x 2 17.74 177 266 355 532 17.44 16.61 45 0.39

2 x 3 20.46 205 307 409 614 19.24 17.51 36 0.57

2 x 3 22.95 229 344 459 688 22.21 20.73 48 0.48

2 x 3 24.99 250 375 500 750 23.86 22.30 48 0.52

2 x 3 26.62 266 399 532 799 26.17 24.92 60 0.44

2 x 3 29.57 296 443 591 887 27.49 25.83 72 0.41

2 x 3 31.42 314 471 628 943 30.24 28.95 90 0.35

2 x 4 39.24 392 589 785 1177 36.89 33.59 30 1.31

2 x 4 43.72 437 656 874 1311 41.75 38.99 40 1.09

2 x 4 45.90 459 689 918 1377 45.12 42.96 50 0.92

2 x 5 54.78 548 822 1096 1643 52.32 48.86 60 0.91

2 x 5 57.38 574 861 1148 1722 56.41 53.71 75 0.77

2 x 6 65.74 657 986 1315 1972 62.78 58.64 60 1.10

2 x 6 68.85 689 1033 1377 2066 67.68 64.45 75 0.92

10°F

(5.56°C)

TEMPERATURE DIFFERENCE (TD)

12 FPI 10 FPI 8 FPI

15°F

(8.3°C)

20°F

(11.1°C)

Single Row Models

Double Row Models

30°F

(16.7°C)

1°F

(0.56°C)

1°F

(0.56°C)

Maximum

No. of

Feeds

MBH

@ 1° F TD

Per Feed

(12 FPI)

To calculate capacities with other refrigerants, multiply the R22 capacity by the appropriate correction factor.

Refer to the table accompanying each of the R22 tables.

NOTES: (1) Above capacity data based on 0°F subcooling and at sea level.

(2) TD = Condensing temperature - ambient temperature

(3) Standard fin spacing is 12 FPI except models 056 and 112 (13 FPI).

(4) For High Altitude applications apply the following correction factors:

0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

(5) For 50Hz capacity multiply by 0.92.

- 13 -

Page 14

GENERAL SPECIFICATIONS - 550 RPM MODELS - R22

BVC

MODEL

NUMBER

1B11007 4 1.7 0.8 11.0 5.2 4630 7900 1 - 1 1/8 1 - 7/8 360 163

1B11009 8 2.2 1.0 17.0 7.5 4060 6900 1 - 1 3/8 1 - 7/8 375 170

1B11010 9 2.8 1.3 21.0 9.5 4630 7900 1 - 1 3/8 1 - 7/8 420 191

1B11011 8 3.9 1.8 27.0 12.0 4450 7600 1 - 1 3/8 1 - 1 1/8 440 200

1B11012 8 4.3 2.0 31.0 14.0 4660 7900 1 - 1 3/8 1 - 1 1/8 480 218

1B11013 10 5.2 2.4 39.0 18.0 4480 7600 1 - 1 5/8 1 - 1 1/8 505 229

1B12017 14 4.1 1.9 31.0 14.0 8100 13800 1 - 1 5/8 1 - 1 1/8 565 256

1B12019 18 6.1 2.8 44.0 20.0 9300 15700 1 - 2 1/8 1 - 1 3/8 630 286

1B12022 18 7.4 3.4 55.0 25.0 8900 15100 1 - 2 1/8 1 - 1 3/8 675 306

1B12024 18 8.3 3.8 62.0 28.0 9300 15800 1 - 2 1/8 1 - 1 3/8 740 336

1B12027 18 10.0 4.5 75.0 34.0 9000 15300 1 - 2 1/8 1 - 1 3/8 790 358

1B13029 18 9.0 4.1 61.0 28.0 13800 23500 1 - 2 1/8 1 - 1 5/8 840 381

1B13034 24 10.0 4.5 78.0 35.0 13300 22700 1 - 2 1/8 1 - 1 5/8 905 410

1B13037 24 12.0 5.4 94.0 42.0 14000 23800 1 - 2 5/8 1 - 1 5/8 1000 454

1B13041 30 14.0 6.4 113 51.0 13500 22900 1 - 2 5/8 1 - 1 5/8 1070 485

1B13043 36 17.5 7.9 128 57.8 17100 29200 1 - 2 5/8 1 - 1 5/8 1055 479

1B13048 45 20.5 9.3 152 68.9 16700 28300 1 - 2 5/8 1 - 1 5/8 1150 522

2B14056 15 25.9 11.8 183 83.2 23200 39500 1 - 2 5/8 1 - 2 1/8 1600 726

2B14063 20 32.5 14.7 239 108 22800 38800 1 - 2 5/8 1 - 2 1/8 1650 748

2B14068 25 38.0 17.2 286 130 22200 37700 1 - 2 5/8 1 - 2 1/8 1750 794

2B15079 30 38.5 17.5 290 131 28500 48500 1 - 2 5/8 1 - 2 1/8 2063 936

2B15085 37 48.8 22.2 356 161 27700 47200 1 - 2 5/8 1 - 2 5/8 2188 992

2B16095 30 53.5 24.3 365 165 34200 58200 1 - 3 1/8 1 - 3 1/8 2475 1123

2B16103 37 61.2 27.7 436 198 33300 56600 1 - 3 1/8 1 - 3 1/8 2625 1191

1B22039 27 16.0 7.3 104 47.0 18500 31500 2 - 2 1/8 2 - 1 3/8 1060 481

1B22045 36 19.0 8.6 126 57.0 17800 30300 2 - 2 1/8 2 - 1 3/8 1145 519

1B22049 36 21.0 9.5 141 64.0 18600 31700 2 - 2 1/8 2 - 1 3/8 1255 569

1B22054 45 23.0 10.0 167 76.0 17900 30500 2 - 2 1/8 2 - 1 3/8 1350 612

1B23058 36 22.0 10.0 141 64.0 27700 47100 2 - 2 1/8 2 - 1 5/8 1420 644

1B23067 48 26.0 12.0 174 79.0 26700 45300 2 - 2 1/8 2 - 1 5/8 1550 703

1B23073 48 30.0 14.0 212 96.0 28000 47500 2 - 2 5/8 2 - 1 5/8 1710 776

1B23081 60 35.0 16.0 251 114 26900 45800 2 - 2 5/8 2 - 1 5/8 1865 846

1B23086 72 35.0 16.0 255 116 34300 58300 2 - 2 5/8 2 - 1 5/8 2110 957

1B23096 90 41.0 19.0 304 138 33300 56700 2 - 2 5/8 2 - 1 5/8 2300 1043

2B24112 30 53.0 24.0 375 170 46500 79000 2 - 2 5/8 2 - 2 1/8 3200 1451

2B24126 40 65.0 30.0 477 217 45600 77600 2 - 2 5/8 2 - 2 1/8 3300 1497

2B24137 50 77.0 35.0 579 263 44400 75500 2 - 2 5/8 2 - 2 1/8 3500 1588

2B25158 60 77.0 35.0 579 263 57000 96900 2 - 2 5/8 2 - 2 1/8 4125 1871

2B25172 75 99.0 45.0 721 327 55500 94300 2 - 2 5/8 2 - 2 5/8 4375 1984

2B26190 60 107.0 49.0 729 331 68400 116300 2 - 3 1/8 2 - 3 1/8 4950 2245

2B26206 75 124.0 56.0 883 401 66600 113200 2 - 3 1/8 2 - 3 1/8 5250 2381

Total No.

of Feeds

R22 Refrigerant Charge

(2)

Normal

lbs kg lbs kg CFM m3/h lbs kg

(1)

90% FULL

(3)

Single Row Models

Double Row Models

Air Flow Rate

Piping Connections

(4)

Inlet

Qty - OD

Outlet

Condenser Weight

Qty - OD

(5)

NOTES: (1) For R407A, R507 use R22 Charge x 0.87. For R407-C use R22 Charge x 0.97.

For R134a and R502 use R22 Charge. For R12 use R22 Charge x 1.1.

(2) Normal Charge is the refrigerant charge for warm ambient or summer operation. For low ambient

or winter charge with flooded head pressure control and fan cycling see Page 33 and Page 34.

(3) 90% FULL is the liquid refrigerant weight at 90% of internal volume and is for reference ONLY.

(4) For 50Hz Fan data use 60Hz CFM (m3/h) x 0.83.capacity multiply by 0.92.

(5) Less weight pf refrigerant charge.

- 14 -

Page 15

ELECTRICAL DATA - 550 RPM MODELS 60Hz

NO.

OF

FANS

1

2

3

4

5

6

8

10

12

TOTAL

FLA

208-230/3/60 460/3/60 575/3/60

MCA MOP

2.8 3.5 15 1.3 1.6 15 1.1 1.4 15

5.6 6.3 15 2.6 2.9 15 2.2 2.5 15

8.4 9.1 15 3.9 4.2 15 3.3 3.6 15

11.2 11.9 15 5.2 5.5 15 4.4 4.7 15

14.0 16 20 6.5 6.8 15 5.5 5.8 15

16.8 21 25 7.8 8.1 15 6.6 6.9 15

22.4 26 30 10.4 10.7 15 8.8 9.1 15

28.0 31 35 13 16 20 11 11.3 15

33.6 41 45 15.6 15.9 20 13.2 16 20

M.C.A. = Minimum Circuit Ampacity (AMPS)

M.O.P. = Maximum Overcurrent Protection (AMPS)

ELECTRICAL DATA - 550 (450) RPM MODELS 50Hz

NO.

OF

FANS

1

2

3

4

5

6

8

10

12

TOTAL

FLA

2.2 2.7 15 1 1.2 15

4.4 4.9 15 2 2.2 15

6.5 7.1 15 2.9 3.2 15

8.7 9.3 15 3.9 4.2 15

10.9 11.4 15 4.9 5.1 15

13.1 16 20 5.9 6.1 15

17.4 21 25 7.8 8.1 15

17.4 21 25 7.8 8.1 15

26.2 31 35 11.8 12 15

200-220/3/50 380-400/3/50

MCA MOP

TOTAL

FLA

MCA MOP

TOTAL

FLA

TOTAL

FLA

MCA MOP

MCA MOP

M.C.A. = Minimum Circuit Ampacity (AMPS)

M.O.P. = Maximum Overcurrent Protection (AMPS)

- 15 -

Page 16

CAPACITY DATA - 1140 RPM MODELS - R22

BVC

MODEL

NUMBER

007

009

010

011

012

013

017

019

022

024

027

029

034

037

041

043

048

056

063

068

079

085

095

103

039

045

049

054

058

067

073

081

086

096

112

126

137

158

172

190

206

TOTAL HEAT OF REJECTION CAPACITY (MBH)

Fan Rows

1°F

(0.56°C)

1 x 1 3.627 36.3 54.4 72.5 109 3.303 2.911 7 0.52

1 x 1 4.989 49.9 74.8 100 150 4.677 4.220 8 0.62

1 x 1 5.516 55.2 82.7 110 165 5.094 4.572 9 0.61

1 x 1 6.446 64.5 96.7 129 193 6.118 5.589 12 0.54

1 x 1 7.157 71.6 107 143 215 6.710 6.114 12 0.60

1 x 1 7.985 79.9 120 160 240 7.678 7.095 15 0.53

1 x 2 9.971 100 150 199 299 9.348 8.434 14 0.71

1 x 2 10.98 110 165 220 329 10.14 9.100 18 0.61

1 x 2 12.90 129 194 258 387 12.25 11.19 24 0.54

1 x 2 14.34 143 215 287 430 13.44 12.25 24 0.60

1 x 2 15.98 160 240 320 479 15.37 14.20 30 0.53

1 x 3 16.55 166 248 331 497 15.29 13.72 27 0.61

1 x 3 19.31 193 290 386 579 18.33 16.74 36 0.54

1 x 3 21.49 215 322 430 645 20.15 18.36 36 0.60

1 x 3 23.96 240 359 479 719 23.04 21.29 45 0.53

1 x 3 25.40 254 381 508 762 24.03 21.94 36 0.71

1 x 3 28.48 285 427 570 854 27.14 25.19 45 0.63

1 x 4 31.01 310 465 620 930 28.64 25.71 22 1.41

1 x 4 36.76 368 551 735 1103 34.77 31.76 30 1.23

1 x 4 40.34 403 605 807 1210 38.44 35.67 37 1.09

1 x 5 46.06 461 691 921 1382 43.57 39.79 30 1.54

1 x 5 50.43 504 756 1009 1513 48.06 44.59 37 1.36

1 x 6 55.27 553 829 1105 1658 52.29 47.75 30 1.84

1 x 6 60.51 605 908 1210 1815 57.66 53.51 37 1.64

2 x 2 22.04 220 331 441 661 20.35 18.27 36 0.61

2 x 2 25.79 258 387 516 774 24.48 22.37 48 0.54

2 x 2 28.63 286 429 573 859 26.84 24.45 48 0.60

2 x 2 31.92 319 479 638 957 30.69 28.36 60 0.53

2 x 3 33.06 331 496 661 992 30.53 27.40 54 0.61

2 x 3 38.65 386 580 773 1159 36.69 33.52 72 0.54

2 x 3 42.93 429 644 859 1288 40.25 36.67 72 0.60

2 x 3 47.89 479 718 958 1437 46.05 42.55 90 0.53

2 x 3 50.80 508 762 1016 1524 48.06 43.89 72 0.71

2 x 3 56.97 570 854 1139 1709 54.29 50.38 90 0.63

2 x 4 63.44 634 952 1269 1903 58.58 52.58 45 1.41

2 x 4 73.52 735 1103 1470 2205 69.55 63.51 60 1.23

2 x 4 81.76 818 1226 1635 2453 77.92 72.30 75 1.09

2 x 5 92.12 921 1382 1842 2764 87.15 79.59 60 1.54

2 x 5 102.2 1022 1533 2044 3067 97.41 90.39 75 1.36

2 x 6 110.5 1105 1658 2211 3316 104.6 95.50 60 1.84

2 x 6 122.7 1227 1840 2453 3680 116.9 108.5 75 1.64

10°F

(5.56°C)

TEMPERATURE DIFFERENCE (TD)

12 FPI 10 FPI 8 FPI

15°F

(8.3°C)

20°F

(11.1°C)

Single Row Models

Double Row Models

30°F

(16.7°C)

1°F

(0.56°C)

1°F

(0.56°C)

Maximum

No. of

Feeds

MBH

@ 1° F TD

Per Feed

(12 FPI)

Correction Factors for Other refrigerants - Use R22 Values Multiplied By

R134a R12 R507 R404A R407A R407B R502 R407C

0.94 0.95 0.97 0.97 0.97 0.97 0.98 1.00

NOTES: (1) Above capacity data based on 0°F subcooling and at sea level.

(2) TD = Condensing temperature - ambient temperature

(3) Standard fin spacing is 12 FPI except models 056 and 112 (13 FPI).

(4) For High Altitude applications apply the following correction factors:

0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

(5) For 50Hz capacity multiply by 0.92.

- 16 -

Page 17

CAPACITY DATA - 1140 RPM MODELS - R404A

BVC

MODEL

NUMBER

007

009

010

011

012

013

017

019

022

024

027

029

034

037

041

043

048

056

063

068

079

085

095

103

039

045

049

054

058

067

073

081

086

096

112

126

137

158

172

190

206

TOTAL HEAT OF REJECTION CAPACITY (MBH)

TEMPERATURE DIFFERENCE (TD)

Fan Rows

1°F

(0.56°C)

1 x 1 3.518 35.2 52.8 70.4 106 3.204 2.824 7 0.50

1 x 1 4.839 48.4 72.6 96.8 145 4.537 4.093 8 0.60

1 x 1 5.351 53.5 80.3 107 161 4.941 4.435 9 0.59

1 x 1 6.252 62.5 93.8 125 188 5.935 5.422 12 0.52

1 x 1 6.943 69.4 104 139 208 6.509 5.930 12 0.58

1 x 1 7.746 77.5 116 155 232 7.448 6.882 15 0.52

1 x 2 9.672 96.7 145 193 290 9.068 8.181 14 0.69

1 x 2 10.65 106 160 213 319 9.834 8.827 18 0.59

1 x 2 12.52 125 188 250 375 11.88 10.85 24 0.52

1 x 2 13.91 139 209 278 417 13.04 11.88 24 0.58

1 x 2 15.50 155 233 310 465 14.91 13.77 30 0.52

1 x 3 16.06 161 241 321 482 14.83 13.31 27 0.59

1 x 3 18.73 187 281 375 562 17.78 16.24 36 0.52

1 x 3 20.85 208 313 417 625 19.54 17.81 36 0.58

1 x 3 23.24 232 349 465 697 22.35 20.65 45 0.52

1 x 3 24.64 246 370 493 739 23.31 21.29 36 0.68

1 x 3 27.63 276 414 553 829 26.33 24.43 45 0.61

1 x 4 30.08 301 451 602 903 27.78 24.93 22 1.37

1 x 4 35.65 357 535 713 1070 33.73 30.80 30 1.19

1 x 4 39.13 391 587 783 1174 37.29 34.60 37 1.06

1 x 5 44.68 447 670 894 1340 42.27 38.60 30 1.49

1 x 5 48.92 489 734 978 1467 46.61 43.26 37 1.32

1 x 6 53.61 536 804 1072 1608 50.72 46.32 30 1.79

1 x 6 58.69 587 880 1174 1761 55.93 51.90 37 1.59

2 x 2 21.38 214 321 428 641 19.74 17.72 36 0.59

2 x 2 25.02 250 375 500 751 23.75 21.70 48 0.52

2 x 2 27.77 278 417 555 833 26.03 23.72 48 0.58

2 x 2 30.96 310 464 619 929 29.77 27.51 60 0.52

2 x 3 32.07 321 481 641 962 29.61 26.58 54 0.59

2 x 3 37.49 375 562 750 1125 35.59 32.51 72 0.52

2 x 3 41.64 416 625 833 1249 39.04 35.57 72 0.58

2 x 3 46.45 465 697 929 1394 44.66 41.27 90 0.52

2 x 3 49.28 493 739 986 1478 46.62 42.57 72 0.68

2 x 3 55.26 553 829 1105 1658 52.66 48.86 90 0.61

2 x 4 61.53 615 923 1231 1846 56.82 51.00 45 1.37

2 x 4 71.31 713 1070 1426 2139 67.46 61.61 60 1.19

2 x 4 79.31 793 1190 1586 2379 75.58 70.14 75 1.06

2 x 5 89.36 894 1340 1787 2681 84.53 77.20 60 1.49

2 x 5 99.15 992 1487 1983 2975 94.49 87.68 75 1.32

2 x 6 107.2 1072 1608 2145 3217 101.4 92.64 60 1.79

2 x 6 119.0 1190 1785 N/A N/A 113.4 105.2 75 1.59

10°F

(5.56°C)

12 FPI 10 FPI 8 FPI

15°F

(8.3°C)

Double Row Models

20°F

(11.1°C)

Single Row Models

30°F

(16.7°C)

1°F

(0.56°C)

1°F

(0.56°C)

Maximum

No. of

Feeds

MBH

@ 1° F TD

Per Feed

(12 FPI)

To calculate capacities with other refrigerants, multiply the R22 capacity by the appropriate correction factor.

Refer to the table accompanying each of the R22 tables.

NOTES: (1) Above capacity data based on 0°F subcooling and at sea level.

(2) TD = Condensing temperature - ambient temperature

(3) Standard fin spacing is 12 FPI except models 056 and 112 (13 FPI).

(4) For High Altitude applications apply the following correction factors:

0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

(5) For 50Hz capacity multiply by 0.92.

- 17 -

Page 18

GENERAL SPECIFICATIONS - 1140 RPM MODELS

BVC

MODEL

NUMBER

1C11007 7 1.7 0.8 11.0 5.2 9590 16300 1 - 1 1/8 1 - 7/8 360 163

1C11009 8 2.2 1.0 17.0 7.5 8420 14300 1 - 1 3/8 1 - 7/8 375 170

1C11010 9 2.8 1.3 21.0 9.5 9590 16300 1 - 1 3/8 1 - 7/8 420 191

1C11011 12 3.9 1.8 27.0 12.0 9230 15700 1 - 1 3/8 1 - 1 1/8 440 200

1C11012 12 4.3 2.0 31.0 14.0 9660 16400 1 - 1 3/8 1 - 1 1/8 480 218

1C11013 15 5.2 2.4 39.0 18.0 9290 15800 1 - 1 5/8 1 - 1 1/8 505 229

1C12017 14 4.1 1.9 31.0 14.0 16800 28500 1 - 1 5/8 1 - 1 1/8 565 256

1C12019 18 6.1 2.8 44.0 20.0 19200 32600 1 - 2 1/8 1 - 1 3/8 630 286

1C12022 24 7.4 3.4 55.0 25.0 18400 31200 1 - 2 1/8 1 - 1 3/8 675 306

1C12024 24 8.3 3.8 62.0 28.0 19300 32800 1 - 2 1/8 1 - 1 3/8 740 336

1C12027 30 10.0 4.5 75.0 34.0 18600 31700 1 - 2 1/8 1 - 1 3/8 790 358

1C13029 27 9.0 4.1 61.0 28.0 28700 48800 1 - 2 1/8 1 - 1 5/8 840 381

1C13034 36 10.0 4.5 78.0 35.0 27600 47000 1 - 2 1/8 1 - 1 5/8 905 410

1C13037 36 12.0 5.4 94.0 42.0 29000 49200 1 - 2 5/8 1 - 1 5/8 1000 454

1C13041 45 14.0 6.4 113 51.0 27900 47400 1 - 2 5/8 1 - 1 5/8 1070 485

1C13043 36 17.5 7.9 128 57.8 35500 60400 1 - 2 5/8 1 - 1 5/8 1055 479

1C13048 45 20.5 9.3 152 68.9 34500 58700 1 - 2 5/8 1 - 1 5/8 1150 522

2C14056 22 25.9 11.8 183 83.2 48100 81900 1 - 2 5/8 1 - 2 1/8 1600 726

2C14063 30 32.5 14.7 239 108 47300 80400 1 - 2 5/8 1 - 2 1/8 1650 748

2C14068 37 38.0 17.2 286 130 46000 78200 1 - 2 5/8 1 - 2 1/8 1750 794

2C15079 30 38.5 17.5 290 131 59100 100500 1 - 2 5/8 1 - 2 1/8 2063 936

2C15085 37 48.8 22.2 356 161 57500 97800 1 - 2 5/8 1 - 2 5/8 2188 992

2C16095 30 53.5 24.3 365 165 70900 120600 1 - 3 1/8 1 - 3 1/8 2475 1123

2C16103 37 61.2 27.7 436 198 69000 117300 1 - 3 1/8 1 - 3 1/8 2625 1191

1C22039 36 16.0 7.3 104 47.0 38400 65200 2 - 2 1/8 2 - 1 3/8 1060 481

1C22045 48 19.0 8.6 126 57.0 36900 62700 2 - 2 1/8 2 - 1 3/8 1145 519

1C22049 48 21.0 9.5 141 64.0 38600 65700 2 - 2 1/8 2 - 1 3/8 1255 569

1C22054 60 23.0 10.0 167 76.0 37200 63200 2 - 2 1/8 2 - 1 3/8 1350 612

1C23058 54 22.0 10.0 141 64.0 57400 97600 2 - 2 1/8 2 - 1 5/8 1420 644

1C23067 72 26.0 12.0 174 79.0 55300 93900 2 - 2 1/8 2 - 1 5/8 1550 703

1C23073 72 30.0 14.0 212 96.0 57900 98500 2 - 2 5/8 2 - 1 5/8 1710 776

1C23081 90 35.0 16.0 251 114 55800 94800 2 - 2 5/8 2 - 1 5/8 1865 846

1C23086 72 35.0 16.0 255 116 71100 120800 2 - 2 5/8 2 - 1 5/8 2110 957

1C23096 90 41.0 19.0 304 138 69100 117400 2 - 2 5/8 2 - 1 5/8 2300 1043

2C24112 45 53.0 24.0 375 170 96300 163700 2 - 2 5/8 2 - 2 1/8 3200 1451

2C24126 60 65.0 30.0 477 217 94600 160700 2 - 2 5/8 2 - 2 1/8 3300 1497

2C24137 75 77.0 35.0 579 263 92000 156400 2 - 2 5/8 2 - 2 1/8 3500 1588

2C25158 60 77.0 35.0 579 263 118200 200900 2 - 2 5/8 2 - 2 1/8 4125 1871

2C25172 75 99.0 45.0 721 327 115000 195500 2 - 2 5/8 2 - 2 5/8 4375 1984

2C26190 60 107.0 49.0 729 331 141800 241100 2 - 3 1/8 2 - 3 1/8 4950 2245

2C26206 75 124.0 56.0 883 401 138000 234600 2 - 3 1/8 2 - 3 1/8 5250 2381

Total No.

of Feeds

R22 Refrigerant Charge

(2)

Normal

lbs kg lbs kg CFM m3/h lbs kg

(1)

90% FULL

(3)

Single Row Models

Double Row Models

Air Flow Rate

Piping Connections

(4)

Inlet

Qty - OD

Outlet

Qty - OD

Condenser Weight

(5)

NOTES: (1) For R407A, R507 use R22 Charge x 0.87. For R407-C use R22 Charge x 0.97.

For R134a and R502 use R22 Charge. For R12 use R22 Charge x 1.1.

(2) Normal Charge is the refrigerant charge for warm ambient or summer operation. For low ambient

or winter charge with flooded head pressure control and fan cycling see Page 33 and Page 34.

(3) 90% FULL is the liquid refrigerant weight at 90% of internal volume and is for reference ONLY.

(4) For 50Hz Fan data use 60Hz CFM (m3/h) x 0.83.capacity multiply by 0.92.

(5) Less weight pf refrigerant charge.

- 18 -

Page 19

ELECTRICAL DATA - 1140 RPM MODELS 60Hz

NO.

OF

FANS

1

2

3

4

5

6

8

10

12

TOTAL

FLA

208-230/3/60 460/3/60 575/3/60

MCA MOP

6.6 8.3 15 3.1 3.9 15 2.5 3.1 15

13.2 14.9 20 6.2 7 15 5 5.6 15

19.8 21.5 25 9.3 10.1 15 7.5 8.1 15

26.4 31 35 12.4 13.2 15 10 10.6 15

33 34.7 40 15.5 16.3 20 12.5 13.1 15

39.6 46 50 18.6 21 25 15 15.6 20

52.8 61 70 24.8 25.6 30 20 20.6 25

66 71 80 31 36 40 25 25.6 30

79.2 91 100 37.2 41 45 30 36 40

M.C.A. = Minimum Circuit Ampacity (AMPS)

M.O.P. = Maximum Overcurrent Protection (AMPS)

ELECTRICAL DATA - 1140 (950) RPM MODELS 50Hz

NO.

OF

FANS

1

2

3

4

5

6

8

10

12

TOTAL

FLA

5.9 7.4 15 2.7 3.4 15

11.8 13.3 15 5.4 6 15

17.7 19.1 25 8.0 8.7 15

23.6 25 30 10.7 11.4 15

29.5 36 40 13.4 16 20

35.3 41 45 16.1 16.8 20

47.1 51 60 21.4 26 30

58.9 71 80 26.8 31 35

70.7 81 90 32.2 36 40

M.C.A. = Minimum Circuit Ampacity (AMPS)

M.O.P. = Maximum Overcurrent Protection (AMPS)

200-220/3/50 380-400/3/50

MCA MOP

TOTAL

FLA

MCA MOP

TOTAL

FLA

TOTAL

FLA

MCA MOP

MCA MOP

- 19 -

Page 20

CONDENSER THEORY

The purpose of a refrigeration system is to absorb

heat from an area where it is not wanted and reject

this heat to an area where it is unobjectionable.

By referring to the diagram below, it can be seen

that only a few components are required to perform

this task.

High pressure/high temperature vapor leaves the

compressor and is forced into the condenser via the

discharge line. The condenser first desuperheats the

vapor down to its saturation point. This saturation

point can be expressed as the condensing

temperature of the refrigerant and varies with

condenser size, load and ambient temperature.

Now the condenser must remove the latent heat of

condensation from the refrigerant so that it may fully

condense. After the refrigerant has fully condensed,

it will be subcooled to some extent.

The liquid leaving the condenser is still at a high

pressure but at a much lower temperature and drains

into the receiver. As the liquid level in the receiver

increases, the vapor is allowed to vent back up to the

condenser via the condensate line.

Because the dip tube almost reaches the bottom of the

receiver, only liquid will enter the liquid line. This liquid

now passes through the metering device where its

pressure is reduced to the evaporating pressure.

The temperature will drop with pressure since the

refrigerant will always attempt to meet its saturation

point during a change of state.

The condensing temperature decreases as the

ambient temperature drops and/or as the condenser

surface increases.

THE BASIC REFRIGERATION CYCLE

- 20 -

Page 21

GLOSSARY OF TERMS

Balance point - after a system stabilizes, the heat

added to the refrigerant during the refrigeration cycle

will equal the heat rejected at the condenser. The

balance point usually refers to the actual TD that the

system is operating at. The balance point could

refer to a low side balance or a high side balance.

For example, a system operating with a 120 oF

condensing temperature in a 90 oF ambient will have

a condenser balance point of 30 oF TD.

Circuit - a circuit can be considered a group of

feeds. A condenser may be sized to handle several

refrigeration systems at one time. Each system is

considered one circuit and the number of feeds

required for each circuit depends on the THR for

that particular system. Each circuit has its own inlet

and outlet header. The number of circuits on a

condenser can not exceed the total number of feeds

available.

Compression Ratio - Compression ratio equals

the discharge pressure in pounds per square inch

absolute (psia) divided by the suction pressure in

psia. The compression ratio in a compressor

increases as suction pressure decreases and as

discharge pressure increases. (at sea-level, psia is

equal to psig plus 14.7).

Compressor Capacity - can be defined as the

actual refrigerating capacity available at the

evaporator and suction line after considering the

overall system balance point. Compressor capacity

is mainly affected by the evaporating and

condensing temperatures of the system.

Condensing Temperature (CT) - is the

temperature where the refrigerant vapor condenses

back to a liquid. This temperature varies with

condenser size. Condensing temperature should be

kept as low as possible to maintain higher

refrigerating capacity and system efficiency

Desuperheat - refers to the lowering of refrigerant

superheat. Hot vapor entering a condenser must

first be desuperheated before any condensing of the

refrigerant can take place.

Evaporating Temperature - the temperature at

which heat is absorbed in the evaporator, at this

temperature, the refrigerant changes from a liquid to

a vapor. This evaporating temperature is dependent

on pressure and must be lower than the surrounding

temperature for heat transfer to take place.

Feed - a single path for refrigerant flow inside a

condenser. This path begins at the inlet header and

terminates at the condenser’s outlet header. These

feeds can be grouped together to accommodate one

or more circuits.

Heat of Compression - heat is added to the

refrigerant as it is compressed. Evidence of this can

be observed on the pressure-enthalpy diagram for

the refrigerant being used. The amount of this heat

is dependent on the refrigerant type and

compression ratio.

Additional heat from friction also increases the heat

of compression. All of this heat along with the heat

absorbed in the evaporator, suction line and any

motor heat must be rejected by the condenser.

Condensate Line - (also called “Drain Leg”) is a

term that describes the refrigerant line between the

condenser and the receiver.

The condensate line should drop vertically and is

typically larger than the liquid line. This is to

promote free draining of the refrigerant from the

condenser to the receiver.

Condenser Temperature Difference (TD) - is the

difference between the condensing temperature of

the refrigerant and the temperature of the air

entering the condenser.

.

Latent Heat of Vaporization (also Latent Heat of

Condensation) - refers to the heat required to fully

vaporize or condense a refrigerant. This latent heat

varies with temperature and pressure. Latent heat is

often referred to as hidden heat since adding heat to a

saturated liquid or removing heat from a saturated

vapor will result in a change of state and heat

content but not a change in temperature.

Liquid Line - is the piping between the receiver and

the metering device. On systems without a receiver,

the liquid line runs between the condenser and the

metering device.

- 21 -

Page 22

GLOSSARY OF TERMS

Open Drive - This term is given to a compressor

where its driving motor is separate from the

compressor. In this type of compressor, motor heat

is not transferred to the refrigerant.

Refrigerating Effect - the total amount of heat

absorbed by the evaporator. This heat includes both

latent heat and superheat. This value is usually

expressed in BTU/Hour, (BTUH), or 1000

BTU/Hour (MBH)

Saturation - occurs whenever the refrigerant exists

in both a vapor and liquid state, example: a

cylinder of refrigerant is in a saturated condition or

state of equilibrium. Any heat removed from a

saturated vapor will result in condensation.

Conversely, any heat added to a saturated liquid

will result in evaporation of the refrigerant.

Temperature pressure charts for the various

refrigerants indicate saturation values. For a single

component refrigerant, each temperature value can

only have one pressure when the refrigerant is

either a saturated vapor or saturated liquid.

A single component refrigerant can not change

state until it approaches its saturation temperature

or pressure. For refrigerant blends, the pressuretemperature relationship is more complex. Simply

stated, Dew point temperature (saturation point in

evaporator-low side) and Bubble point temperature

(saturation point in condenser-high side) are used to

define their saturated condition.

Subcool - to reduce a refrigerant’s temperature below

its saturation point or bubble point. Subcooling of the

refrigerant is necessary in order to maintain a solid

column of liquid at the inlet to the metering device.

Subcooling can take place naturally (in the condenser)

or it can be accomplished by a suction liquid heat

exchanger or a mechanical sub-cooler (separate

refrigeration system).

Superheat - to heat a refrigerant above its saturation

point or dew point. The “amount of superheat” is the

difference between the actual refrigerant temperature

and its saturation temperature. This value is usually

expressed in degrees Fahrenheit or degrees Celsius.

Total Heat of Rejection (THR) is the heat absorbed

at the evaporator plus the heat picked up in the

suction line plus the heat added to the refrigerant in

the compressor. Condensers are sized according to

the required THR. Compressor capacity and the heat

of compression are usually enough to determine the

THR.

- 22 -

Page 23

CONDENSER SELECTION

During a condenser selection process, the

application engineer should choose a condenser

which is large enough to reject all of the heat added

to the refrigerant during the refrigerating cycle. When

the condenser is sized to equal the total heat

of rejection (THR) at design conditions, enough heat

will be rejected to maintain the required condensing

temperature. This will ensure that sufficient

refrigeration capacity will be maintained at the

evaporator during the warm summer period when it

is needed the most.

If a condenser is undersized, the condensing

temperature (CT) will be driven upwards. This

naturally occurs as the system seeks its new

balance point. As the CT increases, the operating

temperature difference (TD) oF the condenser also

increases. Even though the capacity of the

condenser increases with the higher TD, the

refrigerating capacity of the compressor will

decrease due to the higher condensing temperature.

An undersized condenser may perform

satisfactorily when ambient temperatures are

below design, but the overall system capacity will

not be high enough during the warmer periods.

Oversizing a condenser increases project costs and

can also lead to undesirable operating conditions.

Low ambient control devices such as pressure

regulators and fan cycling switches operate to

maintain a sufficient pressure in the condenser

during low ambient periods.

On systems utilizing a receiver and flooding type of

head pressure control, more refrigerant will be

required to flood the condenser in order to achieve

the desired condensing pressure.

Consider an air conditioning system with an

oversized condenser which is only used during the

summer time and does not have any type of head

pressure control. This particular system may

experience problems due to a lack of subcooling.

Since the condenser was oversized the amount of

natural subcooling available is less. The maximum

amount of natural subcooling possible is the difference between the condensing temperature and the

ambient temperature. If this amount of subcooling is

not enough to offset the pressure losses in the liquid

line, then flashing is certain to occur.

Flashing produces vapor at the metering device

which was designed to meter 100% liquid. One cure

for this is to apply head pressure control devices to

the system that will increase the head pressure and

ensure adequate liquid subcooling.

UNDERSIZED

CONDENSER

+30°F

+95°F

- 23 -

PROPERLY SELECTED

CONDENSER

+95°F

-15°F

Page 24

CONDENSER SELECTION

PRELIMINARY DATA REQUIREMENTS

There are several factors that influence the size of an air

cooled condenser. Before a condenser can be properly

selected, this information must be obtained. It may be

convenient for you to refer to the calculation worksheets

(P. 26 and 27) as you read through the following

information.

suction vapor picks up heat as it travels through the

warm motor windings. The condenser must be sized to

reject this heat along with any other heat absorbed by

the refrigerant. It can be observed in Table 2 that

hermetic refrigerant cooled compressors have higher

heat of rejection factors.

1. What are the Desired Evaporating and

Condensing Temperatures?

The evaporating temperature is needed to determine

the THR (total heat of rejection) of the condenser. As the

evaporating temperature is lowered, the heat of

compression increases due to the higher compression

ratio. This affects THR.

The required condensing temperature (CT) must be known

before the temperature difference can be determined. This

is necessary since condenser capacity varies with

temperature difference. The required compressor capacity

will determine the maximum CT since the compressor can

only provide this capacity at certain operating conditions.

You could also refer to Table 1 for CT recommendations.

The heat of compression varies with compression ratio.

Both evaporating and condensing temperatures affect the

compression ratio.

Often customers may request a specified TD value (i.e 10,

15 etc.). The condensing temperature is then established

as being the sum of this TD value and the design ambient

temperature. (i.e 10 + 95 = 105 oF)

2. Compressor Capacity

Determine the capacity of the compressor at the desired

evaporating and condensing conditions. Remember, tons

refrigeration does not necessarily equal horsepower. As the

evaporating temperature decreases and/or the condensing

temperature increases, tons refrigeration per horsepower

decreases. One ton refrigeration equals 12000 Btuh.

3.Condenser Ambient Design Temperature

This will be the maximum design temperature of the air

entering the condenser. It is typical to add about 5 oF

to the maximum outdoor design temperature in some

instances to compensate for radiation from a dark

surface such as a black roof.

4. Type of Compressor

It is necessary to identify the type of compressor to be

utilized in the application so that accurate heat of

rejection information may be obtained. For example, opendrive compressors can be belt driven or direct coupled to

the motor. Electrical energy from the motor is converted to

heat energy which is not transferred to the refrigerant as in

a refrigerant cooled compressor.

In a hermetic refrigerant cooled compressor, the cool

5. Heat of Compression

As the refrigerant is compressed in the compressor, its

heat content increases due to the physical and

thermodynamic properties of the refrigerant. Additional

heat from friction between moving parts in the compressor

also increases the heat content of the refrigerant. The

amount of heat added to the refrigerant is dependent on

the refrigerant type, the compression ratio and the type of

compressor.

Accurate THR or heat of compression factors may be

available from the compressor manufacturer. Always

attempt to access this information prior to using other

methods. If this information is not available, refer to the

heat of rejection factors in Table 2.

However, in situations where your application exceeds the

limits of this table, such as in compound compression and

cascade systems, one of the following calculations may be

performed.

For OPEN DRIVE COMPRESSORS:

Total heat of Rejection = Compressor Capacity (Btuh) + (2545 x BHP)

(BHP - Brake Horsepower of the motor)

For SUCTION COOLED COMPRESSORS:

Total heat Rejection = Compressor Capacity (Btuh) + (3413 x KW)

(KW may be obtained from the power input curve for that compressor)

6. What is the Refrigerant Type?

A condenser’s capacity can vary by 8 to 10% due to

differences in physical and thermodynamic properties.

Refer to the correct refrigerant capacity table or use factor

as indicated. (see P. 2)

7. Altitude

The volume of a given mass of air increases as it rises

above sea level. As its volume increases, its density

decreases. As the air becomes less dense, its heat

capacity decreases. Therefore, more air volume would

have to be forced through the condenser at 6,000 feet

above sea level than at sea level.

Since condenser capacities are based on operation at

sea level, an altitude correction factor must be applied to

the total heat of rejection. Basically, the load on the

condenser will be increased to a point which will compen

sate for the higher altitude.

to the maximum outs

- 24 -

Page 25

CONDENSER SELECTION

8.Are you Replacing a Water Cooled Condenser with

a Remote Air Cooled Condenser?

If this is the case, it should be remembered that the

compressor will operate at a higher discharge pressure

after converting to air cooled. To help minimize the

resulting loss in capacity, the condenser should be sized

generously. In other words, you may consider keeping the

balance point of the condenser as low as possible.

9. Is this an application for multiple circuits?

If you wish to utilize the condenser for multiple circuits,

then all of the above data must be obtained for EACH

circuit. After obtaining this information, proceed to the

MULTIPLE CIRCUIT WORKSHEET (P. 27) (for single

circuit applications refer to the SINGLE CIRCUIT

WORKSHEET (P. 26) ).

TABLE 1 - CONDENSING TEMPERATURE GUIDELINES

Evaporating

Temperature

Low Temp Systems

(-40 oF to +9 oF Evap Temps)

Medium Temp Systems

(+10 oF to +34 oF Evap Temps)

High Temp Systems

(+35 oF to +50 oF Evap Temps)

Air Conditioning Systems

(+40 oF to +50 oF Evap Temps)

* TD - Condenser TD guideline

85 oF 90 oF 95 oF 100 oF 105 oF

95-100 oF 100-105 oF 105-110 oF 110-115 oF 115-120 oF 10-15

100-105 oF 105-110 oF 110-115 oF 115-120 oF 120-125 oF 15-20

105-110 oF 110-115 oF 115-120 oF 120-125 oF 125-130 oF 20-25

110-115 oF 115-120 oF 120-125 oF 125-130 oF 130-135 oF 25-30

Condensing Temperature Guidelines

(at 85o to 105o Ambient Temperature)

TD*

TABLE 2 - HEAT OF REJECTION FACTORS

EVAPORATOR

TEMPERATURE

o

-40

-30

-20

-10

10

20

30

40

50

F

0

o

-40

-34

-29

-23

-18

-12

10

90oF (32oC) 100oF (38oC) 105oF (41oC) 110o(43oC) 115oF (46oC) 120oF (49oC) 130oF (55oC) 140oF (60oC)

C OPEN

*

1.37

1.33

1.28

1,24

1.21

-7

1.17

-1

1.14

4

1.12

1,09

HERM

1.66

1.57

1.49

1.42

1.36

1.31

1.26

1.22

1.18

1.14

OPEN

*

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

HERM

1.73

1.62

1.53

1.46

1.40

1.34

1.29

1.25

1.21

1.17

OPEN

*

1.44

1.39

1.34

1.30

1.26

1.22

1.18

1.16

1.13

OPEN - Direct Drive or Belt Drive open compressors

HERM - Hermetic or semi-Hermetic, Refrigerant (suction) cooled motor compressors.

CONDENSING TEMPERATURE

HERM

1.76

1.65

1.55

1.48

1.42

1.36

1.31

1.26

1.23

1.19

OPEN

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.14

HERM

1.80

1.68

1.58

1.50

1.44

1.38

1.33

1.28

1.24

1.20

OPEN

1.44

1.39

1.34

1.30

1.26

1.22

1.18

1.16

HERM

1.90

*

1.74

*

1.61

1.53

1.47

1.40

1.35

1.30

1.25

1.22

OPEN

*

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

HERM

2.00

1.80

1.65

1.57

1.50

1.43

1.37

1.32

1.27

1.23

OPEN

*

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

HERM

*

*

*

1.64

1.56

1.49

1.43

1.37

1.31

1.26

OPEN

*

*

*

*

1.47

1.42

1.37

1.32

1.28

1.24

HERM

*

*

*

*

1.62

1.55

1.49

1.42

1.35

1.29

- 25 -

Page 26

(REFER TO P. 24 FOR GUIDELINES, SEE SAMPLE SELECTION ON P. 28)

1. SYSTEM DATA REQUIREMENTS

WORKSHEETS - SINGLE CIRCUIT

SINGLE CIRCUIT WORKSHEET

JOB REF:

EVAP TEMP =

COMPR. CAPACITY= Btuh / 1000 = MBH

COND. DESIGN AMBIENT TEMP= (AT) oF TD= (Cond. Temp. - Ambient Temp)

COMPRESSOR TYPE= OPEN HERMETIC (Refrigerant cooled)

REFRIGERANT= R REF. FACTOR= (see P. 2)

ALTITUDE= AT SEA LEVEL or FEET ALT. FACTOR=

2. THR (Total Heat of Rejection) CALCULATION

COMPR. CAPACITY (MBH) X HR f X ALT f X REF f =THR (MBH)

Where HR f =Heat of rejection factor (see Table 2, P. 25)

o

F COND TEMP=

(See P.2)

X X X =

ALT f = Altitude/elevation factor (Sea level=1, or above factor)

REF f = Refrigerant Correction factor (R22 = 1)

Alternate refrigerant based on factors from P. 2

R12 = 1/.95 = 1.05, R134a = 1/.94 = 1.06,

R502 = 1/.98 = 1.02, R404A/R507/R407A/B = 1/.97 = 1.03

THR = Total Heat of Rejection (MBH, factored in R22) to be rejected by condenser

o

F

3. CONDENSER MODEL SELECTION

Refer to the R22 CAPACITY section (P. 2) and select a condenser at the TD (required above) that will closely match

the above calculated THR value. (NOTE: use the R22 capacity Table. The above calculation has already been

adjusted for alternate types).

COND. MODEL #

4. ACTUAL CONDENSING TEMP CALCULATION

THR (from sec. 2) / value (B) = ATD (actual Temperature Difference)

/ =

To find the Actual Condensing Temp. (ACT) just add the Actual Temperature Difference (ATD)

to the design Ambient Temperature (AT).

ATD + AT = ACT

+ =

NOTE: The Actual Condensing Temp. MUST EQUAL or BE LESS THAN the condensing temp recorded in section 1 above.

This ensures the compressor capacity is maintained when operating the condenser at the designed ambient temperature.

For further assistance please contact your local BALLY sales representative.

For the model selected

record the THR PER 1oF TD value = (B) (see P. 2)

o

F

- 26 -

Page 27

WORKSHEETS - MULTIPLE CIRCUITS

MULTIPLE CIRCUIT WORKSHEET

(REFER TO P. 24 FOR GUIDELINES & SEE SAMPLE SELECTION ON P. 29)

1. SYSTEM DATA REQUIREMENTS

CONDENSER DESIGN AMBIENT TEMP = (AT ) oF

ALTITUDE = SEA LEVEL or FEET FACTOR = (See P. 2)

CIRCUIT INFORMATION

CIRC # 1 CIRC # 2 CIRC # 3 CIRC # 4

OPEN

HERMETIC

EVAP. TEMP oF =

CONDENSING TEMP =

COMPR CAP. (MBH) =

REFRIGERANT =

TD =

(Cond Temp - Amb.)

2. THR (Total Heat of Rejection) CALCULATION

COMPR CAPACITY (MBH) X HRf X ALTf X REFf = THR (MBH) / TD = CL

CIRC # 1 X X X = / =

CIRC # 2 X X X = / =

CIRC # 3 X X X = / =

CIRC # 4 X X X = / =

TOTAL THR Capacity (MBH / 1 oF TD) =

Where HR f =Heat of rejection factor (see Table 2, P. 25)

ALT f = Altitude/elevation factor (Sea level=1, see P. 2 for Higher)

REF f = Refrigerant Correction factor (R22 = 1)

R12 = 1/.95 = 1.05, R134a = 1/.94 = 1.06,

R502 = 1/.98 = 1.02, R404A / R507 / R407A/B = 1/.97 = 1.03

Alternate refrigerant based on factors from P. 2

THR = Total Heat of Rejection (MBH) to be rejected by condenser (R22 capacity)

TD = Condensing Temp - Ambient Temperature

CL = Circuit loading per 1oF TD

JOB REF:

3. CONDENSER SELECTION

Refer to the R22 CAPACITY selection (P.2) and select a condenser at the 1oF TD that will closely match the above Total THR Capacity (MBH/ 1oF TD).

4. ACTUAL CONDENSING TEMP (per circuit) CALCULATION ATD

First calculate the ATD (Actual TD) as follows: { THR (from sec. 2) / NF value} / value (B) = (Actual Temperature Difference)

To find the Actual Condensing Temperature (ACT) just add the Actual Temperature Difference (ATD) to the design ambient (AT)

NOTE: The Actual Condensing Temp. MUST EQUAL or BE LESS THAN the condensing temp recorded in section 1 above.

COND. MODEL # For the model selected, refer to P. 2 and enter...

calculate the number of feeds required for each circuit.

CL (MBH / 1o F TD) / (B) value = NF number of feeds required (round off to nearest whole #)

CIRC # 1 / =

CIRC # 2 / =

CIRC # 3 / =

CIRC # 4 / =

Total number of feeds required NF =

(must not exceed value (A))

If number of feeds required exceeds number of feeds available then select the next larger size

condenser model that can handle the number and repeat above process.

CIRC # 1 { / } / =

CIRC # 2 { / } / =

CIRC # 3 { / } / =

CIRC # 4 { / } / =

ATD + AT = ACT

CIRC # 1 + =

CIRC # 2 + =

CIRC # 3 + =

CIRC # 4 + =

This ensures the compressor capacity is maintained when operating the condenser at the design ambient tremperature.

For further assistance please contact your local BALLY sales representative.

Max no. of Feeds = (A)

MBH @ 1oF TD per feed = (B)

o

F

o

F

o

F

o

F

- 27 -

Page 28

WORKSHEETS - SAMPLE SELECTION #1

Preliminary Data Given:

1. Evaporating temp = -20 oF

2. Condensing temp = 105 oF

3. Compressor capacity = 300,000 Btuh

4. Design ambient = 90 oF

Use WORKSHEET - SINGLE CIRCUIT (P 26) to complete selection of condenser

JOB REF:

1. SYSTEM DATA REQUIREMENTS

o

EVAP TEMP =

COMPR. CAPACITY= Btuh / 1000 = MBH

COND. DESIGN AMBIENT TEMP= (AT ) oF TD= (Cond. Temp. - Ambient Temp)

COMPRESSOR TYPE= OPEN HERMETIC (Refrigerant cooled)

REFRIGERANT= R REF. FACTOR= (see P. 2)

ALTITUDE= AT SEA LEVEL or FEET ALT. FACTOR=

2. THR (Total Heat of Rejection) CALCULATION

COMPR. CAPACITY (MBH) X HR f X ALT f X REF f = THR (MBH)

300 1.55

-20

F COND TEMP=

300,000

90

22 1

X X X =

105

o

F

300

(See P.2)

1

15

1

TC 1500

1

465

3. CONDENSER MODEL SELECTION

COND. MODEL #

4. ACTUAL CONDENSING TEMP CALCULATION

THR (from sec. 2) / value (B) = ATD (actual Temperature Difference)

465

To find the Actual Condensing Temp. (ACT) just add the Actual Temperature Difference (ATD)

to the design Ambient Temperature (AT).

ATD + AT = ACT

14.5

BVC1A23067

/ =

90

+ =

32.165

104.5

For the model selected

record the THR PER 1oF TD value = (B) (see P. 2)

14.5 OF

o

F

32.165

Above selection using condenser model BVC1A23067 ensures condensing temperature will be at 105 oF or below during

design ambient conditions. See SAMPLE SELECTION # 2 for multiple circuit selections.

- 28 -

Page 29

WORKSHEETS - SAMPLE SELECTION # 2

Preliminary Data Given:

1. Location at Reno, Nevada, 95 oF design ambient and 4,000 feet elevation.

2. Multiple circuits required with evaporating temperatures, condensing temperatures, compressor capacities and

refrigerant types as listed below.

Use WORKSHEET-MULTIPLE CIRCUITS (P. 27) to complete selection of condenser.

1. SYSTEM DATA REQUIREMENTS

CONDENSER DESIGN AMBIENT TEMP = (AT ) oF

ALTITUDE = SEA LEVEL or FEET FACTOR =

OPEN

HERMETIC

EVAP. TEMP oF =

CONDENSING TEMP =

COMPR CAP. (MBH) =

REFRIGERANT =

TD =

(Cond Temp - Amb.)

2. THR (Total Heat of Rejection) CALCULATION

COMPR CAPACITY (MBH) X HRf X ALTf X REFf = THR (MBH) / TD = CL

CIRC # 1 X X X = / =

CIRC # 2 X X X = / =

CIRC # 3 X X X = / =

CIRC # 4 X X X = / =

3. CONDENSER SELECTION

Refer to the R22 CAPACITY selection (P. 2) and select a condenser at the 1oF TD that will closely match the above Total THR Capacity

(MBH/ 1oF TD).

COND. MODEL # For the model selected, refer to P. 2 and enter...

calculate the number of feeds required for each circuit.

CL (MBH / 1o F TD) / (B) value = NF number of feeds required (round off to nearest whole #)

CIRC # 1 / =

CIRC # 2 / =

CIRC # 3 / =

CIRC # 4 / =

CIRC # 1 CIRC # 2 CIRC # 3 CIRC # 4

+20

110

13

22

15

13

25

4.6

31.5

1.314

2.622

.799

5.733

95

4,000

(See P. 2)

BVC1A12022

CIRCUIT INFORMATION

+10

110

25

22

15

1.33

1.38

1.48

1.55

Max no. of Feeds = (A)

MBH @ 1oF TD per feed = (B)

.447

.447

.447

.447

1.14

1.14

1.14

1.14

TOTAL THR Capacity (MBH / 1 oF TD) =

(2.93) 3

(5.86) 6

(1.78) 2

(12.82) 13

-10

105

4.6

404A

10

1

1

1.03

1.03

JOB REF:

1.14

19.71

39.33

7.99

57.33

24

.447

TC2000

-20

105

31.5

404A

10

15

15

10

10

10.468

1.314

2.622

.799

5.733

Total number of feeds required NF =

(must not exceed value (A))

If number of feeds required exceeds number of feeds available then select the next larger size

condenser model that can handle the number and repeat above process.

4. ACTUAL CONDENSING TEMP (per circuit) CALCULATION

First calculate the ATD (Actual TD) as follows: {THR (from sec. 2) / NF value} / value (B) = ATD (Actual Temperature Difference)

CIRC # 1 { / } / =

CIRC # 2 { / } / =

CIRC # 3 { / } / =

CIRC # 4 { / } / =

To find the Actual Condensing Temperature (ACT) just add the Actual Temperature Difference (ATD) to the design ambient (AT)

CIRC # 1 + =

CIRC # 2 + =

CIRC # 3 + =

CIRC # 4 + =

19.71

39.33

7.99

57.33

ATD + AT = ACT

14.7

14.7

8.9

9.9

95

95

95

95

3

6

2

13

109.7

109.7

103.9

104.9

o

o

o

o

24

.447

.447

.447

.447

F

F

F

F

14.7

14.7

8.9

9.9

- 29 -